Abstract

The continuous increase in solid waste materials, such as waste tires, underscores the critical importance of recycling them to mitigate environmental impact and promote sustainable resource management. This research study evaluated the effectiveness of utilizing waste tire pyrolysis oils (WTPOs) as recycling agents for asphalt materials. The chemical composition and thermal behavior of WTPO were analyzed using Fourier transform infrared (FT-IR) spectroscopy and thermogravimetric analysis (TGA). Mechanically, the prepared WTPO binders were assessed by measuring dynamic viscosity and changes in high- and intermediate-temperature performance grades. Additionally, the cracking susceptibility of the binders was evaluated using the Glover-Rowe (G-R) parameter. The findings indicated that WTPOs might contain water and light aromatics in varying percentages, depending on the pyrolysis process. Incorporating WTPOs enhanced the workability of asphalt mixtures and ensured a high degree of blending between recycled/aged asphalt and raw binder. A 12% WTPO dosage was identified as the most effective for enhancing fatigue and low-temperature cracking resistance, facilitating improved interactions between the virgin binder and recycled asphalt materials. Finally, utilizing WTPOs as rejuvenating agents in pavement construction supports sustainable practices by recycling waste materials and significantly improving the performance and durability of asphalt mixtures.

1. Introduction

The United States (US) produces approximately 4.45 million tons of scrap tires and 35 million tons of waste plastic materials, with 75.8% of the scrap tires and less than 10% of the waste plastic materials being utilized in the market [,]. Tires are composed of numerous components, including rubber, carbon black, accelerators, and inorganic fillers. A typical tire’s main composition percentages are 60–65% rubber, 25–35% carbon black (CB), and 3% inorganic fillers []. The primary concern with incorporating waste tires and plastics into asphalt binders is the poor storage stability of the modified binders. Consequently, the risk of phase separation between the asphalt binder and these modifiers is high due to differences in density, viscosity, and chemical incompatibility. Consequently, the effective utilization and recycling of municipal solid waste (MSW), including plastics, tires, and wood, are crucial for mitigating environmental impact and enhancing economic sustainability by reducing landfill use, conserving natural resources, and promoting the circular economy.

Pyrolysis has emerged as an effective solution for converting these wastes into valuable energy forms: solid, liquid, and gas. This thermal decomposition process occurs in the absence of oxygen at varying temperature ranges (300–900 °C). The pyrolysis of waste tires, in particular, produces three primary components: oil (light), char (carbon black), and gas. The pyrolysis temperature and heating rate significantly influence oil and gas yield; higher temperatures convert more oil into gas, while the solid component’s content changes insignificantly (±3%) []. Waste tire pyrolysis oil (WTPO) is a medium-viscosity, brown/dark-colored liquid with an aromatic odor. This complex liquid contains over a hundred components, including aromatic and aliphatic hydrocarbons, heteroatom (nonhydrocarbon) components, and polar fractions. WTPO has diverse applications: fuel (e.g., hydrogen or upgraded to higher quality fuel), chemicals (e.g., resins, adhesives, and fertilizers), heat generation (e.g., co-firing in boilers and furnaces), and power generation (e.g., diesel and turbines) []. The adaptability and utility of pyrolysis products highlight the potential of this technology to address growing MSW challenges and contribute to sustainable energy solutions.

Recently, the use of reclaimed asphalt pavement (RAP) and reclaimed asphalt shingles (RASs) in newly constructed flexible pavements has increased. The United States produces approximately 400 million tons of RAP annually from old pavements, with around 21.1% of this RAP being incorporated into new asphalt pavements []. Notably, utilizing these materials offers environmental and economic benefits by balancing the usage of virgin materials and conserving landfill space. However, concerns remain regarding the content of recycled materials in new asphalt mixes. The binder in recycled materials is significantly stiffer than standard paving-grade binders, reducing the blending efficiency between virgin and recycled asphalt and consequently degrading the long-term performance of the asphalt mix. Furthermore, research indicates heterogeneity in the blending of virgin and RAP materials, influenced by the content and preheating process of RAP materials and the stiffness of the RAP binders (high PG is around 85–90 °C) [,,]. Therefore, to enhance the degree of blending (DoB) and address durability concerns, it is essential to incorporate softer asphalt binders, oils [,,,,], or chemicals additives [,] into asphalt mixes containing high amounts of recycled materials (i.e., over 25% for RAP and 5% for RASs) [,,,,]. Studies have reported improvements in moisture and rutting resistance [,,,]. However, Mogawer et al. [] found that the addition of rejuvenators increased the susceptibility of asphalt mixes to rutting and moisture.

The asphalt industry utilizes diverse rejuvenators, including various types of super-soft asphalt binders (typically with low asphaltene content), waste-derived oils, plant oils, and engineered products. According to the ASTM D4552 standard, rejuvenators are classified into six groups based on their viscosity at 60 °C. Rejuvenators with lower viscosity tend to have better diffusivity and softening efficiency but exhibit poorer thermal stability [,]. The amount of rejuvenator required to revitalize the rheological properties of aged binders typically constitutes less than 10% of the weight of the asphalt binder. However, there are instances where higher percentages have been utilized. However, few studies have investigated the impact of WTPO on the rheological properties of recycled asphalt materials [,,]. Table 1 provides examples of various rejuvenators employed in the asphalt industry to enhance the thermo-mechanical and rheological properties of asphalt materials [,,].

Table 1.

Summary of previous studies on bio-oils as rejuvenating agents.

The application of pyrolysis oil (PO) in pavement construction offers significant sustainability and resource conservation benefits by recycling waste materials and reducing the carbon footprint associated with traditional pavement materials. WTPO is an effective recycling agent or rejuvenator for asphalt binders, enhancing their performance and durability. Research indicates that bio-oils improve asphalt binders’ rheological and physical properties, leading to better resistance to fatigue and overall pavement performance. However, limited studies have investigated the applicability of WTPO in pavement construction. Consequently, evaluating the effectiveness of utilizing WTPO in pavement construction is crucial to ensure its practical application and to optimize its benefits. The utilization of WTPO in pavement construction contributes to a circular economy by transforming waste products into valuable resources, thereby promoting environmental stewardship and economic efficiency. This innovative approach aligns with sustainable development goals and paves the way for more resilient and long-lasting road infrastructure.

