Quality of Meat and Fat from Immunocastrated Boars and Uncastrated Boars Slaughtered at Different Body Weights

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Animals

2.2. Feeding

2.3. Slaughter of Animals, Slaughter Indicators

2.4. Meat Analyses

2.5. Backfat Analyses

2.6. Analysis of Compounds Responsible for Odour in Meat and Backfat

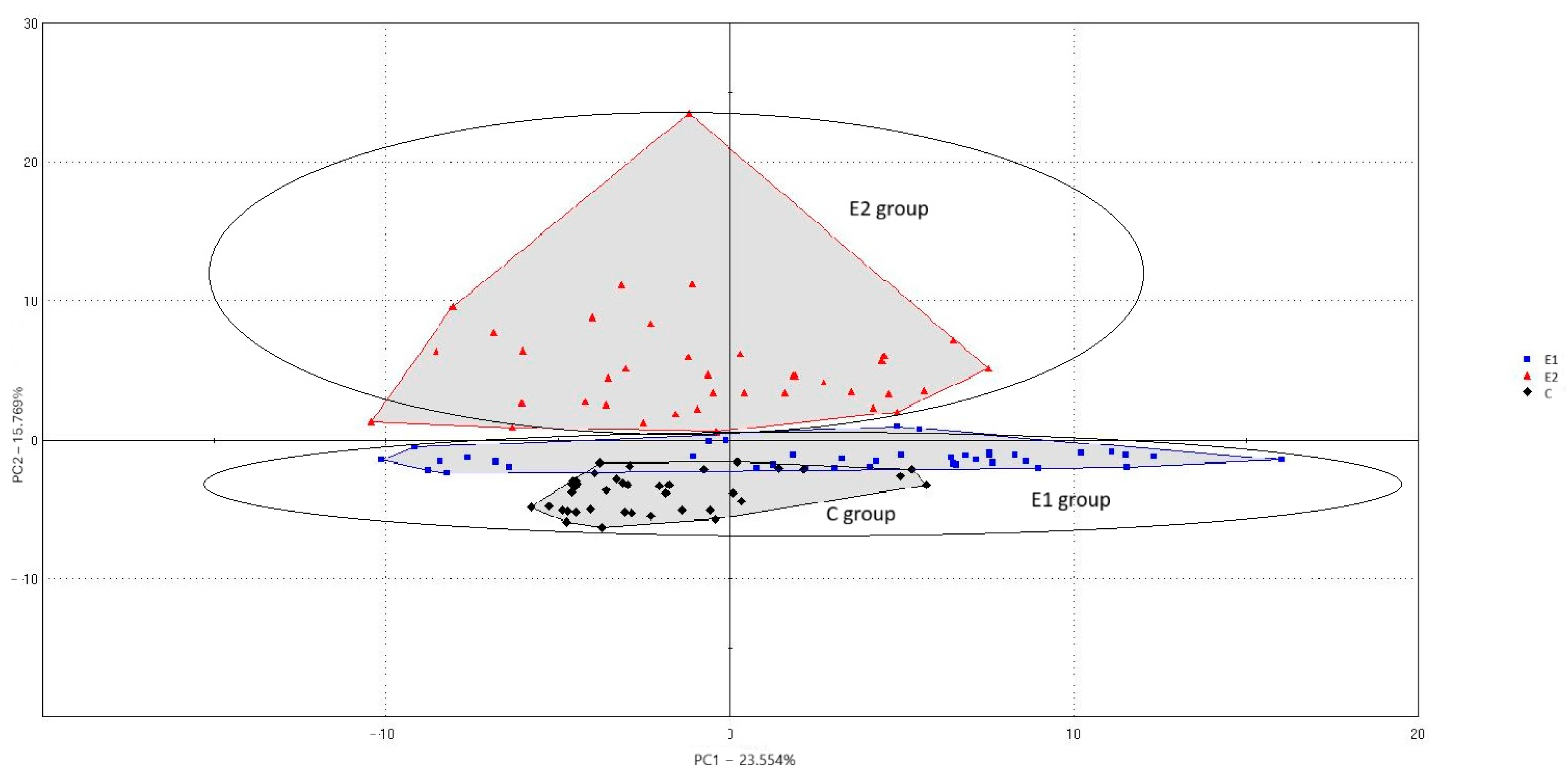

2.7. Instrumental Measurement of Volatile Compounds—e-Nose Analysis

2.8. Statistical Analysis

3. Results

3.1. Results of Meat Quality Assessment

3.2. Results of Backfat Quality Assessment

3.3. Compounds Responsible for Boar Taint

4. Discussion

4.1. Quality of Meat

4.2. Quality of Backfat

4.3. Fatty Acid Profile in Meat and Backfat

4.4. Contents of Indole, Skatole, Androstenol, and Androsterone in Meat and Backfat

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Heyrman, E.; Millet, S.; Tuyttens, F.A.M.; Ampe, B.; Janssens, S.; Buys, N.; Wauters, J.; Vanhaecke, L.; Aluwé, M. On-Farm Prevalence of and Potential Risk Factors for Boar Taint. Animal 2021, 15, 100141. [Google Scholar] [CrossRef]

- Duarte, D.A.S.; Schroyen, M.; Mota, R.R.; Vanderick, S.; Gengler, N. Recent Genetic Advances on Boar Taint Reduction as an Alternative to Castration: A Review. J. Appl. Genet. 2021, 62, 137–150. [Google Scholar] [CrossRef]

- Squires, E.J.; Bone, C.; Cameron, J. Pork Production with Entire Males: Directions for Control of Boar Taint. Animals 2020, 10, 1665. [Google Scholar] [CrossRef]

- Hess, R.A.; Park, C.J.; Soto, S.; Reinacher, L.; Oh, J.E.; Bunnell, M.; Ko, C.M.J. Male Animal Sterilization: History, Current Practices, and Potential Methods for Replacing Castration. Front. Vet. Sci. 2024, 11, 1409386. [Google Scholar] [CrossRef] [PubMed]

