Innovative Pavement Materials: Utilizing Corn Stover and Fly Ash in Geopolymers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Geopolymer, Fly Ash, and Corn Stover Ratios

2.2.2. Geopolymer Sample Preparation

2.2.3. Geopolymer Sample Compression Testing

2.2.4. Geopolymer Sample Porosity Testing

3. Results and Discussion

3.1. Compression Tests of Synthesized Geopolymer with Corn Stover (CS) at 0%, 5%, and 10%

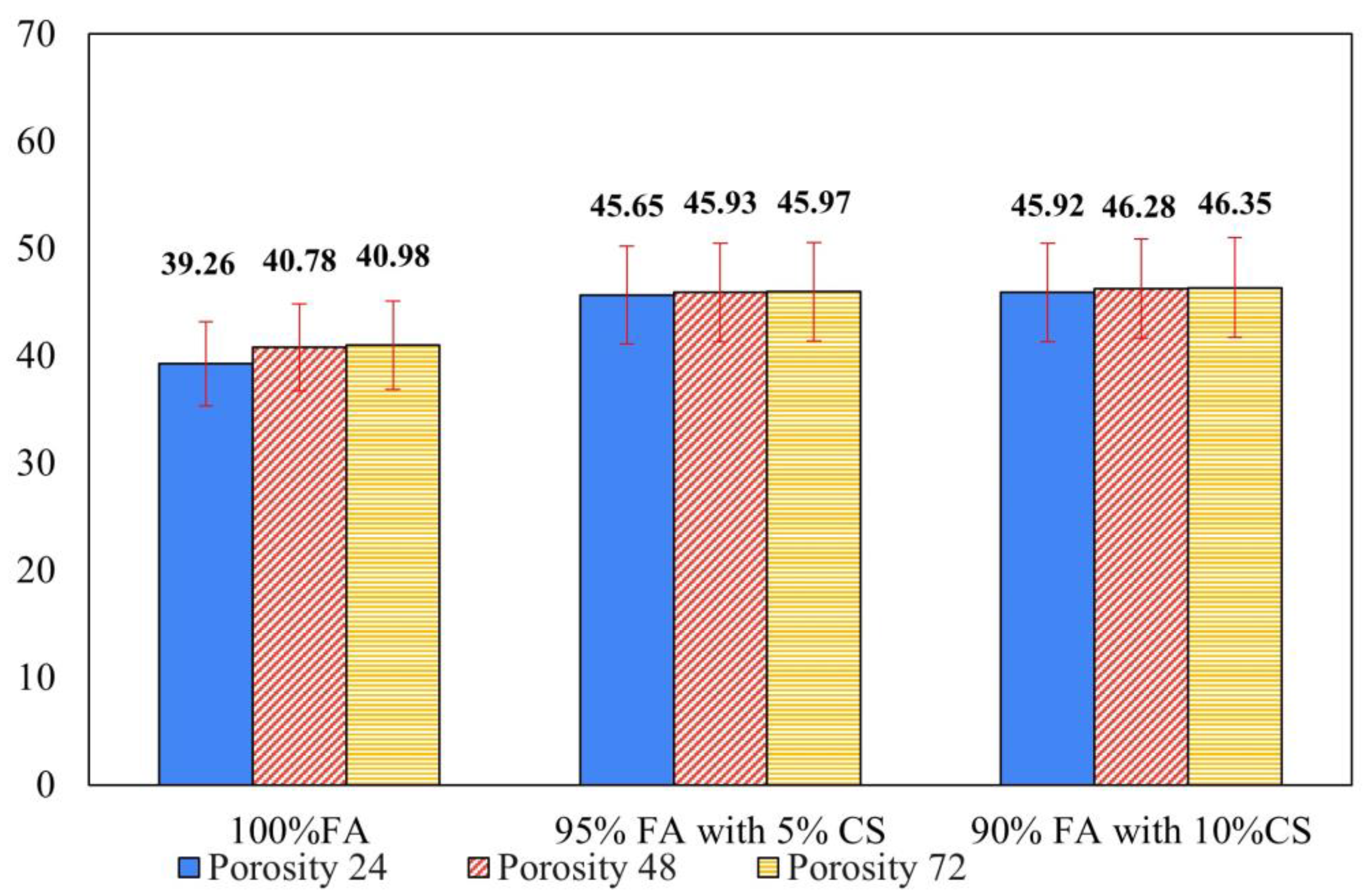

3.2. Porosity Testing of Synthesized Geopolymer with CS at 0%, 5%, and 10%

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kayhanian, M.; Fruchtman, B.D.; Gulliver, J.S.; Montanaro, C.; Ranieri, E.; Wuertz, S. Review of highway runoff characteristics: Comparative analysis and universal implications. Water Res. 2012, 46, 6609–6624. [Google Scholar] [CrossRef]

