The Geoscience of In-Situ Combustion and High-Pressure Air Injection

Abstract

1. Introduction

- How and why is ISC currently used?

- What is the role of laboratory experiments in the process workflow?

- Where are current projects taking place and how successful are they?

- How is numerical modelling used in conjunction with experimental work in the project design process?

- What are the roles of sub-surface geology and oil chemistry in project success?

- How can current knowledge be used to develop ISC as a clean energy source?

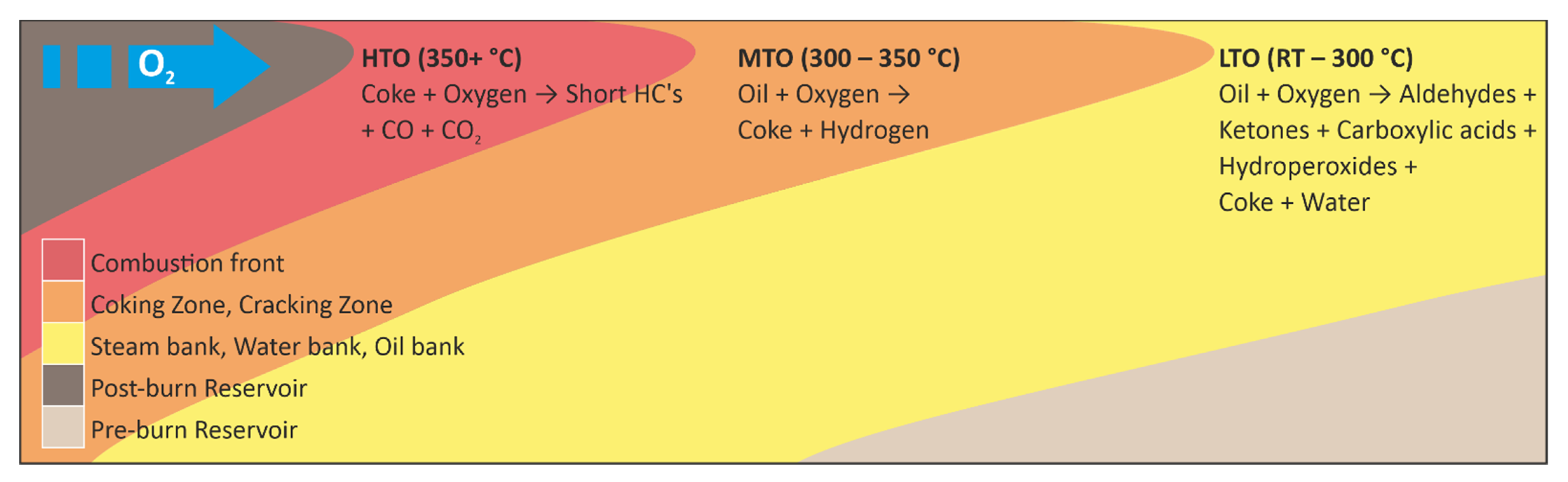

2. What Is In-Situ Combustion?

3. Current Reasons for Using In-Situ Combustion (ISC)

3.1. Enhanced Oil Recovery

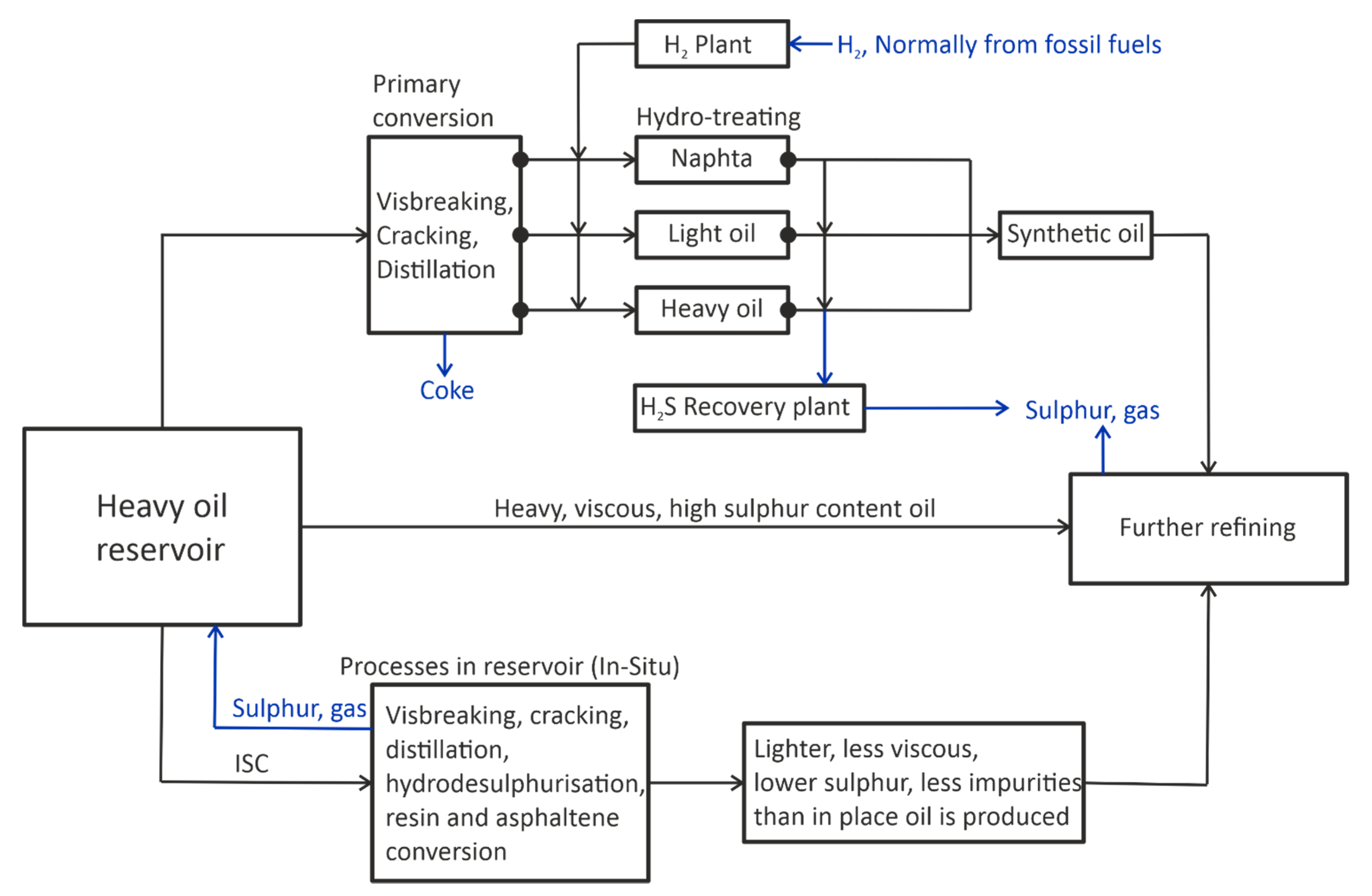

3.2. In-Situ Upgrading

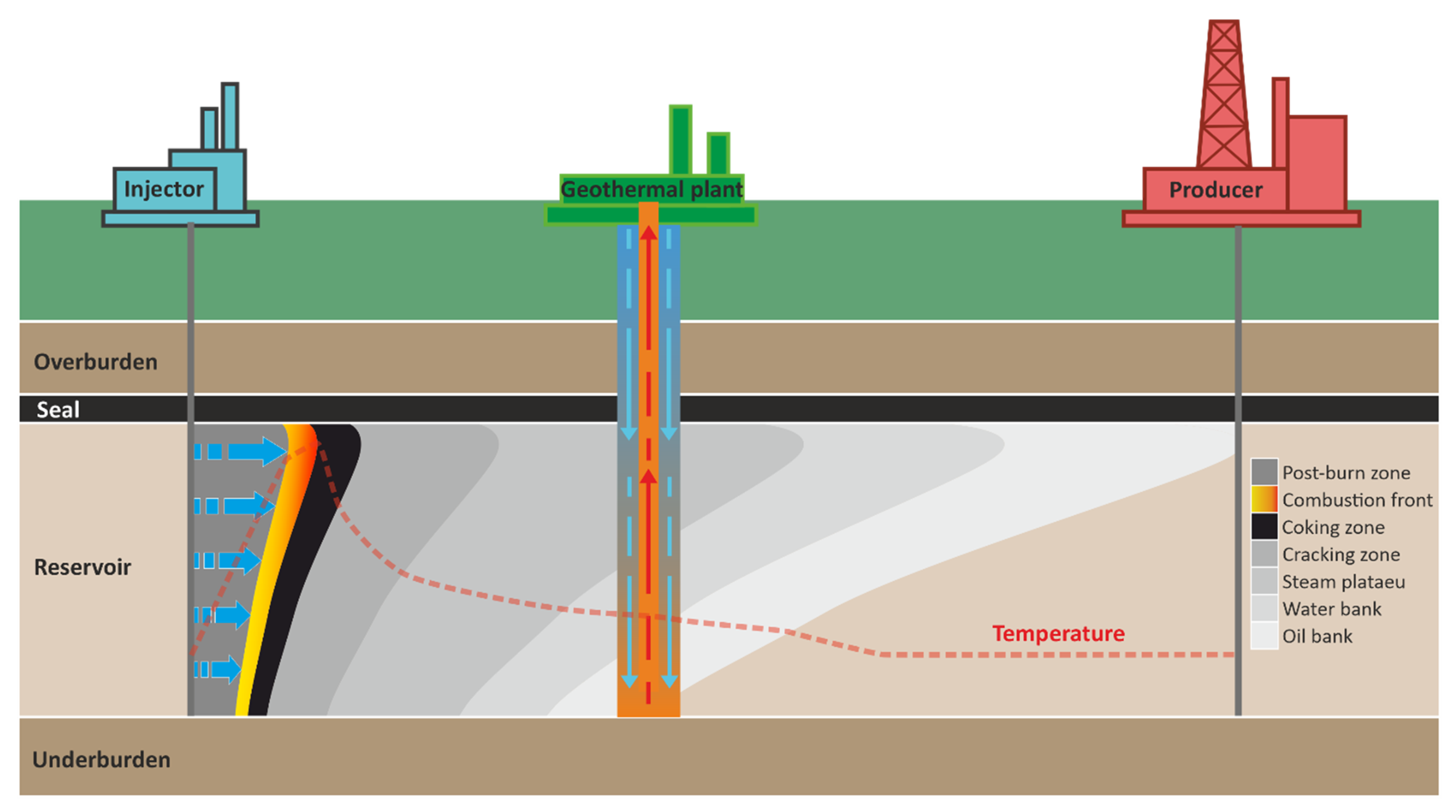

3.3. Geothermal Energy Production

4. Sources of Information on ISC

4.1. Field Application and Case Studies

4.1.1. Midway-Sunset Field

4.1.2. Bellevue Oil Field

4.1.3. Medicine Pole Hills Field

4.1.4. Other Fields

| Field | Country | Rock | Depth (m) | Thickness (m) | Porosity (%) | Permeability (mD) | Temperature (°C) | Oil Gravity (°API) | Viscosity (cp) | Recovery (%) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Athabasca | Canada | Sand | - | 100 | 35 | 3000–4000 | 18 | 5 | 1,000,000 | 43 | [90] |

| Azraq Basin | Jordan | Mixed | 1112 | - | 18 | 1000 | 40 | 17 | 1000 | 69 | [110] |

| Balaria | Romania | Sand | 85 | 15 | 30 | 500 | 48 | 19 | 120 | 40 | [111] |

| Balol | India | Sand | 1049 | 6.5 | 28 | 8000–15,000 | 70 | 15 | 300 | 45 | [112,113] |

| Bellevue | USA | Sand | 104 | 21 | 32 | 700 | 24 | 19 | 676 | 60 | [59] |

| Buffalo | USA | Carbonate | 2591 | 5 | 15–20 | 10 | 102 | 32 | 2 | 18 | [29] |

| Buffalo | USA | Carbonate | 2576 | 3 | 15–28 | 18–25 | 102 | 27 | 2 | 15 | [36] |

| Cado Pine Island | USA | Sand | 305 | - | 37 | 603 | 32 | 21 | 112 | - | [114] |

| Capa Maddison | USA | Carbonate | 2560 | 6 | 11 | 1 | 108 | 41 | 0.28 | - | [36] |

| Cedar Hills | USA | Carbonate | 3048 | 8 | 5–25 | 1–30 | 110 | 38 | 0.48 | 15 | [36] |

| Charco Redondo | USA | Sand | 61 | - | 30–35 | 2500 | 23 | 18 | 90 | - | [115] |

