Reduction in Brake Wear Emissions with Cr2O3 and WC-CoCr Coatings for Cast Iron Discs

Abstract

1. Introduction

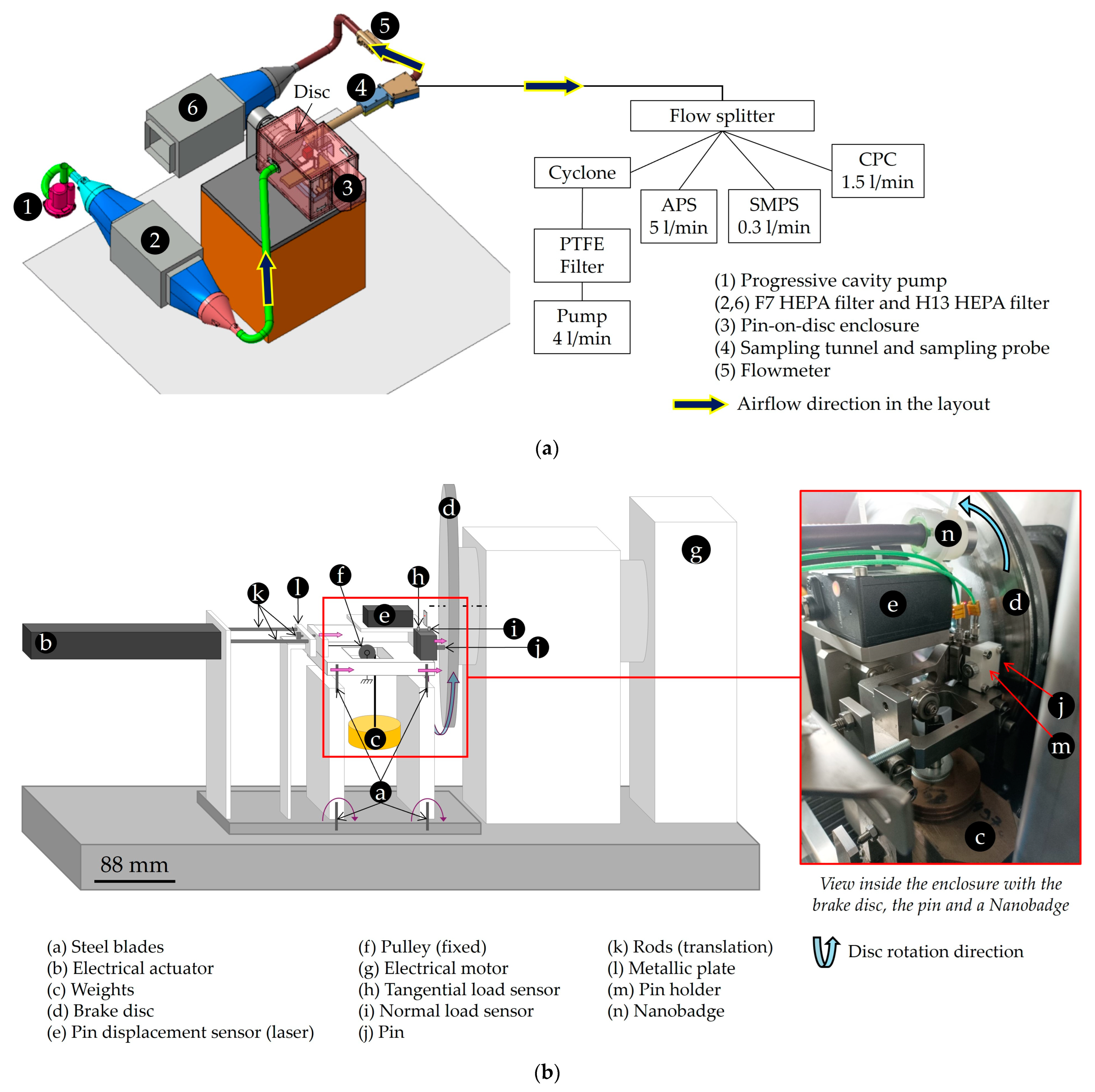

2. Methodology

2.1. Description of the Layout and Measuring Devices

2.2. Friction Materials and Brake Disc