- Aluwé, M.; Heyrman, E.; Almeida, J.M.; Babol, J.; Battacone, G.; Čítek, J.; Furnols, M.F.I.; Getya, A.; Karolyi, D.; Kostyra, E.; et al. Exploratory Survey on European Consumer and Stakeholder Attitudes towards Alternatives for Surgical Castration of Piglets. Animals 2020, 10, 1758. [Google Scholar] [CrossRef]

- Hay, M.; Vulin, A.; Génin, S.; Sales, P.; Prunier, A. Assessment of Pain Induced by Castration in Piglets: Behavioral and Physiological Responses over the Subsequent 5 Days. Appl. Anim. Behav. Sci. 2003, 82, 201–218. [Google Scholar] [CrossRef]

- Breitenlechner, A.; Bünger, M.; Ruczizka, U.K.; Dolezal, M.; Auer, U.; Buzanich-Ladinig, A. Comparison between Intramuscular and Intranasal Administration of Sedative Drugs Used for Piglet Castration. Animals 2024, 14, 2325. [Google Scholar] [CrossRef]

- Hokkanen, A.H.; Coutant, M.; Heinonen, M.; Norring, M.; Adam, M.; Oliviero, C.; Bergqvist, T.; Valros, A. Two Restraining Devices in Connection to Surgical Castration with or without Local Anesthesia: Effects on Piglet Stress. Porc. Health Manag. 2025, 11, 21. [Google Scholar] [CrossRef]

- Pesenti Rossi, G.; Dalla Costa, E.; Filipe, J.F.S.; Mazzola, S.M.; Motta, A.; Borciani, M.; Gastaldo, A.; Canali, E.; Pilia, F.; Argenton, M.; et al. Does Immunocastration Affect Behaviour and Body Lesions in Heavy Pigs? Vet. Sci. 2022, 9, 410. [Google Scholar] [CrossRef] [PubMed]

- Pejsak, Z.; Truszczyński, M. Immunologiczna Kastracja Knurków. Życie Weter. 2009, 84, 374–376. [Google Scholar]

- Čandek-Potokar, M.; Škrlep, M.; Zamaratskaia, G.; Čandek-Potokar, M.; Škrlep, M.; Zamaratskaia, G. Immunocastration as Alternative to Surgical Castration in Pigs. Theriogenology 2017, 6, 109–126. [Google Scholar] [CrossRef]

- Kress, K.; Millet, S.; Labussière, É.; Weiler, U.; Stefanski, V. Sustainability of Pork Production with Immunocastration in Europe. Sustainability 2019, 11, 3335. [Google Scholar] [CrossRef]

- von Borell, E.; Bonneau, M.; Holinger, M.; Prunier, A.; Stefanski, V.; Zöls, S.; Weiler, U. Welfare Aspects of Raising Entire Male Pigs and Immunocastrates. Animals 2020, 10, 2140. [Google Scholar] [CrossRef]

- Škrlep, M.; Tomašević, I.; Mörlein, D.; Novaković, S.; Egea, M.; Garrido, M.D.; Linares, M.B.; Peñaranda, I.; Aluwé, M.; Font-I-furnols, M. The Use of Pork from Entire Male and Immunocastrated Pigs for Meat Products—An Overview with Recommendations. Animals 2020, 10, 1754. [Google Scholar] [CrossRef] [PubMed]

- CIE. Official Recommendations of the International Commission on Illumination; No. 15.2; CIE: Vienna, Austria, 1986. [Google Scholar]

- Honikel, K.O. Reference Methods for the Assessment of Physical Characteristics of Meat. Meat Sci. 1998, 49, 447–457. [Google Scholar] [CrossRef] [PubMed]

- Grau, R.; Hamm, R. Eine Einfache Methode Zur Bestimmung Der Wasserbindung Im Muskel. Naturwissenschaften 1953, 40, 29–30. [Google Scholar] [CrossRef]

- Pohja, N.S.; Ninivaara, F.P. Die Estimmung Der Wasserbindung Des Fleisches Mittels Der Konstandruckmethods. Fleischwirtschaft 1957, 9, 193–195. [Google Scholar]

- PN-A 82109; Meat and Meat Products. Determination of Contents of Fat, Protein, and Water. Near Infrared Transmission (NIT) Spectrometry Using Calibration on Artificial Neural Networks (ANN). PCS: Warsaw, Poland, 2010.

- AOAC. Official Methods of Analysis of the AOAC, 18th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2007. [Google Scholar]

- ISO 5509; Animal and Vegetable Fats and Oils Preparation of Methyl Esters of Fatty Acids. Polish Standard Method PN-EN ISO. ISO: Geneva, Switzerland, 2000.

- Puppel, K.; Kuczyńska, B.; Nalecz-Tarwacka, T.; Grodzki, H. Influence of Linseed Variety on Fatty Acid Profile in Cow’s Milk. J. Sci. Food Agric. 2013, 93, 2276–2280. [Google Scholar] [CrossRef]

- Ulbricht, T.L.V.; Southgate, D.A.T. Coronary Heart Disease: Seven Dietary Factors. Lancet 1991, 338, 985–992. [Google Scholar] [CrossRef] [PubMed]

- Wojtasik-Kalinowska, I.; Guzek, D.; Górska-Horczyczak, E.; Brodowska, M.; Sun, D.W.; Wierzbicka, A. Diet with Linseed Oil and Organic Selenium Yields Low N-6/n-3 Ratio Pork Semimembranosus Meat with Unchanged Volatile Compound Profiles. Int. J. Food Sci. Technol. 2018, 53, 1838–1846. [Google Scholar] [CrossRef]

