A Case Study of Renewable Natural Gas Techno-Economics and Emissions at a Wastewater Treatment Plant

Abstract

1. Introduction

2. Materials and Methods

2.1. Gas Chromatography

2.2. Techno-Economic Model

2.3. Model Inputs and Limits

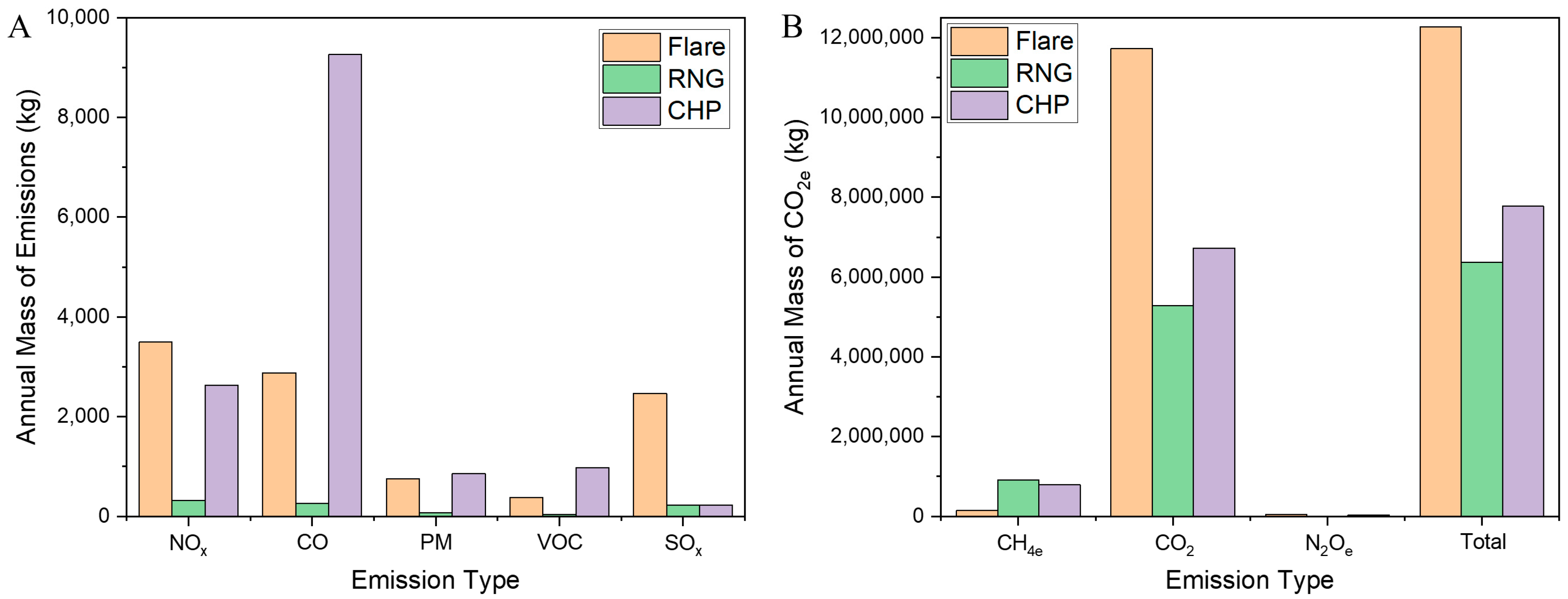

2.4. Emission Analysis

2.5. CHP Analysis

3. Results

3.1. Gas Chromatography

3.2. Techno-Economic Analysis Results

3.3. Emission Reduction

3.4. Comparison to CHP

3.5. Model Validation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BGmax | Max biogas flowrate |

| CC | Capital cost |

| CHP | Combined heat and power |

| EPA | Environmental Protection Agency |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| IC | Interconnect cost |

| LNG | Liquefied natural gas |

| LR | Leak rate |

| NG | Natural gas |

| NGC | Natural gas cost |

| NPV | Net present value |

| O&M | Operations and maintenance |

| PBP | Payback period |

| PC | Pipeline cost |

| RFS | Renewable fuel |

| RIN | Renewable identification number |

| RNG | Renewable natural gas |

| USD | United States dollar |

| U.S. | United States |

| VOC | Volatile organic compound |

| WWTP | Wastewater treatment plant |

References

- Sheets, J.P.; Shah, A. Techno-Economic Comparison of Biogas Cleaning for Grid Injection, Compressed Natural Gas, and Biogas-to-Methanol Conversion Technologies. Biofuels Bioprod. Biorefining 2018, 12, 412–425. [Google Scholar] [CrossRef]

