Properties of Rennet Cheese Made from Whole and Skimmed Summer and Winter Milk on a Traditional Polish Dairy Farm

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Farm Characteristics

2.2. Diet and Feeding

2.3. Animals and Milk Collections

2.4. Soft Cheese Making

2.5. Physicochemical Analysis

2.6. Rheological and Profile Texture Analysis

2.7. Organoleptic Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Milk Composition

3.2. The Physicochemical Analysis of the Milk

3.3. Cheese Yield, the Physicochemical and Rheological Analysis of the Cheeses

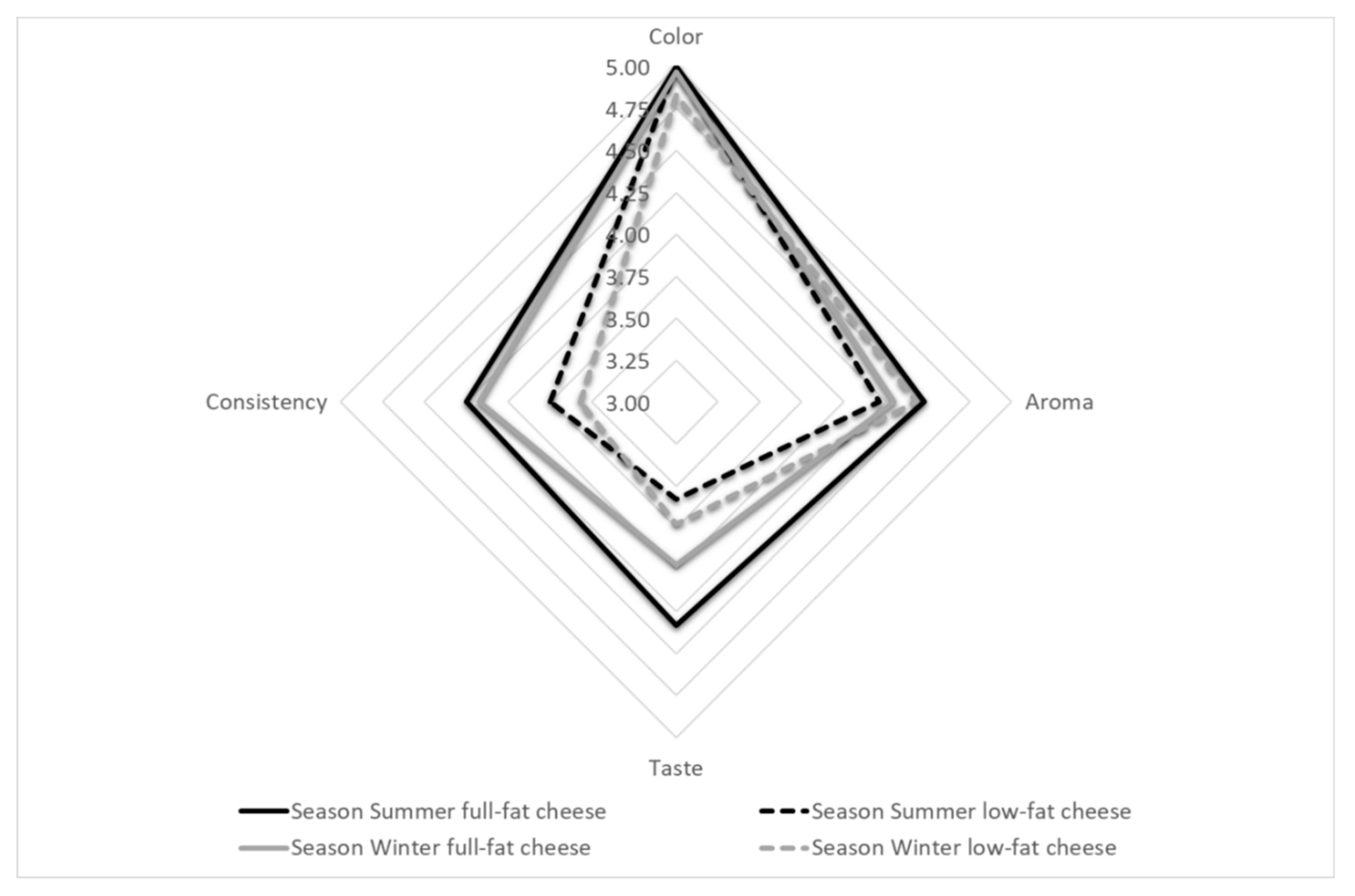

3.4. Organoleptic Analysis of the Cheeses

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAOSTAT. Food and Agriculture Organization of the United Nations. 2020. Available online: http://www.fao.org/faostat/en/#data/QA (accessed on 17 May 2020).