| Countess | Canada | Sand | 1080 | 8 | 23 | 800–2000 | 28 | 5.8 | 9 | [116] | |

| Driza | Albania | Sand | 450 | 95 | 25 | - | - | 11 | 9000 | - | [117] |

| Esperson Dome | USA | Sand | 814 | 24 | 31 | 200–6300 | 52 | 21 | 90 | 60 | [118] |

| Eyehill | Canada | Sand | 747 | 30 | 34 | 6000 | 29 | 14 | 2750 | 5 | [96] |

| Forest Hill | USA | Sand | 1463 | 4.6 | 27 | 626 | 85 | 10 | 1002 | - | [119] |

| Fosterton | Canada | Sand | 945 | 8.4 | 28 | 958 | 135 | 24 | 15.6 | 33 | [120] |

| Glass Bluff | USA | Carbonate | 2896 | 4 | 10–20 | 18 | 106 | 43 | 0.33 | - | [36] |

| Glen Hummel | USA | Sand | 741 | 3 | 36 | 1000 | 45 | 22 | 74 | 56 | [121] |

| Gloriana | USA | Sand | 488 | 1 | 35 | 1000 | 44 | 21 | 112 | 58 | [121] |

| Government Wells | USA | Sand | 707 | 18 | 32 | 800 | 49 | 22 | 10 | - | [122] |

| Holt Sand Unit | USA | Sand | - | 12 | 20 | 131 | 29 | 32 | 14 | - | [123] |

| Horse Creek | USA | Carbonate | 2781 | 14 | 8–20 | 1–97 | 104 | 32 | 1 | - | [36] |

| Kinsella-B | Canada | Sand | - | 5 | 30 | 200 | 27 | 20 | 90 | 1 | [124] |

| Liaohe Field | China | Sand | 1300 | 6.7 | 25 | 781 | - | 18 | 2000 | - | [125] |

| Little Beaver | USA | Dolomite | 1615 | 12 | 9–20 | 1–10 | 89 | 33 | 3 | 12 | [36] |

| Lower Hospah | USA | Sand | 495 | 9 | 27 | 1100 | 27 | 26 | 55 | 33 | [100] |

| Medicine Pole Hills | USA | Carbonate | 2896 | 4 | 18 | 1–30 | 116 | 39 | 0.48 | 93 | [27] |

| Midway Sunset | USA | Sand | 457 | - | 32 | 1500–4000 | 54 | 12 | 1630 | 73 | [56] |

| Morgan | Canada | Sand | 579 | 9 | 31 | 2000 | 21 | 11 | 1800 | 10 | [126] |

| Pennel | USA | Dolomite | 1661 | 18 | 9–20 | 1–10 | 93 | 31 | 1 | - | [36] |

| Pontotoc | USA | Sand | - | 5 | 27 | 7680 | 19 | 18 | 5000 | 51 | [95] |

| Santhal | India | Sand | 1000 | 15 | 28 | 3000–5000 | 70 | 18 | 200 | - | [4] |

| Silverdale South | Canada | Sand | 564 | 5.5 | 24 | 487 | 28 | 14 | 4420 | 25.5 | [127] |

| South Belridge | USA | Sand | - | 12 | 36 | 8000 | 31 | 13 | 2700 | 71 | [128] |

| Suplacu de Barcau | Romania | Sand | 200 | 10 | 32 | 1700 | 18 | 26 | 2000 | 85 | [129] |

| Trix-Liz | USA | Sand | 1113 | 3 | 28 | 500 | 59 | 24 | 138 | 60 | [121] |

| Utah Tar Sand | USA | Sand | 107 | 4 | 31 | 85 | 11 | 14 | 100,000 | - | [130] |

| Videle Field | Romania | Sand | 850 | 10 | 30 | 300–1500 | 55 | 19 | 66 | 40 | [111] |

| Wabasca | Canada | Sand | 427 | 7 | 30 | 3000 | 15 | 14 | 10,000 | 20 | [131] |

| West Heidellberg | USA | Sand | 3475 | 19 | 14 | 85 | 105 | 18 | 6 | 22 | [132] |

| Wolf Lake | Canada | Sand | 450 | 34 | 31 | - | 15 | 12 | 100,000 | - | [133] |