- Cyrs, T.; Feldmann, J.; Gasper, R. Renewable Natural Gas as A Climate Strategy: Guidance for State Policymakers; World Resources Institute: Washington, DC, USA, 2020. [Google Scholar]

- Gai, H.; Wang, A.; Fang, J.; Lou, H.H.; Chen, D.; Li, X.; Martin, C. Clean Combustion and Flare Minimization to Reduce Emissions from Process Industry. Curr. Opin. Green. Sustain. Chem. 2020, 23, 38–45. [Google Scholar] [CrossRef]

- Williams, R.B.; Ely, C.; Martynowicz, T.; Kosuko, M. Evaluating the Air Quality, Climate & Eco-Nomic Impacts of Biogas Management Technologies Office of Research and Development; U.S. Environmental Protection Agency: Washington, DC, USA, 2016. [Google Scholar]

- Riley, D.M.; Tian, J.; Güngör-Demirci, G.; Phelan, P.; Villalobos, J.R.; Milcarek, R.J. Techno-Economic Assessment of CHP Systems in Wastewater Treatment Plants. Environments 2020, 7, 74. [Google Scholar] [CrossRef]

- Golmakani, A.; Ali Nabavi, S.; Wadi, B.; Manovic, V. Advances, Challenges, and Perspectives of Biogas Cleaning, Upgrading, and Utilisation. Fuel 2022, 317, 123085. [Google Scholar] [CrossRef]

- Amaraibi, R.J.; Joseph, B.; Kuhn, J.N. Techno-Economic and Sustainability Analysis of Siloxane Removal from Landfill Gas Used for Electricity Generation. J. Environ. Manag. 2022, 314, 115070. [Google Scholar] [CrossRef]

- Environmental Protection Agency. Landfill Gas Energy Project Development Handbook. Chapter 4. Project Economics and Financing; Environmental Protection Agency: Denver, CO, USA, 2021. [Google Scholar]

- Pratson, L.F.; Fay, J.; Parvathikar, S. Market Prospects for Biogas-to-Energy Projects in the U.S.A. Based on a Techno-Economic Assessment of Major Biogas Sources in North Carolina. Sustain. Energy Technol. Assess. 2023, 60, 103557. [Google Scholar] [CrossRef]

- Water Environment Federation. The Water Resources Utility of the Future A Blueprint for Action; Water Environment Federation: Alexandria, Virginia, 2013. [Google Scholar]

- Tanigawa, S. Fact Sheet|Biogas: Converting Waste to Energy. Available online: https://www.eesi.org/papers/view/fact-sheet-biogasconverting-waste-to-energy (accessed on 13 December 2022).

- Ullah Khan, I.; Hafiz Dzarfan Othman, M.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Wan Azelee, I. Biogas as a Renewable Energy Fuel—A Review of Biogas Upgrading, Utilisation and Storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar]

- Al-Wahaibi, A.; Osman, A.I.; Al-Muhtaseb, A.H.; Alqaisi, O.; Baawain, M.; Fawzy, S.; Rooney, D.W. Techno-Economic Evaluation of Biogas Production from Food Waste via Anaerobic Digestion. Sci. Rep. 2020, 10, 15719. [Google Scholar] [CrossRef]

- Yang, M.; Baral, N.R.; Anastasopoulou, A.; Breunig, H.M.; Scown, C.D. Cost and Life-Cycle Greenhouse Gas Implications of Integrating Biogas Upgrading and Carbon Capture Technologies in Cellulosic Biorefineries. Environ. Sci. Technol. 2020, 54, 12810–12819. [Google Scholar] [CrossRef]

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of Appropriate Biogas Upgrading Technology—A Review of Biogas Cleaning, Upgrading and Utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar]

- Keogh, N.; Corr, D.; Monaghan, R.F.D. Biogenic Renewable Gas Injection into Natural Gas Grids: A Review of Technical and Economic Modelling Studies. Renew. Sustain. Energy Rev. 2022, 168, 112818. [Google Scholar] [CrossRef]

