1. Introduction

The MEET project is a Multidisciplinary and multi-context demonstration of Enhanced Geothermal Systems exploration and Exploitation Techniques and potentials, which received funding from the European Commission in the framework of the Horizon 2020 program. During the four years of the project, two main types of exploitations were investigated: Enhanced Geothermal Systems (EGS) and oil-to-geothermal conversion or co-production. The following topics were addressed: the upscaling of thermal power production and optimized operation of EGS plants (papers [

1,

2,

3,

4,

5]); variscan geothermal reservoirs in granitic and metamorphic rocks (papers [

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17]); and technical, economic and environmental assessment for oil-to-geothermal fields and EGS integration into energy systems (papers [

18,

19,

20]). These 20 papers give an overview of some of the work performed in the MEET project, but they are not exhaustive of all the results obtained in this frame. Additional results are available at

https://zenodo.org/communities/eu_project_meet/ (accessed on 1 September 2022). The MEET Project (

Figure 1) received funding by the European Commission in the framework of the H2020 Program (Grant Agreement No. 792037) for a

Multidisciplinary and multi-context demonstration of

Enhanced Geothermal Systems exploration and

Exploitation

Techniques and potentials.

The MEET project dealt with the gains in geothermal energy that can be achieved using a variety of techniques, depending on the geological setting of the underground. Among the list of exploitation concepts, Enhanced Geothermal Systems (EGS) are particularly interesting, as their application is little dependent on the underground setting, allowing, in turn, for a large geographical deployment and market penetration in Europe. The challenges of EGS are multiple in terms of investment costs, the testing of novel reservoir exploitation approaches with an inherent risk of induced seismicity and the presence of aggressive geothermal brines that can damage infrastructures due to scaling and corrosion. The use of co-produced hot brines in mature oil fields is another target of the project.

MEET aimed at 1- gathering knowledge of EGS heat and power production in various geological settings; 2- helping increase heat production from existing plants and convert oil wells into geothermal wells; 3- enhancing heat-to-power conversion at low flow (<10 l/s) and/or low temperature (60–90 °C) by using smart mobile Organic Rankine Cycle (ORC) units; and 4- replicating the technology by promoting the penetration of EGS power and/or heat plants.

