Abstract

The remediation of environments contaminated with per- and polyfluoroalkyl substances (PFAS) has become a growing priority due to the persistent, bioaccumulative, and toxic characteristics of these compounds. To promote green and sustainable remediation practices, it is crucial to assess and minimize the environmental impacts of PFAS remediation projects through life cycle assessment (LCA) at the early stages of planning. So far, no systematic literature review has been published to assess the current state of the art or identify the challenges associated with applying LCA to PFAS remediation. This article provides a review of the recent literature on LCAs of PFAS remediation, following the ISO 14040 and 14044 standards. The results indicate that the application of LCA to PFAS remediation remains in its infancy and is highly fragmented. Significant methodological variations, including differences in system boundaries and data quality, hinder the comparability and benchmarking of LCA results across studies. To enhance the use of LCA as a decision support tool for environmental assessment, there is a pressing need for methodological harmonization and improved practices. Key areas for improvement include enhancing data quality, reducing uncertainties, and increasing the robustness of PFAS LCAs, thereby enabling more informed and sustainable decision-making in PFAS remediation efforts.

1. Introduction

Concerning concentrations of per- and polyfluoroalkyl substances (PFAS) have been detected in soil and water around the world; therefore, the remediation of environments contaminated with PFAS has become a growing global concern [1]. PFAS, also known as “forever chemicals”, are a group of more than 9000 man-made and persistent hazardous chemicals used in industrial processes and consumer products since the 1940s [2]. PFAS contaminants are released to the environment through point and nonpoint sources, such as manufacturing plants, aqueous film-forming foam (AFFF) used in firefighting, waste treatment facilities, landfill leachate, and sewage sludge [3,4]. PFAS-impacted soil and water environments can pose significant challenges to the safeguarding of human health and the environment. A variety of PFAS components, such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), have been proven to be persistent, bioaccumulative, and toxic both to humans and the environment [5,6]. Exposure to PFAS-contaminated drinking water may lead to harmful effects on human health, including cancer, liver damage, fertility and fertility problems, hormone subjugation, and thyroid disease [2,7].

There is a growing body of literature with a focus on the technical efficacy of existing and emerging techniques for the remediation of PFAS in solid and aqueous media. Examples of remediation approaches and technologies for PFAS-contaminated soils are mobilization/separation (such as soil washing, soil flushing, liquefractionation, and phytoremediation), immobilization (such as sorption and stabilization/solidification), and destruction (such as bioremediation, chemical and thermal treatment, and ball milling) [5,8]. To remove PFAS from water sources, a range of techniques have been developed, including adsorption (utilizing adsorbents, such as granular activated carbon (GAC) and ion exchange (IEX) resins), membrane filtration/separation (such as reverse osmosis and nanofiltration), chemical precipitation, and advanced oxidation processes [9,10]. Although various PFAS remediation tests have been reported at the laboratory scale, there are very few published studies on the implementation of PFAS remediation techniques at the pilot, demonstration, and commercial scales [8,9,11,12].

The currently available PFAS remediation techniques have both advantages and disadvantages [4,6,8,11]. Previous studies have reported technical challenges, related, for instance, to the efficiency of the degradation method [13] and the choice of soil remediation technology [14]. The removal efficiency of some remediation techniques depends on the PFAS carbon chain length, electrical charge (e.g., anionic, cationic, and zwitterionic), and functional group (e.g., carboxylate, sulfonate, and phosphate) [11,12]. The efficacy of PFAS adsorption from aqueous media can be affected by adsorbent properties (e.g., particle size, pore size, and specific surface area) and solution chemistry (e.g., pH, co-existing ions, and co-existing organic matters) [9]. Moreover, degradation techniques for PFAS are not universally effective for all groups of PFAS [15]. Therefore, it is common to employ multiple remediation technologies to ensure the achievement of acceptable cleanup levels without introducing additional risks across different spatial and temporal scales.

It is crucial to integrate the environmental dimension into PFAS remediation decision-making to select more sustainable remediation options. According to the standard ISO 18504:2017 [16], sustainable remediation is defined as the “elimination and/or control of unacceptable risks in a safe and timely manner whilst optimizing the environmental, social, and economic value of the work”. Typical efforts to improve the efficiency of treatment systems for more sustainable remediation include reducing the environmental footprint, social impacts, and life-cycle costs throughout all stages of remediation and implementation [16].

Life cycle assessment (LCA) is an internationally standardized method for assessing the potential environmental impacts associated with a product or service throughout its life cycle, from raw material acquisition and manufacturing, through the use phase, to end-of-life treatment and final disposal [17]. An LCA-based comprehensive environmental assessment can serve as a basis for identifying environmental hotspots and avoiding possible problem shifting among life cycle stages or environmental impact categories in the early planning stages of a project [17]. In contrast to retrospective (or ex post) LCA studies intended for completed remediation projects, prospective (or ex ante) LCA studies [18,19] can contribute to understanding and optimizing the environmental performance of emerging PFAS remediation technologies before they are commercially implemented. According to Arvidsson et al. [19], the term prospective LCA can be defined as “LCA that models the production system at a future point in time relative to the time at which the study is conducted”.

The need for a broader application of LCA in PFAS remediation has been emphasized in recent years, particularly to support environmentally sustainable decision-making at various levels [9,11,20,21]. To our knowledge, however, no previous publications have systematically reviewed the literature on LCAs of PFAS remediation to synthesize the current knowledge in this emerging field.

This paper aims to shed light on the current state of research on LCAs of PFAS remediation through a literature review. It has two main objectives: (i) to summarize and explore the current practices in the application of LCA for PFAS remediation, and (ii) to identify the methodological challenges and research needs related to the quality and credibility of future PFAS LCA studies. The findings can contribute to the advancement of knowledge and understanding in the field of LCAs of PFAS remediation and support evidence-based decision-making from an environmental sustainability perspective.

2. Materials and Methods

2.1. Literature Search and Selection

To ensure a comprehensive review of the relevant literature, a systematic search was conducted across multiple databases, including the Web of Science, Scopus, and Google Scholar. The search strategy employed the following terms and Boolean operations: “per- and polyfluoroalkyl substances” OR “PFAS” AND “life cycle assessment” OR “LCA”. The approach was designed to capture a wide range of publications related to the application of LCA in PFAS remediation. The final literature search was conducted on 15 April 2024, with no restrictions on publication date to ensure inclusion of all relevant studies. Titles and abstracts of the retrieved articles were initially screened for relevance, followed by a full-text review to assess eligibility based on predefined inclusion and exclusion criteria. The inclusion criteria were as follows: (i) studies presenting at least one LCA case study on PFAS remediation techniques or projects, and (ii) peer-reviewed international journal articles written in English. Exclusion criteria included: (i) publications other than international journal articles, and (ii) studies focusing solely on the production of remediation materials, such as regeneration options for anion exchange resin [22]. The refinement process resulted in a final selection of eight articles, which formed the basis for this review.

Table 1 presents some general features of the selected articles on the LCA of PFAS remediation, including PFAS-impacted environmental media, targeted PFAS contaminants, and PFAS remediation techniques. Besides the LCA-based environmental assessment, other sustainability dimensions were included in four articles and mentioned in the table.

