Opportunities for Regulatory Authorities to Assess Animal-Based Measures at the Slaughterhouse Using Sensor Technology and Artificial Intelligence: A Review

Abstract

:Simple Summary

Abstract

1. Introduction

1.1. Animal Welfare Inspections at the Slaughterhouse

1.2. Use of Animal-Based Measures to Asses Animal Welfare

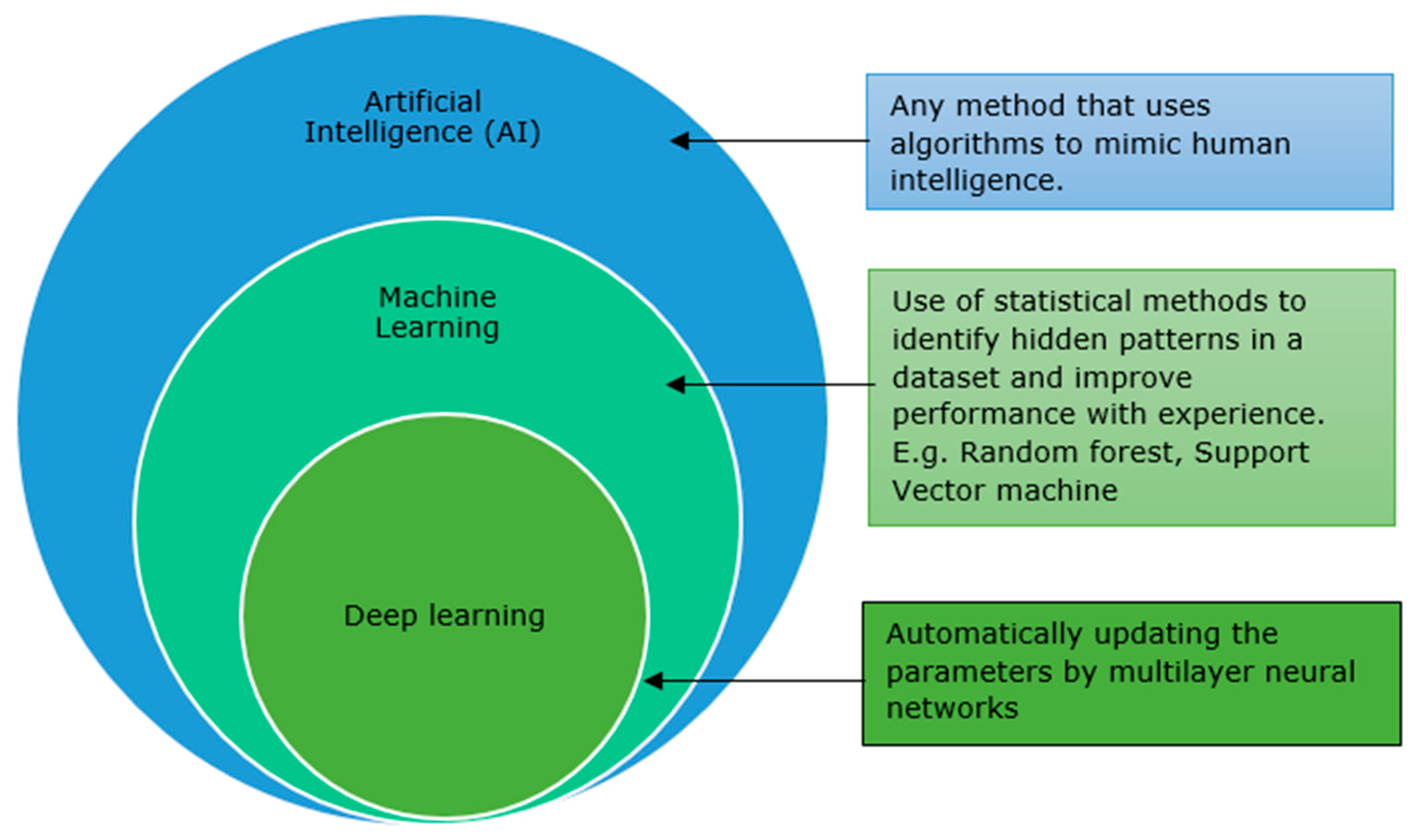

1.3. Sensor Technology and Artificial Intelligence

- Collecting data about the health and welfare of the animals from sensors;

- Labelling of the data by experts or by “smart” sensors;

- Training the algorithm to classify a wanted or an unwanted event with a certain threshold;

- Testing the trained algorithm with new data to make sure it works as intended (the more training/testing the better);

- Using the trained and tested algorithm in real-life situation for flagging certain events;

- Maintaining/adjusting the algorithm to ensure proper performance.