- Górska-Horczyczak, E.; Wojtasik-Kalinowska, I.; Guzek, D.; Sun, D.W.; Wierzbicka, A. Differentiation of Chill-Stored and Frozen Pork Necks Using Electronic Nose with Ultra-Fast Gas Chromatography. J. Food Process. Eng. 2017, 40, e12540. [Google Scholar] [CrossRef]

- Pauly, C.; Spring, P.; Odoherty, J.V.; Ampuero Kragten, S.; Bee, G. Growth Performance, Carcass Characteristics and Meat Quality of Group-Penned Surgically Castrated, Immunocastrated (Improvac®) and Entire Male Pigs and Individually Penned Entire Male Pigs. Animal 2009, 3, 1057–1066. [Google Scholar] [CrossRef]

- Škrlep, M.; Poklukar, K.; Kress, K.; Vrecl, M.; Fazarinc, G.; Lukač, N.B.; Weiler, U.; Stefanski, V.; Čandek-Potokar, M. Effect of Immunocastration and Housing Conditions on Pig Carcass and Meat Quality Traits. Transl. Anim. Sci. 2020, 4, 1224–1237. [Google Scholar] [CrossRef] [PubMed]

- Gispert, M.; Àngels Oliver, M.; Velarde, A.; Suarez, P.; Pérez, J.; Font i Furnols, M. Carcass and Meat Quality Characteristics of Immunocastrated Male, Surgically Castrated Male, Entire Male and Female Pigs. Meat Sci. 2010, 85, 664–670. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, É.R.; Bridi, A.M.; da Silva, C.A.; Alfieri, A.A.; Fritzen, J.T.T.; Terto, D.K.; Correia, E.R. Gender Effects on Pork Quality and Calpain-1 and Calpastatin Gene Expression in Male Pig Muscle. Meat Sci. 2021, 172, 108366. [Google Scholar] [CrossRef]

- Aluwé, M.; Langendries, K.C.M.; Bekaert, K.M.; Tuyttens, F.A.M.; Brabander, D.L.D.; De Smet, S.; Millet, S. Effect of Surgical Castration, Immunocastration and Chicory-Diet on the Meat Quality and Palatability of Boars. Meat Sci. 2013, 94, 402–407. [Google Scholar] [CrossRef] [PubMed]

- Corino, C.; Rossi, R.; Musella, M.; Pastorelli, G.; Cannata, S. Effect of Different Production Typologies on Chemical, Physical and Sensory Characteristics of Italian Commercial Pork. J. Sci. Food Agric. 2009, 89, 463–469. [Google Scholar] [CrossRef]

- Ba, H.V.; Seo, H.W.; Seong, P.N.; Cho, S.H.; Kang, S.M.; Kim, Y.S.; Moon, S.S.; Choi, Y.M.; Kim, J.H. Live Weights at Slaughter Significantly Affect the Meat Quality and Flavor Components of Pork Meat. Anim. Sci. J. 2019, 90, 667–679. [Google Scholar] [CrossRef]

- Cheng, Q.; Sun, D.W. Factors Affecting the Water Holding Capacity of Red Meat Products: A Review of Recent Research Advances. Crit. Rev. Food Sci. Nutr. 2008, 48, 137–159. [Google Scholar] [CrossRef]

- Roy, B.C.; Bruce, H.L. Contribution of Intramuscular Connective Tissue and Its Structural Components on Meat Tenderness-Revisited: A Review. Crit. Rev. Food Sci. Nutr. 2024, 64, 9280–9310. [Google Scholar] [CrossRef]

- Paul, C.; Leser, S.; Oesser, S. Significant Amounts of Functional Collagen Peptides Can Be Incorporated in the Diet While Maintaining Indispensable Amino Acid Balance. Nutrients 2019, 1079. [Google Scholar] [CrossRef]

- Škrlep, M.; Tomažin, U.; Lukač, N.B.; Poklukar, K.; Čandek-Potokar, M. Proteomic Profiles of the Longissimus Muscles of Entire Male and Castrated Pigs as Related to Meat Quality. Animals 2019, 9, 74. [Google Scholar] [CrossRef] [PubMed]

- Latorre, M.A.; Lázaro, R.; Valencia, D.G.; Medel, P.; Mateos, G.G. The Effects of Gender and Slaughter Weight on the Growth Performance, Carcass Traits, and Meat Quality Characteristics of Heavy Pigs. J. Anim. Sci. 2004, 82, 526–533. [Google Scholar] [CrossRef]

- Grela, E.R.; Świątkiewicz, M.; Kowalczuk-Vasilev, E.; Florek, M.; Kosior-Korzecka, U.; Skałecki, P. An Attempt of Implementation of Immunocastration in Swine Production—Impact on Meat Physicochemical Quality and Boar Taint Compound Concentration in the Meat of Two Native Pig Breeds. Livest. Sci. 2020, 232, 103905. [Google Scholar] [CrossRef]

- Božičković, I.; Savić, R.; Panella-Riera, N.; Radojković, D.; Brun, A.; Font-i-Furnols, M. Pork Quality and Histological Properties of Longissimus Muscle from Boars and Early and Late Immunocastrated Pigs. Meat Sci. 2025, 219, 109688. [Google Scholar] [CrossRef]

- Krasnowska, G.; Salejda, A.M. Wybrane Cechy Jakościowe Tłuszczu Pochodzącego z Tusz Tuczników Różnych Grup Genetycznych. Żywność Nauka-Technol.-Jakość 2008, 2, 95–105. [Google Scholar]

- Salejda, A.; Krasnowska, G.; Blaszczuk, M. Analysis of Quality Properties in Raw Meat and Fats from Fatteners Breeding in Wielkopolska. Acta Sci. Polonorum. Med. Vet. 2009, 8, 3. [Google Scholar]

