Evaluation of Proppant Placement Efficiency in Linearly Tapering Fractures

Abstract

1. Introduction

2. Materials and Methods

2.1. Modeling of Fracture

2.2. Grid Independence Testing and Segmentation

2.3. Mathematical Models

3. Results and Analysis

3.1. Model Validation

3.2. Effect of the Injection Rate

3.3. Effect of Sand Concentration

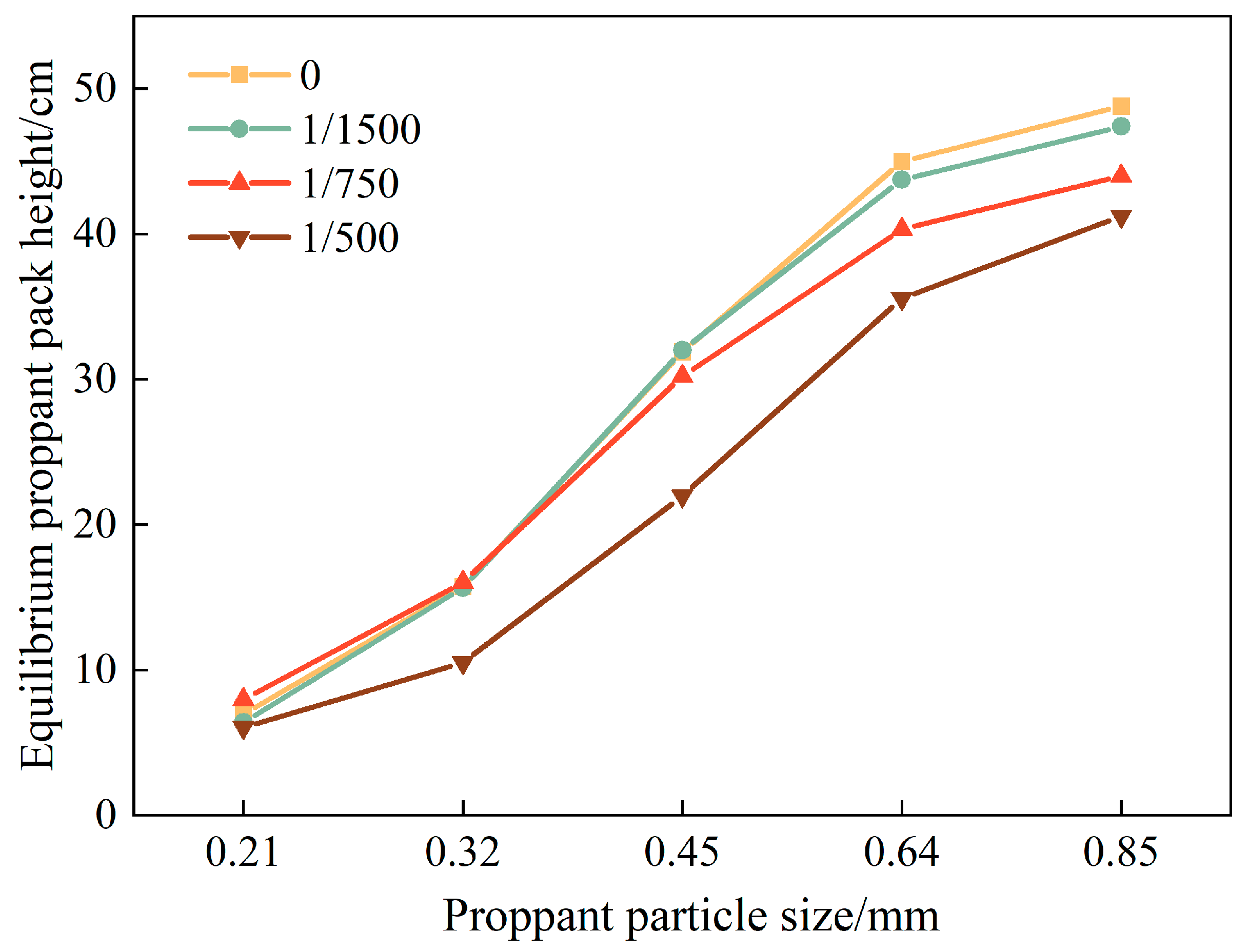

3.4. Effect of Proppant Particle Size

3.5. Effect of Proppant Density

3.6. Sensitivity to Key Modeling Choices

4. Conclusions

- (1)