2.2. LCA Methodology

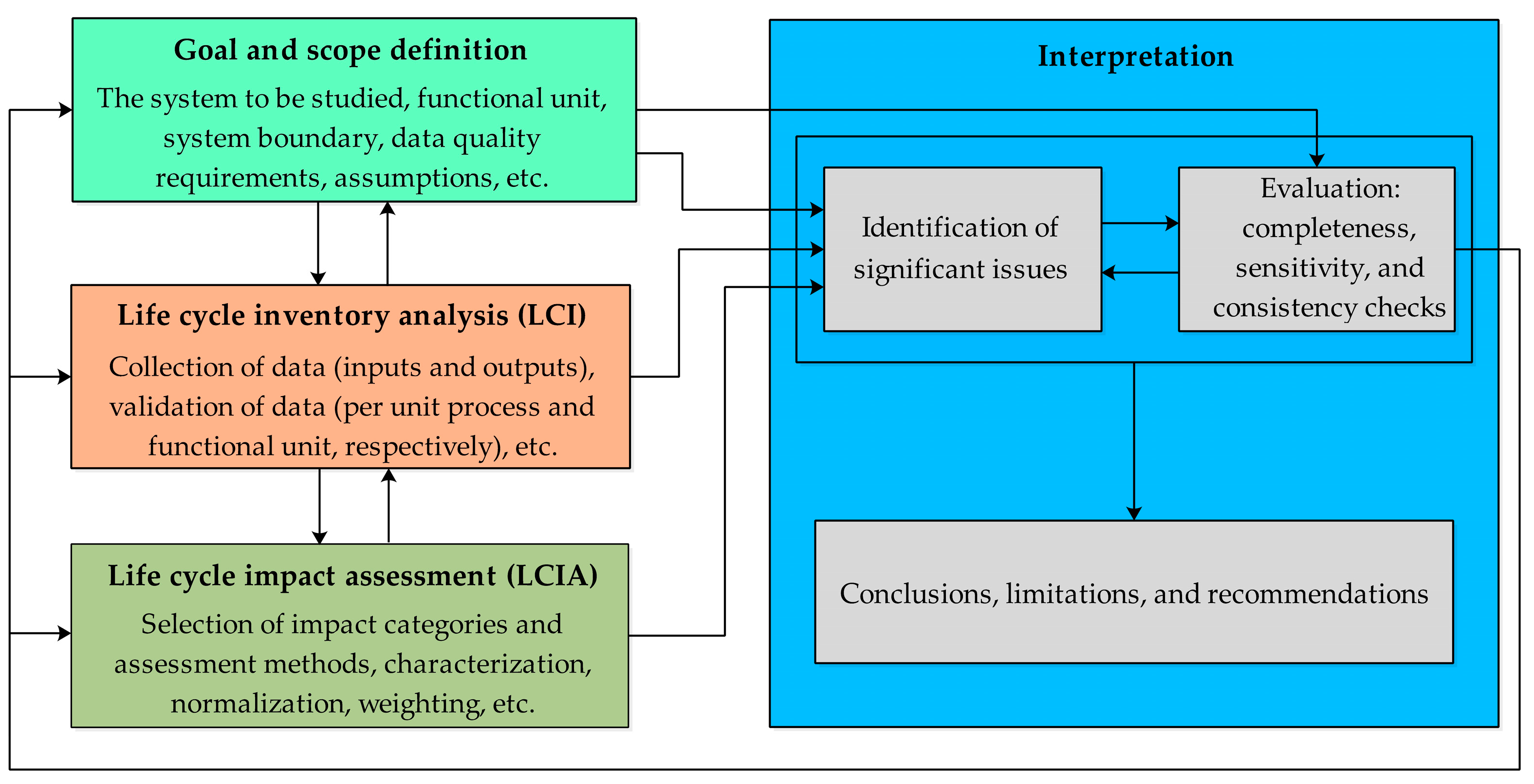

Following the ISO standards 14040 [17] and 14044 [23], an LCA study includes four iterative phases: (i) goal and scope definition, (ii) life cycle inventory analysis, (iii) life cycle impact assessment, and (iv) interpretation. When performing an LCA, the requirements of ISO 14044 should be applied [23]. Figure 1 illustrates the LCA framework, depicting the four phases of LCAs and examples of significant items to be addressed in each phase.

Figure 1.

The LCA framework based on ISO 14044 [23].

Table 1.

Overview of the selected articles on the LCA of PFAS remediation in this review.

Table 1.

Overview of the selected articles on the LCA of PFAS remediation in this review.

| Reference | PFAS | Target PFAS Contaminant | PFAS Remediation | Sustainability Assessment | ||

|---|---|---|---|---|---|---|

| Environmental Media | Location | Technology Studied | Type (Data Basis) of Case Study | (Dimension & Tool) | ||

| [24] | Groundwater | Ohio, USA | PFOA, PFOS | GAC (reactivation & reuse) | Scenario (similar facility, literature) | Environment (LCA) |

| IEX resin (regeneration & reuse) | Scenario (pilot-scale data, literature) | |||||

| [25] | Groundwater | USA | PFOA, PFOS, PFBA, FOSA | In-situ ultrasonic reactor | Scenario (author’s previous study) | Environment (LCA), economy (cost analysis) |

| Pump-and-treat with GAC | Scenario (literature) | |||||

| [26] | Spent fire-extinguishing water | Germany | PFAS | Flocculation/precipitation (PerfluorAD) | Scenario (lab-scale data, literature) | Environment (LCA) |

| GAC (single use) | Scenario (literature) | |||||

| Thermal treatment (incineration) | Scenario (literature) | |||||

| [27] | Landfill leachate | ZhuZhou, China | PFAS | On-site membrane bioreactor treatment | Scenario (similar facility, literature) | Environment (LCA), economy (LCCA) 3 |

| Off-site membrane bioreactor treatment | Scenario (literature) | |||||

| [28] | Groundwater | USA | 10 PFAS substances 1 | IEX resin (single use) + incineration | Scenario (lab-scale data, literature) | Environment (LCA) |

| IEX resin (single use) + electrochemical oxidation (EO) | ||||||

| IEX resin (regeneration & reuse) + EO | ||||||

| [29] | Groundwater | Brighton, USA | PFOA, PFOS | IEX resin 2 | Scenario (literature) | Environment (LCA), economy (WBS), society (SSEM, etc.) 4 |

| GAC 2 | ||||||

| [30] | Groundwater | USA | PFOA, PFOS | In-situ microbial remediation (RAPIMER) | Scenario (lab-scale data) | Environment (LCA) |

| Activated carbon (AC) 2 | Scenario (literature) | |||||

| IEX resin 2 | Scenario (literature) | |||||

| [31] | Groundwater (AFFF-impacted) | Willow Grove, USA | PFOA, PFOS | Anion exchange resin (AER, single use); AER (regeneration & reuse); GAC (single use); GAC (reactivation & reuse) | Scenario (pilot-scale data, literature) | Environment (LCA), economy (LCCA) |

1 PFBA, PFPeA, PFHxA, PFHpA, PFOA, PFBS, PFPeS, PFHxS, PFHpS, and PFOS. 2 Lack of information on whether AC and IEX resin had been reused or not in this article. 3 LCCA: Life cycle cost analysis. 4 WBS: Work Breakdown Structure model; SSEM: Social Sustainability Evaluation Matrix.

In the present study, the following key LCA elements were addressed: system boundaries, functional unit, inventory data and data quality, life cycle impact assessment, and interpretation.

