The Mechanical Properties of Fly-Ash-Stabilized Sands

Abstract

1. Introduction

2. Materials and Methods

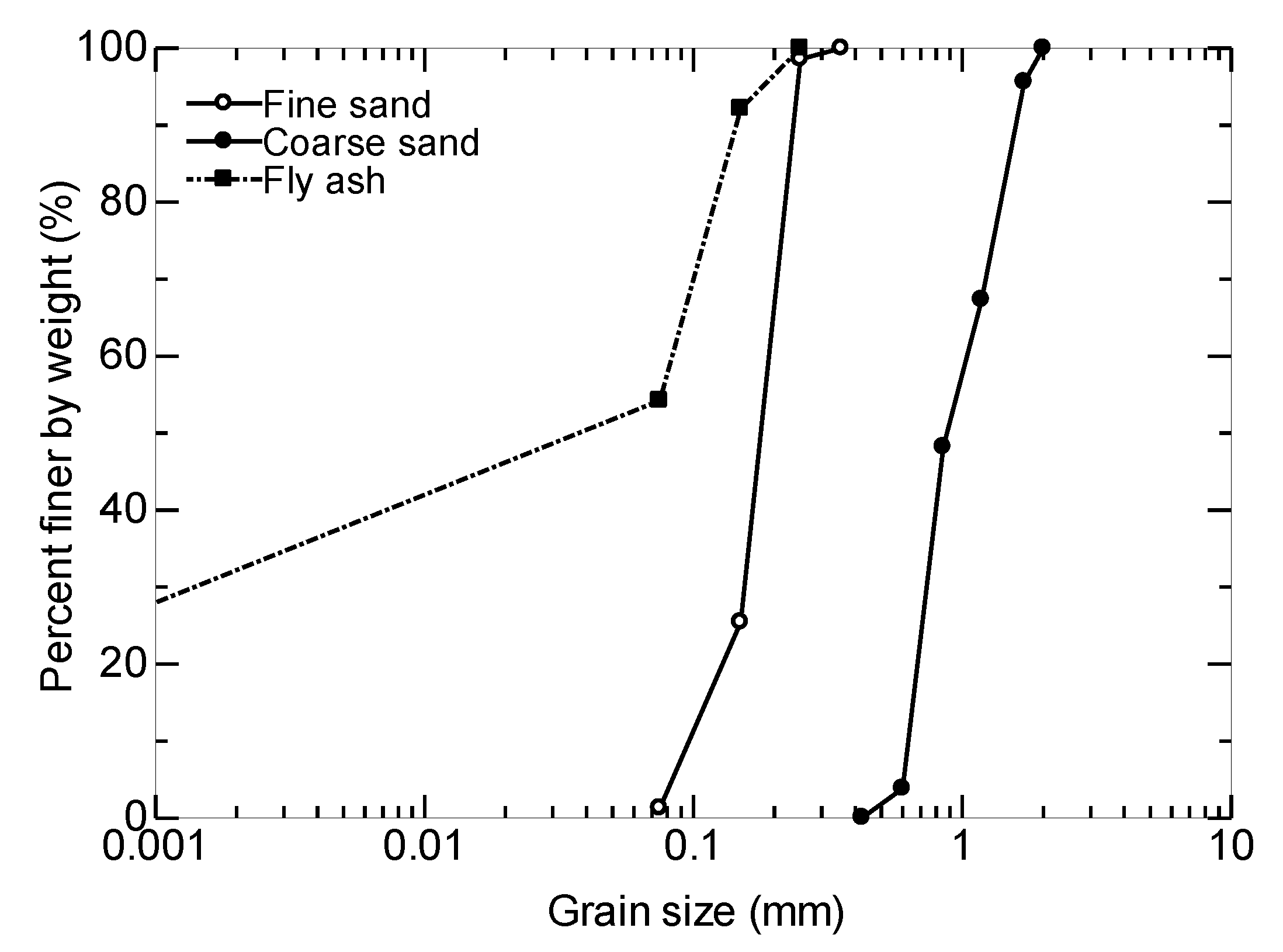

2.1. Materials

2.2. Methods

2.3. Test Conditions

3. Results and Discussion

3.1. Results

3.2. Discussion

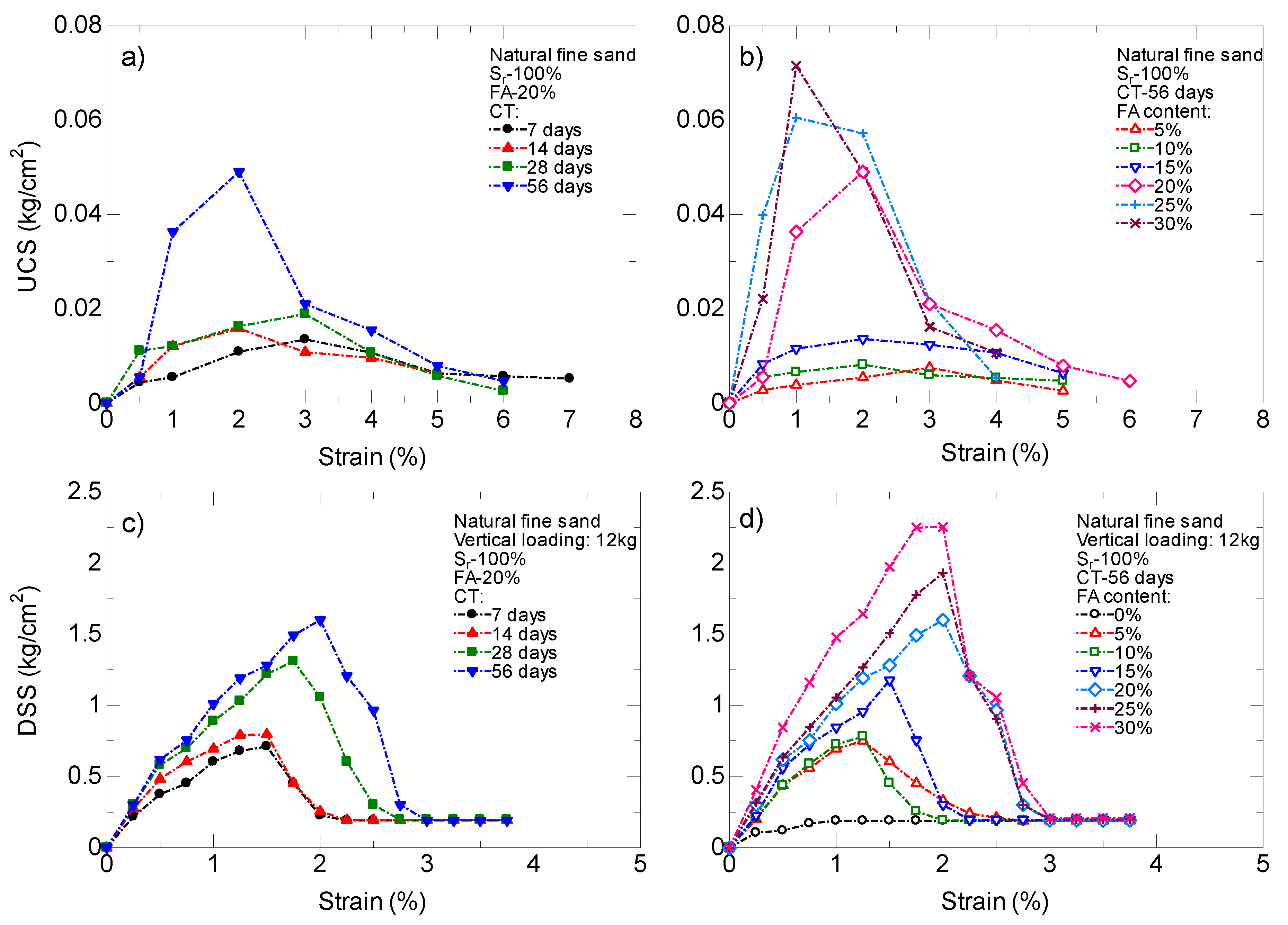

3.2.1. Typical Stress–Strain Behaviors

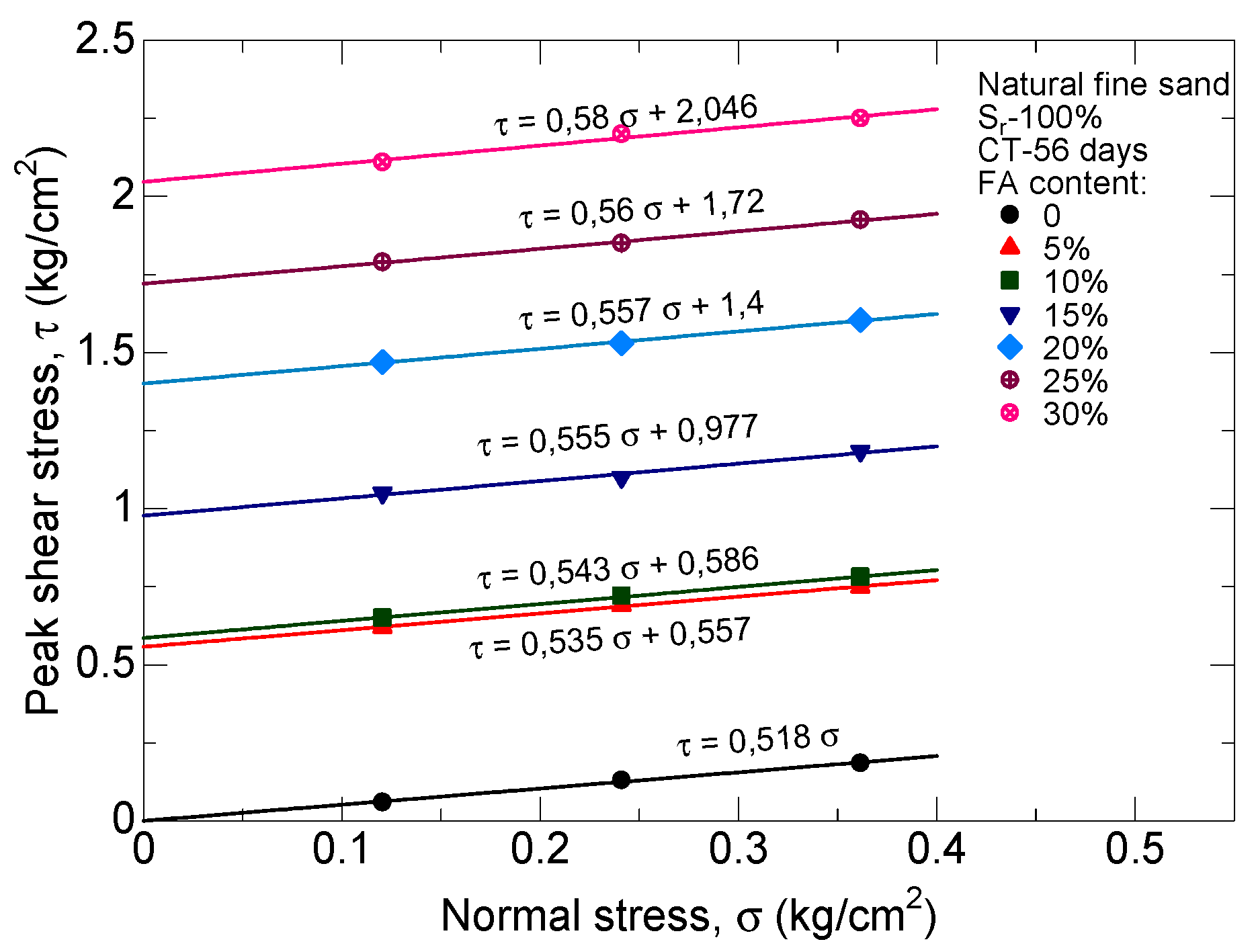

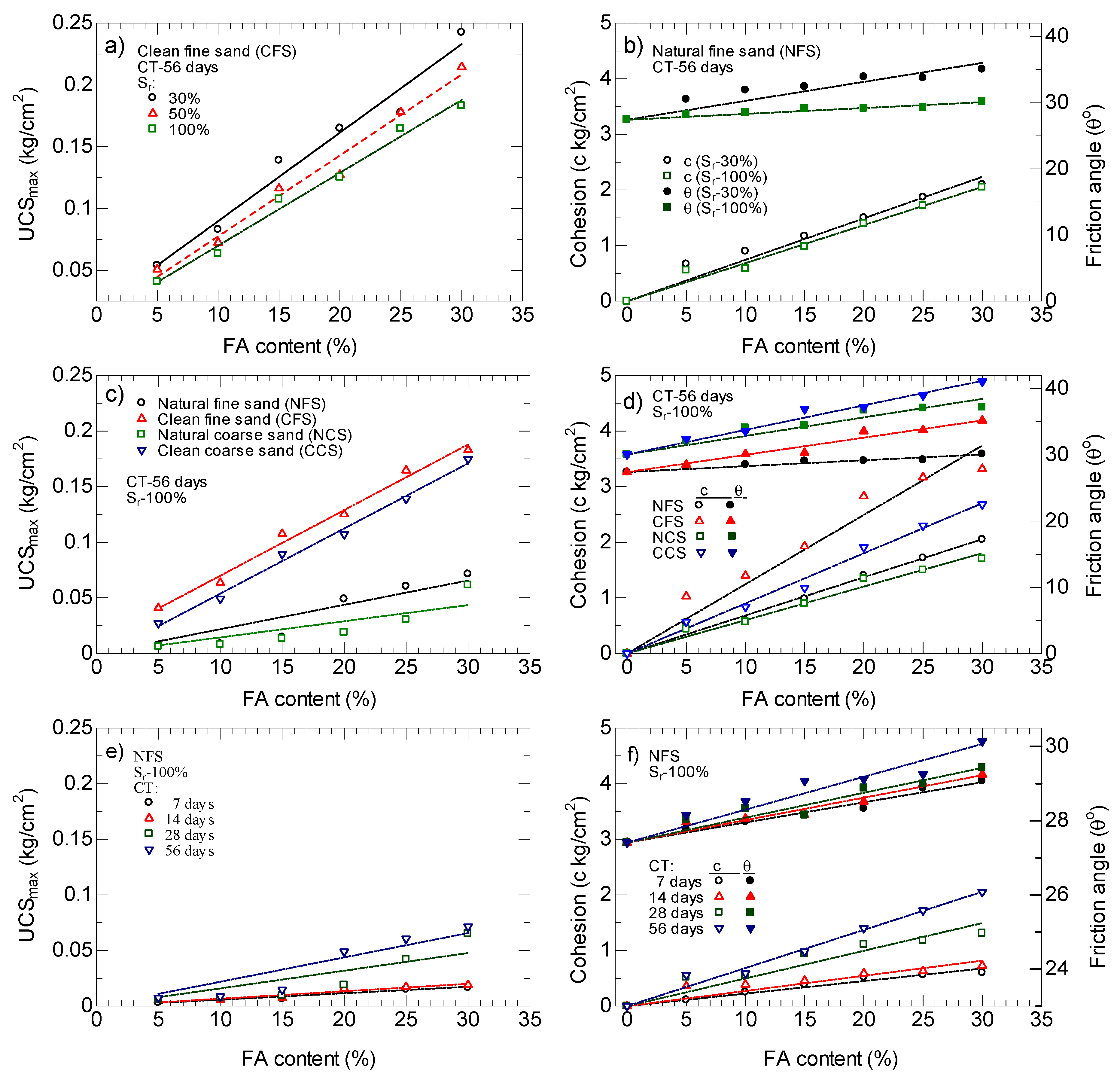

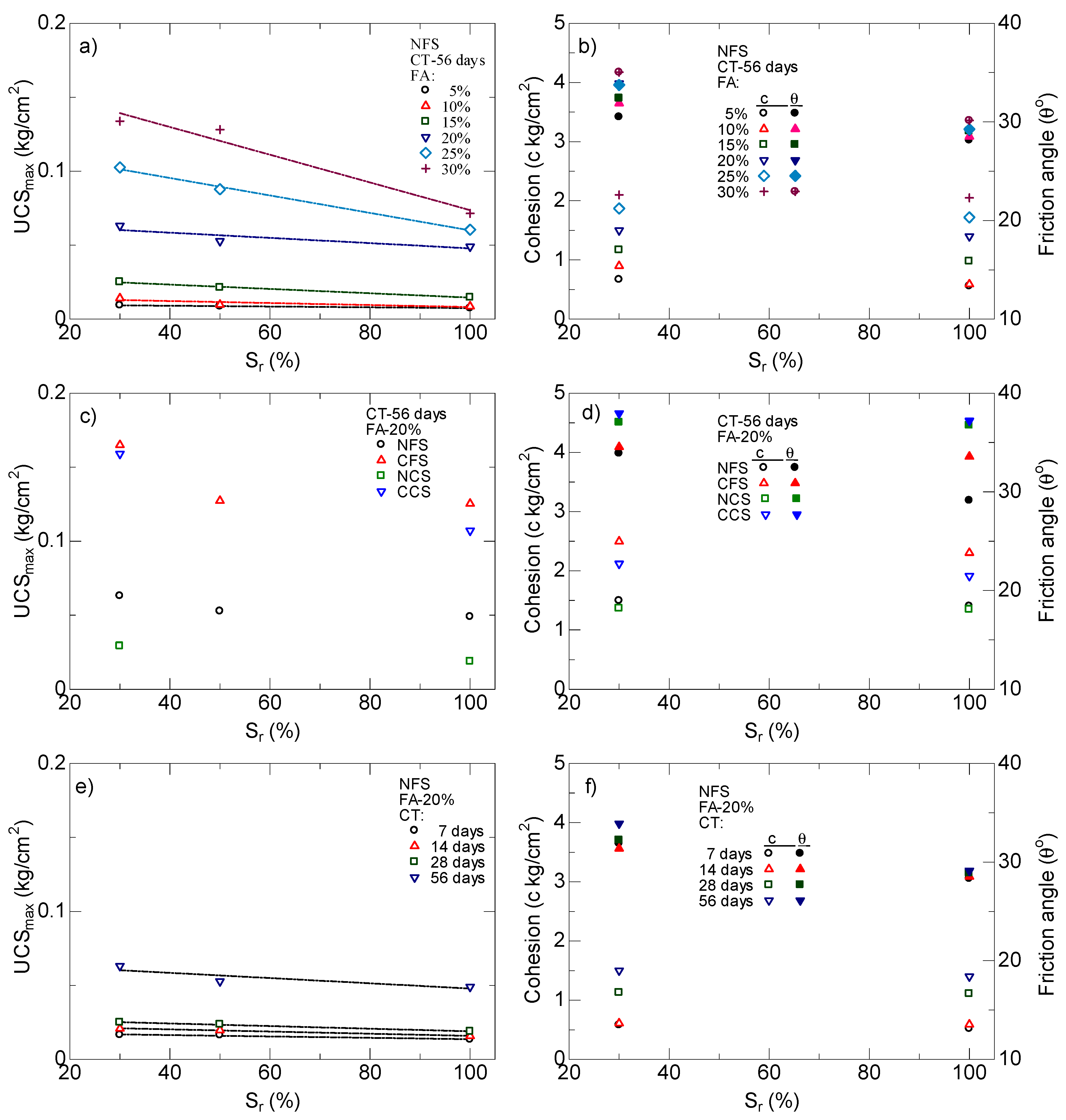

3.2.2. Effect of the Fly Ash Percentage

3.2.3. The Effect of Curing Time

3.2.4. The Effect of Degrees of Saturation

3.2.5. The Effect of Grain Size

3.2.6. The Effect of Content of Fines

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dano, C.; Hicher, P.-Y. Behaviour of Uncemented Sands and Grouted Sands before Peak Strength. Soils Found. Jpn. Geotech. Soc. 2003, 43, 13–19. [Google Scholar] [CrossRef]

- Dano, C.; Hicher, P.Y.; Tailliez, S. Engineering Properties of Grouted Sands. J. Geotech. Geoenviron. Eng. ASCE 2004, 130, 328–338. [Google Scholar] [CrossRef]

- Delfosse-Ribay, E.; Djeran-Maigre, I.; Cabrillac, R.; Gouvenot, D. Shear Modulus and Damping Ratio of Grouted Sand. Soil Dyn. Earthq. Eng. 2004, 24, 461–471. [Google Scholar] [CrossRef]

