Changes in the Physicochemical Parameters of Yoghurts with Added Whey Protein in Relation to the Starter Bacteria Strains and Storage Time

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Milk

2.2. Yoghurt

Yoghurt Analysis

2.3. Statistical Analysis

3. Results and Discussion

3.1. Milk

3.2. Yoghurts

3.2.1. Acidity

3.2.2. Chemical Composition

3.2.3. Water-Holding Capacity

3.2.4. Water Activity

3.2.5. Texture

3.2.6. Colour Parameters

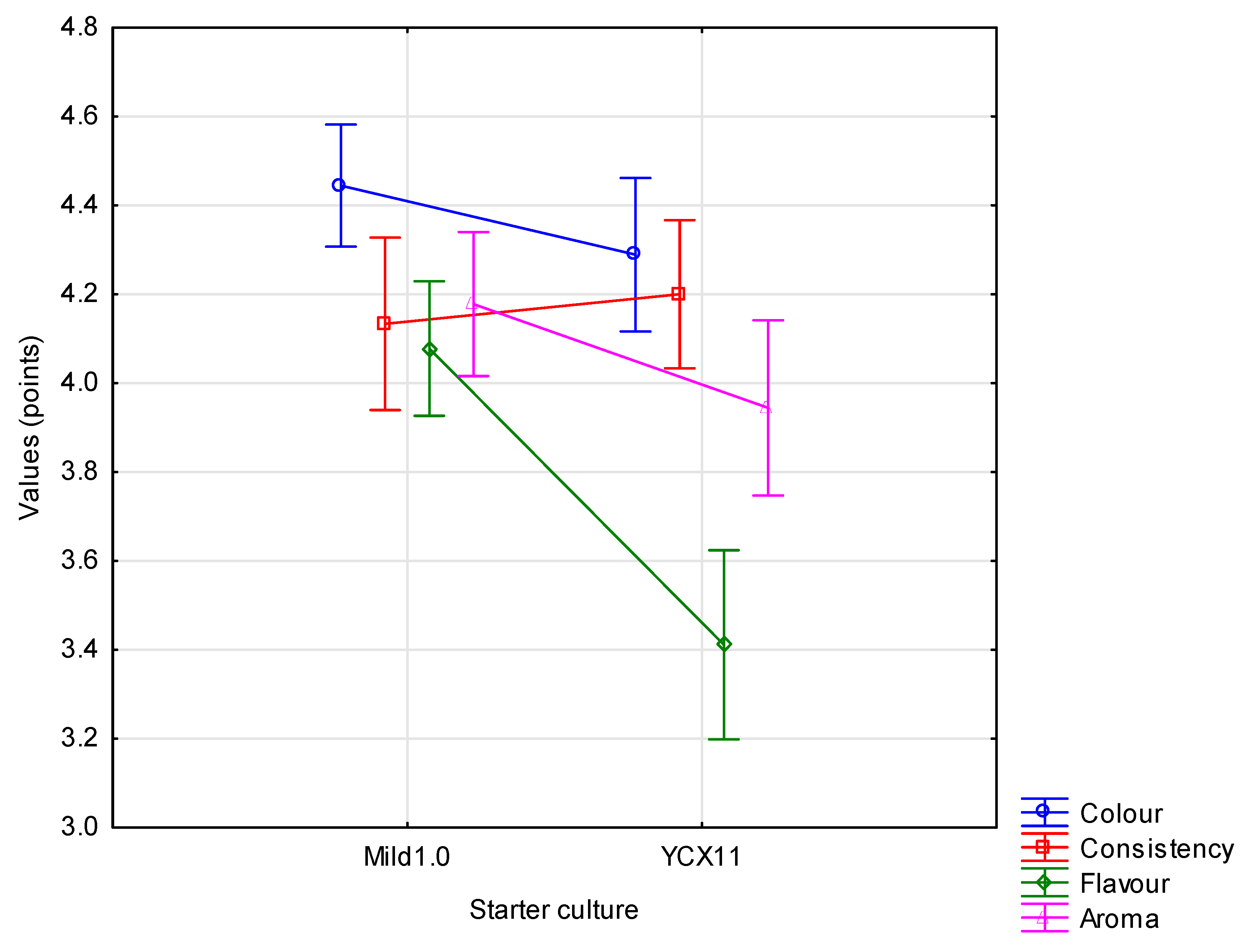

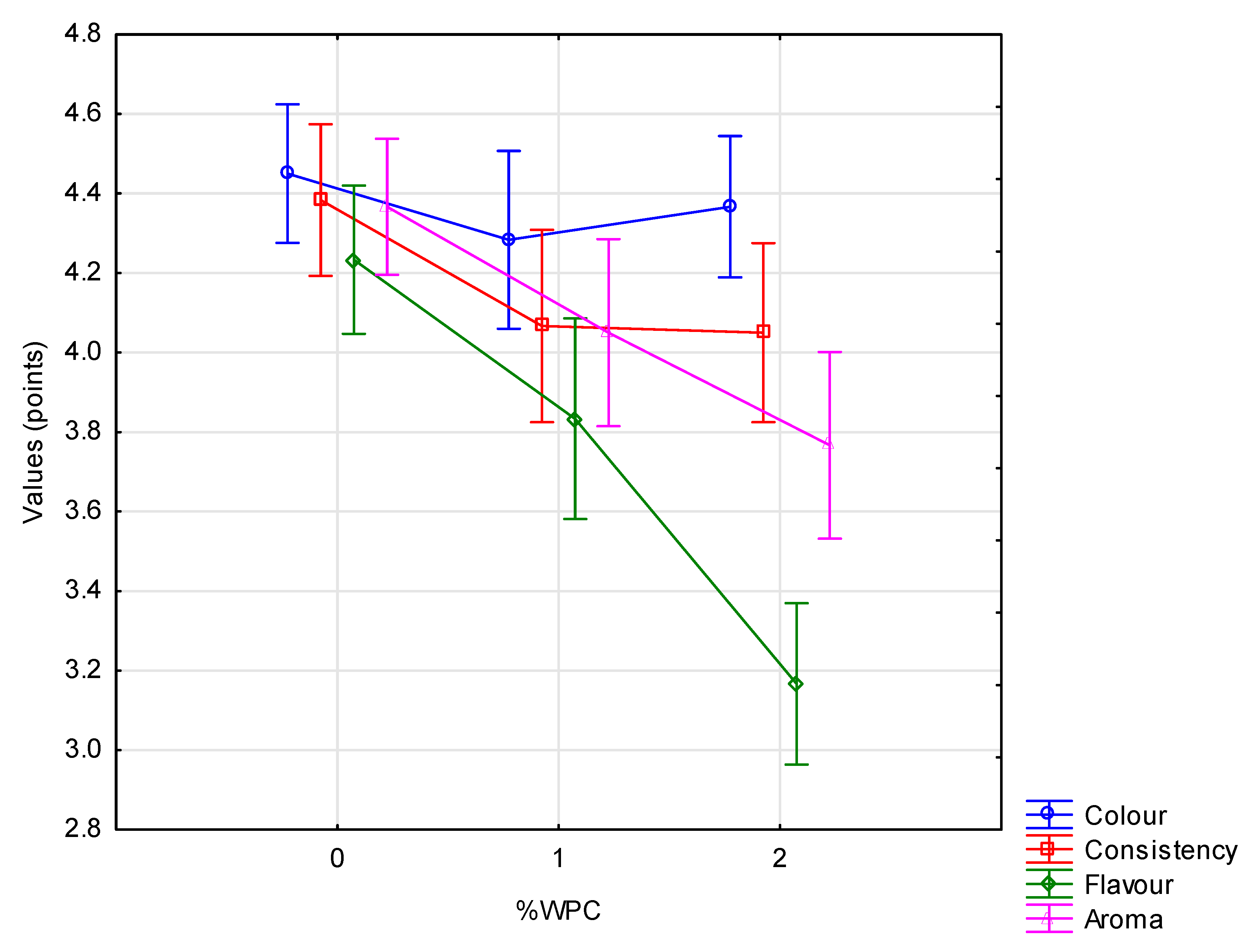

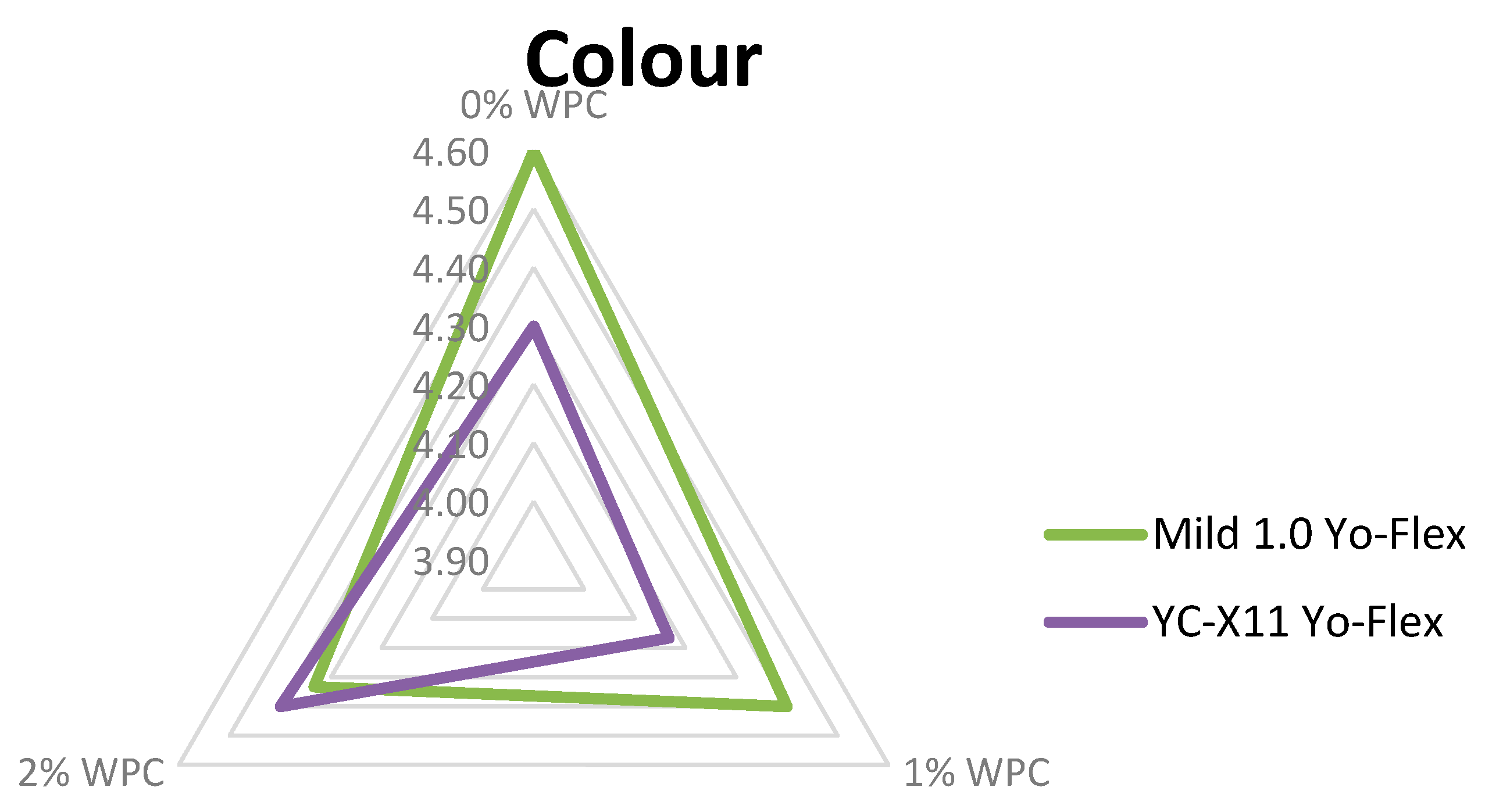

3.2.7. Sensory Characteristics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sołowiej, B.; Szafrańska, J. Characteristics of traditional yogurt microflora and its metabolites. Pol. Dairy J. 2018, 3, 10–15. [Google Scholar]

- Sarkar, S. Potentiality of probiotic yoghurt as a functional food—A review. Nutr. Food Sci. 2019, 49, 182–202. [Google Scholar]

- FAO/WHO Codex Alimentarius: Milk and Milk Products. Codex Standard for Fermented Milk. 2011, pp. 6–16. Available online: http://www.fao.org/3/i2085e/i2085e00.pdf (accessed on 12 June 2020).

- Fernandez, M.A.; Panahi, S.; Daniel, N.; Tremblay, A.; Marette, A. Yogurt and cardiometabolic diseases: A critical review of potential mechanisms. Adv. Nutr. 2017, 8, 812–829. [Google Scholar]