- Olkiewicz, M.; Moch, P. Zawartość Głównych Ilościowo Składników Surowcowych w Wybranych Elementach Zasadniczych Półtuszy Wieprzowej Oraz Ich Skład Podstawowy. Postępy Nauk. i Technol. Przemysłu Rolno-Spożywczego 2011, 66, 67–80. [Google Scholar]

- Poklukar, K.; Čandek-Potokar, M.; Vrecl, M.; Batorek-Lukač, N.; Fazarinc, G.; Kress, K.; Weiler, U.; Stefanski, V.; Škrlep, M. The Effect of Immunocastration on Adipose Tissue Deposition and Composition in Pigs. Animal 2021, 15, 100118. [Google Scholar] [CrossRef]

- Kress, K.; Hartung, J.; Jasny, J.; Stefanski, V.; Weiler, U. Carcass Characteristics and Primal Pork Cuts of Gilts, Boars, Immunocastrates and Barrows Using AutoFOM III Data of a Commercial Abattoir. Animals 2020, 10, 1912. [Google Scholar] [CrossRef]

- Wood, J.D.; Enser, M.; Fisher, A.V.; Nute, G.R.; Sheard, P.R.; Richardson, R.I.; Hughes, S.I.; Whittington, F.M. Fat Deposition, Fatty Acid Composition and Meat Quality: A Review. Meat Sci. 2008, 78, 343–358. [Google Scholar] [CrossRef]

- Dinh, T.T.; To, K.V.; Schilling, M.W. Fatty Acid Composition of Meat Animals as Flavor Precursors. Meat Muscle Biol. 2021, 5. [Google Scholar] [CrossRef]

- Enser, M.; Hallett, K.; Hewitt, B.; Fursey, G.A.J.; Wood, J.D. Fatty Acid Content and Composition of English Beef, Lamb and Pork at Retail. Meat Sci. 1996, 42, 443–456. [Google Scholar] [CrossRef]

- Skiba, G.; Raj, S.; Poławska, E. Profile of Fatty Acids and Activity of Elongase and Δ5 and Δ9 Desaturase of Growing Pigs Differ in Concentration of Intramuscular Fat in Musculus Longissimus Dorsi. Anim. Sci. Pap. Rep. 2013, 31, 123–137. [Google Scholar]

- Gandemer, G. Lipids in Muscles and Adipose Tissues, Changes during Processing and Sensory Properties of Meat Products. Meat Sci. 2002, 62, 309–321. [Google Scholar] [CrossRef]

- Xu, R.; Molenaar, A.J.; Chen, Z.; Yuan, Y. Mode and Mechanism of Action of Omega-3 and Omega-6 Unsaturated Fatty Acids in Chronic Diseases. Nutrients 2025, 17, 1540. [Google Scholar] [CrossRef]

- Dutkowska, A.; Rachoń, D. Role of N-3 and n-6 Unsaturated Fatty Acids in the Prevention of Cardiovascular Diseases. Chor. Serca i Naczyń 2015, 12, 154–159. [Google Scholar]

- Grela, E.R.; Kowalczuk-Vasilev, E.; Klebaniuk, R. Performance, Pork Quality and Fatty Acid Composition of Entire Males, Surgically Castrated or Immunocastrated Males, and Female Pigs Reared under Organic. Pol. J. Vet. Sci. 2013, 16, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Covaciu, F.D.; Feher, I.; Cristea, G.; Dehelean, A. Nutritional Quality and Safety Assessment of Pork Meat Cuts from Romania: Fatty Acids and Elemental Profile. Foods 2024, 13, 804. [Google Scholar] [CrossRef]

- Metz, C.; Hohl, K.; Waidelich, S.; Drochner, W.; Claus, R. Active Immunization of Boars against GnRH at an Early Age: Consequences for Testicular Function, Boar Taint Accumulation and N-Retention. Livest. Prod. Sci. 2002, 74, 147–157. [Google Scholar] [CrossRef]

- Brunius, C.; Zamaratskaia, G.; Andersson, K.; Chen, G.; Norrby, M.; Madej, A.; Lundström, K. Early Immunocastration of Male Pigs with Improvac®—Effect on Boar Taint, Hormones and Reproductive Organs. Vaccine 2011, 29, 9514–9520. [Google Scholar] [CrossRef] [PubMed]

- Pawlicki, P.; Galuszka, A.; Pardyak, L.; Tuz, R.; Płachno, B.J.; Malopolska, M.; Dubniewicz, K.; Yang, P.; Kotula-Balak, M.; Tarasiuk, K. Leydig Cells in Immunocastrated Polish Landrace Pig Testis: Differentiation Status and Steroid Enzyme Expression Status. Int. J. Mol. Sci. 2022, 23, 6120. [Google Scholar] [CrossRef]

- Fazarinc, G.; Batorek-Lukač, N.; Škrlep, M.; Poklukar, K.; Van den Broeke, A.; Kress, K.; Labussière, E.; Stefanski, V.; Vrecl, M.; Čandek-Potokar, M. Male Reproductive Organ Weight: Criteria for Detection of Androstenone-Positive Carcasses in Immunocastrated and Entire Male Pigs. Animals 2023, 13, 2042. [Google Scholar] [CrossRef]

- Zeng, X.Y.; Turkstra, J.A.; Meloen, R.H.; Liu, X.Y.; Chen, F.Q.; Schaaper, W.M.M.; Oonk, H.B.; Guo, D.Z.; Van de Wiel, D.F.M. Active Immunization against Gonadotrophin-Releasing Hormone in Chinese Male Pigs: Effects of Dose on Antibody Titer, Hormone Levels and Sexual Development. Anim. Reprod. Sci. 2002, 70, 223–233. [Google Scholar] [CrossRef]

- Kubale, V.; Batorek, N.; Škrlep, M.; Prunier, A.; Bonneau, M.; Fazarinc, G.; Čandek-Potokar, M. Steroid Hormones, Boar Taint Compounds, and Reproductive Organs in Pigs According to the Delay between Immunocastration and Slaughter. Theriogenology 2013, 79, 69–80. [Google Scholar] [CrossRef]

