Influence of the Milking Units on the Pulsation Curve in Dairy Sheep Milking

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Milking Units

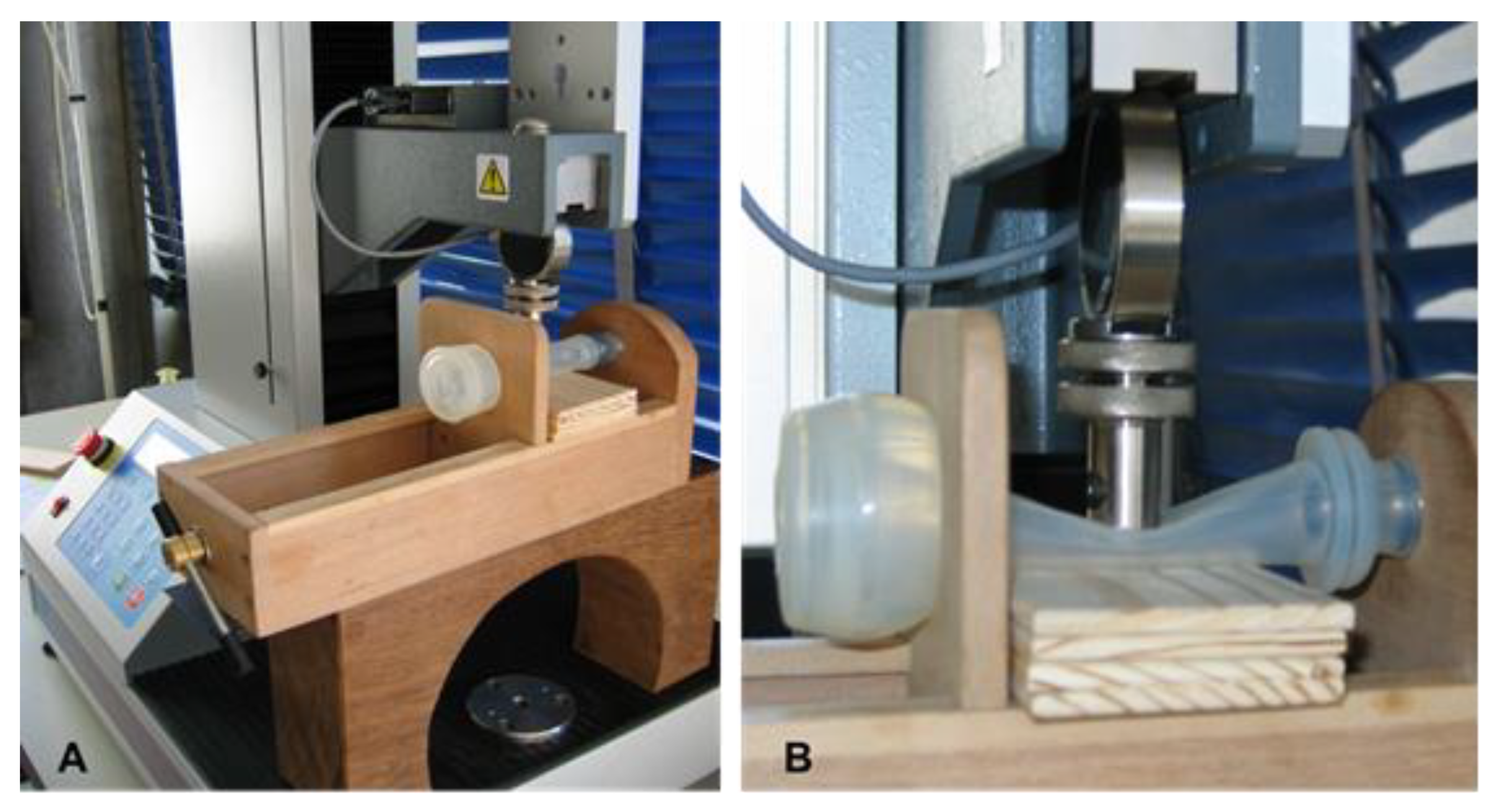

2.2. Liner Touch Point Pressure Tests

2.3. Statistical Analysis

- Operative vacuum, 38 kPa and 44 kPa;

- pulsator rate, 120 cycles/min and 180 cycles/min.