1.4. State of Play on Use of Sensor Technology and AI at the Slaughterhouse and Animal Welfare

2. Methods

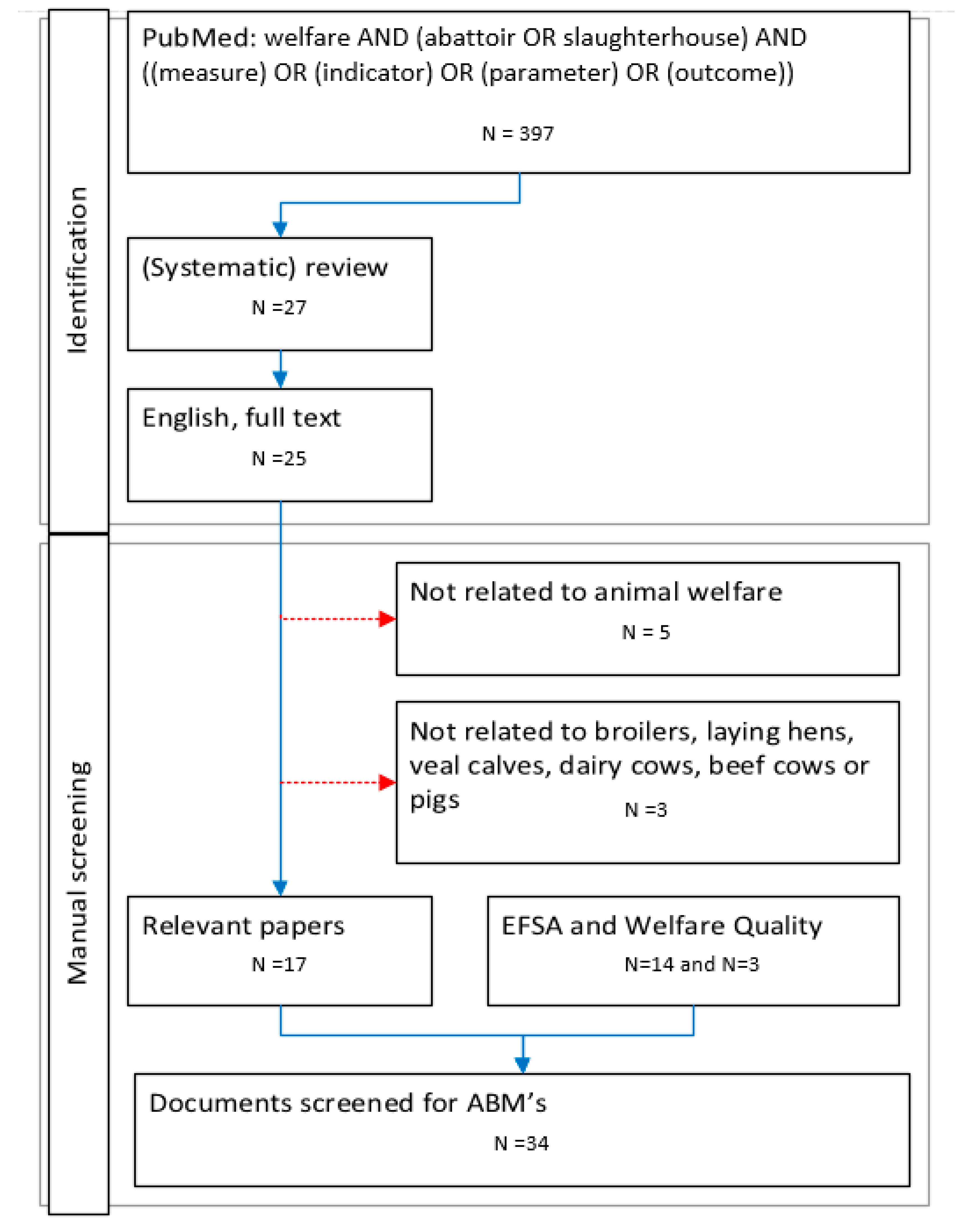

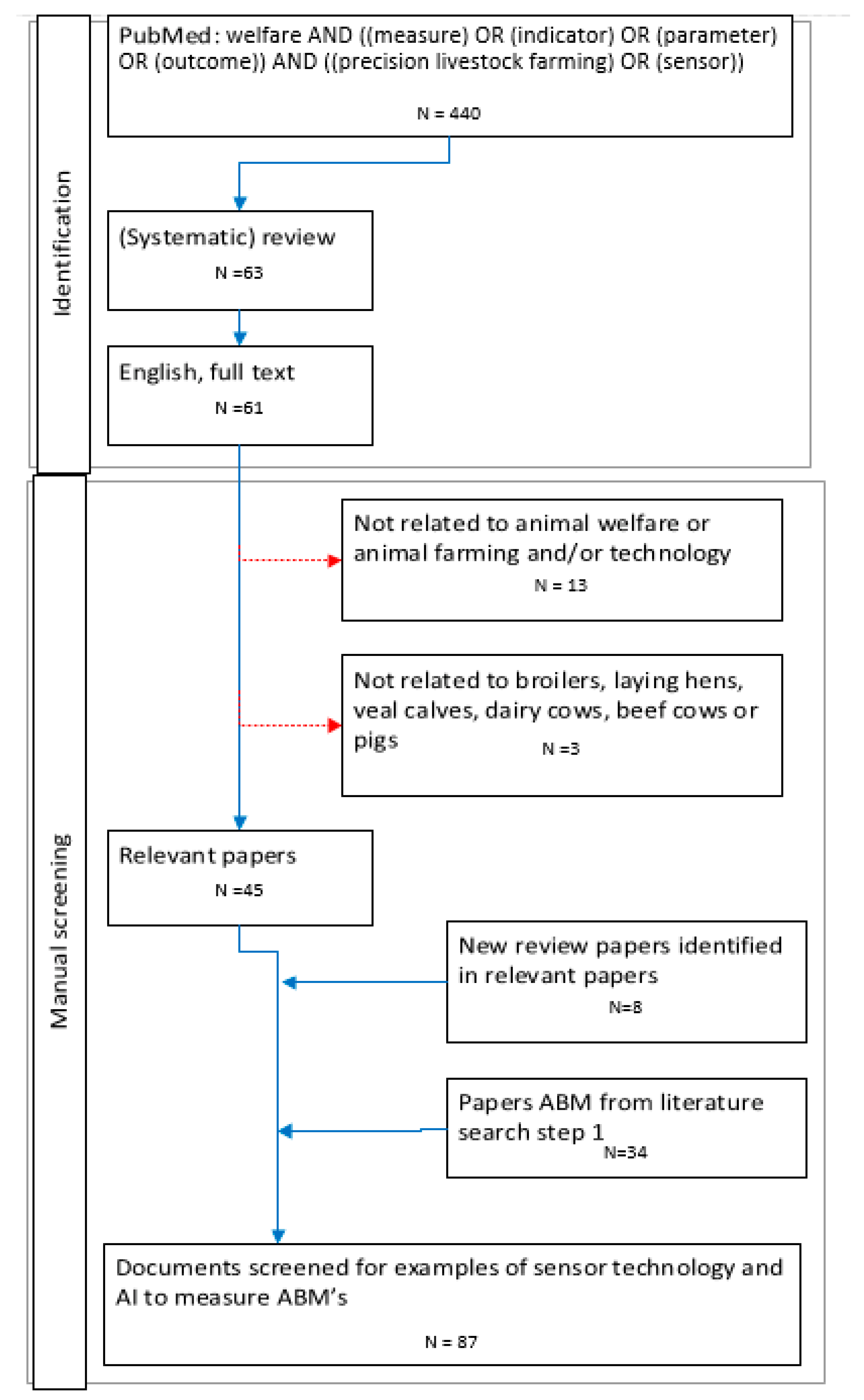

2.1. Literature Search

2.2. Analysis of the Literature

3. Recording Animal-Based Measures at the Slaughterhouse

3.1. Animal-Based Measures at the Slaughterhouse

3.2. Animal-Based Measures at the Slaughterhouse Recorded by the RA

3.3. The Use of Sensor Technology and AI to Record Animal-Based Measures

| Broilers and Laying Hens | Development Phase | ||||

|---|---|---|---|---|---|

| Welfare Quality Principle | Welfare Consequence | ABM | Research | Research at Slaughterhouse | Commercially Available |

| Good feeding | Prolonged hunger | Emaciated animals, body weight | ChickSort 3.0 [89] TrueWeigher 707 [90] SmartWeigher [91] | ||

| Good health | Injuries (pain) | Breast blisters | Meyn [92] ChickenCheck [93] | ||

| Hock burn | ClassifEYE® [94] ChickSort 3.0 [89] ChickenCheck [93] | ||||

| Footpad lesions | [83,84,85,86] | Meyn * [95] ChickenCheck * [93] | |||

| Plumage damage | [99,100,101] † | [87] | |||

| Wing injuries (bone fractures) | Meyn [92] ClassifEYE® [94] ChickSort 3.0 [89] IRIS [96,97,98] | ||||

| Bruises and skin damage | [88] | Meyn [92] ClassifEYE® [94] ChickSort 3.0 [89] IRIS [96,97,98] ChickenCheck [93] | |||

| Disease | Ascites | [88] | |||

| Hepatitis | [88] | ||||

| Appropriate behaviour | Fear and pain | Vocalisations | [102,103,104,105] † | ||

| Cattle | Development Phase | |||||

|---|---|---|---|---|---|---|

| Welfare Quality Principle | Welfare Consequence | ABM | Research | Research at Slaughterhouse | Commercially Available Slaughterhouse | Commercially Available on Farm |

| Good feeding | Prolonged hunger | Body condition score | [106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,140] | DeLaval * [141] 4DRT-Alpha [142] | ||

| Good health | Lameness (pain) | Lameness | [122,127,128,129,130,131,132,133,134,135,136] | |||

| Anaemia | Carcass colour | [138,139] † | Chromameter † (e.g., Minolta CR400) [143] | |||

| Appropriate behaviour | Social stress | Aggressive behaviour | [137] | |||

| Pigs | Development phase | |||||

|---|---|---|---|---|---|---|

| Welfare Quality Principle | Welfare Consequence | ABM | Research | Research at Slaughterhouse | Commercially Available at Slaughterhouse | Commercially Available on Farm |

| Good feeding | Prolonged hunger | Body condition | [144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161,162] | PigWei [184] OptiScan [185] WUGGL [186] GroStat [187] Fancom [188] | ||

| Good housing | Cold stress | Huddling | [189,190,191] | |||

| Restricted movement | Slipping | [192] | ||||

| Good health | Injuries (pain) | Ear injuries | [193] | CLK GmbH * [176] | ||

| Tail injuries | [193,194,195] | CLK GmbH * [176] | ||||

| Lameness (pain) | Lameness | [196] | ||||

| Disease | Abnormalities organs (lung, stomach, heart, liver, pleura) | [25,197,198] | Lung: F4TLaB [177] | |||

| Consciousness during stunning and killing process | Body movement | Argus [179] Genba Solutions GmbH [180] AI4Animals [181] | ||||

| Bleeding rate | [199] | VisStick * [183] CLK GmbH [182] | ||||

| Appropriate behaviour | Social stress | Aggressive behaviour | [200,201,202,203,204,205,206] † | |||

| Mounting | [207,208,209,210,211,212] | |||||

| Fear | Reluctance to move, freezing | [213] | [192,214] | AI4Animals [178] | ||

| Fear and pain | High-pitched vocalisations | [163,164,165,166,167,168,169,170,171,172,173,174,175] | ||||

3.4. Validation

4. The Use of Sensor Technology and AI to record Animal-Based Measures by the Regulatory Authorities

4.1. Existing Technologies and AM and PM Inspection

4.2. Current Use of Sensor Technology by the RA

4.3. Legal Framework and Use of Sensor Technology by the RA

5. Discussion

5.1. Research on Sensor Technology to Record Animal-Based Measures

5.2. Observations by a System Versus Human Observation

5.3. Commercial Application

5.4. Legal Barriers

5.5. Opportunities on the Use of Sensortechonology and AI by the RA

5.6. Limitations of This Study

5.7. Future Research

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CBS. Vleesproductie; Aantal Slachtingen en Geslacht Gewicht per Diersoort. 2022. Available online: https://opendata.cbs.nl/statline/#/CBS/nl/dataset/7123slac/table?fromstatweb (accessed on 9 March 2022).

- NVWA. Roodvleesbijlage Nieuwe Controleverordening: Gevolgen Voor Keuring en Toezicht. 2020. Available online: https://www.nvwa.nl/documenten/export/veterinair/ks-documenten/werkvoorschriften-veterinair-algemeen/roodvleesbijlage-nieuwe-controleverordening-gevolgen-voor-keuring-en-toezicht (accessed on 22 March 2021).

- BuRO. Advies over de Risico’s van de Pluimveevleesketen; NVWA: Utrecht, Netherlands, 2018. [Google Scholar]

- NVWA. Nvwa Schorst Erkenning Slachterij. NVWA. 2022. Available online: https://www.nvwa.nl/dierenwelzijn/nieuws/2022/06/30/nvwa-schorst-erkenning-slachterij (accessed on 12 September 2023).

- NVWA. Nvwa Schorst Slachthuiserkenning Slachterij Gosschalk. NVWA. 2021. Available online: https://www.nvwa.nl/dierenwelzijn/nieuws/2021/07/02/vwa-schorst-slachthuiserkenning-slachterij-gosschalk (accessed on 12 September 2023).

- RTLNieuws. Levend Koken van Varkens in Slachthuizen Gaat nog Altijd Door. 2022. Available online: https://www.rtlnieuws.nl/nieuws/nederland/artikel/5289897/varkens-slachthuizen-verdrinken-broeibak-nvwa (accessed on 12 September 2023).

- The Guardian. Suffering of Gassed Pigs Laid Bare in Undercover Footage from UK Abattoir. The Guardian. 2023. Available online: https://www.theguardian.com/environment/2023/may/02/suffering-of-gassed-pigs-laid-bare-in-undercover-footage-from-uk-abattoir (accessed on 12 September 2023).

- Dalmau, A.; Nande, A.; Vieira-Pinto, M.; Zamprogna, S.; Di Martino, G.; Ribas, J.C.; da Costa, M.P.; Halinen-Elemo, K.; Velarde, A. Application of the Welfare Quality® protocol in pig slaughterhouses of five countries. Livest. Sci. 2016, 193, 78–87. [Google Scholar] [CrossRef]

- Vitali, M.; Sardi, L.; Martelli, G.; Nannoni, E. Literature Review on the Pre-Slaughter Welfare of Italian Heavy Pigs. Animals 2021, 11, 3352. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on AHAW. Scientific Opinion Concerning the Welfare of Animals during Transport. EFSA J. 2011, 9, 1966. [Google Scholar] [CrossRef]

- EFSA Panel on AHAW. Slaughter of animals: Poultry. EFSA J. 2019, 17, e05849. [Google Scholar] [CrossRef]

- EFSA Panel on AHAW. Welfare of pigs at slaughter. EFSA J. 2020, 18, e06148. [Google Scholar] [CrossRef]

- EFSA Panel on AHAW. Welfare of cattle at slaughter. EFSA J. 2020, 18, e06275. [Google Scholar] [CrossRef]

- De Jong, I.; Berg, C.; Butterworth, A.; Estevéz, I. Scientific report updating the EFSA opinions on the welfare of broilers and broiler breeders. EFSA Support. Publ. 2012, 9, 295E. [Google Scholar] [CrossRef]

- EFSA. Scientific Opinion on the public health hazards to be covered by inspection of meat (poultry). EFSA J. 2012, 10, 2741. [Google Scholar] [CrossRef]

- EFSA. Scientific Opinion on the public health hazards to be covered by inspection of meat (swine). EFSA J. 2011, 9, 2351. [Google Scholar] [CrossRef]

- Huneau-Salaün, A.; Stärk, K.D.C.; Mateus, A.; Lupo, C.; Lindberg, A.; Le Bouquin-Leneveu, S. Contribution of Meat Inspection to the surveillance of poultry health and welfare in the European Union. Epidemiol. Infect. 2015, 143, 2459–2472. [Google Scholar] [CrossRef]

- EFSA Panel on AHAW. Welfare of calves. EFSA J. 2023, 21, e07896. [Google Scholar] [CrossRef]

- Official Journal of the European Union. Regulation (EU) 2017/625 of the European Parliament and of the Council of 15 March 2017 on Official Controls and Other Official Activities Performed to Ensure the Application of Food and Feed Law, Rules on Animal health and Welfare, Plant Health and Plant Protection Products, Amending REGULATIONS (EC) No 999/2001, (EC) No 396/2005, (EC) No 1069/2009, (EC) No 1107/2009, (EU) No 1151/2012, (EU) No 652/2014, (EU) 2016/429 and (EU) 2016/2031 of the European Parliament and of the Council, Council Regulations (EC) No 1/2005 and (EC) No 1099/2009 and Council Directives 98/58/EC, 1999/74/EC, 2007/43/EC, 2008/119/EC and 2008/120/EC, and repealing Regulations (EC) No 854/2004 and (EC) No 882/2004 of the European Parliament and of the Council, Council Directives 89/608/EEC, 89/662/EEC, 90/425/EEC, 91/496/EEC, 96/23/EC, 96/93/EC and 97/78/EC and Council Decision 92/438/EEC (Official Controls Regulation)Text with EEA Relevance; L 95/1; pp. 1–142. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32017R0625 (accessed on 6 April 2022).