2.3. Test Conditions

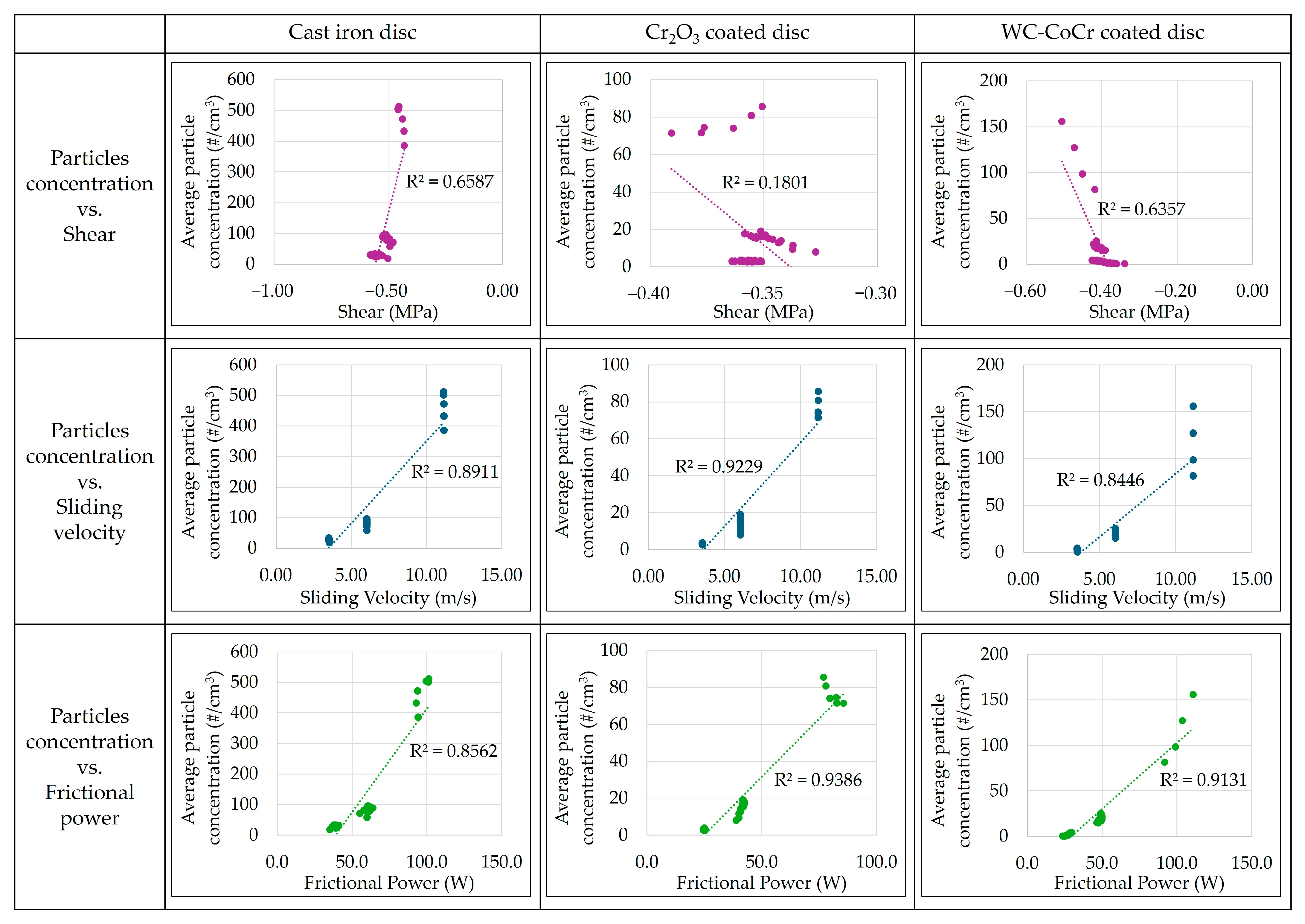

3. Results

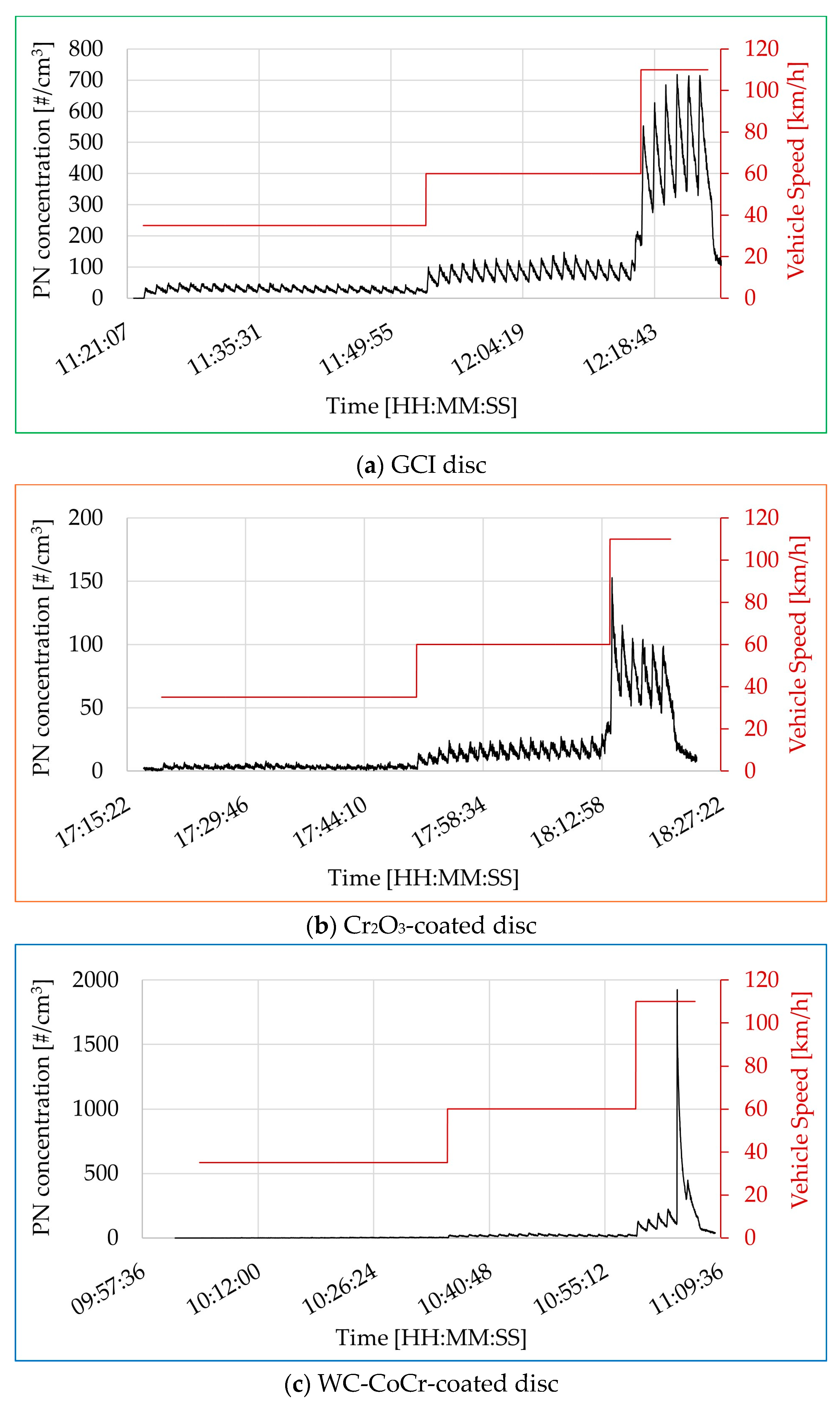

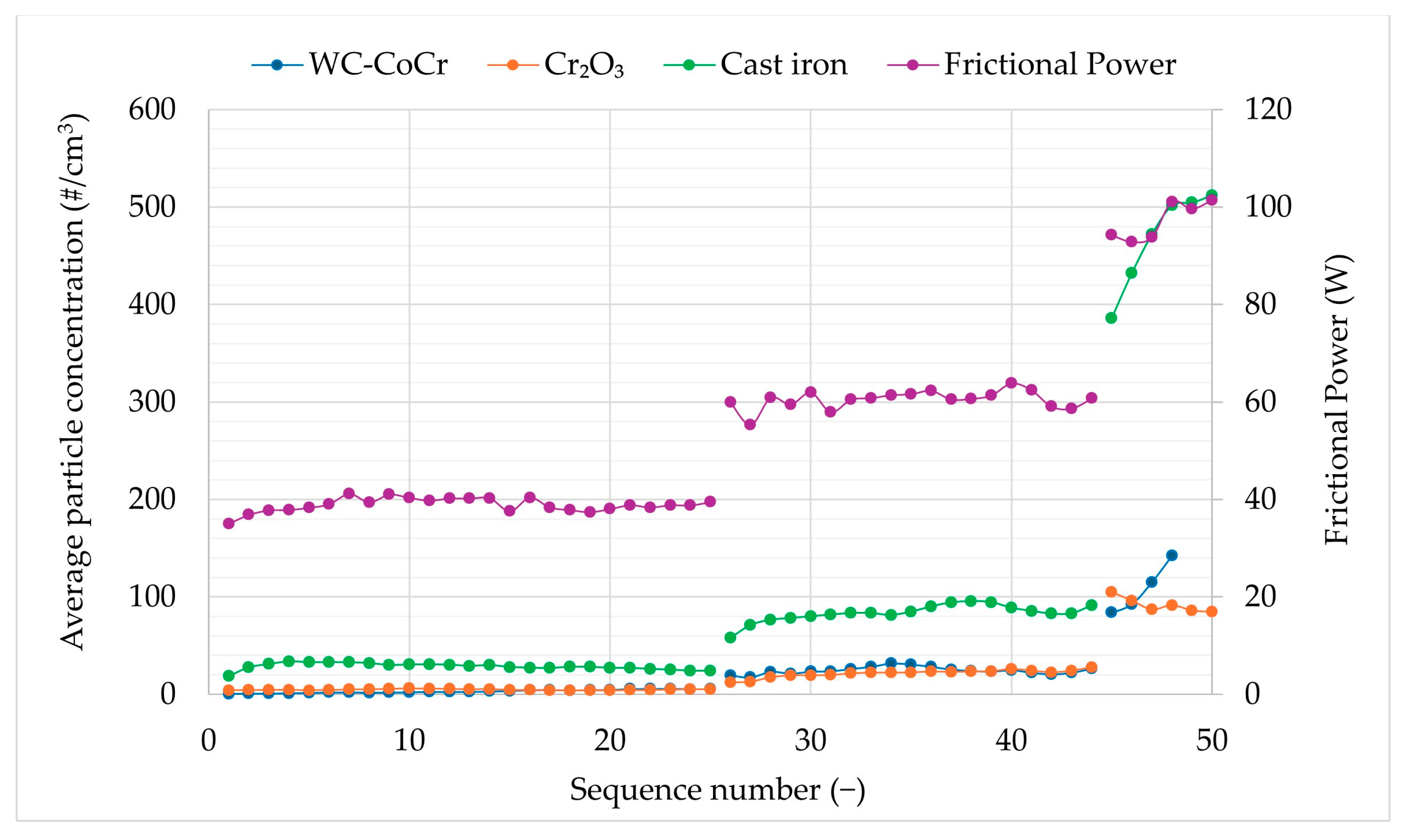

3.1. Particle Number Emissions

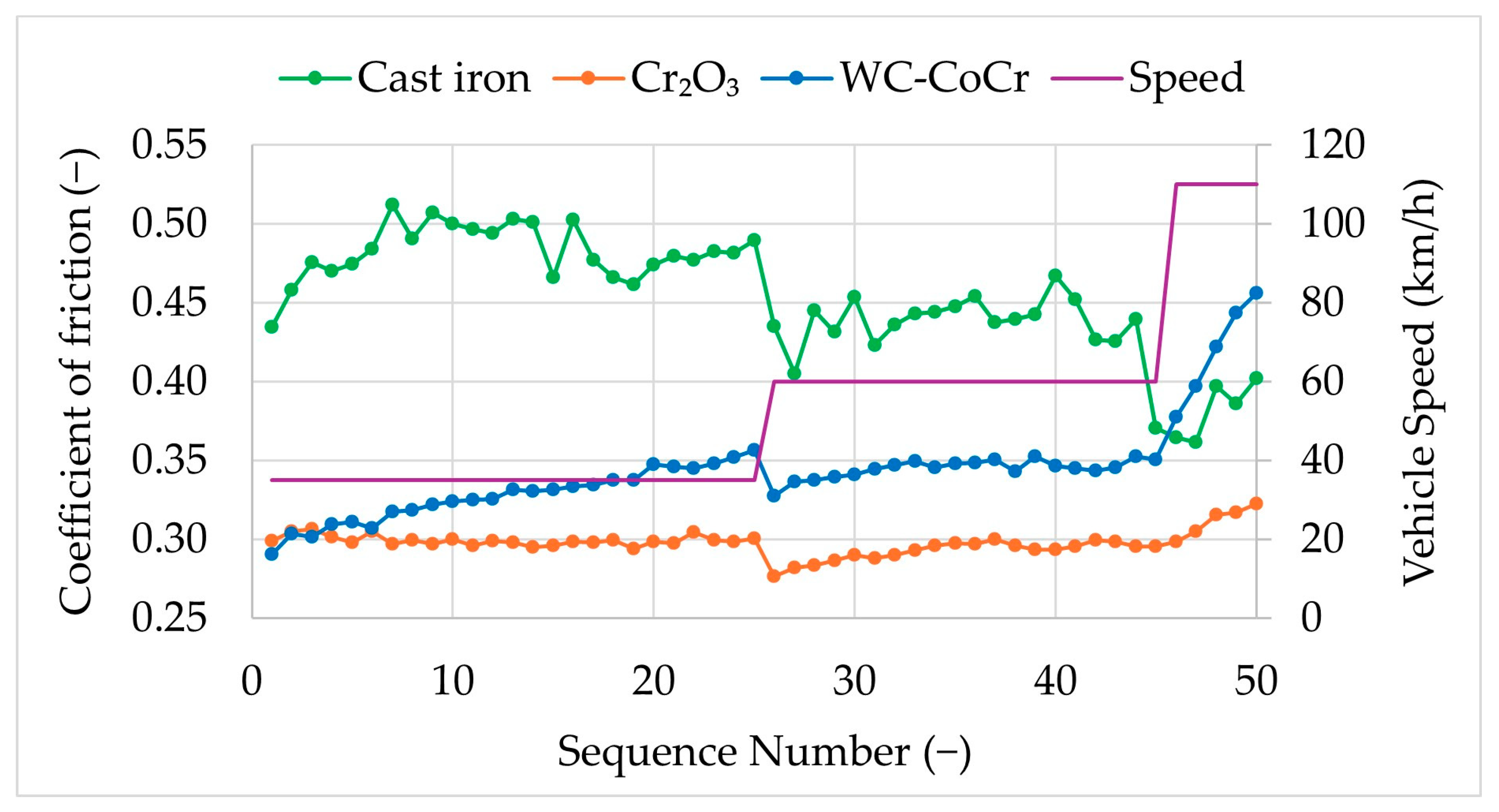

