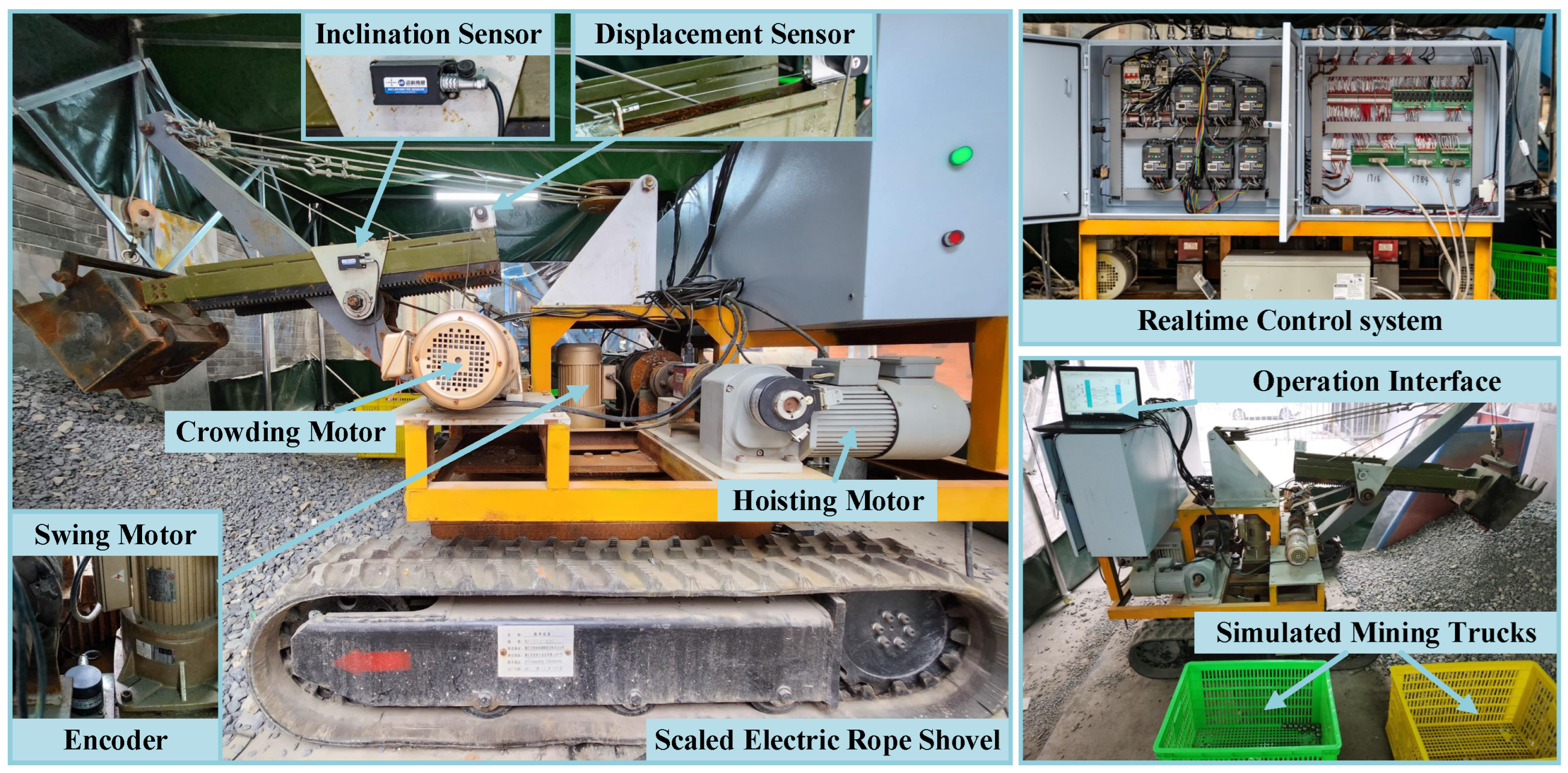

In this section, we will evaluate the feasibility of the proposed positioning and trajectory planning method and the accuracy of the control method using a scaled model.

