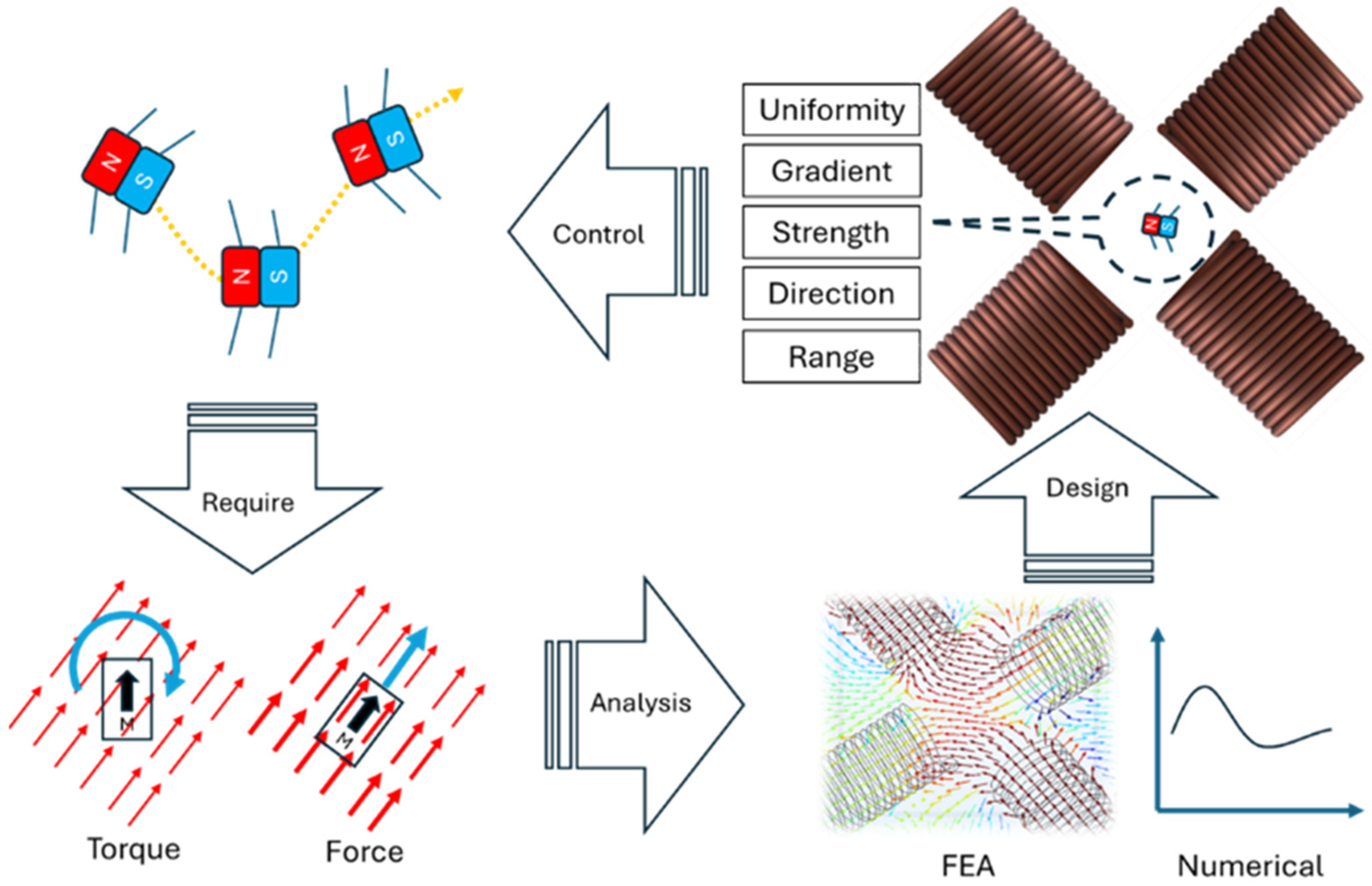

A Framework of Designing Multi-Coil Electromagnetic System for 6-DOF Manipulation of Magnetic Miniature Robot