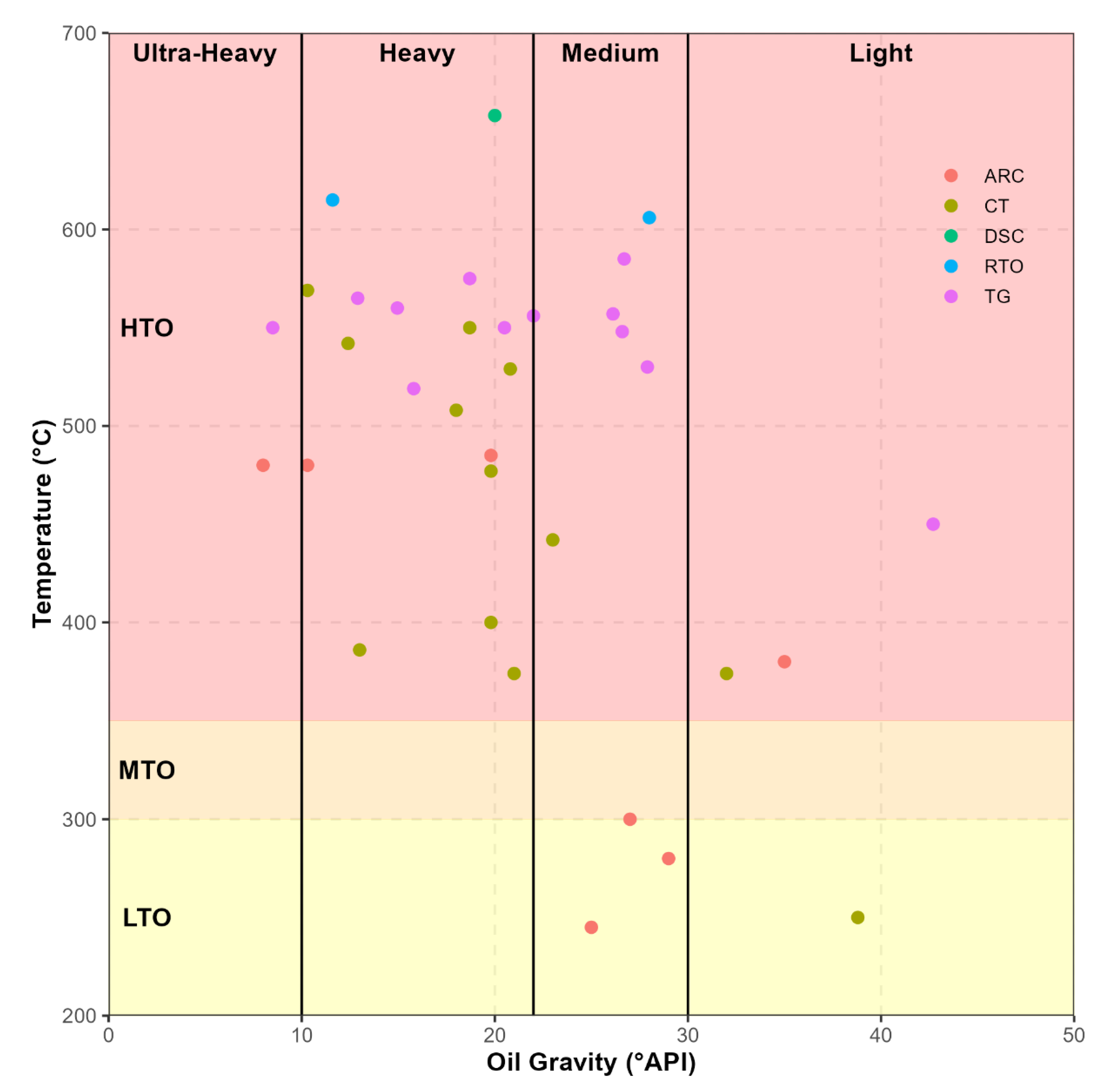

4.2. Laboratory Experiments

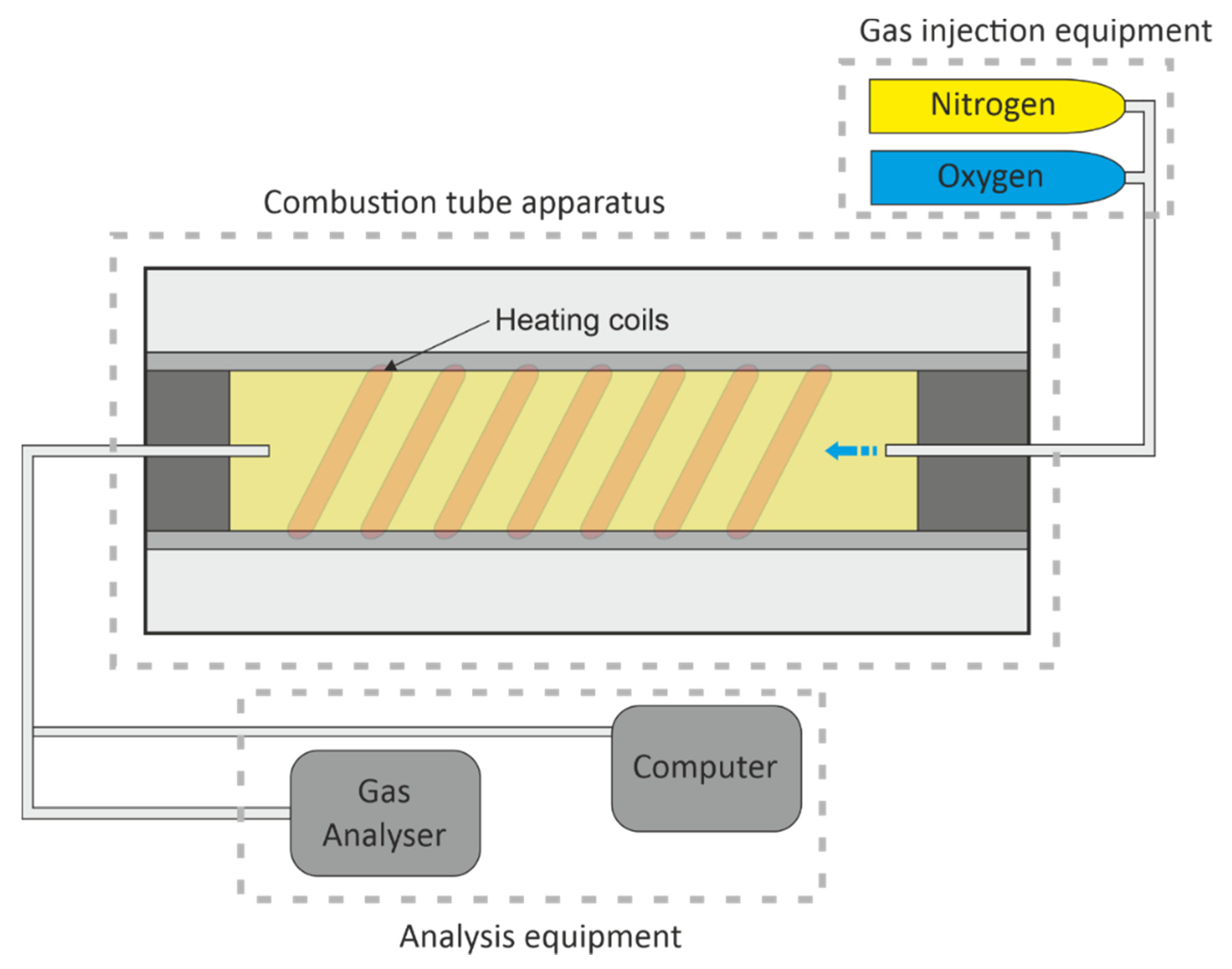

4.2.1. Combustion Tube Experiments

4.2.2. Other Analytical Approaches Adopted during Experiments

| Oil | API | Temperature | Technique | Reference |

|---|---|---|---|---|

| Adryaman | 26.6 | 548 | CT | [152] |

| Athabasca Bitumen | 8.5 | 550 | TG/DSC | [153] |

| Athabasca Bitumen | 8 | 480 | ARC | [154] |

| Australian light | 38.8 | 255 | CT | [26] |

| Bati Kozluca | 12.4 | 542 | CT | [152] |

| Bati Raman Crude | 11.6 | 615 | RTO | [155] |

| Bati Raman Crude | 14.95 | 560 | TG/DTG | [156] |

| Camurlu | 10.3 | 569 | CT | [152] |

| Clair | 19.8 | 485 | ARC | [154] |

| Clair | 19.8 | 600 | CT | [26] |

| Countess-B | 28 | 606 | CT | [148] |

| Crude oil | 20.8 | 529 | CT | [157] |

| Crude oil 1 | 26.7 | 585 | TG/DTG | [158] |

| Crude oil 2 | 18.7 | 575 | TG/DTG | [158] |

| Crude oil 3 | 12.9 | 565 | TG/DTG | [158] |

| Fosterton oil | 20.5 | 550 | TGA | [150] |

| Garzan | 26.12 | 557 | TG/DTG | [156] |

| Heavy | 20 | 658 | DSC | [159] |

| Heavy 1 | 13 | 386 | CT | [160] |

| Iola | 19.8 | 477 | TG/DSC | [149] |

| Liahoe | 18 | 508 | CT | [161] |

| Light 1 | 32 | 374 | CT | [160] |

| Light oil D | 42.7 | 450 | TG/DSC | [153] |

| Medium 1 | 21 | 374 | CT | [160] |

| Medium 2 | 23 | 442 | CT | [160] |

| Medium oil E | 27.9 | 530 | TG/DSC | [153] |

| Middle east | 29 | 280 | ARC | [162] |

| Neilburg oil | 15.8 | 519 | TG/DTG | [163] |

| North American oil A | 25 | 245 | ARC | [162] |

| North American oil B | 35 | 380 | ARC | [162] |

| North American oil C | 27 | 300 | ARC | [162] |

| Raman | 18.7 | 550 | CT | [152] |

| Tahe Heavy | 22 | 556 | TG/DSC | [164] |

| Wolf lake | 10.3 | 480 | ARC | [154] |

4.3. Modelling

Reaction Models

| Model | Reactions |

|---|---|

| Crookston, et al. [184] | |

| Coats [181] | |

| Belgrave, et al. [176] | |

| Belgrave, et al. [167] | |

| Akin, et al. [23] | |

| Akin, et al. [23] | |

| Sequera, et al. [187] | |

| Zhu [173] | |

| Zhu [173] | |

| Lovett, et al. [174] | |

| Mercado and Trevisan [188] | |

| Rojas, et al. [185] | |

5. Design and Implementation of In-Situ Combustion Projects

5.1. Geology of The Reservoir

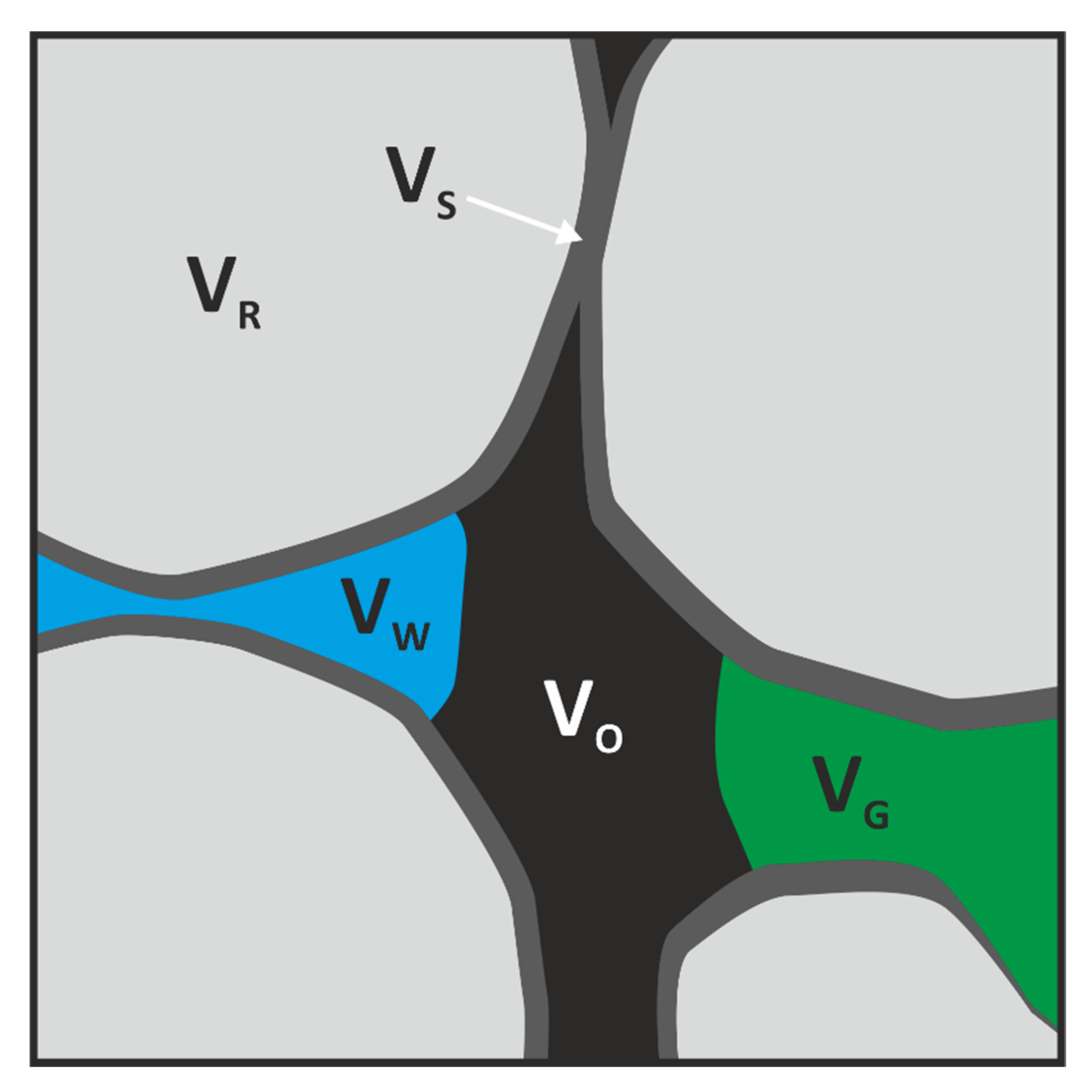

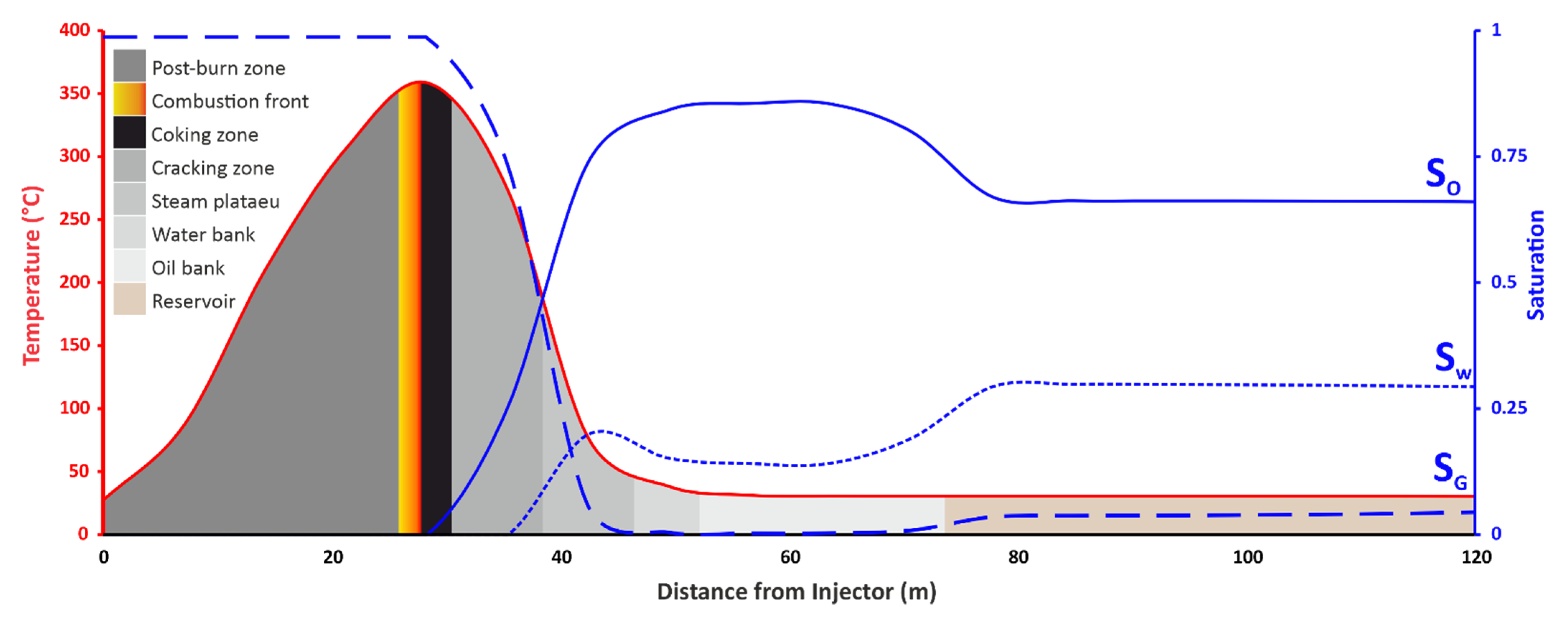

5.1.1. Porosity and Permeability

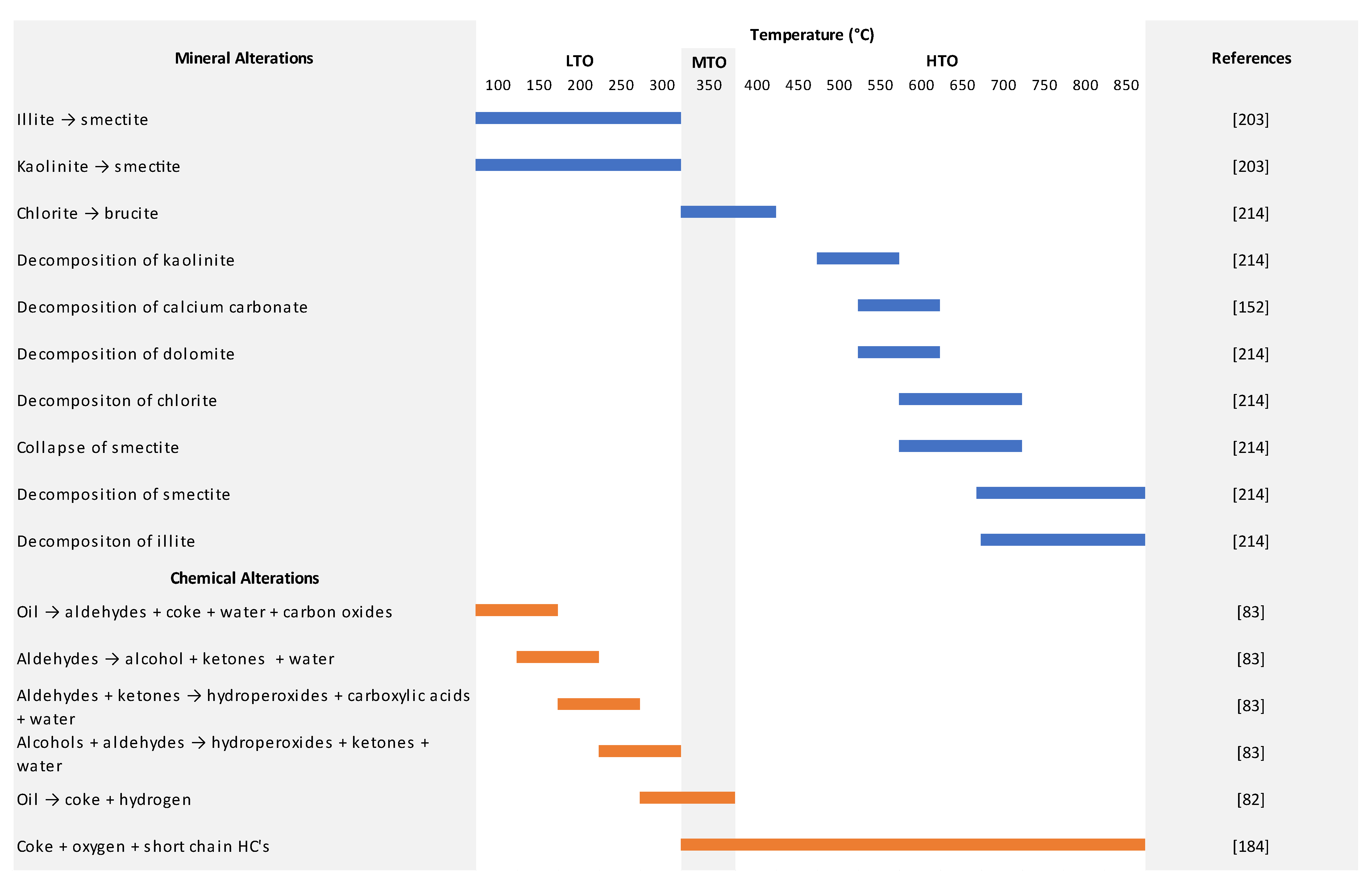

5.1.2. Mineralogy

Clay Mineral Catalysis

Mineral Alterations

Carbonate Rocks

5.1.3. Reservoir Geometry and Heterogeneity

5.1.4. Reservoir Geomechanics

5.2. Type of Oil

5.3. Well Configuration

6. Conclusions

- Over the past 100 years, ISC and HPAI have been used as a primary, secondary and tertiary production method for both heavy and light oil reservoirs.