- Pantazopoulos, I.A.; Atmatzidis, D.K. Dynamic Properties of Microfine Cement Grouted Sands. Soil Dyn. Earthq. Eng. 2012, 42, 17–31. [Google Scholar] [CrossRef]

- Acar, Y.B.; El-Tahir, E.-T.A. Low Strain Dynamic Properties of Artificially Cemented Sand. J. Geotech. Eng. 1986, 112, 1001–1015. [Google Scholar] [CrossRef]

- Al Qabany, A.; Soga, K. Effect of Chemical Treatment used in MICP on Engineering Properties of Cemented Soils. Géotechnique 2013, 63, 331–339. [Google Scholar] [CrossRef]

- Yasuhara, H.; Neupane, D.; Hayashi, K.; Okamura, M. Experiments and Predictions of Physical Properties of Sand Cemented by Enzymatically-Induced Carbonate Precipitation. Soils Found. Jpn. Geotech. Soc. 2012, 52, 539–549. [Google Scholar] [CrossRef]

- Simatupang, M.; Okamura, M. Liquefaction Resistance of Sand Remediated with Carbonate Precipitation at Different Degrees of Saturation during Curing. Soils Found. Jpn. Geotech. Soc. 2017, 57, 619–631. [Google Scholar] [CrossRef]