3.2. Friction Coefficient

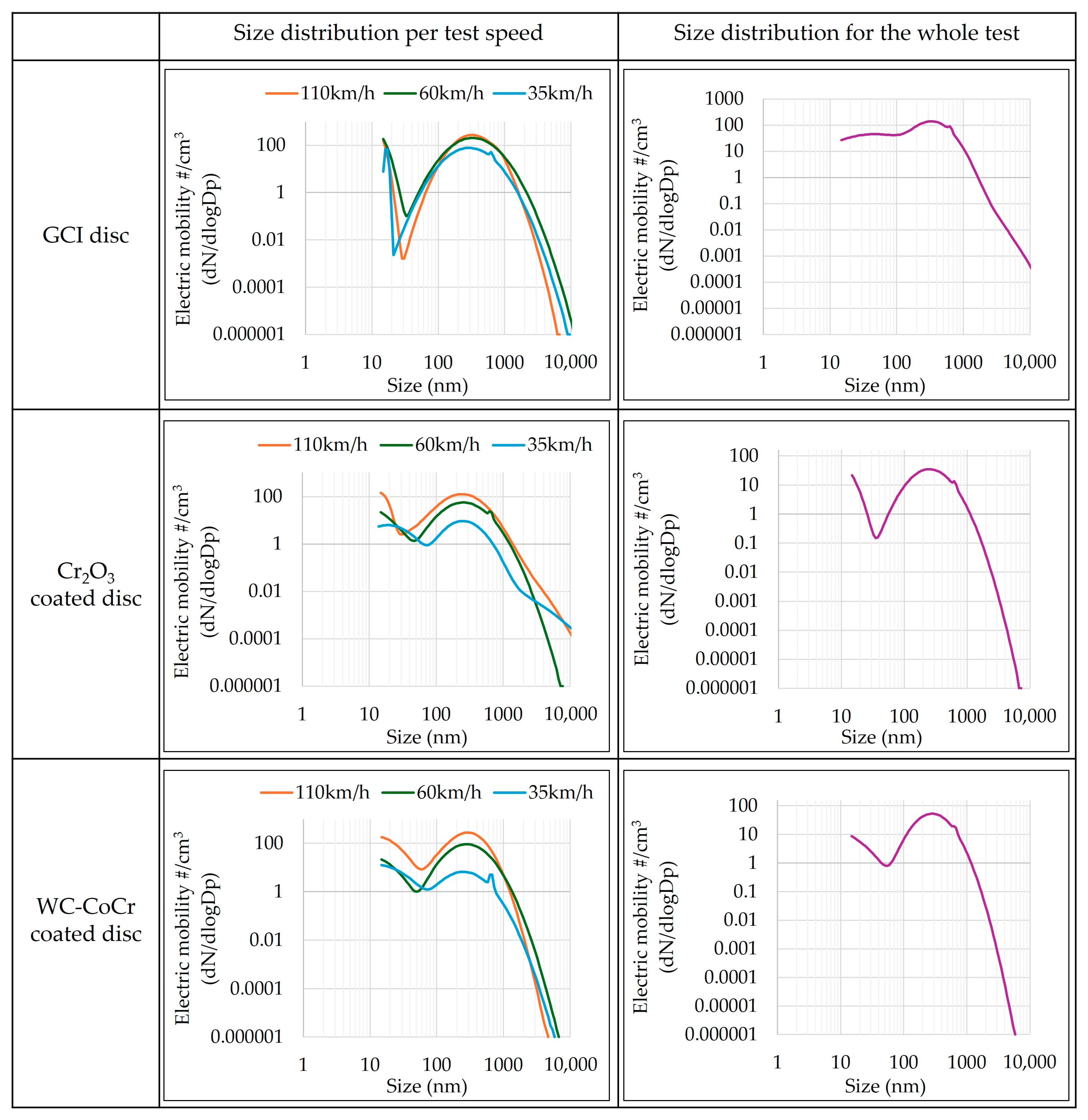

3.3. Particle Size Distribution

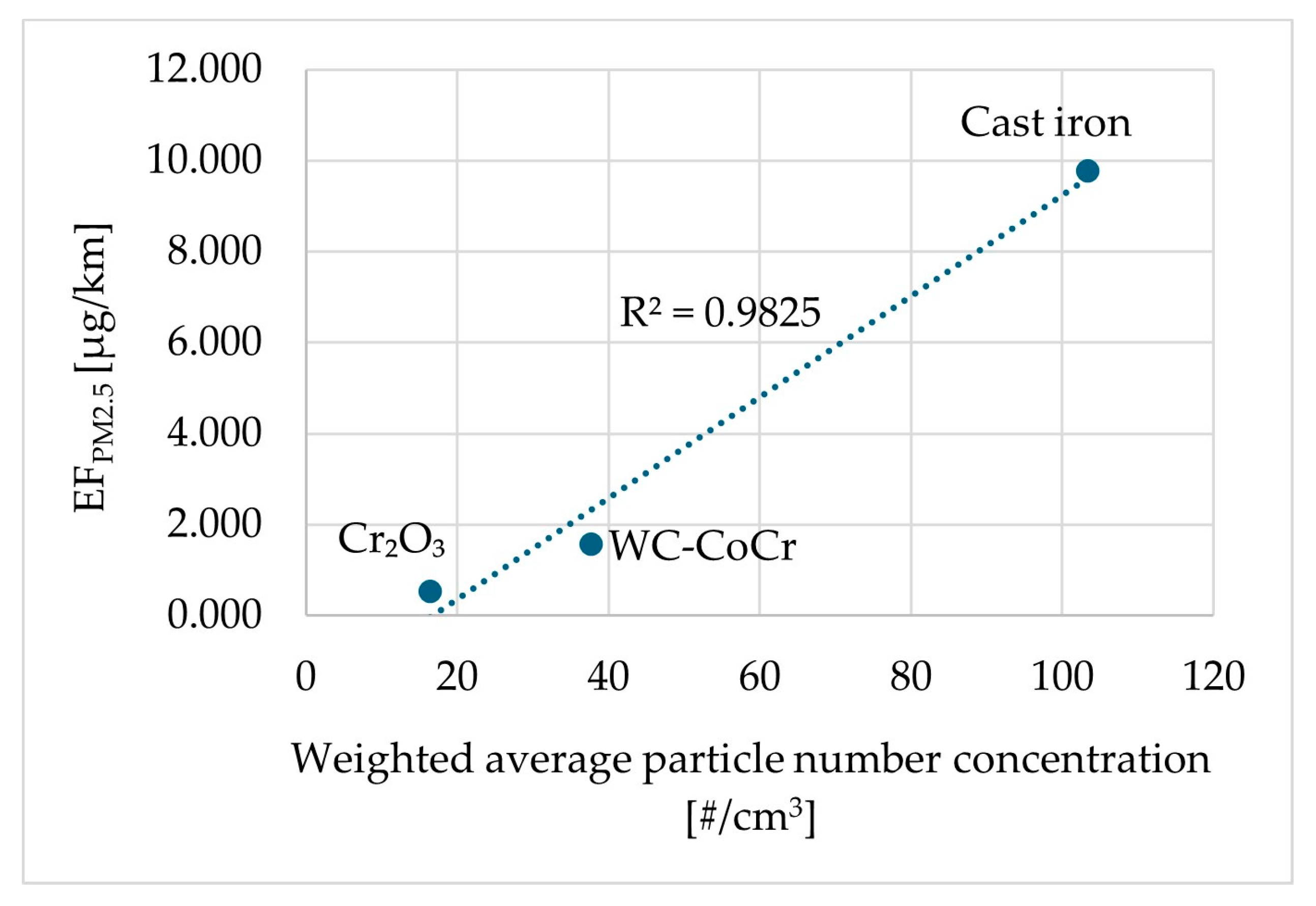

3.4. PM2.5 Emissions

3.5. Chemical Composition of the Generated Particles

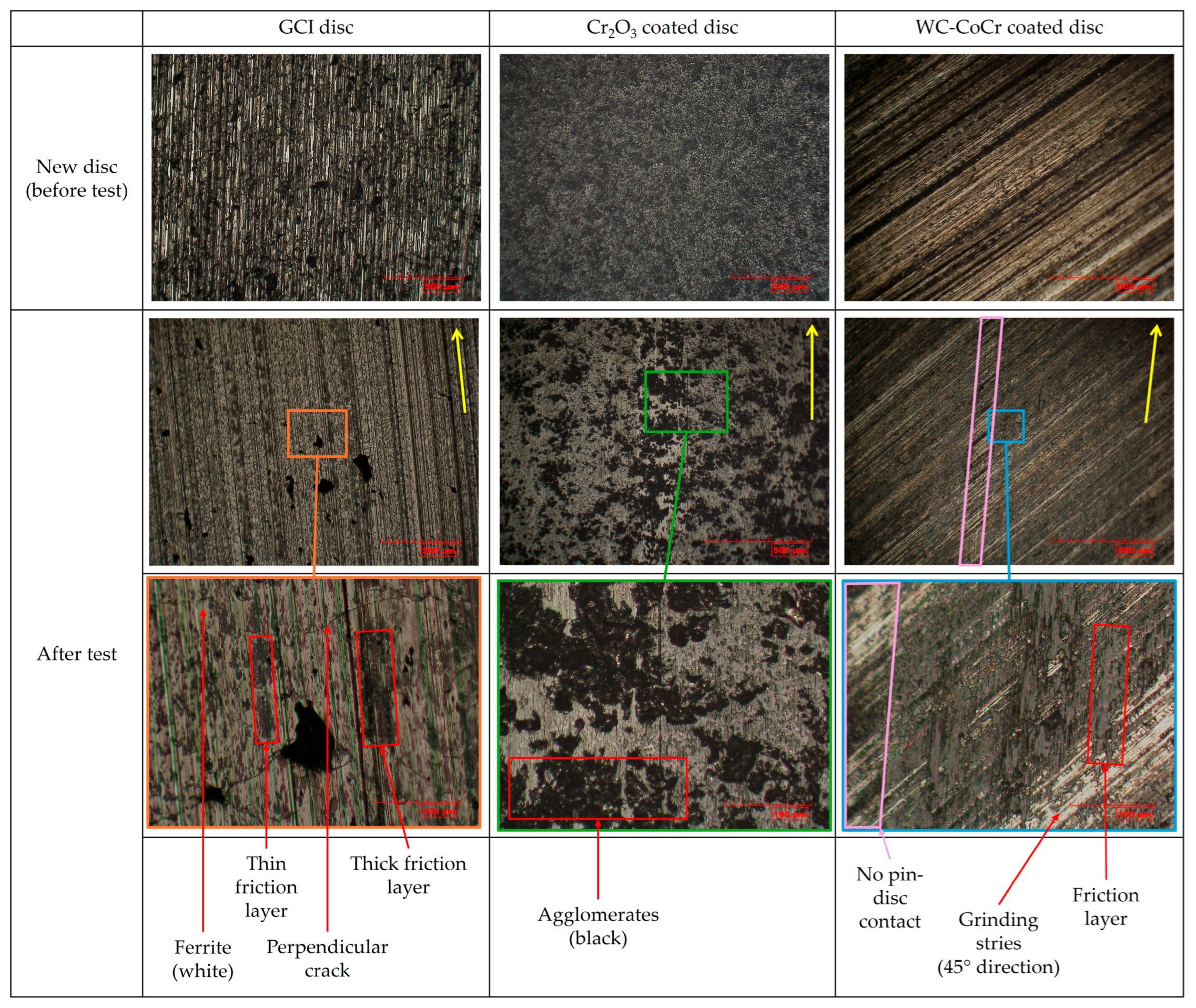