- Senadeera, S.S.; Prasanna, P.H.P.; Jayawardana, I.; Gunasekara, D.; Senadeera, P.; Chandrasekara, A. Antioxidant, physicochemical, microbiological, and sensory properties of probiotic yoghurt incorporated with various Annona species pulp. Heliyon 2018, 4, e00955. [Google Scholar]

- Aryana, K.J.; Olson, D.W. A 100-Year Review: Yogurt and other cultured dairy products. J. Dairy Sci. 2017, 100, 9987–10013. [Google Scholar]

- Donovan, S.M.; Hutkins, R. Introduction to the fifth global summit on the health effects of yogurt. Nutr. Rev. 2018, 76, 1–3. [Google Scholar]

- Sodini, I.; Montella, J.; Tong, P. Physical properties of yogurt fortified with various commercial whey proteins concentrates. J. Sci. Food Agric. 2005, 85, 853–859. [Google Scholar]

- Marafon, A.P.; Sumi, A.; Alcântara, M.R.; Tamime, A.Y.; Oliveira, M.N. Optimization of the rheological properties of probiotic yoghurts supplemented with milk proteins. Food Sci. Technol. 2011, 44, 511–519. [Google Scholar]

- Yildiz, E.; Ozcan, T. Functional and textural properties of vegetable-fibre enriched yoghurt. Int. J. Dairy Technol. 2019, 72, 199–207. [Google Scholar]

- Yildiz-Akgül, F. Enhancement of torba yoghurt with whey protein isolates. Int. J. Dairy Technol. 2018, 71, 898–905. [Google Scholar]

- Glibowski, P.; Rybak, P. Rheological and sensory properties of stirred yoghurt with inulin-type fructans. Int. J. Dairy Technol. 2016, 69, 122–128. [Google Scholar]