- Dalmau, A.; Temple, D.; Rodriguez, P.; Llonch, P.; Velarde, A. Application of the Welfare Quality® protocol at pig slaughterhouses. Anim. Welf. 2009, 18, 497–505. [Google Scholar] [CrossRef]

- Dalmau, A.; Geverink, N.; Van Nuffel, A.; Van Steenbergen, L.; Van Reenen, K.; Hautekiet, V.; Vermeulen, K.; Velarde, A.; Tuyttens, F. Repeatability of lameness, fear and slipping scores to assess animal welfare upon arrival in pig slaughterhouses. Animal 2010, 4, 804–809. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on AHAW. Statement on the use of animal-based measures to assess the welfare of animals. EFSA J. 2012, 10, 2767. [Google Scholar] [CrossRef]

- De Luca, S.; Zanardi, E.; Alborali, G.L.; Ianieri, A.; Ghidini, S. Abattoir-Based Measures to Assess Swine Welfare: Analysis of the Methods Adopted in European Slaughterhouses. Animals 2021, 11, 226. [Google Scholar] [CrossRef] [PubMed]

- Leruste, H.; Brscic, M.; Heutinck, L.F.M.; Visser, E.K.; Wolthuis-Fillerup, M.; Bokkers, E.A.M.; Stockhofe-Zurwieden, N.; Cozzi, G.; Gottardo, F.; Lensink, B.J.; et al. The relationship between clinical signs of respiratory system disorders and lung lesions at slaughter in veal calves. PLoS ONE 2012, 105, 93–100. [Google Scholar] [CrossRef] [PubMed]

- Trachtman, A.R.; Bergamini, L.; Palazzi, A.; Porrello, A.; Capobianco Dondona, A.; Del Negro, E.; Paolini, A.; Vignola, G.; Calderara, S.; Marruchella, G. Scoring pleurisy in slaughtered pigs using convolutional neural networks. Vet. Res. 2020, 51, 51. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on AHAW. Welfare of laying hens on farm. EFSA J. 2023, 21, e07789. [Google Scholar] [CrossRef]

- Velarde, A.; Dalmau, A. Animal welfare assessment at slaughter in Europe: Moving from inputs to outputs. Meat Sci. 2012, 92, 244–251. [Google Scholar] [CrossRef]

- Maisano, A.M.; Luini, M.; Vitale, N.; Rota Nodari, S.; Scali, F.; Alborali, G.L.; Vezzoli, F. Animal-based measures on fattening heavy pigs at the slaughterhouse and the association with animal welfare at the farm level: A preliminary study. Animal 2020, 14, 108–118. [Google Scholar] [CrossRef]

- Spigarelli, C.; Zuliani, A.; Battini, M.; Mattiello, S.; Bovolenta, S. Welfare Assessment on Pasture: A Review on Animal-Based Measures for Ruminants. Animals 2020, 10, 609. [Google Scholar] [CrossRef]

- Bracke, M.B.; Spruijt, B.M.; Metz, J.H. Overall animal welfare reviewed. Part 3: Welfare assessment based on needs and supported by expert opinion. NJAS Wagening. J. Life Sci. 1999, 47, 307–322. [Google Scholar] [CrossRef]

- Losada-Espinosa, N.; Villarroel, M.; Maria, G.A.; Miranda-de la Lama, G.C. Pre-slaughter cattle welfare indicators for use in commercial abattoirs with voluntary monitoring systems: A systematic review. Meat Sci. 2018, 138, 34–48. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on AHAW. Scientific Opinion on the use of animal-based measures to assess welfare in pigs. EFSA J. 2012, 10, 2512. [Google Scholar] [CrossRef]

- Allain, V.; Salines, M.; Le Bouquin, S.; Magras, C. Designing an innovative warning system to support risk-based meat inspection in poultry slaughterhouses. Food Control 2018, 89, 177–186. [Google Scholar] [CrossRef]

- Welfare Quality®. Welfare Quality® Assessment Protocol for Poultry; ASG Veehouderij BV: Lelystad, The Netherlands, 2009; Available online: https://edepot.wur.nl/233471 (accessed on 10 March 2023).

- Velarde, A.; Dalmau, A.; Keeling, L.; Veissier, I. Welfare Quality® Assessment Protocol for Pigs (Sows and Piglets, Growing and Finishing Pigs); ASG Veehouderij BV: Lelystad, The Netherlands, 2009. [Google Scholar]

- Herlin, A.; Brunberg, E.; Hultgren, J.; Högberg, N.; Rydberg, A.; Skarin, A. Animal Welfare Implications of Digital Tools for Monitoring and Management of Cattle and Sheep on Pasture. Animals 2021, 11, 829. [Google Scholar] [CrossRef] [PubMed]

- Van Erp-van der Kooij, E.; Rutter, S.B. Using precision farming to improve animal welfare. CAB Rev. Perspect. Agric. Vet. Sci. Nutr. Nat. Resour. 2020, 15, 1–10. [Google Scholar] [CrossRef]

- Rushen, J.; Chapinal, N.; De Passille, A. Automated monitoring of behavioural-based animal welfare indicators. Anim. Welf. 2012, 21, 339. [Google Scholar] [CrossRef]

- Benjamin, M.; Yik, S. Precision livestock farming in swine welfare: A review for swine practitioners. Animals 2019, 9, 133. [Google Scholar] [CrossRef]

- Norton, T.; Berckmans, D. Precision livestock farming: The future of livestock welfare monitoring and management? In Animal Welfare in a Changing World; CABI: Wallingford, UK, 2018; p. 130. [Google Scholar] [CrossRef]

- Russell, S.J.; Norvig, P. Artificial Intelligence: A Modern Approach, 4th ed.; Pearson Education, Inc.: Hoboken, NJ, USA, 2021. [Google Scholar]

- Shimizu, H.; Nakayama, K.I. Artificial intelligence in oncology. Cancer Sci. 2020, 111, 1452. [Google Scholar] [CrossRef]

- Tuyttens, F.A.M.; Molento, C.F.M.; Benaissa, S. Twelve Threats of Precision Livestock Farming (PLF) for Animal Welfare. Front. Vet. Sci. 2022, 9, 889623. [Google Scholar] [CrossRef] [PubMed]

- Gómez, Y.; Stygar, A.H.; Boumans, I.J.M.M.; Bokkers, E.A.M.; Pedersen, L.J.; Niemi, J.K.; Pastell, M.; Manteca, X.; Llonch, P. A Systematic Review on Validated Precision Livestock Farming Technologies for Pig Production and Its Potential to Assess Animal Welfare. Front. Vet. Sci. 2021, 8, 660565. [Google Scholar] [CrossRef] [PubMed]

- Stygar, A.H.; Gómez, Y.; Berteselli, G.V.; Dalla Costa, E.; Canali, E.; Niemi, J.K.; Llonch, P.; Pastell, M. A Systematic Review on Commercially Available and Validated Sensor Technologies for Welfare Assessment of Dairy Cattle. Front. Vet. Sci. 2021, 8, 63433. [Google Scholar] [CrossRef] [PubMed]

- Larsen, M.L.; Wang, M.; Norton, T. Information technologies for welfare monitoring in pigs and their relation to Welfare Quality®. Sustainability 2021, 13, 692. [Google Scholar] [CrossRef]

- Rios, H.V.; Waquil, P.D.; de Carvalho, P.S.; Norton, T. How are information technologies addressing broiler welfare? A systematic review based on the welfare quality® assessment. Sustainability 2020, 12, 1413. [Google Scholar] [CrossRef]

- Rowe, E.; Dawkins, M.S.; Gebhardt-Henrich, S.G. A systematic review of precision livestock farming in the poultry sector: Is technology focussed on improving bird welfare? Animals 2019, 9, 614. [Google Scholar] [CrossRef] [PubMed]

- Leliveld, L.M.C.; Provolo, G. A Review of Welfare Indicators of Indoor-Housed Dairy Cow as a Basis for Integrated Automatic Welfare Assessment Systems. Animals 2020, 10, 1430. [Google Scholar] [CrossRef]

- Ben Sassi, N.; Averós, X.; Estevez, I. Technology and Poultry Welfare. Animals 2016, 6, 62. [Google Scholar] [CrossRef]

- Wurtz, K.; Camerlink, I.; D’Eath, R.B.; Fernández, A.P.; Norton, T.; Steibel, J.; Siegford, J. Recording behaviour of indoor-housed farm animals automatically using machine vision technology: A systematic review. PLoS ONE 2019, 14, e0226669. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Edwards, S.A.; Sturm, B. Implementation of machine vision for detecting behaviour of cattle and pigs. Livest. Sci. 2017, 202, 25–38. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, H.; Qiao, Y.; Jiang, S.; Lin, H.; Sun, Q. The Research Progress of Vision-Based Artificial Intelligence in Smart Pig Farming. Sensors 2022, 22, 6541. [Google Scholar] [CrossRef] [PubMed]

- García, R.; Aguilar, J.; Toro, M.; Pinto, A.; Rodríguez, P. A systematic literature review on the use of machine learning in precision livestock farming. Comput. Electron. Agric. 2020, 179, 105826. [Google Scholar] [CrossRef]

- Brandt, P.; Aaslyng, M.D. Welfare measurements of finishing pigs on the day of slaughter: A review. Meat Sci. 2015, 103, 13–23. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on AHAW. Welfare of broilers on farm. EFSA J. 2023, 21, e07788. [Google Scholar] [CrossRef]

- EFSA Panel on AHAW. Welfare of pigs on farm. EFSA J. 2022, 20, e07421. [Google Scholar] [CrossRef]

- Sandberg, M.; Ghidini, S.; Alban, L.; Capobianco Dondona, A.; Blagojevic, B.; Bouwknegt, M.; Lipman, L.; Seidelin Dam, J.; Nastasijevic, I.; Antic, D. Applications of computer vision systems for meat safety assurance in abattoirs: A systematic review. Food Control 2023, 150, 109768. [Google Scholar] [CrossRef]

- Brscic, M.; Contiero, B.; Magrin, L.; Riuzzi, G.; Gottardo, F. The Use of the General Animal-Based Measures Codified Terms in the Scientific Literature on Farm Animal Welfare. Front. Vet. Sci. 2021, 8, 634498. [Google Scholar] [CrossRef] [PubMed]

- European Community. Council Regulation (EC) No 1099/2009 of 24 September 2009 on the Protection of Animals at the Time of Killing; United Nations Environment Programme: Nairobi, Kenya, 2009. [Google Scholar]

- Official Journal of the European Union. Commission Implementing Regulation (eu) 2019/627 of 15 March 2019 Laying Down Uniform Practical Arrangements for the Performance of Official Controls on Products of Animal Origin Intended for Human Consumption in Accordance with Regulation (eu) 2017/625 of the European Parliament and of the Council and Amending Commission Regulation (ec) no 2074/2005 as Regards Official Controls; L 131/51; p. 51–100. Available online: https://eur-lex.europa.eu/eli/reg_impl/2019/627/oj (accessed on 17 May 2022).

