Abstract

As a legacy of historical metal mining and the processing and smelting of metalliferous ores, metal pollution is a serious environmental problem in many areas around the globe. This review summarizes the history, technical development and environmental hazards of historic metal mining and metallurgical activities in the Harz Region (Germany), one of the oldest and most productive mining landscapes in Central Europe. The release of large amounts of metal-containing waste into rivers during historic ore processing and the ongoing leaching of metals from slag heaps, tailings dumps and contaminated soils and sediments are the main sources of metal pollution in the Harz Mountains and its foreland. This pollution extends along river systems with tributaries from the Harz Mountains and can even be detected in mudflats of the North Sea. In addition to fluvial discharges, atmospheric pollution by smelter smoke has led to long-term damage to soils and vegetation in the Harz Region. Currently, the ecological hazards caused by the legacy pollution from historical metal mining and metallurgy in the Harz Region are only partially known, particularly regarding the effects of changes in river ecosystems as a consequence of climate change. This review discusses the complexity and dynamics of human–environment interactions in the Harz Mountains and its surroundings, with a focus on lead (Pb) pollution. The paper also identifies future research directions with respect to metal contamination.

1. Introduction

Human interventions into nature are often associated with profound effects on landscapes and may have irreversible negative consequences for entire ecosystems [1]. Thus, the extraction and processing of metalliferous ores are invariably associated with detrimental impacts on the environment due to the release of toxic substances via different routes [2,3]. The consequences of anthropogenic pollution by metals from mining and metallurgical activities, and, more recently, from fossil fuel burning, are detectable at local, regional and supra-regional levels. Contamination of the environment from metal mining and metallurgy has been known since ancient times [4,5,6,7,8,9]. According to Grattan et al. [10], the release of mining wastes had already caused metal contamination of floodplain areas in the Middle East 7000 years ago. Thus, metal mining and the associated processing of metalliferous ores constitute the earliest proven source of widespread anthropogenic environmental pollution [5,10]. Access to water is essential for large-scale metal mining and metallurgy, and, in consequence, rivers have been contaminated with huge amounts of toxic wastes from these processes [11].

Analysis of various environmental archives, e.g., overbank deposits, lake sediments, bogs, and ice cores, demonstrated long-range dispersal of anthropogenically released metals via river systems and also by atmospheric transport [11,12]. These environmental archives can be used to reconstruct temporal changes in the intensity of metal mining and metallurgical activities around the world. The released metals were, and still are, redistributed within and between ecosystems and constitute an immediate and long-term hazard to environmental and human health. In addition, the anthropogenic impact on the environment in mining areas led to complex and mostly irreversible landscape changes, affecting surface relief, hydrological system and vegetation cover [13,14]. Ever since the start of large-scale metal mining by ancient Greeks and Romans, mining and metallurgy went along with massive deforestation, due to the enormous amounts of wood and charcoal needed as fuel and of timber for below-ground and above-ground constructions [5,15]. The smelting of metal ores, in particular, consumed great quantities of wood in the form of charcoal, with seven tons of wood yielding one ton of charcoal [5]. If forest destruction was followed by reforestation, this typically went along with major changes in tree species composition, resulting in a predominance of fast-growing conifers.

Several studies have addressed the persisting impact of historical metal mining activities on present-day floodplain ecosystems and thus on current human, animal and plant health [11,16,17,18,19,20,21,22]. Macklin et al. [11] used hydrological modeling to assess the global pollution of river systems and affected floodplains by active and inactive metal mines and tailings. They concluded that, worldwide, 164,400 km2 of floodplains and 480,700 km of river courses are affected by past and present mining activities, affecting approximately 23.48 million people and 5.72 million livestock living in these areas.

Studies addressing the history of metal contamination in the Northern Hemisphere indicate major metal mining and metallurgical activities already in Greek and Roman times, which peaked in the 1st and 2nd centuries CE and released large amounts of lead into the atmosphere. The resulting pollution signal can be detected not only at local and regional scales, but also in remote regions far from the emission centers, e.g., in Greenland ice-cores [6,7,23,24,25,26,27]. Following a decline related to the fall of the Roman Empire, metal mining and extractive metallurgy increased again in the Middle Ages. This increase was prompted by a rising population, economic growth, and exploitation of new mining districts, as well as by numerous technological innovations. Temporary decreases in lead (Pb) pollution during medieval times coincide with periods of climate deterioration, famines, plagues, and larger conflicts. Environmental archives indicate a first post-Roman peak of Pb pollution around 1200 CE, followed by a decline to a minimum around 1600 CE and a subsequent strong increase during recent centuries, especially since the begin of industrialization in the 19th century [7,23,25,28,29,30].

Lead (Pb, from Latin plumbum, atomic number 82, atomic weight 207.2) is a toxic element that has no known physiological or biochemical function and exerts multiple negative effects on organisms [31,32,33,34,35,36]. Lead rarely occurs in pure form in the Earth’s crust. Instead, it is bound to other elements, the most important Pb ores being the minerals galena (PbS), cerussite (PbCO3) and anglesite (PbSO4) [37,38]. In the environment, lead occurs in four stable isotopes (204Pb, 206Pb, 207Pb, and 208Pb). While 204Pb is primordial, the other three isotopes are radiogenic, originating from the radioactive decay of, respectively, 238U, 235U and 232Th. Lead isotopic signatures are widely used to identify the source of Pb in the environment [18,22,39,40,41,42,43].

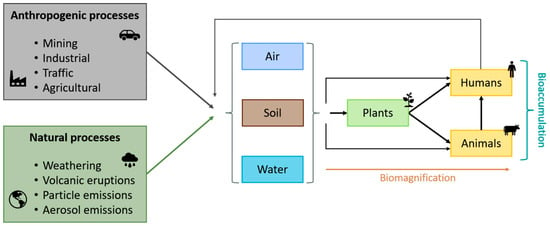

In addition to its occurrence from natural sources, lead is released into the biosphere by various human activities. Besides the mining, processing and smelting of Pb-containing ores, this includes the industrial production and use of Pb-containing products (e.g., batteries, paint and ammunition), fossil fuel combustion (especially use of leaded gasoline), runoff of Pb from waste heaps and landfills and agricultural use of Pb-containing materials (e.g., fertilizers, pesticides, or insecticides) [2,44,45]. Figure 1 provides an overview of how Pb enters biota from the abiotic environment and via trophic transfer. In the biosphere, lead is subject to the processes of bioaccumulation and biomagnification.

Figure 1.

Sources and transport of lead in the environment (modified after [46]).

This paper provides an overview of historic metal mining and metallurgical activities in the Harz Region (Germany), which constitutes one of the oldest and most productive mining landscapes in Europe. The term “Harz Region” as used here includes the Harz Mountains and their foreland. We further review the environmental consequences of these activities at local, regional and supra-regional levels, with a focus on Pb pollution. In this context, consideration is also given to current ecological dynamics and the socio-ecological impacts resulting from this legacy pollution.

2. Geology and Mining History of the Harz Mountains

2.1. Geological Situation and Landscape

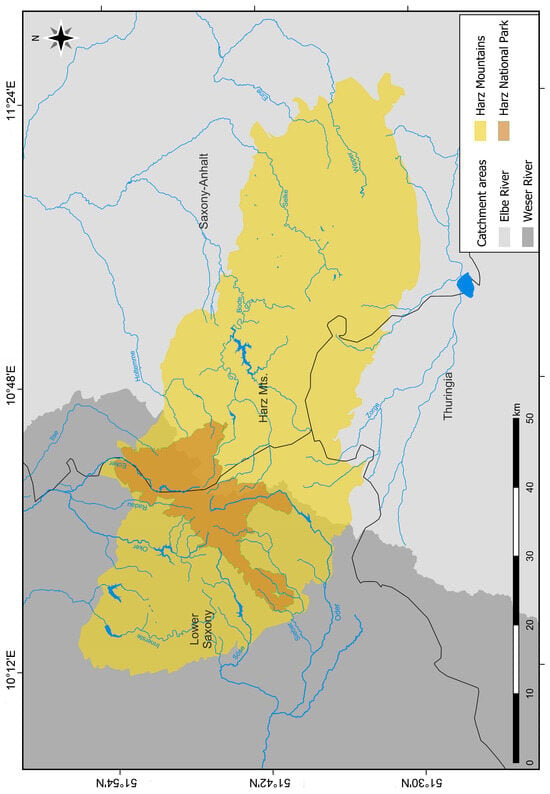

The Harz Mountains are Germany’s northernmost mountain range, which covers a total area of about 2000 km2 and administratively belongs to the federal states of Lower Saxony, Saxony-Anhalt and Thuringia (Figure 2). Roughly ten percent of the Harz Mountains area forms the Harz National Park, while the other parts are mainly landscape protection areas. The Harz Region is an important cultural landscape, in which traces of past mining activities are visible in many places, some of which have been declared UNESCO World Heritage Sites. The scenic attractions and rich cultural heritage of the area form the basis for extensive year-round tourism.

Figure 2.

Catchment areas of the Elbe and Weser Rivers in the Harz Mountains and their surroundings. Rivers and water reservoirs are indicated in blue. Black lines indicate the borders between the federal states of Lower Saxony, Saxony-Anhalt and Thuringia.

The Harz Mountains feature a stepped, plateau-like morphology, and are elevated above the surrounding landscape, the highest peak being the Brocken at 1141 m above sea level. Geologically, the Harz Mountains can be subdivided into three large districts, viz., the Upper Harz, the Middle Harz and the Lower Harz, which themselves can be further subdivided into about 25 stratigraphic–tectonic subunits. The current form of the Harz Mountains is the result of a long and complex geological development, with folding and overthrust events and alternating processes of sedimentation and erosion [47,48,49,50].

The higher mountain ranges (≥650 m altitude), which drain towards the Weser River via the rivers Oder, Sieber, Söse, Nette, Innerste, Oker, Radau, Ecker and Ilse, represent the Upper and Middle Harz districts. The mountain ranges of the Lower Harz are, on average, 500 m in altitude, and the rivers Bode, Wipper, Selke, Holtemme, Eine, Bere and Zorge belong to the Elbe River catchment area [51,52] (Figure 2).

Following the opening of the narrow Rhenish Seaway about 390 to 400 million years ago (Emsian to middle-Devonian, Paleozoic era), today’s Harz Mountains area was a marine subsidence zone that became filled with coarse and fine weathering material. During the Variscan orogeny, the tectonic processes (Variscan folding front) captured the sediment-filled basins, changing the originally horizontal layers into folds with saddles and troughs and causing the formation of nappes. Towards the end of the Carboniferous, extensive magmatic (granitic and gabbroic) intrusions into these folded sediments occurred. Following the Variscan uplift, the Harz and its surroundings were temporarily dry land exposed to erosion [47,49,50,53].