- Simatupang, M.; Okamura, M.; Hayashi, K.; Yasuhara, H. Small-strain Shear Modulus and Liquefaction Resistance of Sand with Carbonate Precipitation. Soil Dyn. Earthq. Eng. 2018, 115, 710–718. [Google Scholar] [CrossRef]

- Kitazume, M.; Okamura, M. Contributions to “Soils and Foundations”: Ground Improvement. Soils Found. Jpn. Geotech. Soc. 2010, 50, 965–975. [Google Scholar] [CrossRef]

- Xiao, Y.; He, X.; Evans, T.M.; Stuedlein, A.W.; Liu, H. Unconfined Compressive and Splitting Tensile Strength of Basalt Fiber-Reinforced Biocemented Sand. J. Geotech. Geoenviron. Eng. 2019, 145. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Csentanyi, L.J.; Jones, M.R.; Sachdeva, A. Clay-Lime Stabilization: Charecterizing Fly Ash Effects in Minimizing the Risk of Sulfate Heave. In Proceedings of the World Coal Ash Conference, Denver, CO, USA, 9–12 May 2011. [Google Scholar]

- Tastan, E.O.; Edil, T.B.; Benson, C.H.; Aydilek, A.H. Stabilization of Organic Soils with Fly Ash. J. Geotech. Geoenviron. Eng. ASCE 2011, 137, 819–833. [Google Scholar] [CrossRef]

- Edil, T.B.; Acosta, H.A.; Benson, C.H. Stabilizing Soft Fine-Grained Soils with Fly Ash. J. Mater. Civ. Eng. 2006, 18, 283–294. [Google Scholar] [CrossRef]

