1. Introduction

The constantly growing poultry sector faces daily challenges in meeting the nutritional needs of laying hens and maintaining sustainable egg production [

1]. One of the main challenges is the high cost of commodities, especially corn, which drives the search for viable feed alternatives to reduce production costs and enrich the birds’ diet. In the midst of these challenges, Brazil, as the world’s fifth largest producer, registered in 2022 a production of 52 billion eggs and an average of 241 eggs consumed per person, highlighting the need for innovative solutions in poultry nutrition [

2]. At the same time, there is a growing consumer trend for eggs from sources that provide functional properties, such as antioxidant properties, for health benefits and the prevention of diseases, including chronic diseases, such as coronary heart disease. This trend highlights the importance of exploring innovative and sustainable food alternatives, combining the needs of the industry and consumers [

3].

Cactus pear, from the Cactaceae family, comprises around 130 genera and 1500 species, with

Opuntia and

Nopalea being the most prominent genera in animal feeding. In Brazil, the species

Opuntia fícus-indica (L.) Mill with the cultivars Gigante and Redonda and

Nopalea cochenillifera (L.) Salm-Dyck with the cultivar Miúda are widely cultivated, covering around 600,000 ha [

4]. This extensive cultivation, particularly in northeastern Brazil, is due to its adaptability to the region’s soil and climate conditions and its high concentration of non-fiber carbohydrates, offering an efficient and viable source of energy for animal nutrition [

5,

6,

7]. Among the cactus pear cultivars, Miúda (

Nopalea cochinilifera (L.) Salm Dyck) stands out for its nutritional qualities: high levels of total carbohydrates (822.1 g kg

−1), non-fiber carbohydrates (597.5 g kg

−1), mineral matter (128.8 g kg

−1) and low levels of neutral detergent fiber (224.6 g kg

−1) and acid detergent fiber (189.7 g kg

−1) [

6], as well as high energy content (3653 kcal g

−1) [

8].

The Miúda cactus pear meal (CPM), obtained by dehydrating the cladodes, has 82.2% dry matter (DM), 8% crude protein (CP), 1% ether extract (EE), 25.1% neutral detergent fiber (NDF), and 46.7% non-fiber carbohydrates (NFC). It is rich in minerals, with 18.5% mineral matter, including 2.3% calcium and 0.2% phosphorus [

9]. In addition, with an energy value of 3647 kcal/g gross energy (GE) [

8], Miúda CPM stands out for its energy efficiency. In addition, the presence of bioactive compounds such as polyphenols (207.92 mg 100 g

−1 of total soluble phenols, 647.99 mg 100 g

−1 of hydrolysable polyphenols, and 3.55 mg g

−1 of condensed tannins) and β-carotene (4.36 mg 100g

−1) endorse it as a promising source of natural antioxidants. The antioxidant activity is significant, with values of 15.28 mmol DPPH, 20.97 mmol for FRAP, and 51.31 mmol for ABTS+, offering protection against free radicals and promoting health benefits for consumers [

10].

Although previous studies explored the promising results of CPM in broilers and quails [

8,

11,

12], the literature still needs research into its applicability in laying hen diets. Therefore, this research aims to evaluate the potential of using Miúda CPM to feed layers in a semi-intensive system, with an emphasis on egg production and quality. By investigating this sustainable alternative, we hope to contribute to new perspectives for optimizing egg production, combining the sector’s economic interests with new scientific advances and consumer market expectations in terms of nutritional quality and sustainability.