- Thamsiriroj, T.; Smyth, H.; Murphy, J.D. A Roadmap for the Introduction of Gaseous Transport Fuel: A Case Study for Renewable Natural Gas in Ireland. Renew. Sustain. Energy Rev. 2011, 15, 4642–4651. [Google Scholar] [CrossRef]

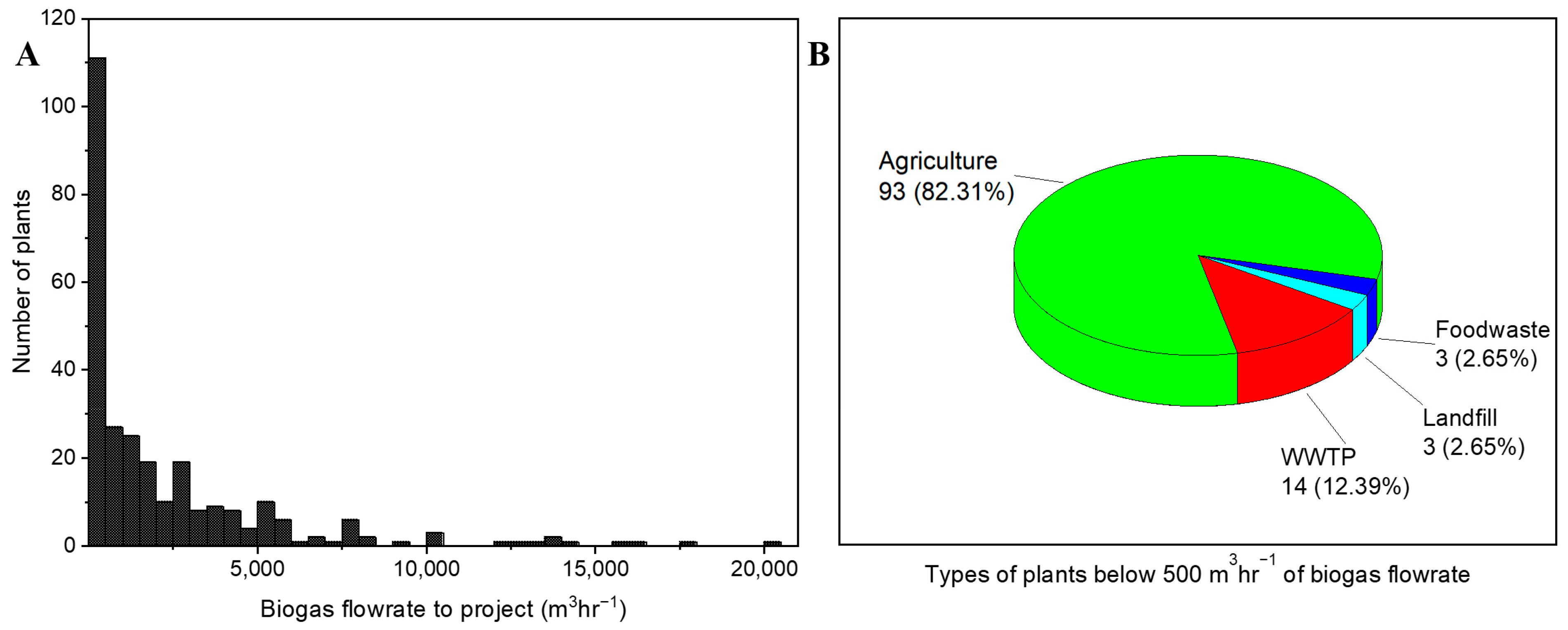

- Environmental Protection Agency RNG Project Map. Available online: https://www.epa.gov/lmop/renewable-natural-gas#rngmap (accessed on 3 January 2023).

- Mintz, M.; Vos, P. Renewable Natural Gas Database. Available online: https://www.anl.gov/esia/reference/renewable-natural-gas-database (accessed on 16 May 2023).

- Cucchiella, F.; D’adamo, I.; Gastaldi, M. International Journal of Energy Economics and Policy Profitability Analysis for Biomethane: A Strategic Role in the Italian Transport Sector. Int. J. Energy Econ. Policy 2015, 5, 440–449. [Google Scholar]

- Statista Monthly Prices for Natural Gas in the United States and Europe from January 2014 to August 2022. Available online: https://www.statista.com/statistics/673333/monthly-prices-for-natural-gas-in-the-united-states-and-europe/ (accessed on 3 January 2023).