Defining system boundaries and the functional unit are two important aspects in the goal and scope definition (GSD) phase. The system boundary determines the inclusion and exclusion of processes in an LCA study, which should be consistent with the defined goal of the study. The criteria used for setting the system boundary should be identified and explained [23]. The deletion of life cycle stages, processes, inputs, or outputs is only permitted if it does not significantly change the overall conclusions of the study [23]. To aid in defining and communicating the system boundary, the terminology for life cycle information and life cycle stages has been standardized in several areas. For example, the life cycle stages defined in the European standard EN 17472:2022 on sustainability assessment of civil engineering works [32] include module A0 (the pre-construction stage), modules A1–A3 (the product stage), modules A4–A5 (the construction stage), modules B1–B8 (the use stage), and modules C1–C4 (the end-of-life stage). However, there is currently no standardized or widely accepted terminology for life cycle stages for environmental remediation projects.

The functional unit is used as a reference unit for the quantitative description of the identified function (performance characteristics) of the system under study [17]. The definition of a functional unit generally involves answering the following five questions [33] (with examples for a LCA of a PFAS remediation system): “what?” (e.g., specific PFAS species under study), “how much?” (e.g., treating 1 m3 of PFAS-polluted groundwater), “for how long?” (i.e., the selected timescale), “where?” (e.g., geographic location of the remediation system), and “how well?” (e.g., the quantity of pollutants removed or to meet relevant treatment criteria).

The life cycle inventory analysis (LCI) phase involves the compilation and quantification of inputs and outputs of the system under study [23]. In general, the types of LCI data include primary data (“foreground data”), generic data (“background data”), and estimations (e.g., to fill data gaps). In ISO 14044 [23], the data quality requirements involve ten issues, including representativeness (related to time-related coverage, geographical coverage, and technology coverage), reproducibility (whether the reported results can be reproduced by an independent practitioner), sources of the data, and uncertainty of the information (e.g., assumptions, models, and data).

The life cycle impact assessment (LCIA) phase aims to understand and evaluate the potential environmental impacts of the system under study. Unlike environmental impact assessment (EIA) and environmental risk assessment (ERA), LCIA is a relative approach based on a functional unit defined in an LCA study [23]. To date, there are several existing impact assessment methods, comprising of a varied set of impact categories and characterization factors. The ISO LCA standards do not specify any choice in selection of impact assessment methods, but they state that the selected characterization model and characterization factors “should be scientifically and technically valid” [23]. According to the European Commission, LCA studies should preferably cover all relevant environmental issues related to the analyzed system under study [34].

The interpretation phase consists of three main elements: (i) identifying significant issues based on the LCI and LCIA results, (ii) conducting an evaluation that includes completeness, sensitivity, and consistency checks, and (iii) drawing conclusions, identifying limitations, and making recommendations [23]. Moreover, issues related to the goal of the LCA study must be considered, including the appropriateness of the defined functional unit and system boundary, as well as limitations identified by the sensitivity analysis and data quality assessment [23].

3. Results

3.1. Goal and Scope Definition

All the reviewed articles aimed to compare the environmental impacts of the alternative PFAS remediation technologies selected in each study. All articles focused on the removal of PFAS from various waters, including groundwater [24,25,28,29,30,31], spent fire-extinguishing water [26], and landfill leachate [27]. At the time of writing, we did not find published LCA studies on the remediation of PFAS-impacted soil. Two physical treatment methods were the most studied in the reviewed articles, namely adsorption with activated carbon [24,25,26,29,30,31] and ion-exchange resins [24,28,29,30,31]. Other PFAS remediation methods in the reviewed articles include (i) in-situ remediation using sonolysis [25], (ii) thermal treatment (direct incineration) [26], (iii) precipitation agents (PerfluorAd process) [26], (iv) electrochemical oxidation [28], (v) membrane bioreactor treatment (both on-site and off-site) [27], and (vi) in-situ microbial remediation [30].

3.1.1. System Boundary

In the reviewed articles, the chosen system boundaries (Table 2) vary partly depending on the goal of each LCA study. The provision of the materials (e.g., GAC, IEX resin, and precipitation agents) directly used in the remediation process was included in all the reviewed articles. One article [30] focused only on the manufacturing of three different sorbents required to meet the remediation goal, without considering all the other aspects related to the remediation processes.

Table 2.

Functional units and system boundaries defined in the reviewed articles.

Regarding the pre-treatment preparation stage, infrastructure construction was included in three articles [24,27,31] and excluded in one article [28]. In four articles [25,26,29,30], there was a lack of clear description of the inclusion or exclusion of infrastructure construction. Treatment equipment (assembly and/or installation) was included in four articles [24,25,29,31], while it was not reported in the other articles [26,27,28,30].

As for final waste disposal options, incineration was employed in four articles related to spent GAC [24,31], chemical precipitation sludge and spent GAC [26], and spent IEX resin [28]. Landfilling of spent IEX resin was employed in three articles [27,28,29]. In one article [25], it was reported that the final disposal of spent GAC was excluded based on the authors’ assumption that the environmental impacts from the incineration of spent GAC would be minimal.

In three articles [28,29,31] one common exclusion criterion was applied to unit processes or resource usage that were the same or equivalent across different remediation treatment systems under study. In a comparative LCA study on PFAS remediation using ion exchange and electrochemical oxidation technology, Li et al. [28] excluded identical infrastructure from all treatment scenarios to “eliminate the unnecessary complexity and increase the transferability of the results”. In two scenarios involving alternative PFAS adsorbents (GAC and IEX resin) for groundwater remediation, Moeini et al. [29] excluded five pre-treatment processes assumed to occur before the PFAS adsorption process: coagulation, flocculation, sedimentation, disinfection, and filtration. Similarly, Ellis et al. [31] excluded the same amount of electricity used for pumping groundwater as well as the equivalent groundwater pretreatment operations (e.g., filters) in the comparison between remediation scenarios with GAC and IEX resin.

In a specific comparative LCA study, it is possible to exclude several similar processes or resource usages for simplification purposes. However, such simplification can pose challenges in identifying the environmental hotspots of the whole remediation system. For example, the study carried out by Moeini et al. [29] revealed that stainless steel, as the main material for the contactors/vessels, contributed to over 95% of the impact category “human toxicity, cancer” for both GAC and IEX resin systems, as well as to 91% of the impact category of ecotoxicity for the GAC system and 76.7% for the IEX resin system. In another study, Emery et al. [24] pointed out that the environmental impacts from transportation related to the reactivation of spent GAC can be an important factor in decision-making on the design of treatment systems for groundwater with higher PFAS concentrations at or above 70 µg/L. In general, LCA studies with varied system boundaries can make it hard or impossible to compare or benchmark the results among different LCA studies.

3.1.2. Functional Unit

Several functional units were defined in the reviewed articles (Table 2). Firstly, five articles used one cubic meter of water as a basis for the functional unit, focusing on groundwater [24,30,31], leachate [27], or spent-extinguishing water [26]. One article [25] defined the functional unit based on a specific PFAS-contaminated plume (15 ft thick, 350 ft wide, and 1000 ft in length. Another article [28] used 1000 m3 of groundwater as a functional unit. In the article by Moeini et al. [29], 800,000 gallons of groundwater were selected to represent the total daily drinking water needs in the studied area. Moreover, two articles [27,30] used multiple functional units, including “1 g of PFAS removed from leachate” [27] and “1 kg of sorbent materials” [30].