6.2. Relative Positioning and Trajectory Planning

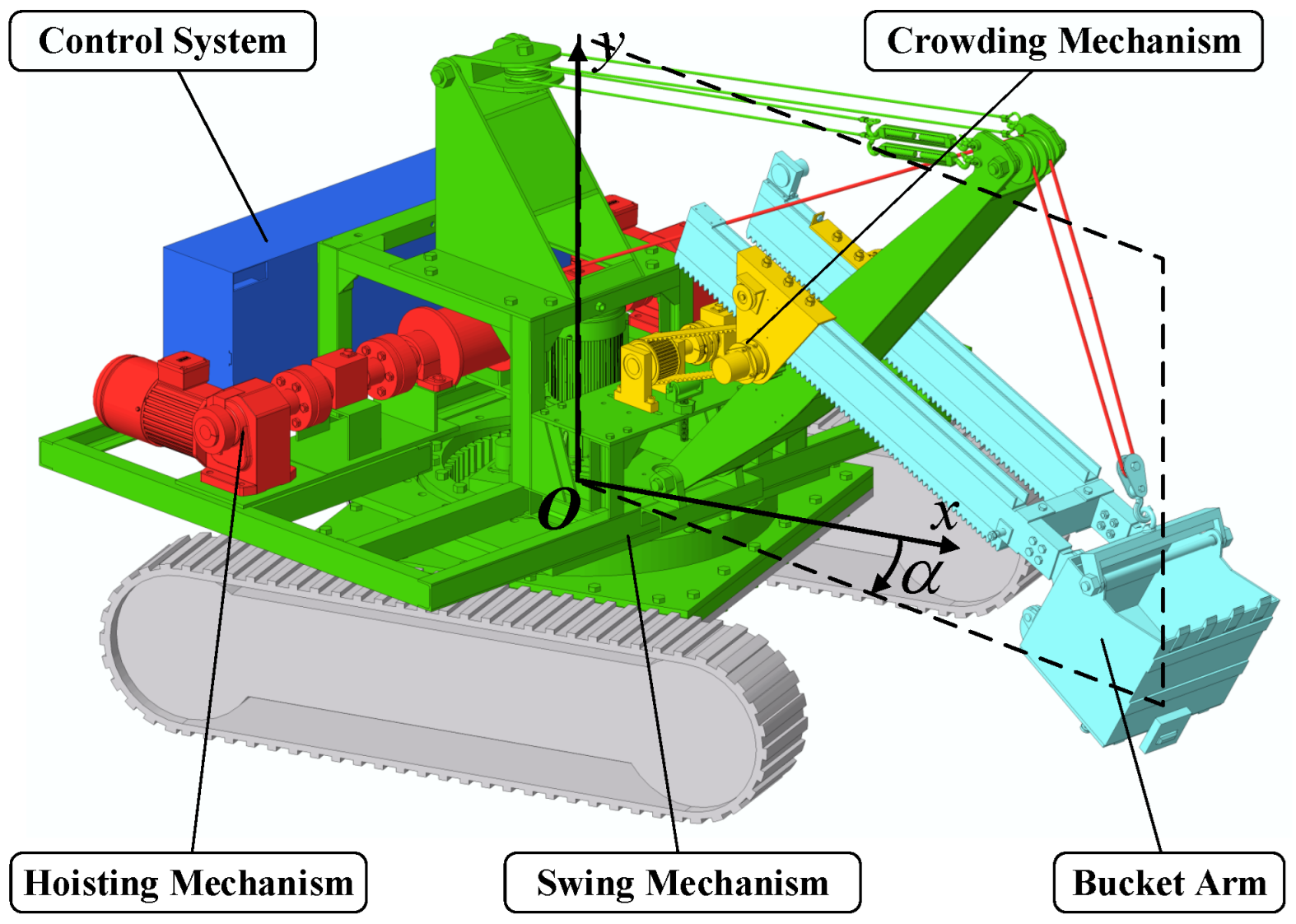

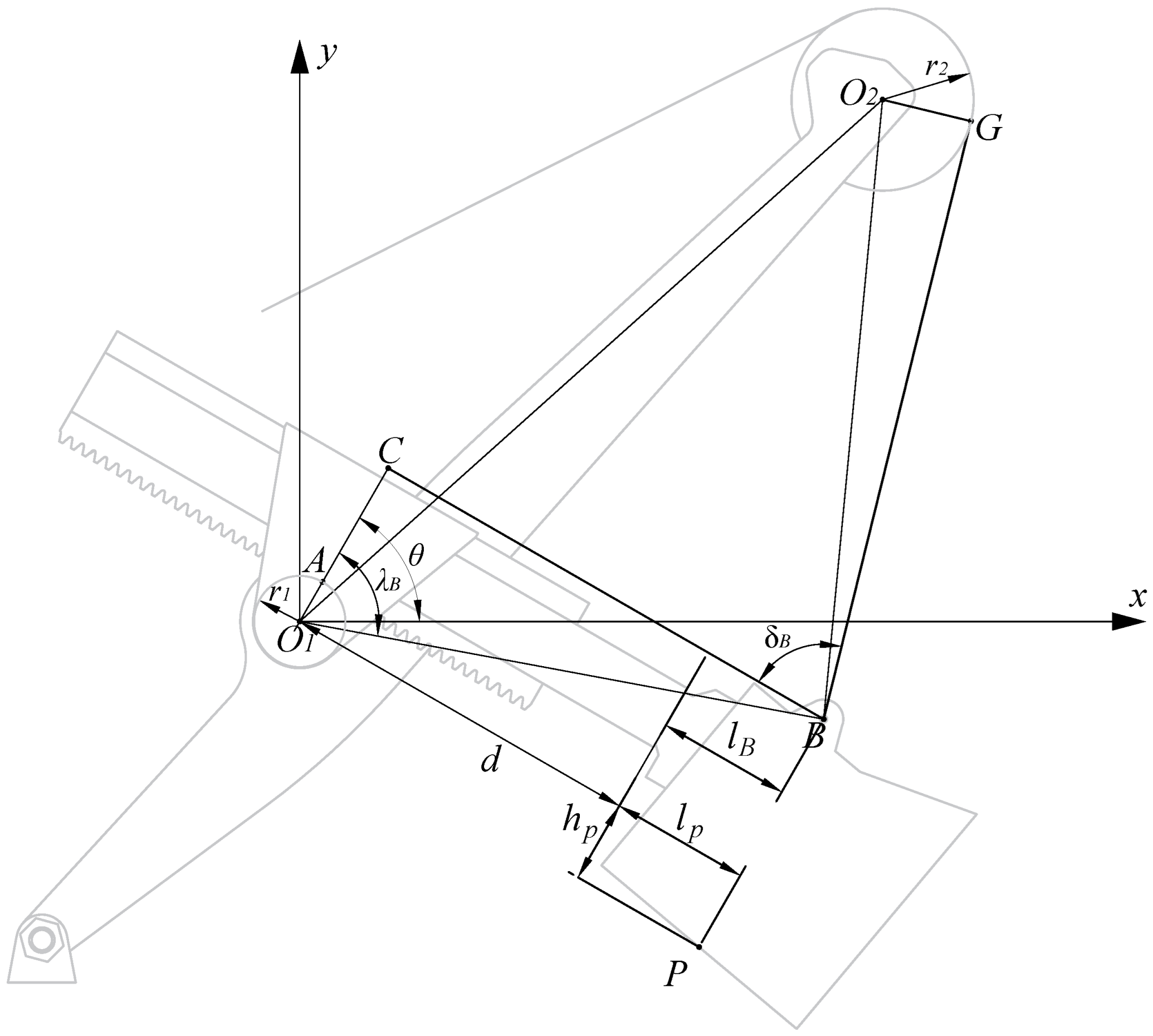

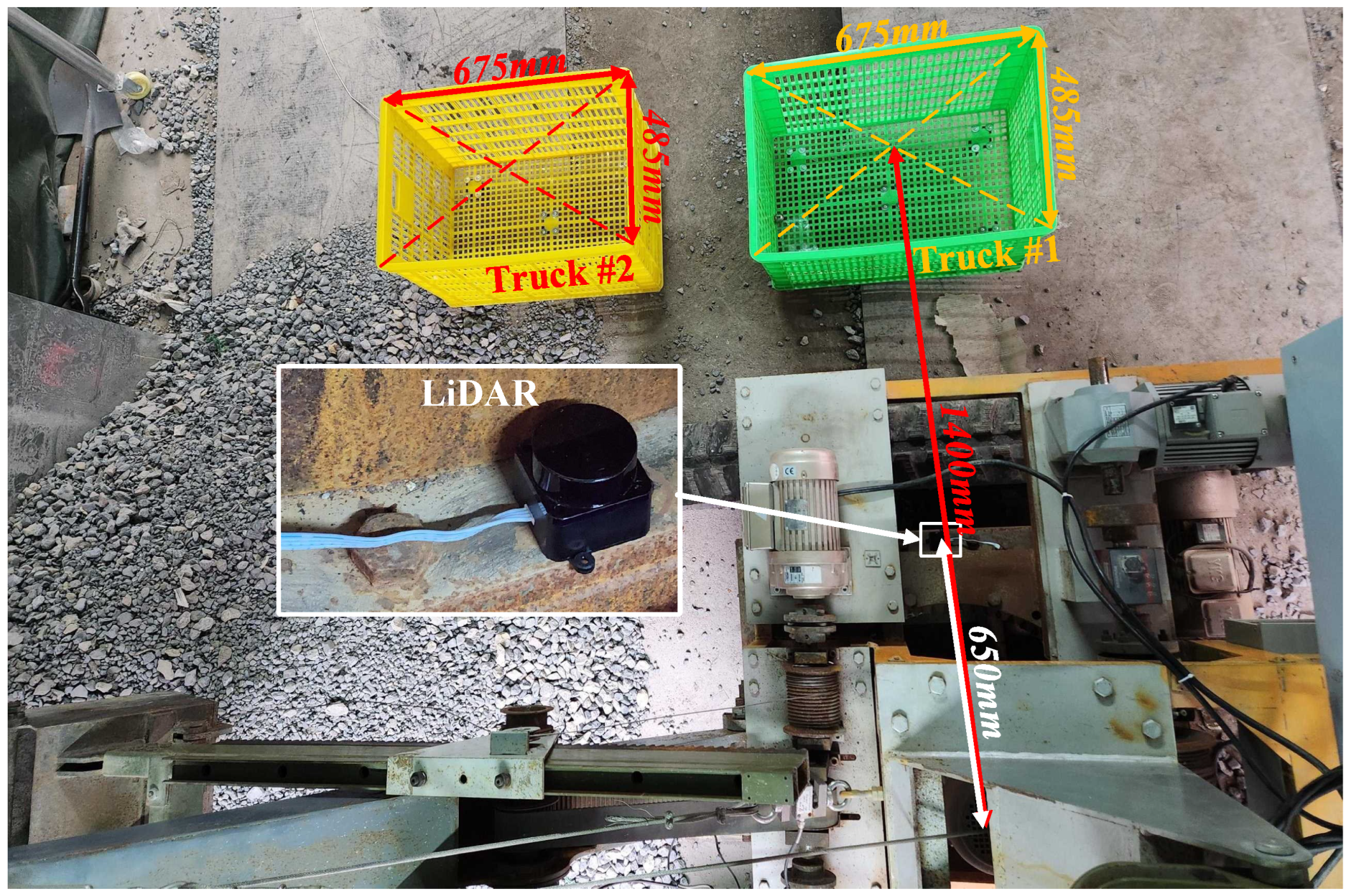