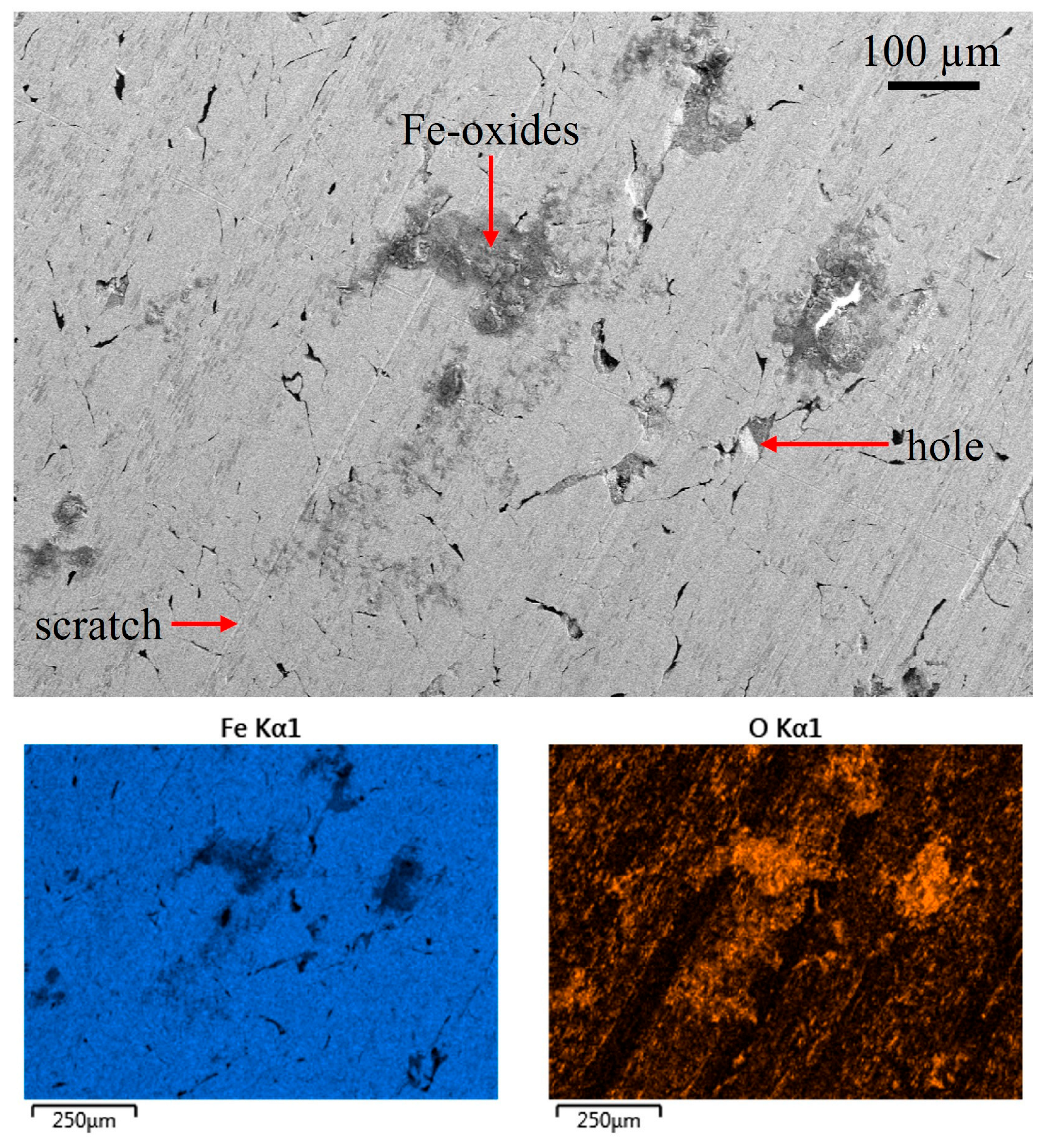

3.6. Light Microscopy and Scanning Electron Microscopy

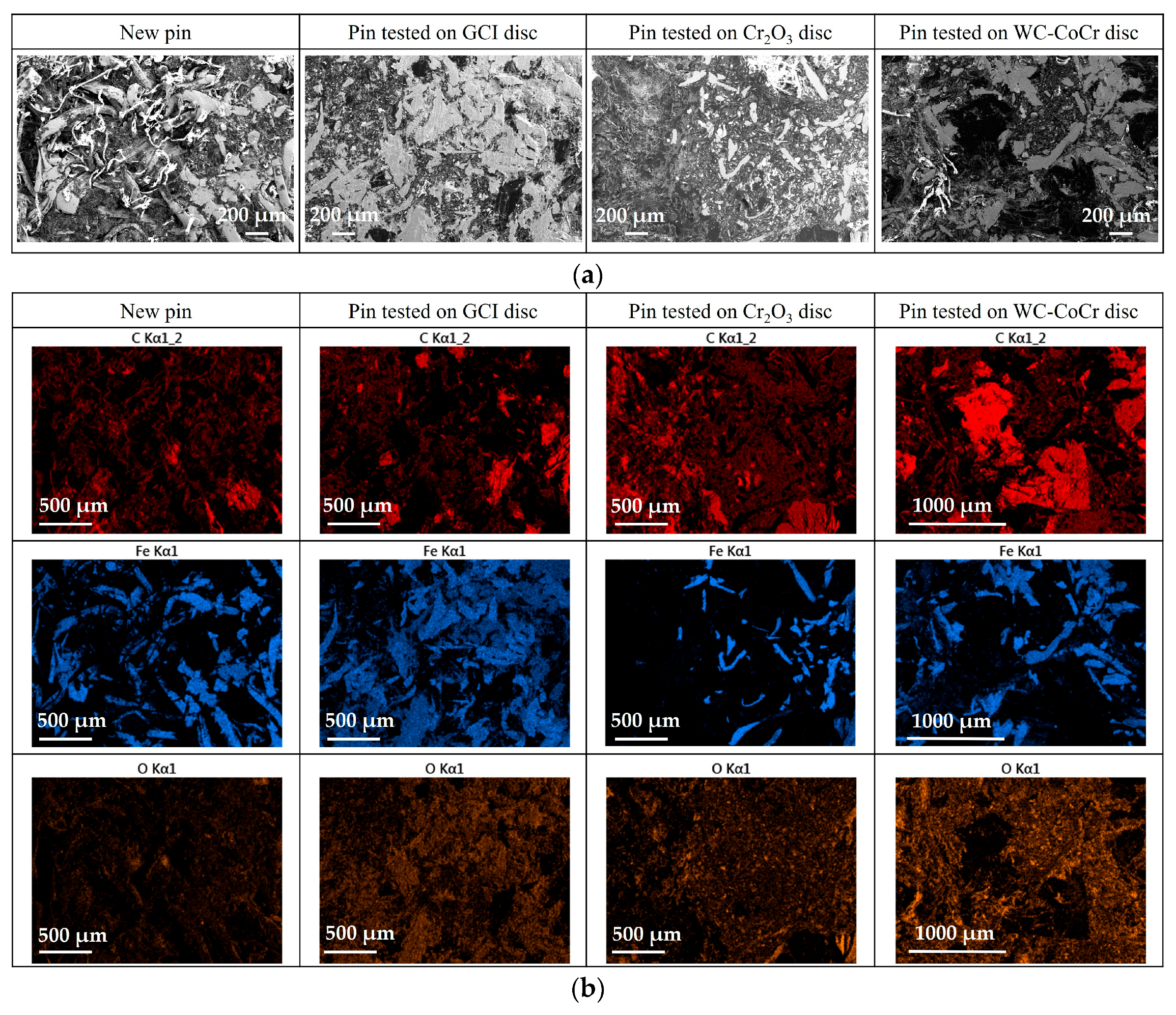

- On the surface of the new pin, the steel fibers that make up the friction material are not oxidized (Figure 8b).