- Council Regulation (EC) No 1/2005 of 22 December 2004 on the Protection of Animals during Transport and Related Operations and Amending Directives 64/432/EEC and 93/119/EC and Regulation (EC) No 1255/97. The Council of The European Union: Brussels, Belgium, 2005; OJ L 3, 5.1.2005, pp 1–44. Available online: EUR-Lex-02005R0001-20191214-EN-EUR-Lex (accessed on 27 January 2023).

- NVWA. Werkvoorschrift Toezicht op Welzijn van Pluimvee en Konijnen in Het Slachthuis. 2020. Available online: https://www.nvwa.nl/documenten/export/veterinair/ks-documenten/werkvoorschriften-dierwelzijn/k-pl-wlz-wv-01-werkvoorschrift-toezicht-op-welzijn-van-pluimvee-en-konijnen-in-het-slachthuis (accessed on 25 January 2023).

- K-RV-AM-WV04; Fysieke Beoordeling van Slachtdieren Tijdens de am-Keuring van als Landbouwhuisdier Gehouden Hoefdieren en Gekweekt Wild. NVWA: Utrecht, The Netherlands, 2021.

- K-PL-PM-WV01; Werkvoorschrift Postmortem Keuring Pluimvee en Lagomorfen. NVWA: Utrecht, The Netherlands, 2021.

- WLZVL-017; Toezicht op Welzijn van Hoefdieren en Gekweekt Wild in Slachthuizen. NVWA: Utrecht, The Netherlands, 2022.

- Jones, B.; Manteca, X. Practical Strategies for Improving Farm Animal Welfare: An Information Resource. Welfare Quality® Project. 2009. Available online: http://www.welfarequality.net/en-us/home/ (accessed on 25 January 2023).

- EFSA Panel on AHAW. Scientific Opinion on the use of animal-based measures to assess welfare of broilers. EFSA J. 2012, 10, 2774. [Google Scholar] [CrossRef]

- Grandin, T. Auditing animal welfare at slaughter plants. Meat Sci. 2010, 86, 56–65. [Google Scholar] [CrossRef]

- Terlouw, C.; Bourguet, C.; Deiss, V. Consciousness, unconsciousness and death in the context of slaughter. Part II. Eval. Methods. Meat Sci. 2016, 118, 147–156. [Google Scholar] [CrossRef]

- EFSA Panel on AHAW. Scientific Opinion on the use of animal-based measures to assess welfare of dairy cows. EFSA J. 2012, 10, 2554. [Google Scholar] [CrossRef]

- Welfare Quality®. Welfare Quality® Assessment Protocol for Cattle; ASG Veehouderij BV: Lelystad, The Netherlands, 2009. [Google Scholar]

- Edwards-Callaway, L.N.; Calvo-Lorenzo, M.S. Animal welfare in the U.S. slaughter industry-a focus on fed cattle. J. Anim. Sci. 2020, 98, skaa040. [Google Scholar] [CrossRef]

- da Costa, M.J.; Huertas, S.M.; Gallo, C.; Dalla Costa, O.A. Strategies to promote farm animal welfare in Latin America and their effects on carcass and meat quality traits. Meat Sci. 2012, 92, 221–226. [Google Scholar] [CrossRef] [PubMed]

- Howell, A.K.; McCann, C.M.; Wickstead, F.; Williams, D.J.L. Co-infection of cattle with Fasciola hepatica or F. gigantica and Mycobacterium bovis: A systematic review. PLoS ONE 2020, 14, e0226300. [Google Scholar] [CrossRef] [PubMed]

- Verhoeven, M.T.W.; Gerritzen, M.A.; Hellebrekers, L.J.; Kemp, B. Indicators used in livestock to assess unconsciousness after stunning: A review. Animal 2015, 9, 320–330. [Google Scholar] [CrossRef] [PubMed]

- Kamenik, J.; Paral, V.; Pyszko, M.; Voslarova, E. Cattle stunning with a penetrative captive bolt device: A review. Anim. Sci. J. 2019, 90, 307–316. [Google Scholar] [CrossRef] [PubMed]

- Johnson, C.B.; Mellor, D.J.; Hemsworth, P.H.; Fisher, A.D. A scientific comment on the welfare of domesticated ruminants slaughtered without stunning. N. Z. Vet. J. 2015, 63, 58–65. [Google Scholar] [CrossRef]

- Driessen, B.; Freson, L.; Buyse, J. Fasting Finisher Pigs before Slaughter Influences Pork Safety, Pork Quality and Animal Welfare. Animals 2020, 10, 2206. [Google Scholar] [CrossRef]

- BWBR0035217; Besluit Houders van Dieren. Wettenbank Overheid: Amsterdam, The Netherlands, 2023. Available online: https://wetten.overheid.nl/BWBR0035217/2023-07-01 (accessed on 15 August 2023).

- RVO.nl. Voetzoollaesies bij Vleeskuikens. Available online: https://www.rvo.nl/onderwerpen/agrarisch-ondernemen/dieren-houden/dierenwelzijn/regels-voor-huisvesting-en-verzorging/vleeskuikens/aanvullende-eisen-categorie-2-en-3 (accessed on 10 November 2020).

- BWBR0035248; Regeling Houders van Dieren. Wettenbank Overheid: Amsterdam, The Netherlands, 2023. Available online: https://wetten.overheid.nl/BWBR0035248/2023-07-01 (accessed on 15 August 2023).

- Van Harn, J.; De Jong, I.C. Validation of Meyn Footpad Inspection System; Wageningen Livestock Research: Wageningen, The Netherlands, 2017. [Google Scholar]

- Louton, H.; Bergmann, S.; Piller, A.; Erhard, M.; Stracke, J.; Spindler, B.; Schmidt, P.; Schulte-Landwehr, J.; Schwarzer, A. Automatic Scoring System for Monitoring Foot Pad Dermatitis in Broilers. Agriculture 2022, 12, 221. [Google Scholar] [CrossRef]

- Vanderhasselt, R.F.; Sprenger, M.; Duchateau, L.; Tuyttens, F.A.M. Automated assessment of footpad dermatitis in broiler chickens at the slaughter-line: Evaluation and correspondence with human expert scores. Poult. Sci. 2013, 92, 12–18. [Google Scholar] [CrossRef]

- Kaewtapee, C.; Thepparak, S.; Rakangthong, C.; Bunchasak, C.; Supratak, A. Objective scoring of footpad dermatitis in broiler chickens using image segmentation and a deep learning approach: Camera-based scoring system. Br. Poult. Sci. 2022, 63, 427–433. [Google Scholar] [CrossRef] [PubMed]

- Jung, L.; Nasirahmadi, A.; Schulte-Landwehr, J.; Knierim, U. Automatic Assessment of Keel Bone Damage in Laying Hens at the Slaughter Line. Animals 2021, 11, 163. [Google Scholar] [CrossRef] [PubMed]

- Sandberg, M.; Jørgensen, A.; Fagertun, J. VetInspector-A tool for post mortem inspection of chicken. In Proceedings of the 4th International Conference on Animal Health Surveillance, Copenhagen, Denmark, 3–5 May 2022. [Google Scholar]

- Foodmate, B.V. ChickSort 3.0. 2021. Available online: https://foodmate.nl/chicksort-3-0/4517/4517/ (accessed on 18 October 2021).

- BAADER. TrueWeigher 707. 2023. Available online: https://poultry.baader.com/distribution/trueweigher-707 (accessed on 6 March 2023).

- Marel. SmartWeigher DF. Available online: https://marel.com/en/products/smartweigher-df (accessed on 6 March 2023).

- Meyn Food Processing Technology, B.V. Meyn Quality grading system M2.0. 2019. Available online: https://www.meyn.com/products/plant-automation/weighing-grading/qgs-whole-bird-m2-0 (accessed on 18 October 2021).

- CLK GmbH. ChickenCheck. Available online: https://www.clkgmbh.de/en/chicken-check/ (accessed on 27 March 2023).

- LINCO Food Systems A/S. ClassifEYE® Vision System, 06-2018 VER01 EN 15; LINCO Food Systems A/S Trige: Trige, Denmark, 2018. [Google Scholar]

- Meyn Food Processing Technology, B.V. Meyn Footpad Inspection System. 2018. Available online: https://www.meyn.com/ (accessed on 14 February 2022).

- Marel. IRIS DF. Available online: https://marel.com/en/products/iris-df (accessed on 6 March 2023).

- Marel. IRIS GDR. Available online: https://marel.com/en/products/iris-gdr (accessed on 6 March 2023).

- Marel. IRIS NT. Available online: https://marel.com/en/products/iris-nt (accessed on 6 March 2023).

- Döhring, S.; Jung, L.; Andersson, R. Plumage damage in laying hens-automated detection in practical test-technical note. Eur. Poult. Sci. 2020, 84, 317. [Google Scholar]

- Lamping, C.; Derks, M.; Groot Koerkamp, P.; Kootstra, G. ChickenNet—An end-to-end approach for plumage condition assessment of laying hens in commercial farms using computer vision. Comput. Electron. Agric. 2022, 194, 106695. [Google Scholar] [CrossRef]

- Pichová, K.; Bilčík, B.; Košt’ál, L. Assessment of the effect of housing on feather damage in laying hens using IR thermography. Animal 2017, 11, 661–669. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Lao, F.; Teng, G. A Sound Source Localisation Analytical Method for Monitoring the Abnormal Night Vocalisations of Poultry. Sensors 2018, 18, 2906. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Carpentier, L.; Teng, G.; Liu, M.; Wang, C.; Norton, T. Assessment of Laying Hens’ Thermal Comfort Using Sound Technology. Sensors 2020, 20, 473. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Noh, B.; Jang, S.; Park, D.; Chung, Y.; Chang, H.H. Stress detection and classification of laying hens by sound analysis. Asian-Australas. J. Anim. Sci. 2015, 28, 592–598. [Google Scholar] [CrossRef]

- Pereira, E.M.; Nääs, I.d.A.; Garcia, R.G. Identification of acoustic parameters for broiler welfare estimate. Eng. Agrícola 2014, 34, 413–421. [Google Scholar] [CrossRef]

- Martins, B.M.; Mendes, A.L.C.; Silva, L.F.; Moreira, T.R.; Costa, J.H.C.; Rotta, P.P.; Chizzotti, M.L.; Marcondes, M.I. Estimating body weight, body condition score, and type traits in dairy cows using three dimensional cameras and manual body measurements. Livest. Sci. 2020, 236, 104054. [Google Scholar] [CrossRef]