- Regardless of the taper rate, proppant pack formation follows the same overall sequence. The equilibrium proppant pack height increases with higher sand concentration, greater proppant density, and larger particle size, but decreases as injection rate rises. Higher sand concentrations and injection rates improve proppant placement but can worsen perforation erosion and screen-out, risking uncontrolled fracture growth. Operators should balance these trade-offs via the real-time monitoring and adaptive adjustment of sand concentration and injection rate.

- (2)

- As δ increases and the fracture aperture narrows downstream, the flow channel constricts and turbulence intensifies, enhancing the fluid’s carrying capacity. Raising the in-fracture velocity from 1.38 m/s to 3.24 m/s reduces the main pack height by about 32.5 % in the uniform (δ = 0) model and by approximately 59.9 % in the δ = 1/1500 taper model; inlet pack height is largely unaffected.

- (3)

- Variations in sand concentration and particle size significantly alter the morphology of the main pack. In fractures with higher taper rates, higher sand concentrations or larger particles lead to a transition from a dome shaped to a flatter “table top” pack. During late injection stages, settling predominantly occurs on the downstream face, and the pack advances toward the fracture tip at its equilibrium height with gentler slopes and more uniform placement.

- (4)

- A low-density proppant, with its lower settling velocity, remains suspended and resists build up, whereas a high-density proppant forms more stable packs. In tapering fractures, the peak of the equilibrium pack shifts farther downstream as δ increases, indicating longer transport distances and a flatter pack profile for a heavy proppant.

- (5)

- Operators can leverage high taper rates (δ) in reservoirs with strong stress contrasts to accelerate downstream flow, lower pack heights, and extend the propped half-length. By tailoring perforation spacing, cluster sequencing, and proppant design to create controlled aperture narrowing—alongside optimized injection rates and particle properties—fracture conductivity can be maximized while minimizing near-wellbore plugging.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Description | Unit |

|---|---|---|

| δ | Fracture width taper rate, defined as Δw/L | – |

| Δw | Total change in fracture aperture (win − wout) | m |

| L | Distance over which fracture aperture tapers | m |

| w(x) | Fracture aperture at position x along the fracture | m |

| Q | Injection flow rate | m3/h |

| v | Average fluid velocity in the fracture | m/s |

| dp | Proppant particle diameter | m |

| ρp | Proppant density | kg/m3 |

| Cs | Sand concentration (volumetric fraction of slurry) | – |

| Heq | Equilibrium proppant pack height | m |

| Nnells | Number of mesh cells (grid resolution) | – |

| k | Turbulent kinetic energy | m2/s2 |

| ε | Turbulent dissipation rate | m2/s3 |

References

- Krzaczek, M.; Nitka, M.; Kozicki, J.; Tejchman, J. Simulations of Hydro-Fracking in Rock Mass at Meso-Scale Using Fully Coupled DEM/CFD Approach. Acta Geotech. 2020, 15, 297–324. [Google Scholar] [CrossRef]

- Raimbay, A.; Babadagli, T.; Kuru, E.; Develi, K. Quantitative and Visual Analysis of Proppant Transport in Rough Fractures. J. Nat. Gas Sci. Eng. 2016, 33, 1291–1307. [Google Scholar] [CrossRef]

- Liu, D.; Lecampion, B. Propagation of a Plane-Strain Hydraulic Fracture Accounting for a Rough Cohesive Zone. J. Mech. Phys. Solids 2021, 149, 104322. [Google Scholar] [CrossRef]

- Xu, J.; Ding, Y.; Yang, L.; Liu, Z.; Gao, R.; Wang, Z.; Mo, S. Numerical Analysis of Proppants Transport in Tortuous Fractures of Shale Gas Reservoirs after Shear Deformation. J. Nat. Gas Sci. Eng. 2020, 78, 103285. [Google Scholar] [CrossRef]