In the early Mesozoic era, the area of today’s Harz Mountains sank below the sea level, and huge amounts of sediments were deposited in the region. As a result of renewed tectonic activity starting mainly in the Upper Cretaceous, the Harz block was elevated above its surroundings. This uplift took place in several steps. Along the northern boundary fault, a prominent mountain edge was formed, whereby a steepening and partly northward overturning of the Harz boundary sediments occurred. Denudation processes during the Tertiary then gradually removed the Mesozoic overburden and exposed the ancient Paleozoic Mountain core. During the Pleistocene, firn fields and small glaciers were present in the Harz Mountains, the glaciers and meltwater significantly shaping their present-day morphology. Karstification occurred in some areas, with the formation of karst landscapes and typical karst features like caves [47,49,53].

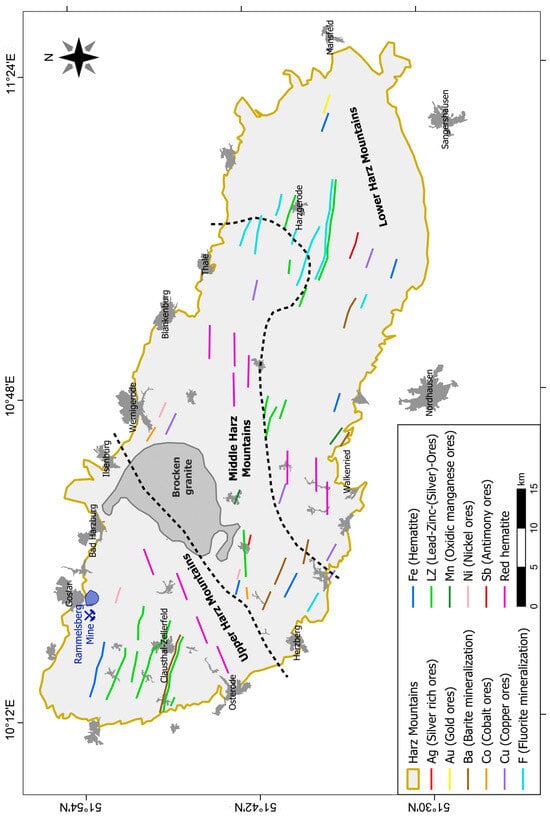

The diverse tectonic processes occurring during the geological development of the Harz Mountains mainly in the Mesozoic led to the formation of fracture fissures that enabled the ascent and circulation of water and entrained solute/metal loads. A large number of vein structures with silver-bearing Pb-Zn-Cu sulfides (Upper and Middle Harz districts) developed, which strike fault-bound mainly from northwest to southeast [48,49] (Figure 3). However, there are also strata-bound orebodies like the Rammelsberg polymetallic deposit, which constitutes the largest and richest metal deposit in the Harz Mountains [49,54]. The (now exhausted) deposit is hosted in Middle Devonian sediments and was exploited until 1988.

Figure 3.

Metal ore and other mineral deposits in the Upper, Middle and Lower Harz Mountains (modified after [48]). The dashed lines mark the boundaries between the three districts.

Regarding the occurrence of ores, there exist considerable differences between the Upper, Middle and Lower Harz districts. Thus, the silver-bearing lead-zinc ores of the Lower Harz district are of much less economic importance than those of the Upper Harz Mountains, while the Middle and Lower Harz districts are richer in polymetallic ores and fluorspar [48,49].

2.2. Mining History of the Harz Mountains

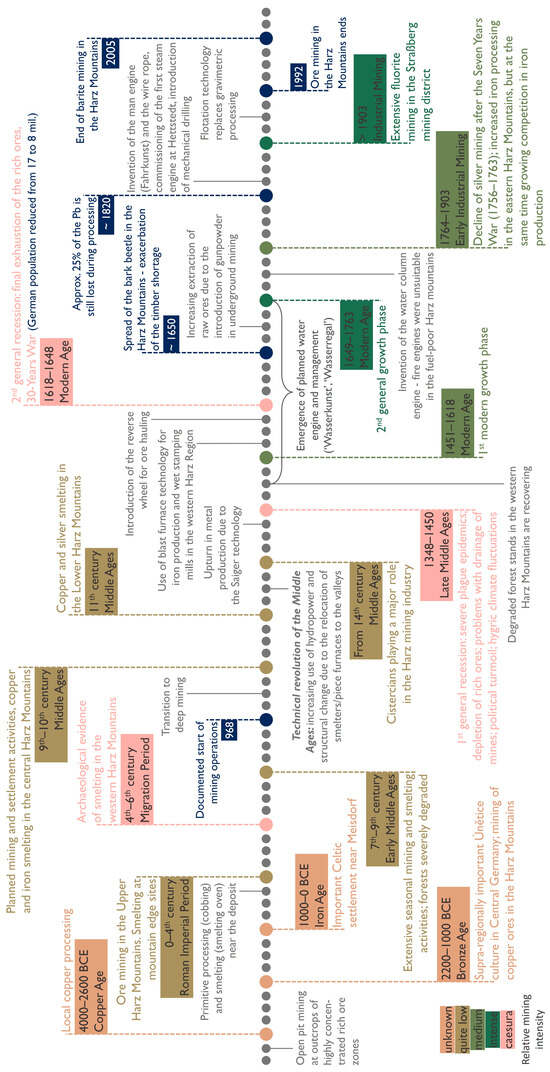

The Harz Region with its rich deposits of metal ores (Figure 3) has a long history of metal mining and extractive metallurgy, making it one of the oldest industrial regions in Central Europe. Figure 4 provides an overview of the historical development of mining and metallurgical activities, the influence of these activities on landscape development, and the associated impact on the environment in the Harz Region.

While the actual beginning of metal mining activities in the Harz Mountains is unknown, it has been suggested that local processing of copper ores had already started by around 4000–2600 BCE [55]. Monna et al. [43] used Pb isotope ratios in overbank sediments from the river Weser to separate the regional background (in sediments deposited prior to 3500 BP) from younger sediments with contributions derived from ore bodies in the Harz Mountains, indicative of early mining and smelting activities.

The first clear archaeological indications of the peopling of the Harz Mountains and the mining of metal ores in this region date to the Bronze Age (2200–1000 BCE). These mining activities or prospecting attempts were limited to small outcrops of ores, and are considered to have been directed at the extraction of copper-bearing, rather than argentiferous ores [55,56,57]. Human skeletal remains from the Lichtenstein cave in the southern Harz Mountains near the town of Osterode am Harz have been identified as a large Bronze Age family group, and genetic analyses confirmed that direct descendants of these people are today still living in the area [58].

Figure 4.

Overview of relevant mining eras, developments and related historical events in the Harz Region. Based on data from [15,48,55,56,57,59,60,61,62,63,64,65,66,67,68,69,70].

Evidence of metal extraction in the Harz Region during the Iron Age (1000–0 BCE) is provided by peat deposits of the “Silberhohl” sinkhole near the town of Seesen in the western Harz. The massive atmospheric metal deposition (Cd, Cu, Pb and Zn) detectable in this environmental archive has allowed a detailed reconstruction of mining and metallurgical activities [71,72]. The oldest archaeological evidence for the processing of metal deposits in the Harz Region and the smelting of ores from the Rammelsberg area dates back to at least the Roman Imperial Period (0–4th centuries CE) and was found near the village of Düna on the southern edge of the Harz [48,73].

During pre-medieval times, mining activity was still limited to the exploitation of well recognizable, vegetation-free, highly concentrated and easily accessible outcrops of metal ores. The extracted ores were sometimes transported over longer distances to smelting places where larger amounts of charcoal were within reach. Here, the ores were processed by picking and beating by hand and smelted in seasonally operated furnaces [55,61,62]. During this period, the forests and surrounding areas around the outcrops were subject to only minor changes, due to the rather small quantities of extracted ore and the low depth of extraction [55].

Little is known about mining activities in Central Europe during the Migration Period (4th–6th centuries CE), but a temporal and local disruption of mining activities compared to the Iron Age and Roman Imperial Period can be assumed as a consequence of depopulation. There is, however, archaeological evidence of ongoing non-ferrous metal smelting at Düna in the southern Harz and at the Iberg near Bad Grund in the northwestern Harz [15,55,63].

The intensity of the mining activities during the Early Middle Ages (7th–9th centuries CE) was similar to that during the Iron Age. According to radiocarbon dating of charcoal from kilns, the Harz Mountains were characterized by a natural forest cover until around 800 CE [62,73,74]. Subsequently, mining in the Harz underwent major changes. Thus, during the 9th and 10th centuries CE, settlement and mining activities became more systematic, especially in the Middle and Upper Harz. The smelting places were centralized, and charcoal pits became more frequent and were located further away from settlements, indicative of a more widespread forest use [55,62,75]. Furthermore, different types of slag can be differentiated, which vary in their regional distribution. Small slag heaps occur more frequently near streams, where various Rammelsberg ores or Upper Harz lead/zinc ores were smelted [73], while on wind-exposed plateaus, slag sites are concentrated where copper-rich Rammelsberg ore was smelted [61]. With an estimated 27 million tons of rich sulfide ores and 2 million tons of less-rich banded ores, the Rammelsberg was the largest and most remarkable non-ferrous metal deposit site not only in the Harz Mountains, but also far beyond [76]. Hardly any other ore deposit in the world can look back on a similarly long, almost continuous mining history, during which approximately 25 million tons of the estimated 29 million tons of ore reserves were mined [76].

3. Technological Development of Mining and Extractive Metallurgy in the Harz Mountains

3.1. Early Activities

To evaluate the influence of mining and extractive metallurgy on landscape changes and pollution of the environment in the Harz Mountains, the technological development of these activities will be briefly reviewed.

Although the actual onset of mining activities in the Harz Mountains is not known, it may be assumed that early on people had noticed the (vegetation-free) outcrops of metal ores. These outcrops were also conspicuous because their runoff caused a discoloration of the adjacent rocks. In addition, the characteristic vegetation growing around the outcrops of the metal ores must have helped in prospecting such deposits, part of which were probably exploited by open-cast mining [64].