- Čandek-Potokar, M.; Prevolnik, M.; Škrlep, M. Testes Weight Is Not a Reliable Tool for Discriminating Immunocastrates from Entire Males. In Proceedings of the International Symposium on Animal Science, Belgrade, Serbia, 23–25 September 2014; pp. 43–49. [Google Scholar]

- Van den Broeke, A.; Aluwé, M.; Kress, K.; Stefanski, V.; Škrlep, M.; Batorek, N.; Ampe, B.; Millet, S. Effect of Dietary Energy Level in Finishing Phase on Performance, Carcass and Meat Quality in Immunocastrates and Barrows in Comparison with Gilts and Entire Male Pigs. Animal 2022, 16, 100437. [Google Scholar] [CrossRef]

- Werner, D.; Baldinger, L.; Bussemas, R.; Büttner, S.; Weißmann, F.; Ciulu, M.; Mörlein, J.; Mörlein, D. Early Immunocastration of Pigs: From Farming to Meat Quality. Animals 2021, 11, 298. [Google Scholar] [CrossRef]

- Škrlep, M.; Batorek, N.; Bonneau, M.; Fazarinc, G.; Šegula, B.; čandek-Potokar, M. Elevated Fat Skatole Levels in Immunocastrated, Surgically Castrated and Entire Male Pigs with Acute Dysentery. Vet. J. 2012, 194, 417–419. [Google Scholar] [CrossRef] [PubMed]

- Weiler, U.; Götz, M.; Schmidt, A.; Otto, M.; Müller, S. Influence of Sex and Immunocastration on Feed Intake Behavior, Skatole and Indole Concentrations in Adipose Tissue of Pigs. Animal 2013, 7, 300–308. [Google Scholar] [CrossRef] [PubMed]

- Zamaratskaia, G.; Andersson, H.K.; Chen, G.; Andersson, K.; Madej, A.; Lundström, K. Effect of a Gonadotropin-Releasing Hormone Vaccine (ImprovacTM) on Steroid Hormones, Boar Taint Compounds and Performance in Entire Male Pigs. Reprod. Domest. Anim. 2008, 43, 351–359. [Google Scholar] [CrossRef]

- Needham, T.; Gous, R.M.; Lambrechts, H.; Pieterse, E.; Hoffman, L.C. Combined Effect of Dietary Protein, Ractopamine, and Immunocastration on Boar Taint Compounds, and Using Testicle Parameters as an Indicator of Success. Foods 2020, 9, 1665. [Google Scholar] [CrossRef]

- Škrlep, M.; Šegula, B.; Zajec, M.; Kastelic, M.; Košorok, S. Effect of Immunocastration (Improvac®) in Fattening Pigs I: Growth Performance, Reproductive Organs and Malodorous Compounds. Slov. Vet. Res. 2010, 47, 57–64. [Google Scholar]

- Aleksić, J.; Dokmanović, M.; Aleksić, Z.; Teodorović, V.; Stojić, V.; Trbović, D.; Baltić, M.Z. Investigation of The Efficacy of Immunocastration Aimed at The Prevention of Sex Odour in Boar Meat. Acta Vet. 2012, 62, 653–663. [Google Scholar] [CrossRef]

- Stupka, R.; Čítek, J.; Vehovský, K.; Zadinová, K.; Okrouhlá, M.; Urbanová, D.; Stádník, L. Effects of Immunocastration on Growth Performance, Body Composition, Meat Quality, and Boar Taint. Czech J. Anim. Sci. 2017, 62, 249–258. [Google Scholar] [CrossRef]

- Han, X.; Zhou, M.; Cao, X.; Du, X.; Meng, F.; Bu, G.; Kong, F.; Huang, A.; Zeng, X. Mechanistic Insight into the Role of Immunocastration on Eliminating Skatole in Boars. Theriogenology 2019, 131, 32–40. [Google Scholar] [CrossRef]

- Chen, G.; Zamaratskaia, G.; Madej, A.; Lundström, K. Effect of HCG Administration on the Relationship between Testicular Steroids and Indolic Compounds in Fat and Plasma in Entire Male Pigs. Meat Sci. 2006, 72, 339–347. [Google Scholar] [CrossRef]

- Meinert, L.; Lund, B.; Bejerholm, C.; Aaslyng, M.D. Distribution of Skatole and Androstenone in the Pig Carcass Correlated to Sensory Characteristics. Meat Sci. 2017, 127, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Rius, M.A.; García-Regueiro, J.A. Skatole and Indole Concentrations in Longissimus Dorsi and Fat Samples of Pigs. Meat Sci. 2001, 59, 285–291. [Google Scholar] [CrossRef]

- Thomsen, R.; Edwards, S.A.; Jensen, B.B.; Rousing, T.; Sorensen, J.T. Effect of Faecal Soiling on Skatole and Androstenone Occurrence in Organic Entire Male Pigs. Animal 2015, 9, 1587–1596. [Google Scholar] [CrossRef] [PubMed]

- Kjeldsen, N. Practical Experience with Production and Slaughter of Entire Male Pigs; Institut National de la Recherche Agronomique: Paris, France, 1993. [Google Scholar]

- Czech, A.; Kusior, G.; Zięba, G.; Łukaszewicz, M.; Grela, E.R. Effect of Immunocastration on the Steroid Hormones Content, Serum Lipid Profile, and Fatty Acid Profile in Tissues of Porkers Fed Dry or Wet Diet. Anim. Sci. Pap. Rep. 2022, 40, 171–184. [Google Scholar]