- Nyamukamba, P.; Mukumba, P.; Chikukwa, E.S.; Makaka, G. Biogas Upgrading Approaches with Special Focus on Siloxane Removal—A Review. Energies 2020, 13, 6088. [Google Scholar] [CrossRef]

- Pascual, C.; Cantera, S.; Lebrero, R. Volatile Siloxanes Emissions: Impact and Sustainable Abatement Perspectives. Trends Biotechnol. 2021, 39, 1245–1248. [Google Scholar] [CrossRef]

- Abu Seman, N.; Harun, N. Simulation of Pressurized Water Scrubbing Process for Biogas Purification Using Aspen Plus. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2019; Volume 502. [Google Scholar]

- Noorain, R.; Kindaichi, T.; Ozaki, N.; Aoi, Y.; Ohashi, A. Biogas Purification Performance of New Water Scrubber Packed with Sponge Carriers. J. Clean. Prod. 2019, 214, 103–111. [Google Scholar] [CrossRef]

- Gantina, T.M.; Iriani, P.; Maridjo; Wachjoe, C.K. Biogas Purification Using Water Scrubber with Variations of Water Flow Rate and Biogas Pressure. In Journal of Physics: Conference Series; Institute of Physics Publishing: Bristol, UK, 2020; Volume 1450. [Google Scholar]

- McDonald, T.M.; Anderson, C.E.; Herm, Z.R.; Wenz, G.B. Efficient Biogas Upgrading Technology Based on Metal-Organic Frameworks; California Energy Commission: Sacramento, CA, USA, 2020. [Google Scholar]

- Grande, C.A. Biogas Upgrading by Pressure Swing Adsorption. In Biofuel's Engineering Process Technology; In-Tech Electronics Ltd.: Hong Kong, 2011. [Google Scholar]

- Augelletti, R.; Conti, M.; Annesini, M.C. Pressure Swing Adsorption for Biogas Upgrading. A New Process Configuration for the Separation of Biomethane and Carbon Dioxide. J. Clean. Prod. 2017, 140, 1390–1398. [Google Scholar] [CrossRef]

- Bahrun, M.H.V.; Bono, A.; Othman, N.; Zaini, M.A.A. Carbon Dioxide Removal from Biogas through Pressure Swing Adsorption—A Review. Chem. Eng. Res. Des. 2022, 183, 285–306. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Lin, P.-W.; Chen, W.-H.; Yen, F.-Y.; Yang, H.-S.; Chou, C.-T. Biogas Upgrading by Pressure Swing Adsorption with Design of Experiments. Processes 2021, 9, 1325. [Google Scholar] [CrossRef]

- Carranza-Abaid, A.; Wanderley, R.R.; Knuutila, H.K.; Jakobsen, J.P. Analysis and Selection of Optimal Solvent-Based Technologies for Biogas Upgrading. Fuel 2021, 303, 121327. [Google Scholar] [CrossRef]

- Wang, H.; Ma, C.; Yang, Z.; Lu, X.; Ji, X. Improving High-Pressure Water Scrubbing through Process Integration and Solvent Selection for Biogas Upgrading. Appl. Energy 2020, 276, 115462. [Google Scholar] [CrossRef]

- Capra, F.; Fettarappa, F.; Magli, F.; Gatti, M.; Martelli, E. Biogas Upgrading by Amine Scrubbing: Solvent Comparison between MDEA and MDEA/MEA Blend. Energy Procedia 2018, 148, 970–977. [Google Scholar] [CrossRef]

- Vrbová, V.; Ciahotný, K. Upgrading Biogas to Biomethane Using Membrane Separation. Energy Fuels 2017, 31, 9393–9401. [Google Scholar] [CrossRef]

- Zito, P.F.; Brunetti, A.; Barbieri, G. Multi-Step Membrane Process for Biogas Upgrading. J. Memb. Sci. 2022, 652, 120454. [Google Scholar] [CrossRef]

- Fajrina, N.; Yusof, N.; Ismail, A.F.; Aziz, F.; Bilad, M.R.; Alkahtani, M. A Crucial Review on the Challenges and Recent Gas Membrane Development for Biogas Upgrading. J. Environ. Chem. Eng. 2023, 11, 110235. [Google Scholar] [CrossRef]