4. Discussion

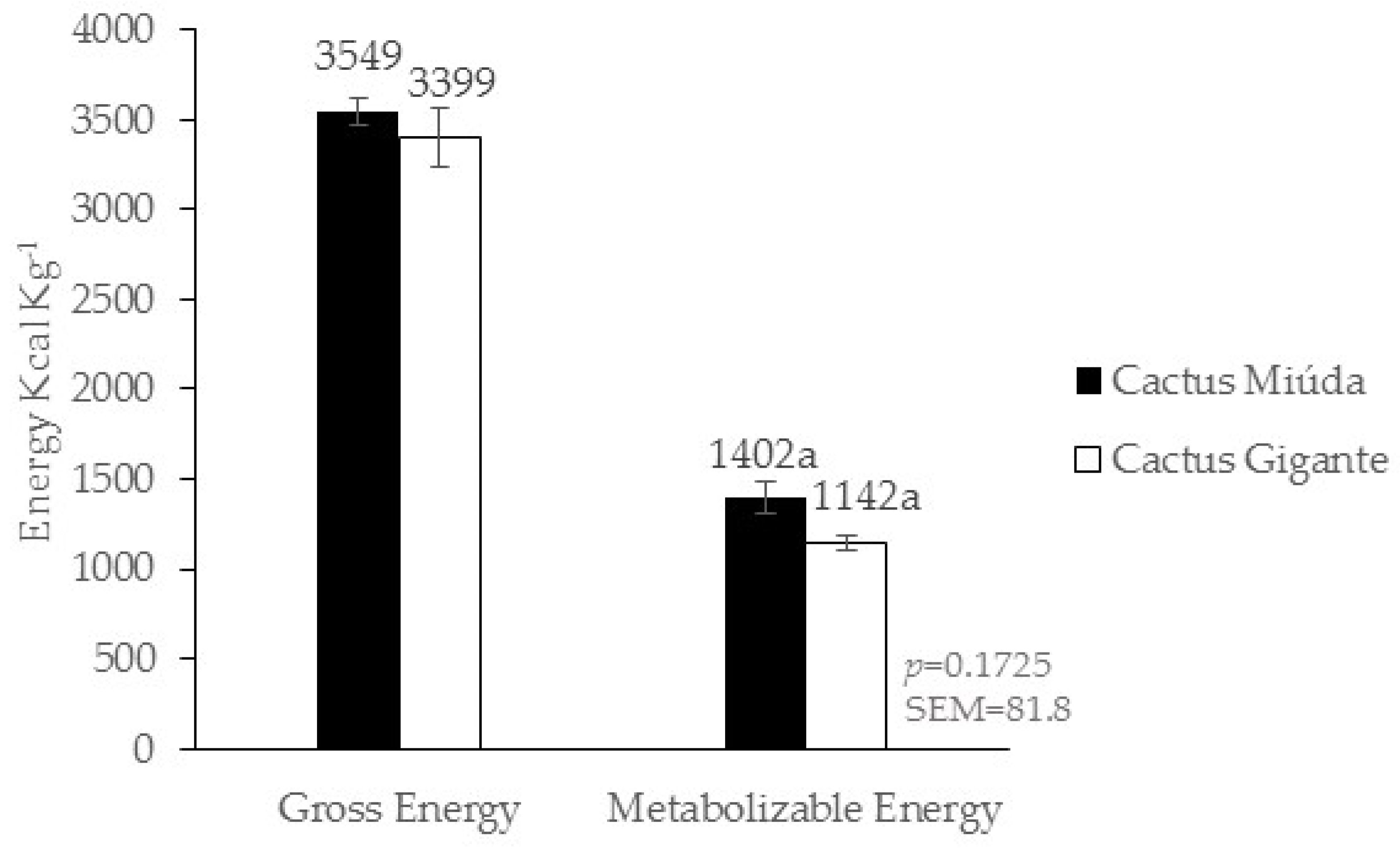

The contents of 3549 and 3399 kcal kg

−1 of GE and 1402 and 1142 kcal kg

−1 AME (

Figure 2) were found in the present study for the varieties of Miúda cactus pear meal (CPM) and Gigante cactus pear meal (CPM). The study of [

30] found values of 4009, 3757, and 3945 kcal kg

−1 GE; 3144, 3019, and 1624 kcal kg

−1 AME for corn, sorghum, and wheat bran, respectively, were reported for chicks aged 26 to 33 days. The authors [