Second, the target PFAS species (Table 1), the initial PFAS concentration (before remediation), and the remediation goals (Table 2) varied across the reviewed articles. A total of four types of PFAS species were targeted: (i) two PFAS species (PFOA and PFOS) in four articles [24,29,30,31], four PFAS species (PFOA, PFOS, PFBA, and FOSA) in one article [25], (iii) 10 PFAS in one article [28], and (iv) the whole PFAS group in two articles [26,27]. For the four articles focusing on PFOA and PFOS, three remediation goals were set: (i) 70 ng/L following the USEPA’s reference value for drinking water [24], (ii) 8 ng/L for PFOA and 16 ng/L for PFOS following the Michigan Department of Environment, Great Lakes, and Energy’s (EGLE) standards [29], and (iii) zero effluent PFOA and PFOS [30,31]. For the two articles focusing on the overall PFAS group, the remediation goals were defined as “the removal of more than 99% of the influent PFAS” [26] and “two orders of magnitude removal of PFAS” [28], respectively. However, one article [27], which compared the environmental impacts of on-site versus off-site scenarios on membrane bioreactor treatment of PFAS in landfill leachate, did not specify a remediation goal. This lack of specificity might lead to an unfair comparison of the environmental impacts between the two scenarios, given the differences in PFAS removal efficiency (99% for the on-site treatment and 21% for the off-site treatment) for 1 m3 of landfill leachate.

Third, the timescale associated with the functional unit was specified in four articles [24,25,27,31] but omitted in the other four articles [26,28,29,30]. Specifically, the timescale selection in three articles was based on the estimated operational lifespan of treatment infrastructure: 20 years for a groundwater treatment plant [24], 15 years for a wastewater treatment plant [27], and 30 years for capital infrastructure in the studied remediation system [31]. One article [27] defined the timescale as an operation period ranging from 1 to 30 years due to a lack of monitoring data to determine the operational time needed for the studied PFAS-impacted plume. None of the reviewed articles provided a clear description of the operation time or the breakthrough time (“efficiency”) needed for different PFAS treatment techniques to achieve the expected remediation goals of the system under study.

3.2. Inventory Data Sources and Quality

The background LCI data used in the reviewed articles (Table 3) were derived from several databases, including USEI v2.2 (last updated in 2014) and USLCI v1.10.1 (last updated in 2012) available in SimaPro v9.1. The two most employed databases were different versions of ecoinvent (as cited by four articles [24,28,30,31]) and USLCI (as cited by three articles [28,30,31]. In fact, the four articles that employed the European database ecoinvent focused on PFAS remediation studies in non-European countries.

Table 3.

Background LCI data sources.

Three articles [25,27,29] did not clarify which background databases or specific LCI datasets had been used. The actual LCI datasets used in some articles [24,30] were not clearly described, due to the simplified dataset names. A good example of how to document LCI datasets was provided by Ellis et al. [31], who published the full names of the selected LCI datasets, the names of databases, and the representative geographical coverage of each LCI dataset.

Regarding foreground data, the project-specific LCI results were not reported in two articles [25,29], making it impossible to know the amount of material and energy use in detail. In the other six articles, the LCI results were presented with a varied level of detail and based on various data sources (Table 1). Moreover, as exemplified in Table 4, several studies estimated the required mass of sorbents based on the maximum adsorption capacity of sorbents reported in the literature. In general, the PFAS removal efficiency of the GAC and IEX resin system can be influenced, among other factors, by the PFAS chain length [35] and resin properties (e.g., polymer composition or pore structure) [36], respectively. However, none of these reviewed articles with literature-based case studies provided a thorough explanation of the representativeness of the selected maximum PFAS adsorption capacity of adsorbents in different contexts.

Table 4.

Examples of selected maximum adsorption capacities of single-use sorbents.

3.3. Life Cycle Impact Assessment

All reviewed articles included the life cycle impact assessment (LCIA) phase, based on the selected impact assessment methods and impact categories (Table 5). Seven articles provided characterization results for at least one environmental impact category. An exception was the article by Moeini et al. [29], which only presented the comparative results of the overall environmental impacts between the GAC and resin treatment systems.

Table 5.

Selection of impact categories and impact assessment methods in the reviewed articles.

The most employed impact assessment method was the USEPA Tool for the Reduction and Assessment of Chemical and other environmental Impacts (TRACI) [37], utilized in five articles [24,27,28,29,31]. The EU-recommended product environmental footprint (PEF) method [38] was used in one article [26], which focused on treating PFAS in spent fire-extinguishing water within the European context. However, two articles did not report sources of LCIA characterization factors, or the impact assessment methods used: one relied on the SiteWise Sustainable Environmental Remediation tool [25] and the other on OpenLCA software [30]. Climate change was the only impact category addressed by all reviewed articles. Nonetheless, litter consideration was given to other environmental impact categories, such as “land use” and “water use”.

Results of the LCIA from different treatment systems in the review articles showed a large variation (Table 6), even among those based on the same type of remediation technique. Regarding the single-use GAC system, for example, the greenhouse gas (GHG) emissions ranged from 28.3 CO2eq/m3 water with a PFAS influent concentration of 2300 µg/L [26] to 0.44 kg CO2eq/m3 water with a PFAS influent concentration of 50 µg/L [31]. The article by Li et al. [30] reported the lowest GHG emissions from both the AC and IEX resin systems, mainly due to the higher adsorption capacity of the sorbents used (Table 4).

Table 6.

GHG emissions from PFAS remediation reported in the reviewed articles.

3.4. Interpretation

All the reviewed articles presented system-level comparison results of the environmental performance of the alternative PFAS treatment systems under study. However, several articles [24,25,29] did not report the results of a detailed contribution analysis of various unit processes included in the PFAS treatment systems. Except for three articles [25,29,30], the others performed sensitivity analyses focusing on varying parameters. For example, Maga et al. [26] investigated the potential influence of different adsorption capacities of activated carbon and the dilution of AFFF on GHG emissions. Feng et al. [27] used two alternative impact assessment methods to verify their LCIA results associated with electricity usages and membrane bioreactor operations. Only two articles [24,28] performed quantitative uncertainty analyses, both utilizing a Monte Carlo simulation tool in the SimaPro software [39]. It should be noted that neither sensitivity analysis nor uncertainty analysis was reported in three of the articles [25,29,30].

Regarding sensitivity analysis in the reviewed articles, there is also a lack of broader discussion of the factors that may potentially affect the total environmental impacts of a PFAS remediation project, such as those related to the production and transportation of sorbents. For example, Vilén et al. [40] reported a range of cradle-to-gate GHG emissions from the production of GAC based on various raw materials, including 1.1 kg CO2eq/kg for coal GAC, 1.1 kg CO2eq/kg for coconut GAC, and 0.9 kg CO2eq/kg for wood GAC. In this context, the climate impact of sorbent transportation may vary significantly, depending on the types and distances of transportation.

4. Discussion and Recommendations

Moving towards green and sustainable PFAS remediation practice requires a more comprehensive understanding of the overall environmental performance of alternative remediation options from a life cycle perspective. LCA has been recognized as a valuable decision-support tool for identifying environmental hotspots and comparing the environmental performance of different remediation systems [41]. Despite the considerable amount of research on the feasibility of emerging remediation technologies, there are still limited publications worldwide that provide detailed LCA studies on PFAS remediation. To enhance the quality and comparability of results from PFAS LCA studies, several methodological challenges remain, particularly those related to system boundaries, functional units, representative background LCI datasets, environmental impact assessments, and prospective LCAs of emerging technologies.