- Mullins, I.L.; Truman, C.M.; Campler, M.R.; Bewley, J.M.; Costa, J.H.C. Validation of a Commercial Automated Body Condition Scoring System on a Commercial Dairy Farm. Animals 2019, 9, 287. [Google Scholar] [CrossRef]

- O’Leary, N.; Leso, L.; Buckley, F.; Kenneally, J.; McSweeney, D.; Shalloo, L. Validation of an Automated Body Condition Scoring System Using 3D Imaging. Agriculture 2020, 10, 246. [Google Scholar] [CrossRef]

- Halachmi, I.; Klopčič, M.; Polak, P.; Roberts, D.J.; Bewley, J.M. Automatic assessment of dairy cattle body condition score using thermal imaging. Comput. Electron. Agric. 2013, 99, 35–40. [Google Scholar] [CrossRef]

- Bercovich, A.; Edan, Y.; Alchanatis, V.; Moallem, U.; Parmet, Y.; Honig, H.; Maltz, E.; Antler, A.; Halachmi, I. Development of an automatic cow body condition scoring using body shape signature and Fourier descriptors. J. Dairy. Sci. 2013, 96, 8047–8059. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; He, D.; Norton, T. Automatic estimation of dairy cattle body condition score from depth image using ensemble model. Biosyst. Eng. 2020, 194, 16–27. [Google Scholar] [CrossRef]

- Huang, X.; Hu, Z.; Wang, X.; Yang, X.; Zhang, J.; Shi, D. An improved single shot multibox detector method applied in body condition score for dairy cows. Animals 2019, 9, 470. [Google Scholar] [CrossRef]

- Salau, J.; Haas, J.H.; Junge, W.; Bauer, U.; Harms, J.; Bieletzki, S. Feasibility of automated body trait determination using the SR4K time-of-flight camera in cow barns. Springerplus 2014, 3, 225. [Google Scholar] [CrossRef]

- Fischer, A.; Luginbühl, T.; Delattre, L.; Delouard, J.M.; Faverdin, P. Rear shape in 3 dimensions summarized by principal component analysis is a good predictor of body condition score in Holstein dairy cows. J. Dairy. Sci. 2015, 98, 4465–4476. [Google Scholar] [CrossRef]

- Kuzuhara, Y.; Kawamura, K.; Yoshitoshi, R.; Tamaki, T.; Sugai, S.; Ikegami, M.; Kurokawa, Y.; Obitsu, T.; Okita, M.; Sugino, T.; et al. A preliminarily study for predicting body weight and milk properties in lactating Holstein cows using a three-dimensional camera system. Comput. Electron. Agric. 2015, 111, 186–193. [Google Scholar] [CrossRef]

- Spoliansky, R.; Edan, Y.; Parmet, Y.; Halachmi, I. Development of automatic body condition scoring using a low-cost 3-dimensional Kinect camera. J. Dairy. Sci. 2016, 99, 7714–7725. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez Alvarez, J.; Arroqui, M.; Mangudo, P.; Toloza, J.; Jatip, D.; Rodríguez, J.M.; Teyseyre, A.; Sanz, C.; Zunino, A.; Machado, C.; et al. Body condition estimation on cows from depth images using Convolutional Neural Networks. Comput. Electron. Agric. 2018, 155, 12–22. [Google Scholar] [CrossRef]

- Song, X.; Bokkers, E.A.M.; van Mourik, S.; Groot Koerkamp, P.W.G.; van der Tol, P.P.J. Automated body condition scoring of dairy cows using 3-dimensional feature extraction from multiple body regions. J. Dairy. Sci. 2019, 102, 4294–4308. [Google Scholar] [CrossRef] [PubMed]

- Yukun, S.; Pengju, H.; Yujie, W.; Ziqi, C.; Yang, L.; Baisheng, D.; Runze, L.; Yonggen, Z. Automatic monitoring system for individual dairy cows based on a deep learning framework that provides identification via body parts and estimation of body condition score. J. Dairy. Sci. 2019, 102, 10140–10151. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez Alvarez, J.; Arroqui, M.; Mangudo, P.; Toloza, J.; Jatip, D.; Rodriguez, J.M.; Teyseyre, A.; Sanz, C.; Zunino, A.; Machado, C.; et al. Estimating Body Condition Score in Dairy Cows From Depth Images Using Convolutional Neural Networks, Transfer Learning and Model Ensembling Techniques. Agronomy 2019, 9, 90. [Google Scholar] [CrossRef]

- Zin, T.T.; Seint, P.T.; Tin, P.; Horii, Y.; Kobayashi, I. Body Condition Score Estimation Based on Regression Analysis Using a 3D Camera. Sensors 2020, 20, 3705. [Google Scholar] [CrossRef] [PubMed]

- Hansen, M.F.; Smith, M.L.; Smith, L.N.; Abdul Jabbar, K.; Forbes, D. Automated monitoring of dairy cow body condition, mobility and weight using a single 3D video capture device. Comput. Ind. 2018, 98, 14–22. [Google Scholar] [CrossRef]

- Tedin, R.; Becerra, J.A.; Duro, R.J.; Martínez Lede, I. Towards automatic estimation of the body condition score of dairy cattle using hand-held images and active shape models. In Advances in Knowledge-Based and Intelligent Information and Engineering Systems; IOS Press: Amsterdam, The Netherlands, 2012; pp. 2150–2159. [Google Scholar] [CrossRef]

- Halachmi, I.; Polak, P.; Roberts, D.J.; Klopcic, M. Cow Body Shape and Automation of Condition Scoring. J. Dairy. Sci. 2008, 91, 4444–4451. [Google Scholar] [CrossRef]

- Bewley, J.M.; Peacock, A.M.; Lewis, O.; Boyce, R.E.; Roberts, D.J.; Coffey, M.P.; Kenyon, S.J.; Schutz, M.M. Potential for Estimation of Body Condition Scores in Dairy Cattle from Digital Images. J. Dairy. Sci. 2008, 91, 3439–3453. [Google Scholar] [CrossRef]

- Azzaro, G.; Caccamo, M.; Ferguson, J.D.; Battiato, S.; Farinella, G.M.; Guarnera, G.C.; Puglisi, G.; Petriglieri, R.; Licitra, G. Objective estimation of body condition score by modeling cow body shape from digital images. J. Dairy. Sci. 2011, 94, 2126–2137. [Google Scholar] [CrossRef]

- Van Hertem, T.; Schlageter Tello, A.; Viazzi, S.; Steensels, M.; Bahr, C.; Romanini, C.E.B.; Lokhorst, K.; Maltz, E.; Halachmi, I.; Berckmans, D. Implementation of an automatic 3D vision monitor for dairy cow locomotion in a commercial farm. Biosyst. Eng. 2018, 173, 166–175. [Google Scholar] [CrossRef]

- Schlageter-Tello, A.; Van Hertem, T.; Bokkers, E.A.M.; Viazzi, S.; Bahr, C.; Lokhorst, K. Performance of human observers and an automatic 3-dimensional computer-vision-based locomotion scoring method to detect lameness and hoof lesions in dairy cows. J. Dairy. Sci. 2018, 101, 6322–6335. [Google Scholar] [CrossRef] [PubMed]

- Van Hertem, T.; Viazzi, S.; Steensels, M.; Maltz, E.; Antler, A.; Alchanatis, V.; Schlageter-Tello, A.A.; Lokhorst, K.; Romanini, E.C.; Bahr, C. Automatic lameness detection based on consecutive 3D-video recordings. Biosyst. Eng. 2014, 119, 108–116. [Google Scholar] [CrossRef]

- Kang, X.; Zhang, X.D.; Liu, G. Accurate detection of lameness in dairy cattle with computer vision: A new and individualized detection strategy based on the analysis of the supporting phase. J. Dairy. Sci. 2020, 103, 10628–10638. [Google Scholar] [CrossRef]

- Poursaberi, A.; Bahr, C.; Pluk, A.; Van Nuffel, A.; Berckmans, D. Real-time automatic lameness detection based on back posture extraction in dairy cattle: Shape analysis of cow with image processing techniques. Comput. Electron. Agric. 2010, 74, 110–119. [Google Scholar] [CrossRef]

- Viazzi, S.; Bahr, C.; Schlageter-Tello, A.; Van Hertem, T.; Romanini, C.E.; Pluk, A.; Halachmi, I.; Lokhorst, C.; Berckmans, D. Analysis of individual classification of lameness using automatic measurement of back posture in dairy cattle. J. Dairy. Sci. 2013, 96, 257–266. [Google Scholar] [CrossRef]

- Zhao, K.; Bewley, J.M.; He, D.; Jin, X. Automatic lameness detection in dairy cattle based on leg swing analysis with an image processing technique. Comput. Electron. Agric. 2018, 148, 226–236. [Google Scholar] [CrossRef]

- Viazzi, S.; Bahr, C.; Van Hertem, T.; Schlageter-Tello, A.; Romanini, C.E.B.; Halachmi, I.; Lokhorst, C.; Berckmans, D. Comparison of a three-dimensional and two-dimensional camera system for automated measurement of back posture in dairy cows. Comput. Electron. Agric. 2014, 100, 139–147. [Google Scholar] [CrossRef]

- Song, X.; Leroy, T.; Vranken, E.; Maertens, W.; Sonck, B.; Berckmans, D. Automatic detection of lameness in dairy cattle—Vision-based trackway analysis in cow’s locomotion. Comput. Electron. Agric. 2008, 64, 39–44. [Google Scholar] [CrossRef]

- Abdul Jabbar, K.; Hansen, M.F.; Smith, M.L.; Smith, L.N. Early and non-intrusive lameness detection in dairy cows using 3-dimensional video. Biosyst. Eng. 2017, 153, 63–69. [Google Scholar] [CrossRef]

- Guzhva, O.; Ardö, H.; Herlin, A.; Nilsson, M.; Åström, K.; Bergsten, C. Feasibility study for the implementation of an automatic system for the detection of social interactions in the waiting area of automatic milking stations by using a video surveillance system. Comput. Electron. Agric. 2016, 127, 506–509. [Google Scholar] [CrossRef]

- Hulsegge, B.; Engel, B.; Buist, W.; Merkus, G.S.M.; Klont, R.E. Instrumental colour classification of veal carcasses. Meat Sci. 2001, 57, 191–195. [Google Scholar] [CrossRef] [PubMed]

- Vandoni, S.; Sgoifo Rossi, C.A. Instrumental objective measurement of veal calves carcass colour at slaughterhouse. Ital. J. Anim. Sci. 2009, 8, 552–554. [Google Scholar] [CrossRef]

- Zhao, K.; Shelley, A.N.; Lau, D.L.; Dolecheck, K.A.; Bewley, J.M. Automatic body condition scoring system for dairy cows based on depth-image analysis. Int. J. Agric. Biol. Eng. 2020, 13, 45–54. [Google Scholar] [CrossRef]

- DeLaval. DeLaval Bodyconditiescore-Systeem BCS—Dagelijks, Automatisch uw Koeien Scoren. 2015. Available online: https://easyfairsassets.com/sites/237/2022/10/bodyconditiescore-systeem-bcs2.pdf (accessed on 4 March 2022).