- Laboratory experiments have provided much useful information on ISC that is invaluable when it comes to designing an ISC project. Air injection rate, air flux, and the concentration of oxygen are key to the stable propagation of a fire front and can be calculated through experiments. We recommend these experiments as standard practice in the design of future projects

- Modelling is in important step in the workflow to design an ISC project; however, the output from models is only as good as the data put in. For the most successful and meaningful models, they need data (e.g., on reaction rate and type) derived from laboratory experiments. With laboratory experiments used as standard in project design, this ensure the maximum chance of high-quality models.

- In-situ combustion projects are perceived to be high-risk due to the numerous previous failures. However, the poor understanding or appreciation of the geology of the reservoir is considered to be responsible for the majority of failed field applications. The most significant geological factor that affects the success of ISC is permeability heterogeneity, including both fracture-controlled and matrix-controlled permeability heterogeneity. With detailed field study, relevant laboratory experiments, and high-quality models, required factors such as air injection rate, air flux and, oxygen concentration can be calculated to ensure the best chance of the success of future projects.

- Lessons learned from the study of ISC as an EOR process are applicable to green energy projects. Field data, laboratory experiments and numerical modelling methods can be used to help develop ISC as a tool for clean energy production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wolcott, E.R. Method of Increasing the Yield of Oil Wells. U.S. Patent 1,457,479, 5 June 1923. [Google Scholar]

- Wu, C.H.; Fulton, P.F. Experimental simulation of the zones preceding the combustion front of an in-situ combustion process. Soc. Pet. Eng. J. 1971, 11, 38–46. [Google Scholar] [CrossRef]

- Burger, J.G. Chemical aspects of in-situ combustion—Heat of combustion and kinetics. Soc. Pet. Eng. J. 1972, 12, 410–422. [Google Scholar] [CrossRef]

- Turta, A.T.; Chattopadhyay, S.K.; Bhattacharya, R.N.; Condrachi, A.; Hanson, W. Current status of commercial in situ combustion projects worldwide. J. Can. Pet. Technol. 2007, 46, 8–14. [Google Scholar] [CrossRef]

- Akkutlu, I.Y.; Yortsos, Y.C. The dynamics of in-situ combustion fronts in porous media. Combust. Flame 2003, 134, 229–247. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Speight, J.G. Thermal methods of recovery. In Heavy Oil Production Processes; Elsevier Science & Technology: Saint Louis, MO, USA, 2013; pp. 93–130. [Google Scholar]

- Speight, J.G. Heavy Oil Recovery and Upgrading; Gulf Professional Publishing: Cambridge, MA, USA, 2019. [Google Scholar]

- Dingley, A.J. The combustion recovery process—Principles and practice. J. Can. Pet. Technol. 1965, 4, 196–205. [Google Scholar] [CrossRef]

- Nwidee, L.N.; Theophilus, S.; Barifcani, A.; Sarmadivaleh, M.; Iglauer, S. EOR Processes, Opportunities and Technological Advancements. In Chemical Enhanced Oil Recovery (cEOR)—A Practical Overview; InTech: London, UK, 2016. [Google Scholar]

- Martin, W.L.; Alexander, J.D.; Dew, J.N. Process variables of in situ combustion. Trans. AIME 1958, 213, 28–35. [Google Scholar] [CrossRef]

- Razzaghi, S.; Kharrat, R.; Vossoughi, S.; Rashtchian, D. Feasibility study of auto ignition in in-situ combustion process. J. Jpn. Pet. Inst. 2008, 51, 287–297. [Google Scholar] [CrossRef][Green Version]

- Li, Y.-B.; Pu, W.-F.; Zhao, J.-Y.; Zhao, Q.-N.; Sun, L.; Jin, F.-Y.; Zhao, J.-Z.; Zhou, W. Variation of reservoir fluid property during the high pressure air injection process. Int. J. Green Energy 2015, 13, 173–180. [Google Scholar] [CrossRef]

- Yuan, S.; Jiang, H.; Wang, B.; Li, J. Design of steam preheating and ignition program of in situ combustion. Energy Fuels 2017, 31, 8643–8647. [Google Scholar] [CrossRef]

- Huang, S.; Sheng, J.J.; Jiang, Q.; Liu, J. Screening of spontaneous ignition feasibility during air injection EOR process based on thermal experiments. Energies 2019, 12, 3687. [Google Scholar] [CrossRef]

- Yue, P.; Huang, S.; Zeng, F.; Sheng, J.J.; Jiang, Q. Experimental and mechanism study on crude oil spontaneous ignition during the air injection process. Energy Fuels 2020, 34, 7076–7084. [Google Scholar] [CrossRef]

- Perry, R.H.; Green, D.W.; Campbell, J.M. Reverse combustion—A new oil recovery technique. J. Pet. Technol. 1960, 12, 11–12. [Google Scholar] [CrossRef]

- Wilson, L.A.; Reed, R.L.; Reed, D.W.; Clay, R.R.; Harrison, N.H. Some effects of pressure on forward and reverse combustion. Soc. Pet. Eng. J. 1963, 3, 127–137. [Google Scholar] [CrossRef]

- Askarova, A.; Popov, E.; Ursenbach, M.; Moore, G.; Mehta, S.; Cheremisin, A. Experimental investigations of forward and reverse combustion for increasing oil recovery of a real oil field. Energies 2020, 13, 4581. [Google Scholar] [CrossRef]

- Dietz, D.N.; Weijdema, J. Wet and partially quenched combustion. J. Pet. Technol. 1968, 20, 411–415. [Google Scholar] [CrossRef]

- Beckers, H.L.; Harmsen, G.J. The effect of water injection on sustained combustion in a porous medium. Soc. Pet. Eng. J. 1970, 10, 145–163. [Google Scholar] [CrossRef]

- Smith, F.W.; Perkins, T.K. Experimental and numerical simulation studies of the wet combustion recovery process. J. Can. Pet. Technol. 1973, 12, 44–54. [Google Scholar] [CrossRef]

- Akin, S.; Bagci, S.; Kok, M.V. Experimental and numerical analysis of dry forward combustion with diverse well configuration. Energy Fuels 2002, 16, 892–903. [Google Scholar] [CrossRef]

- Alamatsaz, A.; Moore, G.R.; Mehta, S.A.; Ursenbach, M.G. Analysis of dry, wet and superwet in situ combustion using a novel conical cell experiment. Fuel 2018, 234, 482–491. [Google Scholar] [CrossRef]

- Attanasi, E.D.; Meyer, R.F. Heavy oil and natural bitumen; strategic petroleum resources. Fact Sheet U.S. Geol. Surv. 2003. [Google Scholar] [CrossRef]

- Greaves, M.; Young, T.J.; El-Usta, S.; Rathbone, R.R.; Ren, S.R.; Xia, T.X. Air injection into light and medium heavy oil reservoirs. Chem. Eng. Res. Des. 2000, 78, 721–730. [Google Scholar] [CrossRef]

- Kumar, V.K.; Fassihi, M.R.; Yannimaras, D.V. Case history and appraisal of the Medicine Pole Hills unit air-injection project. Soc. Pet. Eng. Reserv. Eng. 1995, 10, 198–202. [Google Scholar] [CrossRef]

- Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. A guide to high pressure air injection (HPAI) based oil recovery. In Proceedings of the Society of Petroleum Engineers/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 13–17 April 2002. [Google Scholar]

- Gutiérrez, D.; Miller, R.J.; Taylor, A.R.; Thies, B.P.; Kumar, V.K. Buffalo Field high-pressure-air-injection projects: Technical performance and operational challenges. Soc. Pet. Eng. Reserv. Eval. Eng. 2009, 12, 542–550. [Google Scholar] [CrossRef]

- Pu, W.; Liu, Z.; Li, Y.; Wei, B.; Jia, H.; Kong, L. A novel insight of laboratory investigation and simulation for high pressure air injection in light oil reservoir. J. Nat. Gas Sci. Eng. 2017, 38, 333–344. [Google Scholar] [CrossRef]

- Gargar, N.K.; Bruining, J.; Kokubun, M.A.E.; Marchesin, D.; Mailybaev, A.A. Combustion in miscible displacement for high-pressure air injection. Comput. Geosci. 2020, 24, 1663–1672. [Google Scholar] [CrossRef]

- Khakimova, L.; Askarova, A.; Popov, E.; Moore, R.G.; Solovyev, A.; Simakov, Y.; Afanasiev, I.; Belgrave, J.; Cheremisin, A. High-pressure air injection laboratory-scale numerical models of oxidation experiments for Kirsanovskoye oil field. J. Pet. Sci. Eng. 2020, 188, 106796. [Google Scholar] [CrossRef]

- Erickson, A.; Legerski, J.R.; Steece, F.V. An appraisal of high pressure air injection (HPAI) on the in situ combustion results from deep, high temperature, high gravity oil reservoirs. In Wyoming Geological Society Guidebook; Wyoming Geological Society: Casper, WY, USA, 1993; pp. 259–270. [Google Scholar]

- Denney, D. 30 years of successful high-pressure air injection: Performance evaluation of Buffalo Field, South Dakota. J. Pet. Technol. 2011, 63, 50–53. [Google Scholar] [CrossRef]

- Anthony, M.J.; Taylor, T.D.; Gallagher, B.J. Fireflooding a high-gravity crude in a watered-out West Texas sandstone. J. Pet. Technol. 1982, 34, 2244–2250. [Google Scholar] [CrossRef]

- Ling, K.; Shen, Z.; Han, G.; He, J. A review of enhanced oil recovery methods applied in Williston Basin. In Proceedings of the 2nd Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014. [Google Scholar]

- Gutiérrez, D.; Taylor, A.R.; Kumar, V.K.; Ursenbach, M.G.; Moore, R.G.; Mehta, S.A. Recovery factors in high-pressure air injection projects revisited. Soc. Pet. Eng. Reserv. Eval. Eng. 2008, 11, 1097–1106. [Google Scholar] [CrossRef]

- Kovscek, A.R.R.; Castanier, L.M.M.; Gerritsen, M.G.G. Improved predictability of in-situ-combustion enhanced oil recovery. Soc. Pet. Eng. Reserv. Eval. Eng. 2013, 16, 172–182. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.; Fan, Z.; Liu, Q. An in situ combustion process for recovering heavy oil using scaled physical model. J. Pet. Explor. Prod. Technol. 2019, 9, 2681–2688. [Google Scholar] [CrossRef]

- Xia, T.X.; Greaves, M.; Turta, A.T.; Ayasse, C. THAI—A ‘short-distance displacement’ in situ combustion process for the recovery and upgrading of heavy oil. Chem. Eng. Res. Des. 2003, 81, 295–304. [Google Scholar] [CrossRef]

- Castanier, L.M.; Brigham, W.E. Upgrading of crude oil via in situ combustion. J. Pet. Sci. Eng. 2003, 39, 125–136. [Google Scholar] [CrossRef]

- Gates, I.D.; Chakrabarty, N.; Moore, R.G.; Mehta, S.A.; Zalewski, E.; Pereira, P. In-situ upgrading of Llancanelo heavy oil using in situ combustion and a downhole catalyst bed. J. Can. Pet. Technol. 2008, 47, 23–31. [Google Scholar] [CrossRef]

- Kapadia, P.R.; Kallos, M.S.; Gates, I.D. Potential for hydrogen generation from in situ combustion of Athabasca bitumen. Fuel 2011, 90, 2254–2265. [Google Scholar] [CrossRef]

- Kapadia, P.R.; Wang, J.; Kallos, M.S.; Gates, I.D. Practical process design for in situ gasification of bitumen. Appl. Energy 2013, 107, 281–296. [Google Scholar] [CrossRef]