- Bandara, K.M.A.S.; Ranjith, P.G.; Rathnaweera, T.D. Laboratory-Scale Study on Proppant Behaviour in Unconventional Oil and Gas Reservoir Formations. J. Nat. Gas Sci. Eng. 2020, 78, 103329. [Google Scholar] [CrossRef]

- Chen, Y.; Li, W.; Wang, X.; Wang, Y.; Fu, L.; Wu, P.; Wang, Z. Research and Application of Geomechanics Using 3D Model of Deep Shale Gas in Luzhou Block, Sichuan Basin, Southwest China. Geosciences 2025, 15, 65. [Google Scholar] [CrossRef]

- Zhang, Q.; Yan, X.; Wang, X.; Feng, G.; Yao, W.; Yin, Y.; Zhang, K. Investigating the Impacts of Nonuniform Proppant Distribution and Fracture Closure on Well Performance in Shale Gas Reservoirs. Front. Earth Sci. 2022, 10, 1–9. [Google Scholar] [CrossRef]

- Lee, J.; Babadagli, T. Effect of Roughness on Fluid Flow and Solute Transport in a Single Fracture: A Review of Recent Developments, Current Trends, and Future Research. J. Nat. Gas Sci. Eng. 2021, 91, 103971. [Google Scholar] [CrossRef]

- Zhang, B.; Lu, N.; Guo, Y.; Wang, Q.; Cai, M.; Lou, E. Modeling and Analysis of Sustained Annular Pressure and Gas Accumulation Caused by Tubing Integrity Failure in the Production Process of Deep Natural Gas Wells. J. Energy Resour. Technol. 2021, 144, 063005. [Google Scholar] [CrossRef]

- Suri, Y.; Islam, S.Z.; Hossain, M. Effect of Fracture Roughness on the Hydrodynamics of Proppant Transport in Hydraulic Fractures. J. Nat. Gas Sci. Eng. 2020, 80, 103401. [Google Scholar] [CrossRef]

- Sun, X.; Tao, L.; Qu, J.; Yao, D.; Hu, Q. Evaluating the Effectiveness of Cleaning Tools for Enhanced Efficiency in Reamed Wellbore Operations. Geoenergy Sci. Eng. 2025, 246, 213620. [Google Scholar] [CrossRef]

- Michael, F.M.; Krishnan, M.R.; Li, W.; Alsharaeh, E.H. A Review on Polymer-Nanofiller Composites in Developing Coated Sand Proppants for Hydraulic Fracturing. J. Nat. Gas Sci. Eng. 2020, 83, 103553. [Google Scholar] [CrossRef]

- Movassagh, A.; Haghighi, M.; Zhang, X.; Kasperczyk, D.; Sayyafzadeh, M. A Fractal Approach for Surface Roughness Analysis of Laboratory Hydraulic Fracture. J. Nat. Gas Sci. Eng. 2021, 85, 103703. [Google Scholar] [CrossRef]

- Li, S.Q.; Tong, Y.S.; Yan, T.; Zhou, Y.C.; Li, W.; Sun, X.F. Numerical Simulation of Rock Breaking by Resonance Coring Based on Laboratory Experiments. SPE J. 2025, 30, 1162–1176. [Google Scholar] [CrossRef]

- Katende, A.; O’Connell, L.; Rich, A.; Rutqvist, J.; Radonjic, M. A Comprehensive Review of Proppant Embedment in Shale Reservoirs: Experimentation, Modeling and Future Prospects. J. Nat. Gas Sci. Eng. 2021, 95, 104143. [Google Scholar] [CrossRef]

- Sahai, R.; Moghanloo, R.G. Proppant Transport in Complex Fracture Networks—A Review. J. Pet. Sci. Eng. 2019, 182, 106199. [Google Scholar] [CrossRef]

- Tang, Y.; Ranjith, P.G.; Perera, M.S.A. Major Factors Influencing Proppant Behaviour and Proppant-Associated Damage Mechanisms during Hydraulic Fracturing. Acta Geotech. 2018, 13, 757–780. [Google Scholar] [CrossRef]