- Bergamaschi, M.; Cipolat-Gotet, C.; Stocco, G.; Valorz, C.; Bazzoli, I.; Sturaro, E.; Ramanzin, M. Cheesemaking in highland pastures: Milk technological properties, cream, cheese and ricotta yields, milk nutrients recovery, and products composition. J. Dairy Sci. 2016, 99, 9631–9646. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Markiewicz-Kęszycka, M.; Czyżak-Runowska, G.; Lipińska, P.; Wójtowski, J. Fatty Acid Profile of Milk—A Review. Bull. Vet. Inst. Pulawy 2013, 57, 135–139. [Google Scholar] [CrossRef] [Green Version]

- Walker, G.P.; Wijesundera, C.; Dunshea, F.R.; Doyle, P.T. Seasonal and stage of lactation effects on milk fat composition in northern Victoria. Anim. Prod. Sci. 2013, 53, 560–572. [Google Scholar] [CrossRef]

- Schwendel, B.H.; Wester, T.J.; Morel, P.C.H.; Fong, B.; Tavendale, M.H.; Deadman, C.; Shadbolt, N.M.; Otter, D.E. Pasture feeding conventional cows removes differences between organic and conventionally produced milk. Food Chem. 2017, 229, 805–813. [Google Scholar] [CrossRef]

- Santiago-López, L.; Aguilar-Toalá, J.E.; Hernández-Mendoza, A.; Vallejo-Cordoba, B.; Liceaga, A.M.; González-Córdova, A.F. Invited review: Bioactive compounds produced during cheese ripening and health effects associated with aged cheese consumption. J. Dairy Sci. 2018, 101, 3742–3757. [Google Scholar] [CrossRef] [Green Version]

- Król, J.; Brodziak, A.; Chabuz, W.; Litwińczuk, Z.; Barłowska, J. Effect of the feeding system and the production season on the protein fraction content in milk. Mljekarstvo 2019, 69, 98–107. [Google Scholar] [CrossRef]

- Seguel, G.; Keim, J.P.; Vargas-Bello-Pérez, E.; Geldsetzer-Mendoza, C.; Ibáñez, R.A.; Alvarado-Gilis, C. Effect of forage brassicas in dairy cow diets on the fatty acid profile and sensory characteristics of Chanco and Ricotta cheeses. J. Dairy Sci. 2020, 103, 228–241. [Google Scholar] [CrossRef] [Green Version]

- Cais-Sokolińska, D.; Pikul, J.; Wójtowski, J.; Danków, R.; Teichert, J.; Czyżak-Runowska, G.; Bagnicka, E. Evaluation of quality of kefir from milk obtained from goats supplemented with a diet rich in bioactive compounds. J. Sci. Food Agric. 2015, 95, 1343–1349. [Google Scholar] [CrossRef]

- Bava, L.; Bacenetti, J.; Gislon, G.; Pellergrino, L.; Sandrucci, A.; Tamburini, A.; Fiala, M.; Zucali, M. Impact assessment of traditional food manufacturing: The case of Grana Padano cheese. Sci. Total Environ. 2018, 626, 1200–1209. [Google Scholar] [CrossRef]

- Childs, J.L.; Drake, M. Consumer perception of fat reduction in cheese. J. Sens. Stud. 2009, 24, 902–921. [Google Scholar] [CrossRef]

- Barłowska, J.; Szwajkowska, M.; Litwińczuk, Z.; Król, J. Nutritional value and technological suitability of milk from various animal species used for dairy production. Compr. Rev. Food Sci. Food Saf. 2011, 291–302. [Google Scholar] [CrossRef]