- Idris, J.; Ahmad, Z.; Eyu, G.D.; Chukwuekezie, C.S. Oil spills hazard and sustainable mitigation approach: A review. Adv. Mater. Res. 2014, 845, 955–959. [Google Scholar] [CrossRef]

- Tanaka, N.; Stigson, B. Cement Technology Roadmap: Carbon Emissions Reductions up to 2050; World Business Council for Sustainable Development: Geneva, Switzerland, 2009; pp. 1–36. [Google Scholar]

- Li, J.; Zhang, X.; Wei, H.; Zhu, H.; Tang, B. Evaluation of volatile organic compounds emissions and rheological properties of Buton rock asphalt modified asphalt. Constr. Build. Mater. 2023, 408, 133575. [Google Scholar] [CrossRef]

- Bai, X.; Liu, W.; Wu, B.; Liu, S.; Liu, X.; Hao, Y.; Lin, S.; Luo, L.; Zhao, S.; Tian, H.; et al. Emission characteristics and inventory of volatile organic compounds from the Chinese cement industry based on field measurements. Environ. Pollut. 2023, 316, 120600. [Google Scholar] [CrossRef] [PubMed]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Zegardło, B. Comparative Assessment of Environmental Effects by LCA Method of Natural Aggregates Extraction Processes and Production of Their Substitutes from Waste in the City Mining System. J. Ecol. Eng. 2021, 22, 251–257. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://ukgbc.org/our-work/topics/embodied-ecological-impacts/aggregates/ (accessed on 14 June 2024).

- Pacheco-Torgal, F.; Ding, Y.; Jalali, S. Properties and durability of concrete containing polymeric wastes (tyre rubber and polyethylene terephthalate bottles): An overview. Constr. Build. Mater. 2012, 30, 714–724. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.C.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Nemaleu, J.G.D.; Kamseu, E.; Kaze, R.C.; Melo, U.C.; Tome, S.; Alomayri, T.; Assaedi, H.; Sglavo, V.M. Powdered banana peel in calcined halloysite replacement on the setting times and engineering properties on the geopolymer binders. Constr. Build. Mater. 2021, 279, 122480. [Google Scholar] [CrossRef]

- Poggetto, G.D.; Barbieri, L.; D’Angelo, A.; Zambon, A.; Zardi, P.; Leonelli, C. Long-term durability of discarded cork-based composites obtained by geopolymerization. Environ. Sci. Pollut. Res 2024, 31, 42251–42263. [Google Scholar] [CrossRef] [PubMed]

- Kua, T.A.; Arulrajah, A.; Horpibulsuk, S.; Du, Y.J.; Shen, S.L. Strength assessment of spent coffee grounds-geopolymer cement utilizing slag and fly ash precursors. Constr. Build. Mater. 2016, 115, 565–575. [Google Scholar] [CrossRef]

- Detphan, S.; Chindaprasirt, P. Preparation of fly ash and rice husk ash geopolymer. Int. J. Miner. Metall. Mater. 2009, 16, 720–726. [Google Scholar]

- Xiao, R.; Dai, X.; Zhong, J.; Wang, Y.; Huang, B.; Ma, Y.; Jiang, X.; He, J. Toward waste glass upcycling: Preparation and characterization of high-volume waste glass geopolymer composites. Sustain. Mater. Technol. 2024, 40, e00890. [Google Scholar] [CrossRef]

- Tan, Z.; Liu, S.; Bliss, N.; Tieszen, L.L. Current and potential sustainable corn stover feedstock for biofuel production in the United States. Biomass Bioenergy 2012, 47, 372–386. [Google Scholar] [CrossRef]

- ASTM C618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Andreola, F.; Leonelli, C.; Romagnoli, M.; Miselli, P. Techniques Used to Determine Porosity. (cover story). Am. Ceram. Soc. Bull. 2000, 79, 49. [Google Scholar]

- Count of Electric Power Industry Power Plants, by Sector, by Predominant Energy Sources within Plant, 2012 through 2022. Available online: https://www.eia.gov/electricity/annual/html/epa_04_01.html (accessed on 15 June 2024).