3. Results and Discussion

3.1. Operative Vacuum Level and Pulsation Frequency

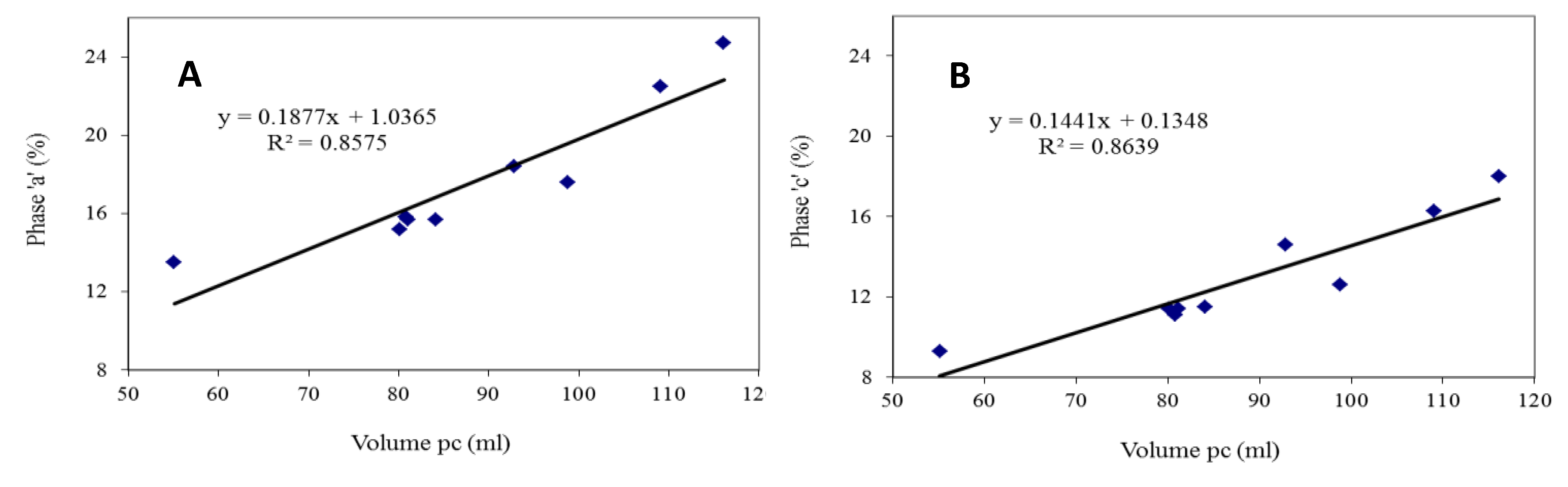

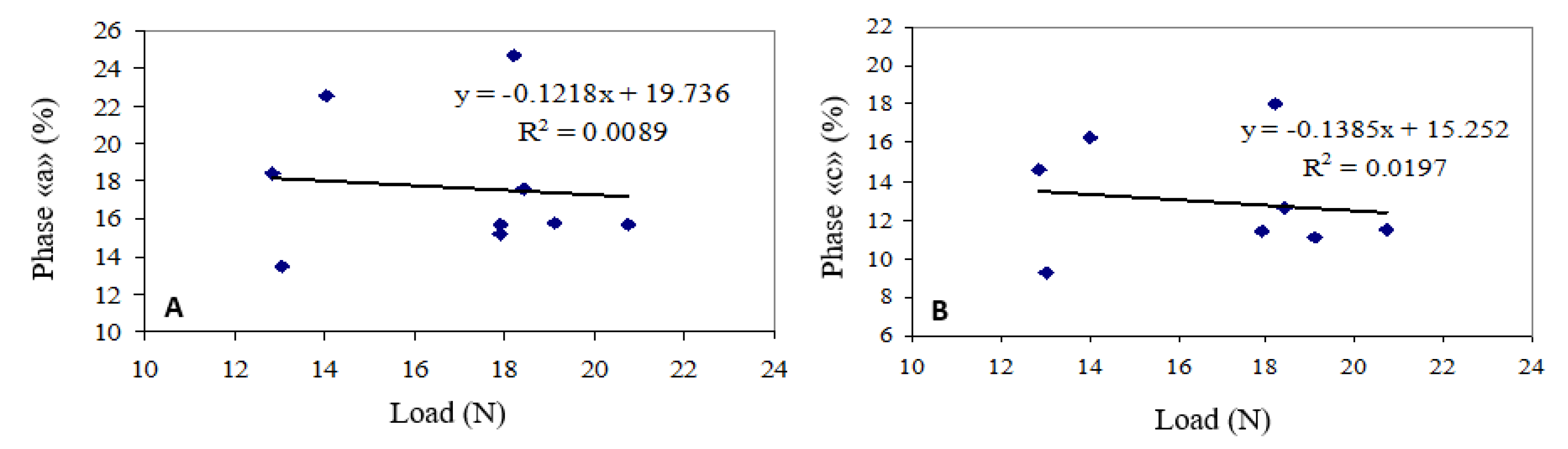

3.2. Pulsation Chamber Volume and Milking Liner’s Touch Point Pressure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Odorčić, M.; Rasmussen, M.D.; Paulrud, C.O.; Bruckmaier, R.M. Review: Milking machine settings, teat condition and milking efficiency in dairy cows. Animal 2019, 13, 94–99. [Google Scholar] [CrossRef] [PubMed]

- Zucali, M.; Tamburini, A.; Sandrucci, A.; Gislon, G.; Bava, L. Effect of vacuum level on milk flow and vacuum stability in Alpine goat milking. Small Ruminant Res. 2019, 171, 1–7. [Google Scholar] [CrossRef]

- Pazzona, A.; Murgia, L. Mungitura ovini: Sistema innovativo Fisiomilk. Macch. Mot. Agric. Edagricole Ed. 1996, 9, 43–47. [Google Scholar]

- Peris, C.; Diaz, J.R.; Torres, A.; Fernandez, N.; Rodriguez, M. Effect of variable traction on the teat-cup during machine milking of ewes. In Proceedings of the 5th International Symposium on Machine Milking of Small Ruminants, Budapest, Hungary, 14–20 May 1993; pp. 385–400. [Google Scholar]

- Akam, D.N.; Spencer, S.B. Design and operation of milking machine components. In Machine Milking and Lactation; Bramley, A.J., Dodd, F.H., Mein, G., Bramley, J.A., Eds.; Insight Books: Burlington, VT, USA, 1992; pp. 141–196. [Google Scholar]

- Murgia, L.; Pazzona, A. Influenza di Alcuni Parametri Dimensionali e Operativi Dell’impianto di Mungitura Sulla Dinamica Della Curva di Pulsazione. In Proceedings of the VII Convegno Nazionale di Ingegneria Agraria (AIIA), Vieste, Foggia, Italy, 11–14 September 2001. [Google Scholar]