- Biondi Engineering SA. 4DRT-Alpha. Available online: https://www.biondiengineering.com/4drt (accessed on 22 April 2022).

- Konica Minolta. CR-400/CR-410. Available online: https://www.konicaminolta.eu/eu-en/hardware/measuring-instruments/colour-measurement/chroma-meters/cr-400-cr-410 (accessed on 26 June 2023).

- Cang, Y.; He, H.; Qiao, Y. An Intelligent Pig Weights Estimate Method Based on Deep Learning in Sow Stall Environments. IEEE Access 2019, 7, 164867–164875. [Google Scholar] [CrossRef]

- Buayai, P.; Piewthongngam, K.; Leung, C.K.; Saikaew, K.R. Semi-automatic pig weight estimation using digital image analysis. Appl. Eng. Agric. 2019, 35, 521–534. [Google Scholar] [CrossRef]

- Fernandes, A.F.A.; Dórea, J.R.R.; Fitzgerald, R.; Herring, W.; Rosa, G.J.M. A novel automated system to acquire biometric and morphological measurements and predict body weight of pigs via 3D computer vision1. J. Anim. Sci. 2018, 97, 496–508. [Google Scholar] [CrossRef]

- Kashiha, M.; Bahr, C.; Ott, S.; Moons, C.P.H.; Niewold, T.A.; Ödberg, F.O.; Berckmans, D. Automatic weight estimation of individual pigs using image analysis. Comput. Electron. Agric. 2014, 107, 38–44. [Google Scholar] [CrossRef]

- Wongsriworaphon, A.; Arnonkijpanich, B.; Pathumnakul, S. An approach based on digital image analysis to estimate the live weights of pigs in farm environments. Comput. Electron. Agric. 2015, 115, 26–33. [Google Scholar] [CrossRef]

- Condotta, I.C.F.S.; Brown-Brandl, T.M.; Silva-Miranda, K.O.; Stinn, J.P. Evaluation of a depth sensor for mass estimation of growing and finishing pigs. Biosyst. Eng. 2018, 173, 11–18. [Google Scholar] [CrossRef]

- Jun, K.; Kim, S.J.; Ji, H.W. Estimating pig weights from images without constraint on posture and illumination. Comput. Electron. Agric. 2018, 153, 169–176. [Google Scholar] [CrossRef]

- Wang, K.; Guo, H.; Ma, Q.; Su, W.; Chen, L.; Zhu, D. A portable and automatic Xtion-based measurement system for pig body size. Comput. Electron. Agric. 2018, 148, 291–298. [Google Scholar] [CrossRef]

- Kongsro, J. Estimation of pig weight using a Microsoft Kinect prototype imaging system. Comput. Electron. Agric. 2014, 109, 32–35. [Google Scholar] [CrossRef]

- Kollis, K.; Phang, C.S.; Banhazi, T.M.; Searle, S.J. Weight estimation using image analysis and statistical modelling: A preliminary study. Appl. Eng. Agric. 2007, 23, 91–96. [Google Scholar] [CrossRef]

- Shuai, S.; Ling, Y.; Shihao, L.; Haojie, Z.; Xuhong, T.; Caixing, L.; Aidong, S.; Hanxing, L. Research on 3D surface reconstruction and body size measurement of pigs based on multi-view RGB-D cameras. Comput. Electron. Agric. 2020, 175, 105543. [Google Scholar] [CrossRef]

- Lee, S.; Ahn, H.; Seo, J.; Chung, Y.; Park, D.; Pan, S. Practical Monitoring of Undergrown Pigs for IoT-Based Large-Scale Smart Farm. IEEE Access 2019, 7, 173796–173810. [Google Scholar] [CrossRef]

- Shi, C.; Teng, G.; Li, Z. An approach of pig weight estimation using binocular stereo system based on LabVIEW. Comput. Electron. Agric. 2016, 129, 37–43. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Milani, V.; Zhu, D.; Guo, H.; Guercini, S.; Marinello, F. On-Barn Pig Weight Estimation Based on Body Measurements by Structure-from-Motion (SfM). Sensors 2018, 18, 3603. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Guarino, M.; Sartori, L.; González, L.A.; Marinello, F. On-barn pig weight estimation based on body measurements by a Kinect v1 depth camera. Comput. Electron. Agric. 2018, 148, 29–36. [Google Scholar] [CrossRef]

- Sa, J.; Ju, M.; Han, S.; Kim, H.; Chung, Y.; Park, D. Detection of low-weight pigs by using a top-view camera. In Proceedings of the Fourth International Conference on Information Science and Cloud Computing (ISCC2015), Guangzhou, China, 18–19 December 2015; pp. 18–19. [Google Scholar]

- Wang, Y.; Yang, W.; Winter, P.; Walker, L. Walk-through weighing of pigs using machine vision and an artificial neural network. Biosyst. Eng. 2008, 100, 117–125. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, J.; Teng, G. Mobile measuring system based on LabVIEW for pig body components estimation in a large-scale farm. Comput. Electron. Agric. 2019, 156, 399–405. [Google Scholar] [CrossRef]

- Banhazi, T.; Tscharke, M.; Ferdous, W.; Saunders, C.; Lee, S. Improved image analysis based system to reliably predict the live weight of pigs on farm: Preliminary results. Aust. J. Multi-Discip. Eng. 2011, 8, 107–119. [Google Scholar] [CrossRef]

- Moi, M.; Nääs, I.d.A.; Caldara, F.R.; Paz, I.C.d.L.; Garcia, R.G.; Cordeiro, A.F. Vocalization data mining for estimating swine stress conditions. Eng. Agrícola 2014, 34, 445–450. [Google Scholar] [CrossRef]

- da Silva, J.P.; de Alencar Nääs, I.; Abe, J.M.; da Silva Cordeiro, A.F. Classification of piglet (Sus Scrofa) stress conditions using vocalization pattern and applying paraconsistent logic Eτ. Comput. Electron. Agric. 2019, 166, 105020. [Google Scholar] [CrossRef]

- Schön, P.; Puppe, B.; Manteuffel, G. Automated recording of stress vocalisations as a tool to document impaired welfare in pigs. Anim. Welf. 2004, 13, 105–110. [Google Scholar] [CrossRef]

- Cordeiro, A.F.d.S.; Nääs, I.d.A.; Oliveira, S.R.d.M.; Violaro, F.; Almeida, A. Efficiency of distinct data mining algorithms for classifying stress level in piglets from their vocalization. Eng. Agrícola 2012, 32, 208–216. [Google Scholar] [CrossRef]

- Vandermeulen, J.; Bahr, C.; Tullo, E.; Fontana, I.; Ott, S.; Kashiha, M.; Guarino, M.; Moons, C.P.; Tuyttens, F.A.; Niewold, T.A.; et al. Discerning pig screams in production environments. PLoS ONE 2015, 10, e0123111. [Google Scholar] [CrossRef] [PubMed]

- Moura, D.J.; Silva, W.T.; Naas, I.A.; Tolón, Y.A.; Lima, K.A.O.; Vale, M.M. Real time computer stress monitoring of piglets using vocalization analysis. Comput. Electron. Agric. 2008, 64, 11–18. [Google Scholar] [CrossRef]

- Schön, P.-C.; Puppe, B.; Manteuffel, G. Linear prediction coding analysis and self-organizing feature map as tools to classify stress calls of domestic pigs (Sus scrofa). J. Acoust. Soc. Am. 2001, 110, 1425–1431. [Google Scholar] [CrossRef]

- Da Silva Cordeiro, A.F.; De Alencar Nääs, I.; Oliveira, S.R.M.; Violaro, F.; De Almeida, A.C.M.; Neves, D.P. Understanding Vocalization Might Help to Assess Stressful Conditions in Piglets. Animals 2013, 3, 923–934. [Google Scholar] [CrossRef]

- Cordeiro, A.F.d.S.; Nääs, I.d.A.; da Silva Leitão, F.; de Almeida, A.C.M.; de Moura, D.J. Use of vocalisation to identify sex, age, and distress in pig production. Biosyst. Eng. 2018, 173, 57–63. [Google Scholar] [CrossRef]

- von Borell, E.; Bünger, B.; Schmidt, T.; Horn, T. Vocal-type classification as a tool to identify stress in piglets under on-farm conditions. Anim. Welf. 2009, 18, 407–416. [Google Scholar] [CrossRef]

- Diana, A.; Carpentier, L.; Piette, D.; Boyle, L.A.; Berckmans, D.; Norton, T. An ethogram of biter and bitten pigs during an ear biting event: First step in the development of a Precision Livestock Farming tool. Appl. Anim. Behav. Sci. 2019, 215, 26–36. [Google Scholar] [CrossRef]

- Manteuffel, G.; Schön, P. STREMODO, ein innovatives Verfahren zur kontinuierlichen Erfas- sung der Stressbelastung von Schweinen bei Haltung und Transport. Arch. Anim. Breed. 2004, 47, 173–181. [Google Scholar] [CrossRef]

- Hong, M.; Ahn, H.; Atif, O.; Lee, J.; Park, D.; Chung, Y. Field-Applicable Pig Anomaly Detection System Using Vocalization for Embedded Board Implementations. Appl. Sci. 2020, 10, 6991. [Google Scholar] [CrossRef]

- CLK GmbH. Evaluation of Animal Welfare Indicators for Slaughter Pigs. Available online: https://www.clkgmbh.de/en/automatic-evaluation-of-animal-welfare-indicators-for-pigs/ (accessed on 27 January 2022).

- F4TLab. ADAL. Available online: https://www.f4tlab.com/adal (accessed on 22 October 2021).

- Dierenbescherming. Betere Monitoring Dierenwelzijn in Slachthuizen. Available online: https://www.dierenbescherming.nl/wat-wij-doen/actueel/nieuws/nieuws-overzicht/betere-monitoring-dierenwelzijn-in-slachthuizen (accessed on 4 May 2021).

- Argus. Our Analyses. Available online: https://argus.cv/analyses-en (accessed on 29 March 2023).

- Genba Solutions GmbH. Intelligent Documentation Systems for Animal Welfare in Slaughterhouses; Genba Solutions GmbH: Zwentendorf, Austria, 2023. [Google Scholar]

- Deloitte. AI4Animals. Available online: https://www2.deloitte.com/nl/nl/pages/consumer/solutions/ai4animals.html (accessed on 17 August 2022).

- CLK GmbH. Measuring the Amount of Pig Blood. Available online: https://www.clkgmbh.de/en/blood-measuring-in-pigs/ (accessed on 27 January 2022).