- Parsons, R.L.; Kneebone, E. Field Performance of Fly Ash Stabilised Subgrades. GR Improv. 2005, 9, 33–38. [Google Scholar] [CrossRef]

- Lirer, S.; Liguori, B.; Capasso, I.; Flora, A.; Caputo, D. Mechanical and Chemical Properties of Composite Materials Made of Dredged Sediments in a Fly-ash based Geopolymer. J. Environ. Manag. 2017, 191, 1–7. [Google Scholar] [CrossRef]

- Capasso, I.; Lirer, S.; Flora, A.; Ferone, C.; Cioffi, R.; Caputo, D.; Liguori, B. Reuse of Mining Waste as Aggregates in Fly ash-based Geopolymers. J. Clean. Prod. 2019, 220. [Google Scholar] [CrossRef]

- Prabakar, J.; Dendorkar, N.; Morchhale, R.K. Influence of Fly Ash on Strength Behavior of Typical Soils. Constr. Build. Mater. 2004, 18, 263–267. [Google Scholar] [CrossRef]

- Trzebiatowski, B.B.D.; Edil, T.B.; Benson, C.H. Case Study of Subgrade Stabilization using Fly Ash: State Highway 32, Port Washington, Wisconsin. Recycl. Mater. Geotech. 2004, 123–136. [Google Scholar] [CrossRef]

- TRB Lime Stabilization: Reaction, Properties, Design, and Construction. State of the Art Report 5. Available online: http://onlinepubs.trb.org/Onlinepubs/state-of-the-art/5/5.pdf (accessed on 7 September 2019).