- The presence of contact plateaus on the surface of the pin tested against the cast iron disc is identifiable in relation to the pins tested against coated discs (Figure 8b).

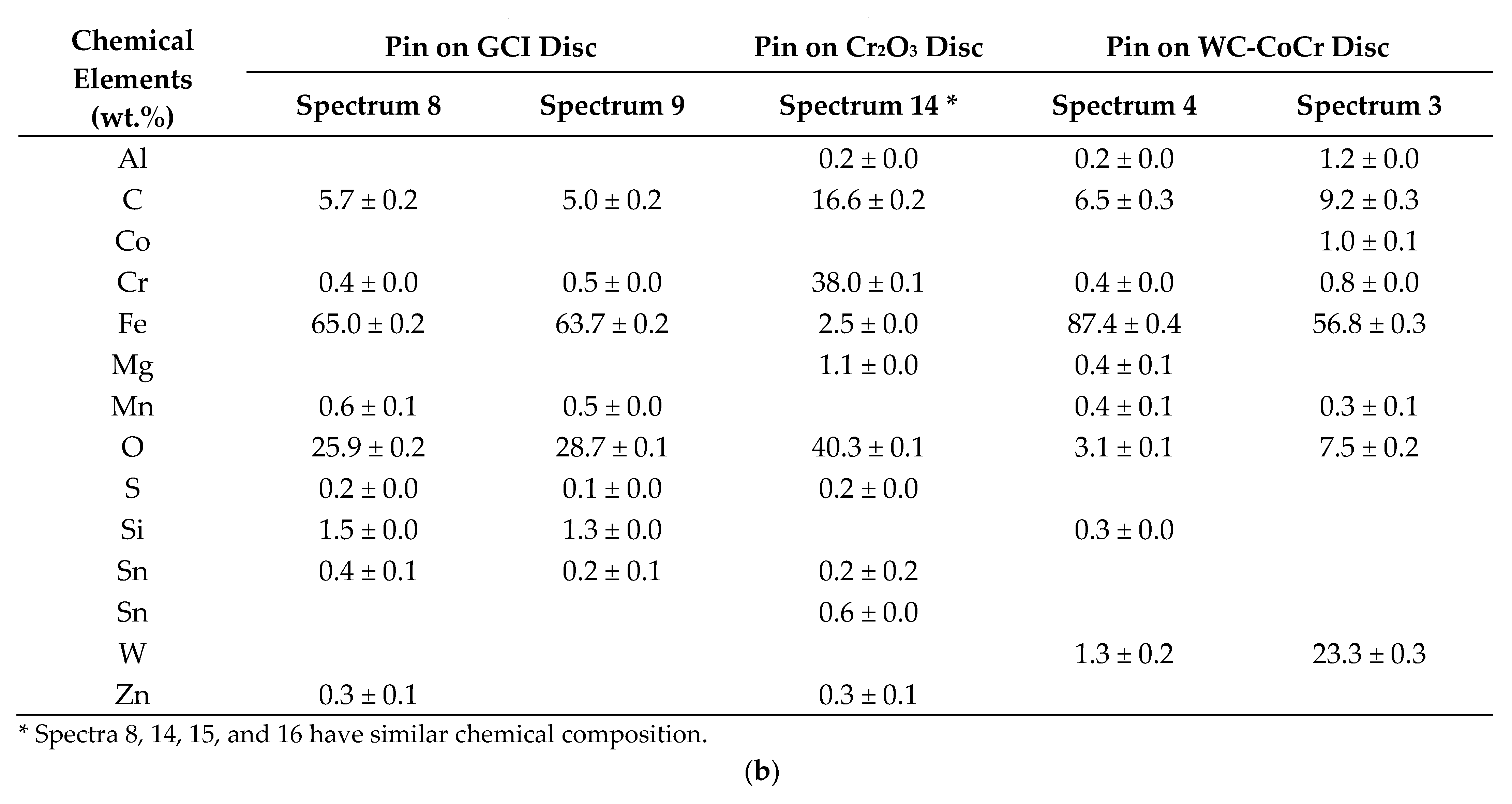

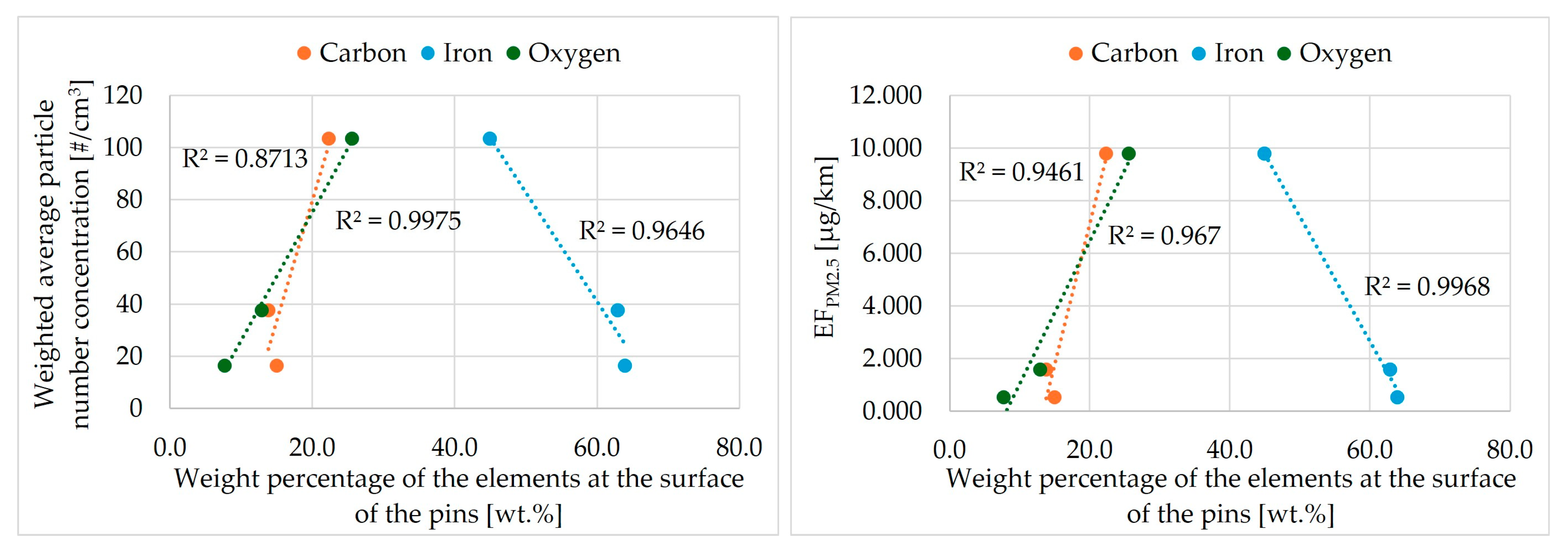

- On the surface of the pin tested against the cast iron disc, the iron and oxygen contents, 25.6 ± 0.1 wt.% and 22.3 ± 0.1 wt.%, respectively, are higher than those observed on the surface of the new pin, 18.3 ± 0.1 wt.% and 14.2 ± 0.1 wt.%, respectively. On the other hand, the carbon content is lower on the surface of the pin tested against the cast iron disc, with a value of 44.9 ± 0.1 wt.%, than on the surface of the new pin, with a value of 57.7 ± 0.1 wt.% (Table 12).

- On the pins tested against the Cr2O3-coated disc and WC-CoCr-coated disc, the surface contents of iron and oxygen are lower than those of the pin tested against the cast iron disc. On the other hand, the carbon content is higher on the surface of the pins tested against coated discs (Table 12).