- Król, J.; Brodziak, A.; Litwińczuk, A. Basic chemical composition and content of selected whey proteins in milk from different cow breeds and in rennet whey. Zywnosc-Nauka Technologia Jakosc 2011, 77, 74–83. [Google Scholar]

- Królczyk, J.; Dawidziuk, T.; Janiszewska-Turak, E.; Sołowiej, B. Use of whey and whey preparations in the food industry—A review. Pol. J. Food Nutr. Sci. 2016, 66, 157–165. [Google Scholar]

- Gupta, C.; Prakash, D. Therapeutic potential of milk whey. Beverages 2017, 3, 1–14. [Google Scholar]

- Brodziak, A. Gelling properties and texture of gels obtained from whey proteins derived from milk of different cow breeds. Zywnosc-Nauka Technologia Jakosc 2012, 83, 161–174. [Google Scholar]

- Dylewska, A.; Mleko, S. The use of modified whey proteins in the production of yoghurts. Pol. Dairy J. 2011, 2, 8–10. [Google Scholar]

- Lesme, H.; Rannou, C.; Famelart, M.H.; Bouhallab, S.; Prosta, C. Yogurts enriched with milk proteins: Texture properties, aroma release and sensory perception. Trends Food Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Institute of Agricultural and Food Economics. Market Milk—State and Prospects; IERiGŻ-PIB Publishing: Warsaw, Poland, 2019; p. 15. [Google Scholar]

- EDA—European Dairy Association. Economic Report 2017/2018. 2018. Available online: http://eda.euromilk.org/fileadmin/user_upload/Public_Documents/Facts_and_Figures/EDA_Economic_Report_2017.pdf (accessed on 19 June 2020).