Expanding these early activities, numerous recoverable ore deposits have since been exploited in the Harz Mountains, initially by near-surface mining and, with gradually improved technology, by underground mining at increasing depths. Intense subsurface mining began as early as the 6th–8th centuries CE [62,65,66]. Based on environmental archaeological records, first changes in landscape and vegetation structure resulting from mining and metallurgical activities occurred in the 7th–8th centuries CE [77]. The mining industry required huge amounts of wood, both as fuel and as timber for constructing shafts and mining galleries, as well as residential and operational buildings. This wood was initially provided by the huge beech forests that originally covered the Harz Mountains [15]. The roasting and smelting processes, in particular, consumed enormous amounts of firewood and charcoal, the latter being initially produced in pit kilns (“Grubenmeiler”) and, from the 12th century onwards, increasingly in above-ground kilns (“Platzmeiler”) [78] (Figure 5).

Figure 5.

Depictions of different charcoal kilns from De La Pirotechnia by Biringuccio [79]; (left): pit kiln (“Grubenmeiler”), (right): above-ground kiln (“Platzmeiler”); images: Accademia della Crusca Library.

3.2. Medieval and Modern Activities

The Rammelsberg mine near Goslar situated at the northwestern edge of the Harz Mountains (Figure 3) is one of the oldest mines in the Harz Region, exploited since the Bronze Age. Construction of the gallery, referred to as the “Ratstiefster Stollen”, began before the year 900, demonstrating the extensive medieval mining activity near Goslar [56]. Contemporaneous mining activities in the Upper and Lower Harz regions, including the copper mineralizations at the Harz rim, lack written records and are basically known only from archaeological finds [55,56,66,67,80]. The first documentary references to the Lower Harz mining districts date to the years 1300 and 1392, respectively [48,55]. According to Dobler [55,81] and Ließmann [48], there has been quite active silver mining in the area around the towns of Straßberg and Harzgerode since the mid-15th century.

Changes in ownership and sovereign rights, military conflicts, natural and mining disasters and epidemics, the depletion of the ore deposits, as well as innovations and technical progress, all had their impacts on the development of the mining industry [48,82]. Based on the development of silver mining activities, Dobler [55] subdivided the history of mining activities in the Harz Mountains into the following four phases:

- Phase I: before 1450 (prehistoric and medieval mining).

- Phase II: 1451–1648 (first (early) modern mining phase).

- Phase III: 1649–1763 (second modern mining phase).

- Phase IV: 1764–1903 (early industrial mining).

Technical aspects of mining during phases I and II, as well as the impacts of metal mining, processing and smelting activities on the environment, are well documented in various monographs from the 16th and 17th centuries by scholars such as Agricola [83], Ercker [84,85] and Löhneyß [86] or in the form of cartographic representations.

3.3. Impact of Mining Activities on the Harz Forests

Until the early Middle Ages, the forests of the Upper and Middle Harz were still quite extensive and capable of producing enough wood to meet human demands. In its montane forest stands, the Upper and Middle Harz was at that time dominated by the European beech, Fagus sylvatica [15,68]. However, human population increase and agricultural expansion from the 10th century CE onwards caused a shrinking of the forest area. In addition, the ever-increasing demand for wood by the mining, metallurgical and various other industries caused a replacement of beech and other hardwood species by fast-growing Norway spruce, Picea abies, which colonized the clear-cut areas previously covered by the deciduous trees [15,74]. At the end of the Middle Ages, the Harz mining industry underwent a recession, mainly due to a lack of wood for energy production and construction, but, in addition, also because of a population decline from epidemics and technical problems of the mining industry, especially the raising of water from deep shafts [68].

From about 1500 onwards, the renewed boom of mining activities and the onset of the Little Ice Age (a period of regional cooling) led to a sharp decline in fast-growing and light-requiring trees, such as birch (Betula), alder (Alnus) and willow (Salix), and the further expansion of spruce stands [15]. The excessive forest exploitation due to the increasing hunger for wood by the mining industry eventually led to extensive forest destruction and a severe wood shortage in the Harz Mountains. In order to maintain metallurgical activities, large amounts of charcoal had to be transported into the Harz Mountains from its foreland and neighboring regions like the Weserbergland, via “coal roads”. The wood crisis also prompted attempts to establish a sustainable forest management in the Harz Mountains and beyond, which in 1788 eventually led to forestry being established as an independent economic service, separated from the mining industry [15,68,87].

In the mid-19th century, ninety percent of the Upper Harz was covered by spruce forests, significant parts of which were subject to damage by exhaust fumes from roasting and smelting operations. In the 20th century, war efforts and the delivery of huge amounts of wood as a reparation measure after the Second World War led to large clear-cut areas predominantly in the Western Harz, which were again reforested with Norway spruce [88]. This resulted in the uniform spruce stands which have characterized the Harz Mountains since the mid-1950s. These spruce stands have suffered heavily from drought and bark-beetle damage during more recent years. Deciduous tree species are still largely absent from extended areas of the Harz Mountains, but are currently strongly promoted by the state forestry administration [89].

3.4. The Environmental Legacy of Technological Progress

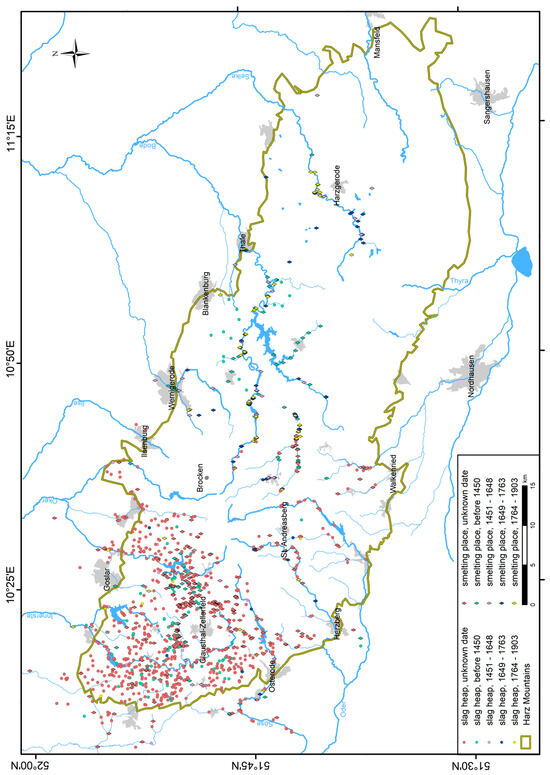

In addition to the changes in forest cover, the increase in mining operations and metallurgical activities had a major and persisting negative impact on air quality, soils, ground and surface water, flora, fauna, and humans in the Harz Region. Thus, for instance, the entire hydrological regime of the Harz Mountains was transformed locally by the construction of mining water management systems. Also, numerous former smelting sites and slag heaps are present in the area (Figure 6). Today, legacy pollution, especially by lead, from these activities, is still a major environmental and human health issue in the Harz Region.

Figure 6.

Overview map showing the location of known slag heaps and smelting places in the Harz Mountains (based on data from [55,61]). Rivers and water reservoirs are indicated in blue.

The extent to which the mining industry has affected ecosystems and the fact that many areas in the Harz Mountains are still highly contaminated with metals is exemplified by the occurrence of metallophyte plant communities (Violetalia calaminariae) capable of growing on soils with high levels of metals (Figure 7) [90,91].

Figure 7.

Examples of metallophytes growing on metal-rich soils in the Harz Mountains. (a) Armeria maritima subsp. halleri. (b) Minuartia caespitosa. (Photos by H.U. Kison, 2007 and 2009.)

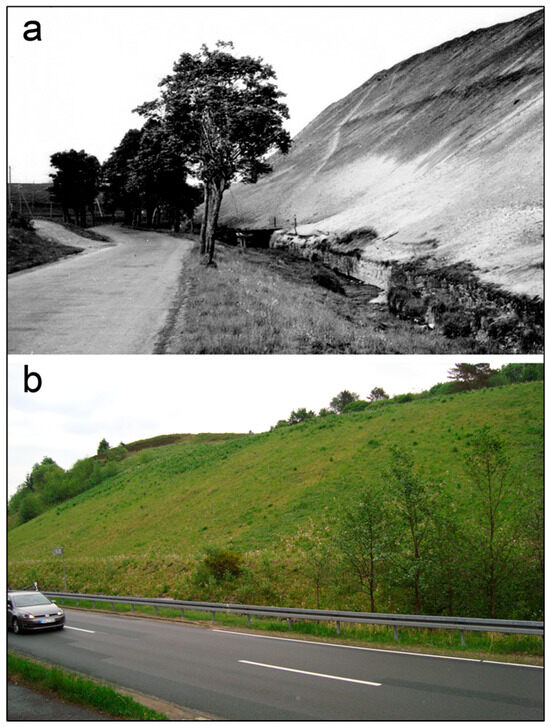

While heavy-metal meadows were originally restricted to natural outcrops of metal ores, the discharge of large amounts of Pb and other metals by the mining industry and the resulting widespread contamination has caused the establishment of secondary heavy-metal meadows in the Harz Region. They are found on deposits of fluvially transported metal-bearing tailings (stamp mill sands) along Harz-borne rivers, as well as on spoil, tailings and slag heaps at ore processing and smelting places. Leaching of metals from these heaps still constitutes a serious environmental hazard today, and has prompted remediation measures in some cases [92,93]. Figure 8 shows a tailings dump near Clausthal-Zellerfeld before (a) and after (b) remediation in 2010. The remediation measures included reshaping (slope reduction) of the dump, and its sealing with a geosynthetic clay liner, followed by covering with (1) a drainage mat, (2) a geogrid of high-tensile strength, and (3) a layer of regional-typical soil that was then seeded with grass.

Figure 8.

Large tailing heaps (roughly 70,000 m3) in the Zellbach Valley at the western outskirts of the town of Clausthal-Zellerfeld before (a) and after (b) the remediation in 2010. Photos by H. Peucker, 1985 (a) and F. Knolle, 2018 (b).

Fluvial transport of metals, mainly via suspended solids, took place, and still takes place, over longer distances, and is especially intense during flooding events. The anthropogenic discharge of metals in the Harz Region resulted in widespread contamination of overbank sediments and floodplain soils of rivers originating in the Harz Mountains [20,90,92,94,95,96,97,98,99,100], and elevated concentrations of metals in biota from these areas [18,90]. Three decades after the closure of the last lead–zinc mine in the Harz Mountains (at Bad Grund in 1992), Harz-borne metals are still found in sediments of the water catchment areas of the rivers Weser and Elbe and can even be detected in the Helgoland mudflats in the North Sea [17,97,101].

4. Metal Ore Mining, Processing, Roasting and Smelting

4.1. Overview

The metal ores mined in the Harz Mountains primarily constitute iron and sulfidic silver-bearing lead ores, zinc ores and copper ores. Below, some basic information on ore mining, processing and smelting is given, with particular reference to the conditions in the Harz Region.