2. Objective and Research Approach

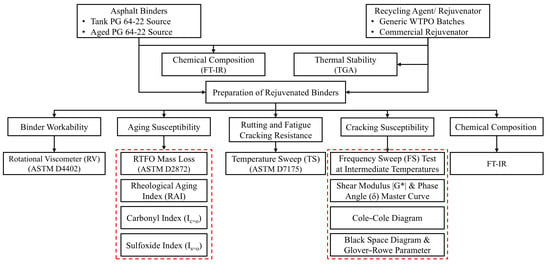

The primary goal of this research study was to evaluate the effectiveness of oil derived from scrap tires as a recycling agent for asphalt pavement construction. Consequently, a systematic approach was undertaken, blending and testing two generic WTPO batches with an asphalt binder at various dosages, up to 16% by the asphalt’s weight, as displayed in Figure 1. The assessment of the modified binders encompassed the workability, rheological properties, and chemical characterization of asphalt. Workability was evaluated by measuring the viscosity of the modified asphalt binder using a rotational viscometer (RV) and by assessing the compatibility of the asphalt mixtures. Rheological properties were measured at different stress and temperature conditions. Chemical characterization was performed using Fourier transform infrared (FT-IR) spectroscopy to identify the chemical composition of the WTPO and to understand the WTPO–asphalt interaction mechanism.

Figure 1.

Experimental plan of the study.

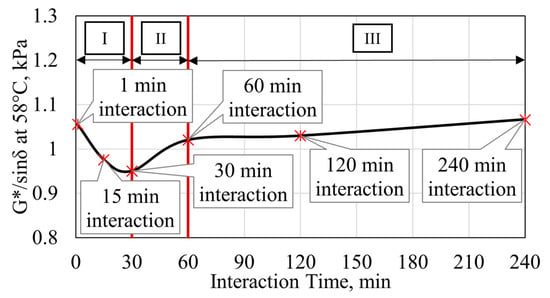

A WTPO was blended with the original asphalt binder at 100 ± 5 °C using a high-shear mixer operating at 500 rpm for 4 h. Binder samples were collected at various intervals (1, 15, 30, 60, 120, and 240 min) during the mixing process to evaluate the interaction mechanism between the WTPO and the asphalt binder. This was done by assessing changes in rheological properties and chemical composition throughout the mixing process. Notably, during the mixing process, foaming (bubbles) was observed for the first 15–30 min, depending on the pyrolysis oil content. This indicates that the WTPO contains water and/or light aromatics, which contribute to bubble formation. The WTPO–binder interaction curve consisted of three main regions, indicated by the G*/sinδ parameter, as illustrated in Figure 2. Initially, after 1 min of mixing, the rutting parameter (G*/sinδ) dropped significantly by almost seven times, continuing to decrease up to 30 min (Region I). However, between 30 and 60 min (Region II), G*/sinδ increased, suggesting that the WTPO binder lost weight due to the volatilization of light aromatics. Finally, after 60 min of interaction (Region III), the G*/sinδ parameter increased slightly, indicating the further stabilization of the binder’s properties. Consequently, an interaction time of 60 min at 100 °C was selected to ensure an optimal interaction time and to avoid the premature aging of the binder.

Figure 2.

The rutting parameter for the 8%B1A binder at different interaction times.

3. Materials and Testing Methods

3.1. Materials

This research study utilized two types of asphalt binders: an original PG 64-22 source, which is commonly used in Missouri, and an aged PG 64-22 binder. Following the asphalt institute recommendation, the long-term aging (LTA) of the asphalt binder was simulated using a forced-draft oven, where the binder was aged for 24 h at 135 °C. This process approximates 7 to 10 years of aging in field conditions for asphalt pavements [,]. The rheological and physical properties of this asphalt binder are detailed in Table 2. Additionally, one commercial rejuvenator, coded as E; two generic WTPO batches, coded as B1A and P4; and a reference rejuvenator, coded as E, were incorporated to evaluate the effectiveness of WTPO as a recycling agent in pavement construction.

Table 2.

Physical and rheological properties of the proposed asphalt binder.

Table 3 summarizes the available data for these WTPO batches provided by the supplier. The WTPOs were blended at varying dosages, up to 16% by weight of the asphalt binder, to identify the optimal dosage needed to enhance the performance of the asphalt binder.

Table 3.

Details of the received WTPOs and the applied dosage.

3.2. Test Methods

3.2.1. Thermogravimetric Analysis (TGA)

The thermal behavior of the three WTPO batches was assessed using the TGA. Approximately 50 mg of WTPO sample was placed in an alumina crucible, and changes in sample mass with temperature were measured using an internal mass balance. Nitrogen gas with a flow rate of 20 mL/min was used as a purging gas. The B1A WTPO batch was heated from room temperature (23 °C) to 500 °C at a ramp rate of 5 °C/min. The same WTPO source was also tested using a stepwise isothermal method to differentiate the WTPO compounds. In parallel, the P4 batch was heated from room temperature to 800 °C. The degradation process was conducted in three stages: (1) a ramp from room temperature to 100 °C, (2) an isothermal hold at 100 °C for 15 min, and (3) a ramp from 100 °C to 800 °C at a rate of 10 °C/min.

3.2.2. Laboratory Aging Techniques

In this research study, the rolling thin-film oven (RTFO) and pressure-aging vessel (PAV) techniques were employed to simulate the short-term aging (STA) and long-term aging (LTA) of the investigated binders, respectively. These procedures were carried out per ASTM D2872 for RTFO [] and ASTM D6521 for PAV [].

3.2.3. Fourier Transform Infrared (FT-IR) Spectroscopy

This study utilized an FT-IR spectrometer to perform FT-IR analysis on the investigated binders. The FT-IR spectra for each sample were recorded over a wavenumber range of 4000 to 400 cm−1 at room temperature, with a resolution of 4 cm−1 and 16 scans per sample. After analyzing each sample, the diamond crystal was meticulously cleaned using a dust-free tissue and ethanol to ensure accuracy and prevent contamination. FT-IR spectroscopy was conducted to identify the functional groups present in the WTPOs and asphalt binders and to evaluate the interaction mechanism between asphalt binders and recycled agents. Additionally, the carbonyl, sulfoxide, and chemical aging indices were computed for the investigated binders, which included neat and rejuvenated binders with effective dosages. These computations were carried out across three aging conditions, unaged, STA-aged, and LTA-aged states, to comprehensively evaluate the aging susceptibility of the binders [].

3.2.4. Brookfield Rotational Viscometer (RV)

The rotational viscometer (RV) test measured the dynamic viscosity (η) of asphalt binders at elevated temperatures ranging from 120 °C to 165 °C. This test was performed using spindle No. 21, rotating at an RPM that keeps the torque within 2 and 98 percent, following ASTM D4402 standards to evaluate the pumpability, mixability, and workability of the asphalt binders.