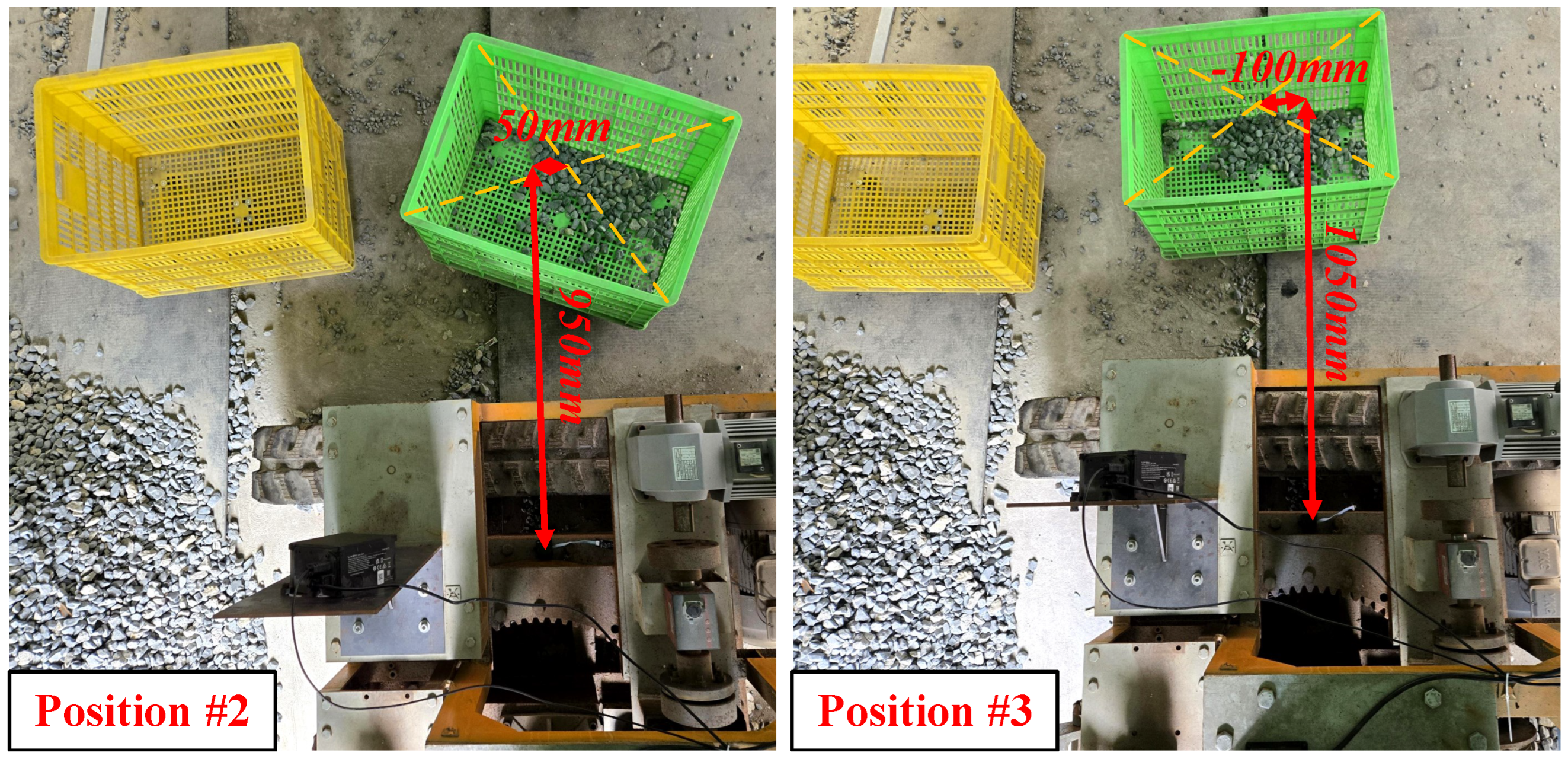

To verify the effectiveness of the relative positioning and trajectory planning methods, two cargo boxes (675 mm × 485 mm × 400 mm) are used to simulate mining trucks for positioning and planning experiments, as shown in

Figure 11. The green one (Truck #1) is the truck being loaded, and the yellow one (Truck #2) is the truck waiting to be loaded. The LiDAR is placed 650mm to the right of the rotation center.