The processes involved in metal production can be divided into mining, processing, roasting, smelting and refining. Sometimes, not all of these processes are necessary to produce the valuable metals from the mined ores. Thus, the choice of procedures depends on the type of the processed ore and the desired end product. When different metals were combined in an ore, two or more of them could be extracted simultaneously. In the case of sulfidic ores, roasting was often required to discharge the sulfur in the form of SO2 [56,67].

The basic purpose of mining is to prospect and open up the usable ore minerals of a deposit, i.e., to make them accessible through trenching, picking, heating of the rock with fire followed by sudden cooling with water or vinegar to crack it (historically), drilling and blasting work (modern times), or hydraulic mining (already performed in Roman times [5]), as well as by constructing shafts and tunnels to access the ore veins [48,51].

The recovered ore is then brought to the surface, where it is subject to various treatments in order to extract the metals economically. Initially, the ore is processed using mechanical treatment (crushing, sorting) to separate the ore from the host rock. In the case of sulfidic ores, the next step is roasting, in which the raw ores are desulfurized in large open-air wood fires. Finally, the pure metals are smelted out by adding thermal energy and, in some cases, using reducing and fluxing agents (e.g., fluorspar) and then purified or separated from each other using metallurgical processes. Regarding the production of silver, it must be kept in mind that the silver content of even the richest lead ores mined in the Harz Mountains did not exceed 0.1% [48,55]. Therefore, enormous amounts of ore had to be mined and processed for a sufficient silver yield.

4.2. Ore Processing and Disposal of Tailings

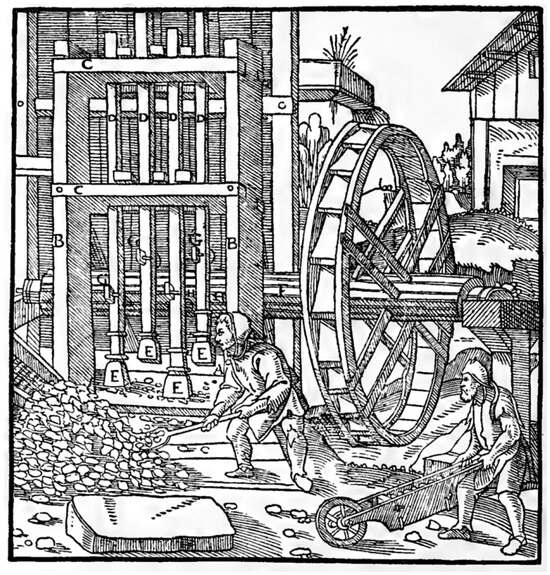

Prior to further treatment, the mined ores had to be crushed (initially by hand, later by stamp mills) to separate the metal-bearing component from the adhering host rock. This started underground and continued after the material had been brought to the surface. Despite progressive mechanization, manual picking on the ore heaps played a major role up to the 20th century. During the picking process, the pieces of ore were pre-sorted according to ore type and degree of intergrowth, and assigned to different quality grades [48]. From the Late Middle Ages, dry- or wet-ore crushing was performed using stamp mills (Pochwerke) that were mostly driven by hydropower and were therefore typically located close to a watercourse [48,51]. The main components of a stamp mill were a battery of vertically oriented, movable heavy stamps (initially made from iron-shod wood and later from iron or steel) and a punching trough or mortar (Figure 9).

Figure 9.

Hydropowered stamp mill in which the ore is crushed with stamps so that the metal can be separated from the host rock. A: mortar, B: vertical posts, C: horizontal beams, D: stamps, E: stamp heads (Pochschuhe), F: axle (drive shaft), G: teeth of stamps (tappets), H: teeth of axle. Illustration from De Re Metallica Libri XII by Agricola, 1556 [83]; image: Wikimedia Commons.

While metal-rich ores were dry-crushed, less-metal-rich ores were, from the second half of the 16th century onward, crushed under running water (wet crushing) [48]. In the case of wet crushing, the water flowing through the punching troughs (with sloped bottom) carried the crushed ore pieces with it and directed them into a system of sludge ditches and hearths in which a stepwise density sorting of ore components and deaf material took place [48,99,102].

The waste water with the finer fractions of the tailings (the so-called Pochsand) was discharged into adjacent brooks and rivers, which led to huge quantities of tailings, still containing large amounts of metals, being deposited along these watercourses. Later on, the metalliferous sludge was collected in special tailings ponds, whose dams were often stepwise increased in height. However, erosion and, in few cases, also rupture of the mine tailing dams could lead to the discharge of huge amounts of tailings into adjacent rivers. Also, today, dam failures of tailings ponds can cause large environmental disasters, as for instance, in the case of the catastrophic failure of the Brumadinho mining tailings dam in Brazil in 2019 [103,104] or the release of 6.5 million m3 of acidic water and metal-bearing tailings following a tailings dam breach in the Aznalcóllar/Los Frailes mine in Spain in 1998 [105]. A further problem is that the bottoms of the tailings and other spoil heaps in the Harz Region are mostly not sealed, allowing the seepage of contaminated water into the underground [15].

It has been estimated that in the late 17th century, between 80.000 and 120.000 t of raw ore were processed annually in the western Harz and that more than half of this material was eventually discharged into the watercourses of the region, finally reaching the Innerste River [48]. The huge sediment loads entering the rivers were then further transported downstream, and this was especially intense during flooding events, when sediments were remobilized [20,99]. When the slope and the associated transport capacity of the rivers declined upon their exit from the Harz Mountains, the sediments were deposited in a fractionated way, with the smallest particles transported furthest.

In the finer fractions, especially, the separation of metal ores from host rock was for a long time inefficient, so that large amounts of metal ores (especially galena, PbS) were released into the water bodies along with the tailings [102,106]. Thus, it has been estimated that during the early 17th century, up to 75% of the metals from the mined raw ore were lost with the tailings, due to poor technology, and ended up directly in the waterways [69]. At the beginning of the 19th century, this loss had been markedly reduced, but still amounted to about 25%. Due to improved technology, in the period 1975–1985 metal loss was reduced to about 3% in the last operating metal mine of the Harz Region at Bad Grund [102,106].

4.3. Roasting and Smelting

Sulfur-containing metal ores require roasting as an intermediate step to desulfurize them before smelting. This was historically done in large fires that consumed enormous amounts of wood. Sometimes, however, special kilns were used for roasting. At temperatures of 800 to 900 °C, the sulfur is released from the metal sulfides, combines with atmospheric oxygen, and escapes as sulfur dioxide (SO2). Depending on the type of ore, the roasting process had to be repeated several times before the sulfur was largely removed [48,67]. The SO2-rich smoke (referred to as “Hüttenrauch” in German) released by the roasting process had devastating effects on the surrounding vegetation, leading to the formation of tree-free areas covered only by Calluna heath and grasses [48].

During the following smelting process, the metal oxides were reduced to their elemental form using charcoal as reducing agent [48,67]. When different metals co-occurred in an ore, these could be extracted simultaneously. Smelting was usually performed in a shaft furnace with the help of fluxing agents, e.g., fluorspar. In the process, the ore was separated into molten metal and slag, which were extracted separately from the furnace. During the smelting process, several gases (SO2, NOx, CO2, and CO) and (metal-containing) flue dust were emitted from the furnace. In addition to the harmful gases of the smoke, the metal dust emitted from the smelters (containing, e.g., PbO) also negatively impacted the environment and caused the accumulation of metals in soil and water in the immediate vicinity of the smelters [48].

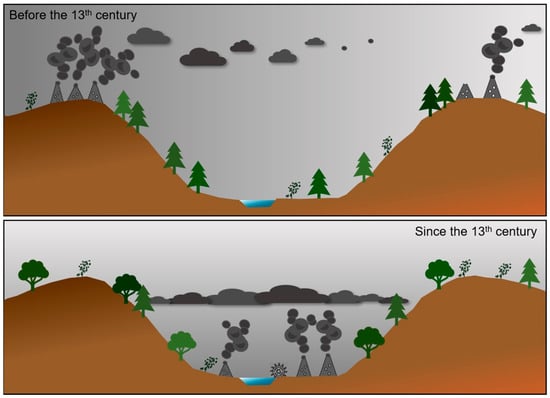

While numerous small smelting operations were spread throughout the Harz Mountains and the Harz foreland before the 13th century, a concentration of smelting places occurred during the following centuries. Because they depended on the use of hydropower, most smelters were eventually located close to the large Harz rivers below the mines, in order to guarantee the necessary water supply [60]. The relocation of the smelting operations from their original location on wind-exposed ridges to wind-protected river valleys limited the atmospheric dispersion of the smelter smoke (Figure 10) and increased the risk of dangerous smog layers forming in the valleys. The largest smelters were located near the edge of the Harz Mountains at Langelsheim, Astfeld and Oker-Harlingerode [90]. In the Upper Harz, important smelters were located near the town of Clausthal (Frankenscharrnhütte, later Clausthaler Bleihütte, until 1967), in Lautenthal (until 1967), Altenau (until 1911) and Sankt Andreasberg (Silberhütte, until 1912). Important smelter locations in the Lower Harz were Straßberg (until around 1810) and Silberhütte (Victor Friedrich Hütte, until 1909) [48]. Additionally, there were large smelters in the copper shale mining region at Mansfeld-Sangerhausen [107].

Figure 10.

Atmospheric transport of smelter smoke is restricted by the relocation of smelting places from ridges to valleys which has taken place since the 13th century (modified after [60]).

5. Impacts of Mining and Metallurgy on Environmental and Human Health

5.1. Effects on Landscape and Biota

Environmental historians see mining and metal processing as the beginning of an era of environmental degradation, with long-lasting effects on ecosystems and human health [13]. The negative impacts of the mining industry on the environment are an important issue, not only at local and regional levels, but globally, as environmental pollution from the processing and smelting of metal ores has been documented around the world [11,19,23].