- Bonadonna, A.; Peira, G.; Giachino, C.; Molinaro, L. Traditional cheese production and an EU labeling scheme: The Alpine cheese producers’ opinion. Agriculture 2017, 7, 65. [Google Scholar] [CrossRef] [Green Version]

- Manzo, N.; Santini, A.; Pizzolongo, F.; Aiello, A.; Marrazzo, A.; Meca, G.; Durazzo, A.; Lucarini, M.; Romano, R. Influence of ripening on chemical characteristics of a traditional Italian cheese: Provolone del Monaco. Sustainability 2019, 11, 2520. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Lewis, M.J.; Grandison, A.S. Effect of seasonal variation on the properties of whipping cream, soft cheese and skim milk powder in the UK. Int. J. Dairy Technol. 2015, 68, 30–38. [Google Scholar] [CrossRef]

- James, C.S. Analytical Chemistry of Foods, 1st ed.; Chapman and Hall: Glasgow, UK, 1995. [Google Scholar]

- AOAC (Association of Oficial Analytical Chemists). Oficial Methods of Analysis, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2019. [Google Scholar]

- Polish Standard PN-68/A-8612. Milk. In Research Methodology; Wydawnictwa Normalizacyjne, 1968. (In Polish) [Google Scholar]

- Madadlou, A.; Khosroshahi, A.; Mousavi, M.E. Rheology, microstructure and functionality of low-fat Iranian white cheese made with different concentrations of rennet. J. Dairy Sci. 2005, 88, 3052–3062. [Google Scholar] [CrossRef] [Green Version]

- Ali, A.K.A.; Shook, G.E. An optimum transformation for somatic cell concentration in milk. J. Dairy Sci. 1980, 63, 487–490. [Google Scholar] [CrossRef]

- Litwińczuk, Z.; Kowal, M.; Barłowska, J. Basic chemical composition, proportion of fatty acids, and cholesterol content in milk of four breeds of cows used in the intensive husbandry technologies. Food Sci. Technol. Qual. 2014, 21, 108–121. [Google Scholar] [CrossRef]

- Bernabucci, U.; Basiricò, L.; Morera, P.; Dipasquale, D.; Vitali, A.; Cappelli, F.P.; Calamari, L. Effect of summer season on milk protein fractions in Holstein cows. J. Dairy Sci. 2015, 98, 1815–1827. [Google Scholar] [CrossRef] [Green Version]

- Coppa, M.; Chassaing, C.; Sibra, C.; Cornu, A.; Verbič, J.; Golecký, J.; Engel, E.; Ratel, J.; Boudon, A.; Ferlay, A.; et al. Forage system is the key driver of mountain milk specificity. J. Dairy Sci. 2019, 102, 10483–10499. [Google Scholar] [CrossRef]

- Křížová, L.; Hanuš, O.; Roubal, P.; Kučera, J.; Hadrová, S. The effect of cattle breed, season and type of diet on nitrogen fractions and amino acid profile of raw milk. Arch. Anim. Breed. 2013, 56, 709–718. [Google Scholar] [CrossRef] [Green Version]

- Mohanty, D.P.; Mohapatra, S.; Misra, S.; Sahu, P.S. Milk derived bioactive peptides and their impact on human health—A review. Saudi J. Biol. Sci. 2016, 23, 577–583. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Regulation (EC) No 853/2004 of the European Parliament and of the Council of 29 April 2004 Laying down Specific Hygiene Rules for Food of Animal Origin [Internet]. Available online: https://eurlex.europa.eu/legalcontent/EN/TXT/PDF/?uri=CELEX,02004R085320130906&from=PL (accessed on 28 May 2020).

