Tunnel-Ventilated Sheds with Negative Pressure Reduce Thermal Stress and Improve the Meat Quality of Broilers

Abstract

:Simple Summary

Abstract

1. Introduction

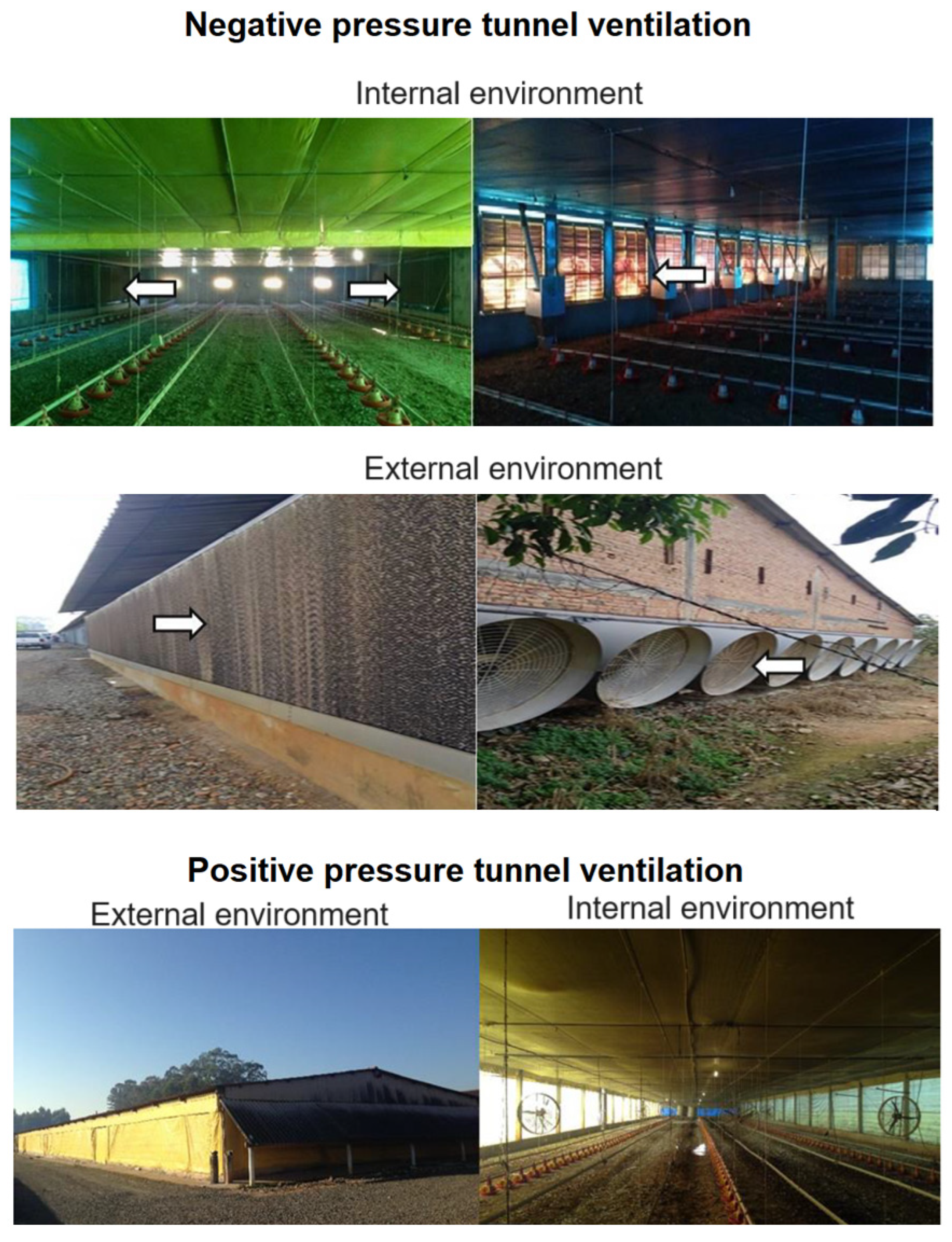

2. Materials and Methods

2.1. Enthalpy Comfort Index (ECI)

2.2. Meat Quality Evaluations

2.2.1. Colour Measurements

2.2.2. pH Measurements

2.2.3. Drip Loss Measurements

2.2.4. Cooking Loss Measurements

2.2.5. Shear Force Measurements

2.3. Classification of the Sample into Quality Groups

2.4. Statistical Analysis

3. Results

3.1. Thermal Performance

3.2. Meat Quality

4. Discussion

4.1. Thermal Performance

4.2. Meat Quality Evaluation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sans, E.C.O.; Vale, M.M.; Vieira, F.M.C.; Vismara, E.S.; Molento, C.F.M. In-barn heterogeneity of broiler chicken welfare in two industrial house designs and two seasons in Southern Brazilian subtropical climate. Livest. Sci. 2021, 250, 104569. [Google Scholar] [CrossRef]

- Jacobs, L.; Delezie, E.; Duchateau, L.; Goethals, K.; Tuyttens, F.A.M. Impact of the separate pre-slaughter stages on broiler chicken welfare. Poult. Sci. 2017, 96, 266–273. [Google Scholar] [CrossRef] [PubMed]

- Støier, S.; Larsen, H.; Aaslyng, M.D.; Lykke, L. Improved animal welfare, the right technology and increased business. Meat Sci. 2016, 120, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Petracci, M.; Bianchi, M.; Cavani, C. Pre-slaughter handling and slaughtering factors influencing poultry product quality. Worlds Poult. Sci. J. 2010, 66, 17–26. [Google Scholar] [CrossRef]

- Grandin, T. Auditing animal welfare at slaughter plants. Meat Sci. 2010, 86, 56–65. [Google Scholar] [CrossRef] [PubMed]

- Jones, T.A.; Donnelly, C.A.; Dawkins, M.S. Environmental and management factors affecting the welfare of chickens on commercial farms in the United Kingdom and Denmark stocked at five densities. Poult. Sci. 2005, 84, 1155–1165. [Google Scholar] [CrossRef]

