A Comparison Study of a Novel Self-Contained Electro-Hydraulic Cylinder versus a Conventional Valve-Controlled Actuator—Part 2: Energy Efficiency

Abstract

1. Introduction

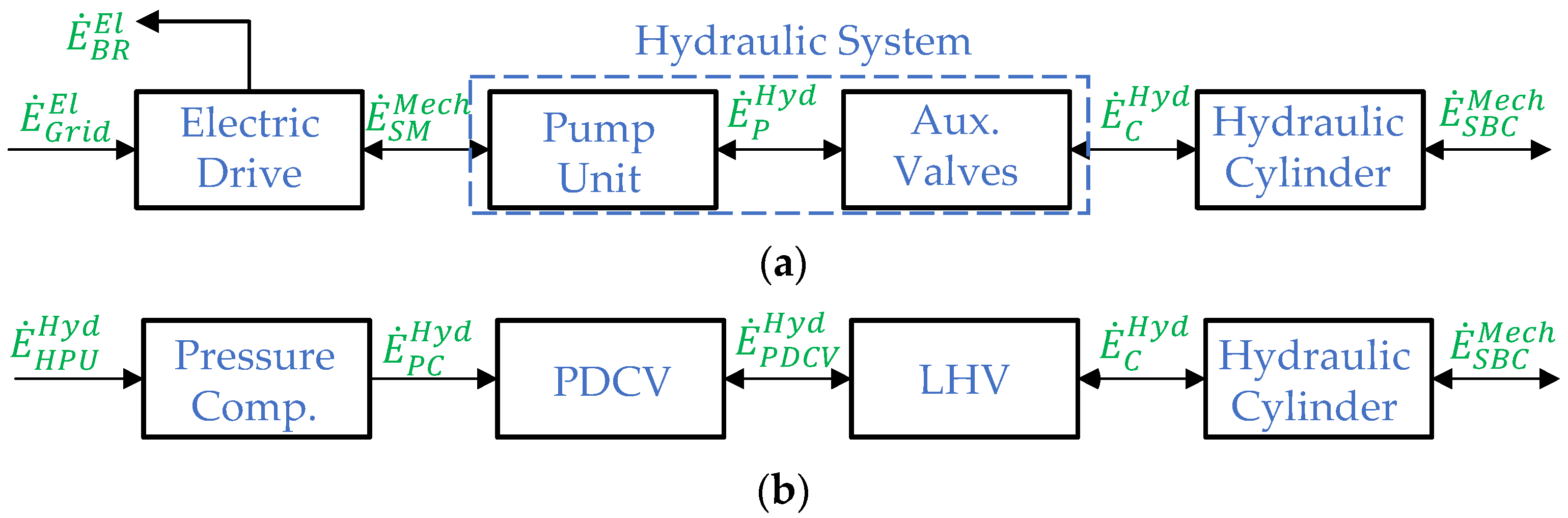

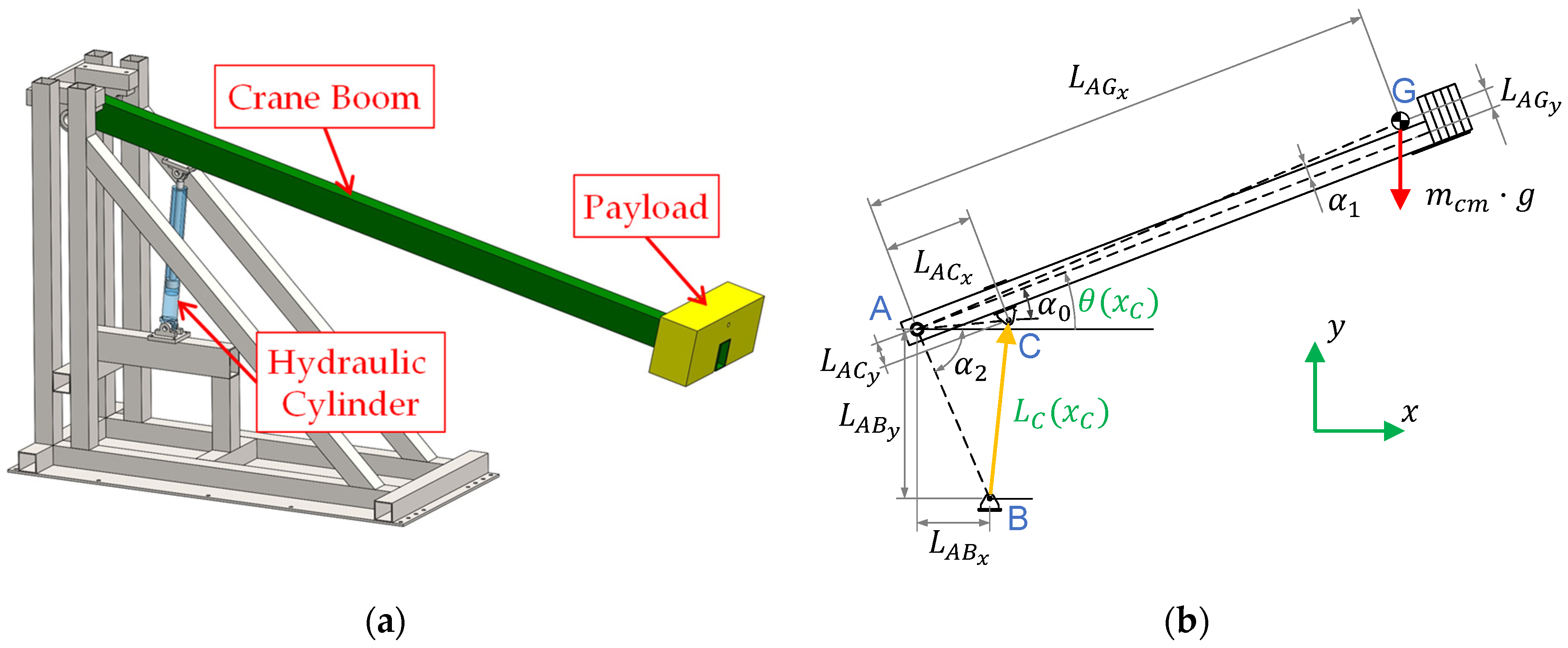

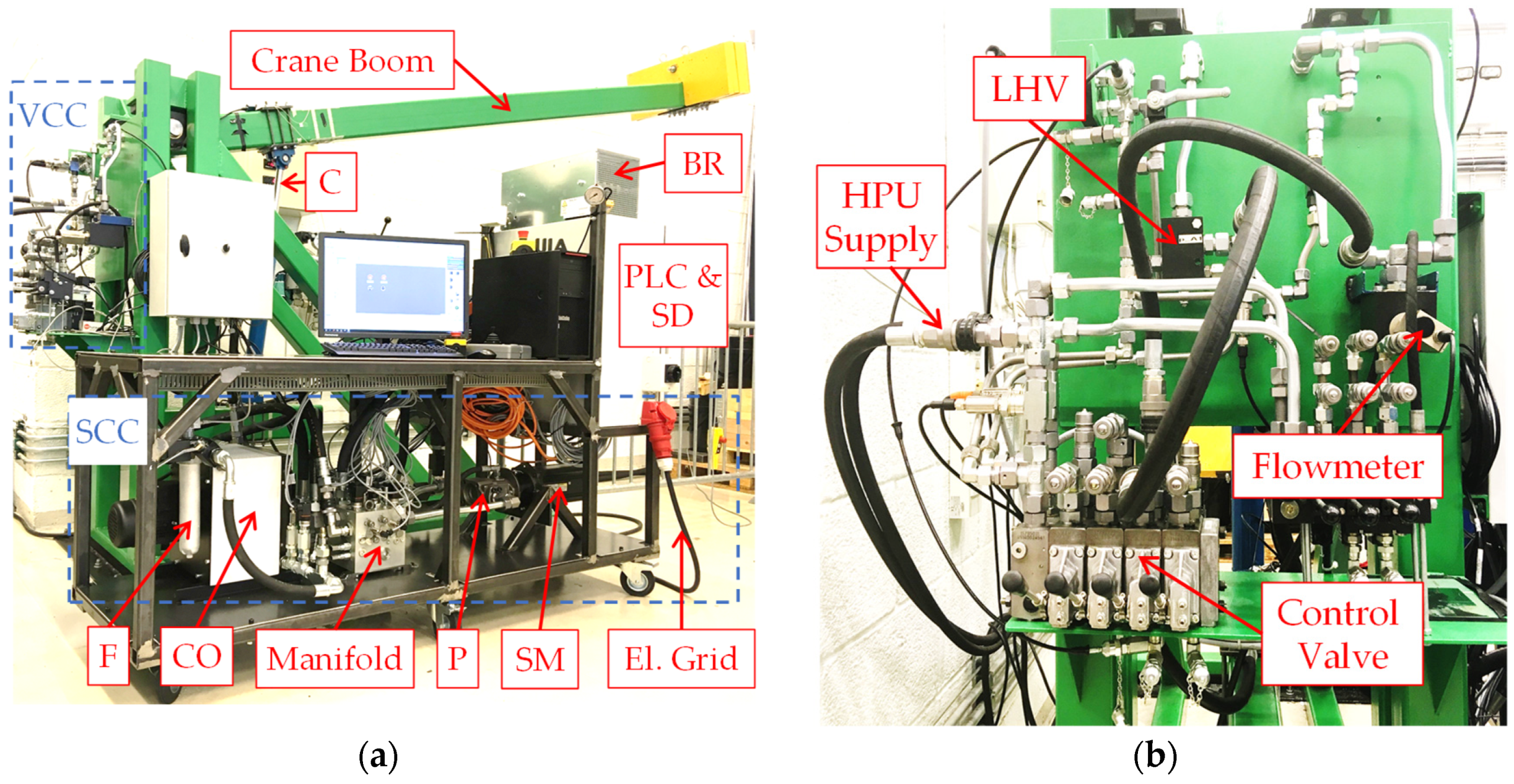

2. The Considered Actuation Systems

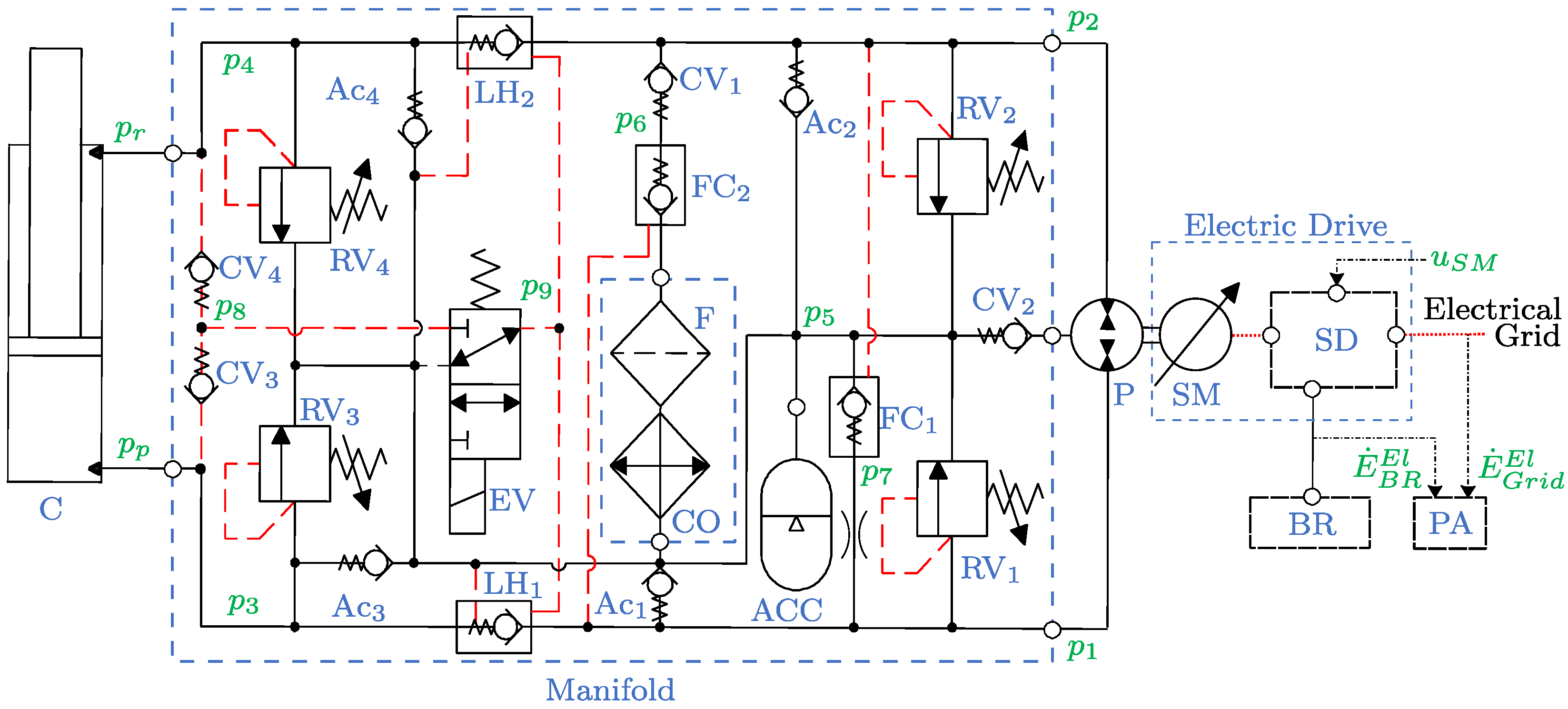

2.1. The Self-Contained Electro-Hydraulic Cylinder