- Božanic, R.; Barukcic, I.; Jakopovic, K.L.; Tratnik, L. Possibilities of whey utilisation. Austin. J. Nutr. Food Sci. 2014, 2, 1036. [Google Scholar]

- IDF/ISO Standard. Yogurt. Determination of Titratable Acidity; No. 150; ISO: Brussels, Belgium, 1991; Available online: https://store.fil-idf.org/publications/?product_cat=standards (accessed on 12 June 2020).

- AOAC—Official Methods of Analysis, No. 998.06, 17th ed.; AOAC International: Arlington, VA, USA, 2000; Available online: http://m.wdfxw.net/goDownFiles.aspx?key=12212363 (accessed on 15 June 2020).

- PN-EN ISO 8261:2002. Milk and Milk Products—General Guidance for the Preparation of Test Samples, Initial Suspensions and Decimal Dilutions for Microbiological Examination. Available online: https://sklep.pkn.pl/ (accessed on 15 June 2020).

- PN-EN ISO 4833-2:2013. Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 2: Colony Count at 30 Degrees C by the Surface Plating Technique. Available online: https://sklep.pkn.pl/ (accessed on 15 June 2020).

- PN-EN ISO 8968-1:2014. Milk and Milk Products—Determination of Nitrogen Content—Part 1: Kjeldahl Principle and Crude Protein Calculation. Available online: https://sklep.pkn.pl (accessed on 15 June 2020).

- PN-A-86061:2006. Milk and Milk Products. Fermented Milk. Available online: https://sklep.pkn.pl/ (accessed on 15 June 2020).

- Bong, D.D.; Moraru, C.I. Use of micellar casein concentrate for Greek-style yogurt manufacturing: Effects on processing and product properties. J. Dairy Sci. 2014, 97, 1259–1269. [Google Scholar]

- CIE. Colorimetry, 3rd ed.; Commission International de l’Eclairage: Vienna, Austria, 2004; pp. 16–20. Available online: https://cielab.xyz/pdf/cie.15.2004%20colorimetry.pdf (accessed on 17 June 2020).

- Bierzuńska, P.; Cais-Sokolińska, D.; Yiğit, A. Storage stability of texture and sensory properties of yogurt with the addition of polymerized whey proteins. Foods 2019, 8, 548. [Google Scholar]

- Baryłko-Pikielna, N.; Matuszewska, I. Sensory food testing. In Basics. Methods. Usage; PTTŻ Scientific Publisher: Krakov, Poland, 2014; pp. 267–275. [Google Scholar]

- Codex Alimentarius International Food Standards, Code of Hygienic Practice for Milk and Milk Products, No. CAC/RCP 57-2004, Modified in 2009. 2009. Available online: http://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXC%2B57-2004%252FCXC_057e.pdf (accessed on 17 June 2020).

- Lorenzen, P.C.; Clawin-Rädecker, I.; Einhoff, K.; Hammer, P.; Hartmann, R.; Hoffmann, W.; Martin, D.; Molkentin, J.; Walte, H.G.; Devrese, A. A survey of the quality of extended shelf life (ESL) milk in relation to HTST and UHT milk. Int. J. Dairy Technol. 2011, 64, 166–178. [Google Scholar]

- Król, J.; Brodziak, A.; Topyła, B. The nutritional value of the milk of Simmental cows in relation to the season and production system. Anim. Prod. Rev. 2016, 6, 20–24. [Google Scholar]

- Brodziak, A.; Król, J.; Litwińczuk, Z.; Barłowska, J. Differences in bioactive protein and vitamin status of milk from certified organic and conventional farms. Int. J. Dairy Technol. 2018, 71, 321–332. [Google Scholar]

- Commission Regulation (EC) No. 1662/2006 of 6 November 2006 amending Regulation (EC) No 853/2004 of the European Parliament and of the Council laying down specific hygiene rules for food of animal origin. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32006R1662 (accessed on 22 June 2020).

- Sady, M.; Domagała, J.; Grega, T.; Najgebauer-Lejko, D. Quality properties of non-fat yoghurt with addition of whey protein concentrate. Biotechnol. Anim. Husb. 2007, 23, 291–299. [Google Scholar]

- Al-Dabbas, M.M.; Al-Ismail, K.; Al-Abdullah, B.M. Effect of chemical composition on the buffering capacity of selected dairy products. Jordan. J. Agric. Sci. 2011, 7, 690–700. [Google Scholar]

- Bonczar, G.; Wszołek, M. Quality characteristics of yoghurts made of ewe’s milk with normalized fat content. Food Sci. Technol. Quality 2002, 30, 109–115. [Google Scholar]

- Moneim, A.E.S.; Rania, M.A.; Zakaria, A.S. Effects of storage on quality of yoghurt prepared from cows’ and goat’s milk and pure strains of lactic acid bacteria. J. Sci. Technol. 2011, 12, 136–143. [Google Scholar]

- Akalin, A.S.; Unal, G.; Dinkci, N.; Hayaloglut, A.A. Microstructural, textural, and sensory characteristics of probiotic yogurts fortified with sodium calcium caseinate or whey protein concentrate. J. Dairy Sci. 2012, 95, 3617–3628. [Google Scholar]