- Penry, J.F.; Leonardi, S.; Upton, J.; Thompson, P.D.; Reinemann, D.J. Assessing liner performance using on-farm milk meters. J. Dairy Sci. 2016, 99, 6609–6618. [Google Scholar] [CrossRef] [PubMed]

- Alejandro, M.; Roca, A.; Romero, G.; Díaz, J.R. Effects of overmilking and liner type and characteristics on teat tissue in small ruminants. J. Dairy Res. 2014, 81, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Penry, J.F.; Upton, J.; Leonardi, S.; Thompson, P.D.; Reinemann, D.J. A method for assessing liner performance during the peak milk flow period. J. Dairy Sci. 2018, 101, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Mein, G.A.; Williams, D.M.; Thiel, C.C. Compressive load applied by the teat cup liner to the bovine teat. J. Dairy Res. 1987, 54, 327–337. [Google Scholar] [CrossRef] [PubMed]

- Boast, D.; Hale, M.; Turner, D.; Hillerton, J.E. Variation in Rubber Chemistry and Dynamic Mechanical Properties of the Milking Liner Barrel with Age. J. Dairy Sci. 2008, 91, 2247–2256. [Google Scholar] [CrossRef] [PubMed]

- Capuco, A.V.; Mein, G.A.; Nickerson, S.C.; Jack, L.J.; Wood, D.L.; Bright, S.A.; Aschenbrenner, R.A.; Miller, R.H.; Bitman, J. Influence of pulsation less milking on teat canal keratin and mastitis. J. Dairy Sci. 1994, 77, 64–74. [Google Scholar] [CrossRef]

- Hamann, J. The milking machine and mastitis. In Proceedings of the 5th IDF (International Dairy Federation) Mastitis Congress, Symposium on Immunology of Ruminant Mammary Gland, Stresa, Italy, 11–14 June 2000. [Google Scholar]

- Mein, G.; Reinemann, D.; O’Callaghan, E.; Ohnstad, I. Where the rubber meets the teat and what happens to milking characteristics. In Proceedings of the IDF Symposium: 100 Years with Liners and Pulsators in Machine Milking, Bruges, Belgium, 12 September 2003; Bull. No. 388. pp. 431–446. [Google Scholar]