Abstract

1. Introduction

2. Results and Discussion

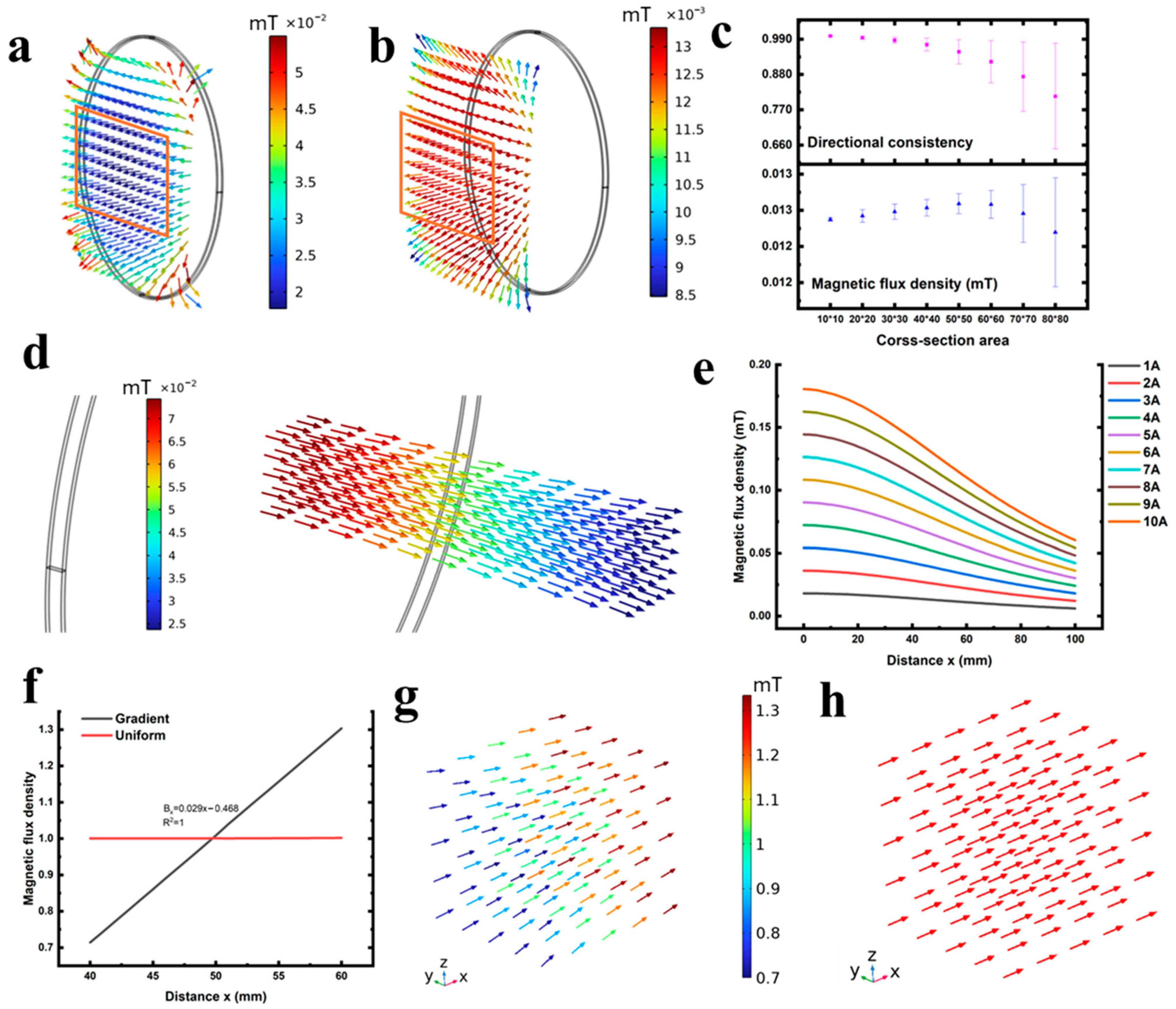

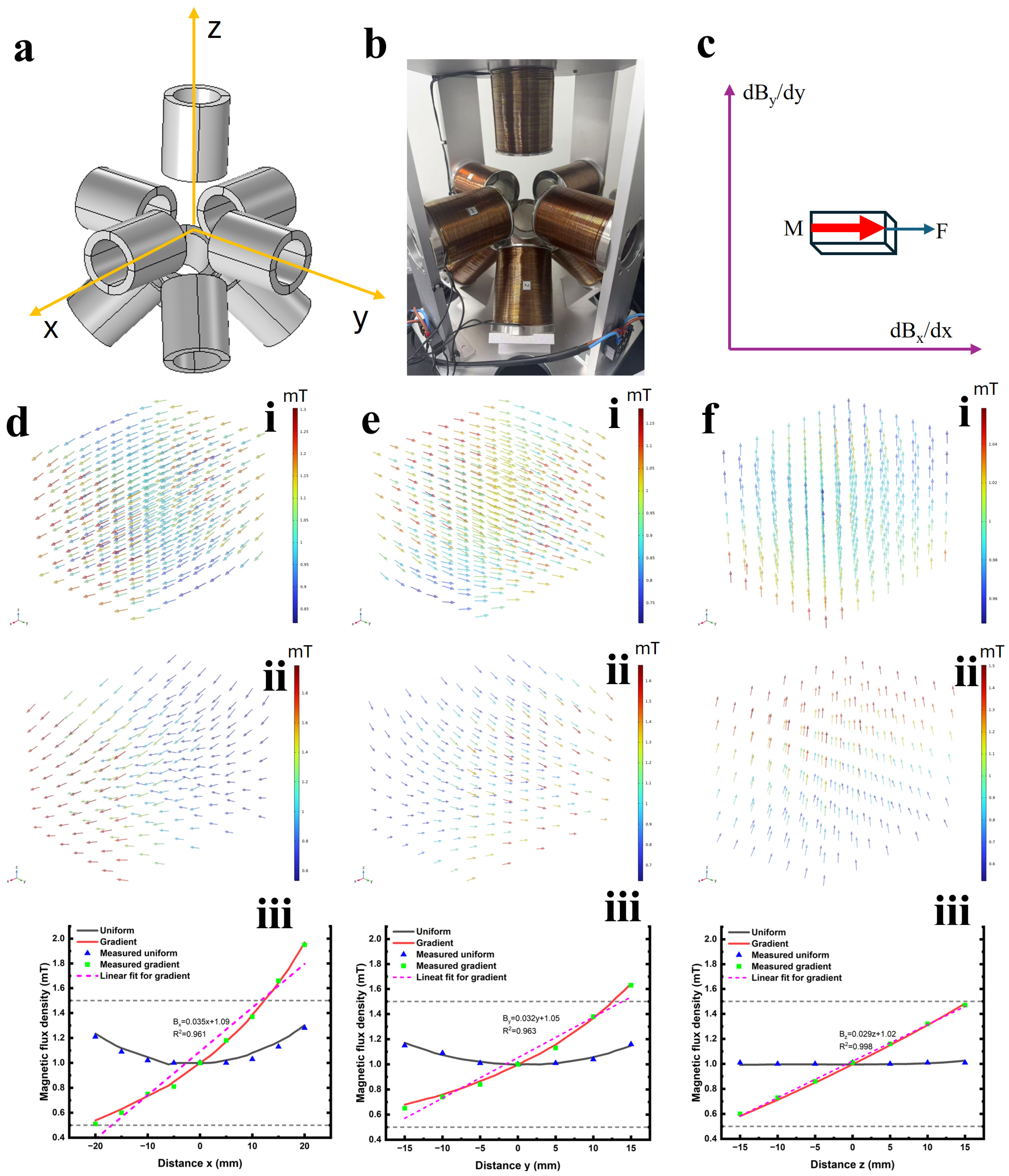

2.1. Spherically Distributed Magnetic Coil Array

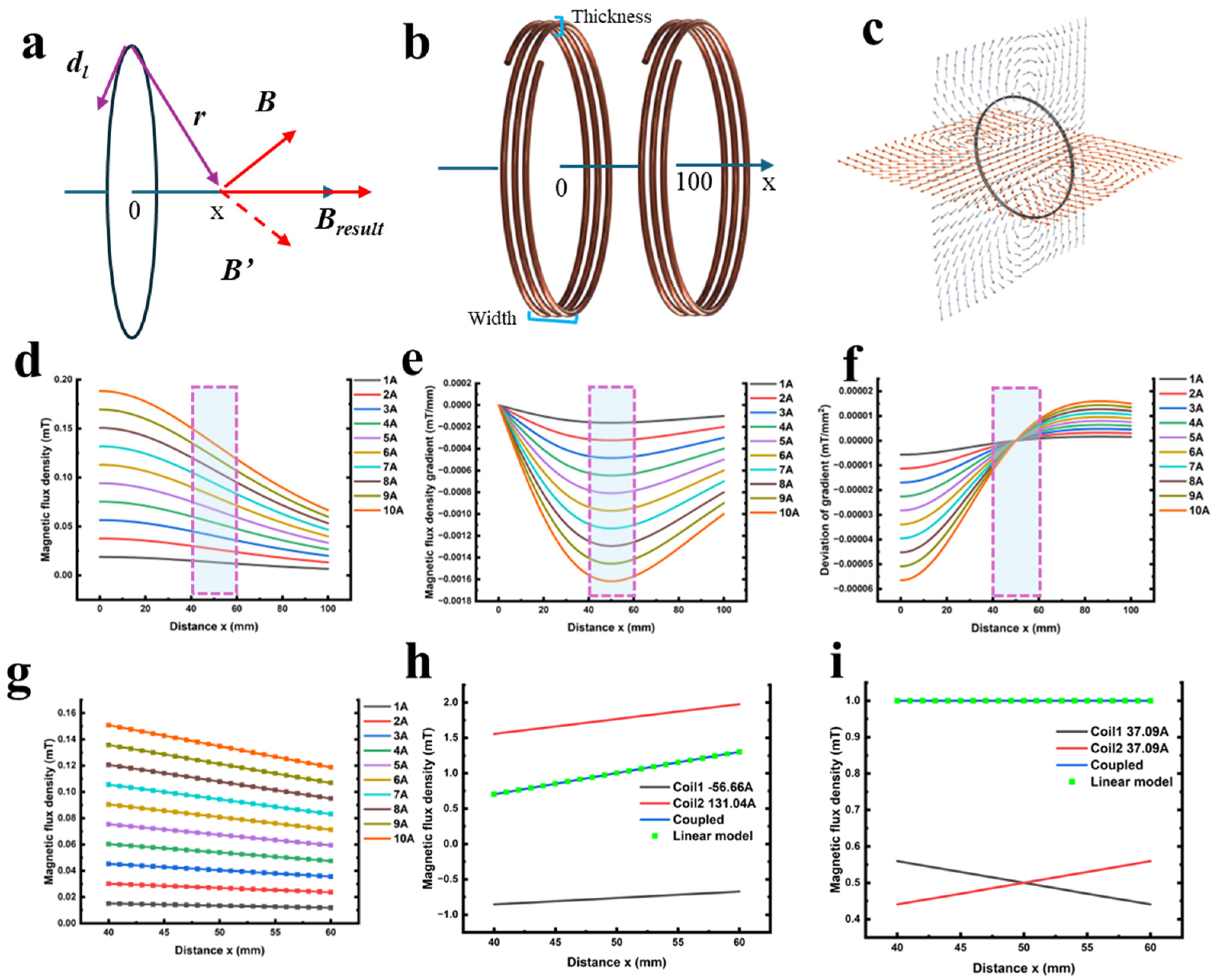

2.1.1. Generation of Gradient Magnetic Field

2.1.2. FEA Model

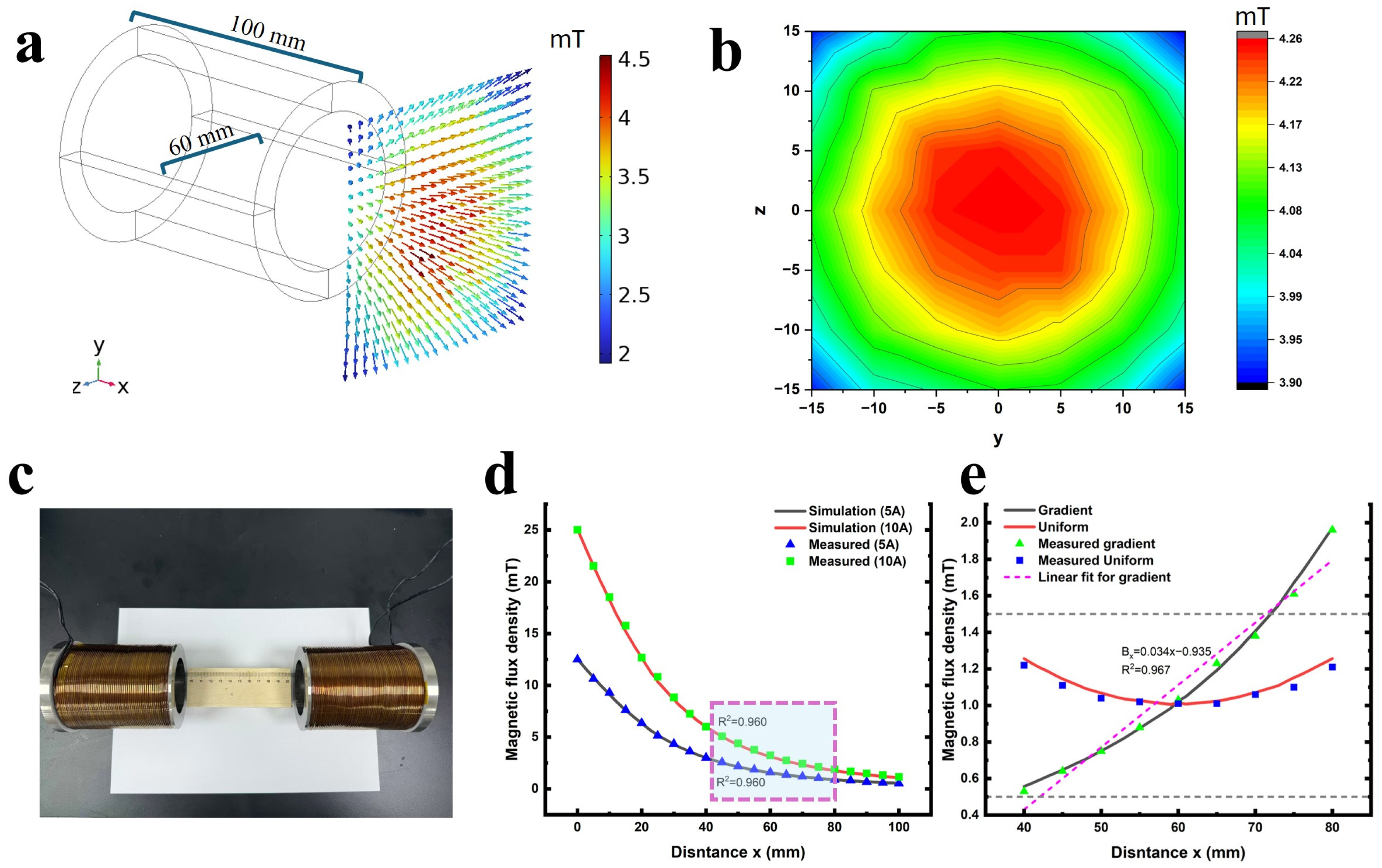

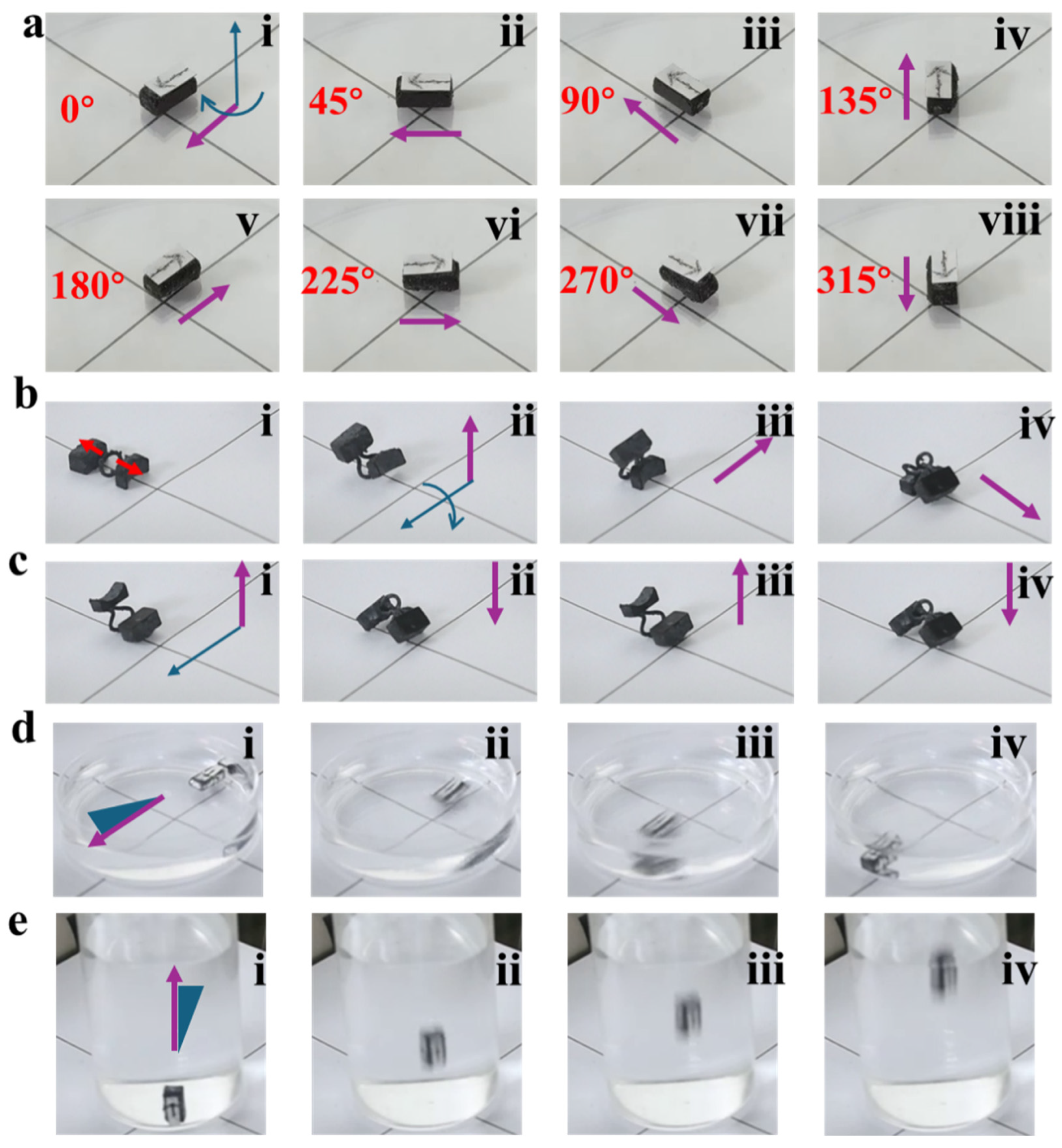

2.2. Validation

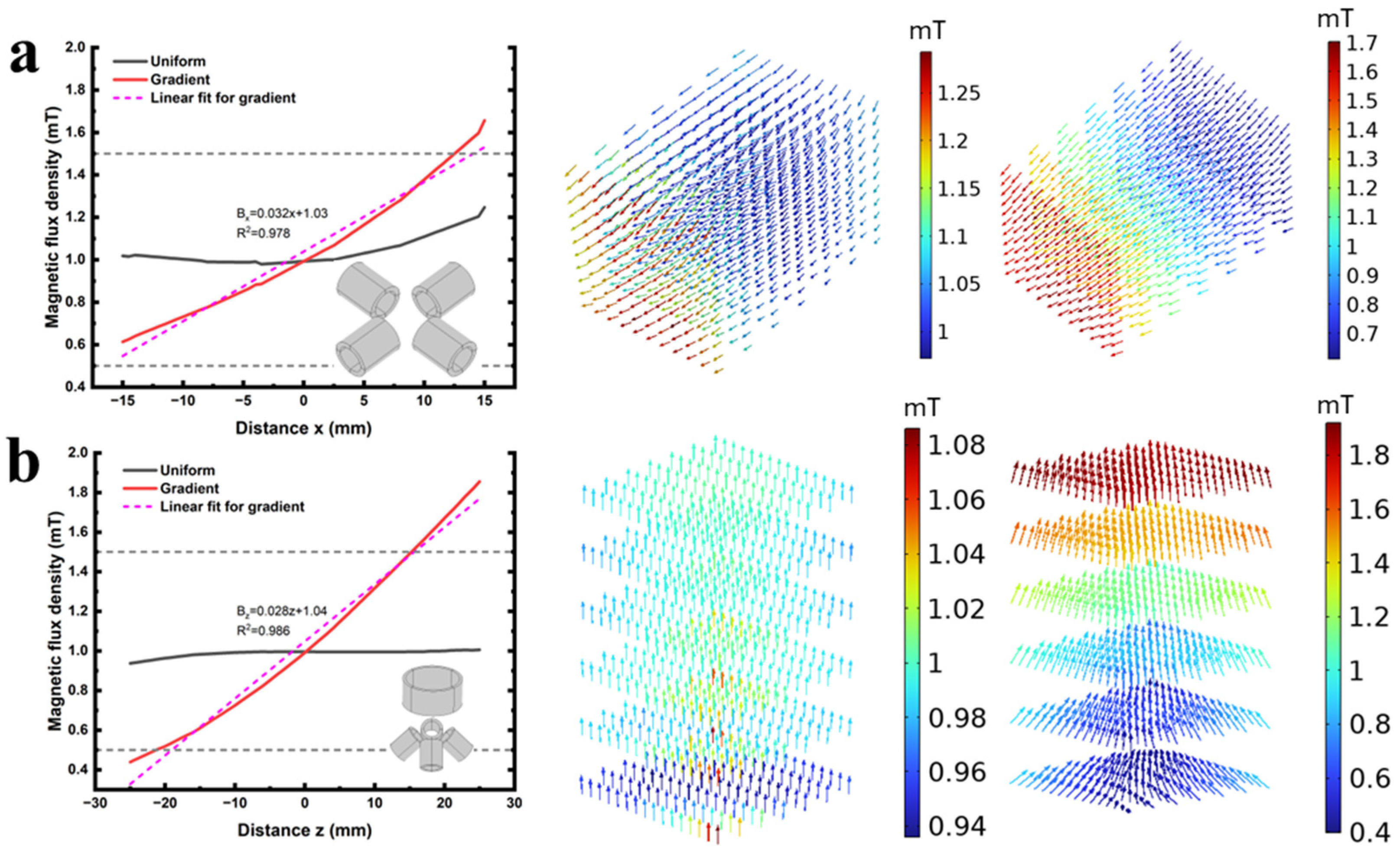

2.3. Generalization in Multi-Dimensional Space