- Kul, E.; Şahin, A.; Atasever, S.; Uğurlutepe, E.; Soydaner, M. The effects of somatic cell count on milk yield and milk composition in Holstein cows. Vet. Arch. 2019, 89, 143–154. [Google Scholar] [CrossRef]

- Alhussien, M.N.; Dang, A.K. Milk somatic cells, factors influencing their release, future prospects, and practical utility in dairy animals. An overview. Vet. World 2018, 11, 562–577. [Google Scholar] [CrossRef] [PubMed]

- Sert, D.; Mercan, E.; Aydemir, S.; Civelek, M. Effects of milk somatic cell counts on some physicochemical and functional characteristics of skim and whole milk powders. J. Dairy Sci. 2016, 99, 5254–5264. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Politis, I.; Ng-Kwai-Hang, K.F. Effects of somatic cell count and milk composition on cheese composition and cheese making efficiency. J. Dairy Sci. 1988, 71, 1711–1719. [Google Scholar] [CrossRef]

- Chen, B.; Grandison, A.S.; Lewis, M.J. Best use for milk—A review. II—Effect of physiological, husbandry and seasonal factors on the physicochemical properties of bovine milk. Int. J. Dairy Technol. 2017, 70, 155–164. [Google Scholar] [CrossRef]

- Brodziak, A.; Litwińczuk, A.; Topyła, B.; Wolanciuk, A. Influence of production season x breed and feeding system interactions on daily yield and milk physical-chemical composition. Roczniki Naukowe PTZ 2012, 8, 19–27. (In Polish) [Google Scholar]

- MacGibbon, A.K.H.; Taylor, M.W. Composition and structure of bovine milk lipids. Adv. Dairy Chem. 2009, 2, 1–42. [Google Scholar] [CrossRef]

- Winkelman, A.M.; Johnson, D.L.; MacGibbon, A.K.H. Estimation of heritabilities and correlations associated with milk color traits. J. Dairy. Sci. 1999, 82, 215–224. [Google Scholar] [CrossRef]

- Faulkner, H.; O’Callaghan, T.F.; McAuliffe, S.; Hennessy, D.; Stanton, C.; O’Sullivan, M.G.; Kerry, J.P.; Kilcawley, K.N. Effect of different forage types on the volatile and sensory properties of bovine milk. J. Dairy Sci. 2018, 101, 1034–1047. [Google Scholar] [CrossRef]

- Scarso, S.; McParland, S.; Visentin, G.; Berry, D.P.; McDermott, A.; De Marchi, M. Genetic and nongenetic factors associated with milk color in dairy cows. J. Dairy Sci. 2017, 100, 7345–7361. [Google Scholar] [CrossRef] [PubMed]

- Nozière, P.; Graulet, B.; Lucas, A.; Martin, B.; Grolier, P. Doreau, M. Carotenoids for ruminants: From forages to dairy products. Anim. Feed Sci. Technol. 2006, 131, 418–450. [Google Scholar] [CrossRef]

- Miloradovic, Z.; Miocinovic, J.; Kljajevic, N.; Tomasevic, I.; Pudja, P. The influence of milk heat treatment on composition, texture, colour and sensory characteristics of cows’ and goats’ Quark-type cheeses. Small Rumin. Res. 2018, 169, 154–159. [Google Scholar] [CrossRef]

- Kahyaoglu, T.; Kaya, S. Effects of heat treatment and fat reduction on the rheological and functional properties of Gaziantep cheese. Int. Dairy J. 2003, 13, 867–875. [Google Scholar] [CrossRef]

- Rahimi, J.; Khosrowshahi, A.; Madadlou, A.; Aziznia, S. Texture of low-fat Iranian white cheese as influenced by gum tragacanth as a fat replacer. J. Dairy Sci. 2007, 90, 4058–4070. [Google Scholar] [CrossRef]

- Mistry, V.V. Low fat cheese technology. Int. Dairy J. 2001, 11, 413–422. [Google Scholar] [CrossRef]

- Lobato-Calleros, C.; Sosa-Pérez, A.; Rodríguez-Tafoya, J.; Sandoval-Castilla, O.; Pérez-Alonso, C.; Vernon-Carter, E.J. Structural and textural characteristics of reduced-fat cheese-like products made from W1/O/W2 emulsions and skim milk. LWT Food Sci. Technol. 2008, 41, 1847–1856. [Google Scholar] [CrossRef]

- Miloradovic, Z.N.; Kljajevic, N.V.; Jovanovic, S.T.; Vucic, T.R.; MacEj, O.D. The effect of heat treatment and skimming on precipitate formation in caprine and bovine milks. J. Dairy Res. 2015, 82, 22–28. [Google Scholar] [CrossRef]