31] found new gross energy values in corn grain (3884 kcal kg

−1), wheat grain (3867 kcal kg

−1), and sorghum grain (3987 kcal kg

−1), while for the metabolizable energy, values of 3719 kcal kg

−1 for corn, 3265 kcal kg

−1 for wheat, and 3695 kcal kg

−1 for sorghum were found for chicks aged 22 to 28 days. At the same time, [

32] found metabolizable energy values of 1259 kcal kg

−1 and 1316 kcal kg

−1 for corn and wheat, respectively, for 7-, 14-, 21-, 28-, and 35-day-old birds. However, these differences in gross energy and metabolizable energy of those feedstuffs were expected since there are variations in soil conditions, climate, raw material obtention, storage time, processing, age of the birds, physiological state, methodology used, and chemical composition [

31,

33,

34].

The AME value of Miúda CPM (1402 kcal kg

−1) was higher than that of Gigante CPM (1142 kcal kg

−1). Although not statistically significant, they may be relevant or indicative of trends that deserve further investigation. Such differences may be related to the species and chemical composition of the varieties of cactus pear, which may interfere with the metabolizable energy. The AME value of cactus pear Miúda stood out due to its bromatological composition, which presented lower contents of soluble fiber when compared to Gigante [

7,

35,

36].

The authors [

37] state that the metabolizable energy is directly and positively affected by the composition of the feed in starch, fat, and protein and negatively affected by the structural carbohydrates of the plant. The AME value of Gigante CPM may have been affected by the soluble fiber content (NSPs and pectin), mainly the high content of pectin and its high water solubility [

36,

38]. These physicochemical characteristics of the soluble fiber fraction result in the increasing viscosity of the digest. High viscosity decreases the diffusion rate of endogenous enzymes in the digest, which will reduce nutrient digestion. In addition, the highly viscous digest will have less interaction with enzymes in the brush border membrane, which also decreases digestibility and nutrient utilization [

38,

39].

On the other hand, the AME value of Miúda CPM was positively affected by the high contents of non-fiber carbohydrates, mainly starch, being the main source of energy for birds [

7,

36,

40,

41]. These results are attributed to the higher intake of non-fiber carbohydrates, which consequently provided higher energy intake [

42].