- Fazli, H.; Yan, D.; Zhang, Y.; Zeng, Q. Effect of size of coarse aggregate on mechanical properties of metakaolin-based geopolymer concrete and ordinary concrete. Materials 2021, 14, 3316. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Wang, J.; Hu, M. Influence of aggregate size on compressive strength of pervious concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Farhana, Z.F.; Kamarudin, H.; Rahmat, A.; Bakri, A.M.M.A. A Study on Relationship between Porosity and Compressive Strength for Geopolymer Paste; Trans Tech Publications Ltd.: Bäch SZ, Switzerland, 2014; Volume 594-595, pp. 1112–1116. [Google Scholar]

- Liu, H.; Li, Q.; Quan, H.; Xu, X.; Wang, Q.; Ni, S. Assessment on the Properties of Biomass-Aggregate Geopolymer Concrete. Appl. Sci. 2022, 12, 3561. [Google Scholar] [CrossRef]

- Nawaz, M.; Heitor, A.; Sivakumar, M. Geopolymers in construction—Recent developments. Constr. Build. Mater. 2020, 260, 120472. [Google Scholar] [CrossRef]

- Zhu, H.; Yu, M.; Zhu, J.; Lu, H.; Cao, R. Simulation study on effect of permeable pavement on reducing flood risk of urban runoff. Int. J. Transp. Sci. Technol. 2019, 8, 373–382. [Google Scholar] [CrossRef]

| Chemical Analysis | Results % | ASTM Limit Class F/C | AASHTO Limit Class F/C |

|---|---|---|---|

| Silicon Dioxide | 51.30 | - | - |

| Aluminum Oxide | 27.18 | - | - |

| Iron Oxide | 12.21 | - | - |

| Sum of Primary Oxides | 90.69 | 70.0/50.0 min | 70.0/50.0 min |

| Sulfur Trioxide | 0.89 | 5.0 max | 5.0 max |

| Calcium Oxide | 2.72 | - | - |

| Magnesium Oxide | 0.83 | - | - |

| Sodium Oxide | 0.23 | - | - |

| Potassium Oxide | 2.41 | - | - |

| Sodium Oxide Equivalent | 1.82 | - | - |

| Moisture | 0.73 | 3.0 max | 3.0 max |

| Loss on Ignition | 3.22 | 6.0 max | 5.0 max |

| Carbon | 2.10 | - | - |

| Available Alkalis | 0.59 | Not required | 1.5 max |

| Component of Corn Stover | % Composition |

|---|---|

| Structural Ash | 3.46 |

| Extractable Inorganics | 2.23 |

| Structural Protein | 1.58 |

| Extractable Protein | 0.96 |

| Water-extracted Glucan | 0.53 |

| Water-extracted Xylan | 0.26 |

| Water extractives Others | 2.36 |

| EtOH Extractives | 2.62 |

| Lignin | 16.52 |

| Glucan | 37.52 |

| Xylan | 21.77 |

| Galactan | 1.66 |

| Arabinan | 3.37 |

| Acetate | 2.45 |

| Total | 97.28 |

| Experimental Condition | Mass Ratio of FA to CS | Particle Size of CS (μm) |

|---|---|---|

| 1 | 100:0 | - |

| 2 | 95:5 | 180 |

| 3 | 90:10 | 180 |

| 4 | 95:5 | 710 |

| 5 | 90:10 | 710 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paneru, A.; Sagar, V.; Tarikuzzaman, M.; Lynam, J.G.; Gordon, S.T., II; Alam, S. Innovative Pavement Materials: Utilizing Corn Stover and Fly Ash in Geopolymers. Environments 2024, 11, 192. https://doi.org/10.3390/environments11090192

Paneru A, Sagar V, Tarikuzzaman M, Lynam JG, Gordon ST II, Alam S. Innovative Pavement Materials: Utilizing Corn Stover and Fly Ash in Geopolymers. Environments. 2024; 11(9):192. https://doi.org/10.3390/environments11090192

Chicago/Turabian StylePaneru, Anu, Viral Sagar, Mohammad Tarikuzzaman, Joan G. Lynam, Stephen T. Gordon, II, and Shaurav Alam. 2024. "Innovative Pavement Materials: Utilizing Corn Stover and Fly Ash in Geopolymers" Environments 11, no. 9: 192. https://doi.org/10.3390/environments11090192

APA StylePaneru, A., Sagar, V., Tarikuzzaman, M., Lynam, J. G., Gordon, S. T., II, & Alam, S. (2024). Innovative Pavement Materials: Utilizing Corn Stover and Fly Ash in Geopolymers. Environments, 11(9), 192. https://doi.org/10.3390/environments11090192