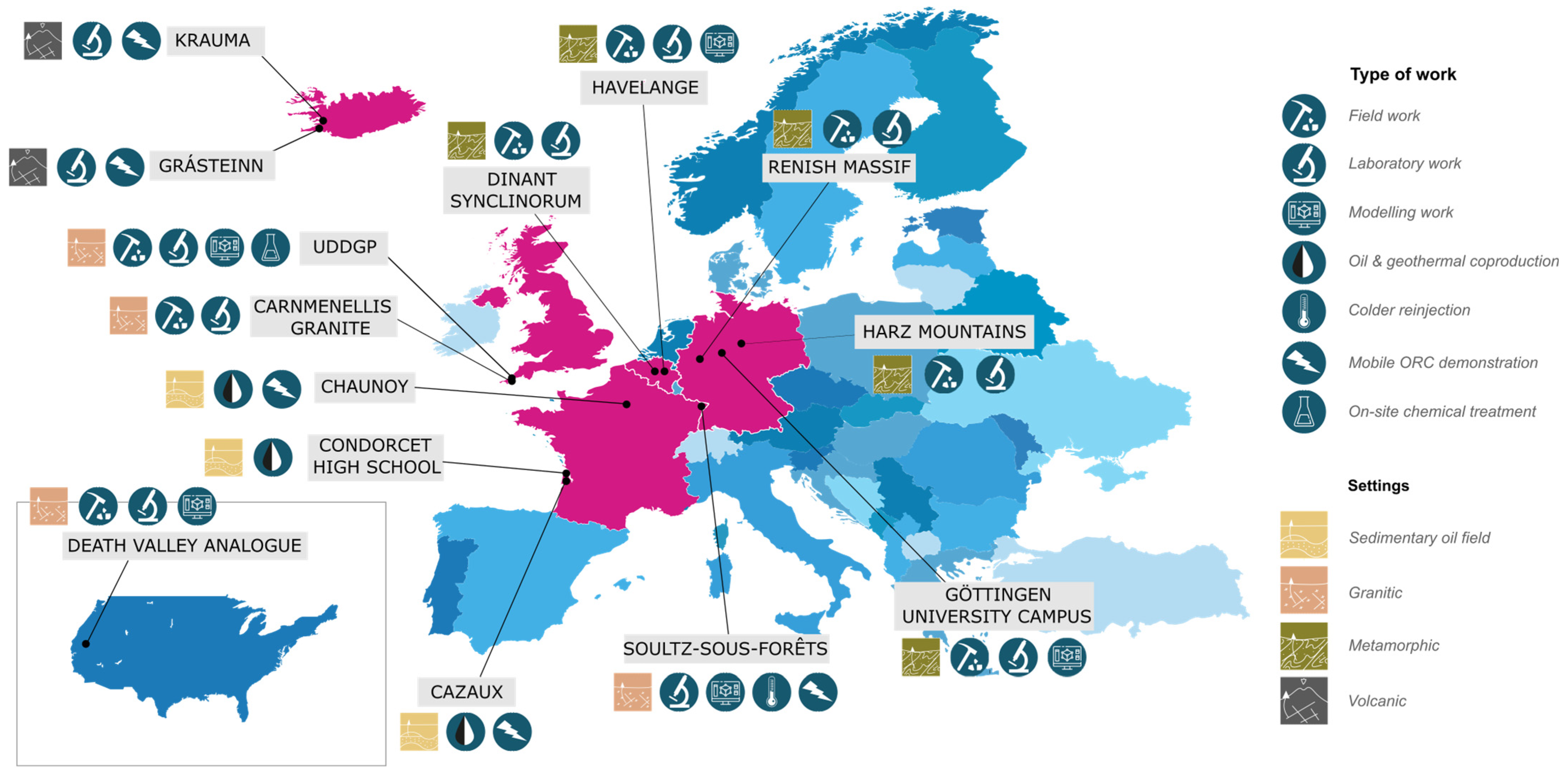

In order to reach those objectives, the MEET project mainly addressed the need to capitalize on the exploitation of the widest range of fluid temperature in oil and geothermal fields (from 90 °C to 160 °C) and apply EGS in different geological settings (sedimentary basins and basements affected or not by post extensional tectonics). The approach was based on a combination of research and demonstration activities. It relied on the study of demonstration sites (

Figure 2), either at the

exploration stage (United Downs Deep Geothermal Project (UDDGP)—UK; Göttingen University campus––Germany; Havelange—Belgium) by studying

analogues (e.g., Death Valley—CA, USA; Carnmenellis granite and Cornubian batholith—UK; Dinant synclinorium—Belgium; Rhenish massif and Harz mountains—Germany) or the

exploitation stage (e.g., Soultz-sous-Forêts EGS plant—France; Chaunoy and Cazaux oil fields—France; Condorcet High School—France; Grásteinn farm and Krauma spa—Iceland).

Various geological settings are represented: volcanic areas (Krauma and Grásteinn), sedimentary basins (Chaunoy, Condorcet High School and Cazaux), granitic basements (Soultz-sous-Forêts; UDDGP; Death Valley analogue) and metamorphic basements (Havelange, Göttingen University campus, Harz Mountains and Rhenish Massif analogues).

After four years of transdisciplinary work, this Special Issue compiles some of the most recent geoscience results obtained by the 16 academic and industrial partners (ES-Géothermie (coordinator), UniLaSalle, GIM-Labs, CY Cergy Paris Université, Technische Universität Darmstadt, Universitätsenergie Göttingen GmbH, Georg-August-Universität Göttingen, Vermilion, Enogia, GFZ, Febus-Optics, University of Zagreb—Faculty of Electrical Engineering and Computing, ICETEC, Geological Survey of Belgium, GeoThermal Engineering and Benkei) coming from 5 countries (Belgium, Croatia, France, Germany and Iceland) that joined their efforts for the development of geothermal energy across Europe. The MEET project was organised in dedicated work-packages (WP) through the technical themes that were developed during the project: upscaling of thermal power production and optimized operation of EGS plants (WP3); enhancing and/or converting petroleum sedimentary basins for geothermal electricity and thermal power production (WP4); variscan geothermal reservoirs (granitic and metamorphic rocks; WP5); demonstration of electricity and thermal power generation (WP6); and economic and environmental assessment for EGS integration into energy systems (WP7). This