- Bandara, K.M.A.S.; Ranjith, P.G.; Rathnaweera, T.D. Improved Understanding of Proppant Embedment Behavior under Reservoir Conditions: A Review Study. Powder Technol. 2019, 352, 170–192. [Google Scholar] [CrossRef]

- Qu, H.; Tang, S.; Liu, Z.; Mclennan, J.; Wang, R. Experimental Investigation of Proppant Particles Transport in a Tortuous Fracture. Powder Technol. 2021, 382, 95–106. [Google Scholar] [CrossRef]

- Zhang, C.P.; Liu, S.; Ma, Z.Y.; Ranjith, P.G. Combined Micro-Proppant and Supercritical Carbon Dioxide (SC-CO2) Fracturing in Shale Gas Reservoirs: A Review. Fuel 2021, 305, 121431. [Google Scholar] [CrossRef]

- Barboza, B.R.; Chen, B.; Li, C. A Review on Proppant Transport Modelling. J. Pet. Sci. Eng. 2021, 204, 108753. [Google Scholar] [CrossRef]

- Yao, S.; Chang, C.; Hai, K.; Huang, H.; Li, H. A Review of Experimental Studies on the Proppant Settling in Hydraulic Fractures. J. Pet. Sci. Eng. 2022, 208, 109211. [Google Scholar] [CrossRef]

- Isah, A.; Hiba, M.; Al-Azani, K.; Aljawad, M.S.; Mahmoud, M. A Comprehensive Review of Proppant Transport in Fractured Reservoirs: Experimental, Numerical, and Field Aspects. J. Nat. Gas Sci. Eng. 2021, 88, 103832. [Google Scholar] [CrossRef]

- Zhang, C.P.; Cheng, P.; Ranjith, P.G.; Lu, Y.Y.; Zhou, J.P. A Comparative Study of Fracture Surface Roughness and Flow Characteristics between CO2 and Water Fracturing. J. Nat. Gas Sci. Eng. 2020, 76, 103188. [Google Scholar] [CrossRef]

- Sun, X.; Bao, J.; Li, Z.; Qu, J. Numerical Investigation of Proppant Transportation Characteristics in Hydraulically Fractured Wedge Fractures. Petroleum 2024, 10, 660–671. [Google Scholar] [CrossRef]

- Fernández, M.E.; Baldini, M.; Pugnaloni, L.A.; Sánchez, M.; Guzzetti, A.R.; Carlevaro, C.M. Proppant Transport and Settling in a Narrow Vertical Wedge-Shaped Fracture. In Proceedings of the 49th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 28 June–1 July 2015; p. ARMA-2015-135. [Google Scholar]

- Chun, T.; Zhu, D.; Zhang, Z.; Mao, S.; Wu, K. Experimental Study of Proppant Transport in Complex Fractures with Horizontal Bedding Planes for Slickwater Fracturing. SPE Prod. Oper. 2021, 36, 83–96. [Google Scholar] [CrossRef]

- Kou, R.; Moridis, G.J.; Blasingame, T.A. Analysis and Modeling of Proppant Transport in Inclined Hydraulic Fractures. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 23–25 January 2018; p. D011S002R001. [Google Scholar]

- Xie, J.; Hu, Y.; Kang, Y.; Chen, H.; Liu, Q. Numerical Study on Proppant Transport in Supercritical Carbon Dioxide under Different Fracture Shapes: Flat, Wedge-Shaped, and Bifurcated. Energy Fuels 2022, 36, 10278–10290. [Google Scholar] [CrossRef]

- Mohammadi, S.; Hemmat, A.; Afifi, H.; Mahmoudi Alemi, F. Improvement of the Rheological Behavior of Viscoelastic Surfactant Fracturing Fluids by Metallic-Type Nanoparticles. ACS Omega 2024, 9, 28676–28690. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, S.; Afifi, H.; Mahmoudi Alemi, F. Review on Enhancing Rheological Characteristics of Viscoelastic Surfactant Fracturing Fluids by Nanoparticles: Advances, Challenges, and Perspectives. Energy Fuels 2024, 38, 4921–4945. [Google Scholar] [CrossRef]