- Tuz, R. Zapobieganie Wystepowaniu Zapachu Plciowego w Tuszach Niekastrowanych Chirurgicznie Knurkow. Zesz. Nauk. Akad. Rol. w Krakowie. Rozpr. 2008, 323, 1–86. [Google Scholar]

| Item | Groups | ||

|---|---|---|---|

| C | E1 | E2 | |

| Number of animals, heads | 10 | 10 | 10 |

| Castration | immunological | none | none |

| Slaughter weight, kg | 120.0 | 120.0 | 105.0 |

| Item | Groups | p-Value | ||

|---|---|---|---|---|

| C | E1 | E2 | ||

| Colour of meat | ||||

| L* | 49.96 ± 2.29 | 48.86 ± 1.33 | 49.92 ± 1.96 | 0.353 |

| a* | 5.22 ± 1.02 | 5.18 ± 0.89 | 4.96 ± 1.11 | 0.818 |

| b* | 4.58 ± 1.76 | 4.71 ± 0.81 | 4.28 ± 1.05 | 0.342 |

| Drip loss, % | 2.86 ± 0.85 | 2.53 ± 0.95 | 2.47 ± 0.66 | 0.698 |

| Cooking loss, % | 17.90 ± 1.90 | 17.34 ± 2.12 | 18.37 ± 1.40 | 0.459 |

| WHC *, cm2/g | 21.63 ± 3.38 | 21.63 ± 3.30 | 24.54 ± 2.84 | 0.080 |

| Chemical composition of meat | ||||

| Water | 72.86 ± 0.77 | 72.39 ± 0.59 | 73.11 ± 0.73 | 0.101 |

| Protein | 22.87 A ± 0.17 | 23.48 B ± 0.45 | 22.99 A ± 0.29 | 0.001 |

| Fat | 3.70 ± 0.57 | 3.83 ± 0.58 | 3.43 ± 0.65 | 0.505 |

| Collagen | 1.13 ± 0.10 | 1.04 ± 0.13 | 1.22 ± 0.23 | 0.059 |

| Item | Groups | p-Value | ||

|---|---|---|---|---|

| C | E1 | E2 | ||

| C14:0 | 1.32 ± 0.01 | 1.32 ± 0.03 | 1.29 ± 0.10 | 0.683 |

| C16:0 | 24.08 ± 0.21 | 23.97 ± 0.30 | 23.76 ± 2.39 | 0.602 |

| C16:1 | 2.43 ± 0.04 | 2.43 ± 0.07 | 2.34 ± 0.16 | 0.355 |

| C18:0 | 14.77 ± 0.20 | 14.79 ± 0.24 | 14.59 ± 2.08 | 0.600 |

| C18:1 | 36.98 ± 0.31 | 36.82 ± 0.62 | 35.04 ± 3.76 | 0.183 |

| C18:2 n-6 | 4.67 ± 0.19 | 4.59 ± 0.23 | 4.31 ± 0.43 | 0.051 |

| C18:3 n-3 | 0.44 ± 0.02 | 0.45 ± 0.01 | 0.43 ± 0.06 | 0.654 |

| C20:1 | 0.03 ± 0.01 | 0.03 ± 0.01 | 0.03 ± 0.01 | 0.304 |

| C20:4 n-6 | 0.53 ± 0.03 | 0.54 ± 0.05 | 0.50 ± 0.08 | 0.552 |

| C22:1 | 0.19 ± 0.01 | 0.20 ± 0.02 | 0.20 ± 0.03 | 0.864 |

| C22:2 | 0.17 ± 0.11 | 0.11 ± 0.31 | 0.16 ± 0.09 | 0.317 |

| C22:5 | 0.03 ± 0.01 | 0.03 ± 0.25 | 0.03 ± 0.02 | 0.395 |

| C22:6 | 0.03 ± 0.02 | 0.04 ± 0.02 | 0.03 ± 0.01 | 0.068 |

| SFA | 40.16 ± 0.37 | 40.07 ± 0.43 | 39.63 ± 4.52 | 0.870 |

| MUFA | 39.63 ± 0.34 | 39.42 ± 0.66 | 37.61 ± 3.90 | 0.169 |

| PUFA | 5.43 ± 0.24 | 5.32 ± 0.22 | 5.02 ± 0.50 | 0.109 |

| PUFA n-3 | 0.50 ± 0.03 | 0.53 ± 0.03 | 0.48 ± 0.06 | 0.339 |

| PUFA n-6 | 5.21 a ± 0.19 | 5.13 ab ± 0.19 | 4.81 b ± 0.49 | 0.039 |

| PUFA n-6/n-3 | 10.40 ± 0.97 | 9.82 ± 0.75 | 9.99 ± 0.66 | 0.374 |

| AI | 0.56 ± 0.01 | 0.56 ± 0.01 | 0.59 ± 0.10 | 0.567 |

| TI | 1.67 ± 0.01 | 1.67 ± 0.02 | 1.76 ± 0.31 | 0.340 |

| Item | Groups | p-Value | ||

|---|---|---|---|---|

| C | E1 | E2 | ||

| Colour of backfat | ||||

| L* | 77.69 ± 1.40 | 77.85 ± 1.48 | 76.60 ± 1.60 | 0.147 |

| a* | 3.41 ± 1.40 | 3.52 ± 1.38 | 3.77 ± 0.66 | 0.789 |

| b* | 5.84 ± 1.54 | 6.21 ± 0.95 | 6.49 ± 0.95 | 0.480 |

| Chemical composition of backfat | ||||

| Water | 25.02 ± 3.68 | 27.70 ± 3.38 | 30.89 ± 6.29 | 0.072 |

| Protein | 4.70 a ± 0.43 | 6.20 b ± 1.55 | 5.69 ab ± 1.23 | 0.025 |