- Kapadia, P.R.; Kallos, M.S.; Gates, I.D. A review of pyrolysis, aquathermolysis, and oxidation of Athabasca bitumen. Fuel Processing Technol. 2015, 131, 270–289. [Google Scholar] [CrossRef]

- Hart, A.; Wood, J.; Greaves, M. Laboratory investigation of CAPRI catalytic THAI-add-on process for heavy oil production and in situ upgrading. J. Anal. Appl. Pyrolysis 2017, 128, 18–26. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Hu, Z.; Xu, B.; Li, Y.; Pu, W.; Zhao, J. A review of in situ upgrading technology for heavy crude oil. Petroleum 2021, 7, 117–122. [Google Scholar] [CrossRef]

- Cinar, M. Creating enhanced geothermal systems in depleted oil reservoirs via in situ combustion. In Proceedings of the Thirty-Eigth Workshop on Geothermal Reservoir Enginerring, Stanford, CA, USA, 11–13 February 2013. [Google Scholar]

- Li, T.; Zhu, J.; Xin, S.; Zhang, W. A novel geothermal system combined power generation, gathering heat tracing, heating/domestic hot water and oil recovery in an oilfield. Geothermics 2014, 51, 388–396. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, K.; Liu, C.; Mgijimi, M.B. Geothermal power production from abandoned oil reservoirs using in situ combustion technology. Energies 2019, 12, 4476. [Google Scholar] [CrossRef]

- Han, Y.; Li, K.; Jia, L. Modeling study on reviving abandoned oil reservoirs by in situ combustion without CO2 production while recovering both oil and heat. J. Energy Resour. Technol. 2021, 143, 082902. [Google Scholar] [CrossRef]

- Hajdo, L.E.; Hallam, R.J.; Vorndran, L.D.L. Hydrogen generation during in-situ combustion. In Proceedings of the Society of Petroleum Engineers 1985 California Regional Meeting, Bakersfield, CA, USA, 27–29 March 1985. [Google Scholar]

- Kapadia, P.R.; Kallos, M.; Chris, L.; Gates, I.D. Potential for hydrogen generation during in-situ combustion of bitumen. In Proceedings of the Society of Petroleum Engineers EUROPEC/EAGE Annual Conference and Exhibition, Amsterdam, The Netherlands, 8–11 June 2009. [Google Scholar]

- Cheng, W.-L.; Li, T.-T.; Nian, Y.-L.; Xie, K. Evaluation of working fluids for geothermal power generation from abandoned oil wells. Appl. Energy 2014, 118, 238–245. [Google Scholar] [CrossRef]

- Davis, A.P.; Michaelides, E.E. Geothermal power production from abandoned oil wells. Energy 2009, 34, 866–872. [Google Scholar] [CrossRef]

- Counihan, T.M. A successful in-situ combustion pilot In the Midway-Sunset Field, California. In Proceedings of the 47th Annual California Regional Meeting of the Society of Petroleum Engineers of AIME, Bakersfield, CA, USA, 13–15 April 1977. [Google Scholar]

- Feng, T.; Wu, Y.; Hu, C.; Gong, Y.; Song, Y. Technology of fire flooding process control: Application to fire flooding in a deep and thick heavy oil reservoir in China. In Proceedings of the Society of Petroleum Engineers Asia Pacific Oil & Gas Conference and Exhibition, Brisbane, QLD, Australia, 23–25 October 2018. [Google Scholar]

- Feng, T.; Wu, Y.; Song, Y. Key technologies for fire flooding in thin interbeded heavy oil reservoirs. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019. [Google Scholar]

- Sharma, J.; Dean, J.; Aljaberi, F.; Altememee, N. In-situ combustion in Bellevue field in Louisiana—History, current state and future strategies. Fuel 2021, 284, 118992. [Google Scholar] [CrossRef]

- Alexander, J.D.; Martin, W.L.; Dew, J.N. Factors affecting fuel availability and composition during in situ combustion. J. Pet. Technol. 1962, 14, 1154–1164. [Google Scholar] [CrossRef]

- Belgrave, J.D.M.; Moore, R.G. A model for improved analysis of in-situ combustion tube tests. J. Pet. Sci. Eng. 1992, 8, 75–88. [Google Scholar] [CrossRef]

- Klock, K.; Hascakir, B. Simplified reaction kinetics model for in-situ combustion. In Proceedings of the PE Latin American and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November 2015. [Google Scholar]

- Aleksandrov, D.; Kudryavtsev, P.; Hascakir, B. Variations in in-situ combustion performance due to fracture orientation. J. Pet. Sci. Eng. 2017, 154, 488–494. [Google Scholar] [CrossRef]

- Genrich, J.F.; Pope, G.A. A simplified performance-predictive model for in-situ combustion processes. Soc. Pet. Eng. Reserv. Eng. 1988, 3, 410–418. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Masoumi, M.; Askarinezhad, R. Evolving connectionist model to monitor the efficiency of an in situ combustion process: Application to heavy oil recovery. Energy Technol. 2014, 2, 811–818. [Google Scholar] [CrossRef]

- Ado, M.R. Effect of reservoir pay thickness on the performance of the THAI heavy oil and bitumen upgrading and production process. J. Pet. Explor. Prod. Technol. 2020, 10, 2005–2018. [Google Scholar] [CrossRef]

- Sarathi, P. Environmental aspects of heavy-oil recovery by thermal EOR processes. J. Pet. Technol. 1991, 43, 662–721. [Google Scholar] [CrossRef]

- Sarathi, P.S. In-situ Combustion Handbook—Principles and Practices; Office of Scientific and Technical Information (OSTI): Tulsa, OK, USA, 1999. [Google Scholar]

- Bagci, S.; Shamsul, A. A comparison of dry forward combustion with diverse well configurations in a 3D physical model using medium and low gravity crudes. J. Can. Pet. Technol. 1999, 38, 50–51. [Google Scholar] [CrossRef]

- Joseph, C.; Jay, C.B.; Eslinger, E.V. Evaluation of an in-situ combustion process by postburn core and log analysis. J. Pet. Technol. 1983, 35, 827–835. [Google Scholar] [CrossRef]

- Paitakhti Oskouei, S.J.; Moore, G.; Maini, B.B.; Mehta, S.A. Front self-correction for in-situ combustion. J. Can. Pet. Technol. 2011, 50, 43–56. [Google Scholar] [CrossRef]

- Gates, C.F.; Sklar, I. Combustion as a primary recovery process—Midway Sunset Field. J. Pet. Technol. 1971, 23, 981–986. [Google Scholar] [CrossRef]

- Amrollahi Biyouki, A.; Hosseinpour, N.; Nassar, N.N. Pyrolysis and oxidation of asphaltene-born coke-like residue formed onto in situ prepared NiO nanoparticles toward advanced in situ combustion enhanced oil recovery processes. Energy Fuels 2018, 32, 5033–5044. [Google Scholar] [CrossRef]

- Dabbous, M.K.; Fulton, P.F. Low-temperature-oxidation reaction kinetics and effects on the in-situ combustion process. Soc. Pet. Eng. AIME J. 1974, 14, 253–262. [Google Scholar] [CrossRef]

- Ranjbar, M. Improvement of medium and light oil recovery with thermocatalytic in situ combustion. J. Can. Pet. Technol. 1995, 34, 25–30. [Google Scholar] [CrossRef]

- Adagulu, G.D.; Akkutlu, I.Y. Influence of in-situ fuel deposition on air injection and combustion processes. J. Can. Pet. Technol. 2007, 46, 54–61. [Google Scholar] [CrossRef]

- Cinar, M.; Hasçakir, B.; Castanier, L.M.; Kovscek, A.R. Predictability of crude oil in-situ combustion by the isoconversional kinetic approach. Soc. Pet. Eng. J. 2011, 16, 537–547. [Google Scholar] [CrossRef]

- Gargar, N.K.; Mailybaev, A.A.; Marchesin, D.; Bruining, H. Compositional effects in light/medium oil recovery by air injection: Vaporization vs. Combustion. J. Porous Media 2014, 17, 937–952. [Google Scholar] [CrossRef]

- Yuan, C.; Sadikov, K.; Varfolomeev, M.; Khaliullin, R.; Pu, W.; Al-Muntaser, A.; Saeed Mehrabi-Kalajahi, S. Low-temperature combustion behavior of crude oils in porous media under air flow condition for in-situ combustion (ISC) process. Fuel 2020, 259, 116293. [Google Scholar] [CrossRef]

- Fassihi, M.R.; Meyers, K.O.; Baslle, P.F. Low-temperature oxidation of viscous crude oils. Soc. Pet. Eng. Reserv. Eng. 1990, 5, 609–616. [Google Scholar] [CrossRef]

- Fassihi, M.R.; Brigham, W.E.; Ramey, H.J. Reaction kinetics of in-situ combustion: Part 1—Observations. Soc. Pet. Eng. J. 1984, 24, 399–407. [Google Scholar] [CrossRef]

- Chavez, M.-L.R.; Glatz, G.; Clemens, T.; Kovscek, A. Near-wellbore and reservoir effects in in-situ combustion. Soc. Pet. Eng. Reserv. Eval. Eng. 2016, 20, 698–707. [Google Scholar] [CrossRef]

- Khansari, Z.; Kapadia, P.; Mahinpey, N.; Gates, I.D. A new reaction model for low temperature oxidation of heavy oil: Experiments and numerical modeling. Energy 2014, 64, 419–428. [Google Scholar] [CrossRef]

- Fassihi, M.R.; Yannimaras, D.V.; Westfall, E.E.; Gillham, T.H. Economics of light oil air injection projects. In Proceedings of the Society of Petroleum Engineers/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 21–24 April 1996; pp. 501–509. [Google Scholar]

- Ranjbar, M.; Pusch, G. Pyrolysis and combustion kinetics of crude oils, asphaltenes and resins in relation to thermal recovery processes. J. Anal. Appl. Pyrolysis 1991, 20, 185–196. [Google Scholar] [CrossRef]

- Ren, S.R.; Greaves, M.; Rathbone, R.R. Air injection LTO Process: An IOR technique for light-oil reservoirs. Soc. Pet. Eng. J. 2002, 7, 90–99. [Google Scholar] [CrossRef]

- Mahinpey, N.; Ambalae, A.; Asghari, K. In situ combustion in enhanced oil recovery (EOR): A review. Chem. Eng. Commun. 2007, 194, 995–1021. [Google Scholar] [CrossRef]

- Babadagli, T. Philosophy of EOR. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 29–31 October 2019. [Google Scholar]

- Hart, A.; Adam, M.; Robinson, J.P.; Rigby, S.P.; Wood, J. Inductive heating assisted-catalytic dehydrogenation of tetralin as a hydrogen source for downhole catalytic upgrading of heavy oil. Top. Catal. 2019, 63, 268–280. [Google Scholar] [CrossRef]

- Ali, S.M.F. Current status of in-situ recovery from the tar sands of Alberta. J. Can. Pet. Technol. 1975, 14, PETSOC-75-01-05. [Google Scholar] [CrossRef]

- Greaves, M.; Ren, S.R.; Rathbone, R.R.; Fishlock, T.; Ireland, R. Improved residual light oil recovery by air injection (LTO process). J. Can. Pet. Technol. 2000, 39, 57–61. [Google Scholar] [CrossRef]

- Pu, W.; Zhao, S.; Hu, L.; Varfolomeev, M.A.; Yuan, C.; Wang, L.; Rodionov, N.O. Thermal effect caused by low temperature oxidation of heavy crude oil and its in-situ combustion behavior. J. Pet. Sci. Eng. 2020, 184, 106521. [Google Scholar] [CrossRef]

- Bu, X.; Ma, W.; Li, H. Geothermal energy production utilizing abandoned oil and gas wells. Renew. Energy 2012, 41, 80–85. [Google Scholar] [CrossRef]

- Li, K.; Zhang, L. Exceptional enhanced geothermal systems from oil and gas reservoirs. In Proceedings of the Thirty-Third Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 28–30 January 2008. [Google Scholar]

- Moss, J.T.; White, P.D.; McNiel, J.S. In situ combustion process—Results of a five-well field experiment in Southern Oklahoma. Trans. AIME 1959, 216, 55–64. [Google Scholar] [CrossRef]

- Farquharson, R.G.; Thornton, R.W. Lessons from Eyehill. J. Can. Pet. Technol. 1986, 25, 47–53. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2018—Analysis; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Tennyson, M.E. Growth history of oil reserves in major california oil fields during the twentieth century. In Geologic, Engineering, and Assessment Studies of Reserve Growth; USGS: Reston, VA, USA, 2005; p. 5. [Google Scholar]