Geosciences Special Issue is mostly presenting the geoscientific work performed within MEET. WP3 and WP5 have a dedicated section, whereas WP4, 6 and 7 are grouped in the section “Technical, economic and environmental assessment for oil to geothermal fields and EGS integration into energy systems”. Other works performed within the MEET project can be found on the Zenodo platform:

https://zenodo.org/communities/eu_project_meet/ (accessed on 1 September 2022).

The geoscience work performed in the MEET project was based on geological field work on high-quality analogues; laboratory experiments; advanced reservoir modelling; specific demonstration activities such as chemical stimulation, colder reinjection or innovative monitoring of deep geothermal wells; and production of electrical power via small-scale binary technology tested in the various geological contexts in Europe shown in

Figure 2.

2. Upscaling of Thermal Power Production and Optimized Operation of EGS Plants

The Soultz-sous-Forêts demonstration site (called Soultz in the following) has been operated since 2016 for the production of electricity from a granitic basement. The temperature of the brine produced at the well head of GPK-2 drill hole is around 160 °C. It is currently reinjected in the ground at a temperature close to 70 °C.

In those operation conditions, minerals precipitate during the lowering of the temperature into the surface installations, producing deposits called scales. Scales have a negative impact on the power plant in lowering the electricity production and inducing specific waste management issues. Thus, scales have to be thoroughly characterized [

1] and their deposition process modelled [

2] to control scaling processes in surface installations. In order to increase energy output, a small-scale heat exchanger prototype, called SHEx in the following, has been tested for 3 months in order to lower the reinjection temperature down to 40 °C. The SHEx is of tubular type, made of an entrance, an exit, water boxes at each end, and tubes made of several alloys and metals in between. The lowering of the temperature of reinjection might have an impact on the geothermal reservoir ([

3,

4]) while the structure of the reservoir ([

3,

5]) is another key parameter to be considered for the sustainability of the EGS.

Ledésert et al. [

1], in “Scaling in a Geothermal Heat Exchanger at Soultz-Sous-Forêts (Upper Rhine Graben, France): A XRD and SEM-EDS Characterization of Sulfide Precipitates”, studied the sulfide scales that deposited in the SHEx by using X-Ray Diffraction (XRD) and a Scanning Electron Microscope (SEM) coupled with an Energy-Dispersive Spectrometer (EDS). The effect of the flow regime on the shape of sulfide crystals was questioned, as well as that of the lowering of temperature on the thickness of the deposit. The scales deposited in the SHEx were compared to scales deposited in normal industrial conditions.

In “Thermodynamic and Kinetic Modelling of Scales Formation at the Soultz-sous-Forêts Geothermal Power Plant”, Kunan et al. [

2] performed the thermodynamic and kinetic modelling of scale deposition by using Phreeqc and the Thermoddem database thanks to the data on the chemical elements, minerals, and gas it contains. The model generated a rough prediction of the scale formation when operating the plant with sulfate scales inhibitors at the Soultz geothermal plant and showed only a small deviation between simulated results and the actual case.

“Soultz-sous-Forêts Geothermal Reservoir: Structural Model Update and Thermo-Hydraulic Numerical Simulations Based on Three Years of Operation Data” by Baujard et al. [

3] presents a thermo-hydraulic numerical simulation to better constrain the parameters that govern the functioning of the Soultz granitic exchanger at depth when colder reinjection is performed. In this article, a 3D hydrothermal study was performed in order to evaluate the spreading of the thermal front during colder reinjection and its impact on production temperature. The fault scale was investigated first, integrating pre-existing models from seismic profiles, seismic cloud structure and borehole image logs calibrated with well data. Secondly, this geometrical model was adapted to be able to run hydrothermal simulations. In a third step, a 3D hydrothermal model was built based on the structural model. After calibration, the effect of colder reinjection on the production temperature was calculated. Finally, the accuracy of the structural model on which the simulations are based is discussed and an update of the structural model is proposed in order to better reproduce the observations.