- Hou, L.; Elsworth, D.; Zhang, F.; Wang, Z.; Zhang, J. Evaluation of Proppant Injection Based on a Data-Driven Approach Integrating Numerical and Ensemble Learning Models. Energy 2023, 264, 126122. [Google Scholar] [CrossRef]

- Ghazanfari, V.; Imani, M.; Shadman, M.M.; Amini, Y.; Zahakifar, F. Numerical Study on the Thermal Performance of the Shell and Tube Heat Exchanger Using Twisted Tubes and Al2O3 Nanoparticles. Prog. Nucl. Energy 2023, 155, 104526. [Google Scholar] [CrossRef]

- Walton, O.R.; Braun, R.L. Viscosity, Granular-temperature, and Stress Calculations for Shearing Assemblies of Inelastic, Frictional Disks. J. Rheol. 1986, 30, 949–980. [Google Scholar] [CrossRef]

- Brilliantov, N.V.; Pöschel, T. Rolling Friction of a Viscous Sphere on a Hard Plane. Europhys. Lett. 1998, 42, 511–516. [Google Scholar] [CrossRef]

- Mathiesen, V.; Solberg, T.; Hjertager, B.H. Predictions of Gas/Particle Flow with an Eulerian Model Including a Realistic Particle Size Distribution. Powder Technol. 2000, 112, 34–45. [Google Scholar] [CrossRef]

- Lun, C.K.K.; Savage, S.B.; Jeffrey, D.J.; Chepurniy, N. Kinetic Theories for Granular Flow: Inelastic Particles in Couette Flow and Slightly Inelastic Particles in a General Flowfield. J. Fluid Mech. 1984, 140, 223–256. [Google Scholar] [CrossRef]

- Huilin, L.; Gidaspow, D.; Bouillard, J.; Wentie, L. Hydrodynamic Simulation of Gas-Solid Flow in a Riser Using Kinetic Theory of Granular Flow. Chem. Eng. J. 2003, 95, 1–13. [Google Scholar] [CrossRef]

| Variable | Values |

|---|---|

| Pumping rate (m3/h) | 3, 4,.4.5, 5, 5.5, 6, 6.5, 7 |

| Corresponding velocity (m/s) | 1.38, 1.85, 2.08, 2.31, 2.55, 2.78, 3, 3.24 |

| Sand concentration (%) | 2, 4, 6, 8 |

| Proppant size (mm) | 0.21, 0.32, 0.45, 0.64, 0.85 |

| Proppant density (kg/m3) | 1760, 2450, 2770, 3200 |

| Fracture taper rate (δ) | 0; 1/1500; 1/750; 1/500 |

| Number of Runs (Group No.) | Flow Rate (m3/h) | Slot Flow Velocity (m/s) | Particle Diameter (mm) | Viscosity of Proppant–Carrying Fluid (mPa·s) | Proppant Density (kg/m3) | Proppant Concentration (%) |

|---|---|---|---|---|---|---|

| 1 | 3–6 | 1.38–2.55 | 0.45 | 1 | 2450 | 0.04 |

| 2 | 5 | 2.31 | 0.45 | 1 | 2450 | 0.04–0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Tao, L.; Bao, J.; Qu, J.; Yang, H.; Yao, S. Evaluation of Proppant Placement Efficiency in Linearly Tapering Fractures. Geosciences 2025, 15, 275. https://doi.org/10.3390/geosciences15070275

Sun X, Tao L, Bao J, Qu J, Yang H, Yao S. Evaluation of Proppant Placement Efficiency in Linearly Tapering Fractures. Geosciences. 2025; 15(7):275. https://doi.org/10.3390/geosciences15070275

Chicago/Turabian StyleSun, Xiaofeng, Liang Tao, Jinxin Bao, Jingyu Qu, Haonan Yang, and Shangkong Yao. 2025. "Evaluation of Proppant Placement Efficiency in Linearly Tapering Fractures" Geosciences 15, no. 7: 275. https://doi.org/10.3390/geosciences15070275

APA StyleSun, X., Tao, L., Bao, J., Qu, J., Yang, H., & Yao, S. (2025). Evaluation of Proppant Placement Efficiency in Linearly Tapering Fractures. Geosciences, 15(7), 275. https://doi.org/10.3390/geosciences15070275