- DMRI. VisStick-for Improved Slaughterhouse Animal Welfare; Danish Meat Research Institute, Taastrup, Denmark. Available online: https://www.dti.dk/monitor-your-sticking-visstick/31918?cms.query=VisS (accessed on 13 December 2021).

- Ymaging. Pigwei. 2015. Available online: https://issuu.com/ymaging/docs/pigwey_presskit_eng (accessed on 4 March 2022).

- H+L. The Pig Scale in Your Hand. Available online: https://hl-agrar.de/en_gb/optiscan/ (accessed on 4 March 2022).

- WUGGL. WUGGL One. Available online: http://www.wuggl.com/produkt/ (accessed on 4 March 2022).

- GroStat. Growth Sensor. Available online: http://grostat.com/growth_sensor.php#prettyPhoto (accessed on 4 March 2022).

- Fancom, B.V. eYeGrow Varkens Weegsysteem. Available online: https://www.fancom.nl/oplossingen/biometrie/eyegrow-varkens-weegsysteem (accessed on 4 March 2022).

- Nasirahmadi, A.; Hensel, O.; Edwards, S.A.; Sturm, B. A new approach for categorizing pig lying behaviour based on a Delaunay triangulation method. Animal 2017, 11, 131–139. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Richter, U.; Hensel, O.; Edwards, S.; Sturm, B. Using machine vision for investigation of changes in pig group lying patterns. Comput. Electron. Agric. 2015, 119, 184–190. [Google Scholar] [CrossRef]

- Shao, B.; Xin, H. A real-time computer vision assessment and control of thermal comfort for group-housed pigs. Comput. Electron. Agric. 2008, 62, 15–21. [Google Scholar] [CrossRef]

- Gronskyte, R.; Clemmensen, L.H.; Hviid, M.S.; Kulahci, M. Pig herd monitoring and undesirable tripping and stepping prevention. Comput. Electron. Agric. 2015, 119, 51–60. [Google Scholar] [CrossRef]

- Blömke, L.; Volkmann, N.; Kemper, N. Evaluation of an automated assessment system for ear and tail lesions as animal welfare indicators in pigs at slaughter. Meat Sci. 2020, 159, 107934. [Google Scholar] [CrossRef]

- Brünger, J.; Dippel, S.; Koch, R.; Veit, C. ‘Tailception’: Using neural networks for assessing tail lesions on pictures of pig carcasses. Animal 2019, 13, 1030–1036. [Google Scholar] [CrossRef] [PubMed]

- Larsen, H.; Black, P.; Vorup, P.; Hass, M. D2.1: Test Report. Description and Functionality of a Prototype System to Measure and Document Tail Length and Tail Lesions at the Slaughterhouse. Available online: https://www.dti.dk/_/media/74221_Final%20-Pigwatch%20test%20report%20D21.pdf (accessed on 16 November 2020).

- Stavrakakis, S.; Li, W.; Guy, J.H.; Morgan, G.; Ushaw, G.; Johnson, G.R.; Edwards, S.A. Validity of the Microsoft Kinect sensor for assessment of normal walking patterns in pigs. Comput. Electron. Agric. 2015, 117, 1–7. [Google Scholar] [CrossRef]

- McKenna, S.; Amaral, T.; Kyriazakis, I. Automated Classification for Visual-Only Postmortem Inspection of Porcine Pathology. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1005–1016. [Google Scholar] [CrossRef]

- Bonicelli, L.; Trachtman, A.R.; Rosamilia, A.; Liuzzo, G.; Hattab, J.; Mira Alcaraz, E.; Del Negro, E.; Vincenzi, S.; Capobianco Dondona, A.; Calderara, S.; et al. Training Convolutional Neural Networks to Score Pneumonia in Slaughtered Pigs. Animals 2021, 11, 3290. [Google Scholar] [CrossRef] [PubMed]

- Borggaard, C.; Claudi-Magnussen, C.; Madsen, N.T.; Støier, S. A new system for Sticking Control (‘VisStick’). In Proceedings of the 57th International Congress of Meat Science and Technology (57th ICoMST), Ghent, Belgium, 7–12 August 2011. [Google Scholar]

- Chen, C.; Zhu, W.; Liu, D.; Steibel, J.; Siegford, J.; Wurtz, K.; Han, J.; Norton, T. Detection of aggressive behaviours in pigs using a RealSence depth sensor. Comput. Electron. Agric. 2019, 166, 105003. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, W.; Ma, C.; Guo, Y.; Huang, W.; Ruan, C. Image motion feature extraction for recognition of aggressive behaviors among group-housed pigs. Comput. Electron. Agric. 2017, 142, 380–387. [Google Scholar] [CrossRef]

- Oczak, M.; Viazzi, S.; Ismayilova, G.; Sonoda, L.T.; Roulston, N.; Fels, M.; Bahr, C.; Hartung, J.; Guarino, M.; Berckmans, D.; et al. Classification of aggressive behaviour in pigs by activity index and multilayer feed forward neural network. Biosyst. Eng. 2014, 119, 89–97. [Google Scholar] [CrossRef]

- Lee, J.; Jin, L.; Park, D.; Chung, Y. Automatic Recognition of Aggressive Behavior in Pigs Using a Kinect Depth Sensor. Sensors 2016, 16, 631. [Google Scholar] [CrossRef]

- Viazzi, S.; Ismayilova, G.; Oczak, M.; Sonoda, L.T.; Fels, M.; Guarino, M.; Vranken, E.; Hartung, J.; Bahr, C.; Berckmans, D. Image feature extraction for classification of aggressive interactions among pigs. Comput. Electron. Agric. 2014, 104, 57–62. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, W.; Steibel, J.; Siegford, J.; Wurtz, K.; Han, J.; Norton, T. Recognition of aggressive episodes of pigs based on convolutional neural network and long short-term memory. Comput. Electron. Agric. 2020, 169, 105166. [Google Scholar] [CrossRef]

- Boileau, A.; Farish, M.; Turner, S.P.; Camerlink, I. Infrared thermography of agonistic behaviour in pigs. Physiol. Behav. 2019, 210, 112637. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cai, J.; Xiao, D.; Li, Z.; Xiong, B. Real-time sow behavior detection based on deep learning. Comput. Electron. Agric. 2019, 163, 104884. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Hensel, O.; Edwards, S.A.; Sturm, B. Automatic detection of mounting behaviours among pigs using image analysis. Comput. Electron. Agric. 2016, 124, 295–302. [Google Scholar] [CrossRef]

- Li, D.; Chen, Y.; Zhang, K.; Li, Z. Mounting Behaviour Recognition for Pigs Based on Deep Learning. Sensors 2019, 19, 4924. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Zhang, K.; Li, Z.; Chen, Y. A Spatiotemporal Convolutional Network for Multi-Behavior Recognition of Pigs. Sensors 2020, 20, 2381. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Li, D.; Huang, J.; Chen, Y. Automated Video Behavior Recognition of Pigs Using Two-Stream Convolutional Networks. Sensors 2020, 20, 1085. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Xiao, D.; Cai, J. Pig mounting behaviour recognition based on video spatial–temporal features. Biosyst. Eng. 2021, 206, 55–66. [Google Scholar] [CrossRef]

- Gronskyte, R.; Kulahci, M.; Clemmensen, L.K.H. Monitoring Motion of Pigs in Thermal Videos. In Proceedings of the Workshop on Farm Animal and Food Quality Imaging 2013, Espoo, Finland, 17 June 2013; p. 31. [Google Scholar]

- Gronskyte, R.; Clemmensen, L.H.; Hviid, M.S.; Kulahci, M. Monitoring pig movement at the slaughterhouse using optical flow and modified angular histograms. Biosyst. Eng. 2016, 141, 19–30. [Google Scholar] [CrossRef]

- Nastasijevic, I.; Vesković, S.; Milijašević, M. Meat safety: Risk based assurance systems and novel technologies. Meat Technol. 2020, 61, 97–119. [Google Scholar] [CrossRef]

- Nastasijevic, I.; Lazic, I.B.; Petrovic, Z. Precision livestock farming in the context of meat safety assurance system. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Kopaonik, Serbia, 22–25 September 2019; p. 012014. [Google Scholar]

- Minister van Landbouw Natuur en Voedselkwaliteit. Brief Openstaande Moties en Toezeggingen n.A.V. Het Tweeminutendebat Voortgang Verbeteren Slachtsysteem; Ministerie van Landbouw Natuur en Voedselkwaliteit: The Hague, The Netherlands, 2021.

- Department for Environment Food and Rural Affairs. The Mandatory Use of Closed Circuit Television in Slaughterhouses (England) Regulations 2018; Department for Environment Food and Rural Affairs: London, UK, 2023.

- Silva, S.R.; Araujo, J.P.; Guedes, C.; Silva, F.; Almeida, M.; Cerqueira, J.L. Precision Technologies to Address Dairy Cattle Welfare: Focus on Lameness, Mastitis and Body Condition. Animals 2021, 11, 2253. [Google Scholar] [CrossRef]

- Boehringer Ingelheim Vetmedica GmbH. Sound Analytics. Available online: https://www.soundtalks.com/soundtalks/ (accessed on 31 March 2023).

- Nagel-Alne, G.E.; Murphy, E.; McCauslin, B.; Hauge, S.J.; Schrøder-Petersen, D.L.; Holthe, J.; Alvseike, O. Meat safety legislation and its opportunities and hurdles for innovative approaches: A review. Food Control 2022, 141, 109160. [Google Scholar] [CrossRef] [PubMed]

- Blagojevic, B.; Nesbakken, T.; Alvseike, O.; Vågsholm, I.; Antic, D.; Johler, S.; Houf, K.; Meemken, D.; Nastasijevic, I.; Pinto, M.V. Drivers, opportunities, and challenges of the European risk-based meat safety assurance system. Food Control 2021, 124, 107870. [Google Scholar] [CrossRef]

- Voogt, A.M.; Ursinus, W.W.; Sijm, D.T.; Bongers, J.H. From the Five Freedoms to a more holistic perspective on animal welfare in the Dutch Animals Act. Front. Anim. Sci. 2023, 4, 1026224. [Google Scholar] [CrossRef]

- Ketenborging.nl. Kwaliteitsschema’s en Status. Available online: https://ketenborging.nl/kwaliteitsschemas-en-status/ (accessed on 24 January 2022).

- NVWA. Kwaliteitssystemen (Controlesystemen) en Toezicht NVWA. Available online: https://www.nvwa.nl/onderwerpen/kwaliteitssystemen-zelfcontrolesystemen-en-toezicht-nvwa (accessed on 16 March 2022).

- Wigham, E.E.; Butterworth, A.; Wotton, S. Assessing cattle welfare at slaughter–Why is it important and what challenges are faced? Meat Sci. 2018, 145, 171–177. [Google Scholar] [CrossRef] [PubMed]

- Farm Animal Welfare Committee. Opinion on CCTV in Slaughterhouses; DEFRA Farm Animal Welfare Committee: London, UK, 2015; p. 22.