- Fassihi, M.R.; Yannimaras, D.V.; Kumar, V.K. Estimation of recovery factor in light-oil air-injection projects. Soc. Pet. Eng. Reserv. Eng. 1997, 12, 173–178. [Google Scholar] [CrossRef]

- Struna, S.M.; Poettmann, F.H. In-situ combustion in the Lower Hospah Formation, McKinley County, New Mexico. Soc. Pet. Eng. Reserv. Eng. 1988, 3, 440–448. [Google Scholar] [CrossRef]

- Clark, G.A.; Jones, R.G.; Kinney, W.L.; Schilson, R.E.; Surkalo, H.; Wilson, R.S. The fry in situ combustion test-field operations. J. Pet. Technol. 1965, 17, 343–347. [Google Scholar] [CrossRef]

- Earlougher, R.C.; Galloway, J.R.; Parsons, R.W. Performance of the Fry in-situ combustion project. J. Pet. Technol. 1970, 22, 551–557. [Google Scholar] [CrossRef]

- Hewitt, C.H.; Morgan, J.T. The Fry in situ combustion test-reservoir characteristics. J. Pet. Technol. 1965, 17, 337–342. [Google Scholar] [CrossRef]

- Clark, G.A.; Jones, R.G.; Kinney, W.L.; Schilson, R.E.; Surkalo, H.; Wilson, R.S. The fry in situ combustion test-performance. J. Pet. Technol. 1965, 17, 348–353. [Google Scholar] [CrossRef]

- Turta, A.; Kapadia, P.; Gadelle, C. THAI process: Determination of the quality of burning from gas composition taking into account the coke gasification and water-gas shift reactions. J. Pet. Sci. Eng. 2020, 187, 106638. [Google Scholar] [CrossRef]

- Abu, I.I.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G.; Mallory, D.G.; Pereira Almao, P.; Carbognani Ortega, L. Upgrading of Athabasca bitumen using supported catalyst in conjunction with in-situ combustion. J. Can. Pet. Technol. 2015, 54, 220–232. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, T.; Xie, Q.; Liu, W.; Wang, L.; Yang, D. Experimental evaluation of live oil oxidation together with its physical properties during air injection in a tight oil reservoir. Fuel 2021, 283. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Hower, J.C.; Hu, S. Mineralogical and geochemical characteristics of pyrometamorphic rocks induced by coal fires in Junggar Basin, Xinjiang, China. J. Geochem. Explor. 2020, 213, 106511. [Google Scholar] [CrossRef]

- Yao, J.; Li, G.; Wu, J. Application of In-situ combustion for heavy oil production in China: A Review. J. Oil Gas Petrochem. Sci. 2018, 1, 69–72. [Google Scholar] [CrossRef]

- Al-Mahasneh, M.A. Toe-to-heel air injection in-situ combustion process: Case study from the Azraq Basin, Jordan. Rud.-Geološko-Naft. Zb. 2020, 35, 77–84. [Google Scholar] [CrossRef]

- Turta, A.T.; Pantazi, I.G. Development of the in-situ combustion process on an industrial scale at Videle Field, Rumania. Soc. Pet. Eng. Reserv. Eng. 1986, 1, 556–564. [Google Scholar] [CrossRef]

- Adabala, D.; Ray, S.P.; Gupta, P.K. In-situ combustion technique to enhance heavy oil recovery at Mehsana, ONGC—A success story. In Proceedings of the 15th SPE Middle East Oil & Gas Show and Conference, Sanabis, Bahrain, 11–14 March 2007. [Google Scholar]

- Dayal, H.S.; Bhushan, B.V.; Mitra, S.; Pandey, V.; Bhandari, A.C.; Dwivedi, M.M. Simulation of in-situ combustion process in Balol Pilot. In Proceedings of the PE Oil and Gas India Conference and Exhibition, Mumbai, India, 28–30 March 2012. [Google Scholar]

- Horne, J.; Bousaid, I.; Dore, T.L.; Smith, L.B. Initiation of an in-situ combustion project in a thin oil column underlain by water. J. Pet. Technol. 1982, 34, 2233–2243. [Google Scholar] [CrossRef]

- Widmyer, R.H.; Howard, C.E.; Fontaine, M.F.; Haynes, S. The Charco Redondo thermal recovery pilot. J. Pet. Technol. 1977, 29, 1522–1532. [Google Scholar] [CrossRef]

- Tzanco, E.T.; Moore, G.R.; Good, W.K. Combustion performance in the Countess project. In Proceedings of the SPE 69th Annual Technical Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994. [Google Scholar]

- Gjini, D.; Buzi, X.; Mastmann, M.; Tare, S. Experience with cyclic in situ combustion in Albania. In Proceedings of the CSPG and Petroleum Society Joint Convention, Digging Deeper, Finding a Better Bottom Line, Calgary, AB, Canada, 14–18 June 1999. [Google Scholar]

- Choquette, S.P.; Krishnaswamy, S.; Northrop, P.S.; Edwards, J.T.; Hooman, L.; Bret, R.; Morrow, D. Esperson Dome oxygen combustion pilot test: Postburn coring results. Soc. Pet. Eng. Reserv. Eng. 1993, 8, 85–93. [Google Scholar] [CrossRef]

- Hvizdos, L.J.; Howard, J.V.; Roberts, G.W. Enhanced oil recovery through oxygen-enriched in-situ combustion: Test results from the Forest Hill Field in Texas. J. Pet. Technol. 1983, 35, 1061–1070. [Google Scholar] [CrossRef]

- Ostapovich, E.; Ross, M.F. Fosterton Northwest: Post in-situ combustion corehole analysis. In Proceedings of the International Thermal Operations Symposium, Bakersfield, CA, USA, 7–8 February 1991. [Google Scholar]

- Buchwald, R.W.; Hardy, W.C.; Neinast, G.S. Case histories of three in-situ combustion projects. J. Pet. Technol. 1973, 25, 784–792. [Google Scholar] [CrossRef]

- Casey, T.J. A field test of the in-situ combustion process in a near-depleted water drive reservoir. J. Pet. Technol. 1971, 23, 153–160. [Google Scholar] [CrossRef]

- Fassihi, M.R.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. Safety considerations for high-pressure air injection into light-oil reservoirs and performance of the holt sand unit project. In Proceedings of the Society of Petroleum Engineers Improved Oil Recovery Symposium, Tulsa, OK, USA, 3 January 2016; pp. 197–206. [Google Scholar]

- Byl, M.L.; Moore, R.G.; Moore, M.G. Field observations of in-situ combustion in a waterflooded reservoir in the Kinsella field. J. Can. Pet. Technol. 1993, 32, PETSOC-93-07-03. [Google Scholar] [CrossRef]

- Teng, L.; Song, H.; Zhang, S.; Wu, F.; Xu, D.; Gong, Y.; Jiang, Z.; Gao, H.; Wang, C.; Zhong, L. Investigation on in-situ combustion in D66, a multilayered heavy oil reservoir, liaohe oilfield. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 October 2017. [Google Scholar]

- Gutiérrez, D.; Ursenbach, M.G.; Moore, R.G.; Mehta, S.A. Oil recovery from thin heavy-oil reservoirs: The case of the combined-thermal-drive pilot in the Morgan Field. J. Can. Pet. Technol. 2013, 52, 120–130. [Google Scholar] [CrossRef]

- Supronovich, P.; Bland, L.H.R.; Ali, S.M.F. Design and operation of the Murphy Silverdale wet in situ combustion pilot. In Proceedings of the 32nd Annual Technical Meeting of the Petroleum Society of CIM Being Held in Conjunction with the 83rd Annual General Meeting of CIM, Calgary, AB, Canada, 3–6 May 1981. [Google Scholar]

- Gates, C.F.; Jung, K.D.; Surface, R.A. In-situ combustion in the Tulare Formation, South Belridge Field, Kern County, California. J. Pet. Technol. 1978, 30, 799–806. [Google Scholar] [CrossRef]

- Cadelle, C.P.; Burger, J.G.; Bardon, C.P.; Machedon, V.; Carcoana, A.; Petcovici, V. Heavy-oil recovery by in-situ combustion—Two field cases in Rumania. J. Pet. Technol. 1981, 33, 2057–2066. [Google Scholar] [CrossRef]

- Johnson, L.A.; Fahy, L.J.; Romanowski, L.J.; Barbour, R.V.; Thomas, K.P. An echoing in-situ combustion oil recovery project in a Utah tar sand. J. Pet. Technol. 1980, 32, 295–305. [Google Scholar] [CrossRef]

- Thornton, B.; Hassan, D.; Eubank, J. Horizontal well cyclic combustion, Wabasca air injection pilot. J. Can. Pet. Technol. 1996, 35, 40–44. [Google Scholar] [CrossRef]

- Huffman, G.A.; Benton, J.P.; El-Messidi, A.E.; Riley, K.M. Pressure maintenance by in-situ combustion, West Heidelberg Unit, Jasper County, Mississippi. J. Pet. Technol. 1983, 35, 1877–1883. [Google Scholar] [CrossRef]

- Strazzi, A.; Trevisan, O.V. Catalytic effect of metallic additives on in-situ combustion of two Brazilian medium and heavy oils. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Maracaibo, Venezuela, 21–23 May 2014. [Google Scholar]

- Fadaei, H.; Castanier, L.; Kamp, A.M.M.; Debenest, G.; Quintard, M.; Renard, G. Experimental and numerical analysis of in-situ combustion in a fractured core. Soc. Pet. Eng. J. 2011, 16, 358–373. [Google Scholar] [CrossRef]

- Greaves, M.; Dong, L.L.; Rigby, S.P. Simulation study of the toe-to-heel air injection three-dimensional combustion cell experiment and effects in the mobile oil zone. Energy Fuels 2012, 26, 1656–1669. [Google Scholar] [CrossRef]

- Gutiérrez, D.; Moore, R.G.; Ursenbach, M.G.; Mehta, S.A. The ABCs of in-situ-combustion simulations: From laboratory experiments to field scale. In Proceedings of the Canadian Unconventional Resources Conference, Calgary, AB, Canada, 7 March 2012; pp. 256–267. [Google Scholar]

- Nissen, A.; Zhu, Z.; Kovscek, A.; Castanier, L.; Gerritsen, M. Upscaling kinetics for field-scale in-situ-combustion simulation. Soc. Pet. Eng. Reserv. Eval. Eng. 2015, 18, 158–170. [Google Scholar] [CrossRef]

- Belgrave, J.D.M.; Gordon Moore, R.; Bennion, D.W. The thermal behavior of vertically-operated near-adiabatic in-situ combustion tubes. J. Pet. Sci. Eng. 1990, 5, 51–65. [Google Scholar] [CrossRef]

- Hunt, J.M. Petroleum Geochemistry and Geology, 2nd ed.; W.H. Freeman: New York, NY, USA, 1996. [Google Scholar]

- Tissot, B.P.; Welte, D.H. Petroleum Formation and Occurrence; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- Abu-Khamsin, S.A.; Brigham, W.E.; Ramey, H.J. Reaction kinetics of fuel formation for in-situ combustion. Soc. Pet. Eng. Reserv. Eng. 1988, 3, 1308–1316. [Google Scholar] [CrossRef]

- Hascakir, B.; Ross, C.M.; Castanier, L.M.; Kovscek, A.R. Fuel formation during in-situ combustion of heavy oil. In Proceedings of the Society of Petroleum Engineers Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011; pp. 2911–2924. [Google Scholar]

- Berna, H.; Ross, C.M.; Castanier, L.M.; Kovscek, A.R. Fuel formation and conversion during in-situ combustion of crude oil. SPE J. 2013, 18, 1217–1228. [Google Scholar] [CrossRef]

- Moore, R.G.; Ursenbach, M.; Ursenbach, D.W. In situ combustion tests on Eyehill Cummings reservoir. J. Can. Pet. Technol. 1990, 29. [Google Scholar] [CrossRef]

- Hansel, J.G.; Benning, M.A.; Fernbacher, J.M. Oxygen in-situ combustion for oil recovery: Combustion tube tests. J. Pet. Technol. 1984, 36, 1139–1144. [Google Scholar] [CrossRef]

- Ismail, N.B.; Hascakir, B. Impact of asphaltenes and clay interaction on in-situ combustion performance. Fuel 2020, 268, 117358. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, C.; Yang, F.; Heng, M.; Shao, P.; Wang, Y. Influence of temperature field on rock and heavy components variation during in-situ combustion process. Fuel 2018, 230, 244–257. [Google Scholar] [CrossRef]

- Tzanco, E.T.; Moore, R.G.; Belgrave, J.D.M.; Ursenbach, M.G. Laboratory combustion behaviour of Countess B light oil. J. Can. Pet. Technol. 1991, 30, 43–51. [Google Scholar] [CrossRef]