- Upton, J.; Reinemann, D.J.; Penry, J.F.; Thompson, P.D. A quarter milking analysis device—Development and demonstration. Biosyst. Eng. 2016, 147, 259–264. [Google Scholar] [CrossRef]

- Romero, G.; Peris, C.; Fthenakis, G.C.; Diaz, J.R. Effects of machine milking on udder health in dairy ewes. Small Ruminant Res. 2020, 188, 106096. [Google Scholar] [CrossRef]

- International Organization for Standardization ISO 5707:2007. Milking Machine Installations—Construction and Performance; International Organization for Standardization: Geneva Switzerland, 2007. [Google Scholar]

- Upton, J.; Penry, J.F.; Rasmussen, M.D.; Thompson, P.D.; Reinemann, D.J. Effect of pulsation rest phase duration on teat end congestion. J. Dairy Sci. 2016, 99, 3958–3965. [Google Scholar] [CrossRef] [PubMed]

- Hamman, J.; Mein, G.A. Teat thickness changes may provide biological test for effective pulsation. J. Dairy Res. 1996, 63, 179–189. [Google Scholar] [CrossRef] [PubMed]

- Østerås, O.; Ronningen, O.; Sandvik, L.; Waage, S. Field studies show associations between pulsator characteristics and udder health. J. Dairy Res. 1995, 62, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Eitam, M.; Hamman, J. Relevance of machine-induced teat tissue reactions in cows for improvement of machine milking in small ruminants. In Proceedings of the 5th International Symposium on Machine Milking of Small Ruminants, Budapest, Hungary, 14–20 May 1993; pp. 401–408. [Google Scholar]

- Mein, G.A. Milk flow from the bovine teat in relation to movement of the teatcup liner. Aust. J. Dairy Technol. 1977, 32, 39–41. [Google Scholar]

- Billon, P.; Gaudin, V. Influence of the duration of a and c phase of pulsation on the milking characteristics and on udder health of dairy cows. Physiol. Tech. Asp. Mach. Milk. ICAR Tech. 2001, 7, 105–111. [Google Scholar]

- Ente Italiano di Normazione (UNI) 11008: 2002. Impianti per la Mungitura meccanica Delle Specie Ovina e Caprina—Terminologia, Requisiti Costruttivi e Prestazionali; Rome, Italy, 2002.

- Pazzona, A.; Murgia, L.; Caria, M. Stato attuale degli impianti per la mungitura di ovini e caprini. In Informatore Zootecnico; Edagricole Editore: Milan, Italy, 2003; Volume 12, pp. 42–50. [Google Scholar]

- International Organization for Standardization ISO 6690: 2007. Milking Machine Installations—Mechanical Tests; International Organization for Standardization: Geneva Switzerland, 2007. [Google Scholar]

- International Organization for Standardization ISO 3918: 2007. Milking Machine Installations—Vocabulary; International Organization for Standardization: Geneva Switzerland, 2007. [Google Scholar]

| Milking Units | Length of the Shell (mm) | Body of the Liners | Pulsation Chamber Volume (mL) b | ||||

|---|---|---|---|---|---|---|---|

| Length (mm) | Extension (%) | Diameter (mm) a | Shape | Material | |||

| G1 | 103 | 93 | 10.9 | 190 | conical | silicon | 55.1 |

| G2 | 104 | 101 | 2.8 | 200 | cylindrical | rubber | 80.1 |

| G3 | 105 | 101 | 3.9 | 180 | cylindrical | rubber | 80.8 |

| G4 | 104 | 101 | 2.8 | 200 | cylindrical | rubber | 81.1 |

| G5 | 105 | 95 | 10.6 | 180 | cylindrical | silicon | 84.1 |

| G6 | 109 | 102 | 7.4 | 18 | cylindrical | silicon | 92.8 |

| G7 | 107 | 100 | 7.0 | 18 | cylindrical | silicon | 98.8 |

| G8 | 134 | 124 | 8.5 | 21 | conical | rubber | 109.1 |

| G9 | 129 | 114 | 13.2 | 22 | cylindrical | silicon | 116.1 |

| Milking Units | Operative Parameters Vacuum (kPa)-Pulsator Rate (cycles/min) | Mean | |||