2.4. Workflow for Designing SDMCA with a Specified Workspace

- a.

- Definition of the target workspace

- b.

- Design of individual electromagnetic coil

- c.

- Optimization of the coil array configuration

- d.

- Calibration of the coil system

2.5. Demonstration of a Nine-Coil SDMCA for Full-Field Control

3. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ng, C.S.X.; Tan, M.W.M.; Xu, C.; Yang, Z.; Lee, P.S.; Lum, G.Z. Locomotion of miniature soft robots. Adv. Mater. 2021, 33, 2003558. [Google Scholar] [CrossRef]

- Feng, B.; Liu, Y.; Zhang, J.; Qu, S.; Yang, W. Miniature origami robot for various biological micromanipulations. Nat. Commun. 2025, 16, 2633. [Google Scholar] [CrossRef]

- Dabbagh, S.R.; Sarabi, M.R.; Birtek, M.T.; Seyfi, S.; Sitti, M.; Tasoglu, S. 3D-printed microrobots from design to translation. Nat. Commun. 2022, 13, 5875. [Google Scholar] [CrossRef]

- Nica, M.; Forbrigger, C.; Diller, E. A novel magnetic transmission for powerful miniature surgical robots. IEEE/ASME Trans. Mechatron. 2022, 27, 5541–5550. [Google Scholar] [CrossRef]

- Wang, C.; Wu, Y.; Dong, X.; Armacki, M.; Sitti, M. In situ sensing physiological properties of biological tissues using wireless miniature soft robots. Sci. Adv. 2023, 9, eadg3988. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, C.; Lee, J.X.; Lum, G.Z. Magnetic miniature soft robot with reprogrammable Drug-Dispensing functionalities: Toward advanced targeted combination therapy. Adv. Mater. 2024, 36, 2408750. [Google Scholar] [CrossRef]

- Merces, L.; Ferro, L.M.M.; Thomas, A.; Karnaushenko, D.D.; Luo, Y.; Egunov, A.I.; Zhang, W.; Bandari, V.K.; Lee, Y.; McCaskill, J.S. Bio-Inspired Dynamically Morphing Microelectronics toward High-Density Energy Applications and Intelligent Biomedical Implants. Adv. Mater. 2024, 36, 2313327. [Google Scholar] [CrossRef]