3.2.5. Temperature Sweep Test (TST)

A dynamic shear rheometer (DSR) was utilized to perform temperature sweep tests at ranges of 5–25 °C and 40–70 °C, with a frequency of 10 rad/sec, to estimate the intermediate and high failure temperatures of all investigated binders following ASTM D7175 []. Two different plate geometries were used: 8 mm plates with a 2 mm gap for lower temperature ranges and 25 mm plates with a 1 mm gap for higher temperature ranges. The critical intermediate and high temperatures of investigated binders were defined in accordance with ASTM D7175 [].

3.2.6. Frequency Sweep Test (FST)

The frequency sweep test was conducted across three logarithmic spans of frequency (100 to 0.1 rad/sec) at temperatures ranging from 5 °C to 25 °C, with five °C intervals. Complex modulus master curves were created using the frequency sweep data. The Christensen–Anderson (CA) model (Equation (1)) was employed to construct the master curves of the investigated binders due to the physical significance of its parameters, including cross angular frequency (ωc) and the R–value []. In contrast, Equation (2) was employed to construct the master curve of phase angle. Additionally, the Williams-Landel-Ferry (WLF) time–temperature superposition model was employed to determine the shift factor at a reference temperature of 15 °C. Subsequently, the Glover-Rowe (G-R) parameter, which represents the age-related cracking resistance of asphalt binders at low temperatures [,], was computed using Equation (3). The G-R parameter was employed to evaluate the aging and cracking susceptibility of the binders.

where G* is the complex shear modulus (kPa), Gg is the glassy modulus (typically 1.0 × 106 kPa), ωr is the reduced angular frequency (rad/sec), ωc is the crossover angular frequency at which phase angle equals 45° in rad/sec, and the R-value is the rheological index (shape factor) that represents the difference between the glassy modulus and the complex modulus at crossover angular frequency on a logarithmic scale. The ωc indicates the overall hardness of binders, and the R-value signifies a gradual transition to steady-state flow from elastic behavior.

where G* and δ are the complex shear modulus and phase angle of binders at 15 °C and 0.005 rad/s.

3.2.7. Low-Temperature Performance Grade

A bending beam rheometer (BBR) was utilized to measure the low-temperature performance grade parameters (flexural creep stiffness and m-value) at two temperatures: 12 and −18 °C. These measurements were conducted in accordance with ASTM D6648.

3.2.8. Evaluation of Binder Aging Susceptibility

The aging susceptibility of the binders was evaluated by measuring the %RTFO mass loss and rheological aging index (RAI) based on the rutting parameter (G*/sinδ). Equation (4) expresses the RAI formula in terms of the rheological parameters (complex modulus “G*” and phase angle “δ”), measured at 64 °C. Higher %RTFO mass loss and RAI values indicate that the binder is susceptible to aging.

4. Results and Discussion

4.1. Thermogravimetric Analysis (TGA)

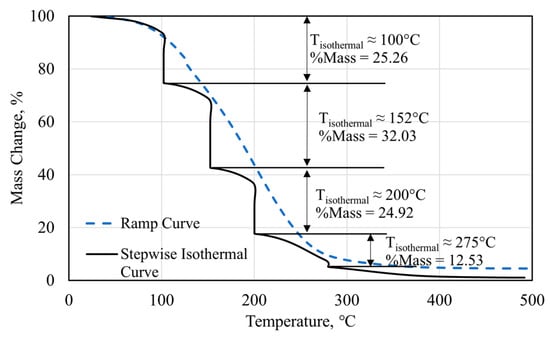

A thermogravimetric curve illustrates the relationship between mass loss and temperature, as illustrated in Figure 3, offering insights into the thermal stability and composition of the initial sample. The TGA results showed that the WTPO undergoes thermal degradation beginning at around 100 °C with different residue percentages (1% to 16% depending on the pyrolysis process), as presented in Table 4. The investigated WTPOs appeared to contain moisture and light volatiles condensed during the production process, as approximately 25% of the oil degraded at 100 °C. The investigated WTPOs began to degrade at approximately 100 °C, with around 40% of the WTPOs degrading at the typical mixing temperature of 163 °C. This observation highlighted the need for modification in the WTPO production process. Techniques such as distillation or vacuum drying can be employed to remove moisture and light volatiles from WTPOs before their use in asphalt mixtures, ensuring optimal performance and longevity.

Figure 3.

The TG curve of the B1A source.

Table 4.

TGA results of the WTPOs.

4.2. Chemical Composition of the Investigated Modifiers and Binders

4.2.1. Chemical Composition of Rejuvenating Agents

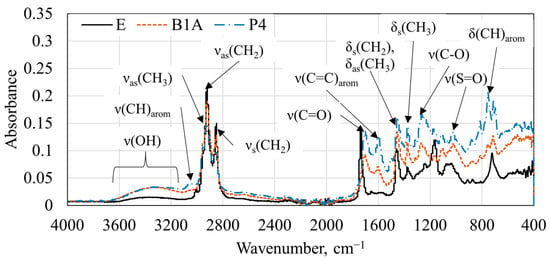

The FT-IR analysis was conducted on the investigated rejuvenating agents, including the commercial rejuvenator and the B1A and P4 batches, to investigate their chemical composition. Qualitative observation of the FT-IR spectra of the WTPO batches revealed the presence of various functional groups, including water/alcohol (band between 3145 and 3435 cm−1), alkanes (aliphatic C-H at 2868–2955 cm−1 and C-H deformation vibrations at 1376–1451 cm−1), alkenes, alkyls, carbonyl groups (C=O) at 1695 cm−1, and aromatic groups (bands at 1604 cm−1 and 695–800 cm−1). Furthermore, the results revealed that all the WTPOs exhibited the same spectral features, with variations in the intensity of some functional groups, as displayed in Figure 4. Table 5 presents the detected functional groups of the WTPOs.

Figure 4.

The FT-IR spectra of the investigated rejuvenators.

Table 5.

Functional group of the WTPOs.