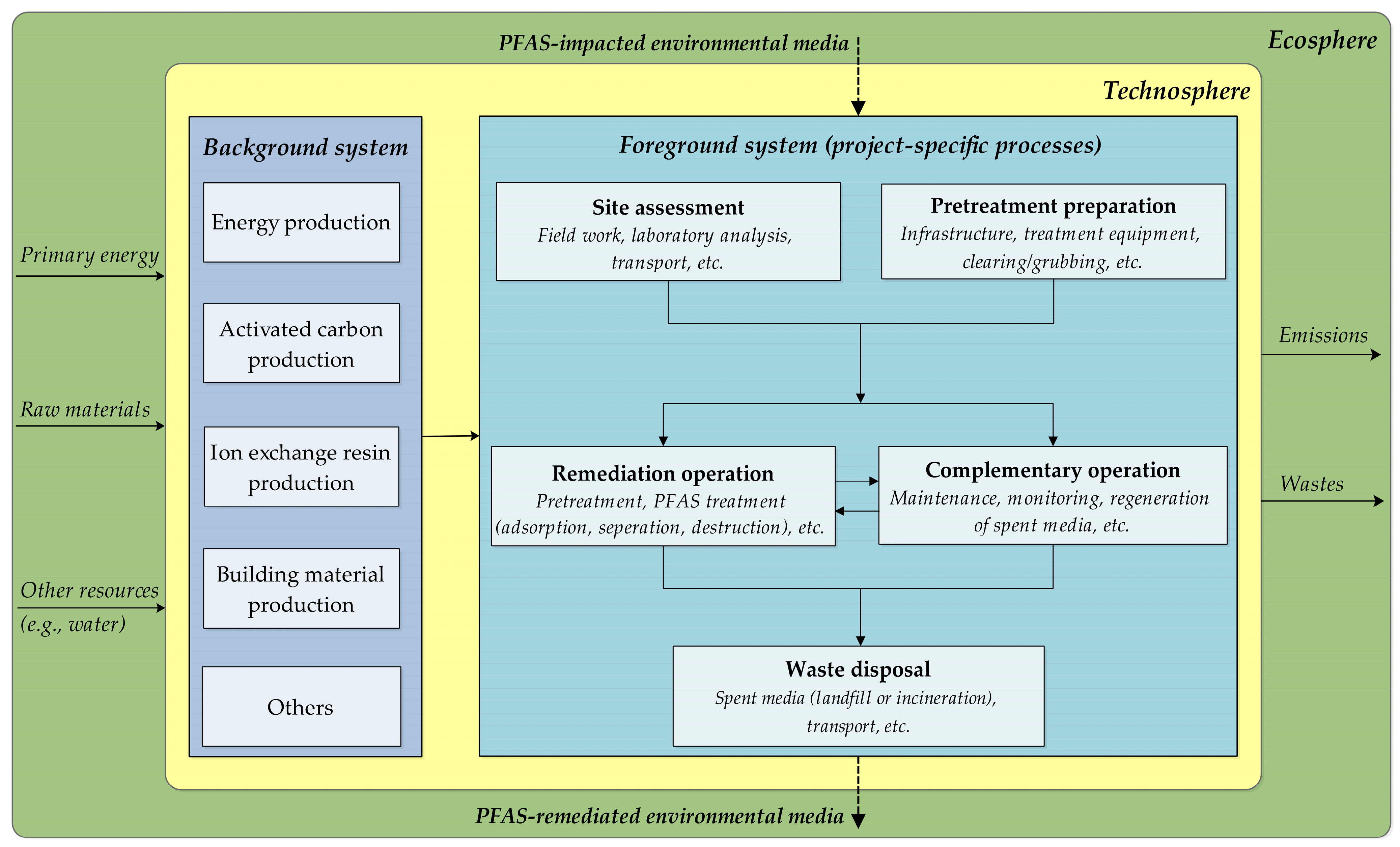

The quality of a PFAS LCA study can be affected by various factors, including the omissions of life cycle stages and unit processes when setting system boundaries. As seen in the reviewed articles (Table 2), varied scopes of system boundaries were employed in comparative LCAs on alternative remediation systems. According to ISO 14044 [23], omissions are permitted when setting the system boundary for an LCA study, provided the selected system boundary is consistent with the goal of the study. To date, there have been few discussions in the literature about the extent to which various omitted material and energy uses in remediation LCA studies can affect the overall life cycle environmental impacts of different remediation systems. Therefore, there is a need for LCA practitioners to include as many relevant unit processes as possible in future PFAS LCA research to allow for a fair comparison or benchmarking of LCA results from different studies. Figure 2 illustrates a simplified flow chart to serve as a basis for communicating and setting the system boundary in future PFAS LCA studies.

Figure 2.

A simplified flow chart to assist in system boundary setting in LCAs of PFAS remediation.

A relevant and well-defined functional unit is essential for all PFAS LCA studies, as it ensures the comparability of LCA results on a common basis. Two important parameters deserve attention and should be considered when defining the functional unit: (i) the efficiency of remediation techniques and (ii) the time frame required for remediation [42]. In a comparative LCA of alternative PFAS remediation systems, these parameters are crucial, especially when substantial differences in remediation time frames may lead to varying environmental impacts from PFAS-contaminated environmental media during the remediation process.

When setting PFAS treatment goals or cleanup levels, it is recommended to consider the relevant country-specific regulations. Several countries have focused on developing regulatory requirement for concentrations of PFAS compounds in drinking water, soil, and sludge/biosolids. For example, in March 2023, the U.S. EPA announced proposed legally enforceable levels for six PFAS in drinking water: 4.0 nanograms per liter (ng/L) for PFOS, 4.0 ng/L for PFOA, and a hazard index (unitless) of 1.0 for a mixture of four PFAS (perfluorononanoic acid (PFNA), hexafluoropropylene oxide dimer acid (HFPO-DA), perfluorohexane sulfonic acid (PFHxS), and perfluorobutane sulfonic acid (PFBS)) [43]. Similarly, the Swedish Food Agency’s Regulation on Drinking Water (LIVSFS 2022:12) will impose the following limit values for PFAS in drinking water from 1 January 2026: 4 ng/L for PFAS-4 (the sum of PFOS, PFOA, PFNA, and PFHxS), and 100 ng/L for PFAS-21 (the sum of 21 PFAS) [44]. Countries with regulations for maximum PFAS concentrations in soil and sludge/biosolids include Canada, Denmark, Norway, Germany, the Netherlands, Australia, and the United Kingdom [4].

More focus needs to be placed on the selection and development of representative background LCI datasets, especially when assessing the potential environmental impacts of the final disposal phase of PFAS-containing sorbents. In several of the reviewed articles [24,26,28,31], incineration was chosen as the disposal method for spent GAC or resin, based on a generic “municipal incineration” or “hazardous waste incineration” process from available background LCI databases. However, the climate impact from the “hazardous waste incineration” process can be five times higher than that from the “municipal incineration” process, as shown by a simplified LCA of five generic LCI datasets in ecoinvent 3.10 using the “Environmental Footprint 3.1 (adapted)” impact assessment method in SimaPro 9.6.0.1 Analyst (Table S1, Supplementary Materials). Moreover, the fate of PFAS after incineration is still not well understood. According to Weitz et al. [45], around 99.99% of PFAS can be destroyed in thermal treatment systems operating at temperatures above 850 °C, although incomplete combustion may lead to the emission of fluorinated organic products, such as tetrafluoromethane (CF4). Björklund et al. [46] reported that certain PFAS cannot be fully degraded by the high temperatures in municipal solid waste incineration, leading to PFAS emissions from incineration processes through ash, flue gas, gypsum, and treated process water. New characterization factors and representative background LCI datasets need to be developed to address more PFAS-specific concerns, such as the ecotoxicity of PFAS and the environmental impacts of the disposal of PFAS-containing spent sorbents.