The detrimental environmental impacts of mining, metallurgy, deforestation, water pollution and the exposure of flora and fauna to toxic substances were already known to ancient Greek and Roman writers [5]. These impacts were also described in detail by later authors, such as the scholar Georgius Agricola, who, in his seminal monograph De re metallica (1556) makes the following statement ([83], quotation from translation by Hoover and Hoover, p. 8): “But besides this, the strongest argument of the detractors is that the fields are devastated by mining operations, for which reason formerly Italians were warned by law that no one should dig the earth for metals and so injure their very fertile fields, their vineyards, and their olive groves. Also they argue that the woods and groves are cut down, for there is need of an endless amount of wood for timbers, machines, and the smelting of metals. And when the woods and groves are felled, then are exterminated the beasts and birds, very many of which furnish a pleasant and agreeable food for man. Further, when the ores are washed, the water which has been used poisons the brooks and streams, and either destroys the fish or drives them away. Therefore, the inhabitants of these regions, on account of the devastation of their fields, woods, groves, brooks and rivers, find great difficulty in procuring the necessaries of life, and by reason of the destruction of the timber they are forced to greater expense in erecting buildings. Thus it is said, it is clear to all that there is greater detriment from mining than the value of the metals which the mining produces.” However, despite their harmful effects on the landscape, Agricola goes on to defend mining activities because they serve the good of society and transform nature into a productive resource through mechanical and physical labor (see discussion in [13,108]).

In his treatise titled Anleitung den Harz und andere Bergwerke mit Nuzen zu bereisen (Instructions for visiting the Harz Mountains and other mines with benefits) published in 1785, Christoph Wilhelm Jakob Gatterer [109] noted that the Innerste River from the Upper Harz Mountains was very turbid, due to the huge amount of tailings discharged with the wastewater from the stamping mills. As mentioned above, these tailings still contained large amounts of metals that were unrecoverable with the methods available at the time, and posed a major health risk to exposed biota.

In 1822, Georg Friedrich Wilhelm Meyer published his two-part treatise subtitled The devastation of the Innerste in the principality of Hildesheim [99], in which he described in great detail the damage to plants, livestock, wildlife and humans caused by the Pb-containing sediments of the Innerste River, which caused large-scale silting and contamination of agricultural areas along the river course during flooding events. He concluded ([99], part 2, p. 7) that “the operation of the stamping and smelting works not only multiplies and increases the river floods, but also gives these the devastating character that is to be regarded as the greatest evil associated with them” (translation by the Authors). Subsequently, other authors have also reported on (sometimes lethal) Pb-intoxication in horses and cattle grazing on contaminated meadows along the rivers Innerste and Oker or fed hay or other forage grown in these areas [110]. Even today, instances of lead poisoning are occasionally observed in horses grazing in the Innerste floodplain after flooding events [111]. Meyer [99] also noted that the fish fauna of the Innerste River, especially in its upper and middle reaches, was depleted, regarding both species richness and abundance, compared to that of tributaries with catchment areas outside the Harz Mountains. Furthermore, he stated that fish from the Innerste River were in poorer physical condition compared to conspecifics from other rivers. This included the occurrence of certain anomalies, such as tail deformations in Northern pike (Esox lucius). Meyer [99] even undertook a self-experiment by consuming water that he had mixed with a precipitate from the substance causing the turbidity of the Innerste water. This caused a medical condition that he diagnosed as lead colic (a typical symptom of acute Pb intoxication), which prompted him to terminate the experiment. Based on his findings, Meyer [99] recommends several precautionary measures regarding the use of water from the Innerste River, and states that it is not suitable for the watering or washing of garden crops or for brewing beer. However, he also points out possible technical applications of the spoil, such as its use for building paths, plastering walls and filling lower floors, which would certainly no longer be recommended today.

The metal-rich deposits along the Harz rivers still pose a major environmental health risk. Thus, in 1968 and 1979, major bird die-offs along the Oker River were caused by lead from such deposits [112]. Recent studies analyzed the uptake of lead and zinc by blackberries (Rubus fruticosus L. agg.) growing in the Innerste floodplain and the transfer of the two metals within the plants [100], and demonstrated elevated Pb uptake of European roe deer (Capreolus capreolus) from the floodplain area [18]. Thus, median Pb concentration in antlers of roebucks culled within the Innerste floodplain at Ahrbergen and Giesen (district Hildesheim) were more than five times higher (12.0 mg/kg dry wt) than those in antlers of roebucks culled in the vicinity of the floodplain (2.3 mg/kg dry wt) in that area [18].

During the smelting processes, elements such as arsenic, lead, cadmium, copper, thallium and zinc are emitted, which can be transported atmospherically over larger distances [59,96]. Emissions from the smelters therefore not only damaged the environment in the immediate vicinity of the smelters, but also areas further away from these point sources [113].

Today, areas covered with metallophytes, soils affected by the deposition of acid-forming smoke components such as SO2, and even vegetation-free areas due to the impact of smelter smoke (Figure 11) can be found in several parts of the Harz Region [87,114,115]. The typical damage to conifer trees by smelter smoke is described as yellowing of the needles, crown drought and dieback in the crown, while the soil in the vicinity of the emission sources is depleted due to acidification, leading to transfer of metals to deeper soil layers and the leaching of these metals from the soils [87,115,116,117].

Figure 11.

Area with sparse Calluna heath and soil-erosion damage as a consequence of insufficient vegetation cover, due to the impacts of smelter smoke in the vicinity of a former lead smelter (Bleihütte Clausthal, also known as Frankenscharrnhütte, operated until 1967), near the town of Clausthal-Zellerfeld. Photo by T. Becker, 2006.

The metal(loid) content of the smelter smoke also caused damage to domestic animals (e.g., cattle and honey bees) and wildlife (e.g., red deer). Regarding arsenic, Schroeder and Reuss [117] and Prell [118] reported on intoxication in several animal species near smelters in, respectively, the Harz Mountains and the region of Tharandt in the Ore Mountains (Saxony). Meyer [99] had already recognized the damage caused by smelter smoke as a result of the lead oxide containing dust emitted with the exhaust gases. In their seminal work Die Beschädigungen der Vegetation durch Rauch und die Oberharzer Hüttenrauchschäden (The damage to vegetation caused by smoke and the Upper Harz smoke released by the roasting process), Schroeder and Reuss [117] provide a detailed description of the detrimental effects of smelter smoke on soil, vegetation and animals.

5.2. “Hüttenkatze”

The emissions from ore roasting and smelting also severely impacted the health condition of the workers in the roasting and smelting houses [48,119,120], who suffered from chronic poisoning from the metal and SO2-containing fumes. The lead vapors, in particular, were highly toxic and were responsible for the colicky abdominal pain that occurred with such a high frequency in the workers that it was given a specific name, viz., Hüttenkatze (“smelter cat”). The workers’ only protection against the toxic fumes was a wet cloth put over mouth and nose.

The production of white arsenic (As2O3) as a by-product in the silver smelter of St. Andreasberg in the Upper Harz Mountains between 1838 and ~1885 additionally exposed the workers from this smelter to As-containing emissions from the roasting and smelting processes. The affected individuals suffered from skin lesions, which went along with unbearable itching. Exposure to the toxic fumes resulted in a significantly lower average life expectancy of workers from the St. Andreasberg smelter (1880/1881: 48 years) compared to miners (1880/1881: 63 years). In the case of adverse weather conditions, the toxic fumes from the silver smelter could even reach the adjacent town, forcing its temporary abandonment by the inhabitants [119].

5.3. The Water Management System

A further legacy of the mining era is the impressive water management system that had been constructed in the western and eastern Harz Mountains and which led to massive changes in the hydrology of the area. For centuries, water was the only available power source for mining and ore processing operations (e.g., stamp mills) in the Harz. One function of water management was to provide the hydropower required for pumping, hauling and transportation work; a further function was to provide the water needed for the wet crushing of ores and the discharge of the tailings. Mining machines driven by water wheels up to 13 m high, both below and above ground, drained the tunnels and transported ore and host rock to the surface. Ever-larger pumping systems were needed to extend the depth of the mines, as the inflowing groundwater had to be drained. In addition, the water had to be routed to increasingly distant shafts using field rods and underground systems. From the 14th/15th centuries until the introduction of the steam engine in the 19th century, the construction of the large-scale water management system (which even crossed the watershed between the southern and northern Harz) brought about a serious change in natural drainage and sedimentation conditions, both near the mining operations and also in more distant regions. In order to provide sufficient hydropower, it was necessary to collect water in artificial reservoirs. Between 1536 and 1866, around 120 dammed ponds, more than 500 km of artificial ditches, 18 km of open wooden water pipes and 30 km of watercourses and underground water galleries were constructed. In the area around the mining towns in the Upper Harz (Altenau, Bad Grund, Clausthal-Zellerfeld, Lautenthal, St. Andreasberg and Wildemann), in particular, a unique water management system was created [48,70,121], which was listed as a UNESCO World Heritage Site in 2010. The Harz Region can, therefore, be seen as a special socio–natural landscape that has been shaped by diverse impacts on both environment and society, from the deep past to the present.

5.4. Current Soil Contamination and Soil Planning Areas of the Harz Region

The metal-rich deposits present throughout the Harz Region currently still pose a risk to the environment, due to a lack of effective remediation. The areas most affected by metal pollution are the Innerste floodplain (the district and city of Hildesheim, district of Wolfenbüttel and city of Salzgitter), the Oker floodplain (district of Wolfenbüttel, the district of Gifhorn, and the city of Braunschweig) and certain regions of the Harz Mountains themselves, especially the districts of Goslar and Osterode am Harz (now part of the administrative district of Göttingen). According to Steingräber et al. [20], average metal concentrations in the soils of regularly flooded areas along the Innerste River range between 912.3 and 11,075 mg/kg dry weight for lead, from 849.6 to 6875 mg/kg dry weight for zinc, and from 4.59 to 28.5 mg/kg dry weight for cadmium. These values are far above the precautionary limits applicable in Germany (70 mg/kg dry weight for Pb, 150 mg/kg dry weight for Zn, and 1 mg/kg dry weight for Cd) stipulated by the Federal Soil Protection and Contaminated Sites Ordinance (BBodSchV, [122]). In order to prevent the metal-containing deposits from becoming spread over larger areas, some of the Harz rivers have been diked, as is the case for the Innerste River downstream of Langelsheim. In the past, occasional dike failures have caused contamination of larger areas along the course of the Innerste and other Harz-borne rivers [123]. The resulting metal contamination can, if possible at all, only be remediated at great expense.

In many cases, locally excavated soil material is classified as hazardous waste in the areas affected by metal pollution, and for this reason several “soil planning areas” have been established. The soil planning-area ordinances for the districts of Goslar and Hildesheim and the towns Braunschweig, Hildesheim and Salzgitter regulate the handling of soil material excavated in these areas. Thus, polluted soil material from the contaminated regions may only be deposited in areas with the same or higher levels of contamination (deterioration ban) to reduce the spreading of contamination to other areas. Moreover, recommendations for the use of playgrounds and sports grounds situated in the contaminated areas are given, as are recommendations on the cultivation and consumption of fruit and vegetables grown in private gardens [15,123,124].