4.2.2. Chemical Composition of the Binders

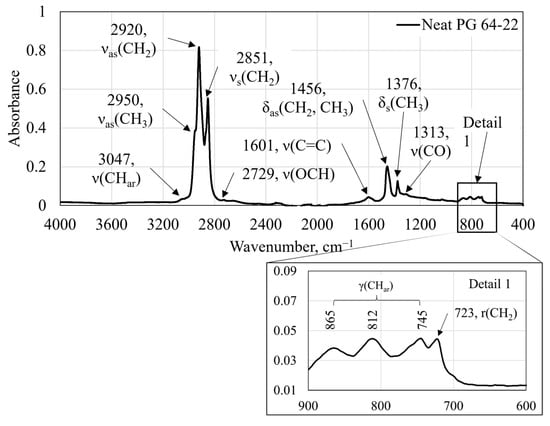

The FT-IR analysis was also conducted on various binders, including the neat and rejuvenated binders with 4% E, 12% B1A, and 16% P4, to investigate the mechanism of interaction between the rejuvenating agents and asphalt binder. Figure 5 illustrates the spectrum of the unaged neat binder, highlighting the predominant peaks.

Figure 5.

The FT-IR analysis of the neat binder.

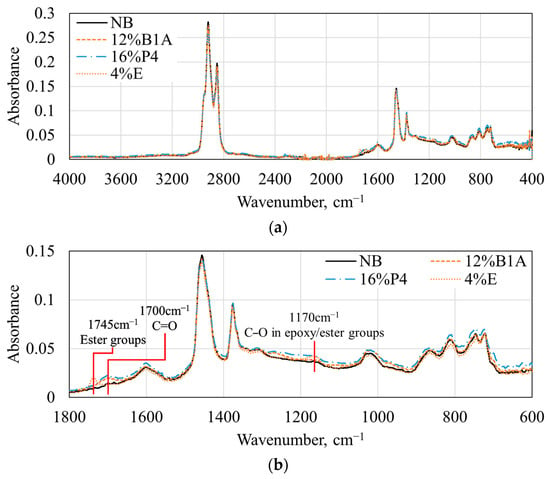

Upon modification, changes in the neat asphalt binder are expected depending on how the WTPOs and other modifiers interact with asphalt. As demonstrated in Figure 6, the WTPO binders exhibited similar features to the neat one, with notable differences in peak intensity, especially aromatic C-H deformation groups (band between 700–900 cm−1), and slight shifts, which could also be attributed to the mixing process. Additionally, the intensity of the carbonyl group (C=O) at around 1700 cm−1 and C-O-C in epoxy/ester groups at around 1170 cm−1 increased with the WTPOs. Conversely, the modified binder with the commercial rejuvenator exhibited a distinct peak at a wavenumber 1745 cm−1, corresponding to the C=O stretching vibrations of the ester group. Since the asphalt binder and WTPOs have almost the same functional groups in the fingerprint region, no distinctive peaks were observed for WTPO-rejuvenated binders; hence, the WTPO–asphalt interaction is physical.

Figure 6.

The FT-IR spectra of the neat, 12%B1A, and 16% P4 binders: (a) from 4000 to 400 cm−1 and (b) from 1800 cm−1 to 600 cm−1.

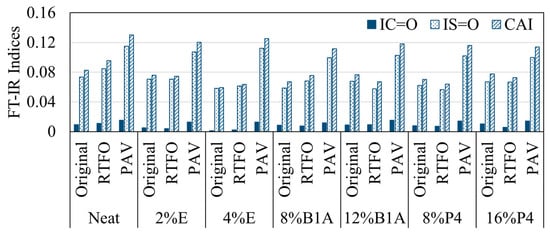

Furthermore, the carbonyl (IC=O), sulfoxide (IS=O), and chemical aging (CAI) indices were computed for the investigated binders, as demonstrated in Figure 7. The analysis revealed that the carbonyl and sulfoxide indices of the rejuvenated binders were lower than those of the neat binder under both short-term and long-term aging cases.

Figure 7.

Carbonyl and sulfoxide indices of tested binders.

4.3. Mechanical and Rheological Characterization of Binders

Initially, the mechanical and rheological properties of rejuvenated tank binders containing 4% WTPO were assessed and compared with those of the commercial rejuvenator, coded as E. Subsequently, the WTPO batches B1A and P4 were mixed with tank binder at varying dosages, up to 16% by weight, to determine the optimal WTPO concentration for enhancing asphalt binder performance in comparison to that of the commercial rejuvenator. Finally, the aged binder was mixed with WTPOs at two dosages, 12% and 16%, for the B1A and P4 batches, respectively.

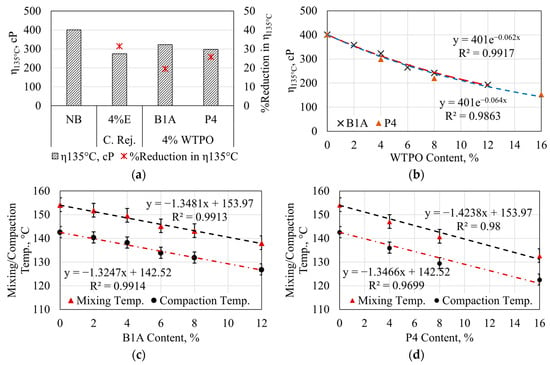

4.3.1. Analysis of Dynamic Viscosity

The measured dynamic viscosity of the rejuvenated binder at 135 °C and computed % reduction in viscosity upon incorporating the rejuvenator are illustrated in Figure 8a. It was observed that the WTPOs enhanced the binder’s workability, although with some variations. These differences are attributed to the distinct chemical compositions of the WTPO batches, which result from the varying pyrolysis conditions used during their production. Additionally, the percentage of reduction in the binder’s viscosity at 135 °C was also computed to evaluate the effectiveness of the WTPOs, as presented in Figure 8a.

Figure 8.

The RV results: (a) the dynamic viscosity of rejuvenated binders at 135 °C, (b) the impact of WTPO content on dynamic viscosity at 135 °C, and the mixing and compaction temperatures of (c) B1A binder and (d) P4 binder.

Furthermore, it was observed that both WTPO batches (B1A and P4) significantly reduced the binder’s viscosity at 135 °C, demonstrating improved workability, following an exponential trend with increasing WTPO content, as displayed in Figure 8b. Additionally, Figure 8c,d illustrates the computed mixing and compaction temperatures of WTPO binders with varying WTPO content. The results showed a linear reduction in both mixing and compaction temperatures as WTPO content increased. This indicates that adding WTPO would enhance workability, promote better blending with recycled asphalt materials such as RAP, and result in energy savings. Consequently, this supports more sustainable and efficient pavement construction practices.