- Damin, M.R.; Minowa, E.; Alcântara, M.R.; Oliveira, M.N. Effect of cold storage on culture viability and some rheological properties of fermented milk prepared with yogurt and probiotic bacteria. J. Texture Stud. 2008, 39, 40–55. [Google Scholar]

- Lee, W.J.; Lucey, J.A. Formation and physical properties of yoghurt. Asian-Aust. J. Anim. Sci. 2010, 23, 1127–1136. [Google Scholar]

- Amatayakul, T.; Sherkat, F.; Shah, N.P. Syneresis of set yoghurt as affected by EPS starter cultures and levels of solids. Int. J. Dairy Technol. 2006, 59, 216–221. [Google Scholar]

- Kozioł, J.; Gustaw, W.; Waśko, A.; Skrzypczak, K.; Sławińska, A.; Sołowiej, B. Effect of selected milk protein preparations on growth and survival of Lactobacillus acidophilus as well as on rheological properties of fermented milk beverages. Food Sci. Technol. Quality 2014, 94, 41–55. [Google Scholar]

- Gharibzahedi, S.M.T.; Chronakis, I.S. Crosslinking of milk proteins by microbial transglutaminase: Utilization in functional yogurt products. Food Chem. 2018, 245, 620–632. [Google Scholar]

- Bhullar, Y.S.; Uddin, M.A.; Shah, N.P. Effects of ingredients supplementation on textural characteristics and microstructure of yoghurt. Milchwissenschaft 2002, 57, 328–332. [Google Scholar]

- Puvanenthiran, A.; Williams, R.P.W.; Augustin, M.A. Structure and visco-elastic properties of set yoghurt with altered casein to whey protein ratios. Int. Dairy J. 2002, 12, 383–391. [Google Scholar]

- Olkowski, M.A.; Pluta, A.; Berthold-Pluta, A.; Wiska, J. Water activity of dairy products. Part, I. Food Ind. 2012, 66, 31–34. [Google Scholar]

- Godlewska, K. Additives: How to determine the best-before date for milk and milk products. Forum. Mlecz. Biznes. 2012, 15, 1–3. [Google Scholar]

- Lucey, J.A.; Johnson, M.E.; Horne, D.S. Perspectives on the basis of the rheology and texture properties of cheese. J. Dairy Sci. 2003, 86, 2725–2743. [Google Scholar]

- Nishinari, K.; Takemasa, M.; Brenner, T.; Su, L.; Fang, Y.; Hirashima, M.; Yoshimura, M.; Nitta, Y.; Moritaka, H.; Tomczyńska-Mleko, M.; et al. The food colloid principle in the design of elderly food. J. Texture Stud. 2016, 47, 284–312. [Google Scholar]

- Glibowski, P.; Krępacka, A. Effect of whey preparations addition on rheological properties of yoghurts. Food Sci. Technol. Quality 2006, 46, 74–82. [Google Scholar]

- Gustaw, W. Changes of rheological properties of whey protein gels during storage. Acta Agrophys. 2006, 8, 347–356. [Google Scholar]

- Mituniewicz-Małek, A.; Ziarno, M.; Dmytrów, I. Application of frozen goat’s milk to production of potentially probiotic fermented drink. Food Sci. Technol. Quality 2015, 103, 140–149. [Google Scholar]

- Pawlos, M.; Znamirowska, A.; Kalicka, D.; Szajnar, K. Effect of storage time and type of vaccine on the texture and sensory quality of yoghurts obtained by the thermostatic method. In Properties of Products and Food Raw Materials; Tarko, T., Duda-Chodak, A., Witczak, M., Najgebauer-Lejko, M., Eds.; Małopolska Branch of the Polish Society of Food Technologists: Krakov, Poland, 2014; Volume I, pp. 15–25. [Google Scholar]

- Glibowski, P. Effect of vegetable oils on the texture of anhydrous milk fat. Acta Agrophys. 2007, 9, 603–612. [Google Scholar]

- Wherry, B.; Barbano, D.M.; Drake, M.A. Use of acid whey protein concentrate as an ingredient in nonfat cup set-style yogurt. J. Dairy Sci. 2019, 102, 8768–8784. [Google Scholar]

- Mituniewicz-Małek, A.; Zielińska, M.; Ziarno, M. Probiotic monocultures in fermented goat milk beverages—Sensory quality of final product. Int. J. Dairy Technol. 2019, 72, 240–247. [Google Scholar]

- Rój, A.; Przybyłowski, P. Colour measurement of natural yoghurts. In Bromatol. Chem. Toksyk; Available online: https://www.ptfarm.pl/download/?file=File%2FBromatologia%2F2012%2F3%2F813-816.pdf (accessed on 4 August 2020).

- Cais-Sokolińska, D.; Pikul, J. Use of colour measurement to evaluate yoghurt quality during storage. Ital. J. Food Sci. 2006, 18, 63–71. [Google Scholar]