- Lackey, J.C.; Peppley, B.; Champagne, P.; Maier, A. Composition and Uses of Anaerobic Digestion Derived Biogas from Wastewater Treatment Facilities in North America. Waste Manag. Res. J. A Sustain. Circ. Econ. 2015, 33, 767–771. [Google Scholar] [CrossRef]

- Abanades, S.; Abbaspour, H.; Ahmadi, A.; Das, B.; Ehyaei, M.A.; Esmaeilion, F.; El Haj Assad, M.; Hajilounezhad, T.; Jamali, D.H.; Hmida, A.; et al. A Critical Review of Biogas Production and Usage with Legislations Framework across the Globe. Int. J. Environ. Sci. Technol. 2022, 19, 3377–3400. [Google Scholar] [CrossRef]

- Admasu, A.; Bogale, W.; Mekonnen, Y.S. Experimental and Simulation Analysis of Biogas Production from Beverage Wastewater Sludge for Electricity Generation. Sci. Rep. 2022, 12, 9107. [Google Scholar] [CrossRef]

- Li, Y.; Alaimo, C.P.; Kim, M.; Kado, N.Y.; Peppers, J.; Xue, J.; Wan, C.; Green, P.G.; Zhang, R.; Jenkins, B.M.; et al. Composition and Toxicity of Biogas Produced from Different Feedstocks in California. Environ. Sci. Technol. 2019, 53, 11569–11579. [Google Scholar] [CrossRef]

- Chua, K.H.; Cheah, W.L.; Tan, C.F.; Leong, Y.P. Harvesting Biogas from Wastewater Sludge and Food Waste. IOP Conf. Ser. Earth Environ. Sci. 2013, 16, 012118. [Google Scholar] [CrossRef]

- Sarker, S.; Lamb, J.J.; Hjelme, D.R.; Lien, K.M. A Review of the Role of Critical Parameters in the Design and Operation of Biogas Production Plants. Appl. Sci. 2019, 9, 1915. [Google Scholar] [CrossRef]

- Shen, Y.; Linville, J.L.; Urgun-Demirtas, M.; Mintz, M.M.; Snyder, S.W. An Overview of Biogas Production and Utilization at Full-Scale Wastewater Treatment Plants (WWTPs) in the United States: Challenges and Opportunities towards Energy-Neutral WWTPs. Renew. Sustain. Energy Rev. 2015, 50, 346–362. [Google Scholar] [CrossRef]

- Gaj, K. Adsorptive Biogas Purification from Siloxanes—A Critical Review. Energies 2020, 13, 2605. [Google Scholar] [CrossRef]