When conducting a PFAS LCA study to support environmental decision-making, it is essential to investigate whether remediation provides a net environmental benefit by comparing the primary and secondary impacts of a site [47]. Typically, primary impacts are associated with human toxicity and ecotoxicity caused by on-site contaminants, while secondary impacts are the life cycle environmental impacts related to material and energy uses during the remediation process [48]. To facilitate assessing the primary impacts of PFAS in LCA, Holmquist et al. [49] proposed an (eco)toxicity LCIA framework for PFAS and highlighted remaining causes of uncertainty, such as those in calculated effect factors. However, this literature review revealed that no published PFAS LCA studies have quantified the primary impacts in a no-action scenario, let alone compared primary and secondary impacts. Very often, the primary impacts of a PFAS-contaminated site are quantified using site-specific models for human and ecological risk assessment [50]. In a site-specific remediation project, determining net environmental benefits also depends on the developed weighting factors for primary and secondary impacts in accordance with stakeholders’ views and perspectives [51].

Although there is increasing interest in the use of LCA during the early stages of technology research and development, systematic guidance for LCA researchers and practitioners to assess and compare the environmental performance of emerging technologies is still lacking [52]. This holds true for prospective LCA studies of PFAS remediation. So far, there has been little discussion on the unique methodological challenges for prospective LCAs of emerging PFAS remediation technologies. In general, the challenges associated with prospective LCAs of emerging technologies include issues related to comparability, data (availability, quality, and scaling of inventory data), and uncertainty [53,54]. To aid in determining the comparability of prospective LCA results, it is important to identify and clarify the levels of technical and market maturity as part of the environmental assessment of emerging technologies [55,56,57]. To optimize upscaling projections of foreground LCI data from the lab-scale or the pilot-scale to the commercial scale, LCA practitioners and technology developers need to cooperate closely to identify the most suitable upscaling method [58]. In many cases, the upscaling challenge is highly technology-specific [59]. As highlighted by Bergerson et al. [57], the different assumptions used to predict future adoption patterns and technical performances of an emerging technology can result in changes to LCA results by an order of magnitude or more. To avoid temporal mismatches between foreground and background systems, Arvidsson et al. [60] recommend reporting the impacts of foreground and background systems separately to enhance the utility of the results in other prospective LCA studies. In recent years, significant progress has been made in modelling future background systems (such as energy production) based on future scenario data from Integrated Assessment Models (IAMs) [61,62]. Approaches to overcoming the challenges of conducting prospective LCAs of emerging technologies at early development stages have been discussed and suggested in the literature, such as in a review article by Moni et al. [54] To better support the development of more environmentally friendly PFAS remediation technologies and projects, further discussions are needed, especially on the current challenges and best practices in prospective LCA methodologies for novel and emerging techniques for PFAS remediation.

5. Conclusions

This study reviewed recent articles featuring LCA case studies of PFAS remediation technologies. The results showed that the current application of LCA in PFAS remediation is still in its infancy, primarily due to the limited number of publications and the diverse methodologies employed across various case studies. All eight reviewed articles focused on the LCA of PFAS remediation of aquatic resources, primarily through scenario analyses based on lab-scale data or data from the literature. The most studied remediation method was adsorption using GAC or IEX resin. Notably, none of the articles were based on primary data on material and energy use from commercial-scale PFAS remediation projects. The variations in system boundaries, functional units, and assumptions across the studies pose challenges to comparing their results. Consequently, the LCA results from these articles should be interpreted cautiously when being applied in different contexts.

More methodological discussions and consensus-building are necessary, for both retrospective and prospective PFAS LCA studies. This is a prerequisite to enable fair comparisons of the environmental performance of various remediation techniques, as well as to benchmark the LCA results from different studies. There is also a need for more detailed LCA case studies of PFAS remediation. Specifically, more foreground LCI data needs to be collected and reported transparently. Detailed and transparent LCA studies can facilitate a comprehensive understanding of the environmental implications of existing and emerging PFAS remediation technologies from a life cycle perspective. Future work should focus on (i) developing high-quality background LCI datasets—especially for the final disposal phase related to PFAS-containing sorbents or other media—(ii) assessing and integrating site-specific primary environmental impacts, and (iii) developing guidelines for both retrospective (or ex post) and prospective (or ex ante) PFAS LCA studies.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/environments11090203/s1, Table S1: Comparison of the life cycle environmental impacts of five solid waste incineration processes.

Author Contributions

Conceptualization, X.S., M.M. and C.C.; methodology, X.S., M.M. and C.C.; software, X.S.; formal analysis, X.S., M.M. and C.C.; writing—original draft preparation, X.S.; writing—review and editing, M.M, C.C. and X.S.; visualization, X.S. and M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in the study are included in the article and in the Supplementary Materials; further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Marquínez-Marquínez, A.N.; Loor-Molina, N.S.; Quiroz-Fernández, L.S.; Maddela, N.R.; Luque, R.; Rodríguez-Díaz, J.M. Recent Advances in the Remediation of Perfluoroalkylated and Polyfluoroalkylated Contaminated Sites. Environ. Res. 2023, 219, 115152. [Google Scholar] [CrossRef]

- Cordner, A.; Goldenman, G.; Birnbaum, L.S.; Brown, P.; Miller, M.F.; Mueller, R.; Patton, S.; Salvatore, D.H.; Trasande, L. The True Cost of PFAS and the Benefits of Acting Now. Environ. Sci. Technol. 2021, 55, 9630–9633. [Google Scholar] [CrossRef]

- Ehsan, M.N.; Riza, M.; Pervez, M.N.; Khyum, M.M.O.; Liang, Y.; Naddeo, V. Environmental and Health Impacts of PFAS: Sources, Distribution and Sustainable Management in North Carolina (USA). Sci. Total Environ. 2023, 878, 163123. [Google Scholar] [CrossRef]

- Zhou, T.; Li, X.; Liu, H.; Dong, S.; Zhang, Z.; Wang, Z.; Li, J.; Nghiem, L.D.; Khan, S.J.; Wang, Q. Occurrence, Fate, and Remediation for per-and Polyfluoroalkyl Substances (PFAS) in Sewage Sludge: A Comprehensive Review. J. Hazard. Mater. 2024, 466, 133637. [Google Scholar] [CrossRef]

- Bolan, N.; Sarkar, B.; Yan, Y.; Li, Q.; Wijesekara, H.; Kannan, K.; Tsang, D.C.W.; Schauerte, M.; Bosch, J.; Noll, H.; et al. Remediation of Poly- and Perfluoroalkyl Substances (PFAS) Contaminated Soils—To Mobilize or to Immobilize or to Degrade? J. Hazard. Mater. 2021, 401, 123892. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Bezerra de Souza, B.; Casarini, M.M.; Kewalramani, J.A. A Review of PFAS Destruction Technologies. Int. J. Environ. Res. Public Health 2022, 19, 16397. [Google Scholar] [CrossRef]

- Verma, S.; Lee, T.; Sahle-Demessie, E.; Ateia, M.; Nadagouda, M.N. Recent Advances on PFAS Degradation via Thermal and Nonthermal Methods. Chem. Eng. J. Adv. 2023, 13, 100421. [Google Scholar] [CrossRef]

- Mahinroosta, R.; Senevirathna, L. A Review of the Emerging Treatment Technologies for PFAS Contaminated Soils. J. Environ. Manag. 2020, 255, 109896. [Google Scholar] [CrossRef]