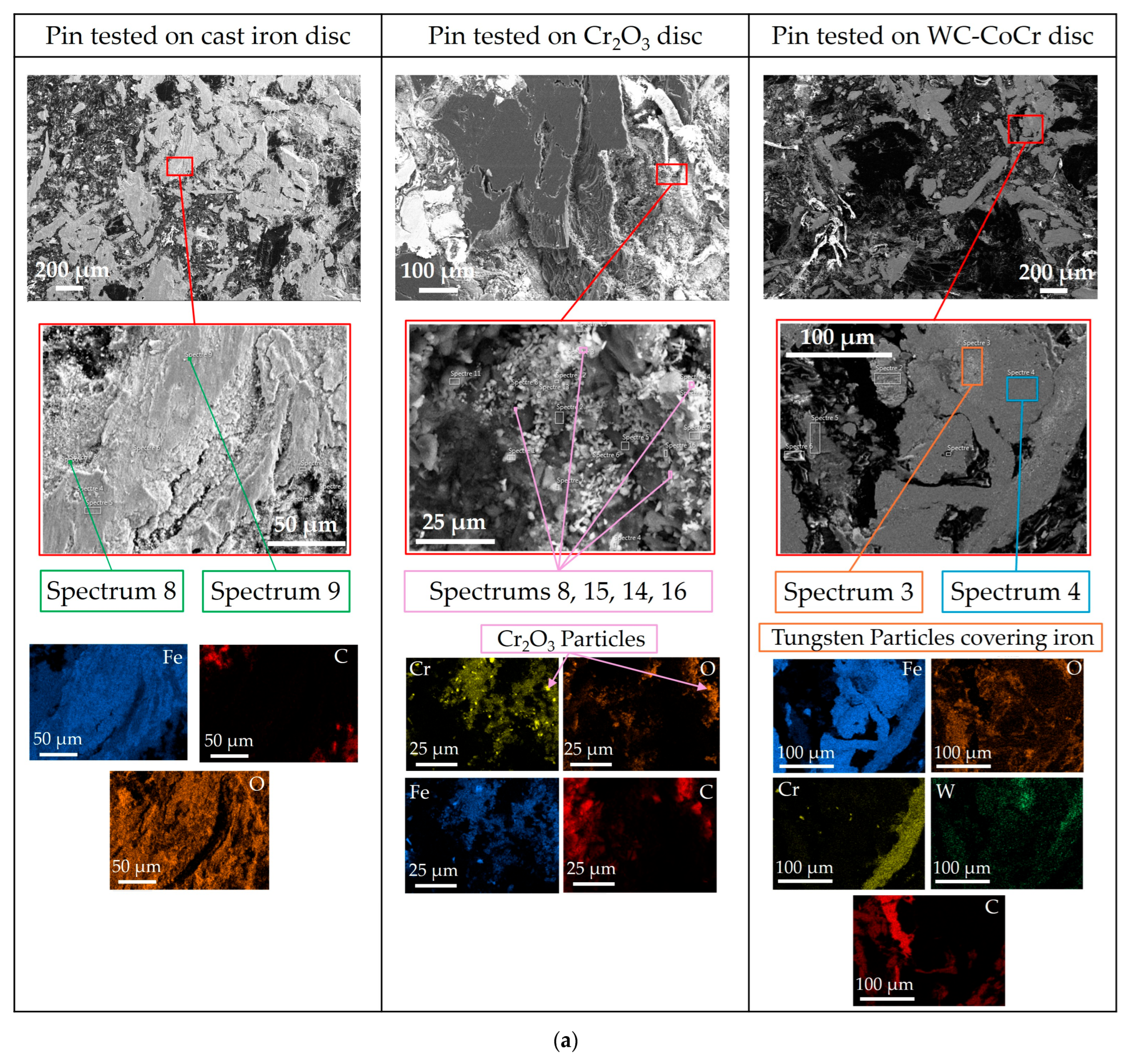

- Elementary mappings of the pin tested against the Cr2O3-coated disc (Figure 9) show the presence of particles composed of oxygen and chromium in the porosities of the pin. In addition, the surface of this pin has the highest chromium content, at 1.8 ± 0.0 wt.% (Table 12). These results suggest the presence of chromium oxide particles (Cr2O3) from the brake disc coating, generated during the loading sequences.

- Elementary mappings of the pin tested against the WC-CoCr-coated disc show the presence of tungsten particles that cover iron particles (Figure 9). A paper from the literature highlights the same observation, showing that the secondary plateaus of the pin tested against the WC-CoCr-coated disc, composed of tungsten particles, were partially covering the primary plateaus composed of steel fibers [20].

- The presence of tungsten particles on the surface of the pin suggests that tungsten carbide particles tear off the brake disc coating and then settle on the surface of the steel fibers of the friction material. The WC-CoCr-coated disc therefore shows signs of wear, as does the Cr2O3-coated disc.

4. Discussion

4.1. Wear Mechanisms and Microscopy Analysis

4.2. Particle Emissions per Number and Mass

4.3. Peak Emission with WC-CoCr-Coated Disc

4.4. Chemical Composition of the Particles

4.5. Friction Coefficient

4.6. Particle Size Distribution

5. Conclusions

- -

- The EFPM2.5 emission factor;

- -

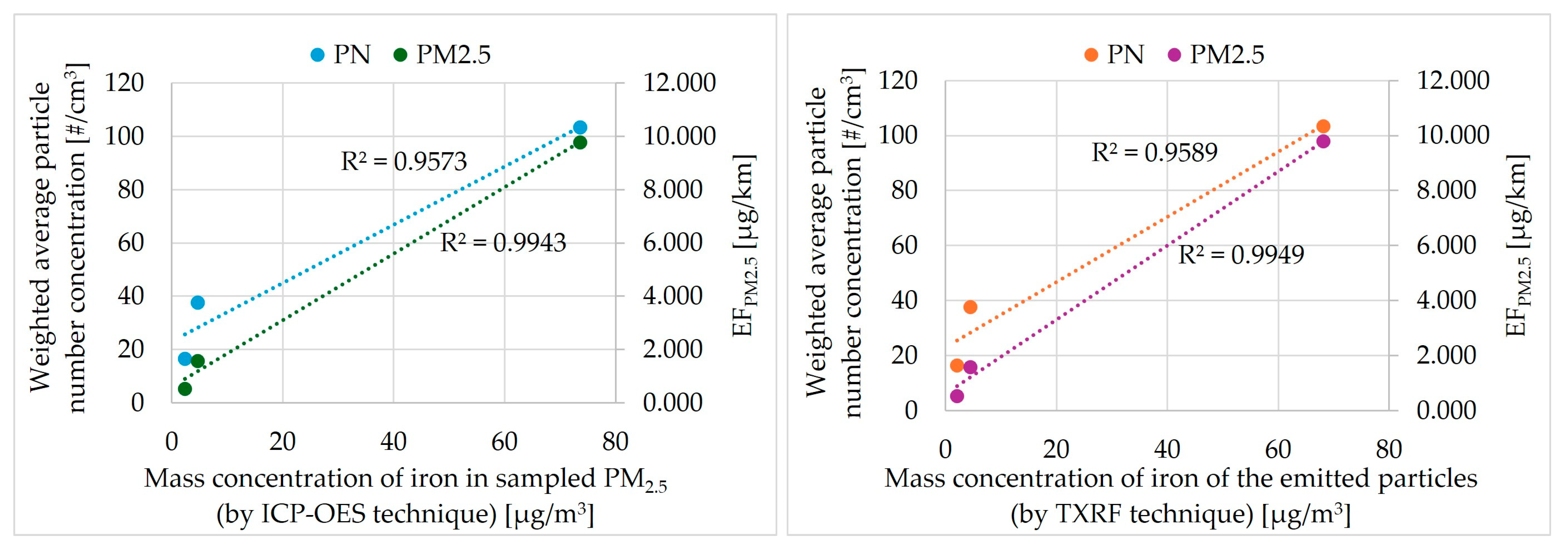

- The mass concentration of iron in the particles generated;

- -

- The concentration of iron, oxygen, and carbon on the surface of the used pins;

- -

- Frictional power and sliding speed.

- -

- The mass concentration of iron in the particles generated;

- -

- The concentration of iron, oxygen, and carbon on the surface of the used pins.

6. Perspectives

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xing, Y.-F.; Xu, Y.-H.; Shi, M.-H.; Lian, Y.-X. The impact of PM2.5 on the human respiratory system. J. Thorac. Dis. 2016, 8, 69–74. [Google Scholar] [CrossRef]

- Geiser, M.; Rothen-Rutishauser, B.; Kapp, N.; Schurch, S.; Kreyling, W.; Schulz, H.; Semmler, M.; Im Hof, V.; Heyder, J.; Gehr, P. Ultrafine particles cross cellular membranes by nonphagocytic mechanisms in lungs and in cultured cells. Environ. Health Perspect 2005, 113, 1555–1560. [Google Scholar] [CrossRef] [PubMed]

- Oberdorster, G.; Oberdorster, E.; Oberdorster, J. Nanotoxicology: An emerging discipline evolving from studies of ultrafine particles. Environ. Health Perspect 2005, 113, 823–839. [Google Scholar] [CrossRef] [PubMed]

- European Environment Agency. Air Quality in Europe 2022; European Environment Agency: Copenhagen, Denmark, 2022. [Google Scholar]

- Milojević, S.; Džunić, D.; Marić, D.; Skrúcaný, T.; Mitrović, S.; Pešić, R. Tribological Assessment of Aluminum Cylinder Material for Piston Compressors in Trucks and Buses Brake Systems. Teh. Vjesn.-Tech. Gaz. 2021, 28, 1268–1276. [Google Scholar] [CrossRef]

- Timmers, V.R.J.H.; Achten, P.A.J. Non-exhaust PM emissions from electric vehicles. Atmos. Environ. 2016, 134, 10–17. [Google Scholar] [CrossRef]

- Gagnepain, L. Emissions des Véhicules Routiers—Les Particules Hors Échappement; La librairie (ADEME): Angers, France, 2022. [Google Scholar]

- The European Parliament and the Council of the European Union. Regulation (EU) 2024/1257 of the European Parliament and of the Council of 24 April 2024; European Union: Brussels, Belgium, 2024. [Google Scholar]

- Wahlström, J.; Lyu, Y.; Matjeka, V.; Söderberg, A. A pin-on-disc tribometer study of disc brake contact pairs with respect to wear and airborne particle emissions. Wear 2017, 384–385, 124–130. [Google Scholar] [CrossRef]

- Perricone, G.; Matějka, V.; Alemani, M.; Valota, G.; Bonfanti, A.; Ciotti, A.; Olofsson, U.; Söderberg, A.; Wahlström, J.; Nosko, O.; et al. A concept for reducing PM 10 emissions for car brakes by 50%. Wear 2018, 396–397, 135–145. [Google Scholar] [CrossRef]