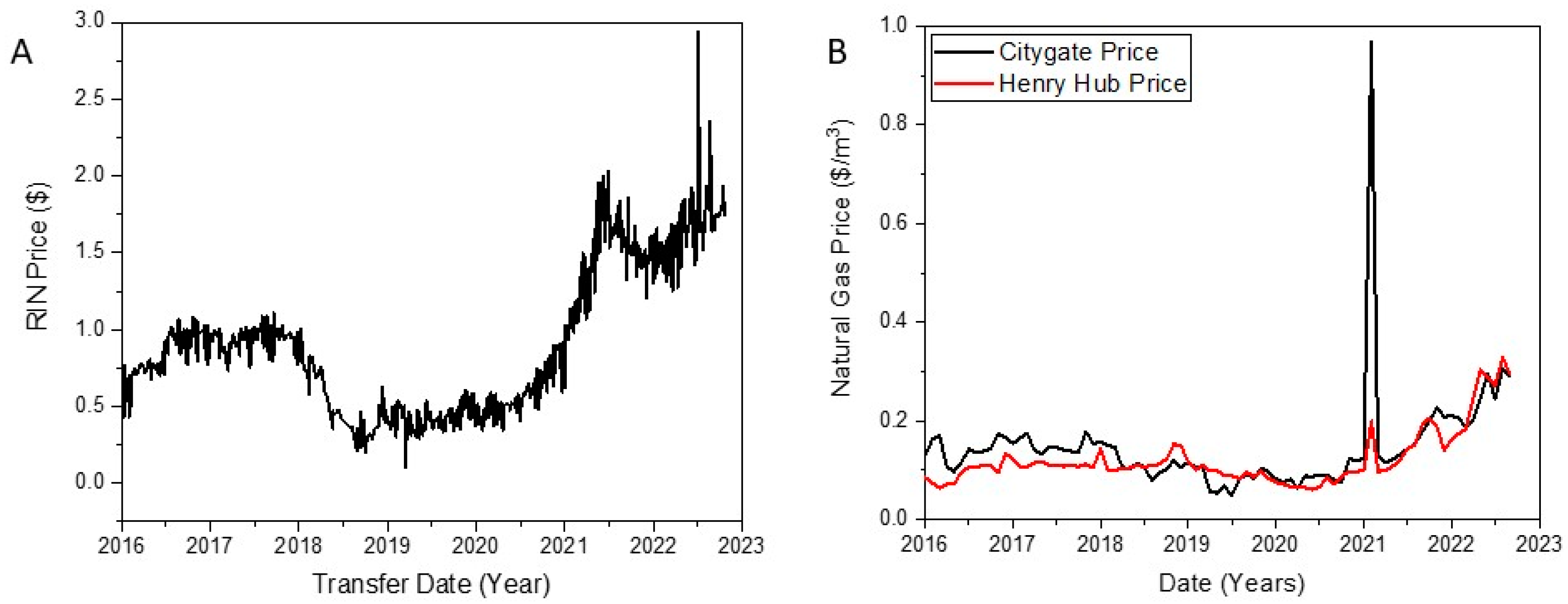

- Environmental Protection Agency Renewable Fuel Standard Program Overview for Renewable Fuel Standard. Available online: https://epa.gov/renewable-fuel-standard-program/ (accessed on 13 December 2022).

- Younes, A.; Fingerman, K.R.; Barrientos, C.; Carman, J.; Johnson, K.; Wallach, E.S. How the U.S. Renewable Fuel Standard Could Use Garbage to Pay for Electric Vehicles. Energy Policy 2022, 166, 112916. [Google Scholar] [CrossRef]

- Kolb, S.; Plankenbühler, T.; Frank, J.; Dettelbacher, J.; Ludwig, R.; Karl, J.; Dillig, M. Scenarios for the Integration of Renewable Gases into the German Natural Gas Market—A Simulation-Based Optimisation Approach. Renew. Sustain. Energy Rev. 2021, 139, 110696. [Google Scholar] [CrossRef]

- Elio, J.; Skabelund, B.; Tian, J.; Phelan, P.; Villalobos, R.; Milcarek, R. Analysis of Biogas Composition of a Waste Water Treatment Facility; Arizona State University: Tempe, AZ, USA, 2022. [Google Scholar]

- Elio, J.; Milcarek, R.J. Techno-Economic Analysis and Case Study of Combined Heat and Power Systems in a Wastewater Treatment Plant. Energy 2022, 260, 125106. [Google Scholar] [CrossRef]

- Arrhenius, K.; Brown, A.S.; van der Veen, A.M.H. Suitability of Different Containers for the Sampling and Storage of Biogas and Biomethane for the Determination of the Trace-Level Impurities—A Review. Anal. Chim. Acta 2016, 902, 22–32. [Google Scholar] [CrossRef] [PubMed]

- U.S. Bureau of Labor Statistics CPI Inflation Calculator. Available online: https://www.bls.gov/data/inflation_calculator.htm (accessed on 14 December 2022).

- Hill, A.; Sishtla, C.; Vronay, J. Biogas Cleanup System Cost Estimator Toolkit Training and User Instruction Manual; Consolidated Management Services Nepal (P) Ltd.: Kathmandu, Nepal, 2014. [Google Scholar]

- Crippen, K.; Manager, R. Interconnect Guide for Renewable Natural Gas (RNG) in New York State; The Northeast Gas Association and Gas Technology Institute Location: Westborough, MA, USA, 2019. [Google Scholar]

- Yang, L.; Ge, X.; Wan, C.; Yu, F.; Li, Y. Progress and Perspectives in Converting Biogas to Transportation Fuels. Renew. Sustain. Energy Rev. 2014, 40, 1133–1152. [Google Scholar] [CrossRef]

- Kaparaju, P.; Rintala, J. Generation of Heat and Power from Biogas for Stationary Applications: Boilers, Gas Engines and Turbines, Combined Heat and Power (CHP) Plants and Fuel Cells. In The Biogas Handbook; Elsevier: Amsterdam, The Netherlands, 2013; pp. 404–427. [Google Scholar]

- Energy Information Administration Natural Gas Citygate Price in Arizona. Available online: https://www.eia.gov/dnav/ng/hist/n3050az3m.htm (accessed on 13 December 2022).