- Mousavi, M.; Heshmati, A.; Garmakhany, A.D.; Vahidinia, A.; Taheri, M. Texture and sensory characterization of functional yogurt supplemented with flaxseed during cold storage. Nutr. Food Sci. 2019, 7, 907–917. [Google Scholar]

| Mild 1.0 Yo-Flex | YC-X11 Yo-Flex |

|---|---|

| WPC content (%) | |

| 0 | 0 |

| 1 | 1 |

| 2 | 2 |

| Acidity | Proximate Chemical Composition | Hygienic Quality | |||||||

|---|---|---|---|---|---|---|---|---|---|

| active (pH value) | Potential-lactic acid content (%) | Fat (%) | Protein (%) | Casein (%) | Lactose (%) | Non-fat dry matter (%) | Dry matter (%) | SCC (thous./mL) | TMC (thous. CFU/mL) |

| 6.73 ± 0.03 | 0.155 ± 0.004 | 4.76 ± 0.06 | 3.74 ± 0.04 | 2.90 ± 0.07 | 4.73 ± 0.05 | 9.02 ± 0.07 | 13.84 ± 0.05 | 203 ± 37 | 6.7 × 104 |

| Type of Bacterial Cultures | WPC Content (%) | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Mild 1.0 Yo-Flex | 0 | 4.62 y ± 0.07 | 4.61 y ± 0.03 | 4.56 y ± 0.06 | 4.49 x ± 0.05 | 4.38 w ± 0.15 |

| 1 | 4.56 x ± 0.06 | 4.57 x ± 0.05 | 4.55 x ± 0.14 | 4.56 x ± 0.09 | 4.41 w ± 0.07 | |

| 2 | 4.54 X ± 0.08 | 4.58 X** ± 0.05 | 4.56 X* ± 0.10 | 4.55 X** ± 0.04 | 4.39 W ± 0.09 | |

| YC-X11 Yo-Flex | 0 | 4.55 y ± 0.08 | 4.47 x ± 0.08 | 4.49 x ± 0.07 | 4.42 x ± 0.11 | 4.34 w ± 0.13 |

| 1 | 4.53 Y ± 0.07 | 4.57 Y ± 0.07 | 4.42 X ± 0.05 | 4.38 WX ± 0.12 | 4.30 W ± 0.19 | |

| 2 | 4.52 y ± 0.05 | 4.39 wx** ± 0.10 | 4.44 x* ± 0.14 | 4.37 w** ± 0.06 | 4.32 w ± 0.06 | |

| Type of Bacterial Cultures | WPC Content (%) | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Mild 1.0 Yo-Flex | 0 | 0.626 W ± 0.039 | 0.810 X ± 0.029 | 0.972 Z ± 0.043 | 0.918 Y ± 0.046 | 0.819 aX ± 0.050 |

| 1 | 0.698 W ± 0.051 | 0.837 X ± 0.046 | 1.026 Y* ± 0.061 | 1.053 Y ± 0.072 | 0.846 aX ± 0.048 | |

| 2 | 0.737 W ± 0.043 | 0.828 X ± 0.021 | 1.062 Z ± 0.031 | 0.972 Y** ± 0.037 | 1.098 bZ ± 0.061 | |

| YC-X11 Yo-Flex | 0 | 0.684 w ± 0.020 | 0.765 w ± 0.040 | 0.855 x ± 0.049 | 0.896 Ax ± 0.031 | 0.855 ax ± 0.035 |

| 1 | 0.676 W ± 0.026 | 0.711 W ± 0.018 | 0.846 X* ± 0.025 | 1.026 BY ± 0.048 | 0.864 aX ± 0.028 | |

| 2 | 0.729 W ± 0.057 | 0.909 X ± 0.034 | 0.936 X ± 0.029 | 1.269 CZ** ± 0.075 | 1.035 bY ± 0.054 | |

| Type of Bacterial Cultures | WPC Content (%) | Protein (%) | Fat (%) | Non-Fat Dry Matter (%) | Dry Matter (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Storage time (day) | 0 | 28 | 0 | 28 | 0 | 28 | 0 | 28 | |

| Mild 1.0 Yo-Flex | 0 | 4.19 A ± 0.10 | 4.16 A ± 0.14 | 4.54 ± 0.14 | 4.54 ± 0.19 | 8.07 ax ± 0.16 | 7.64 aw ± 0.10 | 12.64 ax ± 0.12 | 12.07 aw ± 0.20 |

| 1 | 5.06 B ± 0.19 | 5.02 B ± 0.21 | 4.60 ± 0.15 | 4.60 ± 0.11 | 8.95 bx ± 0.10 | 8.42 bw ± 0.08 | 13.59 bx ± 0.18 | 13.04 bw ± 0.13 | |

| 2 | 5.91 C ± 0.14 | 5.87 C ± 0.12 | 4.59 ± 0.18 | 4.53 ± 0.22 | 10.01 cx ± 0.14 | 9.67 cw ± 0.16 | 14.62 cx ± 0.21 | 14.05 cw ± 0.21 | |

| YC-X11 Yo-Flex | 0 | 4.26 A ± 0.15 | 4.22 A ± 0.16 | 4.56 ± 0.13 | 4.53 ± 0.14 | 8.02 ax ± 0.12 | 7.52 aw ± 0.12 | 12.58 ax ± 0.10 | 12.10 aw ± 0.09 |

| 1 | 5.14 B ± 0.16 | 5.12 B ± 0.18 | 4.54 ± 0.15 | 4.53 ± 0.20 | 8.99 bx ± 0.17 | 8.48 bw ± 0.15 | 13.55 bx ± 0.16 | 12.98 bw ± 0.18 | |

| 2 | 5.97 C ± 0.13 | 5.93 C ± 0.15 | 4.59 ± 0.16 | 4.56 ± 0.10 | 10.06 cx ± 0.09 | 9.46 cw ± 0.11 | 14.60 cx ± 0.14 | 13.95 cw ± 0.24 | |