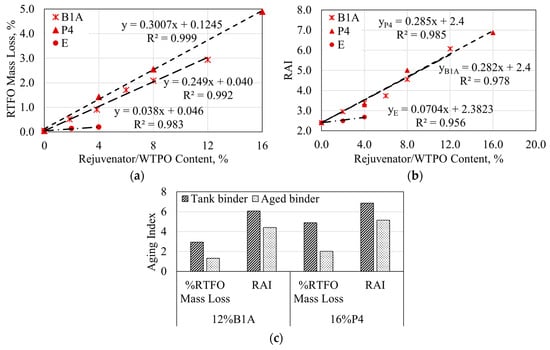

4.3.2. Aging Sustainability

The percentage of RTFO mass loss and RAI of the investigated binders were computed to evaluate the aging susceptibility and thermal stability of the WTPOs in normal asphalt mixture production (163 °C). The results revealed that the commercial rejuvenator exhibited the smallest increase in RTFO mass loss, indicating better aging resistance. In contrast, the WTPOs showed high RTFO mass loss percentages and RAI parameters. The RTFO mass loss percentage and RAI correlated linearly with the rejuvenator content, as illustrated in Figure 9. This significantly high mass loss suggested the presence of light compounds and/or moisture, which evaporate at the RTFO conditioning temperature, which aligns the TGA results, leading to the increased aging susceptibility. It can be concluded that the WTPO batches were more volatile and more susceptible to aging, underscoring the need for modification in the WTPO production process. Additionally, these results highlight the potential benefit of applying WTPO in the production of warm asphalt mixtures and low-temperature applications.

Figure 9.

The relationships between the B1A and P4 WTPO dosage and (a) %RTFO mass loss, (b) RAI index for rejuvenated unaged binder, and (c) RTFO mass loss and RAI at 64 °C for rejuvenated aged binder.

Furthermore, the RTFO mass loss and RAI were evaluated for aged binder, as illustrated in Figure 9c. The results revealed that both parameters decreased significantly for the rejuvenated aged binder. This indicated that the addition of WTPOs to recycled asphalt materials enhanced their efficiency. The aged materials have a greater affinity for light component, thereby restoring their rheological properties. In contrast, tank binders are stable.

4.3.3. Temperature Sweep Test Results

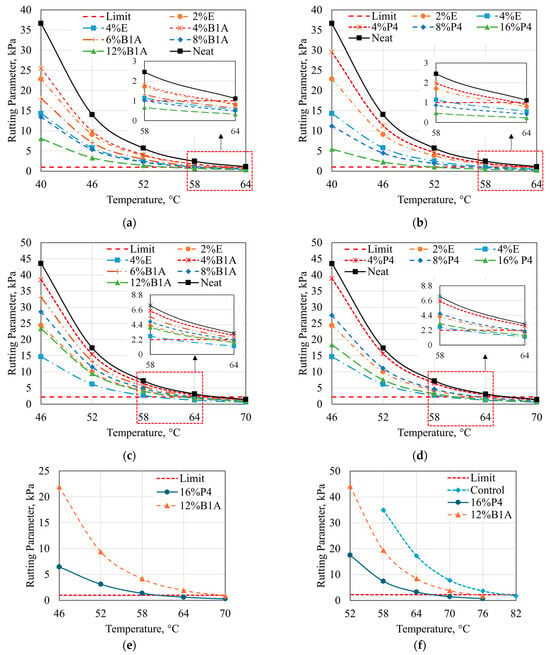

High-Temperature Performance Grade (PG)

The rutting parameter (G*/sinδ) of all investigated binders was measured between 40 and 64 °C for unaged and RTFO-aged conditions, as illustrated in Figure 10. The rutting parameter of unaged binders was reduced significantly with the addition of 4% WTPOs, reducing the high-temperature PG by one grade. However, this influence diminished after RTFO conditioning for the WTPO-rejuvenated binders, indicating high aging susceptibility. In contrast, the high-temperature PG dropped by one grade for the binder with a 2% commercial rejuvenator, as demonstrated in Figure 10. Furthermore, the results for the rejuvenated aged binder showed that the addition of 16% of WTPO decreased the high-temperature grade by three levels, from 76 to 58, as illustrated in Figure 10e,f. However, after RTFO conditioning, the high-temperature PG increased by one level, suggesting the volatilization of light components during the asphalt mixture production process.

Figure 10.

The rutting parameter vs. temperature of the tank binder for (a) unaged B1A, (b) unaged P4, (c) RTFO-aged B1A and (d) RTFO-aged P4 binders, and aged binder for (e) unaged rejuvenated binders and (f) RTFO-aged rejuvenated binders.

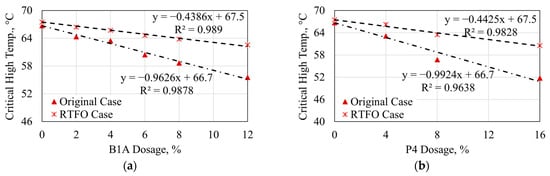

Furthermore, to determine the optimum WTPO content to drop the high PG by one grade, the critical high PG was computed for both B1A and P4 batches, as illustrated in Figure 11. It was observed that the critical high temperature for both unaged and RTFO-aged conditions showed a linear decrease with increasing WTPO content. The DSR results at the high-temperature range revealed no significant difference in the impact of WTPO batches, especially after the RTFO-aged state, on high-temperature PG. Additionally, a 4% WTPO dosage was sufficient to lower the high-temperature PG of the neat binder by one grade (to PG 58-XX).

Figure 11.

The computed critical high PG of the binders with (a) B1A and (b) P4.

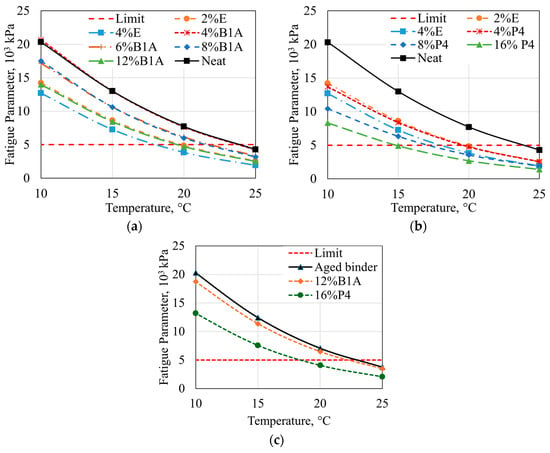

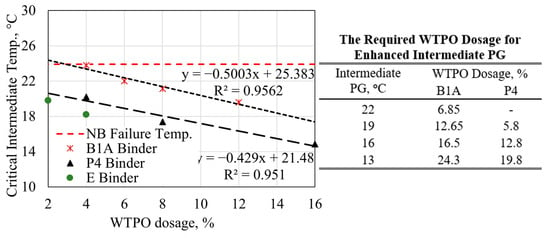

Intermediate-Temperature Performance Grade

Given that long-term aging conditions are critical for assessing cracking susceptibility, the TST was conducted to determine the intermediate-temperature PG. Fatigue parameters (G*·sinδ) were measured for all investigated binders, as illustrated in Figure 12. The results revealed variations in the long-term performance of the WTPO batches among the WTPO batches. Notably, the plant-processed WTPO batch (P4) exhibited better long-term mechanical properties and higher fatigue cracking resistance, comparable to that of the commercial rejuvenator, as illustrated in Figure 12. These findings underscore the critical importance of the processing method in optimizing the performance and efficacy of WTPO as a sustainable and effective rejuvenator for asphalt materials.