- Environmental Protection Agency RIN Price Report Regulatory Categories for Annual RIN Sales Data. Available online: https://www.epa.gov/fuels-registration-reporting-and-compliance-help/rin-trades-and-price-information- (accessed on 3 March 2025).

- Energy Information Administration Natural Gas Henry Hub. Available online: https://www.eia.gov/dnav/ng/hist/rngwhhdm.htm (accessed on 13 December 2022).

- Environmental Protection Agency Greenhouse Gas Emissions Understanding Global Warming Potentials. Available online: https://www.epa.gov/ghgemissions/understanding-global-warming-potentials (accessed on 22 March 2025).

- Turns, S. An Introduction to Combustion: Concepts and Applications, 3rd ed.; McGraw Hill: New York, UK, USA, 2011. [Google Scholar]

- Anderson, L.G. Effects of Using Renewable Fuels on Vehicle Emissions. Renew. Sustain. Energy Rev. 2015, 47, 162–172. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, F.; Carnevale, M.; Gallucci, F.; Perilli, M.; Esposito, G.; Segreto, M.; Occulti, L.G.; Scaglione, D.; Ianniello, A.; et al. Characterisation and Cleaning of Biogas from Sewage Sludge for Biomethane Production. J. Environ. Manag. 2018, 217, 288–296. [Google Scholar] [CrossRef]

- Energy Information Administration. US Electricity Profile 2021; Institute for Energy Economics and Financial Analysis: Lakewood, OH, USA, 2022. [Google Scholar]

- Parker, N.; Williams, R.; Dominguez-Faus, R.; Scheitrum, D. Renewable Natural Gas in California: An Assessment of the Technical and Economic Potential. Energy Policy 2017, 111, 235–245. [Google Scholar] [CrossRef]

- Li, X.; Song, C.; El Abbadi, S.H.; Stokes-Draut, J.R.; Ren, Z.J. The Impact of Clean Grid Transition on Wastewater Sector Greenhouse Gas Emissions. Environ. Sci. Technol. Lett. 2025, 12, 144–150. [Google Scholar] [CrossRef]

| Organic Silicon (Siloxanes) | Abbreviation | Molecular Formula |

|---|---|---|

| Decamethylcyclopentasiloxane | D5 | C10H30O5Si5 |

| Dodecamethylpentasiloxane | L5 | C12H36O4Si5 |

| Octamethylcyclotetrasiloxane | D4 | C8H24O4Si4 |

| Decamethyltetrasiloxane | L4 | C10H30O3Si4 |

| Hexamethylcyclotrisiloxane | D3 | C6H18O3Si3 |

| Octamethyltrisiloxane | L3 | C8H24O2Si3 |

| Hexamethyldisiloxane | L2 | C6H18OSi2 |

| Parameter | Value |

|---|---|

| CH4 concentration | 62.24 vol% |

| CO2 concentration | 37.36 vol% |

| Siloxanes | |

| H2S | 126 ppmv |

| Max biogas flowrate (BGmax) | 641 m3h−1 |

| Discount rate (r) | 5% |

| Capital cost (CC) | USD 6186 |

| Pipeline cost (PC) | USD 372,824/km |

| Interconnect cost (IC) | USD 400,000 |

| O&M cost (O&Mcost) | |

| Natural gas cost (NGC) | USD 0.24 m−3 |

| Organic Silicon (Siloxanes) | Conc. Unit | August | October | December | February |