| Type of Bacterial Cultures | WPC Content (%) | Storage Time (day) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Mild 1.0 Yo-Flex | 0 | 80.35 BY ± 2.99 | 57.90 aW ± 4.52 | 59.65 W ± 8.49 | 66.18 X ± 3.36 | 54.02 W* ± 1.58 |

| 1 | 64.57 Ax** ± 1.05 | 66.89 bx ± 1.05 | 62.55 x ± 3.06 | 67.05 x* ± 2.18 | 57.13 w ± 4.25 | |

| 2 | 64.73 Ax** ± 1.95 | 64.33 abx* ± 2.58 | 61.68 w* ± 3.07 | 69.65 x* ± 1.30 | 56.33 w* ± 3.97 | |

| YC-X11 Yo-Flex | 0 | 79.56 By ± 2.09 | 57.48 aw ± 4.28 | 59.70 w ± 3.29 | 65.72 x ± 3.83 | 51.43 aw* ± 1.20 |

| 1 | 76.75 BY** ± 3.08 | 65.48 bW ± 5.41 | 60.68 W ± 4.43 | 71.23 X* ± 1.60 | 59.12 bW ± 3.88 | |

| 2 | 69.16 Ax** ± 2.10 | 61.18 abx* ± 4.70 | 58.62 w* ± 2.26 | 66.30 x* ± 3.56 | 53.17 aw* ± 1.45 | |

| Type of Bacterial Cultures | WPC Content (%) | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Mild 1.0 Yo-Flex | 0 | 0.938 W ± 0.002 | 0.948 W ± 0.004 | 0.953 X ± 0.017 | 0.964 Y ± 0.013 | 0.966 Y ± 0.012 |

| 1 | 0.934 W ± 0.003 | 0.946 X ± 0.006 | 0.956 X ± 0.009 | 0.950 X ± 0.020 | 0.968 Y ± 0.011 | |

| 2 | 0.938 W ± 0.002 | 0.952 X ± 0.003 | 0.956 X ± 0.013 | 0.961 XY ± 0.017 | 0.968 Y ± 0.013 | |

| YC-X11 Yo-Flex | 0 | 0.958 X ± 0.002 | 0.962 bX ± 0.002 | 0.966 bX ± 0.002 | 0.947 W ± 0.001 | 0.971 X ± 0.008 |

| 1 | 0.956 x ± 0.004 | 0.958 abx ± 0.002 | 0.948 aw ± 0.008 | 0.948 w ± 0.001 | 0.960 x ± 0.010 | |

| 2 | 0.950 W ± 0.002 | 0.952 aW ± 0.005 | 0.954 abWX ± 0.003 | 0.948 W ± 0.002 | 0.962 X ± 0.007 | |

| Type of Bacterial Cultures | WPC Content (%) | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Mild 1.0 Yo-Flex | 0 | 6.21 z ± 1.50 | 3.37 aw** ± 0.85 | 4.78 bx ** ± 0.98 | 5.76 By** ± 1.45 | 5.95 By* ± 1.69 |

| 1 | 6.17 Z ± 1.73 | 4.51 abX* ± 0.49 | 3.80 abW ± 0.77 | 4.97 BXY ± 1.14 | 5.09 BY** ± 1.75 | |

| 2 | 5.36 Y ± 1.63 | 5.11 bY ± 0.73 | 2.46 bX* ± 0.51 | 2.25 AWX* ± 0.97 | 1.70 AW** ± 0.58 | |

| YC-X11 Yo-Flex | 0 | 6.32 By ± 1.34 | 6.14 cY** ± 0.92 | 2.26 aW ** ± 0.34 | 3.04 W** ± 1.28 | 4.90 X* ± 1.62 |

| 1 | 5.32 aby ± 1.28 | 5.79 by* ± 1.31 | 4.18 bx ± 1.13 | 3.97 wx ± 1.40 | 3.35 w** ± 1.07 | |

| 2 | 4.47 ax ± 1.57 | 4.54ax ± 0.96 | 3.98 bw* ± 0.99 | 3.94 w* ± 1.17 | 3.91 w** ± 1.39 | |

| Type of Bacterial Cultures | WPC Content (%) | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Mild 1.0 Yo-Flex | 0 | 3.78 ay ± 1.03 | 1.95 Aw** ± 0.46 | 2.02 aw ± 0.20 | 2.25 w ± 0.69 | 2.74 bx ± 0.71 |

| 1 | 4.47 abX ± 1.67 | 5.34 CX* ± 1.30 | 2.24 aW* ± 0.76 | 2.38 W* ± 0.88 | 2.17 bW ± 0.53 | |

| 2 | 5.21 By ± 1.24 | 3.29 BX* ± 0.32 | 3.37 bX ± 0.96 | 3.00 X ± 0.24 | 1.48 aW ± 0.38 | |

| YC-X11 Yo-Flex | 0 | 2.93 AX ± 0.64 | 3.90 y** ± 1.12 | 1.54 AW ± 0.17 | 1.73 AW ± 0.64 | 1.90 AW ± 0.72 |

| 1 | 5.02 BY ± 1.25 | 3.98 X* ± 0.37 | 3.79 BX* ± 0.58 | 3.47 BX* ± 0.27 | 2.67 BW ± 0.65 | |

| 2 | 6.12 BZ ± 1.19 | 4.75 YZ* ± 1.06 | 3.74 BY ± 1.14 | 2.81 ABX ± 0.86 | 1.16 AW ± 0.20 | |

| Type of Bacterial Cultures | WPC Content (%) | Storage Time (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Mild 1.0 Yo-Flex | 0 | 0.96 Cx** ± 0.10 | 1.06 Cx* ± 0.15 | 0.97 Cx* ± 0.08 | 0.86 Cw** ± 0.10 | 0.78 Cw** ± 0.12 |