- Xavier, M.S.; Tawk, C.D.; Zolfagharian, A.; Pinskier, J.; Howard, D.; Young, T.; Lai, J.; Harrison, S.M.; Yong, Y.K.; Bodaghi, M. Soft pneumatic actuators: A review of design, fabrication, modeling, sensing, control and applications. IEEE Access 2022, 10, 59442–59485. [Google Scholar] [CrossRef]

- Li, J.; Deng, J.; Zhang, S.; Chen, W.; Zhao, J.; Liu, Y. Developments and challenges of miniature piezoelectric robots: A review. Adv. Sci. 2023, 10, 2305128. [Google Scholar] [CrossRef]

- Ye, Z.; Zheng, L.; Chen, W.; Wang, B.; Zhang, L. Recent advances in bioinspired soft robots: Fabrication, actuation, tracking, and applications. Adv. Mater. Technol. 2024, 9, 2301862. [Google Scholar] [CrossRef]

- Chen, F.; Liu, C.; He, H.; Shen, F.; Yang, S. Review on Development and Recent Achievements of Origami Robots in Perspectives of Structures, Materials, and Actuations. In Proceedings of the IFToMM China International Conference on Mechanism and Machine Science & Engineering, Tianjin, China, 12–14 August 2024; Springer: Berlin/Heidelberg, Germany, 2025; pp. 113–143. [Google Scholar]

- Deng, Q.; Jia, H.; An, C.; Wu, S.; Zhao, S.; Hu, N. Progress and prospective of electrochemical actuator materials. Compos. Part A Appl. Sci. Manuf. 2023, 165, 107336. [Google Scholar] [CrossRef]

- Kim, Y.; Zhao, X. Magnetic soft materials and robots. Chem. Rev. 2022, 122, 5317–5364. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Yang, H.; Cao, Y.; Cui, Y.; Zhang, L. Magnetically actuated continuum medical robots: A review. Adv. Intell. Syst. 2023, 5, 2200416. [Google Scholar] [CrossRef]

- Shao, Y.; Fahmy, A.; Li, M.; Li, C.; Zhao, W.; Sienz, J. Study on magnetic control systems of micro-robots. Front. Neurosci. 2021, 15, 736730. [Google Scholar] [CrossRef]

- Zhou, A.; Xu, C.; Kanitthamniyom, P.; Ng, C.S.X.; Lim, G.J.; Lew, W.S.; Vasoo, S.; Zhang, X.; Lum, G.Z.; Zhang, Y. Magnetic soft millirobots 3D printed by circulating vat photopolymerization to manipulate droplets containing hazardous agents for in vitro diagnostics. Adv. Mater. 2022, 34, 2200061. [Google Scholar] [CrossRef]

- Zhou, H.; Mayorga-Martinez, C.C.; Pané, S.; Zhang, L.; Pumera, M. Magnetically driven micro and nanorobots. Chem. Rev. 2021, 121, 4999–5041. [Google Scholar] [CrossRef]

- Chen, W.; Sui, J.; Wang, C. Magnetically actuated capsule robots: A review. IEEE Access 2022, 10, 88398–88420. [Google Scholar] [CrossRef]

- Hu, W.; Lum, G.Z.; Mastrangeli, M.; Sitti, M. Small-scale soft-bodied robot with multimodal locomotion. Nature 2018, 554, 81–85. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, L.; Xia, N.; Yang, Z.; Zhang, C.; Pan, C.; Jin, D.; Zhang, J.; Majidi, C.; Zhang, L. Untethered small-scale magnetic soft robot with programmable magnetization and integrated multifunctional modules. Sci. Adv. 2022, 8, eabn8932. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, L. Magnetic actuation systems for miniature robots: A review. Adv. Intell. Syst. 2020, 2, 2000082. [Google Scholar] [CrossRef]

- Chen, X.; Yu, J.; Wu, Z.; Meng, Y.; Kong, S. Toward a maneuverable miniature robotic fish equipped with a novel magnetic actuator system. IEEE Trans. Syst. Man Cybern. Syst. 2018, 50, 2327–2337. [Google Scholar] [CrossRef]

- Diller, E.; Giltinan, J.; Lum, G.Z.; Ye, Z.; Sitti, M. Six-degree-of-freedom magnetic actuation for wireless microrobotics. Int. J. Robot. Res. 2016, 35, 114–128. [Google Scholar] [CrossRef]

- Xu, C.; Yang, Z.; Lum, G.Z. Small-scale magnetic actuators with optimal six degrees-of-freedom. Adv. Mater. 2021, 33, 2100170. [Google Scholar] [CrossRef]

- Nelson, B.J.; Pané, S. Delivering drugs with microrobots. Science 2023, 382, 1120–1122. [Google Scholar] [CrossRef]

- Gwisai, T.; Mirkhani, N.; Christiansen, M.G.; Nguyen, T.T.; Ling, V.; Schuerle, S. Magnetic torque–driven living microrobots for increased tumor infiltration. Sci. Robot. 2022, 7, eabo0665. [Google Scholar] [CrossRef]