Soil contamination within the district of Goslar has been investigated on behalf of the responsible authorities since the Federal Soil Protection Act came into force, and the data has been compiled in a soil information system. Maximum concentrations reported for heavy-metal contaminated soils within the district of Goslar were 30,189 mg/kg dry weight for lead, 73,991 mg/kg dry weight for zinc, and 205 mg/kg dry weight for cadmium [125]. The persisting human health risk emanating from the widespread metal pollution was recently highlighted by a study reporting elevated blood lead levels in primary school children living in two former mining areas in the district of Goslar (Oker, part of the town Goslar, and Harlingerode, part of the town Bad Harzburg) [21]. The exact exposure pathways in the affected children are currently still unclear, but the soil seems to play an important role, and further research is needed to implement effective preventive measures. These findings, as well as those of our previous study on biota in the Innerste floodplain area [18,20,100], further highlight the need for continuous monitoring of environmental and human health in areas impacted by historical or ongoing metal mining and metallurgical activities.

6. Conclusions and Outlook

This review summarizes the history of mining and metallurgical activities in the Harz Mountains and its foreland, and their environmental impacts. The mining industry left almost no site unchanged—forests were cleared and successively reshaped, millions of tons of ore were mined and processed. The wastes from the mining, processing, and smelting operations were deposited in the Harz Mountains, but also transported into the Harz foreland and even further into the North Sea, where they pose a persisting risk to environmental and human health. All these historical human–nature interactions led to irreversible and ongoing changes in the Harz Region ecosystem. The pollution legacy of historical mining and extractive metallurgy in the Harz Mountains therefore requires constant monitoring. An example is the Oker floodplain, where, in addition to metal contamination, also increased dioxin contamination of floodplain soils has recently been reported [126].

The large-scale environmental pollution is the downside of the mining-related UNESCO World Heritage Site, but has so far received only little attention in the literature. Further research on the prospective fate of the huge amounts of toxic waste present in various environmental compartments of the area and options for environmental remediation is needed. This research must also address the effects of ongoing climate change, such as more frequent extreme rainfall and flooding events, on the remobilization and spreading of contaminated sediments. For example, during the last two decades, four major flooding events of the Innerste river have occurred (2007, 2013, 2017, and 2023) that were partly associated with dike failures causing the contamination of larger floodplain areas by river sediments rich in metals. The urgent need for inventories and the management of reservoirs of persistent, bioaccumulating and toxic substances, including remediation and securing measures, in the face of climate change, was recently also emphasized by other authors [127].

Information derived from former mines, forests, or water systems, as well as from historical sources such as old maps and drawings, as well as written accounts of mining, metallurgy or alchemy, is of central importance for reconstructing and understanding the complex dynamics of human–environmental interactions in mining areas. Such transdisciplinary research, combining approaches from science and the humanities, is also required to achieve a deeper insight into the environmental history of the Harz Region and the shaping of today’s Harz landscape.

Author Contributions

Conceptualization, L.F.S. and U.K.; methodology, L.F.S. and U.K.; resources, L.F.S., F.K., H.K., C.L. and U.K.; writing—original draft preparation, L.F.S. and U.K.; writing—review and editing, L.F.S., F.K., H.K., C.L. and U.K.; visualization, L.F.S.; supervision, H.K. and U.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data are available upon reasonable request to the first or the corresponding author.

Acknowledgments

We are grateful to Tina Asmussen, Pamela Smith and Guy Geltner for helpful discussions on the mining history of the Harz Mountains and the sociocultural aspects of mining and metallurgy, and to Georg Drechsler for providing the data used for producing Figure 6. We further thank Hans-Ulrich Kison (Figure 7), Hartmut Peucker (Figure 8) and Thomas Becker (Figure 11) for permission to reproduce photographs taken by them. The images shown in Figure 5 are distributed under a CC-BY-3.0 license.

Conflicts of Interest

The authors declare no conflicts of interests.

References

- Iturrizaga, L. The Harz Mountains and the St. Andreasberg Mining District (Germany) as a Key Region for an Interdisciplinary Anthropocene Discourse. In Proceedings of the EGU General Assembly 2021, Online, 19–30 April 2021. [Google Scholar] [CrossRef]

- Masindi, V.; Muedi, K.L. Environmental contamination by heavy metals. In Heavy Metals; Saleh, H.E.-D.M., Aglan, R.F., Eds.; InTech Open: London, UK, 2018; pp. 115–133. [Google Scholar] [CrossRef]

- Ran, H.; Guo, Z.; Yi, L.; Xiao, X.; Zhang, L.; Hu, Z.; Li, C.; Zhang, Y. Pollution characteristics and source identification of soil metal(loid)s at an abandoned arsenic-containing mine, China. J. Hazard. Mater. 2021, 413, 125382. [Google Scholar] [CrossRef]

- Forghani Tehrani, G.; Rubinos, D.A.; Kelm, U.; Ghadimi, S. Environmental and human health risks of potentially harmful elements in mining-impacted soils: A case study of the Angouran Zn-Pb mine, Iran. J. Environ. Manag. 2023, 334, 117470. [Google Scholar] [CrossRef] [PubMed]

- Hughes, J.D. Environmental Problems of the Greeks and Romans: Ecology in the Ancient Mediterranean, 2nd ed.; Johns Hopkins University Press: Baltimore, MD, USA, 2014; ISBN 1-4214-1210-1. [Google Scholar]

- Manteca, J.-I.; Ros-Sala, M.; Ramallo-Asensio, S.; Navarro-Hervás, F.; Rodríguez-Estrella, T.; Cerezo-Andreo, F.; Ortiz-Menéndez, J.-E.; de-Torres, T.; Martínez-Andreu, M. Early metal pollution in southwestern Europe: The former littoral lagoon of El Almarjal (Cartagena mining district, S.E. Spain). A sedimentary archive more than 8000 years old. Environ. Sci. Pollut. Res. 2017, 24, 10584–10603. [Google Scholar] [CrossRef] [PubMed]

- McConnell, J.R.; Wilson, A.I.; Stohl, A.; Arienzo, M.M.; Chellman, N.J.; Eckhardt, S.; Thompson, E.M.; Pollard, A.M.; Steffensen, J.P. Lead pollution recorded in Greenland Ice indicates European emissions tracked plagues, wars, and imperial expansion during antiquity. Proc. Natl. Acad. Sci. USA 2018, 115, 5726–5731. [Google Scholar] [CrossRef]

- Robu, M.; Mirea, I.-C.; Veres, D.; Olive, S.; Vlaicu, M.; Telouk, P.; Martin, J.E. Earliest evidence for heavy metal pollution on wildlife in middle age Europe. Environ. Pollut. 2025, 368, 125766. [Google Scholar] [CrossRef]

- Santana, C.S.; Montalván Olivares, D.M.; Silva, V.H.C.; Luzardo, F.H.M.; Velasco, F.G.; Jesus, R.M. Assessment of water resources pollution associated with mining activity in a semi-arid region. J. Environ. Manag. 2020, 273, 111148. [Google Scholar] [CrossRef]

- Grattan, J.P.; Adams, R.B.; Friedman, H.; Gilbertson, D.D.; Haylock, K.I.; Hunt, C.O.; Kent, M. The first polluted river? Repeated copper contamination of fluvial sediments associated with late neolithic human activity in southern Jordan. Sci. Total Environ. 2016, 573, 247–257. [Google Scholar] [CrossRef]

- Macklin, M.G.; Thomas, C.J.; Mudbhatkal, A.; Brewer, P.A.; Hudson-Edwards, K.A.; Lewin, J.; Scussolini, P.; Eilander, D.; Lechner, A.; Owen, J.; et al. Impacts of metal mining on river systems: A global assessment. Science 2023, 381, 1345–1350. [Google Scholar] [CrossRef]

- Li, M.; Zhou, J.; Cheng, Z.; Ren, Y.; Liu, Y.; Wang, L.; Cao, L.; Shen, Z. Pollution levels and probability risk assessment of potential toxic elements in soil of Pb-Zn smelting areas. Environ. Geochem. Health 2024, 46, 165. [Google Scholar] [CrossRef]

- Geltner, G. Ecological impacts and environmental perceptions of mining in Europe, 1200–1550: Preliminary notes. Parergon 2023, 40, 157–180. [Google Scholar] [CrossRef]

- Iturrizaga, L.; Ließmann, W. Anthropogenic Landscape Transformations and Geomorphological Landform Assemblages in the Context of Historical Mining in the Harz Mountains (Germany): Case Study Sankt Andreasberg Mining District. In Proceedings of the EGU General Assembly 2024, Vienna, Austria, 14–19 April 2024. [Google Scholar] [CrossRef]

- Knolle, F.; Wegener, U.; Rupp, H. 6.000 Jahre Umweltfolgen der Harzer Montanwirtschaft. In Das reichste Erz—Im UNESCO-Weltkulturerbe Rammelsberg: Exkursionsführer und Veröffentlichungen der Deutschen Gesellschaft für Geowissenschaften, 265; Stedingk, K., Kleeberg, K., Großewinkelmann, J., Eds.; Mecke Druck und Verlag: Duderstadt, Germany, 2020; pp. 121–147. ISBN 978-3-86944-203-7. [Google Scholar]

- Boehnert, S.; Ruiz Soto, S.; Fox, B.R.S.; Yokoyama, Y.; Hebbeln, D. Historic development of heavy metal contamination into the firth of Thames, New Zealand. Geo-Mar. Lett. 2020, 40, 149–165. [Google Scholar] [CrossRef]

- Boxberg, F.; Asendorf, S.; Bartholomä, A.; Schnetger, B.; Lange, W.P.; Hebbeln, D. Historical anthropogenic heavy metal input to the south-eastern North Sea. Geo-Mar. Lett. 2020, 40, 135–148. [Google Scholar] [CrossRef]

- Ludolphy, C.; Kierdorf, U.; Kierdorf, H. Antlers of European roe deer (Capreolus capreolus) as monitoring units to assess lead pollution in a floodplain contaminated by historical metal ore mining, processing, and smelting in the Harz Mountains, Germany. Environ. Pollut. 2022, 302, 119080. [Google Scholar] [CrossRef]

- Macklin, M.G.; Hudson-Edwards, K.A.; Dawson, E.J. The significance of pollution from historic metal mining in the Pennine orefields on river sediment contaminant fluxes to the North Sea. Sci. Total Environ. 1997, 194–195, 391–397. [Google Scholar] [CrossRef]