- Cai, R.; Zhang, J.; Nie, X.; Tjong, J.; Matthews, D.T.A. Wear mechanism evolution on brake discs for reduced wear and particulate emissions. Wear 2020, 452–453, 203283. [Google Scholar] [CrossRef]

- Dizdar, S.; Lyu, Y.; Lampa, C.; Olofsson, U. Grey Cast Iron Brake Discs Laser Cladded with Nickel-Tungsten Carbide—Friction, Wear and Airborne Wear Particle Emission. Atmosphere 2020, 11, 621. [Google Scholar] [CrossRef]

- Seo, H.; Joo, B.; Park, J.; Kim, Y.C.; Lee, J.J.; Jang, H. Effect of disc material on particulate matter emissions during high-temperature braking. Tribol. Int. 2021, 154, 106713. [Google Scholar] [CrossRef]

- Hesse, D.; Hamatschek, C.; Augsburg, K.; Weigelt, T.; Prahst, A.; Gramstat, S. Testing of Alternative Disc Brakes and Friction Materials Regarding Brake Wear Particle Emissions and Temperature Behavior. Atmosphere 2021, 12, 436. [Google Scholar] [CrossRef]

- Babu, P.S.; Sen, D.; Jyothirmayi, A.; Krishna, L.R.; Rao, D.S. Influence of microstructure on the wear and corrosion behavior of detonation sprayed Cr2O3-Al2O3 and plasma sprayed Cr2O3 coatings. Ceram. Int. 2018, 44, 2351–2357. [Google Scholar] [CrossRef]

- Cellard, A.; Garnier, V.; Fantozzi, G.; Baret, G.; Fort, P. Wear resistance of chromium oxide nanostructured coatings. Ceram. Int. 2009, 35, 913–916. [Google Scholar] [CrossRef]

- Rastegar, F.; Craft, A.E. Piston ring coatings for high horsepower diesel engines. Surf. Coat. Technol. 1993, 61, 36–42. [Google Scholar] [CrossRef]

- Güney, B.; Mutlu, I. Tribological Properties of Brake Discs Coated with Cr2O3–40% TiO2 by Plasma Spraying. Surf. Rev. Lett. 2019, 26, 1950075. [Google Scholar] [CrossRef]

- Mutlu, I.; Güney, B.; Erkurt, I. Investigation of the effect of Cr2O3-2% TiO2 coating on braking performance. Int. J. Automot. Eng. Technol. 2020, 9, 29–41. [Google Scholar] [CrossRef]

- Federici, M.; Menapace, C.; Moscatelli, A.; Gialanella, S.; Straffelini, G. Pin-on-disc study of a friction material dry sliding against HVOF coated discs at room temperature and 300 °C. Tribol. Int. 2017, 115, 89–99. [Google Scholar] [CrossRef]

- Lyu, Y.; Sinha, A.; Olofsson, U.; Gialanella, S.; Wahlström, J. Characterization of ultrafine particles from hardfacing coated brake rotors. Friction 2022, 11, 125–140. [Google Scholar] [CrossRef]

- Hoff, M.; Chen, Y.-M.; Meunier, L.; Bressot, C.; Morgeneyer, M. Effect of Friction Material on Vehicle Brake Particle Emissions. Atmosphere 2025, 16, 1075. [Google Scholar] [CrossRef]

- Wahlstrom, J.; Soderberg, A.; Olander, L.; Jansson, A.; Olofsson, U. A pin-on-disc simulation of airborne wear particles from discbrakes. Wear 2010, 268, 763–769. [Google Scholar] [CrossRef]

- Sanders, P.G.; Xu, N.; Dalka, T.M.; Maricq, M.M. Airborne brake wear debris: Size distributions, composition, and a comparison of dynamometer and vehicle tests. Environ. Sci. Technol. 2003, 37, 4060–4069. [Google Scholar] [CrossRef]

- Candeo, S.; Leonardi, M.; Gialanella, S.; Straffelini, S. Influence of contact pressure and velocity on the brake behaviour and particulate matter emissions. Wear 2023, 514–515, 204579. [Google Scholar] [CrossRef]

- Dridi, B.; Hjelm, R.; Lattanzi, L.; Awe, S.; Pagels, J.; Wahlström, J.; Lyu, Y. On the influence of carbides in laser-cladded coating on friction, wear, and airborne particle emissions of disc brakes. Wear 2025, 576–577, 206107. [Google Scholar] [CrossRef]

- Philippe, F. Measure and Characterization of Braking Particles Emitted from Cars on a Pin-in-Disc Bench. Ph.D. Thesis, Université de Technologie de Compiègne, Compiègne, France, 2021. Available online: https://theses.fr/2021COMP2615 (accessed on 16 September 2025).

- Philippe, F.; Xiang, M.; Bressot, C.; Chen, Y.; Guingand, F.; Charles, P.; Loigerot, J.; Morgeneyer, M. Relevance of pin-on-disc and inertia dynamometer bench experiments for braking emission studies. J. Phys. Conf. Ser. 2019, 1323, 012025. [Google Scholar] [CrossRef]

- Philippe, F.; Morgeneyer, M.; Xiang, M.; Manokaran, M.; Berthelot, B.; Chen, Y.-m.; Charles, P.; Guingand, F.; Bressot, C. Representativeness of airborne brake wear emission for the automotive industry: A review. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 2651–2666. [Google Scholar] [CrossRef]

- Motellier, S.; Lhaute, K.; Guiot, A.; Golanski, L.; Geoffroy, C.; Tardif, F. Direct quantification of airborne nanoparticles composition by TXRF after collection on filters. J. Phys. Conf. Ser. 2011, 304, 012009. [Google Scholar] [CrossRef]

- NF-EN-14385; Stationary Source Emissions—Determination of the Total Emission of As, Cd, Cr, Co, Cu, Mn, Ni, Pb, Sb, TI and V. Association Française de Normalisation: La Plaine Saint-Denis, France, 2024.

- NF-EN-17294-2; Water Quality—Application of Inductively Coupled Plasma Mass Spectrometry (ICP-MS)—Part 2: Determination of Selected Elements Including Uranium Isotopes. Association Française de Normalisation: La Plaine Saint-Denis, France, 2023.

- NF-EN-ISO-11885; Water quality—Determination of Selected Elements by Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES). Association Française de Normalisation: La Plaine Saint-Denis, France, 2009.

- Federici, M.; Menapace, C.; Moscatelli, A.; Gialanella, S.; Straffelini, G. Effect of roughness on the wear behavior of HVOF coatings dry sliding against a friction material. Wear 2016, 368–369, 326–334. [Google Scholar] [CrossRef]

- Abbasi, S.; Wahlström, J.; Olander, L.; Larsson, C.; Olofsson, U.; Sellgren, U. A study of airborne wear particles generated from organic railway brake pads and brake discs. Wear 2011, 273, 93–99. [Google Scholar] [CrossRef]

- Federici, M.; Perricone, G.; Gialanella, S.; Straffelini, G. Sliding Behaviour of Friction Material Against Cermet Coatings: Pin-on-Disc Study of the Running-in Stage. Tribol. Lett. 2018, 66, 53. [Google Scholar] [CrossRef]

- Lyu, Y.; Wahlström, J.; Tu, M.; Olofsson, U. A Friction, Wear and Emission Tribometer Study of Non-Asbestos Organic Pins Sliding Against AlSiC MMC Discs. Tribol. Ind. 2018, 40, 274–282. [Google Scholar] [CrossRef]

- Metinoz, I.; Matejka, V.; Alemani, M.; Wahlström, J.; Perricone, G. Could pin-on-disc tribometers be used to study the friction/wear performance of disc brake materials? In Proceedings of the Eurobrake 2016, Milan, Italy, 13–15 June 2016. [Google Scholar]

- Philippe, F.; Xiang, M.; Morgeneyer, M.; Chen, Y.-M.; Charles, P.; Guingand, F.; Bressot, C. Emission rate assessment of airborne brake particles by characterization of the pad and disc surfaces from a pin-on-disc tribometer. Toxicol. Res. Appl. 2020, 4, 2397847320977782. [Google Scholar] [CrossRef]

- Wahlström, J.; Söderberg, A.; Olander, L.; Olofsson, U.; Jansson, A. Airborne wear particles from passenger car disc brakes: A comparison of measurements from field tests, a disc brake assembly test stand, and a pin-on-disc machine. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 224, 179–188. [Google Scholar] [CrossRef]

- UNECE. UN GTR No.24—Laboratory Measurement of Brake Emissions for Light-Duty Vehicles (17/07/2023); UNECE: Geneva, Switzerland, 2023. [Google Scholar]

- Neukirchen, C.; Saraji-Bozorgzad, M.R.; Mader, M.; Mudan, A.P.; Czasch, P.; Becker, J.; Di Bucchianico, S.; Trapp, C.; Zimmermann, R.; Adam, T. Comprehensive elemental and physical characterization of vehicle brake wear emissions from two different brake pads following the Global Technical Regulation methodology. J. Hazard. Mater. 2025, 482, 136609. [Google Scholar] [CrossRef]

- Lyu, Y.; Varriale, F.; Malmborg, V.; Ek, M.; Pagels, J.; Wahlström, J. Tribology and airborne particle emissions from grey cast iron and WC reinforced laser cladded brake discs. Wear 2024, 556–557, 205512. [Google Scholar] [CrossRef]

- Eriksson, M.; Jacobson, S. Tribological surfaces of organic brake pads. Tribol. Int. 2000, 33, 817–827. [Google Scholar] [CrossRef]

- Alemani, M.; Wahlström, J.; Olofsson, U. On the influence of car brake system parameters on particulate matter emissions. Wear 2018, 396–397, 67–74. [Google Scholar] [CrossRef]