- Amadi, A.A. Enhancing Durability of Quarry Fines Modified Black Cotton Soil Subgrade with Cement Kiln Dust Stabilization. Transp. Geotech. 2014, 1, 55–61. [Google Scholar] [CrossRef]

- Miller, G.A.; Azad, S. Influence of Soil Type on Stabilization with Cement Kiln Dust. Constr. Build. Mater. 2000, 14, 89–97. [Google Scholar] [CrossRef]

- Oriola, F.O.P.; Moses, G. Compacted Black Cotton Soil Treated with Cement Kiln Dust as Hydraulic Barrier Material. Am. J. Sci. Ind. Res. 2011, 2, 521–530. [Google Scholar] [CrossRef]

- Osinubi, K.J. Stabilisation of Tropical Black Clay with Cement and Pulverised Coal Bottom Ash Admixture. Adv. Unsatur. Geotech. ASCE Geotech. Spec. Publ. 2000, 99, 289–302. [Google Scholar]

- Peethamparan, S.; Olek, J. Study of the Effectiveness of Cement Kiln Dusts in Stabilizing Na-Montmorillonite Clay. J. Mater. Civ. Eng. ASCE 2008, 20, 137–146. [Google Scholar] [CrossRef]

- Salahudeen, A.B.; Eberemu, A.; Osinubi, K.J. Assessment of Cement Kiln Dust-Treated Expansive Soil for the Construction of Flexible Pavements. Geotech. Geol. Eng. 2014. [Google Scholar] [CrossRef]

- Sreekrishnavilasam, A.; Rahardja, S.; Kmetz, R.; Santagata, M. Soil Treatment using Fresh and Landfilled Cement Kiln Dust. Constr. Build. Mater. 2007, 21, 318–327. [Google Scholar] [CrossRef]

- Sridharan, A.; Prashanth, J.P.; Sivapullaiah, P.V. Effect of Fly Ash on the Unconfined Compressive Strength of Black Cotton Soil. GR Improv. 1997, 1, 169–175. [Google Scholar] [CrossRef]

- Brooks, R.M. Soil Stabilization With Flyash and Rice Husk Ash. Int. J. Res. Rev. Appl. Sci. 2009, 1, 2076–7366. [Google Scholar]

- Sezer, A.; Inan, G.; Yılmaz, H.R.; Ramyar, K. Utilization of a Very High Lime Fly Ash for Improvement of Izmir Clay. Build. Environ. 2006, 41, 150–155. [Google Scholar] [CrossRef]

- Jha, J.N.; Gill, K.S.; Choudhary, A.K. Effect of High Fraction Class F Flyash on Lime Stabilization of Soil. Int. J. Geotech. Environ. 2009, 1, 105–128. [Google Scholar]

- Jalali, S.; Abyaneh, M.Y.; Keedwell, M.J. Differential Scanning Calorimetry Tests Applied to Lime—Fly Ash Soil Stabilization. In Test Soil Mix with Waste or Recycl Mater STP 1275; ASTM: West Conshohocken, PA, USA, 1997; pp. 181–191. [Google Scholar]

- Cheng, L.; Cord-Ruwisch, R. In Situ Soil Cementation with Ureolytic Bacteria by Surface Percolation. Ecol. Eng. 2012, 42, 64–72. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M.A. Cementation of Sand Soil by Microbially Induced Calcite Precipitation at Various Degrees of Saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar] [CrossRef]

- ASTM Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). Available online: https://www.scribd.com/document/339563388/ASTM-D-2487-06-Soil-Clasification-pdf (accessed on 21 October 2019).

- ASTM Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Available online: https://kupdf.net/download/astm-c6181203394-1_59ce2c1508bbc5a942686f32_pdf (accessed on 21 October 2019).

- Ola, S.A. Geotechnical Properties and Behaviour of Some Stabilized Nigerian Lateritic Soils Geotechnical Properties and Behaviour of Some Stabilized Nigerian Lateritic Soils. Q. J. Eng. Geol. Hydrogeol. Geotech. 1978, 11, 145–160. [Google Scholar] [CrossRef]

- Bell, F.G. Lime Stabilization of Clay Soils. Bull. Int. Assoc. Eng. Geol. 1989, 39, 67–74. [Google Scholar] [CrossRef]

- Harichane, K.; Ghrici, M.; Kenai, S. Effect of Curing Time on Shear Strength of Cohesive Soils Stabilized with Combination of Lime and Natural Pozzolana. Int. J. Civ. Eng. 2011, 9, 90–96. [Google Scholar]

- Gay, G.; Schad, H. Influence of Cement and Lime Additives on the Compaction Properties and Shear Parameters of Fine Grained Soils. Otto Graf J. 2000, 11, 19–32. [Google Scholar]

- Simatupang, M.; Sukri, A.S.; Nasrul, S.; Putri, T.S. Effect of Confining Pressures on the Shear Modulus of Sand Treated with Enzymatically Induced Calcite Precipitation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 615. [Google Scholar] [CrossRef]

- Mulilis, J.R.; Seed, H.B.; Chan, C.K.; Michell, J.K.; Arulanandan, K. Effect of Sample Preparation on Sand Liquefaction. J. Geotech. Geoenviron. Eng. ASCE 1977, 103, 91–108. [Google Scholar]

- Lin, H.; Suleiman, M.T.; Brown, D.G.; Kavazanjian, E. Mechanical Behavior of Sands Treated by Microbially Induced Carbonate Precipitation. J. Geotech. Geoenviron. Eng. 2016, 142, 04015066. [Google Scholar] [CrossRef]

- Chu, J.; Stabnikov, V.; Ivanov, V. Microbially Induced Calcium Carbonate Precipitation on Surface or in the Bulk of Soil. Geomicrobiol. J. 2012, 29, 544–549. [Google Scholar] [CrossRef]