- Lei, X.; Lian, Q.; Zhang, X.; Karsili, T.K.; Holmes, W.; Chen, Y.; Zappi, M.E.; Gang, D.D. A Review of PFAS Adsorption from Aqueous Solutions: Current Approaches, Engineering Applications, Challenges, and Opportunities. Environ. Pollut. 2023, 321, 121138. [Google Scholar]

- Amen, R.; Ibrahim, A.; Shafqat, W.; Hassan, E.B. A Critical Review on PFAS Removal from Water: Removal Mechanism and Future Challenges. Sustainability 2023, 15, 16173. [Google Scholar] [CrossRef]

- Sharma, N.; Kumar, V.; Sugumar, V.; Umesh, M.; Sondhi, S.; Chakraborty, P.; Kaur, K.; Thomas, J.; Kamaraj, C.; Maitra, S.S. A Comprehensive Review on the Need for Integrated Strategies and Process Modifications for Per- and Polyfluoroalkyl Substances (PFAS) Removal: Current Insights and Future Prospects. Case Stud. Chem. Environ. Eng. 2024, 9, 100623. [Google Scholar] [CrossRef]

- Grimison, C.; Knight, E.R.; Nguyen, T.M.H.; Nagle, N.; Kabiri, S.; Bräunig, J.; Navarro, D.A.; Kookana, R.S.; Higgins, C.P.; McLaughlin, M.J.; et al. The Efficacy of Soil Washing for the Remediation of Per- and Poly-Fluoroalkyl Substances (PFASs) in the Field. J. Hazard. Mater. 2023, 445, 130441. [Google Scholar] [CrossRef]

- Thapa, B.S.; Pandit, S.; Mishra, R.K.; Joshi, S.; Idris, A.M.; Tusher, T.R. Emergence of Per- and Poly-Fluoroalkyl Substances (PFAS) and Advances in the Remediation Strategies. Sci. Total Environ. 2024, 916, 170142. [Google Scholar] [CrossRef]

- Shih, C.-H.; Kim, J.; Yang, S.-H.; Soker, O.; Strathmann, T.J.; Chu, K.-H. Remediation of PFAS-Impacted Soils Using Magnetic Activated Carbon (MAC) and Hydrothermal Alkaline Treatment (HALT). Sci. Total Environ. 2024, 912, 168931. [Google Scholar] [CrossRef]

- Dickman, R.A.; Aga, D.S. A Review of Recent Studies on Toxicity, Sequestration, and Degradation of per- and Polyfluoroalkyl Substances (PFAS). J. Hazard. Mater. 2022, 436, 129120. [Google Scholar] [CrossRef]

- ISO 18504:2017; Soil Quality—Sustainable Remediation. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- van der Giesen, C.; Cucurachi, S.; Guinée, J.; Kramer, G.J.; Tukker, A. A Critical View on the Current Application of LCA for New Technologies and Recommendations for Improved Practice. J. Clean. Prod. 2020, 259, 120904. [Google Scholar] [CrossRef]

- Arvidsson, R.; Svanström, M.; Sandén, B.A.; Thonemann, N.; Steubing, B.; Cucurachi, S. Terminology for Future-Oriented Life Cycle Assessment: Review and Recommendations. Int. J. Life Cycle Assess. 2024, 29, 607–613. [Google Scholar] [CrossRef]

- Cantoni, B.; Bergna, G.; Baldini, E.; Malpei, F.; Antonelli, M. PFAS in Textile Wastewater: An Integrated Scenario Analysis for Interventions Prioritization to Reduce Environmental Risk. Process Saf. Environ. Prot. 2024, 183, 437–445. [Google Scholar] [CrossRef]

- Dahlbom, S.; Bjarnemark, F.; Nguyen, B.; Petronis, S.; Mallin, T. Analysis of Per- and Polyfluoroalkyl Substances (PFAS) Extraction from Contaminated Firefighting Materials: Effects of Cleaning Agent, Temperature, and Chain-Length Dependencies. Emerg. Contam. 2024, 10, 100335. [Google Scholar] [CrossRef]

- Boyer, T.H.; Ellis, A.; Fang, Y.; Schaefer, C.E.; Higgins, C.P.; Strathmann, T.J. Life Cycle Environmental Impacts of Regeneration Options for Anion Exchange Resin Remediation of PFAS Impacted Water. Water Res. 2021, 207, 117798. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Emery, I.; Kempisty, D.; Fain, B.; Mbonimpa, E. Evaluation of Treatment Options for Well Water Contaminated with Perfluorinated Alkyl Substances Using Life Cycle Assessment. Int. J. Life Cycle Assess. 2019, 24, 117–128. [Google Scholar] [CrossRef]

- Laramay, F.; Crimi, M. A Sustainability Assessment of an in Situ Ultrasonic Reactor for Remediation of PFAS-Contaminated Groundwater. Remediation 2020, 31, 59–72. [Google Scholar] [CrossRef]

- Maga, D.; Aryan, V.; Bruzzano, S. Environmental Assessment of Various End-of-Life Pathways for Treating Per- and Polyfluoroalkyl Substances in Spent Fire-Extinguishing Waters. Environ. Toxicol. Chem. 2021, 40, 947–957. [Google Scholar] [CrossRef]

- Feng, D.; Song, C.; Mo, W. Environmental, Human Health, and Economic Implications of Landfill Leachate Treatment for per- and Polyfluoroalkyl Substance Removal. J. Environ. Manag. 2021, 289, 112558. [Google Scholar] [CrossRef]

- Li, G.; Dunlap, J.; Wang, Y.; Huang, Q.; Li, K. Environmental Life Cycle Assessment (LCA) of Treating PFASs with Ion Exchange and Electrochemical Oxidation Technology. ACS ES T Water 2022, 2, 1555–1564. [Google Scholar] [CrossRef]

- Moeini, M.; Modaresahmadi, K.; Tran, T.; Reddy, K.R. Sustainability Assessment of PFAS Adsorbents for Groundwater Remediation. Mater. Today Proc. 2022, 60, 2209–2216. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Da, Y.; Yu, J.; Long, B.; Zhang, P.; Bakker, C.; McCarl, B.A.; Yuan, J.S.; Dai, S.Y. Sustainable Environmental Remediation via Biomimetic Multifunctional Lignocellulosic Nano-Framework. Nat. Commun. 2022, 13, 1–13. [Google Scholar] [CrossRef]

- Ellis, A.C.; Boyer, T.H.; Fang, Y.; Liu, C.J.; Strathmann, T.J. Life Cycle Assessment and Life Cycle Cost Analysis of Anion Exchange and Granular Activated Carbon Systems for Remediation of Groundwater Contaminated by Per- and Polyfluoroalkyl Substances (PFASs). Water Res. 2023, 243, 120324. [Google Scholar] [CrossRef]

- EN 17472:2022; Sustainability of Construction Works—Sustainability Assessment of Civil Engineering Works—Calculation Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2022.