Mahmoodpour et al., [

4] in “Hydro-Thermal Modeling for Geothermal Energy Extraction from Soultz-sous-Forêts, France”, propose another hydro-thermal modelling for geothermal energy extraction from Soultz, based on structures identified in [

3], at temperature lower than the current 70 °C fluid reinjection temperature. Two injection-production rate scenarios were modelled, and the drop in the production wellhead temperature for 100 years of operation was quantified. For each scenario, reinjection temperatures of 40℃, 50℃ and 60℃ were chosen and compared with the 70 °C current reinjection condition.

In “Sensitivity Analysis of FWI Applied to OVSP Synthetic Data for Fault Detection and Characterization in Crystalline Rocks”, Abdelfettah and Barnes [

5] used the Full Wave Inversion (FWI) method to detect, delineate and better characterize faults in the granitic geothermal reservoir, from Multi-Offset Vertical Seismic Profile (OVSP) data in order to further characterize the geothermal resource at Soultz. They made several sensitivity studies to show the dip and thickness of a fault that can be imaged by FWI, even in the presence of additive Gaussian noise. Their work was applied to the Soultz site to help a better characterization of the fracture network.

4. Technical, Economic and Environmental Assessment for Oil to Geothermal Fields and EGS Integration into Energy Systems

Numerous oil fields are approaching the end of their lifetime and have great geothermal potential considering temperature and water cut. EGS is also a promising source of energy. However, electricity and thermal power generation is threatened by technical issues [

18], and a proper economic evaluation of different scenarios is crucial for further implementation of these solution at larger scale [

19,

20].

In “Study of Corrosion Resistance Properties of Heat Exchanger Metals in Two Different Geothermal Environments”, Davíðsdóttir et al. [

18] investigated the corrosion resistance of different alloy candidates for heat exchangers. They exposed in situ corrosion-resistant alloy coupon samples 316L, 254SMO, Inconel 625 and titanium grade 2 at two locations and geological settings (Triassic clastic sediments, Paris Basin, France; volcanic setting, Iceland). Coupons were exposed for four months at the Chaunoy oil field in France and one month at the Reykjanes powerplant in Iceland. After exposition, the tested alloys were analysed regarding corrosion with macro- and microscopic techniques using optical and electron microscopes.

Romanov and Leiss [

19] focused their study entitled “Analysis of Enhanced Geothermal System Development Scenarios for District Heating and Cooling of the Göttingen University Campus” on potential scenarios of EGS development in the poorly known Variscan basement below Göttingen, for district heating and cooling of the University campus. On average, they demonstrated that a single EGS doublet could cover about 20% of the heat demand and 6% of the cooling demand of the campus. The levelized cost of heat (LCOH), net present value (NPV) and CO

2 abatement cost were evaluated. Based on a sensitivity analysis, the EGS heat output was estimated for potential profitability. The most influential parameters on the outcome were identified and are presented in this paper. Key prerequisites for launching EGS project in Göttingen are also given.

Hranić et al. [

20] worked on oil fields that are approaching the end of their lifetime and have great geothermal potential considering temperature and water cut, for which oil companies consider switching from oil business to investments into geothermal projects on existing oil wells. The used methodology presents the evaluation of the existing geothermal potential for several oil fields in terms of water temperature, flow rate and spatial distribution of existing oil wells. This paper entitled “Two-Stage Geothermal Well Clustering for Oil-to-Water Conversion on Mature Oil Fields” proposes a two-stage clustering approach for grouping similar wells in terms of temperature and then spatial arrangement to optimize the location of production facilities. The outputs regarding the production quantities and economic and environmental aspects provide insight into the optimal scenario for oil-to-water conversion. A case study has also been developed.

This Special Issue hence compiles 20 scientific contributions resulting from some of the work performed during the H2020 MEET project. It shows that a multidisciplinary approach including geology, material science, petrophysics, geophysics, reservoir modeling and the collaboration between academics and the industry is essential. This Special Issue brings some tangible scientific content to convince the readers about the opportunity to generalize EGS in Europe in different geological contexts and cogenerate hot water and oil in order to tackle the challenge of energy transition.