- Vossoughi, S.; Bartlett, G.W.; Willhite, G.P. Prediction of in-situ combustion process variables by use of TGA/DSC techniques and the effect of sand-grain specific surface area on the process. Soc. Pet. Eng. J. 1985, 25, 656–664. [Google Scholar] [CrossRef]

- Murugan, P.; Mahinpey, N.; Mani, T.; Freitag, N. Pyrolysis and combustion kinetics of Fosterton oil using thermogravimetric analysis. Fuel 2009, 88, 1708–1713. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Mallory, D.G.; Moore, R.G.; Ursenbach, M.G.; Mehta, S.A. Vapor-phase combustion in accelerating rate calorimetry for air-injection enhanced-oil-recovery processes. Soc. Pet. Eng. Reserv. Eval. Eng. 2016, 20, 669–680. [Google Scholar] [CrossRef]

- Bagci, S.; Kok, M.V. In-situ combustion laboratory studies of Turkish heavy oil reservoirs. Fuel Processing Technol. 2001, 74, 65–79. [Google Scholar] [CrossRef]

- Li, J.; Mehta, S.A.; Moore, R.G.; Ursenbach, M.G. New insights into oxidation behaviours of crude oils. J. Can. Pet. Technol. 2009, 48, 12–15. [Google Scholar] [CrossRef]

- Greaves, M.; Bentaher, A.H. Exothermicity characteristics of Wolf Lake heavy oil, Athabasca tar sand and Clair medium heavy oil. J. Can. Pet. Technol. 2007, 46, 16–19. [Google Scholar] [CrossRef]

- Deniz-Paker, M.; Cinar, M. Investigation of the combustion characteristics of Bati Raman oil with sand. J. Pet. Sci. Eng. 2017, 157, 793–805. [Google Scholar] [CrossRef]

- Kok, M.V.; Karacan, C.O. Behavior and effect of SARA fractions of oil during combustion. Soc. Pet. Eng. Reserv. Eval. Eng. 2000, 3, 380–385. [Google Scholar] [CrossRef]

- Penberthy, W.L.; Ramey, H.J. Design and operation of laboratory combustion tubes. Soc. Pet. Eng. J. 1966, 6, 183–198. [Google Scholar] [CrossRef]

- Kök, M.V.; Karacan, Ö.; Pamir, R. Kinetic analysis of oxidation behavior of crude oil SARA constituents. Energy Fuels 1998, 12, 580–588. [Google Scholar] [CrossRef]

- Zhao, S.; Pu, W.; Yuan, C.; Peng, X.; Zhang, J.; Wang, L.; Emelianov, D.A. Thermal behavior and kinetic triplets of heavy crude oil and its SARA fractions during combustion by high-pressure differential scanning calorimetry. Energy Fuels 2019, 33, 3176–3186. [Google Scholar] [CrossRef]

- Shahani, G.H.; Hansel, J.G. Oxygen fireflooding: Combustion tube tests with light, medium, and heavy crude oils. Soc. Pet. Eng. Reserv. Eng. 1987, 2, 583–590. [Google Scholar] [CrossRef]

- Liu, D.; Tang, J.; Zheng, R.; Song, Q. Influence of steam on the coking characteristics of heavy oil during in situ combustion. Fuel 2020, 264. [Google Scholar] [CrossRef]

- Yannimaras, D.V.; Tiffin, D.L. Screening of oils for in-situ combustion at reservoir conditions by accelerating-rate calorimetry. Soc. Pet. Eng. Reserv. Eng. 1995, 10, 36–39. [Google Scholar] [CrossRef]

- Ren, Y.; Freitag, N.P.; Mahinpey, N. A simple kinetic model for coke combustion during an in-situ combustion (ISC) process. J. Can. Pet. Technol. 2007, 46, 47–52. [Google Scholar] [CrossRef]

- Li, Y.-B.; Chen, Y.; Pu, W.-F.; Gao, H.; Bai, B. Experimental investigation into the oxidative characteristics of Tahe heavy crude oil. Fuel 2017, 209, 194–202. [Google Scholar] [CrossRef]

- Lie, K.A. An Introduction to Reservoir Simulation Using MATLAB/GNU Octave: User Guide for the Matlab Reservoir Simulation Toolbox (MRST); Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Li, Y.-B.; Zhang, Y.-Q.; Luo, C.; Gao, H.; Li, K.; Xiao, Z.-R.; Wang, Z.-Q.; Pu, W.-F.; Bai, B. The experimental and numerical investigation of in situ re-energization mechanism of urea-assisted steam drive in superficial heavy oil reservoir. Fuel 2019, 249, 188–197. [Google Scholar] [CrossRef]

- Belgrave, J.D.M.; Moore, R.G.; Ursenbach, M.G. Comprehensive kinetic models for the aquathermolysis of heavy oils. J. Can. Pet. Technol. 1997, 36, 38–44. [Google Scholar] [CrossRef]

- Yang, M.; Harding, T.G.; Chen, Z. Field-scale modeling of hybrid steam and in-situ-combustion recovery process in oil-sands reservoirs using dynamic gridding. Soc. Pet. Eng. Reserv. Eval. Eng. 2019, 23, 311–325. [Google Scholar] [CrossRef]

- Cannon, S. 1.4 What is a reservoir model? In Reservoir Modelling—A Practical Guide; John Wiley & Sons: Chichester, UK, 2018. [Google Scholar]

- Greaves, M.; Dong, L.L.L.; Rigby, S.P.P. Validation of toe-to-heel air-injection bitumen recovery using 3d combustion-cell results. Soc. Pet. Eng. Reserv. Eval. Eng. 2012, 15, 72–85. [Google Scholar] [CrossRef]

- Alizadeh, A.; Moore, R.G.; Mehta, R.; Nourozieh, H. Phase behaviour modelling of Athabasca bitumen for in situ combustion applications. Can. J. Chem. Eng. 2019, 98, 404–411. [Google Scholar] [CrossRef]

- Ado, M.R. A detailed approach to up-scaling of the Toe-to-Heel Air Injection (THAI) In-Situ Combustion enhanced heavy oil recovery process. J. Pet. Sci. Eng. 2020, 187, 106740. [Google Scholar] [CrossRef]

- Zhu, Z. Upscaling for field-scale in-situ combustion simulation. In Proceedings of the Society of Petroleum Engineers Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar]

- Lovett, S.; Monmont, F.; Nikiforakis, N. An experimentally-based in-situ combustion model with adaptive meshing. Combust. Flame 2015, 162, 960–977. [Google Scholar] [CrossRef]

- Ado, M.R.; Greaves, M.; Rigby, S.P. Numerical simulation of the impact of geological heterogeneity on performance and safety of THAI heavy oil production process. J. Pet. Sci. Eng. 2019, 173, 1130–1148. [Google Scholar] [CrossRef]

- Belgrave, J.D.M.; Moore, R.G.; Ursenbach, M.G.; Bennion, D.W. A comprehensive approach to in-situ combustion modeling. Soc. Pet. Eng. Adv. Technol. Ser. 1993, 1, 98–107. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Masoumi, M.; Askarinezhad, R. Evolving smart model to predict the combustion front velocity for in situ combustion. Energy Technol. 2015, 3, 128–135. [Google Scholar] [CrossRef]

- Jia, N.; Law, D.H.S.; Naccache, P.; Giddins, M.A. Applicability of kinetic models for in situ combustion processes with different oil types. Nat. Resour. Res. 2016, 26, 37–55. [Google Scholar] [CrossRef]

- Ado, M.R. Predictive capability of field scale kinetics for simulating toe-to-heel air injection heavy oil and bitumen upgrading and production technology. J. Pet. Sci. Eng. 2020, 187, 106843. [Google Scholar] [CrossRef]

- Mahmudi, M.; Sadeghi, M.T. A novel three pseudo-component approach (ThPCA) for thermodynamic description of hydrocarbon-water systems. J. Pet. Explor. Prod. Technol. 2014, 4, 281–289. [Google Scholar] [CrossRef][Green Version]

- Coats, K.H. In-situ combustion model. Soc. Pet. Eng. J. 1980, 20, 533–554. [Google Scholar] [CrossRef]

- Anderson, T.I.; Kovscek, A.R. Analysis and comparison of in-situ combustion chemical reaction models. Fuel 2022, 311, 122599. [Google Scholar] [CrossRef]

- Haydary, J. 13.1 Petroleum assays and blends. In Chemical Process Design and Simulation—Aspen Plus and Aspen HYSYS Applications; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Crookston, R.B.; Culham, W.E.; Chen, W.H. A numerical simulation model for thermal recovery processes. Soc. Pet. Eng. J. 1979, 19, 37–58. [Google Scholar] [CrossRef]

- Rojas, A.A.; Yuan, C.; Emelianov, D.A.; Saifullin, E.R.; Mehrabi-Kalajahi, S.; Varfolomeev, M.A.; Sudakov, V.A.; Lotfullin, B.R.; Shevchenko, D.V.; Ganiev, B.G.; et al. A 3-step reaction model for numerical simulation of in-situ combustion. In Proceedings of the Society of Petroleum Engineers Russian Petroleum Technology Conference, Virtual, 12–15 October 2021. [Google Scholar]

- Kuppe, G.J.M.; Mehta, S.A.; Moore, R.G.; Ursenbach, M.G.; Zalewski, E. Heats of combustion of selected crude oils and their SARA fractions. J. Can. Pet. Technol. 2008, 47, 38–42. [Google Scholar] [CrossRef]

- Sequera, B.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. Numerical simulation of in-situ combustion experiments operated under low temperature conditions. J. Can. Pet. Technol. 2010, 49, 55–64. [Google Scholar] [CrossRef]

- Mercado, D.; Trevisan, O.V. Pseudokinetic model for field-scale simulation of in-situ combustion. Soc. Pet. Eng. Reserv. Eval. Eng. 2016, 20, 161–167. [Google Scholar] [CrossRef]

- Binning, P.J.; Celia, M.A. Pseudokinetics arising from the upscaling of geochemical equilibrium. Water Resour. Res. 2008, 44. [Google Scholar] [CrossRef]

- Couch, E.J.; Rodriguez, H.V. Effects of porosity and permeability on in-situ combustion fuel consumption. In Proceedings of the 45th Annual Fall Meeting of the Society of Petroleum Engineers of AIME, Houston, TX, USA, 4–7 October 1970. [Google Scholar]

- Xia, T.; Greaves, B.; Werfilli, M.S.; Rathbone, R.R. THAI process-effect of oil layer thickness on heavy oil recovery. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 11–13 June 2002. [Google Scholar]

- Akkutlu, I.Y.; Yortsos, Y.C. The effect of heterogeneity on in-situ combustion: Propagation of combustion fronts in layered porous media. Soc. Pet. Eng. J. 2005, 10, 394–404. [Google Scholar] [CrossRef]

- Shojaiepour, M.; Kharrat, R.; Shojaiepour, M.; Hashemi, A. Experimental and simulation study of in-situ combustion process in carbonate fractured porous media. J. Jpn. Pet. Inst. 2014, 57, 208–215. [Google Scholar] [CrossRef][Green Version]

- Galas, C.M.F.; Ejiogu, G.C.; Donnelly, J.K. Fluid and heat movements during in-situ combustion in a channelled reservoir. J. Can. Pet. Technol. 1991, 30, PETSOC-91-03-03. [Google Scholar] [CrossRef]

- Gluyas, J.G.; Swarbrick, R.E. Petroleum Geoscience; Blackwell Publishing: Malden, MA, USA, 2004. [Google Scholar]

- Alvarado, V.; Manrique, E. Enhanced oil recovery: An update review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Moore, R.G.; Laureshen, C.J.; Mehta, S.A.; Ursenbach, M.G. Observations and design considerations for in situ combustion projects. J. Can. Pet. Technol. 1999, 38, 55. [Google Scholar] [CrossRef]

- Aagaard, P.; Jahren, J.S.; Harstad, A.O.; Nilsen, O.; Ramm, M. Formation of grain-coating chlorite in sandstones. Laboratory synthesized vs. natural occurrences. Clay Miner. 2000, 35, 261–269. [Google Scholar] [CrossRef]

- Bloch, S.; Lander, R.H.; Bonnell, L.M. Anomalously high porosity and permeability in deeply buried sandstone reservoirs: Origin and predictability. AAPG 2002, 2, 301–328. [Google Scholar]