- van Paassen, L.A.; Ghose, R.; van der Linden, T.J.M.; van der Star, W.R.L.; van Loosdrecht, M.C.M. Quantifying Biomediated Ground Improvement by Ureolysis: Large-Scale Biogrout Experiment. J. Geotech. Geoenviron. Eng. ASCE 2010, 136, 1721–1728. [Google Scholar] [CrossRef]

- Canakci, H.; Sidik, W.; Halil, I.H. Effect of Bacterial Calcium Carbonate Precipitation on Compressibility and Shear Strength of Organic Soil. Soils Found. 2015, 55, 1211–1221. [Google Scholar] [CrossRef]

- Amadi, A.A.; Osu, A.S. Effect of Curing Time on Strength Development in Black Cotton Soil—Quarry Fines Composite Stabilized with Cement Kiln Dust ( CKD ). J. King Saud. Univ.–Eng. Sci. 2018, 30, 305–312. [Google Scholar] [CrossRef]

- Consoli, B.N.C.; Prietto, P.M.D.; Carraro, J.A.H.; Heineck, K.S. Behaviour of Compacted Soil-Fly Ash-Carbide Lime Mixtures. J. Geotech. Geoenviron. Eng. ASCE 2001, 127, 774–782. [Google Scholar] [CrossRef]

- Al Qabany, A.; Soga, K.; Santamarina, C. Factors Affecting Efficiency of Microbially Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. ASCE 2012, 138, 992–1001. [Google Scholar] [CrossRef]

- DeJong, J.T.; Fritzges, M.B.; Nüsslein, K. Microbially Induced Cementation to Control Sand Response to Undrained Shear. J. Geotech. Geoenviron. Eng. ASCE 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Feng, K.; Montoya, B.M. Influence of Confinement and Cementation Level on the Behaviour of Microbially-Induced Calcite Precipitated Sands under Monotonic Drained Loading. J. Geotech. Geoenviron. Eng. ASCE 2015, 142, 04015057. [Google Scholar] [CrossRef]

- Axelsson, K.; Johansson, S.-E.; Andersson, R. Stabilization of Organic Soils by Cement and Puzzolanic Reactions—Feasibility Study; Swedish Geotechnical Institute: Linkoping, Sweden, 2002. [Google Scholar]

- Janz, M.; Johansson, S.-E. The Function of Different Binding Agents in Deep Stabilization; Swedish Geotechnical Institute: Linkoping, Sweden, 2002. [Google Scholar]

- Tremblay, H.; Duchesne, J.; Locat, J.; Leroueil, S. Influence of the Nature of Organic Compounds on Fine Soil Stabilization with Cement. Can. Geotech. J. 2002, 39, 535–546. [Google Scholar] [CrossRef]

- Hampton, M.B.; Edil, T.B. Strength Gain of Organic Ground with Cement-Type Binders. In Soil Improvement for Big Digs; ASCE: Reston, WV, USA, 1998; pp. 135–148. [Google Scholar]

- Seed, H.B.; Tokimatsu, K.; Harder, L.F.; Chung, R.M. Influence of SPT Procedures in Soil Liquefaction Resistance Evaluations. J. Geotech. Eng. ASCE 1985, 111, 1425–1445. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, L. The Effects of Small Particles on Soil Seismic Liquefaction Resistance: Current Findings and Future Challenges. Nat. Hazards 2018. [Google Scholar] [CrossRef]

- Tokimatsu, K.; Yoshimi, Y. Empirical Correlation of Soil Liquefaction based on SPT N-Value and Fines Content. Soils Found. Jpn. Soc. Soil Mech. Found. Eng. 1983, 23, 56–74. [Google Scholar] [CrossRef]

| Fine Sand | Coarse Sand | ||

|---|---|---|---|

| Specific gravity | Gs | 2.67 | 2.72 |

| Maximum void ratio | emax | 1.23 | 0.98 |

| Minimum void ratio | emin | 0.88 | 0.76 |

| Mean grain size | D50 | 0.18 | 0.88 |

| SiO2 | CaO | Al2O3 | Fe2O3 | MgO | TiO2 | MnO2 | Na2O | K2O | P2O5 | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 19.88 | 24.04 | 12.00 | 12.63 | 8.72 | 0.58 | 0.22 | 7.47 | 2.23 | 0.18 | 10.26 | 1.134 |

| Parameter | |

|---|---|

| Fly ash percentages (%) | 5, 10, 15, 20, 25, 30 |

| Curing time (days) | 7, 14, 28, 56 |

| Degrees of saturation during sample preparation—Sr (%) | 30, 50, 100 |

| Grain sizes | Fine and coarse |

| Type of sand | Natural and clean |

| Sr | Dry Sand + Fly Ash (gr) | Water Volume (mL) | ||||||

|---|---|---|---|---|---|---|---|---|

| (%) | Fine sand | Coarse sand | Fine sand | Coarse sand | ||||

| UCS | DSS | UCS | DSS | UCS | DSS | UCS | DSS | |

| 30 | 40.41 | 11.29 | 36.49 | 10.19 | ||||

| 50 | 339.6 | 94.9 | 380.1 | 106.2 | 67.23 | 18.78 | 60.82 | 16.99 |

| 100 | 134.12 | 37.47 | 121.64 | 33.98 | ||||

| Sr | FA | UCS (kg/cm2) | |||||||

| (%) | (%) | Fine Sand (0.075−0.25 mm) | |||||||

| Natural | Clean | ||||||||

| CT = 7 days | 14 | 28 | 56 | 7 | 14 | 28 | 56 | ||

| 30 | 5 | 0.0061 | 0.0076 | 0.0086 | 0.0094 | 0.0064 | 0.0118 | 0.0475 | 0.0540 |