Figure 12.

The fatigue parameter vs. the temperature of the tank binders with (a) B1A and (b) P4 and of (c) aged binder with B1A and P4.

Furthermore, Figure 12c illustrates the improvement in the intermediate-temperature PG of the aged binder with WTPO. The critical fatigue temperature decreased by 2.2 with the addition of 12% B1A and by 19.5% with the addition of 16% P4. Additionally, the critical intermediate PG temperature was computed for both B1A and P4 binders, as demonstrated in Figure 13. Notably, the fatigue resistance of the binders improved significantly upon increasing the WTPO dosage, particularly that of the P4 batch. This indicated that the low-temperature performance of the binders would be improved as well, matching the FT-IR analysis.

Figure 13.

The critical intermediate temperatures of the WTPO binders.

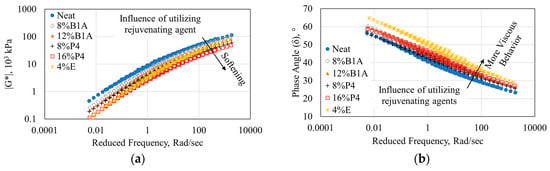

4.3.4. Complex Modulus Master Curve

The CA model was adopted to construct the dynamic shear modulus (|G*|) at 15 °C of the investigated binders, as illustrated in Figure 14. The results indicated that the inclusion of WTPOs softened the binder, allowing it to absorb and dissipate stresses more effectively. This softening effect would reduce the likelihood of cracks forming, thereby improving the pavement’s service life. Consequently, WTPO would enhance the durability of asphalt pavement by improving both low- and intermediate-temperature cracking resistance.

Figure 14.

Master curve at 15 °C of the neat binder (a) complex modulus and (b) phase angle and the aged binder (c) complex modulus and (d) phase angle.

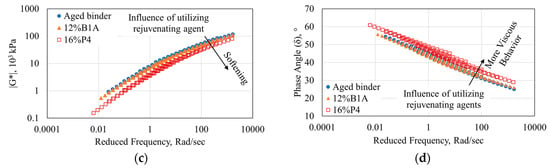

4.3.5. Cole–Cole Diagram

The modified Cole–Cole diagram, which depicts the components of the complex shear modulus, the elastic component (G′) against the viscous component (G″), is commonly used to characterize the elastic and viscous behaviors of asphalt binders, as illustrated in Figure 15. An equality line (G′ = G″) is also superimposed to differentiate between these behaviors: data points to the left of the line indicate a predominance of viscous properties, while those to the right represent more elastic behavior. At low temperatures, the elastic component of the complex modulus is predominant. As the temperature increases, the binder loses some of its elasticity, becoming more viscous. Adding rejuvenating agents to the control binder increased the viscosity, primarily by increasing the phase angle. Furthermore, all tested binders exhibited an almost linear relationship in the Cole–Cole diagram, indicating that the addition of either commercial rejuvenators or WTPO batches did not cause any significant structural changes.

Figure 15.

The Cole–Cole diagram of the tested binders: (a) rejuvenated tank binder and (b) rejuvenated aged binder.

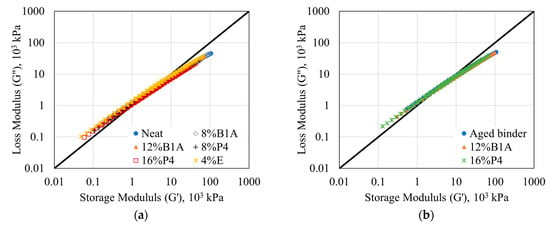

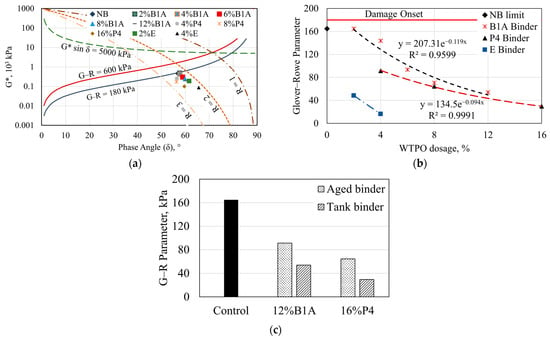

4.3.6. Black Space Diagram and Glover-Rowe Damage Parameter

Figure 16 demonstrates the Glover-Rowe (G-R) results for the investigated binders, including both the neat and the WTPO binders, at PAV conditions. As the WTPO dosage increases, the rheological characteristics shift from the upper left towards the lower right on the black space diagram. This indicates better cracking resistance with aging and improved recovery properties. The binder with the P4 batch exhibited superior cracking resistance compared to the B1A binder. As illustrated in Figure 16b, increasing the WTPO dosage significantly enhanced the cracking resistance of both the B1A and P4 binders, as evidenced by the exponential decrease in the G-R parameter. The P4 binder, in particular, showed superior performance with lower G-R values at dosages similar to those of the B1A binder. The G-R parameter was reduced by almost 67% and 82% for the 12%B1A and 16%P4 batches, respectively, suggesting it may be more effective in improving binder durability.

Figure 16.

G-R black space diagram: (a) G-R black space diagram, (b) the G-R parameter with rejuvenator dosage, and (c) Comparison of G-R parameter for investigated control, 12%B1A, and 16%P4 binders.

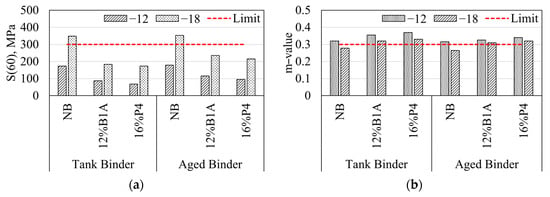

4.3.7. Low-Temperature Performance Grade

Considering the critical importance of long-term aging conditions for assessing thermal cracking, the BBR test was conducted to determine the low-temperature PG. The flexural creep stiffness (S(T)) and m-value were measured for neat, 12%B1A, and 16%P4 binders at two temperatures, −12 and −18 °C, as illustrated in Figure 17. The results revealed that the plant-processed WTPO batch (P4) exhibited better long-term performance, as illustrated in Figure 17. These findings highlight the crucial role of the processing method in optimizing the performance and efficacy of WTPO as a sustainable and effective rejuvenator for asphalt materials.