| Fat | 70.09 a ± 3.36 | 65.90 b ± 5.57 | 64.75 b ± 4.32 | 0.033 |

| Item | Groups | p-Value | ||

|---|---|---|---|---|

| C | E1 | E2 | ||

| C14:0 | 1.21 ± 0.08 | 1.21 ± 0.05 | 1.20 ± 0.04 | 0.792 |

| C16:0 | 22.67 a ± 0.87 | 22.62 a ± 0.70 | 21.67 b ± 0.70 | 0.027 |

| C16:1 | 2.13 ± 0.21 | 2.02 ± 0.22 | 2.17 ± 0.21 | 0.310 |

| C18:0 | 13.43 A ± 0.57 | 13.49 A ± 0.89 | 12.21 B ± 0.75 | 0.003 |

| C18:1 | 35.76 ± 1.24 | 35.47 ± 1.41 | 34.47 ± 0.87 | 0.064 |

| C18:2 n-6 | 3.96 ± 0.33 | 4.21 ± 0.16 | 4.29 ± 0.26 | 0.059 |

| C18:3 n-3 | 0.67 A ± 0.06 | 0.70 a ± 0.08 | 0.83 Bb ± 0.07 | 0.002 |

| C20:1 | 0.03 ± 0.01 | 0.02 ± 0.01 | 0.03 ± 0.01 | 0.714 |

| C20:4 n-6 | 0.48 a ± 0.19 | 0.24 b ± 0.05 | 0.36 ab ± 0.15 | 0.016 |

| C22:1 | 0.18 ab ± 0.03 | 0.16 a ± 0.03 | 0.19 b ± 0.02 | 0.019 |

| C22:2 | 0.28 a ± 0.10 | 0.36 A ± 0.19 | 0.16 Bb ± 0.12 | 0.009 |

| C22:5 | 0.03 ± 0.02 | 0.05 ± 0.02 | 0.05 ± 0.02 | 0.225 |

| C22:6 | 0.06 a ± 0.02 | 0.05 ab ± 0.02 | 0.03 b ± 0.02 | 0.033 |

| SFA | 37.32 A ± 1.15 | 37.32 A ± 1.57 | 35.08 B ± 1.34 | 0.003 |

| MUFA | 38.10 ± 1.25 | 37.67 ± 1.52 | 36.85 ± 0.97 | 0.083 |

| PUFA | 4.81 ± 0.26 | 4.91 ± 0.29 | 4.89 ± 0.40 | 0.727 |

| PUFA n-3 | 0.76 A ± 0.08 | 0.80 AB ± 0.09 | 0.91 B ± 0.07 | 0.003 |

| PUFA n-6 | 4.44 ± 0.17 | 4.45 ± 0.15 | 4.65 ± 0.32 | 0.088 |

| PUFA n-6/n-3 | 5.90 a ± 0.62 | 5.62 ab ± 0.57 | 5.17 b ± 0.72 | 0.020 |

| AI | 0.55 ± 0.03 | 0.56 ± 0.03 | 0.54 ± 0.02 | 0.447 |

| TI | 1.57 a ± 0.07 | 1.58 a ± 0.10 | 1.48 b ± 0.08 | 0.031 |

| Item | Groups | p-Value | |||

|---|---|---|---|---|---|

| C | E1 | E2 | |||

| Indole | Undetectable Average Minimum Maximum Median | - 43.7 ± 20.61 18.4 80.2 39.9 | - 32.7 ± 20.21 10.9 76.8 28.8 | - 33.0 ± 12.06 10.9 48.9 32.8 | 0.301 |

| Skatole | Undetectable Average Minimum Maximum Median | - 19.1 ± 13.12 3.7 40.7 16.6 | 1 9.9 ± 4.36 4.3 17.4 10.4 | - 11.5 ± 6.20 1.2 19.8 10.9 | 0.289 |

| Androstenol | Undetectable Average Minimum Maximum Median | - 59.6 a ± 9.50 49.7 78.0 56.4 | - 70.9 b ± 13.29 57.4 96.2 66.8 | - 67.0 ab ± 10.41 55.7 88.2 64.2 | 0.025 |

| Androsterone | Undetectable Average Minimum Maximum Median | 6 120.7 25.1 169.7 143.9 | 2 141.3 40.8 331.7 136.5 | 3 147.6 43.6 386.7 112.4 | - |

| Item | Groups | p-Value | |||

|---|---|---|---|---|---|

| C | E1 | E2 | |||

| Indole | Undetectable Average Minimum Maximum Median | 6 11.0 9.6 12.4 11.0 | 5 13.0 10.0 14.6 13.5 | 6 53.3 11.9 171.6 14.8 | - |

| Skatole | Undetectable Average Minimum Maximum Median | 10 - | 10 - | 9 405.0 | - |

| Androstenol | Undetectable Average Minimum Maximum Median | - 493.0 a ± 193.77 307.9 974.7 457.9 | - 996.6 b ± 623.01 309.4 2214.1 816.5 | - 779.2 ab ± 517.30 362.8 2007.8 573.9 | 0.018 |

| Androsterone | Undetectable Average Minimum Maximum Median | 9 6823.1 | 1 6017.8 1463.2 13,475.1 3321.0 | 3 4646.7 203.9 12,294.1 3278.1 | - |

| Possibly Matching Compounds | IR KMXT-5 * | Chemical Groups of Compounds | Sensory Descriptors | Groups | ||