- Hagino, H.; Oyama, M.; Sasaki, S. Airborne brake wear particle emission due to braking and accelerating. Wear 2015, 334–335, 44–48. [Google Scholar] [CrossRef]

- Candeo, S.; Varriale, F.; Nogueira, A.P.; Gialanella, S.; Straffelini, G. Performance of a cast-iron and WC Co-free iron-based coated disc under mild and severe brake conditions. Wear 2024, 548–549, 205369. [Google Scholar] [CrossRef]

- Xiang, M.; Morgeneyer, M.; Aguerre-Chariol, O.; Lefebvre, C.; Philippe, F.; Meunier, L.; Bressot, C. A Quantitative Method for Characterizing of Structures’ Debris Release. Eng 2025, 6, 157. [Google Scholar] [CrossRef]

- Xiang, M.; Morgeneyer, M.; Philippe, F.; Bressot, C. Airborne nanoparticle (Nanoaerosol) sampling efficiency analysis based on filtration on TEM grid. J. Phys. Conf. Ser. 2019, 1323, 012002. [Google Scholar] [CrossRef]

- Nosko, O.; Alemani, M.; Olofsson, U. Temperature effect on emission of airborne wear particles from car brakes. In Proceedings of the EuroBrake 2015, Dresden, Germany, 4–6 May 2015. [Google Scholar]

- Nosko, O.; Olofsson, U. Effective density of airborne wear particles from car brake materials. J. Aerosol Sci. 2017, 107, 94–106. [Google Scholar] [CrossRef]

- Kukutschová, J.; Roubíček, V.; Malachová, K.; Pavlíčková, Z.; Holuša, R.; Kubačková, J.; Mička, V.; MacCrimmon, D.; Filip, P. Wear mechanism in automotive brake materials, wear debris and its potential environmental impact. Wear 2009, 267, 807–817. [Google Scholar] [CrossRef]

- Nosko, O.; Vanhanen, J.; Olofsson, U. Emission of 1.3–10 nm airborne particles from brake materials. Aerosol Sci. Technol. 2016, 51, 91–96. [Google Scholar] [CrossRef]

| Instrument | CPC | SMPS | APS | Filter | Nanobadge |

|---|---|---|---|---|---|

| Model | TSI 3775 | TSI 3082 | TSI 3321 | ||

| Measurable particle diameter range, nm | 4–3000 | 14–700 | 520–20,000 | <2500 | 10–4500 |

| Aerosol inlet flow rate, L/min | 1.5 | 0.3 | 5.0 | 4.0 | 1.0 |

| Elementary Composition [wt.%] | |||||

|---|---|---|---|---|---|

| Element | LS | GCI Disc | Element | LS | GCI Disc |

| Al | 9.62 | ≤0.015 | Ni | 0.047 | |

| C | 3.37 | P | 0.037 | ||

| Ca | 0.34 | S | 4.34 | 0.065 | |

| Cr | 1.19 | 0.18 | Si | 0.50 | 2.06 |

| Cu | 0.02 | 0.32 | Sn | 3.84 | 0.048 |

| Fe | 34.28 | Rest | Ti | 0.013 | |

| Mg | 37.43 | ≤0.010 | Zn | 7.68 | |

| Mn | 0.72 | Zr | 0.01 | ||

| Mo | 0.09 | 0.016 | Other | 0.66 | |

| Disc Type | Surface Composition | Surface Porosity | Hardness | Roughness (Ra) | Relative Load Length Ratio (Rmr) |

|---|---|---|---|---|---|

| GCI | 93% Fe, 3.37% C, 2.06% Si, main elements | 0% | |||

| Cr2O3 | >99.6% of Cr2O3 | 5% | 1100 HV0.3 | 0.528 µm | ≈80% |

| WC-CoCr | 86% WC, 10% Co, 4% Cr | <1% | 1100 HV0.3 | 0.133 µm | ≈50% |

| Test Phases | Cycle Name | Number of Sequences | Loading Sequences’ Duration (s) | Break Between Each Loading Sequence (s) | Contact Pressure (MPa) | Sliding Velocity (m/s) | Vehicle Speed (km/h) |

|---|---|---|---|---|---|---|---|

| 1 | Bedding | 50 | 10 | 60 | 1.2 | 8.2 | 80 |

| 2 | Emission | 25 | 10 | 60 | 1.2 | 3.6 | 35 |

| 3 | Emission | 19 | 10 | 60 | 1.2 | 6.1 | 60 |

| 4 | Emission | 6 | 10 | 60 | 1.2 | 11.2 | 110 |

| Vehicle Parameters | Pin-on-Disc Parameters | |||||

|---|---|---|---|---|---|---|

| Test Inertia (WLTP) (kg.m2) | Rolling Radius (mm) | Effective Radius (mm) | Brake Piston Diameter (mm) | Brake Pad Surface (mm2) | Test Radius (mm) | Pin Diameter (mm) |

| 55.68 | 295 | 108.5 | 54 | 4510 | 108.5 | 5 |

| Cast Iron | Cr2O3 | WC-CoCr | |

|---|---|---|---|

| Average particle concentration at 35 km/h, #/cm3 | 29 | 3 | 2 |

| Average particle concentration at 60 km/h, #/cm3 | 86 | 15 | 20 |

| Average particle concentration at 110 km/h, #/cm3 | 468 | 77 | 242 (115) |

| Weighted average particle concentration *, #/cm3 | 103 | 16 | 38 (22) |

| Cast Iron | Cr2O3 | WC-CoCr | |

|---|---|---|---|

| Min value | 0.36 | 0.28 | 0.29 |

| Max value | 0.51 | 0.32 | 0.46 |

| Average 35 km/h | 0.48 | 0.30 | 0.33 |

| Average 60 km/h | 0.44 | 0.29 | 0.34 |

| Average 110 km/h | 0.38 | 0.31 | 0.42 |

| Cast Iron | Cr2O3 | WC-CoCr | ||

|---|---|---|---|---|

| First mode | Whole test | 330 nm | 250 nm | 285 nm |

| 35 km/h | 330 nm | 265 nm | 265 nm | |

| 60 km/h | 330 nm | 250 nm | 285 nm | |

| 110 km/h | 350 nm | 250 nm | 285 nm | |

| Second mode | Whole test | 50 nm | <14 nm (suspected) | <14 nm (suspected) |

| 35 km/h | 15 nm | 20 nm | <14 nm (suspected) | |

| 60 km/h | <14 nm (suspected) | <14 nm (suspected) | <14 nm (suspected) | |

| 110 km/h | <14 nm (suspected) | <14 nm (suspected) | <14 nm (suspected) |

| Cast Iron | Cr2O3 | WC-CoCr | |

|---|---|---|---|

| Filter mass [mg] | 0.037 | 0.002 | 0.006 |

| Total distance [km] | 53.022 | 53.126 | 53.128 |

| qm/qp ratio | 14.019 | 13.999 | 13.944 |

| EFPM2.5 [μg/km] | 9.78 | 0.53 | 1.58 |

| Chemical Elements (µg/m3) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| B | Na | Mg | Al | Ti | Cr | Fe | Zn | Sn | |

| Cast iron | 0.36 | 0.52 | 73.67 | 0.60 | 0.50 | ||||

| Cr2O3 | 0.75 | 0.04 | 0.16 | 0.30 | 0.08 | 0.70 | 2.41 | 0.59 | 0.14 |

| WC-CoCr | 0.29 | 0.21 | 4.68 | 0.79 | 0.30 | ||||

| Chemical Elements (µg/m3) | ||

|---|---|---|

| Fe | Zn | |

| Cast iron | 68.06 | 0.38 |

| Cr2O3 | 2.14 | 0.53 |

| WC-CoCr | 4.53 | 0.40 |

| New Pin | Pin Tested on Cast Iron Disc | Pin Tested on Cr2O3-Coated Disc | Pin Tested on WC-CoCr-Coated Disc | |

|---|---|---|---|---|

| Carbon | 57.7 | 44.9 | 63.9 | 62.9 |

| Iron | 18.3 | 25.6 | 7.7 | 12.9 |

| Oxygen | 14.2 | 22.3 | 15.0 | 13.8 |

| Chrome | 0.0 | 0.6 | 1.8 | 1.0 |

| Tungsten | 0.0 | 0.0 | 0.0 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoff, M.; Bressot, C.; Chen, Y.-M.; Meunier, L.; Morgeneyer, M. Reduction in Brake Wear Emissions with Cr2O3 and WC-CoCr Coatings for Cast Iron Discs. Environments 2025, 12, 341. https://doi.org/10.3390/environments12100341

Hoff M, Bressot C, Chen Y-M, Meunier L, Morgeneyer M. Reduction in Brake Wear Emissions with Cr2O3 and WC-CoCr Coatings for Cast Iron Discs. Environments. 2025; 12(10):341. https://doi.org/10.3390/environments12100341

Chicago/Turabian StyleHoff, Marie, Christophe Bressot, Yan-Ming Chen, Laurent Meunier, and Martin Morgeneyer. 2025. "Reduction in Brake Wear Emissions with Cr2O3 and WC-CoCr Coatings for Cast Iron Discs" Environments 12, no. 10: 341. https://doi.org/10.3390/environments12100341

APA StyleHoff, M., Bressot, C., Chen, Y.-M., Meunier, L., & Morgeneyer, M. (2025). Reduction in Brake Wear Emissions with Cr2O3 and WC-CoCr Coatings for Cast Iron Discs. Environments, 12(10), 341. https://doi.org/10.3390/environments12100341