- Nascimento, G.R.D.; Nääs, I.A.; Baracho, M.S.; Pereira, D.F.; Neves, D.P. Termografia infravermelho na estimativa de conforto térmico de frangos de corte. Rev. Bras. Eng. Agríc. Ambient. 2014, 18, 658–663. [Google Scholar] [CrossRef]

- Lara, L.J.; Rostagno, M.H. Impact of Heat Stress on Poultry Production. Animals 2013, 3, 356–369. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Cason, J.; Lyon, C.; Papa, C. Effect of muscle opposition during rigor on development of broiler breast meat tenderness. Poult. Sci. 1997, 76, 785–787. [Google Scholar] [CrossRef] [PubMed]

- Dadgar, S.; Crowe, T.G.; Classen, H.L.; Watts, J.M.; Shand, P.J. Broiler chicken thigh and breast muscle responses to cold stress during simulated transport before slaughter. Poult. Sci. 2012, 91, 1454–1464. [Google Scholar] [CrossRef]

- Barbut, S.; Zhang, L.; Marcone, M. Effects of pale, normal, and dark chicken breast meat on microstructure, extractable proteins, and cooking of marinated fillets. Poult. Sci. 2005, 84, 797–802. [Google Scholar] [CrossRef] [PubMed]

- Dadgar, S.; Lee, E.S.; Leer, T.L.V.; Burlinguette, N.; Classen, H.L.; Crowe, T.G.; Shand, P.J. Effect of microclimate temperature during transportation of broiler chickens on quality of the pectoralis major muscle. Poult. Sci. 2010, 89, 1033–1041. [Google Scholar] [CrossRef] [PubMed]

- Box, G.E.P.; Cox, D.R. An analysis of transformations. J. R. Stat. Soc. B 1964, 26, 211–243. [Google Scholar] [CrossRef]

- Ferrari, S.; Cribari-Neto, F. Beta regression for modelling rates and proportions. J. Appl. Stat. 2004, 31, 799–815. [Google Scholar] [CrossRef]

- Núcleo de Pesquisa em Ambiência (NUPEA). Tabelas Práticas de Entalpia. 2019. Available online: http://www.nupea.esalq.usp.br/tabelas-de-entalpia (accessed on 25 August 2023).