| 1 | 0.74 Bx** ± 0.08 | 0.69 Bx** ± 0.11 | 0.79Bx** ± 0.06 | 0.64 Bw** ± 0.09 | 0.59 Bw** ± 0.08 | |

| 2 | 0.45 AY** ± 0.06 | 0.43 AY ± 0.07 | 0.45 AX* ± 0.05 | 0.40 AWX* ± 0.07 | 0.37 AW** ± 0.08 | |

| YC-X11 Yo-Flex | 0 | 1.22 Cx** ± 0.14 | 1.14 Cw* ± 0.10 | 1.11 Bw* ± 0.13 | 1.16 Cw** ± 0.10 | 1.12 Cw** ± 0.13 |

| 1 | 1.04 Bx** ± 0.12 | 1.00 Bxw** ± 0.11 | 1.05 Bx** ± 0.09 | 0.97 Bxw** ± 0.07 | 0.93 Bw** ± 0.10 | |

| 2 | 0.63 Ay** ± 0.08 | 0.59 Awy ± 0.06 | 0.55 Axw* ± 0.06 | 0.54 Aw* ± 0.06 | 0.51 Aw** ± 0.07 | |

| Type of Bacterial Cultures | WPC Content (%) | L* | a* | b* | WI | YI | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Storage Time (days) | 0 | 28 | 0 | 28 | 0 | 28 | 0 | 28 | 0 | 28 | |

| Mild 1.0 Yo-Flex | 0 | 95.17 CX* ± 0.15 | 92.91 CW* ± 0.41 | −4.56 AW* ± 0.04 | −0.95 BX** ± 0.07 | 18.54 AW** ± 0.04 | 18.93 AX* ± 0.24 | 19.68 ± 0.34 | 20.30 a ± 0.21 | 27.83 aW ± 0.52 | 29.12 AX ± 0.30 |

| 1 | 94.10 AX ± 0.16 | 91.67 BW* ± 0.29 | −3.44 BW ± 0.05 | −2.24 AX** ± 0.10 | 18.50 AW** ± 0.02 | 18.92 AX** ± 0.26 | 19.72 w ± 0.23 | 20.79 ax ± 0.18 | 28.08 abw** ± 0.27 | 29.48 Ax ± 0.43 | |

| 2 | 94.68 BX* ± 0.25 | 90.15 AW ± 0.26 | −3.12 CW* ± 0.01 | −1.07 CX** ± 0.05 | 19.05 BW** ± 0.03 | 19.37 BX* ± 0.19 | 20.04 W ± 0.32 | 21.75 bX ± 0.27 | 28.74 bW ± 0.55 | 30.69 BX ± 0.61 | |

| YC-X11 Yo-Flex | 0 | 95.67 CX* ± 0.22 | 91.73 CW* ± 0.28 | −4.35 AW* ± 0.02 | −2.96 AX** ± 0.08 | 18.10 BW** ± 0.02 | 18.59 BX* ± 0.14 | 19.11 w ± 0.15 | 20.57 ax ± 0.34 | 27.03 Aw ± 0.37 | 28.96 ax ± 0.44 |

| 1 | 94.07 AX ± 0.20 | 89.76 AW* ± 0.36 | −3.37 BW ± 0.02 | −1.89 BX** ± 0.05 | 17.74 AW** ± 0.02 | 18.01 AX** ± 0.25 | 19.00 W ± 0.26 | 20.80 abX ± 0.41 | 26.94 AW** ± 0.26 | 28.68 aX ± 0.52 | |

| 2 | 95.26 BX* ± 0.18 | 90.84 BW ± 0.32 | −2.90 CW* ± 0.04 | −0.68 CX** ± 0.02 | 18.76 CW** ± 0.04 | 19.04 CX* ± 0.13 | 19.56 W ± 0.48 | 21.14 bX ± 0.35 | 28.13 Bw ± 0.40 | 29.93 bx ± 0.29 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brodziak, A.; Król, J.; Barłowska, J.; Teter, A.; Florek, M. Changes in the Physicochemical Parameters of Yoghurts with Added Whey Protein in Relation to the Starter Bacteria Strains and Storage Time. Animals 2020, 10, 1350. https://doi.org/10.3390/ani10081350

Brodziak A, Król J, Barłowska J, Teter A, Florek M. Changes in the Physicochemical Parameters of Yoghurts with Added Whey Protein in Relation to the Starter Bacteria Strains and Storage Time. Animals. 2020; 10(8):1350. https://doi.org/10.3390/ani10081350

Chicago/Turabian StyleBrodziak, Aneta, Jolanta Król, Joanna Barłowska, Anna Teter, and Mariusz Florek. 2020. "Changes in the Physicochemical Parameters of Yoghurts with Added Whey Protein in Relation to the Starter Bacteria Strains and Storage Time" Animals 10, no. 8: 1350. https://doi.org/10.3390/ani10081350

APA StyleBrodziak, A., Król, J., Barłowska, J., Teter, A., & Florek, M. (2020). Changes in the Physicochemical Parameters of Yoghurts with Added Whey Protein in Relation to the Starter Bacteria Strains and Storage Time. Animals, 10(8), 1350. https://doi.org/10.3390/ani10081350