- Du, X.; Wang, Q.; Jin, D.; Chiu, P.W.Y.; Pang, C.P.; Chong, K.K.L.; Zhang, L. Real-time navigation of an untethered miniature robot using mobile ultrasound imaging and magnetic actuation systems. IEEE Robot. Autom. Lett. 2022, 7, 7668–7675. [Google Scholar] [CrossRef]

- Son, D.; Ugurlu, M.C.; Sitti, M. Permanent magnet array–driven navigation of wireless millirobots inside soft tissues. Sci. Adv. 2021, 7, eabi8932. [Google Scholar] [CrossRef]

- Saqib, M.; Francis, S.; Francis, J. Design and development of Helmholtz coils for magnetic field. In Proceedings of the 2020 International Youth Conference on Radio Electronics, Electrical and Power Engineering (REEPE), Moscow, Russia, 12–14 March 2020; IEEE: New York, NY, USA, 2020; pp. 1–5. [Google Scholar]

- Ramos-Sebastian, A.; Kim, S.H. Magnetic force-propelled 3D locomotion control for magnetic microrobots via simple modified three-axis Helmholtz coil system. Ieee Access 2021, 9, 128755–128764. [Google Scholar] [CrossRef]

- Gao, J.; Tian, S.; Yuan, C.; Ma, Z.; Gao, C.; Yan, G.; Li, R.; Tan, Q.; Zhang, L. Design and optimization of a novel double-layer Helmholtz coil for wirelessly powering a capsule robot. IEEE Trans. Power Electron. 2023, 39, 1826–1839. [Google Scholar] [CrossRef]

- Jeon, S.; Jang, G.; Choi, H.; Park, S. Magnetic navigation system with gradient and uniform saddle coils for the wireless manipulation of micro-robots in human blood vessels. IEEE Trans. Magn. 2010, 46, 1943–1946. [Google Scholar] [CrossRef]

- Erin, O.; Antonelli, D.; Tiryaki, M.E.; Sitti, M. Towards 5-dof control of an untethered magnetic millirobot via mri gradient coils. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; IEEE: New York, NY, USA, 2020; pp. 6551–6557. [Google Scholar]

- Song, L.; Dai, Y.; Wang, L.; Zhang, W.; Ji, Y.; Cao, Y.; Wei, J.; Wang, F.; Zhong, J.; Yang, J. Motion control of capsule robot based on adaptive magnetic levitation using electromagnetic coil. IEEE Trans. Autom. Sci. Eng. 2022, 20, 2720–2731. [Google Scholar] [CrossRef]

- Du, X.; Yang, L.; Yu, J.; Chan, K.F.; Chiu, P.W.Y.; Zhang, L. Robomag: A magnetic actuation system based on mobile electromagnetic coils with tunable working space. In Proceedings of the 2020 5th International Conference on Advanced Robotics and Mechatronics (ICARM), Shenzhen, China, 18–21 December 2020; IEEE: New York, NY, USA, 2020; pp. 125–131. [Google Scholar]

- Charreyron, S.L.; Boehler, Q.; Kim, B.; Weibel, C.; Chautems, C.; Nelson, B.J. Modeling electromagnetic navigation systems. IEEE Trans. Robot. 2021, 37, 1009–1021. [Google Scholar] [CrossRef]

- Kummer, M.P.; Abbott, J.J.; Kratochvil, B.E.; Borer, R.; Sengul, A.; Nelson, B.J. OctoMag: An electromagnetic system for 5-DOF wireless micromanipulation. IEEE Trans. Robot. 2010, 26, 1006–1017. [Google Scholar] [CrossRef]

- Petruska, A.J.; Nelson, B.J. Minimum bounds on the number of electromagnets required for remote magnetic manipulation. IEEE Trans. Robot. 2015, 31, 714–722. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Zhang, Q.; Zhou, A.; Zhang, Y. A Framework of Designing Multi-Coil Electromagnetic System for 6-DOF Manipulation of Magnetic Miniature Robot. Actuators 2026, 15, 11. https://doi.org/10.3390/act15010011

Zhang Q, Zhou A, Zhang Y. A Framework of Designing Multi-Coil Electromagnetic System for 6-DOF Manipulation of Magnetic Miniature Robot. Actuators. 2026; 15(1):11. https://doi.org/10.3390/act15010011

Chicago/Turabian StyleZhang, Qiang, Aiwu Zhou, and Yi Zhang. 2026. "A Framework of Designing Multi-Coil Electromagnetic System for 6-DOF Manipulation of Magnetic Miniature Robot" Actuators 15, no. 1: 11. https://doi.org/10.3390/act15010011

APA StyleZhang, Q., Zhou, A., & Zhang, Y. (2026). A Framework of Designing Multi-Coil Electromagnetic System for 6-DOF Manipulation of Magnetic Miniature Robot. Actuators, 15(1), 11. https://doi.org/10.3390/act15010011