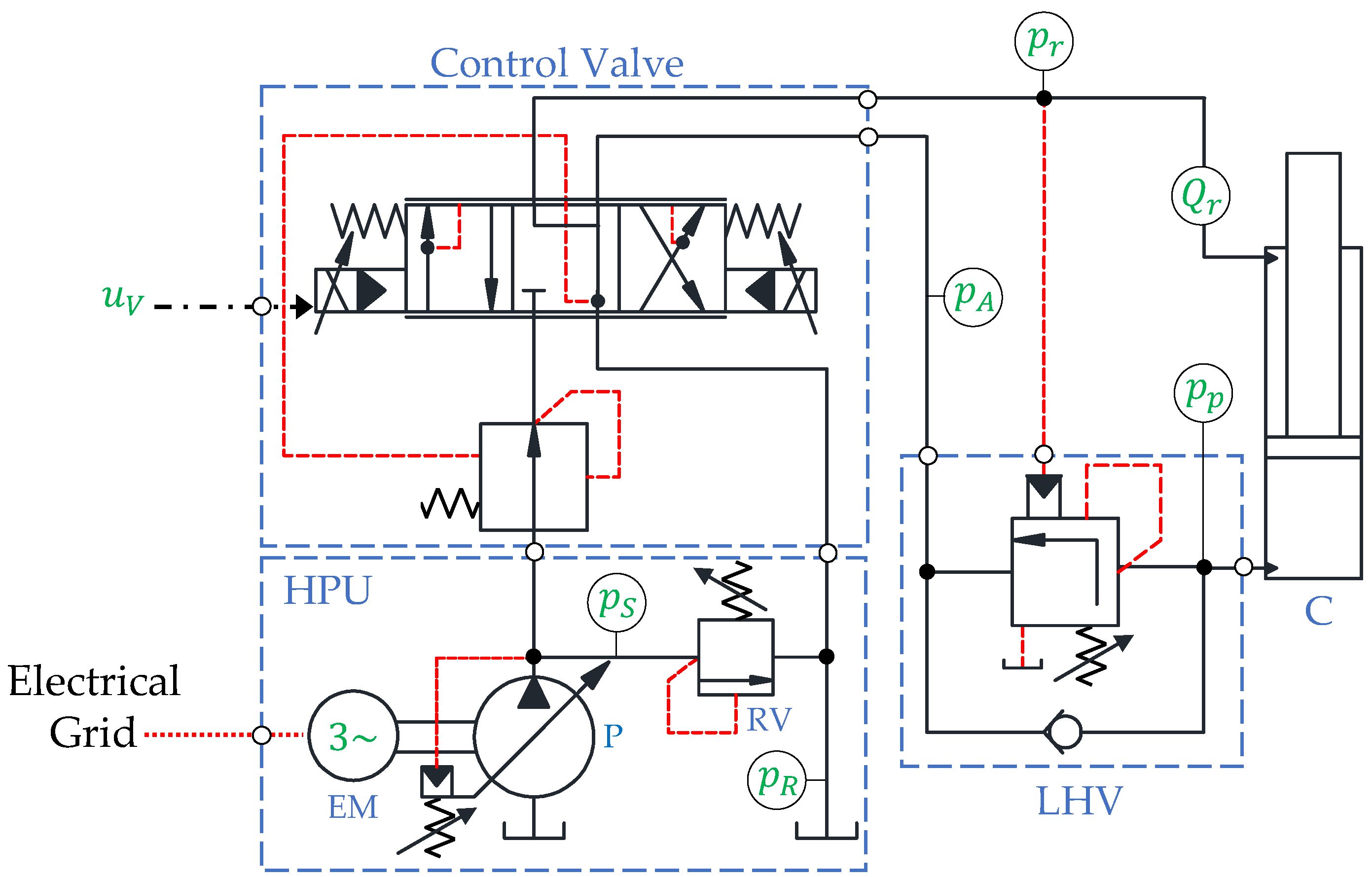

2.2. The Valve-Controlled System

3. Theoretical Background

3.1. Power and Energy Distribution

3.1.1. Input Power

3.1.2. Transferred Power Losses

3.1.3. Output Power

3.2. Efficiency of the Systems

4. Experimental Results and Discussion

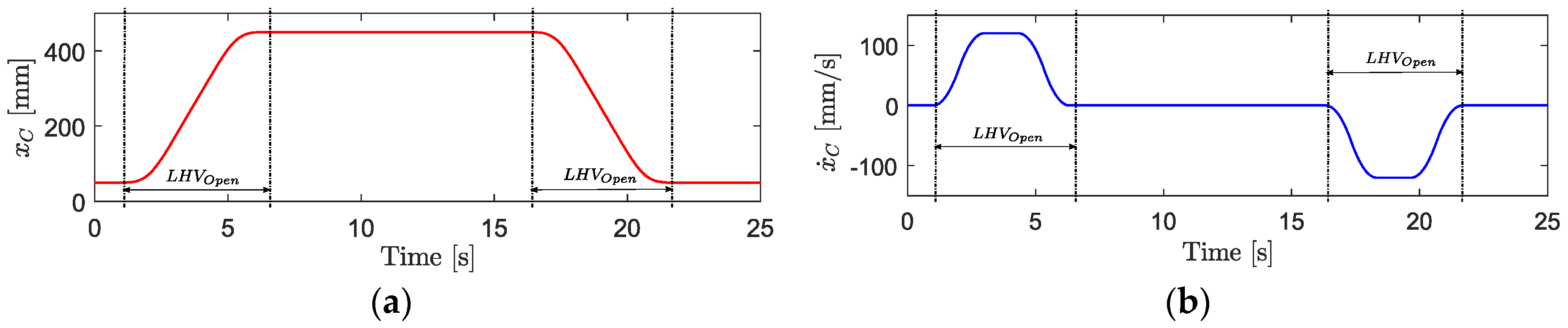

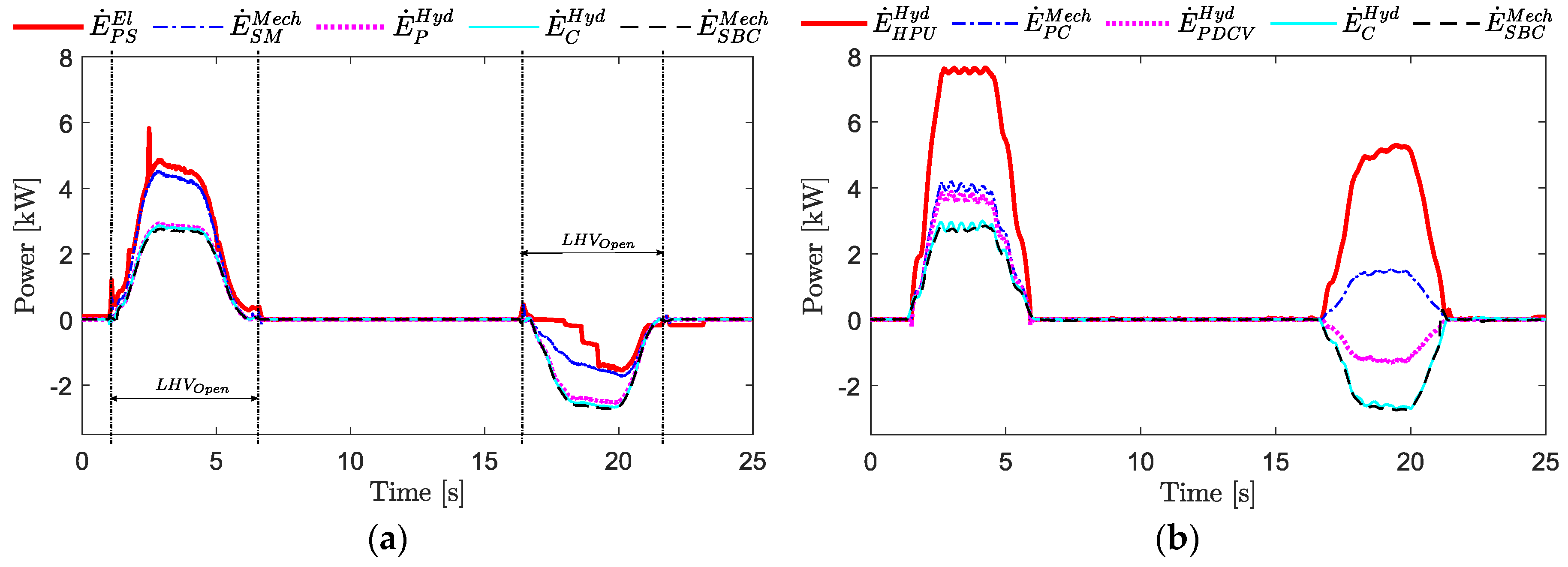

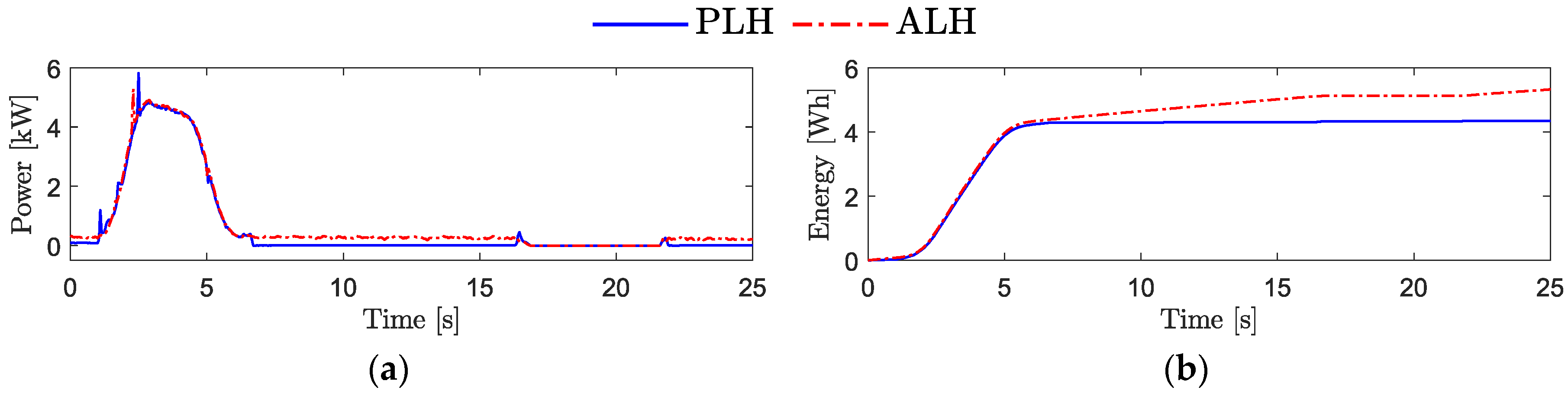

4.1. Power Levels