- Koczura, M.; Martin, B.; Turille, G.; De Marchi, M.; Kreuzer, M.; Berard, J. Milk composition, but not cheese properties are impaired the day after transhumance to alpine pastures. Int. Dairy J. 2019, 99, 104540. [Google Scholar] [CrossRef]

- Bergamaschi, M.; Bittante, G. From milk to cheese: Evolution of flavor fingerprint of milk, cream, curd, whey, ricotta, scotta, and ripened cheese obtained during summer Alpine pasture. J. Dairy Sci. 2018, 101, 3918–3934. [Google Scholar] [CrossRef] [Green Version]

- Sipahioglu, O.; Alvarez, V.B.; Solano-Lopez, C. Structure, physico-chemical and sensory properties of feta cheese made with tapioca starch and lecithin as fat mimetics. Int. Dairy J. 1999, 9, 783–789. [Google Scholar] [CrossRef]

- Amelia, I.; Drake, M.A.; Nelson, B.; Barbano, D.M. A new method for the production of low-fat Cheddar cheese. J. Dairy Sci. 2013, 96, 4870–4884. [Google Scholar] [CrossRef] [PubMed]

- Bugaud, C.; Buchin, S.; Hauwuy, A.; Coulon, J.B. Relationships between flavour and chemical composition of Abondance cheese derived from different types of pastures. Le Lait 2001, 81, 757–773. [Google Scholar] [CrossRef]

- Romeih, E.A.; Michaelidou, A.; Biliaderis, C.G.; Zerfiridis, G.K. Low-fat white-brined cheese made from bovine milk and two commercial fat mimetics. Chemical, physical and sensory attributes. Int. Dairy J. 2002, 12, 525–540. [Google Scholar] [CrossRef]

- Johnson, M.E. A 100-Year Review: Cheese production and quality. J. Dairy Sci. 2017, 100, 9952–9965. [Google Scholar] [CrossRef]

| Item | Season | p-Value | |||||

|---|---|---|---|---|---|---|---|

| Summer | Winter | ||||||

| x | SD | Range | x | SD | Range | ||

| Dry matter (%) | 12.30 | 0.78 | 10.83–14.59 | 13.06 | 1.17 | 11.15–16.32 | 0.0003 |

| Fat (%) | 3.75 | 0.67 | 2.07–5.95 | 4.15 | 0.85 | 2.85–7.10 | 0.0115 |

| Protein (%) | 3.20 | 0.35 | 2.65–4.19 | 3.49 | 0.60 | 2.79–5.79 | 0.0041 |

| Casein (%) | 2.49 | 0.27 | 2.06–3.29 | 2.72 | 0.46 | 2.11–4.48 | 0.0042 |

| Lactose (%) | 4.66 | 0.20 | 4.32–5.22 | 4.69 | 0.44 | 3.02–5.12 | 0.6432 |

| SCC (×103 /mL) | 232 | 161 | 8–400 | 246 | 149 | 5–400 | 0.6624 |

| Item | Season | Season | Type of Milk | Season × Type of Milk | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Summer | Winter | p-Value | ||||||||||

| Full-Fat Milk | Low-Fat Milk | Full-Fat Milk | Low-Fat Milk | |||||||||

| x | SD | x | SD | x | SD | x | SD | |||||

| pH | 6.54 a | 0.08 | 6.83 b | 0.02 | 6.60 c | 0.06 | 6.68 d | 0.03 | 0.0039 | 0.0001 | 0.0001 | |

| Color | L* | 88.58 a | 0.24 | 86.65 b | 0.92 | 88.81 a | 0.39 | 88.48 a | 0.50 | 0.0001 | 0.0001 | 0.0001 |

| a* | −3.38 a | 0.32 | −6.14 b | 0.47 | −3.44 a | 0.10 | −5.50 c | 0.23 | 0.0082 | 0.0001 | 0.0003 | |

| b* | 14.03 a | 0.87 | 9.19 b | 0.97 | 10.53 c | 0.44 | 7.58 d | 1.40 | 0.0001 | 0.0001 | 0.0018 | |