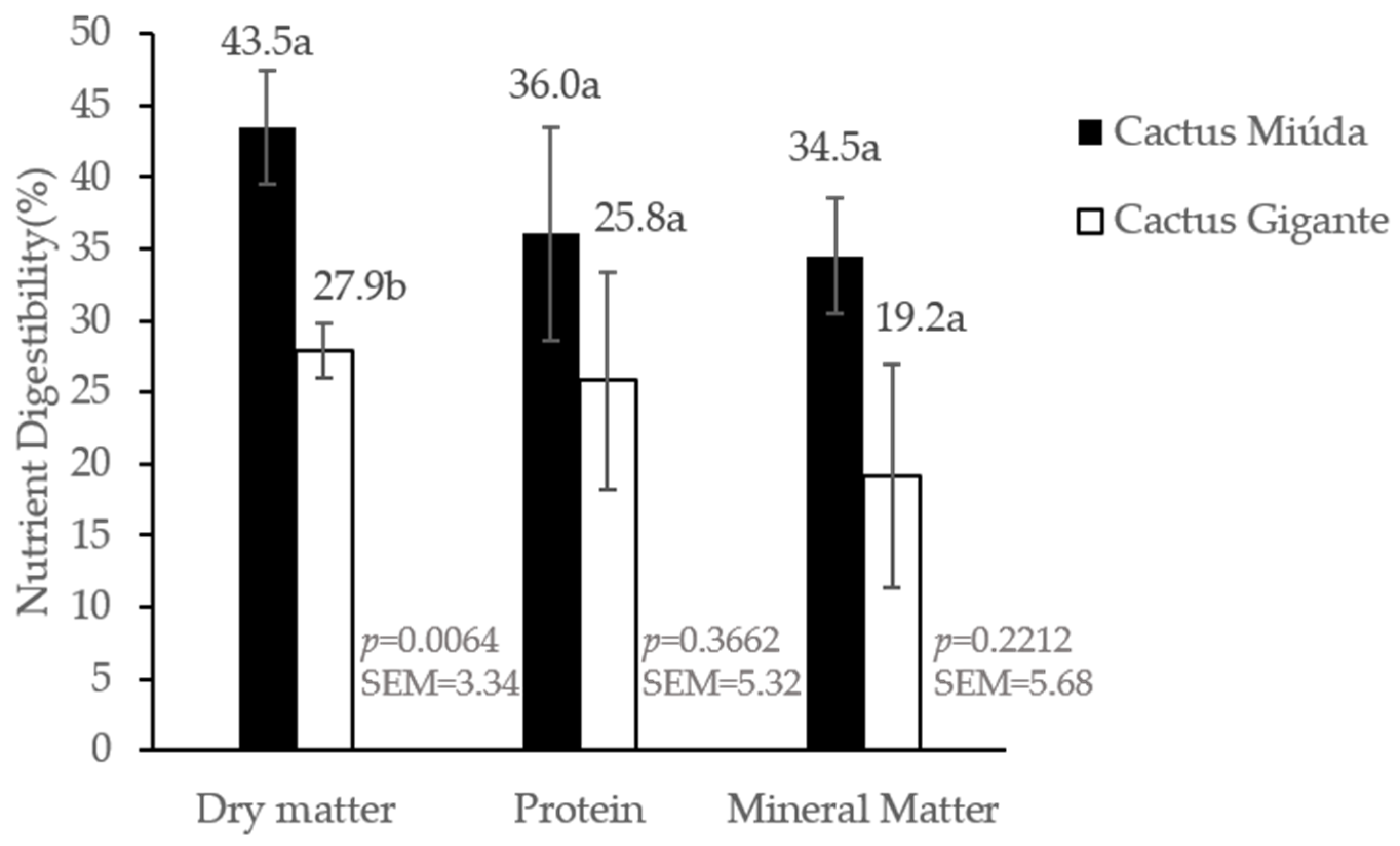

The DMDC value of Miúda CPM (43.5%) was higher than Gigante’s CPM (27.9%). The reduced dry matter digestibility of the cactus pear varieties, mainly for the Gigante CPM, may be attributed to considerable amounts of NSP that cannot be digested by birds because they lack endogenous enzymes. Soluble NSPs can increase the viscosity of the digestate and reduce nutrient digestibility [

43]. The superiority in DMDC of Miúda CPM can be attributed to the sugar and starch contents [

7,

36] since the concentration of these carbohydrates contributes considerably to high palatability, which explains the higher dry matter digestibility of that variety, corroborating the results represented in

Figure 2.

The CPDC values of Miúda CPM (36.0%) and Gigante CPM (25.8%), found in this study, were lower than the values found by [

44], who reported a protein digestibility coefficient of 92.69% for corn and 91.41% for sorghum for Isa Label chickens from 28 to 35 days. Moreover, [

45] found a protein digestibility coefficient of 75.24% for corn and 87.84% for sorghum for Label Rouge birds. These significant differences in the CPDC of CPM, corn, and sorghum are related to the chemical composition of the feed (antinutritional factors and the amount of fiber), in addition to the strain of the birds that can influence the digestibility of nutrients. The lower CPDC may be because the cactus pears are from the genera

Opuntia (Gigante) and

Nopalea (Miúda); that is, the genus influences composition, and the composition influences nutrient utilization. The cactus pear variety Gigante presents a higher concentration of soluble fibers [

7,

35,

36]. Soluble fibers impair protein digestibility because they increase the viscosity of the intestinal contents, reducing the action of proteolytic enzymes and consequently causing endogenous nitrogen losses [

46]. Another possible explanation is that lignin is a substance of the insoluble fraction of fiber, and its binding with proteins makes it unavailable for animal absorption [

35].