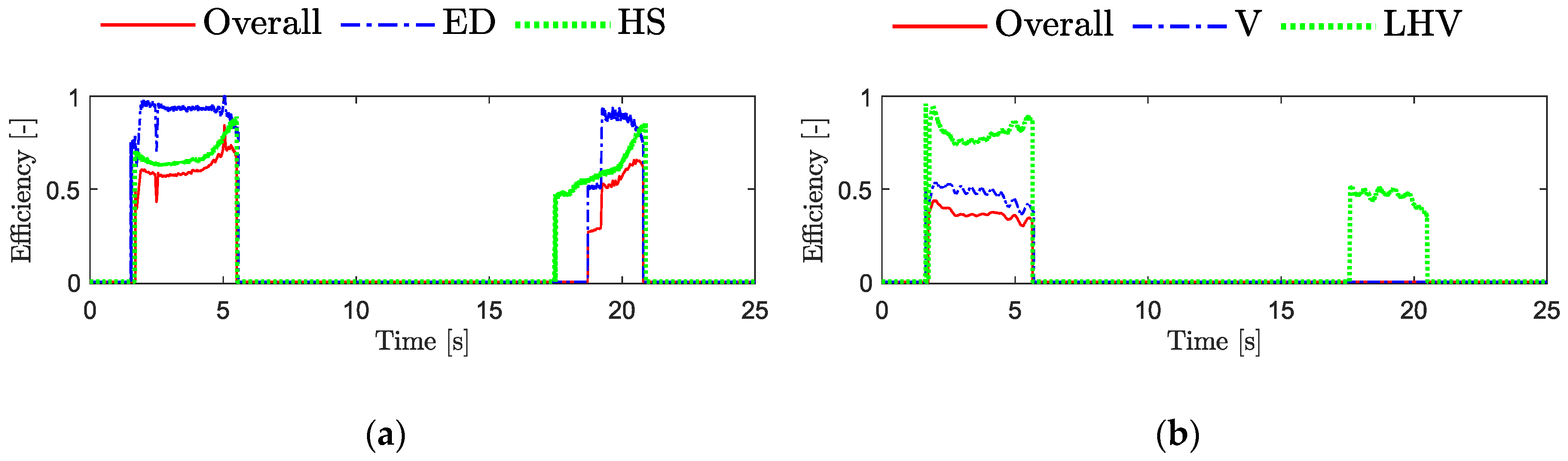

4.2. Systems Efficiency

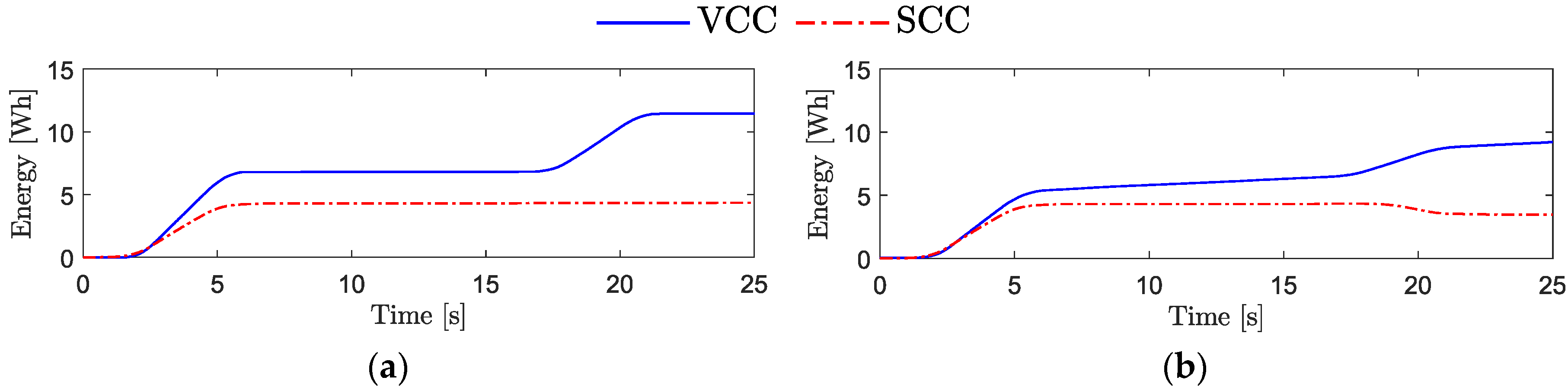

4.3. Energy Consumption

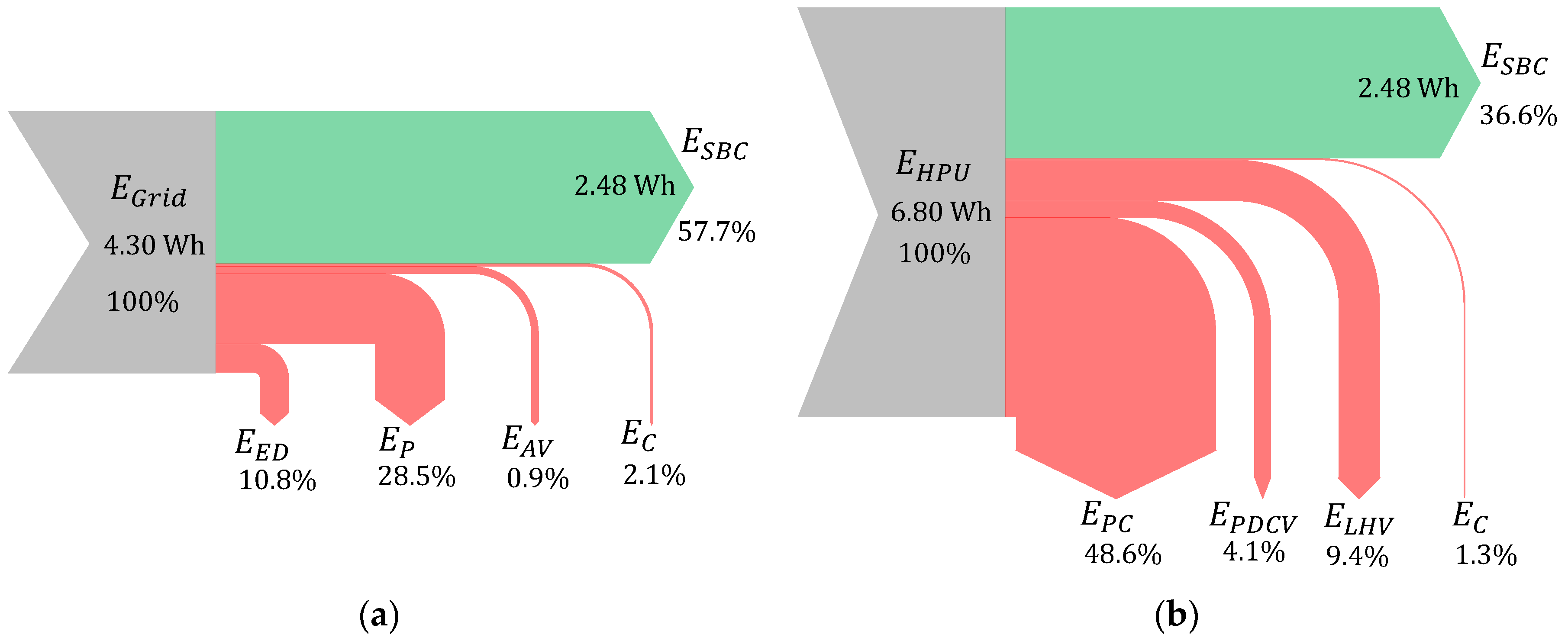

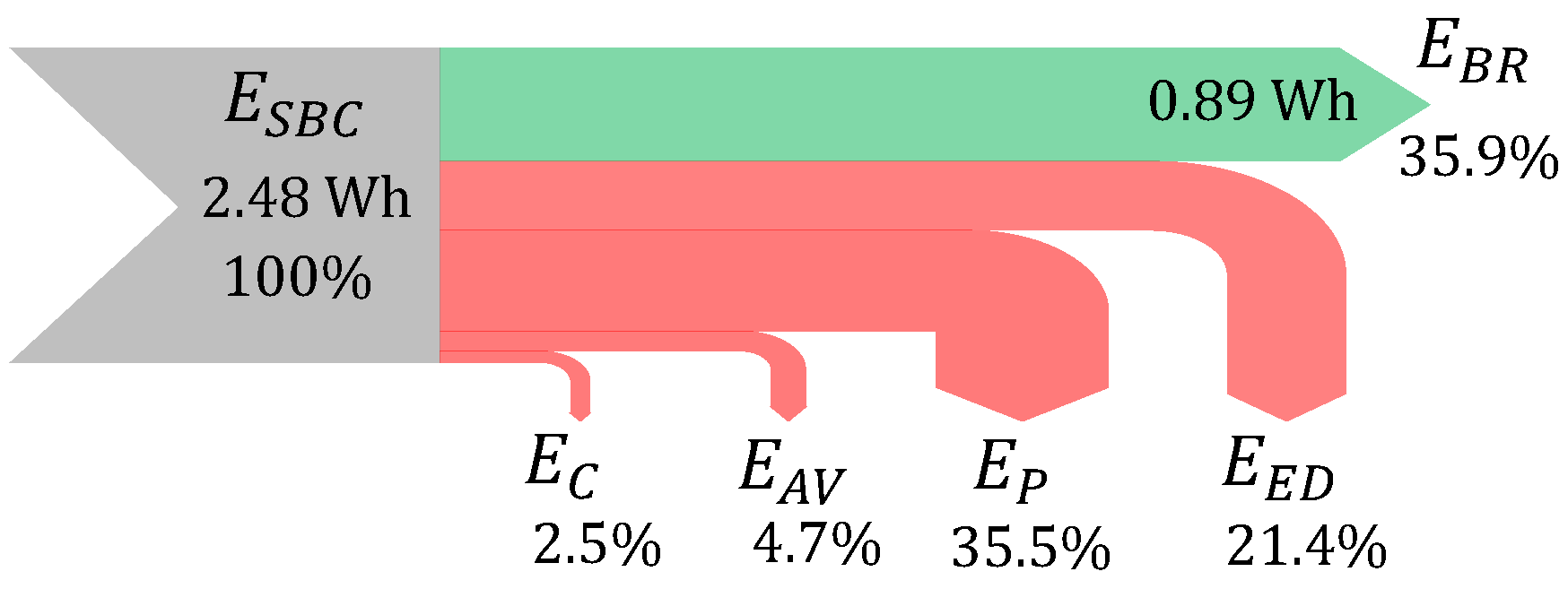

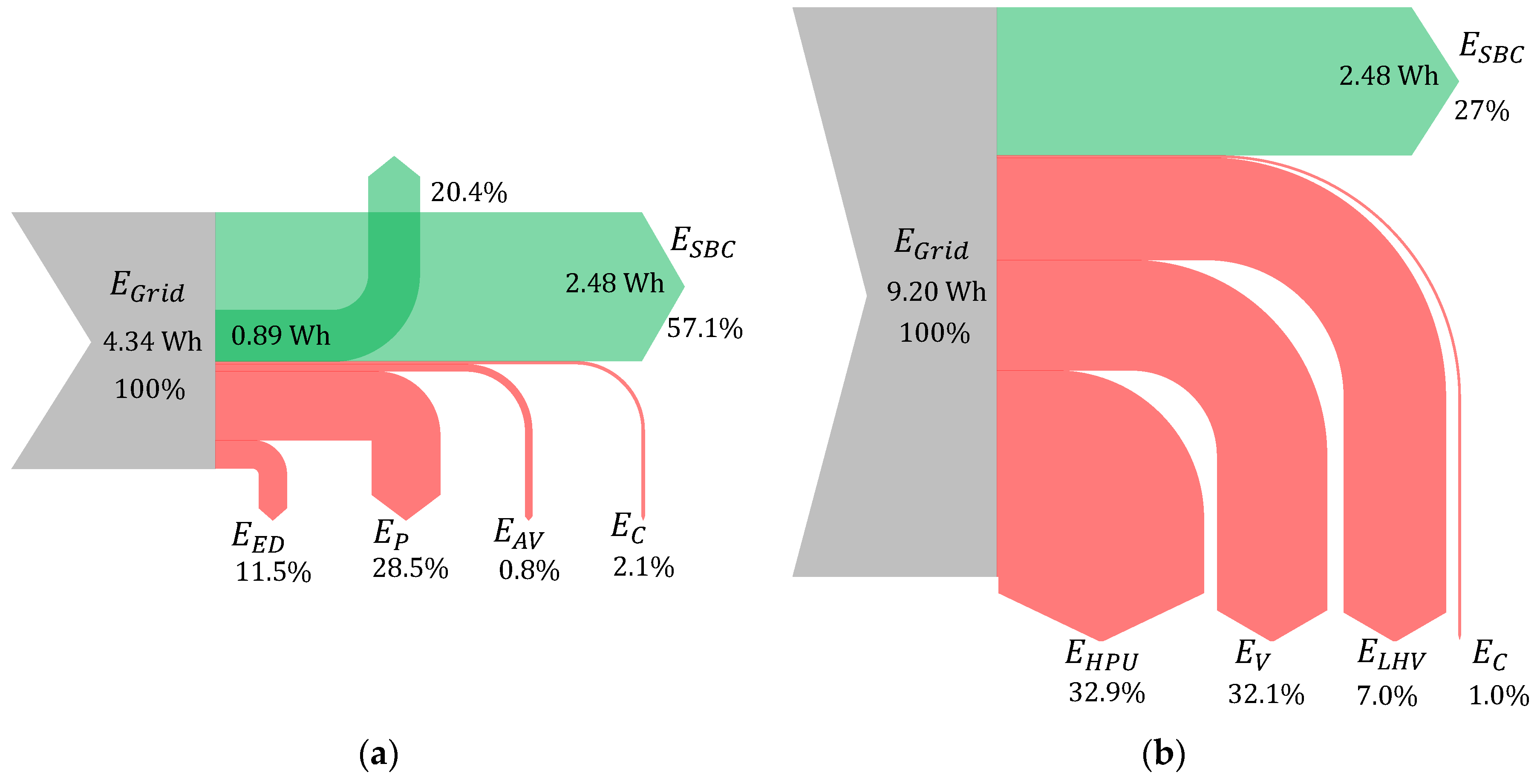

4.4. Energy Distribution

5. Conclusions

- The power demand to the prime mover during steady-state operations reduces to 4.8 kW against the 7.6 kW in the valve-controlled system (37% less) throughout the investigated working cycle;

- Utilizing passive load-holding results in an energy saving of 18.4% compared to actively controlling the SCC’s desired position using the prime mover during load holding phases;

- The system’s overall efficiency of the self-contained drive, being approximately 57% during actuation, turns out to be highly satisfactory compared to the 22% efficiency of the valve-controlled system with a constant-pressure supply;

- A significant amount of energy (i.e., 20% of the consumed energy) is recovered by the self-contained solution during the proposed working cycle. Hence, when assuming a realistic 94% conversion efficiency to return the recovered energy to the grid, then 77% of the total energy taken from the source can be used effectively. In contrast, this efficient operation is not possible in the valve-controlled system where, rather than being recovered, the available energy is dissipated when the load acting on the actuator is overrunning;

- An alternative scenario based on the load-sensing concept is also considered for the valve-controlled system; its energy consumption reduces from 11.44 Wh to 9.20 Wh but remains inefficient with respect to the electro-hydraulic actuator (i.e., total consumption 4.34 Wh).