- Petracci, M.; Betti, M.; Bianchi, M.; Cavani, C. Color variation and characterisation of broiler breast meat during processing in italy. Poult. Sci. 2004, 83, 2086–2092. [Google Scholar] [CrossRef] [PubMed]

- Kee, M.; Sams, A.R. The effect of seasonal heat stress on rigor development and the incidence of pale, exudative turkey meat. Poult. Sci. 1997, 76, 1616–1620. [Google Scholar] [CrossRef]

- Mancini, R.A.; Hunt, M.C. Current research in meat color. Meat Sci. 2005, 71, 100–121. [Google Scholar] [CrossRef] [PubMed]

- Warriss, P.D. Meat Quality: An Introductory Text, 2nd ed.; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Wang, R.H.; Liang, R.R.; Lin, H.; Zhu, L.X.; Zhang, Y.M.; Mao, Y.W.; Dong, P.C.; Niu, L.B.; Zhang, M.H.; Luo, X. Effect of acute heat stress and slaughter processing on poultry meat quality and postmortem carbohydrate metabolism. Poult. Sci. 2017, 96, 738–746. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Rosenvold, K.; Karlsson, A.H.; Horn, P.; Hedegaard, J.; Steffensen, C.L.; Andersen, H.J. Relationship between thermal denaturation of porcine muscle proteins and water-holding capacity. J. Food Sci. 2002, 67, 1642–1647. [Google Scholar] [CrossRef]

- Dos Santos, V.M.; Dallago, B.S.L.; Racanicci, A.M.C.; Santana, P.; Bernal, F.E.M. Effects of season and distance during transport on broiler chicken meat. Poult. Sci. 2017, 96, 4270–4279. [Google Scholar] [CrossRef] [PubMed]

- Queiroz, M.L.V.; Barbosa Filho, J.A.D.; Vieira, F.M.C. Evaluation of the thermal comfort of broilers in a direct and practical way. Rev. Produção Anim.-Avic. 2012, 66, 21–24. [Google Scholar]

- Thielke, S.; Lhafi, S.K.; Kühne, M. Effects of aging prior to freezing on poultry meat tenderness. Poult. Sci. 2005, 84, 607–612. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, H.; Savage, E.M. Comparisons of sensory descriptive flavor and texture profiles of cooked broiler breast fillets categorised by raw meat color lightness values. Poult. Sci. 2010, 89, 1049–1055. [Google Scholar] [CrossRef] [PubMed]

- Jiang, N.; Xing, T.; Xu, X. Effects of pre-slaughter showering and ventilation on stress, meat quality and metabolite concentrations of broilers in summer. Anim. Sci. J. 2015, 87, 293–298. [Google Scholar] [CrossRef] [PubMed]

- Xing, T.; Xu, X.; Jiang, N.; Deng, S. Effect of transportation and pre-slaughter water shower spray with resting on amp-activated protein kinase, glycolises and meat quality of broilers during summer. Anim. Sci. J. 2015, 87, 299–307. [Google Scholar] [CrossRef]

- Barbut, S. Review: Automation and meat quality-global challenges. Meat Sci. 2014, 96, 335–345. [Google Scholar] [CrossRef] [PubMed]

- Bowker, B.C.; Zhuang, H.; Buhr, R.J. Impact of carcass scalding and chilling on muscle proteins and meat quality of broiler breast fillets. LWT-Food Sci. Technol. 2014, 59, 156–162. [Google Scholar] [CrossRef]

- Sandercock, D.A.; Hunter, R.R.; Mitchell, M.A.; Hocking, P.M. Thermoregulatory capacity and muscle membrane integrity are compromised in broilers compared with layers at the same age or body weight. Br. Poult. Sci. 2006, 47, 322–329. [Google Scholar] [CrossRef] [PubMed]

- Barbut, S.; Sosnicki, A.; Lonergan, S.; Knapp, T.; Ciobanu, D.; Gatcliffe, L.; Huff-Lonergan, E.; Wilson, E. Progress in reducing the pale, soft and exudative (pse) problem in pork and poultry meat. Meat Sci. 2007, 79, 46–63. [Google Scholar] [CrossRef] [PubMed]

| Variables | Positive Pressure Tunnel Ventilation | Negative Pressure Tunnel Ventilation | p-Value |