For MMDC, the value found for Miúda CPM in this study was higher than the value found by [

47], while the variety Gigante CPM responded inferiorly but very close to the value found of a digestibility coefficient of 27.66 and 21.42% for young and adult Label Rouge birds, respectively, fed with feed based on corn and soybean meal. Cactus pear is considered a good source of minerals, regardless of the species (

Opuntia and

Nopalea), with the highest concentrations found for Ca, K, Mg, and P and the lowest for Cu, Fe, Sr, and Zn [

48,

49]. However, cacti possess the antinutritional factor calcium oxalate, which binds to calcium and possibly other minerals in a nutritionally unavailable form, thus interfering with the bioavailability of calcium for animal absorption [

35,

50]. The researchers [

51] observed that the morphology of calcium oxalate crystals was different since the crystals were larger (ranging from 30 to 100 ÿm) and more abundant in fresh cladode tissues of the three

Opuntia fícus-indica cultivars (Argelina, Morado e Gymno-carpo) than in

Opuntia robusta, which were smaller (ranging from 6 ÿm to 35 ÿm), more rounded, very sparse, and observed mainly near the epidermis. This caused a reduction in the calcium concentration in

Opuntia Robusta. Possibly, the lower mineral matter digestibility coefficient of Gigante CPM (19.2%) may be associated with calcium oxalate crystals.

Diets containing different levels of Miúda CPM usage did not compromise the variables of productive performance despite the presence of NSPs and oxalic acid. Although there are no studies available in the scientific literature on the use of CMP for laying hens, various research works point to alternatives to corn for these birds, but with problems that limit their use. For example, rice bran, an alternative to corn, contains a high percentage of phytic acid and NSPs [

52], making it a feed similar to CPM due to its chemical composition and presence of antinutritional factors. Knowing about the presence of the antinutritional factors in rice bran, [

53] tested the inclusion of rice bran in laying hens’ feed and found that it had no significant effect on egg production, feed intake, feed conversion, and egg mass, as did the present study.

This study is important because it is the first to investigate the use of Miúda CPM in laying hens. The genetic variety of the hens, as well as the specific conditions of the semi-intensive system and the duration of the experiment, provided an opportunity to evaluate the effects of using Miúda CPM on egg production. Although this study focused on only two varieties of Miúda CPM, it opens the way for a wide range of future research that can explore other varieties. The finding that Miúda CPM had no adverse effects on the variables studied is a significant step toward understanding the viability of Miúda CPM as a feed alternative in poultry systems. It is essential that further research is carried out to confirm and expand these results, exploring different scenarios and experimental conditions, as well as evaluating parameters such as the general health of the birds to provide a more comprehensive understanding of the effects of Miúda CPM in poultry farming.

Yolk percentage, shell percentage, shell thickness, specific gravity, Haugh Unit, yolk strength, and yolk brightness values had no significant effects from the increasing levels of Miúda CPM. Miúda CPM has a high concentration of non-fiber carbohydrates [

9], which makes it a good alternative source to corn; however, there is a limitation of use due to the concentration of NSPs [

54]. There are no reports in the scientific environment of its use in laying hens, so it is acceptable to compare results with similar feedstuffs in terms of energy and fiber (NSPs). Wheat bran is widely used for laying hens due to its availability and energy, but it is limited due to the amount of NSPs. They [

6] found that hens responded similarly to the present study; that is, there was no significant effect of adding 3 and 6% wheat bran and beet pulp in the diets of 90-week-old laying hens on egg shape index, yolk percentage, shell percentage, shell thickness, Haugh Unit, and specific gravity.

Eggs from birds that received Miúda CPM levels showed lower yolk diameter values. In contrast, those fed a corn and soybean meal-based diet exhibited larger yolk diameters. However, there is a lack of studies exploring this trait with similar feeds. Yolk diameter is an important variable since it is directly related to the reactions that occur in the albumen, where the water from the albumen crosses the yolk membrane by osmosis and is retained in the yolk. Excess water in the yolk determines the increase of its volume, leading to the weakening of the yolk membrane. This makes the yolk appear larger and flattened when the egg is observed on a flat surface after it is broken [

55].