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Abbreviations | |

| AC | Alternating current |

| ACC | Accumulator |

| Ac | Anti-cavitation valve |

| ALH | Active load-holding |

| AV | Auxiliary valves |

| BR | Brake resistor |

| C | Hydraulic cylinder |

| CO | Oil cooler |

| CV | Check valve |

| DC | Direct current |

| ED | Electric drive |

| EM | Electric motor |

| EV | Electro-valve |

| F | Low pressure oil filter |

| FC | Flow compensation valve |

| HPU | Hydraulic power unit |

| HS | Hydraulic system |

| LHV | Load-holding valve |

| P | Axial piston machine (pump) |

| PDCV | Proportional directional control valve |

| PLC | Programmable logic controller |

| RV | Pressure-relief valve |

| SBC | Single-boom crane |

| SCC | Self-contained electro-hydraulic cylinder |

| SD | Servo-drive |

| SM | Servo-motor |

| V | Control valve |

| VCC | Valve-controlled cylinder |

| Symbols | |

| Cylinder area on the piston-side | |

| Cylinder area on the rod-side | |

| Kinetic energy | |

| Potential energy | |

| Energy | |

| Power | |

| ,, | Three-phase current of the electric power supply |

| Direct current of the brake resistor | |

| Torque-producing current component | |

| Inertia at center of mass | |

| Torque constant | |

| Length between joint A and B | |

| Length between joint A and C | |

| Length between joint A and G in x-direction | |

| Length between joint A and G in y-direction | |

| Length of the hydraulic cylinder when fully retracted | |

| Effective total length of the hydraulic cylinder | |

| Mass at center of mass | |

| Rotational speed of the servo-motor in radians per seconds | |

| Actuator’s flow demand | |

| Rod-side flow rate | |

| Fixed pressure-drop across the proportional directional control valve | |

| Pressure at the pump/motor port on the piston-side of the actuator | |

| Pressure at the pump/motor port on the rod-side of the actuator | |

| Actuator’s piston chamber pressure | |

| Actuator’s rod chamber pressure | |

| Return pressure | |

| Supply pressure | |

| Commanded servo-motor speed | |

| Commanded opening of the control valve’s spool position | |

| Three-phase voltage of the electric power supply | |

| Direct current voltage of the brake resistor | |

| Actuator’s piston position | |

| Actuator’s piston velocity | |

| Greek Symbols | |

| Arctangent of the xy-length between the i-th joints | |

| Efficiency of the i-th system | |

| Angular position of the boom | |

References

- Pawlus, W.; Choux, M.; Hansen, M.R. Hydraulic vs. electric: A review of actuation systems in offshore drilling equipment. Model. Identif. Control 2016, 37, 1–17. [Google Scholar] [CrossRef]

- Hagen, D.; Pawlus, W.; Ebbesen, M.K.; Andersen, T.O. Feasibility Study of Electromechanical Cylinder Drivetrain for Offshore Mechatronic Systems. Model. Identif. Control 2017, 38, 59–77. [Google Scholar] [CrossRef]

- Michel, S.; Weber, J. Electrohydraulic Compact-Drives for Low Power Applications Considering Energy-efficiency and High Inertial Loads. In Proceedings of the 7th FPNI PhD Symposium on Fluid Power, Reggio Emilia, Italy, 27–30 June 2012; pp. 27–30. [Google Scholar]

- Minav, T.A.; Sainio, P.; Pietola, M. Direct Driven Hydraulic Drive without Conventional Oil Tank. In Proceedings of the ASME/BATH 2014 Symposium on Fluid Power and Motion Control, Bath, UK, 10–12 September 2014. [Google Scholar]

- Altare, G.; Vacca, A.; Richter, C. A Novel Pump Design for an Efficient and Compact Electro-Hydraulic Actuator. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2014. [Google Scholar]

- Altare, G.; Vacca, A. A design solution for efficient and compact electro-hydraulic actuators. Procedia Eng. 2015, 106, 8–16. [Google Scholar] [CrossRef]

- Rexroth, B. Electrification and Digitalization: The Fitness Program for Hydraulics. 2015. Available online: https://www.boschrexroth.com/en/xc/products/product-groups/industrial-hydraulics/the-fitness-program-for-hydraulics (accessed on 21 September 2019).

- Helbig, A.; Boes, C. Electric Hydrostatic Actuation-Modular Building Blocks for Industrial Applications. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016; pp. 93–102. [Google Scholar]

- Pedersen, H.C.; Schmidt, L.; Andersen, T.O.; Brask, M.H. Investigation of New Servo Drive Concept Utilizing Two Fixed Displacement Units. Int. J. Fluid Power Syst. 2014, 8, 1–9. [Google Scholar] [CrossRef]

- Hagen, D.; Padovani, D.; Ebbesen, M.K. Study of a Self-Contained Electro-Hydraulic Cylinder Drive. In Proceedings of the 2018 Global Fluid Power Society Ph.D. Symposium (GFPS), Samara, Russia, 18–20 July 2018. [Google Scholar]

- Michel, S.; Weber, J. Energy-Efficient Electrohydraulic Compact Drives for Low Power Applications. In Proceedings of the ASME/BATH 2012 Symposium on Fluid Power and Motion Control, Bath, UK, 12–14 September 2012; pp. 93–107. [Google Scholar]

- Padovani, D.; Ketelsen, S.; Hagen, D.; Schmidt, L. A Self-Contained Electro-Hydraulic Cylinder with Passive Load-Holding Capability. Energies 2019, 12, 292. [Google Scholar] [CrossRef]

- Jalayeri, E.; Imam, A.; Tomas, Z.; Sepehri, N. A throttle-less single-rod hydraulic cylinder positioning system: Design and experimental evaluation. Adv. Mech. Eng. 2015, 7, 1687814015583249. [Google Scholar] [CrossRef]

- Weber, I.J.; Schneider, D.I.; Shabi, M.S.; Sitte, D.I.; Weber, D.I.; Willkomm, D.I.; Beck, D.I.; Fischer, D.I.; Ivantysyn, M.S.; Kolks, D.I.; et al. Novel System Architectures by Individual Drives. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016; pp. 29–62. [Google Scholar]

- Ketelsen, S.; Padovani, D.; Andersen, T.; Ebbesen, M.; Schmidt, L. Classification and Review of Pump-Controlled Differential Cylinder Drives. Energies 2019, 12, 1293. [Google Scholar] [CrossRef]

- Schmidt, L.; Ketelsen, S.; Brask, M.H.; Mortensen, K.A. A class of energy efficient self-contained electro-hydraulic drives with self-locking capability. Energies 2019, 12, 1866. [Google Scholar] [CrossRef]

- Minav, T.A.; Laurila, L.I.E.; Pyrhönen, J.J. Analysis of electro-hydraulic lifting system’s energy efficiency with direct electric drive pump control. Autom. Constr. 2013, 30, 144–150. [Google Scholar] [CrossRef]

- Minav, T.A.; Sainio, P.; Pietola, M. Efficiency of Direct Driven Hydraulic Setup in Arctic Conditions. In Proceedings of the Fourteenth Scandinavian International Conference on Fluid Power, Tampere, Finland, 20–22 May 2015. [Google Scholar]