- Steingräber, L.F.; Ludolphy, C.; Metz, J.; Germershausen, L.; Kierdorf, H.; Kierdorf, U. Heavy metal concentrations in floodplain soils of the Innerste river and in leaves of wild blackberries (Rubus fruticosus L. agg.) growing within and outside the floodplain: The legacy of historical mining activities in the Harz Mountains (Germany). Environ. Sci. Pollut. Res. 2022, 29, 22469–22482. [Google Scholar] [CrossRef] [PubMed]

- Strieker, S.; Radon, K.; Forster, F.; Örnek, Ö.K.; Wengenroth, L.; Schmotz, W.; Sonnemann, F.; Hoopmann, M.; Hepp, M.; Nowak, D.; et al. Biomonitoring of lead in blood of children living in a former mining area in Lower Saxony, Germany. Environ. Sci. Pollut. Res. 2024, 31, 29971–29978. [Google Scholar] [CrossRef]

- Woo, J.-S.; Choi, M.-S.; Song, Y.-H. Spatio-temporal accumulation and sources of anthropogenic Pb in Ulleung basin sediments, East/Japan Sea, based on stable Pb isotope ratios. Environ. Sci. Pollut. Res. 2023, 30, 89442–89458. [Google Scholar] [CrossRef]

- Brännvall, M.-L.; Bindler, R.; Renberg, I.; Emteryd, O.; Bartnicki, J.; Billström, K. The medieval metal industry was the cradle of modern large-scale atmospheric lead pollution in northern Europe. Environ. Sci. Technol. 1999, 33, 4391–4395. [Google Scholar] [CrossRef]

- Hong, S.; Candelone, J.-P.; Patterson, C.C.; Boutron, C.F. Greenland Ice evidence of hemispheric lead pollution two millennia ago by Greek and Roman civilizations. Science 1994, 265, 1841–1843. [Google Scholar] [CrossRef]

- McConnell, J.R.; Chellman, N.J.; Wilson, A.I.; Stohl, A.; Arienzo, M.M.; Eckhardt, S.; Fritzsche, D.; Kipfstuhl, S.; Opel, T.; Place, P.F.; et al. Pervasive arctic lead pollution suggests substantial growth in medieval silver production modulated by plague, climate, and conflict. Proc. Natl. Acad. Sci. USA 2019, 116, 14910–14915. [Google Scholar] [CrossRef]

- Shotyk, W.; Weiss, D.; Appleby, P.G.; Cheburkin, A.K.; Frei, R.; Gloor, M.; Kramers, J.D.; Reese, S.; Van Der Knaap, W.O. History of atmospheric lead deposition since 12,370 (14)C Yr BP from a peat bog, Jura Mountains, Switzerland. Science 1998, 281, 1635–1640. [Google Scholar] [CrossRef]

- Silva-Sánchez, N.; Armada, X.-L. Environmental impact of Roman mining and metallurgy and its correlation with the archaeological evidence: A European perspective. Environ. Archaeol. 2023, 1–25. [Google Scholar] [CrossRef]

- Longman, J.; Veres, D.; Ersek, V.; Tamas, C.G.; Haliuc, A.; Magyari, E.; Gogaltan, F.; Panajiotidis, S.; Papadopoulou, M. Central-eastern Europe as a centre of middle ages extractive metallurgy. J. Archaeol. Sci. 2024, 172, 106093. [Google Scholar] [CrossRef]

- Makra, L.; Brimblecombe, P. Selections from the history of environmental pollution, with special attention to air pollution. Part 1. Int. J. Environ. Pollut. 2004, 22, 641. [Google Scholar] [CrossRef]

- Nriagu, J.O. Occupational exposure to lead in ancient times. Sci. Total. Environ. 1983, 31, 105–116. [Google Scholar] [CrossRef]

- Caito, S.; Lopes, A.C.B.A.; Paoliello, M.M.B.; Aschner, M. Toxicology of lead and its damage to mammalian organs. In Lead—Its Effects on Environment and Health; Sigel, A., Sigel, H., Sigel, R.K.O., Eds.; De Gruyter: Berlin, Germany, 2017; pp. 501–534. ISBN 978-3-11-043433-0. [Google Scholar]

- Collin, M.S.; Venkatraman, S.K.; Vijayakumar, N.; Kanimozhi, V.; Arbaaz, S.M.; Stacey, R.G.S.; Anusha, J.; Choudhary, R.; Lvov, V.; Tovar, G.I.; et al. Bioaccumulation of lead (Pb) and its effects on human: A review. J. Hazard. Mater. Adv. 2022, 7, 100094. [Google Scholar] [CrossRef]

- Hernberg, S. Lead poisoning in a historical perspective. Am. J. Ind. Med. 2000, 38, 244–254. [Google Scholar] [CrossRef]

- Pattee, O.; Pain, D. Lead in the Environment. In Handbook of Ecotoxicology, 2nd ed.; Hoffman, D., Rattner, B., Allen Burton, G., Jr., Cairns, J., Jr., Eds.; CRC Press: Boca Raton, FL, USA, 2002; ISBN 978-1-56670-546-2. [Google Scholar]

- Zulfiqar, U.; Farooq, M.; Hussain, S.; Maqsood, M.; Hussain, M.; Ishfaq, M.; Ahmad, M.; Anjum, M.Z. Lead toxicity in plants: Impacts and remediation. J. Environ. Manag. 2019, 250, 109557. [Google Scholar] [CrossRef]

- Ma, W.-C. Lead in mammals. In Environmental Contaminants in Biota: Interpreting Tissue Concentrations, 2nd ed.; Beyer, W.N., Meador, J.P., Eds.; CRC Press: Boca Raton, FL, USA, 2011; pp. 595–607. ISBN 978-1-4200-8405-4. [Google Scholar]

- Ewers, U.; Schlipköter, H.W. Lead. In Metals and Their Compounds in the Environment: Occurrence, Analysis, and Biological Relevance; Merian, E., Ed.; VCH: Weinheim, Germany, 1991; ISBN 978-3-527-26521-3. [Google Scholar]

- Greenwood, N.N.; Earnshaw, A. Chemistry of the Elements, 2nd ed.; Elsevier-Butterworth-Heinemann: Amsterdam, The Netherlands, 1997; ISBN 978-0-7506-3365-9. [Google Scholar]

- Åberg, G.E. Tracing pollution and its sources with isotopes. Water Air Soil Pollut. 2001, 130, 1577–1582. [Google Scholar] [CrossRef]

- Durali-Mueller, S.; Brey, G.P.; Wigg-Wolf, D.; Lahaye, Y. Roman lead mining in Germany: Its origin and development through time deduced from lead isotope provenance studies. J. Archaeol. Sci. 2007, 34, 1555–1567. [Google Scholar] [CrossRef]

- Farmer, J.G.; MacKenzie, A.B.; Moody, G.H. Human teeth as historical biomonitors of environmental and dietary lead: Some lessons from isotopic studies of 19th and 20th century archival material. Environ. Geochem. Health 2006, 28, 421–430. [Google Scholar] [CrossRef] [PubMed]

- Komárek, M.; Ettler, V.; Chrastný, V.; Mihaljevic, M. Lead isotopes in environmental sciences: A review. Environ. Int. 2008, 34, 562–577. [Google Scholar] [CrossRef]

- Monna, F.; Hamer, K.; Lévêque, J.; Sauer, M. Pb isotopes as a reliable marker of early mining and smelting in the northern Harz province (Lower Saxony, Germany). J. Geochem. Explor. 2000, 68, 201–210. [Google Scholar] [CrossRef]

- Ali, H.; Khan, E.; Ilahi, I. Environmental chemistry and ecotoxicology of hazardous heavy metals: Environmental persistence, toxicity, and bioaccumulation. J. Chem. 2019, 2019, 6730305. [Google Scholar] [CrossRef]

- Briffa, J.; Sinagra, E.; Blundell, R. Heavy metal pollution in the environment and their toxicological effects on humans. Heliyon 2020, 6, e04691. [Google Scholar] [CrossRef]

- Proshad, R.; Kormoker, T.; Mursheed, N.; Islam, M.; Bhuyan, I.; Islam, S.; Mithu, T.N. Heavy metal toxicity in agricultural soil due to rapid industrialization in Bangladesh: A review. Int. J. Adv. Geosci. 2018, 6, 83. [Google Scholar] [CrossRef]

- Knolle, F.; Oesterreich, B.; Schulz, R.; Wrede, V. Der Harz: Geologische Exkursionen, 1st ed.; Perthes Exkursionsführer; Perthes: Gotha, Germany, 1997; ISBN 978-3-623-00659-8. [Google Scholar]

- Ließmann, W. Historischer Bergbau Im Harz, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 978-3-540-31327-4. [Google Scholar]

- Mohr, K. Geologie und Minerallagerstätten des Harzes, 2nd ed.; Schweizerbart: Stuttgart, Germany, 1993; ISBN 978-3-510-65154-2. [Google Scholar]

- Linnemann, U.; Zweig, M.; Zieger-Hofmann, M.; Vietor, T.; Zieger, J.; Haschke, J.; Gärtner, A.; Mende, K.; Krause, R.; Knolle, F. The Harz Mountains (Germany)—Cadomia meets Avalonia and Baltica: U–Pb ages of detrital and magmatic zircon as a key for the decoding of Pangaea’s central suture. Geol. Soc. Spec. Publ. 2024, 542, 403–431. [Google Scholar] [CrossRef]

- Hoppe, O. Die Bergwerke, Aufbereitungsanstalten und Hütten im Ober—Und Unterharz; Grosse: Clausthal, Germany, 1883. [Google Scholar]

- Holm, K.; Wüstemann, O. Gewässer. In Der Hochharz—Vom Brocken bis in das nördliche Vorland. Landschaften in Deutschland, Band 73; Brückner, J., Denecke, D., Porada, H.T., Wegener, U., Eds.; Böhlau Verlag: Köln/Weimar, Germany, 2016; pp. 37–43. ISBN 978-3-412-20467-9. [Google Scholar]

- Matschullat, J.; Malessa, V. Naturräumliche Grundlagen, eine Einführung. In Gefahr für Ökosysteme und Wasserqualität: Ergebnisse Interdisziplinärer Forschung im Harz; Matschullat, J., Schneider, J., Heinrichs, H., Ulrich, B., Eds.; Springer: Berlin/Heidelberg, Germany, 1994; pp. 26–28. [Google Scholar] [CrossRef]

- Large, D.; Walcher, E. The Rammelsberg massive sulphide Cu-Zn-Pb-Ba-deposit, Germany: An example of sediment-hosted, massive sulphide mineralisation. Miner. Deposita. 1999, 34, 522–538. [Google Scholar] [CrossRef]