The percentage of albumen increased proportionally as the levels of Miúda CPM increased. An opposite behavior was observed between the percentage of albumen and yolk, particularly evident when using 9% Miúda CPM. This inversely proportional relationship manifests itself with an increase in the percentage of albumen accompanied by a decrease in the percentage of yolk. Presumably, this increase in albumen percentage must be related to the linoleic acid in the birds’ diets (

Table 2). The experimental diets were formulated to contain the same metabolizable energy, so as the level of cactus pear increased, it was necessary to increase the amount of soybean oil in the feed to standardize the metabolizable energy. Soybean oil has a reasonable amount of linolenic acid [

56], and this acid promotes increased concentrations of estrogen, which is important in controlling egg weight since dietary fats influence egg weight [

57,

58]. The authors [

57] found that diets with supplemental fat and linoleic acid increased the albumen weight of eggs of Isa Brown hens from the 22nd to 65th week of age.

Alternative feeds to corn are well explored to reduce the cost of poultry production. Understanding the importance of exploring the effects of these feeds on egg quality, ref. [

59] evaluated a combination of alternative ingredients and found that the percentage of albumen was higher in group 4 (64.06) than in the other groups (1–63.24, 2–63.27, and 3–63.56); these values are close to those found in the present study.

Hens fed 9% Miúda CPM had lower shell strength when compared to the eggs of hens receiving the control feed, reflecting a decrease in shell strength as the Miúda CPM level increased. This reduction may be due to the effect of oxalic acid present in the cactus pear since it is an organic compound that binds to calcium or other minerals in an unavailable nutritional form, affecting the availability for absorption by the animal [

35,

60], thus causing a deficiency of important minerals for the formation of the shell since about 94–95% of the dry eggshell is composed of calcium carbonate (CaCO

3).

For yolk coloration, brightness had no significant effect among the experimental diets, but hens fed with 9% Miúda CPM had significantly lower values in the red-to-green region and coloration in the yellow-to-blue range. However, the intensity of the yolk color was higher in the control diet, which may be due to the reduced amount of corn in the experimental diets (3%, 6%, and 9%). A possible reason for this result is that corn is the ingredient source of carotenoids in poultry feeds, and these carotenoids are classified into xanthophylls and carotenes [

61,

62] added 15% almond shell in the feed of laying hens and found a decrease in the values of a (greener) and b (less yellow) in yolk coloration.

The method of texture profile analysis is based on compressing the food at least two times, simulating the action of two bites on the food. There was no significant effect on the conversion indicator, which deals with changes suffered (weight increase or reduction) by the cooking process. The hardness property, which is the force required to achieve a deformation of the sample, had no significant effect. Regarding the cohesiveness property, there was a linear increase according to the levels of Miúda CPM used. Cohesivity is defined as the degree to which a material is deformed before it breaks (physical) or between the teeth before it breaks (sensory) [

63]. Probably, this significant effect on cohesiveness is related to the amount of fat present in the yolk (

Table 8) since [

64] reported that fat in the yolk increases cohesiveness. No significant effect was observed on the elasticity property, which is defined as the degree to which the deformed material returns to its original condition after a force was applied (physical) or pressed between the teeth (sensory). No effects were found for the parameter gumminess either. This is a parameter defined as the energy required to disintegrate a food into a swallowable state. Regarding chewability, which is the number of chews required, at a constant force, for the food to be swallowed [

64], there was no significant effect either.

The cooked yolk coloration parameters a* and b* were affected by Miúda CPM levels since as the level of Miúda CPM increased, the yolk color reduced. The reduction in yolk color intensity may be related to the presence of natural pigments (lutein, zeaxanthin, and β-carotene) [

65]. Possibly, this variation is because corn is the main carotenoid source in poultry feed [

61], which means that the presence of pigments is higher in corn than in cactus pear. Moreover, [

66] showed that the average contents of lutein, zeaxanthin, and beta-carotene in green corn kernels are 0.71, 9.85, and 0.88 µg g

−1 in the fresh sample, respectively.

The mineral matter of eggs from hens fed with Miúda CPM was reduced; however, dry matter and crude protein did not differ between treatments. This possibly occurred because cactus pear has the antinutritional factor calcium oxalate, which is an organic compound that binds to calcium or other minerals in an unavailable nutritional form, affecting availability for animal absorption [

35,

60].