- Schmidt, L.; Roemer, D.B.; Pedersen, H.C.; Andersen, T.O. Speed-Variable Switched Differential Pump System for Direct Operation of Hydraulic Cylinders. In Proceedings of the ASME/BATH Symposium on Fluid Power and Motion Control, Chicago, IL, USA, 12–14 October 2015. [Google Scholar]

- Schneider, M.; Koch, O.; Weber, J. Green Wheel Loader—Improving Fuel Economy through Energy Efficient Drive and Control Concepts. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016; pp. 63–78. [Google Scholar]

- Schmidt, L.; Ketelsen, S.; Padovani, D.; Mortensen, K.A. Improving the Efficiency and Dynamic Properties of a Flow Control Unit in a Self-Locking Compact Electro-Hydraulic Cylinder Drive. In Proceedings of the ASME/Bath Symposium on Fluid Power and Motion Control, Longboat Key, FL, USA, 7–9 October 2019. [Google Scholar]

- Michel, S.; Weber, J. Prediction of the Thermo-Energetic Behaviour of an Electrohydraulic Compact Drive. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016; pp. 219–234. [Google Scholar]

- Minav, T.; Papini, L.; Pietola, M. A Thermal Analysis of Direct Driven Hydraulics. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016; pp. 235–248. [Google Scholar]

- Karlén, N.; Minav, T.A.; Pietola, M. Investigation of Thermal Effects in Direct Driven Hydraulic System for Off-Road Machinery. In Proceedings of the 9th FPNI Ph.D. Symposium on Fluid Power, Florianópolis, Brazil, 26–28 October 2016. [Google Scholar]

- Schmidt, L.; Groenkjaer, M.; Pedersen, H.C.; Andersen, T.O. Position Control of an Over-Actuated Direct Hydraulic Cylinder Drive. Control Eng. Pract. 2017, 64, 1–14. [Google Scholar] [CrossRef]

- Ketelsen, S.; Schmidt, L.; Donkov, V.H.; Andersen, T.O. Energy saving potential in knuckle boom cranes using a novel pump controlled cylinder drive. Model. Identif. Control 2018, 39, 73–89. [Google Scholar] [CrossRef]

- Hagen, D.; Padovani, D.; Choux, M. Enabling Energy Savings in Offshore Mechatronic Systems by using Self-Contained Cylinders. Model. Identif. Control 2019, 40, 89–108. [Google Scholar] [CrossRef]

- Hagen, D.; Padovani, D.; Choux, M. A Comparison Study of a Novel Self-Contained Electro-Hydraulic Cylinder versus a Conventional Valve-Controlled Actuator—Part 1: Motion Control. Actuators 2019, in press. [Google Scholar]

- Hagen, D.; Padovani, D.; Choux, M. Design and Implementation of Pressure Feedback for Load-Carrying Applications with Position Control. In Proceedings of the Sixteenth Scandinavian International Conference on Fluid Power, Tampere, Finland, 22–24 May 2019. [Google Scholar]

- Ristic, M.; Wahler, M. Electrification of Hydraulics Opens New Ways for Intelligent Energy-Optimized Systems. In Proceedings of the 11th International Fluid Power Conference, Aachen, Germany, 19–21 March 2018. [Google Scholar]

| Symbol | Component | Manufacturer | Model |

|---|---|---|---|

| C | Hydraulic cylinder | PMC Cylinders 1 | 25CAL |

| SM | Servo-motor | Bosch Rexroth 2 | MSK071E-0300 |

| P | Axial piston machine | Bosch Rexroth | A10FZG |

| SD | Servo-drive | Bosch Rexroth | HCS02.1E-W0054 |

| ACC | Hydro-pneumatic accumulator | Bosch Rexroth | HAB10 |

| CO | Oil cooler | Bosch Rexroth | KOL3N |

| F | Hydraulic return line filter | Bosch Rexroth | 50LEN0100 |

| LHV1,2 | Pilot-operated check valves | Sun Hydraulics 3 | CVEVXFN |

| FC1,2 | Pilot-operated check valves | Sun Hydraulics | CKEBXCN |

| RV1–4 | Pressure-relief valves | Sun Hydraulics | RDDA |

| CV1,3,4 | Check valves | Hawe Hydraulik 4 | RB2 |

| CV2, Ac1,2 | Check valves | Hawe Hydraulik | RK4 |

| Ac3,4 | Check valves | Hawe Hydraulik | RK2 |

| EV | 3/2 Directional valve | Argo Hytos 5 | SD1E-A3 |

| 1–9 | Pressure transducers | Bosch Rexroth | HM20 |

| p,r | Pressure transducers | Parker 6 | SCP-400 |

| Cylinder position sensor | Regal 7 | PS6300 | |

| PLC | Embedded controller | Bosch Rexroth | XM22 |

| BR | Brake resistor | Bosch Rexroth | HLR01.1N-03K8 |

| PA | Power analyzer | Hioki 8 | PW6001 |

| Symbol | Component | Manufacturer | Model |

|---|---|---|---|

| EM | Electric motor | ASEA 1 | M225S60-4 |

| P | Axial piston variable pump | Brueninghaus Hydraulik 2 | A4V-S0-71 |

| RV | Pressure-relief valve | Bosch Rexroth | DBDH6 |

| V | Flow control valve | Sauer Danfoss 3 | PVG32-9781 |

| LHV | Counterbalance valve | Sun Hydraulics | CWCA |

| S,R,A | Pressure transducers | Parker | SCP-400 |

| Qr | Flow rate meter | Parker | SCQ-150 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| (kg) | (mm) | ||

| (kg·m2) | (rad) | ||

| (mm) | (rad) | ||

| (mm) | (rad) | ||

| (mm) | 9.81 (m/s2) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hagen, D.; Padovani, D.; Choux, M. A Comparison Study of a Novel Self-Contained Electro-Hydraulic Cylinder versus a Conventional Valve-Controlled Actuator—Part 2: Energy Efficiency. Actuators 2019, 8, 78. https://doi.org/10.3390/act8040078

Hagen D, Padovani D, Choux M. A Comparison Study of a Novel Self-Contained Electro-Hydraulic Cylinder versus a Conventional Valve-Controlled Actuator—Part 2: Energy Efficiency. Actuators. 2019; 8(4):78. https://doi.org/10.3390/act8040078

Chicago/Turabian StyleHagen, Daniel, Damiano Padovani, and Martin Choux. 2019. "A Comparison Study of a Novel Self-Contained Electro-Hydraulic Cylinder versus a Conventional Valve-Controlled Actuator—Part 2: Energy Efficiency" Actuators 8, no. 4: 78. https://doi.org/10.3390/act8040078

APA StyleHagen, D., Padovani, D., & Choux, M. (2019). A Comparison Study of a Novel Self-Contained Electro-Hydraulic Cylinder versus a Conventional Valve-Controlled Actuator—Part 2: Energy Efficiency. Actuators, 8(4), 78. https://doi.org/10.3390/act8040078