- Dobler, L. Der Einfluß der Bergbaugeschichte im Ostharz auf die Schwermetalltiefengradienten in historischen Sedimenten und die fluviale Schwermetalldispersion in den Einzugsgebieten von Bode und Selke im Harz. Doctoral Thesis, Martin-Luther-Universität Halle-Wittenberg, Halle, Germany, 1999. [Google Scholar]

- Bartels, C.; Fessner, M.; Klappauf, L.; Linke, F.-A. Kupfer, Blei und Silber aus dem Goslarer Rammelsberg von den Anfängen bis 1620: Die Entwicklung des Hüttenwesens von den frühmittelalterlichen Schmelzplätzen im Wald bis zur Metallerzeugung in großem Maßstab am Beginn des 17. Jahrhunderts nach den archäologischen und schriftlichen Quellen; Montanregion Harz; Deutsches Bergbau-Museum: Bochum, Germany, 2007; ISBN 978-3-937203-29-4. [Google Scholar]

- Segers-Glocke, C.; Witthöft, H. (Eds.) Aspects of Mining and Smelting in the Upper Harz Mountains (up to the 13th/14th Century)—in the Early Times of a Developing European Culture and Economy; Scripta Mercaturae Verlag: St. Katharinen, Germany, 2000; Volume 22, ISBN 978-3-89590-101-0. [Google Scholar]

- Flindt, S.; Hummel, S. Rätsel Lichtensteinhöhle. Eine Großfamilie aus der Bronzezeit; WBG Theiss: Darmstadt, Germany, 2021; ISBN 978-3806243642. [Google Scholar]

- Deicke, M. Mining heritage in Germany: Mining and smelting in the Harz Mountains a never-ending environmental story. In Sustainable Mining and Environment: A German-Latin American Perspective; Breitkreuz, C., Drebenstedt, C., Eds.; Freiberger Forschungshefte C Geowissenschaften: Freiberg, Germany, 2009; Volume 523, pp. 71–78. ISBN 978-3-86012-359-1. [Google Scholar]

- Deicke, M.; Ruppert, H. Bergbau und Umweltgeschichte des Oberharzes. Jber. Mitt. Oberrhein. Geol. Ver. N.F. 2013, 95, 259–288. [Google Scholar]

- Klappauf, L. Spuren deuten—Frühe Montanwirtschaft im Harz. In Auf den Spuren einer frühen Industrielandschaft. Naturraum—Mensch—Umwelt im Harz; Arbeitshefte zur Denkmalpflege in Niedersachsen; CW Niemeyer Buchverlag GmbH: Hameln, Germany, 2000; Volume 21, pp. 19–27. [Google Scholar] [CrossRef]

- Klappauf, L. Studies of the development and structure of early metal production. In Aspects of Mining and Smelting in the Upper Harz Mountains (up to the 13th/14th Century)—in the Early Times of a Developing European Culture and Economy; Segers-Glocke, C., Witthöft, H., Eds.; Scripta Mercaturae Verlag: St. Katharinen, Germany, 2000; Volume 22, pp. 1–29. [Google Scholar]

- Stedingk, K.; Ließmann, W.; Bode, R. Harz: Bergbaugeschichte, Mineralienschätze, Fundorte; Bode Verlag GmbH: Salzhemmendorf, Germany, 2016; ISBN 978-3-942588-16-4. [Google Scholar]

- Rettich, M. Das Buch vom Bergwerk; Oetinger: Hamburg, Germany, 2001; ISBN 978-3-7891-4604-6. [Google Scholar]

- Bartels, C. The production of silver, copper, and lead in the Harz Mountains from late medieval times to the onset of industrialization. In Materials and Expertise in Early Modern Europe: Between Market and Laboratory; University of Chicago Press: Chicago, IL, USA, 2010; pp. 71–100. ISBN 978-0226439686. [Google Scholar]

- Bartels, C. Der Bergbau—Ein Überblick. In Auf den Spuren einer Frühen Industrielandschaft: Naturraum–Mensch–Umwelt im Harz; Arbeitshefte zur Denkmalpflege in Niedersachsen; CW Niemeyer Buchverlag GmbH: Hameln, Germany, 2000; Volume 21, pp. 106–111. [Google Scholar] [CrossRef]

- Asmus, B. Medieval Copper Smelting in the Harz Mountains, Germany; Montanregion Harz; Deutsches Bergbau-Museum: Bochum, Germany, 2012; Volume 10. [Google Scholar]

- Malessa, V. Waldgeschichte des Harzes vom 10. bis 19. Jahrhundert. In Gefahr für Ökosysteme und Wasserqualität: Ergebnisse interdisziplinärer Forschung im Harz; Matschullat, J., Schneider, J., Heinrichs, H., Ulrich, B., Eds.; Springer: Berlin/Heidelberg, Germany, 1994; pp. 37–39. [Google Scholar] [CrossRef]

- Bartels, C. Vom frühzeitlichen Montangewerbe zur Bergbauindustrie. Erzbergbau im Oberharz 1635–1866. Veröffentl. Deut. Bergbaumuseum Boch. 1992, 54, 20–23. [Google Scholar]

- Oberharzer Geschichts—Und Museumsverein. Der Historische Oberharzer Bergbau und seine Wasserwirtschaft. Ein Überblick; Oberharzer Geschichts—Und Museumsverein: Clausthal-Zellerfeld, Germany, 1990. [Google Scholar]

- Hettwer, K.; Deicke, M.; Ruppert, H. Fens in karst sinkholes—Archives for long lasting ‘immission’ chronologies. Water Air Soil Pollut. 2003, 149, 363–384. [Google Scholar] [CrossRef]

- Kempter, H.; Frenzel, B. The impact of early mining and smelting on the local tropospheric aerosol detected in ombrotrophic peat bogs in the Harz, Germany. Water Air Soil Pollut. 2000, 121, 93–108. [Google Scholar] [CrossRef]

- Deicke, M. Findings concerning the environmental history of the Harz Mountains and the utilisation of mineral resources. In Aspects of Mining and Smelting in the Upper Harz Mountains (up to the 13th/14th Century)—In the Early Times of a Developing European Culture and Economy; Segers-Glocke, C., Witthöft, H., Eds.; Scripta Mercaturae Verlag: St. Katharinen, Germany, 2000; Volume 22, pp. 66–78. [Google Scholar]

- Hillebrecht, M.-L. Der Wald als Energielieferant für das Berg—Und Hüttenwesen. In Auf den Spuren einer frühen Industrielandschaft. Naturraum—Mensch—Umwelt im Harz; Arbeitshefte zur Denkmalpflege in Niedersachsen; CW Niemeyer Buchverlag GmbH: Hameln, Germany, 2000; Volume 21, pp. 83–95. [Google Scholar] [CrossRef]

- Hillebrecht, M.-L. Energiegewinnung auf Kosten der Umwelt. Berichte zur Denkmalpfl. Niedersachs. 1989, 9, 80–85. [Google Scholar]

- Stedingk, K.; Mueller, A. Der Rammelsberg—Die reichste deutsche Buntmetall-Erzlagerstätte. In Das reichste Erz—Im UNESCO-Weltkulturerbe Rammelsberg: Exkursionsführer und Veröffentlichungen der Deutschen Gesellschaft für Geowissenschaften, 265; Stedingk, K., Kleeberg, K., Großewinkelmann, J., Eds.; Mecke Druck und Verlag: Duderstadt, Germany, 2020; pp. 25–46. ISBN 978-3-86944-203-7. [Google Scholar]

- Frenzel, B.; Kempter, H. Der Einfluss von Erzbergbau und Erzverhüttung auf die Umweltbedingungen des Harzes in der Vergangenheit. In Auf den Spuren einer frühen Industrielandschaft: Naturraum–Mensch–Umwelt im Harz; Arbeitshefte zur Denkmalpflege in Niedersachsen; CW Niemeyer Buchverlag GmbH: Hameln, Germany, 2000; Volume 21, pp. 72–77. [Google Scholar] [CrossRef]

- Willerding, U. Die Landschaft Harz. In Auf den Spuren einer frühen Industrielandschaft. Naturraum—Mensch—Umwelt im Harz; Arbeitshefte zur Denkmalpflege in Niedersachsen; CW Niemeyer Buchverlag GmbH: Hameln, Germany, 2000; Volume 21, pp. 47–54. [Google Scholar] [CrossRef]

- Biringuccio, V. De La Pirotechnia; Venturino Roffinello: Venice, Italy, 1540. [Google Scholar]

- Borg, G.; Piestrzyński, A.; Bachmann, G.H.; Püttmann, W.; Walther, S.; Fiedler, M. An overview of the European Kupferschiefer deposits. Econ. Geol. Spec. Pub. 2012, 16, 455–486. [Google Scholar] [CrossRef]

- Dobler, L. Schwermetalltiefengradienten in Auensedimenten der Selke als Ausdruck der historischen Montanwirtschaft im Ostharz. Hercynia N.F. 2001, 34, 171–186. [Google Scholar] [CrossRef]

- Bachmann, H.-G. Zur Metallerzeugung im Harz während des Früh—Und Hochmittelalters. In Auf den Spuren einer frühen Industrielandschaft. Naturraum—Mensch—Umwelt im Harz; Arbeitshefte zur Denkmalpflege in Niedersachsen; CW Niemeyer Buchverlag GmbH: Hameln, Germany, 2000; Volume 21, pp. 129–139. [Google Scholar] [CrossRef]

- Agricola, G. De Re Metallica Libri XII. Basel, 1556. Translated from the First Latin Edition of 1556 by H. C. Hoover and L. H. Hoover, 3rd ed.; Dover Publications, Inc.: New York, NY, USA, 1950; ISBN 3-423-06086-7. [Google Scholar]

- Ercker, L. Aula Subterranea. Domina Dominantium Subdita Subditorum; Das ist: Untererdische Hofhaltung, Ohne welche weder die Herren regiren/noch die Unterthanen gehorchen können; Johann David Zunners: Franckfurt, Germany, 1684. [Google Scholar]

- Ercker, L. Beschreibung: Allerfürnemisten Mineralischen Ertzt Vnnd Berckwercksarten; Schwartz: Prag, Czechia, 1574. [Google Scholar]

- Löhneyß, G.E. Bericht vom Bergwerck, Wie Man Dieselben Bawen und in Guten Wolstande Bringen Sol, Sampt Allen Dazu Gehörigen Arbeiten, Ordnung und Rechtlichen Processen; Zellerfeld, Germany, 1617. [Google Scholar]