- Bjørn, A.; Owsianiak, M.; Laurent, A.; Olsen, S.I.; Corona, A.; Hauschild, M.Z. Scope Definition. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 75–116. [Google Scholar]

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Leung, S.C.E.; Wanninayake, D.; Chen, D.; Nguyen, N.T.; Li, Q. Physicochemical Properties and Interactions of Perfluoroalkyl Substances (PFAS)—Challenges and Opportunities in Sensing and Remediation. Sci. Total Environ. 2023, 905, 166764. [Google Scholar] [CrossRef]

- Dixit, F.; Dutta, R.; Barbeau, B.; Berube, P.; Mohseni, M. PFAS Removal by Ion Exchange Resins: A Review. Chemosphere 2021, 272, 129777. [Google Scholar] [CrossRef]

- Bare, J. Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts (TRACI), TRACI Version 2.1—User’s Manual. EPA/600/R-12/554; United States Environmental Protection Agency: Washington, DC, USA, 2012. [Google Scholar]

- European Commission (EC). Commission Recommendation (EU) 2021/2279 of 15 December 2021 on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations; European Commission (EC): Brussels, Belgium, 2021. [Google Scholar]

- PRé Sustainability. SimaPro Tutorial; 6.0.; PRé Sustainability: Amersfoort, The Netherlands, 2023. [Google Scholar]

- Vilén, A.; Laurell, P.; Vahala, R. Comparative Life Cycle Assessment of Activated Carbon Production from Various Raw Materials. J. Environ. Manag. 2022, 324, 116356. [Google Scholar] [CrossRef]

- O’Connor, D.; Hou, D. Sustainability Assessment for Remediation Decision-Making. In Sustainable Remediation of Contaminated Soil and Groundwater: Materials, Processes, and Assessment; Dou, D., Ed.; Elsevier: Oxford, UK, 2020; pp. 43–73. [Google Scholar]

- Owsianiak, M.; Lemming, G.; Hauschild, M.Z.; Bjerg, P.L. Assessing Environmental Sustainability of Remediation Technologies in a Life Cycle Perspective Is Not so Easy. Environ. Sci. Technol. 2013, 47, 1182–1183. [Google Scholar] [CrossRef] [PubMed]

- US EPA (United States Environmental Protection Agency). Per- and Polyfluoroalkyl Substances (PFAS): Proposed PFAS National Primary Drinking Water Regulation. Available online: https://www.epa.gov/sdwa/and-polyfluoroalkyl-substances-pfas (accessed on 11 July 2024).

- Swedish Food Agency. Drinking Water Regulations (2022:12). Available online: https://www.livsmedelsverket.se/om-oss/lagstiftning1/gallande-lagstiftning/livsfs-202212 (accessed on 10 July 2024).

- Weitz, K.; Kantner, D.; Kessler, A.; Key, H.; Larson, J.; Bodnar, W.; Parvathikar, S.; Davis, L.; Robey, N.; Taylor, P.; et al. Review of Per- and Poly-Fluoroalkyl Treatment in Combustion-Based Thermal Waste Systems in the United States. Sci. Total Environ. 2024, 932, 172658. [Google Scholar] [CrossRef]

- Björklund, S.; Weidemann, E.; Jansson, S. Emission of Per- and Polyfluoroalkyl Substances from a Waste-to-Energy Plant─Occurrence in Ashes, Treated Process Water, and First Observation in Flue Gas. Environ. Sci. Technol. 2023, 57, 10089–10095. [Google Scholar] [CrossRef]

- Hou, D.; Al-Tabbaa, A.; O’Connor, D.; Hu, Q.; Zhu, Y.G.; Wang, L.; Kirkwood, N.; Ok, Y.S.; Tsang, D.C.W.; Bolan, N.S.; et al. Sustainable Remediation and Redevelopment of Brownfield Sites. Nat. Rev. Earth Environ. 2023, 4, 271–286. [Google Scholar] [CrossRef]

- Sparrevik, M.; Saloranta, T.; Cornelissen, G.; Eek, E.; Fet, A.M.; Breedveld, G.D.; Linkov, I. Use of Life Cycle Assessments to Evaluate the Environmental Footprint of Contaminated Sediment Remediation. Environ. Sci. Technol. 2011, 45, 4235–4241. [Google Scholar] [CrossRef] [PubMed]

- Holmquist, H.; Fantke, P.; Cousins, I.T.; Owsianiak, M.; Liagkouridis, I.; Peters, G.M. An (Eco)Toxicity Life Cycle Impact Assessment Framework for Per-And Polyfluoroalkyl Substances. Environ. Sci. Technol. 2020, 54, 6224–6234. [Google Scholar] [CrossRef]

- Zodrow, J.; Vedagiri, U.; Sorell, T.; McIntosh, L.; Larson, E.; Hall, L.; Dourson, M.; Dell, L.; Cox, D.; Barfoot, K.; et al. PFAS Experts Symposium 2: PFAS Toxicology and Risk Assessment in 2021—Contemporary Issues in Human and Ecological Risk Assessment of PFAS. Remediation 2022, 32, 29–44. [Google Scholar] [CrossRef]

- Søndergaard, G.L.; Owsianiak, M. LCA of Soil and Groundwater Remediation. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer: Cham, Switzerland, 2018; pp. 927–959. [Google Scholar]

- Bergerson, J.; Cucurachi, S.; Seager, T.P. Bringing a Life Cycle Perspective to Emerging Technology Development. J. Ind. Ecol. 2020, 24, 6–10. [Google Scholar] [CrossRef]

- Thonemann, N.; Schulte, A.; Maga, D. How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef]

- Moni, S.M.; Mahmud, R.; High, K.; Carbajales-Dale, M. Life Cycle Assessment of Emerging Technologies: A Review. J. Ind. Ecol. 2020, 24, 52–63. [Google Scholar] [CrossRef]

- Gavankar, S.; Suh, S.; Keller, A.A. The Role of Scale and Technology Maturity in Life Cycle Assessment of Emerging Technologies: A Case Study on Carbon Nanotubes. J. Ind. Ecol. 2015, 19, 51–60. [Google Scholar] [CrossRef]

- Thomassen, G.; Van Dael, M.; Van Passel, S.; You, F. How to Assess the Potential of Emerging Green Technologies? Towards a Prospective Environmental and Techno-Economic Assessment Framework. Green. Chem. 2019, 21, 4868–4886. [Google Scholar] [CrossRef]

- Bergerson, J.A.; Brandt, A.; Cresko, J.; Carbajales-Dale, M.; MacLean, H.L.; Matthews, H.S.; McCoy, S.; McManus, M.; Miller, S.A.; Morrow, W.R.; et al. Life Cycle Assessment of Emerging Technologies: Evaluation Techniques at Different Stages of Market and Technical Maturity. J. Ind. Ecol. 2020, 24, 11–25. [Google Scholar] [CrossRef]

- Erakca, M.; Baumann, M.; Helbig, C.; Weil, M. Systematic Review of Scale-up Methods for Prospective Life Cycle Assessment of Emerging Technologies. J. Clean. Prod. 2024, 451, 142161. [Google Scholar] [CrossRef]

- Pizzol, M.; Sacchi, R.; Köhler, S.; Anderson Erjavec, A. Non-Linearity in the Life Cycle Assessment of Scalable and Emerging Technologies. Front. Sustain. 2020, 1, 611593. [Google Scholar] [CrossRef]

- Arvidsson, R.; Tillman, A.M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental Assessment of Emerging Technologies: Recommendations for Prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef]

- de Souza, N.R.D.; Matt, L.; Sedrik, R.; Vares, L.; Cherubini, F. Integrating Ex-Ante and Prospective Life-Cycle Assessment for Advancing the Environmental Impact Analysis of Emerging Bio-Based Technologies. Sustain. Prod. Consum. 2023, 43, 319–332. [Google Scholar] [CrossRef]

- Steubing, B.; de Koning, D. Making the Use of Scenarios in LCA Easier: The Superstructure Approach. Int. J. Life Cycle Assess. 2021, 26, 2248–2262. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).