|---|---|---|---|

| Air temperature (%) | 26.58 ± 0.48 a | 22.72 ± 0.80 b | <0.0001 |

| Relative humidity (%) | 67.70 ± 2.57 b | 72.87 ± 3.01 a | <0.0001 |

| ECI (kJ.kg−1 of dry air) | 60.14 ± 2.46 a | 51.75 ± 4.24 b | =0.024 |

| ECI | Negative Pressure Tunnel Ventilation | Positive Pressure Tunnel Ventilation | p-Value |

|---|---|---|---|

| Transport | 45.66 ± 2.93 a | 50.05 ± 7.78 a | 0.145 |

| Lairage | 55.15 ± 10.93 a | 63.00 ± 12.06 a | 0.541 |

| Variables | Poultry Houses c | p-Value | |

|---|---|---|---|

| Negative Pressure Tunnel Ventilation | Positive Pressure Tunnel Ventilation | ||

| L* | 60.7 ± 3.86 | 62 ± 2.56 | =0.547 |

| a* | 2.26 ± 1.08 | 2.30 ± 1.35 | =0.721 |

| b* | 4.64 ± 2.30 b | 7.57 ± 3.46 a | <0.001 |

| pH | 6.18 ± 0.20 a | 5.91 ± 0.21 b | =0.012 |

| Shear force | 4.40 ± 1.64 | 4.58 ± 1.94 | =0.351 |

| Cooking loss | 27 ± 3.92 A | 18.6 ± 4.02 B | =0.001 |

| Drip loss | 3.72 ± 1.50 | 3.34 ± 1.51 | =0.245 |

| Meat Quality Variables | ||||||

|---|---|---|---|---|---|---|

| a* | b* | pH | SF | CL | DL | |

| L* | 0.012 | 0.323 | −0.514 * | 0.498 * | −0.196 | 0.665 *** |

| a* | - | 0.060 | −0.090 | 0.035 | 0.333 | 0.003 |

| b* | - | - | −0.219 | −0.131 | 0.245 | 0.046 |

| pH | - | - | - | −0.257 | −0.012 | −0.471 * |

| SF | - | - | - | - | 0.212 | −0.060 |

| CL | - | - | - | - | - | −0.302 |

| Meat Quality Variables | ||||||

|---|---|---|---|---|---|---|

| a* | b* | pH | SF | CL | DL | |

| L* | −0.078 | −0.206 | −0.265 | 0.342 | −0.43 | −0.063 |

| a* | - | 0.399 | 0.318 | −0.202 | 0.28 | −0.14 |

| b* | - | - | 0.335 | −0.681 *** | −0.39 | −0.282 |

| pH | - | - | - | −0.257 | −0.142 | −0.012 |

| SF | - | - | - | - | 0.455 * | 0.185 |

| CL | - | - | - | - | - | 0.102 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakamoto, K.S.; Silveira, R.M.F.; Benincasa, N.C.; Contreras Castillo, C.J.; Lobos, C.M.V.; Silva, I.J.O.d. Tunnel-Ventilated Sheds with Negative Pressure Reduce Thermal Stress and Improve the Meat Quality of Broilers. Animals 2024, 14, 2017. https://doi.org/10.3390/ani14142017

Sakamoto KS, Silveira RMF, Benincasa NC, Contreras Castillo CJ, Lobos CMV, Silva IJOd. Tunnel-Ventilated Sheds with Negative Pressure Reduce Thermal Stress and Improve the Meat Quality of Broilers. Animals. 2024; 14(14):2017. https://doi.org/10.3390/ani14142017

Chicago/Turabian StyleSakamoto, Karina Suemi, Robson Mateus Freitas Silveira, Natália Cristina Benincasa, Carmen Josefina Contreras Castillo, Cristian Marcelo Villegas Lobos, and Iran José Oliveira da Silva. 2024. "Tunnel-Ventilated Sheds with Negative Pressure Reduce Thermal Stress and Improve the Meat Quality of Broilers" Animals 14, no. 14: 2017. https://doi.org/10.3390/ani14142017

APA StyleSakamoto, K. S., Silveira, R. M. F., Benincasa, N. C., Contreras Castillo, C. J., Lobos, C. M. V., & Silva, I. J. O. d. (2024). Tunnel-Ventilated Sheds with Negative Pressure Reduce Thermal Stress and Improve the Meat Quality of Broilers. Animals, 14(14), 2017. https://doi.org/10.3390/ani14142017