| Item | Season | SE | Season | Type of Milk | Season × Type of Milk | ||||

|---|---|---|---|---|---|---|---|---|---|

| Summer | Winter | ||||||||

| Full-Fat Cheese x | Low-Fat Cheese x | Full-Fat Cheese x | Low-Fat Cheese x | p-Value | |||||

| Cheese yield [kg] | 1.04 | 0.80 | 1.08 | 0.88 | 0.03 | 0.2062 | 0.0001 | 0.5817 | |

| pH | 5.76 | 6.05 | 5.94 | 6.29 | 0.06 | 0.0493 | 0.0029 | 0.7444 | |

| SH | 7.40 | 5.97 | 5.60 | 4.50 | 0.31 | 0.0074 | 0.0360 | 0.7792 | |

| Color | L* | 91.25 a | 90.81 b | 91.71 a | 90.60 b | 0.09 | 0.3862 | 0.0001 | 0.0220 |

| a* | −1.60 a | −2.80 b | −1.34 a | −2.94 b | 0.09 | 0.4564 | 0.0001 | 0.0090 | |

| b* | 18.11 a | 13.31 b | 15.24 c | 12.96 b | 0.26 | 0.0001 | 0.0001 | 0.0001 | |

| Firmness (g) | 566.78 a | 833.47 b | 548.98 a | 1137.82 c | 39.52 | 0.0378 | 0.0001 | 0.0198 | |

| Stickiness (g) | −10.66 a | −4.04 b | −3.49 b | −1.02 c | 0.51 | 0.0001 | 0.0001 | 0.0117 | |

| Item | Season | SE | Season | Type of Milk | Season × Type of Milk | |||

|---|---|---|---|---|---|---|---|---|

| Summer | Winter | |||||||

| Full-Fat Cheese x | Low-Fat Cheese x | Full-Fat Cheese x | Low-Fat Cheese x | p-Value | ||||

| Color | 5.00 | 5.00 | 4.97 | 4.83 | 0.02 | 0.0053 | 0.0607 | 0.0607 |

| Aroma | 4.48 | 4.21 | 4.30 | 4.43 | 0.05 | 0.8064 | 0.4961 | 0.0577 |

| Taste | 4.33 a | 3.58 b | 3.97 a | 3.73 a–b | 0.06 | 0.3141 | 0.0001 | 0.0174 |

| Consistency | 4.25 | 3.75 | 4.17 | 3.57 | 0.06 | 0.2151 | 0.0001 | 0.6412 |

| Overall assessment | 4.48 | 4.02 | 4.33 | 4.10 | 0.04 | 0.6162 | 0.0001 | 0.0923 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czyżak-Runowska, G.; Wójtowski, J.A.; Gogół, D.; Wojtczak, J.; Skrzypczak, E.; Stanisławski, D. Properties of Rennet Cheese Made from Whole and Skimmed Summer and Winter Milk on a Traditional Polish Dairy Farm. Animals 2020, 10, 1794. https://doi.org/10.3390/ani10101794

Czyżak-Runowska G, Wójtowski JA, Gogół D, Wojtczak J, Skrzypczak E, Stanisławski D. Properties of Rennet Cheese Made from Whole and Skimmed Summer and Winter Milk on a Traditional Polish Dairy Farm. Animals. 2020; 10(10):1794. https://doi.org/10.3390/ani10101794

Chicago/Turabian StyleCzyżak-Runowska, Grażyna, Jacek Antoni Wójtowski, Danuta Gogół, Janusz Wojtczak, Ewa Skrzypczak, and Daniel Stanisławski. 2020. "Properties of Rennet Cheese Made from Whole and Skimmed Summer and Winter Milk on a Traditional Polish Dairy Farm" Animals 10, no. 10: 1794. https://doi.org/10.3390/ani10101794

APA StyleCzyżak-Runowska, G., Wójtowski, J. A., Gogół, D., Wojtczak, J., Skrzypczak, E., & Stanisławski, D. (2020). Properties of Rennet Cheese Made from Whole and Skimmed Summer and Winter Milk on a Traditional Polish Dairy Farm. Animals, 10(10), 1794. https://doi.org/10.3390/ani10101794