| 10 | 0.0073 | 0.0081 | 0.0094 | 0.0142 | 0.0075 | 0.0120 | 0.0570 | 0.0830 | |

| 15 | 0.0081 | 0.0107 | 0.0109 | 0.0252 | 0.0207 | 0.0274 | 0.0832 | 0.1390 | |

| 20 | 0.0165 | 0.0208 | 0.0250 | 0.0631 | 0.0272 | 0.0330 | 0.1069 | 0.1650 | |

| 25 | 0.0206 | 0.0257 | 0.0505 | 0.1026 | 0.0526 | 0.0590 | 0.1188 | 0.1777 | |

| 30 | 0.0211 | 0.0401 | 0.1053 | 0.1338 | 0.1377 | 0.1525 | 0.1891 | 0.2426 | |

| 50 | 5 | 0.0060 | 0.0068 | 0.0071 | 0.0087 | 0.0065 | 0.0080 | 0.0397 | 0.0509 |

| 10 | 0.0067 | 0.0072 | 0.0092 | 0.0098 | 0.0070 | 0.0091 | 0.0509 | 0.0725 | |

| 15 | 0.0072 | 0.0083 | 0.0097 | 0.0214 | 0.0176 | 0.0220 | 0.0736 | 0.1163 | |

| 20 | 0.0164 | 0.0198 | 0.0236 | 0.0527 | 0.0205 | 0.0291 | 0.0994 | 0.1273 | |

| 25 | 0.0189 | 0.0250 | 0.0426 | 0.0878 | 0.0518 | 0.0534 | 0.1127 | 0.1781 | |

| 30 | 0.0198 | 0.0360 | 0.0930 | 0.1281 | 0.0818 | 0.1336 | 0.1709 | 0.2145 | |

| 100 | 5 | 0.0032 | 0.0052 | 0.0059 | 0.0075 | 0.0033 | 0.0053 | 0.0207 | 0.0409 |

| 10 | 0.0054 | 0.0060 | 0.0075 | 0.0087 | 0.0058 | 0.0065 | 0.0436 | 0.0636 | |

| 15 | 0.0065 | 0.0076 | 0.0092 | 0.0147 | 0.0107 | 0.0143 | 0.0600 | 0.1076 | |

| 20 | 0.0135 | 0.0158 | 0.0189 | 0.0490 | 0.0196 | 0.0217 | 0.0931 | 0.1253 | |

| 25 | 0.0151 | 0.0172 | 0.0421 | 0.0605 | 0.0458 | 0.0510 | 0.1033 | 0.1647 | |

| 30 | 0.0167 | 0.0191 | 0.0650 | 0.0715 | 0.0550 | 0.1220 | 0.1583 | 0.1830 | |

| (%) | (%) | Coarse Sand (0.6−2 mm) | |||||||

| Natural | Clean | ||||||||

| CT = 7 days | 14 | 28 | 56 | 7 | 14 | 28 | 56 | ||

| 30 | 5 | - | - | 0.0072 | 0.0086 | - | - | - | 0.0450 |

| 10 | - | - | 0.0091 | 0.0130 | - | - | 0.0477 | 0.0505 | |

| 15 | 0.0075 | 0.0097 | 0.0107 | 0.0209 | - | 0.0210 | 0.0807 | 0.1308 | |

| 20 | 0.0150 | 0.0188 | 0.0220 | 0.0292 | 0.0270 | 0.0295 | 0.0950 | 0.1590 | |

| 25 | 0.0195 | 0.0251 | 0.0460 | 0.0962 | 0.0477 | 0.0508 | 0.1062 | 0.1710 | |

| 30 | 0.0202 | 0.0388 | 0.0915 | 0.1306 | 0.0976 | 0.1092 | 0.1805 | 0.2171 | |

| 100 | 5 | - | - | 0.0054 | 0.0065 | - | - | 0.0175 | 0.0273 |

| 10 | - | - | 0.0062 | 0.0082 | - | - | 0.0270 | 0.0492 | |

| 15 | 0.0060 | 0.0069 | 0.0084 | 0.0136 | 0.0083 | 0.0109 | 0.0505 | 0.0893 | |

| 20 | 0.0075 | 0.0093 | 0.0114 | 0.0190 | 0.0170 | 0.0205 | 0.0617 | 0.1071 | |

| 25 | 0.0096 | 0.0121 | 0.0144 | 0.0305 | 0.0298 | 0.0390 | 0.0769 | 0.1390 | |

| 30 | 0.0132 | 0.0165 | 0.0603 | 0.0615 | 0.0439 | 0.0916 | 0.1365 | 0.1747 | |

| Sr | FA | Shear Strength Parameters | |||||||||||||||

| (%) | (%) | Fine Sand (0.075−0.25 mm) | |||||||||||||||

| Natural | Clean | ||||||||||||||||

| CT = 7 days | 14 | 28 | 56 | 7 | 14 | 28 | 56 | ||||||||||

| c | θ | c | θ | c | θ | c | θ | c | θ | c | θ | c | θ | c | θ | ||

| 30 | 5 | 0.23 | 28.33 | 0.40 | 29.43 | 0.57 | 30.32 | 0.67 | 30.50 | 0.40 | 29.07 | 0.73 | 30.32 | 0.98 | 31.89 | 1.60 | 32.57 |

| 10 | 0.32 | 28.88 | 0.43 | 30.50 | 0.73 | 31.20 | 0.90 | 31.89 | 0.53 | 30.14 | 0.92 | 30.85 | 1.52 | 32.23 | 1.97 | 33.57 | |

| 15 | 0.45 | 30.14 | 0.51 | 31.02 | 0.97 | 31.89 | 1.17 | 32.40 | 0.95 | 31.02 | 1.00 | 31.89 | 1.97 | 33.57 | 2.13 | 34.06 | |

| 20 | 0.58 | 31.89 | 0.61 | 31.37 | 1.13 | 32.23 | 1.50 | 33.90 | 1.10 | 31.89 | 1.33 | 31.72 | 2.18 | 34.06 | 2.50 | 34.55 | |

| 25 | 0.67 | 31.37 | 0.78 | 31.89 | 1.27 | 33.57 | 1.87 | 33.74 | 1.37 | 33.07 | 1.50 | 33.57 | 2.30 | 34.23 | 3.00 | 35.03 | |

| 30 | 0.80 | 33.57 | 1.00 | 32.40 | 1.37 | 34.23 | 2.10 | 35.03 | 1.53 | 34.39 | 2.00 | 35.19 | 2.60 | 35.19 | 3.23 | 35.51 | |