Figure 17.

The results of the BBR test for the investigated binders: (a) flexural creep stiffness at 60 s and (b) m-value.

5. Conclusions

Recycling waste tires to produce pyrolysis oil (WTPO) is crucial from an environmental perspective, as it enhances the incorporation of recycled asphalt materials, such as RAP and RASs, into pavement construction. This process reduces landfill waste and pollution and converts tires into valuable resources, conserving natural materials and supporting sustainable energy production. Consequently, this research study assessed the effectiveness of utilizing WTPOs as rejuvenating agents for recycled asphalt materials. An asphalt binder source (PG 64-22) was mixed with two generic WTPOs at various dosages, up to 16% by the asphalt’s weight, and their physical, rheological, and chemical properties were evaluated. The following key points were derived:

- Thermal and chemical analyses revealed variations in the chemical composition of the WTPOs, particularly in their aromatic content, depending on the pyrolysis process.

- The workability of the asphalt binder was enhanced significantly by the WTPOs, leading to significantly reduced mixing and compaction temperatures, thereby conserving energy and promoting more efficient pavement construction practices.

- The WTPOs demonstrated potential for enhancing the blending of raw binder and RAP materials, improving the overall performance and cohesion of the recycled asphalt mixture.

- The %RTFO mass loss indicated that WTPOs contain light aromatics and moisture that evaporate at standard mixing temperatures (163 °C). This finding underscores the need to optimize the pyrolysis process to enhance the thermal stability of WTPO, ensuring it remains effective and stable during asphalt production and application.

- The plant-processed WTPO batch exhibited better long-term mechanical properties and higher fatigue cracking resistance comparable to that of the commercial rejuvenator, suggesting the importance of optimizing the pyrolysis process.

- The fatigue cracking resistance and decreased cracking susceptibility of the asphalt binder were enhanced significantly with the incorporation of WTPO. This improvement is evidenced by the Glover-Rowe (G-R) parameter, which showed a reduction of up to 82% for a 16% WTPO content.

- The rheological and physical test results indicated that a WTPO dosage of 12% is the most effective for enhancing the durability of asphalt pavements by improving the cracking resistance.

Finally, incorporating WTPO would significantly increase the likelihood of effectively utilizing RAP materials, thereby advancing sustainability in pavement construction by enhancing the cracking resistance of asphalt pavements. However, it is recommended that the WTPO production process be optimized to eliminate light aromatics and unwanted compounds. These components should be extracted before utilizing the oil, thereby upgrading the WTPO and enhancing its effectiveness as a rejuvenating agent for asphalt binders. This optimization will improve the thermal stability and overall performance of WTPO, making it a more viable and efficient additive in pavement construction. Additionally, a thorough examination of the performance of asphalt mixtures modified with WTPO is necessary. Finally, the environmental benefits and potential impacts of using WTPO in asphalt mixtures should be thoroughly evaluated, including lifecycle analysis and carbon footprint reduction. This evaluation will help quantify the sustainability advantages of incorporating WTPO in pavement construction, ensuring that the use of WTPO not only enhances pavement performance but also contributes positively to environmental conservation and sustainable development.

Author Contributions

Conceptualization, A.S.E.-A. and M.A.; methodology, A.S.E.-A.; formal analysis, A.S.E.-A.; investigation, A.S.E.-A.; resources, M.A.; data curation, A.S.E.-A.; writing—original draft preparation, A.S.E.-A.; writing—review and editing, A.S.E.-A. and M.A.; supervision, M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by CarbonCycle LLC.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Moore, F.S.R. USTMA’ s 14th Scrap Tire Management Report Highlights the Need for Continued Investment in End-Use Markets. 2020. Available online: https://www.ustires.org/sites/default/files/2019%20USTMA%20Scrap%20Tire%20Management%20Summary%20Report.pdf (accessed on 1 March 2024).

- Environmental Protection Agency (EPA). National Overview: Facts and Figures on Materials, Wastes and Recycling; Environmental Protection Agency (EPA): Washington, DC, USA, 2020. [Google Scholar]

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis–A review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Williams, B.A.; Willis, J.R.; Shacat, J. Annual Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2021. 12th Annual Survey (IS 138); National Asphalt Pavement Association: Greenbelt, MD, USA, 2022. [Google Scholar] [CrossRef]

- Abdalfattah, I.A.; Mogawer, W.S.; Stuart, K. Quantification of the degree of blending in hot-mix asphalt (HMA) with reclaimed asphalt pavement (RAP) using Energy Dispersive X-Ray Spectroscopy (EDX) analysis. J. Clean. Prod. 2021, 294, 126261. [Google Scholar] [CrossRef]

- Orešković, M.; Menegusso Pires, G.; Bressi, S.; Vasconcelos, K.; Presti, D.L. Quantitative assessment of the parameters linked to the blending between reclaimed asphalt binder and recycling agent: A literature review. Constr. Build. Mater. 2020, 234, 117323. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Shu, X. Characterizing blending efficiency of plant produced asphalt paving mixtures containing high RAP. Constr. Build. Mater. 2016, 126, 172–178. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of rejuvenator’s effectiveness with conventional mix testing for 100% reclaimed Asphalt pavement mixtures. Transp. Res. Rec. 2013, 2370, 17–25. [Google Scholar] [CrossRef]

- Tran, N.H.; Taylor, A.; Willis, R. Effect of Rejuvenator on Performance Properties of HMA Mixtures with High RAP and RAS Contents; NCAT Report 5–12; National center for asphalt technology, Auburn University: Auburn, Alabama, 2012. [Google Scholar]

- Im, S.; Zhou, F. Field Performance of RAS Test Sections and Laboratory Investigation of Impact of Rejuvenators on Engineering Properties of RAP/RAS Mixes; Texas. Dept. of Transportation. Research and Technology Implementation Office: Austin, TX, USA, 2014. Available online: https://rosap.ntl.bts.gov/view/dot/27281 (accessed on 1 April 2024).