|---|---|---|---|---|---|

| 38–120 | 38–180 | 44–120 | 44–180 | ||

| G1 | 10.5 | 11.5 | 11.1 | 16.9 | 13.5 |

| G2 | 11.7 | 17.2 | 12.8 | 19.1 | 15.2 |

| G3 | 12.1 | 18.0 | 13.4 | 19.6 | 15.8 |

| G4 | 11.9 | 18.1 | 13.1 | 19.7 | 15.7 |

| G5 | 12.0 | 17.7 | 13.4 | 19.7 | 15.7 |

| G6 | 16.1 | 20.08 | 15.0 | 21.8 | 18.4 |

| G7 | 13.2 | 20.5 | 14.8 | 21.9 | 17.6 |

| G8 | 17.9 | 25.8 | 18.7 | 27.6 | 22.5 |

| G9 | 19.5 | 28.0 | 20.1 | 31.0 | 24.7 |

| Mean ± SD | 13.9 ± 3.2 | 20.2 ± 4.2 | 14.7 ± 2.9 | 21.9 ± 4.5 | 17.7 ± 3.7 |

| Milking Units | Operative Parameters Vacuum (kPa)-Pulsator Rate (cycles/min) | Mean | |||

|---|---|---|---|---|---|

| 38–120 | 38–180 | 44–120 | 44–180 | ||

| G1 | 7.3 | 10.8 | 7.7 | 11.4 | 9.3 |

| G2 | 8.9 | 12.9 | 9.6 | 14.3 | 11.4 |

| G3 | 8.6 | 12.6 | 9.4 | 13.9 | 11.1 |

| G4 | 8.8 | 13.0 | 9.6 | 14.1 | 11.4 |

| G5 | 8.8 | 13.0 | 9.8 | 14.4 | 11.5 |

| G6 | 11.5 | 16.5 | 12.2 | 18.0 | 14.6 |

| G7 | 9.7 | 14.5 | 10.5 | 15.7 | 12.6 |

| G8 | 12.9 | 18.7 | 13.6 | 20.0 | 16.3 |

| G9 | 14.2 | 20.8 | 15.1 | 22.0 | 18.0 |

| Mean ± SD | 10.1 ± 2.3 | 14.8 ± 3.3 | 10.8 ± 2.3 | 16.0 ± 3.4 | 12.9 ± 2.8 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | F-Test Statistic | p-Value | F crit |

|---|---|---|---|---|---|---|

| Frequency | 410.737 | 1 | 410.738 | 29.204 | <0.001 | 7.499 |

| Vacuum | 14.951 | 1 | 14.951 | 1.063 | 0.310 | 7.499 |

| Frequency × Vacuum | 1.867 | 1 | 1.867 | 0.133 | 0.718 | 7.499 |

| Within | 450.055 | 32 | 14.064 | |||

| Total | 877.612 | 35 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | F-Test Statistic | p-Value | F crit |

|---|---|---|---|---|---|---|

| Frequency | 217.071 | 1 | 217.071 | 26.582 | <0.001 | 7.499 |

| Vacuum | 8.801 | 1 | 8.801 | 1.077 | 0.307 | 7.499 |

| Frequency × Vacuum | 0.490 | 1 | 0.490 | 0.060 | 0.808 | 7.499 |

| Within | 261.313 | 32 | 8.166 | |||

| Total | 487.675 | 35 |

| Test | Milking Liners | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| G1 | G2 | G3 | G4 | G5 | G6 | G7 | G8 | G9 | |

| Average touch point pressure (N) * | 13.05 ± 0.06 | 17.89 ± 0.07 | 19.11 ± 0.06 | 17.89 ± 0.06 | 20.72 ± 0.45 | 12.89 ± 0.11 | 18.41 ± 0.19 | 14.02 ± 0.03 | 18.19 ± 0.05 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caria, M.; Todde, G.; Pazzona, A. Influence of the Milking Units on the Pulsation Curve in Dairy Sheep Milking. Animals 2020, 10, 1213. https://doi.org/10.3390/ani10071213

Caria M, Todde G, Pazzona A. Influence of the Milking Units on the Pulsation Curve in Dairy Sheep Milking. Animals. 2020; 10(7):1213. https://doi.org/10.3390/ani10071213

Chicago/Turabian StyleCaria, Maria, Giuseppe Todde, and Antonio Pazzona. 2020. "Influence of the Milking Units on the Pulsation Curve in Dairy Sheep Milking" Animals 10, no. 7: 1213. https://doi.org/10.3390/ani10071213

APA StyleCaria, M., Todde, G., & Pazzona, A. (2020). Influence of the Milking Units on the Pulsation Curve in Dairy Sheep Milking. Animals, 10(7), 1213. https://doi.org/10.3390/ani10071213