| 100 | 5 | 0.15 | 27.78 | 0.36 | 27.97 | 0.52 | 28.02 | 0.56 | 28.15 | 0.27 | 27.87 | 0.63 | 28.33 | 1.00 | 28.70 | 1.03 | 28.52 |

| 10 | 0.28 | 27.97 | 0.39 | 28.06 | 0.55 | 28.33 | 0.59 | 28.52 | 0.47 | 28.06 | 0.73 | 29.25 | 1.10 | 29.43 | 1.40 | 30.14 | |

| 15 | 0.43 | 28.15 | 0.46 | 28.15 | 0.94 | 28.15 | 0.98 | 29.07 | 0.80 | 28.33 | 0.83 | 29.61 | 1.30 | 29.79 | 1.93 | 30.32 | |

| 20 | 0.57 | 28.33 | 0.59 | 28.52 | 1.12 | 28.88 | 1.40 | 29.12 | 1.00 | 30.14 | 1.00 | 31.89 | 1.57 | 32.40 | 2.83 | 33.57 | |

| 25 | 0.60 | 28.88 | 0.63 | 29.01 | 1.18 | 28.99 | 1.72 | 29.25 | 1.10 | 30.14 | 1.03 | 32.23 | 1.98 | 32.06 | 3.17 | 33.74 | |

| 30 | 0.64 | 29.07 | 0.96 | 29.25 | 1.31 | 29.43 | 2.05 | 30.14 | 1.13 | 31.89 | 1.17 | 33.57 | 2.13 | 33.57 | 3.33 | 35.19 | |

| Coarse Sand (0.6−2 mm) | |||||||||||||||||

| Natural | Clean | ||||||||||||||||

| CT = 7 days | 14 | 28 | 56 | 7 | 14 | 28 | 56 | ||||||||||

| c | θ | c | θ | c | θ | c | θ | c | θ | c | θ | c | θ | c | θ | ||

| 30 | 5 | 0.19 | 30.67 | 0.33 | 31.02 | 0.47 | 32.74 | 0.60 | 32.57 | 0.21 | 31.20 | 0.33 | 31.89 | 0.47 | 32.23 | 0.60 | 33.07 |

| 10 | 0.28 | 31.02 | 0.36 | 32.06 | 0.67 | 33.90 | 0.86 | 34.55 | 0.30 | 31.89 | 0.43 | 32.57 | 0.67 | 33.90 | 0.86 | 33.90 | |

| 15 | 0.41 | 31.89 | 0.42 | 33.57 | 0.87 | 34.55 | 1.10 | 34.87 | 0.43 | 33.07 | 0.55 | 34.06 | 0.87 | 35.19 | 1.10 | 35.98 | |

| 20 | 0.54 | 33.57 | 0.53 | 34.39 | 1.00 | 35.35 | 1.37 | 37.05 | 0.54 | 33.57 | 0.65 | 34.55 | 1.03 | 37.05 | 1.37 | 37.95 | |

| 25 | 0.60 | 33.90 | 0.68 | 35.19 | 1.20 | 35.66 | 1.60 | 37.65 | 0.63 | 34.06 | 0.78 | 35.03 | 1.20 | 38.97 | 1.80 | 39.40 | |

| 30 | 0.73 | 34.71 | 0.93 | 35.82 | 1.27 | 35.98 | 1.80 | 38.09 | 0.73 | 35.03 | 0.94 | 36.90 | 1.37 | 39.96 | 2.17 | 42.12 | |

| 100 | 5 | 0.11 | 30.14 | 0.32 | 30.32 | 0.48 | 31.89 | 0.54 | 32.06 | 0.13 | 30.85 | 0.33 | 31.20 | 0.48 | 31.89 | 0.57 | 32.40 |

| 10 | 0.25 | 30.50 | 0.34 | 31.72 | 0.49 | 33.57 | 0.57 | 34.06 | 0.28 | 31.02 | 0.42 | 31.89 | 0.60 | 33.24 | 0.84 | 33.57 | |

| 15 | 0.39 | 31.89 | 0.40 | 32.40 | 0.92 | 33.57 | 0.90 | 34.39 | 0.39 | 32.57 | 0.47 | 33.57 | 0.92 | 35.35 | 1.00 | 36.90 | |

| 20 | 0.52 | 32.06 | 0.51 | 33.07 | 1.06 | 35.03 | 1.35 | 36.75 | 0.52 | 32.91 | 0.58 | 31.89 | 1.06 | 36.75 | 1.35 | 37.20 | |

| 25 | 0.56 | 32.74 | 0.61 | 33.57 | 1.08 | 35.19 | 1.70 | 37.05 | 0.61 | 33.57 | 0.73 | 34.39 | 1.10 | 38.24 | 1.73 | 38.97 | |

| 30 | 0.60 | 33.57 | 0.92 | 35.19 | 1.23 | 35.51 | 1.99 | 37.20 | 0.69 | 34.55 | 0.93 | 36.75 | 1.35 | 39.68 | 2.00 | 41.06 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simatupang, M.; Mangalla, L.K.; Edwin, R.S.; Putra, A.A.; Azikin, M.T.; Aswad, N.H.; Mustika, W. The Mechanical Properties of Fly-Ash-Stabilized Sands. Geosciences 2020, 10, 132. https://doi.org/10.3390/geosciences10040132

Simatupang M, Mangalla LK, Edwin RS, Putra AA, Azikin MT, Aswad NH, Mustika W. The Mechanical Properties of Fly-Ash-Stabilized Sands. Geosciences. 2020; 10(4):132. https://doi.org/10.3390/geosciences10040132

Chicago/Turabian StyleSimatupang, Minson, Lukas Kano Mangalla, Romy Suryaningrat Edwin, Adris Ade Putra, Muhammad Thahir Azikin, Nini H. Aswad, and Wayan Mustika. 2020. "The Mechanical Properties of Fly-Ash-Stabilized Sands" Geosciences 10, no. 4: 132. https://doi.org/10.3390/geosciences10040132

APA StyleSimatupang, M., Mangalla, L. K., Edwin, R. S., Putra, A. A., Azikin, M. T., Aswad, N. H., & Mustika, W. (2020). The Mechanical Properties of Fly-Ash-Stabilized Sands. Geosciences, 10(4), 132. https://doi.org/10.3390/geosciences10040132