|---|---|---|---|---|---|---|

| C | E1 | E2 | ||||

| methyl formate | 372 | ester | agreeable | X | X | X |

| ethanol | 450 | alcohol | alcoholic | X | X | X |

| propanal | 491 | aldehyde | earthy | X | X | X |

| 1-propanol | 521 | alcohol | alcoholic | X | X | X |

| 2-mercaptoethanol | 558 | thiol | sulphurous | X | X | |

| 2-methylfuran | 584 | furan | burnt | X | ||

| but-(2)-enal | 635 | aldehyde | green | X | X | X |

| 3-methylbutanal | 652 | aldehyde | fatty | X | X | |

| methyl isobutyrate | 665 | ester | fruity | X | ||

| 2-ethyl furan | 704 | furan | acidic | X | X | X |

| methyl butanorate | 734 | ester | ester | X | X | |

| propylenglycol | 754 | alcohol | alcoholic | X | ||

| 2-methylpentanal | 762 | aldehyde | earthy | X | X | X |

| 2,3-butanediol | 790 | diol | bitter | X | ||

| octane | 825 | alkane | alkane | X | ||

| e-2-hexen-1-ol | 848 | alcohol | green | X | ||

| 1-hexanol | 876 | alcohol | fatty | X | X | |

| pentanoic acid | 905 | acid | rancid | X | X | X |

| 5-methylfurfural | 956 | furan | acidic | X | ||

| 2-(2-ethoxyethoxy)ethanol | 1001 | ether | mild | X | X | |

| pinene | 1003 | terpen | hay | X | ||

| heptyl mercaptan | 1026 | thiol | sulphurous | X | ||

| benzeneacetaldehyde | 1028 | aldehyde | grassy | X | X | |

| 1,8-cineole | 1046 | terpene | herbaceous | X | ||

| 2-propionylpyrrole | 1049 | pyrrole | roast | X | ||

| undecane | 1076 | alkane | alkane | X | ||

| gamma-terpinene | 1078 | terpen | etheral | X | X | |

| p-menthatriene | 1131 | terpene | woody | X | ||

| 2,6-dimethoxy-phenol | 1203 | phenol | phenolic | X | ||

| (e, e)-2,4-nonadienal | 1208 | aldehyde | cereal | X | ||

| decanal | 1229 | aldehyde | fatty | X | X | |

| indole | 1295 | amine | animal | X | X | X |

| Total | 15 | 24 | 19 | |||

| Possibly Matching Compounds | IR KMXT-5 * | Chemical Groups of Compounds | Sensory Descriptors | Groups | ||

|---|---|---|---|---|---|---|

| C | E1 | E2 | ||||

| methyl formate | 373 | ester | agreeable | X | X | X |

| trimethylamine | 420 | amine | ammoniacal | X | X | |

| ethanol | 451 | alcohol | alcoholic, | X | X | X |

| propanal | 492 | aldehyde | acetaldehyde | X | X | X |

| 2-methylpropanal | 521 | aldehyde | aldehydic | X | X | X |

| 1-propanol | 552 | alcohol | alcoholic | X | X | |

| formic acid | 565 | carboxylic acid | pungent | X | ||

| 1-propanol, 2-methyl- | 628 | alcohol | bitter | X | X | X |

| 1-butanamine | 635 | amine | fishy | X | ||

| but-(2)-enal | 652 | aldehyde | green | X | ||

| pent-1-en-3-ol | 677 | alken, alkohol | meaty | X | X | |

| 2-ethyl furan | 704 | furan | pungent | X | X | X |

| 2-methylpentanal | 763 | aldehyde | earthy | X | X | X |

| 2-furanmethanol | 869 | alcohol | bread | X | ||

| 1-hexanol | 877 | alcohol | fatty | X | ||

| nonane | 904 | alkane | alkane | X | X | X |

| 2-octanol | 1000 | alcohol | fatty | X | ||

| hexanoic acid | 1004 | carboxylic acid | fatty | X | ||

| heptyl mercaptan | 1028 | thiol | onion | X | ||

| 1,8-cineole | 1045 | ether | herbaceous | X | X | X |

| terpinolene | 1077 | terpene | anisic | X | ||

| undecane | 1081 | alkane | alkane | X | ||

| p-menthatriene | 1130 | terpene | woody | X | ||

| sotolon | 1134 | lactone | mushroom | X | ||

| pyridine, 2-pentyl- | 1205 | heteroaromatic compound | tallow | X | X | |

| indole | 1296 | amine | animal | X | X | X |

| Total | 16 | 15 | 19 | |||

| Indole | Groups | p-Value | ||

|---|---|---|---|---|

| C | E1 | E2 | ||

| Meat | 7.63 A ± 2.46 | 3.86 B ± 1.15 | 4.29 B ± 1.16 | 0.001 |

| Backfat | 3.74 A ± 1.07 | 4.05 A ± 0.99 | 5.28 B ± 1.29 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zalewska, A.; Sońta, M.; Więcek, J.; Rekiel, A.; Cybulski, P.; Wojtasik-Kalinowska, I.; Półtorak, A.; Puppel, K.; Batorska, M. Quality of Meat and Fat from Immunocastrated Boars and Uncastrated Boars Slaughtered at Different Body Weights. Animals 2025, 15, 3374. https://doi.org/10.3390/ani15233374

Zalewska A, Sońta M, Więcek J, Rekiel A, Cybulski P, Wojtasik-Kalinowska I, Półtorak A, Puppel K, Batorska M. Quality of Meat and Fat from Immunocastrated Boars and Uncastrated Boars Slaughtered at Different Body Weights. Animals. 2025; 15(23):3374. https://doi.org/10.3390/ani15233374

Chicago/Turabian StyleZalewska, Anna, Marcin Sońta, Justyna Więcek, Anna Rekiel, Piotr Cybulski, Iwona Wojtasik-Kalinowska, Andrzej Półtorak, Kamila Puppel, and Martyna Batorska. 2025. "Quality of Meat and Fat from Immunocastrated Boars and Uncastrated Boars Slaughtered at Different Body Weights" Animals 15, no. 23: 3374. https://doi.org/10.3390/ani15233374

APA StyleZalewska, A., Sońta, M., Więcek, J., Rekiel, A., Cybulski, P., Wojtasik-Kalinowska, I., Półtorak, A., Puppel, K., & Batorska, M. (2025). Quality of Meat and Fat from Immunocastrated Boars and Uncastrated Boars Slaughtered at Different Body Weights. Animals, 15(23), 3374. https://doi.org/10.3390/ani15233374