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Elkashef, M.; Podolsky, J.; Williams, R.C.; Cochran, E.W. Introducing a soybean oil-derived material as a potential rejuvenator of asphalt through rheology, mix characterisation and Fourier Transform Infrared analysis. Road Mater. Pavement Des. 2017, 19, 1750–1770. [Google Scholar] [CrossRef]

- Yaseen, G.; Hafeez, I. Effect of cereclor as rejuvenator to enhance the aging resistance of reclaimed asphalt pavement binder. Materials 2020, 13, 1582. [Google Scholar] [CrossRef]

- Wróbel, M.; Woszuk, A.; Ratajczak, M.; Franus, W. Properties of reclaimed asphalt pavement mixture with organic rejuvenator. Constr. Build. Mater. 2021, 271, 121514. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Booshehrian, A.; Vahidi, S.; Austerman, A.J. Evaluating the effect of rejuvenators on the degree of blending and performance of high RAP, RAS, and RAP/RAS mixtures. Road Mater. Pavement Des. 2013, 14, 193–213. [Google Scholar] [CrossRef]

- Ma, T.; Huang, X.; Zhao, Y.; Zhang, Y. Evaluation of the diffusion and distribution of the rejuvenator for hot asphalt recycling. Constr. Build. Mater. 2015, 98, 530–536. [Google Scholar] [CrossRef]

- Ongel, A.; Hugener, M. Impact of rejuvenators on aging properties of bitumen. Constr. Build. Mater. 2015, 94, 467–474. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Raman, N.A.A.; Hainin, M.R.; Hassan, N.A.; Ani, F.N. A review on the application of bio-oil as an additive for asphalt. J. Teknol. 2015, 72. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Ji, J.; Shi, Q.; Suo, Z. A Review of Characteristics of Bio-Oils and Their Utilization as Additives of Asphalts. Molecules 2021, 26, 5049. [Google Scholar] [CrossRef]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233–234, 254–258. [Google Scholar] [CrossRef]

- Ali, A.W.; Mehta, Y.A.; Nolan, A.; Purdy, C.; Bennert, T. Investigation of the impacts of aging and RAP percentages on effectiveness of asphalt binder rejuvenators. Constr. Build. Mater. 2016, 110, 211–217. [Google Scholar] [CrossRef]

- Yang, X.; You, Z. High temperature performance evaluation of bio-oil modified asphalt binders using the DSR and MSCR tests. Constr. Build. Mater. 2015, 76, 380–387. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, G.; Gong, M.; Yang, J. Recycling long-term-aged asphalts using bio-binder/plasticizer-based rejuvenator. Constr. Build. Mater. 2017, 147, 117–129. [Google Scholar] [CrossRef]

- Elkashef, M.; Podolsky, J.; Williams, R.C.; Cochran, E. Preliminary examination of soybean oil derived material as a potential rejuvenator through Superpave criteria and asphalt bitumen rheology. Constr. Build. Mater. 2017, 149, 826–836. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C. Improving fatigue and low temperature performance of 100% RAP mixtures using a soybean-derived rejuvenator. Constr. Build. Mater. 2017, 151, 345–352. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Zaumanis, M.; Mazza, E.; Partl, M.; Poulikakos, L. Effect of ageing on the mechanical and chemical properties of binder from RAP treated with bio-based rejuvenators. Compos. B Eng. 2018, 141, 174–181. [Google Scholar] [CrossRef]

- Cao, X.; Wang, H.; Cao, X.; Sun, W.; Zhu, H.; Tang, B. Investigation of rheological and chemical properties asphalt binder rejuvenated with waste vegetable oil. Constr. Build. Mater. 2018, 180, 455–463. [Google Scholar] [CrossRef]

- Farooq, M.A.; Mir, M.S.; Sharma, A. Laboratory study on use of RAP in WMA pavements using rejuvenator. Constr. Build. Mater. 2018, 168, 61–72. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Ye, M.; Yap, Y.K.; Si, C. The impact of bio-oil as rejuvenator for aged asphalt binder. Constr. Build. Mater. 2019, 196, 134–143. [Google Scholar] [CrossRef]

- Ankush, K.; Rajan, C.; Abhinay, K. A Study on Aging Characteristics of Asphalt Binders Modified with Waste EPDM Rubber and Tire Pyrolysis Oil. J. Mater. Civil. Eng. 2023, 35, 04023473. [Google Scholar] [CrossRef]

- Ankush, K.; Rajan, C.; Abhinay, K. Evaluation of Waste Tire Pyrolytic Oil as a Rejuvenation Agent for Unmodified, Polymer-Modified, and Rubber-Modified Aged Asphalt Binders. J. Mater. Civil. Eng. 2022, 34, 04022246. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Napiah, M.B.; Sutanto, M.H.; Alaloul, W.S.; Yusoff, N.I.M.; Khairuddin, F.H.; Memon, A.M. Evaluation of the high-temperature rheological performance of tire pyrolysis oil-modified bio-asphalt. Int. J. Pavement Eng. 2022, 23, 4007–4022. [Google Scholar] [CrossRef]

- Arega, Z.A.; Bhasin, A.; De Kesel, T. Influence of extended aging on the properties of asphalt composites produced using hot and warm mix methods. Constr. Build. Mater. 2013, 44, 168–174. [Google Scholar] [CrossRef]

- Zhang, R.; Sias, J.E.; Dave, E.V. Evaluation of the cracking and aging susceptibility of asphalt mixtures using viscoelastic properties and master curve parameters. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 106–119. [Google Scholar] [CrossRef]

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM D2872; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- ASTM D6648; Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM D6521; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- Hofko, B.; Porot, L.; Falchetto Cannone, A.; Poulikakos, L.; Huber, L.; Lu, X.; Mollenhauer, K.; Grothe, H. FTIR spectral analysis of bituminous binders: Reproducibility and impact of ageing temperature. Mater. Struct. 2018, 51, 45. [Google Scholar] [CrossRef]

- Petersen, J.C.; Robertson, R.E.; Branthaver, J.F.; Harnsberger, P.M.; Duvall, J.J.; Kim, S.S.; Anderson, D.A.; Christiansen, D.W.; Bahia, H.U. Binder Characterization and Evaluation; Strategic Highway Research Program, National Research Council: Washington, DC, USA, 1994; Volume 1. [Google Scholar]

- Anderson, R.M.; King, G.N.; Hanson, D.I.; Blankenship, P.B. Evaluation of the relationship between asphalt binder properties and non-load related cracking. J. Assoc. Asph. Paving Technol. 2011, 80, 615–664. [Google Scholar]

- Guan, M.; Guo, M.; Tan, Y.; Du, X. Study on the effect of aging on cracking resistance of virgin asphalt binder and its evolution model. Constr. Build. Mater. 2023, 407, 133443. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).