- Worden, R.H.; Armitage, P.J.; Butcher, A.; Churchill, J.; Csoma, A.; Hollis, C.; Lander, R.H.; Omma, J. Petroleum reservoir quality prediction: Overview and contrasting approaches from sandstone and carbonate communities. In Reservoir Quality of Clastic and Carbonate Rocks: Analysis, Modelling and Prediction. Special Publication; Armitage, P.J., Butcher, A., Churchill, J., Csoma, A., Hollis, C., Lander, R.H., Omma, J., Worden, R.H., Eds.; Geological Society: London, UK, 2018; Volume 435, pp. 1–31. [Google Scholar]

- Zheng, R.; Liao, G.; You, H.; Song, X.; Song, Q.; Yao, Q. Montmorillonite-catalyzed thermal conversion of low-asphaltene heavy oil and its main components. J. Pet. Sci. Eng. 2020, 187, 106743. [Google Scholar] [CrossRef]

- Ariskina, K.A.; Yuan, C.; Abaas, M.; Emelianov, D.A.; Rodionov, N.; Varfolomeev, M.A. Catalytic effect of clay rocks as natural catalysts on the combustion of heavy oil. Appl. Clay Sci. 2020, 193, 105662. [Google Scholar] [CrossRef]

- Gunter, W.D.; Zhou, Z.; Perkins, E.H. Modelling formation damage caused by kaolinite from 25 to 300°C in the oil sand reservoirs of Alberta. Soc. Pet. Eng. Adv. Technol. Ser. 1994, 2, 206–213. [Google Scholar] [CrossRef]

- Ranjbar, M. Influence of reservoir rock composition on crude oil pyrolysis and combustion. J. Anal. Appl. Pyrolysis 1993, 27, 87–95. [Google Scholar] [CrossRef]

- Pope, C.; Ismail, N.B.; Hascakir, B. Catalytic impact of clays during in-situ combustion. In Proceedings of the Society of Petroleum Engineers Improved Oil Recovery Conference, Tulsa, OK, USA, 31 August–4 September 2020. [Google Scholar]

- Kozlowski, M.L.; Punase, A.; Nasr-El-Din, H.A.; Hascakir, B. The catalytic effect of clay on in-situ combustion performance. In Proceedings of the Society of Petroleum Engineers Latin American and Caribbean Petroleum Engineering Conference, Quit, Ecuador, 18–20 November 2015. [Google Scholar]

- Ado, M.R. Simulation study on the effect of reservoir bottom water on the performance of the THAI in-situ combustion technology for heavy oil/tar sand upgrading and recovery. SN Appl. Sci. 2019, 2, 29. [Google Scholar] [CrossRef]

- Lore, J.S.; Eichhubl, P.; Aydin, A. Alteration and fracturing of siliceous mudstone during in situ combustion, Orcutt field, California. J. Pet. Sci. Eng. 2002, 36, 169–182. [Google Scholar] [CrossRef]

- Greaves, M.; Xia, T.X.; Turta, A.T. Stability of THAI ™ process-theoretical and experimental observations. J. Can. Pet. Technol. 2008, 47, 65–73. [Google Scholar] [CrossRef]

- Kolodny, Y.; Gross, S. Thermal metamorphism by combustion of organic matter: Isotopic and petrological evidence. J. Geol. 1974, 82, 489–506. [Google Scholar] [CrossRef]

- Bentor, Y.K.; Kastner, M. Combustion metamorphism in southern California. Science 1976, 193, 486–488. [Google Scholar] [CrossRef]

- Bentor, Y.K.; Kastner, M.; Perlman, I.; Yellin, Y. Combustion metamorphism of bituminous sediments and the formation of melts of granitic and sedimentary composition. Geochim. Cosmochim. Acta 1981, 45, 2229–2255. [Google Scholar] [CrossRef]

- Cisowski, S.M.; Fuller, M. The generation of magnetic anomalies by combustion metamorphism of sedimentary rock, and its significance to hydrocarbon exploration. Geol. Soc. Am. Bull. 1987, 99, 21–29. [Google Scholar] [CrossRef]

- Perry, C.; Gillott, J.E. Mineralogical transformations as indicators of combustion zone temperatures during in situ combustion. Bull. Can. Pet. Geol. 1982, 30, 34–42. [Google Scholar]

- Arnold, R.; Anderson, R. Metamorphism by combustion of the hydrocarbons in the oil-bearing shale of California. J. Geol. 1907, 15, 750–758. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Pu, W.-F.; Liu, X.-L.; Li, Y.-B.; Varfolomeev, M.A.; Hui, J. A preliminary feasibility analysis of in situ combustion in a deep fractured-cave carbonate heavy oil reservoir. J. Pet. Sci. Eng. 2019, 174, 446–455. [Google Scholar] [CrossRef]

- Mostafavi, V.; Razzaghi, S.; Kharrat, R. Feasibility study of in-situ combustion in carbonate reservoirs. In Proceedings of the 15th SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 11–14 March 2007. [Google Scholar]

- Alpay, O.A. A practical approach to defining reservoir heterogeneity. J. Pet. Technol. 1972, 24, 841–848. [Google Scholar] [CrossRef]

- Moraes, M.A.S.; Surdam, R.C. Diagenetic heterogeneity and reservoir quality: Fluvial, deltaic, and turbiditic sandstone reservoirs, Potiguar and Reconcavo rift basins, Brazil. AAPG 1993, 77, 1142–1158. [Google Scholar] [CrossRef]

- Morad, S.; Al-Ramadan, K.; Ketzer, J.M.; De Ros, L.F. The impact of diagenesis on the heterogeneity of sandstone reservoirs: A review of the role of depositional facies and sequence stratigraphy. AAPG 2010, 94, 1267–1309. [Google Scholar] [CrossRef]

- Greaves, M.; Al-Honi, M. Three-dimensional studies of in-situ combustion-horizontal wells process with reservoir heterogeneities. J. Can. Pet. Technol. 2000, 39, 25–32. [Google Scholar] [CrossRef]

- Awoleke, O.G. An experimental investigation of in-situ combustion in heterogeneous media. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar]

- Pedersen, T.; Bjørlykke, K. Fluid flow in sedimentary basins: Model of pore water flow in a vertical fracture. Basin Res. 1994, 6, 1–16. [Google Scholar] [CrossRef]

- Jia, H.; Liu, P.-G.; Pu, W.-F.; Ma, X.-P.; Zhang, J.; Gan, L. In situ catalytic upgrading of heavy crude oil through low-temperature oxidation. Pet. Sci. 2016, 13, 476–488. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Pu, W.-F.; Li, Y.-B.; Liu, X.-L.; Jin, F.-Y.; Hui, J.; Gong, X.-L.; Guo, C. Novel insight into the viscosity-temperature characteristic by the comparison of Tahe ordinary- and ultra- heavy oils. Energy Fuels 2018, 32, 12308–12318. [Google Scholar] [CrossRef]

- Kok, M.V.; Keskin, C. Comparative combustion kinetics for in situ combustion process. Thermochim. Acta 2001, 369, 143–147. [Google Scholar] [CrossRef]

- Moore, R.G.; Laureshen, C.J.; Belgrave, J.D.M.; Ursenbach, M.G.; Mehta, S.A. In situ combustion in Canadian heavy oil reservoirs. Fuel 1995, 74, 1169–1175. [Google Scholar] [CrossRef]

- Freitag, N.P.; Exelby, D.R. Heavy oil production by in-situ combustion—Distinguishing the effects of the steam and fire fronts. J. Can. Pet. Technol. 1998, 37, 25–32. [Google Scholar] [CrossRef]

- Al-Saffar, H.B.; Hasanin, H.; Price, D.; Hughes, R. Oxidation reactions of a light crude oil and Its SARA fractions in consolidated cores. Energy Fuels 2000, 15, 182–188. [Google Scholar] [CrossRef]

- Jia, N.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. Kinetic modelling of thermal cracking and low temperature oxidation reactions. J. Can. Pet. Technol. 2006, 45, 21–28. [Google Scholar] [CrossRef]

- Zhao, S.; Pu, W.; Varfolomeev, M.A.; Liu, Y.; Liu, Z. Oxidation characteristics of heavy oil and its SARA fractions during combustion using TG-FTIR. J. Pet. Sci. Eng. 2020, 192, 107331. [Google Scholar] [CrossRef]

- Zhao, S.; Pu, W.; Varfolomeev, M.A.; Ren, H.; Kenjiang, A.; Emelianov, D.A. Evaluation of heat release caused by low-temperature oxidation of heavy oil and its SARA fractions under isothermal conditions. Thermochim. Acta 2020, 690, 178690. [Google Scholar] [CrossRef]

- Glaso, O. Generalized pressure-volume-temperature correlations. J. Pet. Technol. 1980, 32, 785–795. [Google Scholar] [CrossRef]

- Standing, M.B. A pressure-volume-temperature correlation for mixtures of California oils and gases. In Drilling and Production Practice; The American Petroleum Institute (API): Washington, DC, USA, 1947; pp. 275–287. [Google Scholar]

- Ng, J.T.H.; Egbogah, E.O. An improved temperature-viscosity correlation for crude oil systems. In Proceedings of the 34th Annual Technical Meeting of the Petroleum Society, Banff, AB, Canada, 10–13 May 1983. [Google Scholar]

- Beggs, H.D.; Robinson, J.R. Estimating the viscosity of crude oil systems. J. Pet. Technol. 1975, 27, 1140–1141. [Google Scholar] [CrossRef]

- Ado, M.R. Improving heavy oil production rates in THAI process using wells configured in a staggered line drive (SLD) instead of in a direct line drive (DLD) configuration: Detailed simulation investigations. J. Pet. Explor. Prod. Technol. 2021, 11, 4117–4130. [Google Scholar] [CrossRef]

- Greaves, M.; Tuwil, A.A.; Bagci, A.S. Horizontal producer wells in in situ combustion (ISC) processes. J. Can. Pet. Technol. 1993, 32, PETSOC-93-04-04. [Google Scholar] [CrossRef]

- Greaves, M.; Al-Shamali, O. In-situ combustion (ISC) process using horizontal wells. J. Can. Pet. Technol. 1996, 35, 49–55. [Google Scholar] [CrossRef]

- Greaves, M.; Saghr, A.M.; Xia, T.X.; Turtar, A.; Ayasse, C. THAI—New air injection technology for heavy oil recovery and in situ upgrading. J. Can. Pet. Technol. 2001, 40, 38–47. [Google Scholar] [CrossRef]

- Guan, W.; Xi, C.; Chen, L.; Muhetar; Gao, C.; Tang, J.; Li, Q. Field control technologies of combustion assisted gravity drainage (CAGD). Pet. Explor. Dev. 2017, 44, 797–804. [Google Scholar] [CrossRef]

- Rahnema, H.; Barrufet, M.; Mamora, D.D. Combustion assisted gravity drainage—Experimental and simulation results of a promising in-situ combustion technology to recover extra-heavy oil. J. Pet. Sci. Eng. 2017, 154, 513–520. [Google Scholar] [CrossRef]

- Ayasse, C.; Bloomer, C.; Lyngberg, E.; Boddy, W.; Donnelly, J.; Greaves, M. First field pilot of the THAI process. In Proceedings of the Petroleum Society’s 6th Canadian International Petroleum Conference Calgary, Alberta, Canada, 7–9 June 2005. [Google Scholar]

- Zhao, R.; Yu, S.; Yang, J.; Heng, M.; Zhang, C.; Wu, Y.; Zhang, J.; Yue, X.-A. Optimization of well spacing to achieve a stable combustion during the THAI process. Energy 2018, 151, 467–477. [Google Scholar] [CrossRef]

- Ado, M.R. Comparisons of predictive ability of THAI in situ combustion process models with pre-defined fuel against that having fuel deposited based on Arrhenius kinetics parameters. J. Pet. Sci. Eng. 2022, 208, 109716. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Storey, B.M.; Worden, R.H.; McNamara, D.D. The Geoscience of In-Situ Combustion and High-Pressure Air Injection. Geosciences 2022, 12, 340. https://doi.org/10.3390/geosciences12090340

Storey BM, Worden RH, McNamara DD. The Geoscience of In-Situ Combustion and High-Pressure Air Injection. Geosciences. 2022; 12(9):340. https://doi.org/10.3390/geosciences12090340

Chicago/Turabian StyleStorey, Benjamin M., Richard H. Worden, and David D. McNamara. 2022. "The Geoscience of In-Situ Combustion and High-Pressure Air Injection" Geosciences 12, no. 9: 340. https://doi.org/10.3390/geosciences12090340

APA StyleStorey, B. M., Worden, R. H., & McNamara, D. D. (2022). The Geoscience of In-Situ Combustion and High-Pressure Air Injection. Geosciences, 12(9), 340. https://doi.org/10.3390/geosciences12090340