- Kang, X.; Zhang, X.D.; Liu, G. A Review: Development of Computer Vision-Based Lameness Detection for Dairy Cows and Discussion of the Practical Applications. Sensors 2021, 21, 753. [Google Scholar] [CrossRef] [PubMed]

- Arulmozhi, E.; Bhujel, A.; Moon, B.-E.; Kim, H.-T. The Application of Cameras in Precision Pig Farming: An Overview for Swine-Keeping Professionals. Animals 2021, 11, 2343. [Google Scholar] [CrossRef] [PubMed]

- Llonch, P.; King, E.; Clarke, K.; Downes, J.; Green, L. A systematic review of animal based indicators of sheep welfare on farm, at market and during transport, and qualitative appraisal of their validity and feasibility for use in UK abattoirs. Vet. J. 2015, 206, 289–297. [Google Scholar] [CrossRef]

- Losada-Espinosa, N.; Estévez-Moreno, L.X.; Bautista-Fernández, M.; Galindo, F.; Salem, A.Z.M.; Miranda-de la Lama, G.C. Cattle welfare assessment at the slaughterhouse level: Integrated risk profiles based on the animal’s origin, pre-slaughter logistics, and iceberg indicators. Prev. Vet. Med. 2021, 197, 105513. [Google Scholar] [CrossRef]

- BuRO. Advice Regarding the Use of Sensor Technology to Promote Animal Welfare in Slaughterhouses; TRCVWA/2022/8645; Netherlands Food and Consumer Product Safety Authority: Utrecht, The Netherlands, 2022. [Google Scholar]

| Broilers and Laying Hens | Relevant Scenarios for Welfare Assessment at the Slaughterhouse | ||||

|---|---|---|---|---|---|

| Welfare Quality Principle | Welfare Consequence | ABM | Farm | Transport | Slaughterhouse |

| Good feeding | Prolonged hunger | Presence bile/urates/orange discharge at bottom containers | [11] | [11] | |

| Emaciated animals, body weight | [26,34,56,68] | ||||

| Dehydration | Dehydrated animals | [34,68] | |||

| Good housing | Heat stress | Panting | [11] | [11] | |

| Cold stress | Huddling | [11] | [11] | ||

| Piloerection | [11] | [11] | |||

| Shivering | [11] | [11] | |||

| Limited movement | Pilling up (overcrowding in container) | [11] | [11] | ||

| Proper housing | Dirty animals | [69] | |||

| Good health | Injuries (pain) | Breast blisters | [26,34,68,69] | ||

| Hock burn | [34,68,69] | ||||

| Footpad lesions | [26,34,56,68,69] | ||||

| Plumage damage | [26] | ||||

| Keel bone fracture | [26] | [26] | [26] | ||

| Wing injuries (bone fractures) | [11,68,69] | ||||

| Bruises and skin damage | [56,68] | [11,56,68,69] | [11,56,68,69] | ||

| Disease | Ascites | [26,34,68] | |||

| Arthritis | [26,56] | ||||

| Septicaemia | [26,34,56,68] | ||||

| Hepatitis | [26,34,56,68] | ||||

| Pericarditis | [26,34,56,68] | ||||

| Abscesses | [26,34,56] | ||||

| Parasites | [68] | ||||

| Death | Dead on arrival (DOA) | [11,69] | |||

| Respiratory stress during stunning | Deep breathing | [11] | |||

| Hyperventilation | [11] | ||||

| Pain during stunning/killing | Muscle spasms | [11,70] | |||

| Withdrawal reflex | [11] | ||||

| Consciousness during killing process | Eye blinking | [69] | |||

| Corneal reflex | [70] | ||||

| Attempt to regain posture | [11] | ||||

| Maintenance of posture | [11] | ||||

| Appropriate behaviour | Fear | Bunching | [11] | ||

| Wing flapping | [11,69,70] | ||||

| Fear and pain | Escape attempts | [11] | |||

| Head shaking | [11,69] | ||||

| Vocalisations | [11,69] | ||||

| Cattle | Relevant Scenarios for Welfare Assessment at the Slaughterhouse | ||||

|---|---|---|---|---|---|

| Welfare Quality Principle | Welfare Consequence | ABM | Farm | Transport | Slaughterhouse |

| Good feeding | Prolonged hunger | Body condition score | [18,31,69,71] | ||

| Prolonged thirst | Increased aggression at drinking trough | [13] | [13] | ||

| Good housing | Heat stress | Panting | [13] | ||

| Cold stress | Shivering | [13] | |||

| Restricted movement | Slipping | [13,27,31,72,73,74] | |||

| Falling | [13,27,31,69,72,74] | ||||

| Comfortable resting | Swollen hocks or bursa | [18,69] | |||

| Dirty animals | [69] | ||||

| Good health | Injuries (pain) | Bruises and skin damage | [13,27,69,72] | ||

| Broken bones | [13] | ||||

| Lameness (pain) | Lameness | [71] | [13,27,69,72] | [13,69,72,73] | |

| Anaemia | Carcass colour | [18] | |||

| Disease | Abnormalities organs (lung, rumen, heart, liver, intestine, udder) | [18,31,75] | |||

| Fatigue | Exhaustion | [13,69] | [13,73] | ||

| Rapid breathing (tachypnoea) | [13] | ||||

| Consciousness during stunning and killing process | Remaining posture | [13,27,31,69,70,72,73,76,77,78] | |||

| Body movement | [13,31,70,72,73,76] | ||||

| Breathing | [13,27,31,69,70,72,73,76,77] | ||||

| Tonic and clonic seizure | [13,27,78] | ||||

| Cornea and/or palpebral reflex | [13,27,31,70,72,73,76] | ||||

| Spontaneous blinking | [13,27,31,69,70,72,73,76,77] | ||||

| Eye movements | [13,27,31,70,72,73,77] | ||||

| Muscle tone | [13,31] | ||||

| Response to nose prick | [77] | ||||

| Appropriate behaviour | Social stress | Aggressive behaviour | [13,31] | ||

| Mounting | [13] | ||||

| Fear | Escape attempts | [13,31,78] | |||

| Turning around or moving backwards | [13,27,31,72,78] | ||||

| Struggling in the stunning box (kicking) | [27,31,72] | ||||

| Jumping in the stunning box | [27,31,72] | ||||

| Fear and pain | Reluctance to move, freezing | [13,27,31,72,78] | |||

| Vocalisations | [13,27,31,69,70,72,73,74,76,77,78] | ||||

| Pigs | Relevant Scenarios for Welfare Assessment at the Slaughterhouse | ||||

|---|---|---|---|---|---|

| Welfare Quality Principle | Welfare Consequence | ABM | Farm | Transport | Slaughterhouse |

| Good feeding | Prolonged hunger | Body condition | [57] | ||

| Prolonged thirst | Increased aggression at drinking trough | [12] | [12] | ||

| Good housing | Heat stress | Panting | [9,12,27,35] | [9,12,27,35,55] | |

| Discolouration of the skin | [12] | [12] | |||

| Cold stress | Shivering | [12,27,35] | [12,27,35] | ||

| Huddling | [9,12,27,35] | [9,12,27,35] | |||

| Restricted movement | Slipping | [9,12,27,35,55] | |||

| Falling | [9,12,27,35,55,69] | ||||

| Proper housing | Bursitis | [23,57] | |||

| Dirty animals | [69] | ||||

| Good health | Injuries (pain) | Bruises and skin damage | [23,27,57,69] | [12,23,27,32,35,69] | [9,12,27,32,35,69,79] |

| Broken bones | [12] | [12] | |||

| Ear injuries | [32,57] | ||||

| Tail injuries | [23,32,57] | ||||

| Vulva lesions | [57] | ||||

| Lameness (pain) | Lameness | [57] | [12,27,35,57,69] | [12,27,35,57,69] | |

| Fatigue | Exhaustion | [9,12,69] | [9,12] | ||

| Shortness of breath and open mouth breathing (dyspnoea) | [12] | [12] | |||

| Muscle tremors | [12] | [12] | |||

| Disease | Abnormalities organs (lung, stomach, heart, liver, pleura) | [23,27,32,35,57] | |||

| Abscesses | [57] | ||||

| Sick animals | [27,35] | [27,35] | |||

| Death | Dead animals | [9,27,35,69] | [9,27,35] | ||

| Respiratory stress during CO2 stunning | Gasping for air | [12,70,76] | |||

| Hyperventilation | [12] | ||||

| Head shaking | [12] | ||||

| Consciousness during stunning and killing process | Remaining posture | [12,27,35,55,69,70,76] | |||

| Body movement | [12,70,76] | ||||

| Breathing | [9,12,27,35,55,69,70,76] | ||||

| Tonic and clonic seizures (muscle tone) | [12,27,70] | ||||

| Cornea and/or palpebral reflex | [9,12,35,55,70,76] | ||||

| Spontaneous blinking | [9,12,27,69,70,76] | ||||

| Eye movements | [12,70] | ||||

| Response to nose prick or ear pinch | [12,55,69] | ||||

| Bleeding rate | [55] | ||||

| Appropriate behaviour | Social stress | Aggressive behaviour | [12] | ||

| Mounting | [12] | ||||

| Fear | Reluctance to move, freezing | [9,12,27,35] | |||

| Turning or walking backwards | [9,12,27,35] | ||||

| Fear and pain | High-pitched vocalisations | [9,12,27,35,69,70,76] | |||

| Escape attempts | [12] | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voogt, A.M.; Schrijver, R.S.; Temürhan, M.; Bongers, J.H.; Sijm, D.T.H.M. Opportunities for Regulatory Authorities to Assess Animal-Based Measures at the Slaughterhouse Using Sensor Technology and Artificial Intelligence: A Review. Animals 2023, 13, 3028. https://doi.org/10.3390/ani13193028

Voogt AM, Schrijver RS, Temürhan M, Bongers JH, Sijm DTHM. Opportunities for Regulatory Authorities to Assess Animal-Based Measures at the Slaughterhouse Using Sensor Technology and Artificial Intelligence: A Review. Animals. 2023; 13(19):3028. https://doi.org/10.3390/ani13193028

Chicago/Turabian StyleVoogt, Annika M., Remco S. Schrijver, Mine Temürhan, Johan H. Bongers, and Dick T. H. M. Sijm. 2023. "Opportunities for Regulatory Authorities to Assess Animal-Based Measures at the Slaughterhouse Using Sensor Technology and Artificial Intelligence: A Review" Animals 13, no. 19: 3028. https://doi.org/10.3390/ani13193028

APA StyleVoogt, A. M., Schrijver, R. S., Temürhan, M., Bongers, J. H., & Sijm, D. T. H. M. (2023). Opportunities for Regulatory Authorities to Assess Animal-Based Measures at the Slaughterhouse Using Sensor Technology and Artificial Intelligence: A Review. Animals, 13(19), 3028. https://doi.org/10.3390/ani13193028