|---|---|---|---|---|---|

| Decamethylcyclopentasiloxane (D5) | mg/m3 | 6.77 | 7.15 | 5.7 | 5.62 |

| Dodecamethylpentasiloxane (L5) | mg/m3 | 2.67 | 0.37 | 0.069 | <0.3 |

| Octamethylcyclotetrasiloxane (D4) | mg/m3 | 2.01 | 2.64 | 0.34 | 5.37 |

| Decamethyltetrasiloxane (L4) | mg/m3 | 0.64 | 0.52 | 2.81 | 2.24 |

| Hexamethylcyclotrisiloxane (D3) | mg/m3 | 0.2 | 0.28 | 0.13 | <0.3 |

| Octamethyltrisiloxane (L3) | mg/m3 | <0.3 | <0.3 | 1.02 | 2.13 |

| Hexamethyldisiloxane (L2) | mg/m3 | 0.48 | 0.4 | 0.3 | 0.37 |

| Component | Conc. Unit | August | October | December | February |

| Methane | % | 61.07 | 63.2 | 63.39 | 61.31 |

| Carbon Dioxide | % | 38.43 | 36.41 | 36.28 | 38.32 |

| Nitrogen | % | 0.31 | 0.29 | 0.25 | 0.3 |

| Oxygen | % | 0.11 | 0.1 | 0.08 | 0.077 |

| Hydrogen Sulfide | ppmv | 228.8 | 215 | 24 | 36.5 |

| Total Siloxane | mg/m3 | 12.77 | 11.36 | 10.369 | 15.73 |

| Model | Model without RINs | Model with RINs |

|---|---|---|

| Capital cost | USD 4,963,351 | |

| Year 1 operating cost | USD 407,039 | |

| Breakeven price per unit NG | USD 0.373 m−3 | |

| Yearly profit | USD 578,359 | USD 2,456,793 |

| NPV at year 15 | USD (3,185,106) | USD 16,312,396 |

| PBP (year) | 29 | 3 |

| Method | NPV at 15 Years | NPV Percent Change from Base | |

|---|---|---|---|

| Lowest possible | 0.05 | USD (2,587,023) | (115)% |

| Breakeven price | 0.267 | 8657 | (100)% |

| 20% below base | 1.304 | 12,412,896 | (24)% |

| Base 2022 average | 1.63 | 16,312,396 | - |

| 20% above base | 1.956 | 20,211,896 | 24% |

| Max possible | 3 | 32,699,867 | 100% |

| Method | Natural Gas Price | NPV at 15 years (USD) | NPV Percent Change from Base |

| Base + 10% | 0.267 | 16,899,877 | 3.6% |

| 2022 average (base) | 0.243 | 16,307,459 | - |

| 2019–2022 average price | 0.186 | 14,900,467 | (8.6%) |

| 2016–2022 average price | 0.146 | 13,913,104 | (15%) |

| Method | RNG with RIN Credits (15-Year Lifespan) | RNG Without RIN Credits | CHP (20-Year Lifespan) [50] |

|---|---|---|---|

| Capital cost (USD) | 4,963,351 | 4,963,351 | 5,229,856 |

| Annual net revenue (USD) 1 | 2,049,754 | 171,320 | 310,143 |

| NPV at end of lifetime (USD) | 16,312,396 | (3,185,106) | 1,283,149 |

| PBP (years) | 3 | 29 | 17 |

| Model | EPA 2021 [8] | EPA 2016 [4] | Percent Difference |

|---|---|---|---|

| Yearly average flow (m3h−1) | 437 | 451 | −3.1% |

| Methane content | 62% | 60% | 3.3% |

| Capital cost (USD) | 4,963,351 | 6,184,330 | −20% |

| Yearly cost (USD) | 407,039 | 690,180 | −41% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jenkins, C.D.; Tian, J.; Milcarek, R.J. A Case Study of Renewable Natural Gas Techno-Economics and Emissions at a Wastewater Treatment Plant. Environments 2025, 12, 106. https://doi.org/10.3390/environments12040106

Jenkins CD, Tian J, Milcarek RJ. A Case Study of Renewable Natural Gas Techno-Economics and Emissions at a Wastewater Treatment Plant. Environments. 2025; 12(4):106. https://doi.org/10.3390/environments12040106

Chicago/Turabian StyleJenkins, Cody D., Jiashen Tian, and Ryan J. Milcarek. 2025. "A Case Study of Renewable Natural Gas Techno-Economics and Emissions at a Wastewater Treatment Plant" Environments 12, no. 4: 106. https://doi.org/10.3390/environments12040106

APA StyleJenkins, C. D., Tian, J., & Milcarek, R. J. (2025). A Case Study of Renewable Natural Gas Techno-Economics and Emissions at a Wastewater Treatment Plant. Environments, 12(4), 106. https://doi.org/10.3390/environments12040106