According to [

67], chromatographic analyses of total lipids extracted from cactus pear cladodes show that palmitic acid (C16:0), oleic acid (C18:1), linoleic acid (C18:2), and linolenic acid (C18:3) contribute in 13.87, 11.16, 34.87, and 32.83% of the total fatty acid content, respectively. These four fatty acids, therefore, represent over 90% of the total fatty acids, with linoleic and linolenic acids being the main polyunsaturated ones, totaling 67.7%.

The saturated fatty acids identified were myristic, palmitic, and stearic. As the level of Miúda CPM increased, there was a reduction in myristic and palmitic acids. However, the behavior of stearic acid was inversely proportional: as the level of Miúda CPM increased, the value of stearic in the yolks also increased.

The monounsaturated fatty acids identified were myristoylic, palmitoleic, oleic, and vaccenic. All monounsaturated fatty acids showed higher concentrations in the yolk of eggs from hens fed with the control diet (0% Miúda CPM) and reduced as the level of Miúda CPM increased. Regarding the oleic acid, a possible explanation for the reduction is the presence of soybean oil in the feed since, in the study of [

56], the incorporation of soybean oil reduced oleic acid in yolks from chickens fed with corn.

The polyunsaturated fatty acids, linoleic and α-linolenic, increased as the level of Miúda CPM increased, possibly due to the incorporation of soybean oil in the feed. As the level of Miúda CPM increased, the amount of soybean oil also increased. Soybean oil is rich in linoleic acid and has a fair amount of linolenic acid. The inclusion of soybean oil in the diet increased the linoleic and linolenic acid contents and, consequently, increased the linoleic and α-linolenic fatty acids in the yolk [

56]. Linoleic acid promotes increased estrogen concentrations and, thus, stimulates protein synthesis in the oviduct, causing greater protein deposition in the albumen, resulting in a heavier egg [

58]. In addition, linoleic acid has long been accepted as having a hypocholesterolemia effect and inhibitory properties against metastatic colon cancer cells. Omega-3 linolenic acid is known to be beneficial to health, cardiovascular disease, inflammatory conditions, autoimmune disorders, and diabetes [

67]. Arachidonic acid, which is the precursor of linoleic acid, was detected in the yolks, and the lowest concentration was found in eggs from hens receiving the control diet. As the Miúda CPM level increased in the diet, the concentration of this fatty acid also increased.

The cholesterol content in the yolk increased linearly with the use of Miúda CPM (TC = 397.4 + 20.37CPM, R

2 = 0.77). This can be explained by the increase in the polyunsaturated fatty acids, linoleic and α-linolenic. The lipid composition of egg yolk can be altered, especially regarding the fatty acid profile, including the content of n-3 polyunsaturated fatty acids (PUFA) [

68]. The cholesterol content of egg yolks has become an important issue for consumers, especially when it comes to preventing chronic diseases, including coronary heart disease. Cholesterol is synthesized by the human body and consumers have been advised to avoid ingesting cholesterol in the diet to prevent these diseases. More recently, it was determined that exogenous cholesterol actually represents a very small amount of blood cholesterol [

69].

Although feed intake was higher for hens receiving the diet with 6% Miúda CPM, the price of feed was higher in the 9% CPM diet in comparison to the others, which may be due to the increase in soybean oil in the diets to keep them isoenergetic. Consequently, feeding cost was also higher for the diet containing 6% CPM due to the higher feed intake. Egg dozen production (dozen/bird) was higher when hens consumed diets containing 6% Miúda CPM. A plausible explanation is that with 6% cactus pear meal in the diet, there was higher feed intake; consequently, more money was spent to produce the 6% Miúda CPM diet. In contrast, the ratio of feeding cost/egg dozen (BRL/dozen) was higher for the control diet, while for the diet with 6% Miúda CPM, the feeding cost to produce a dozen eggs was higher than the diets with 3% and 9%, respectively.