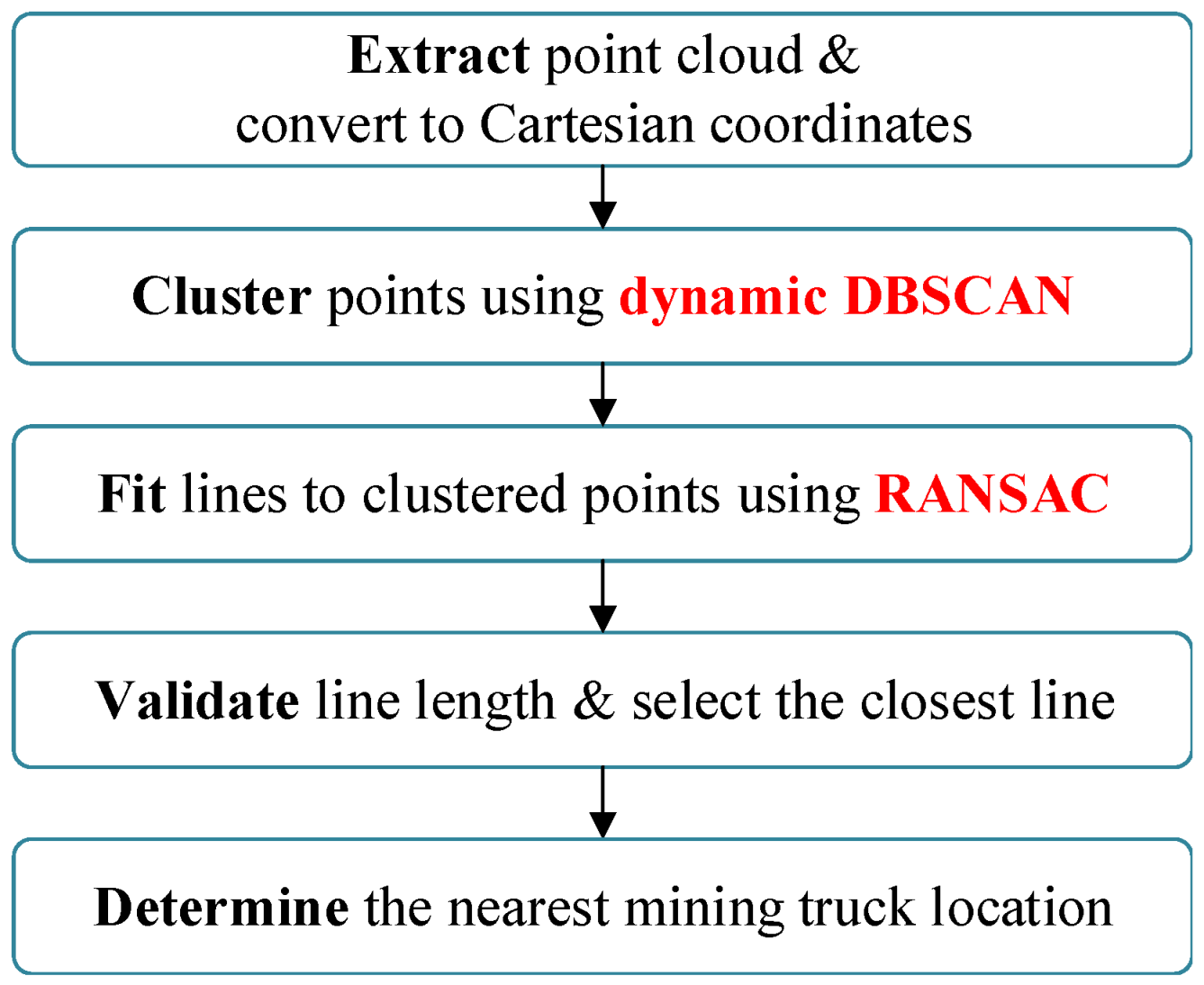

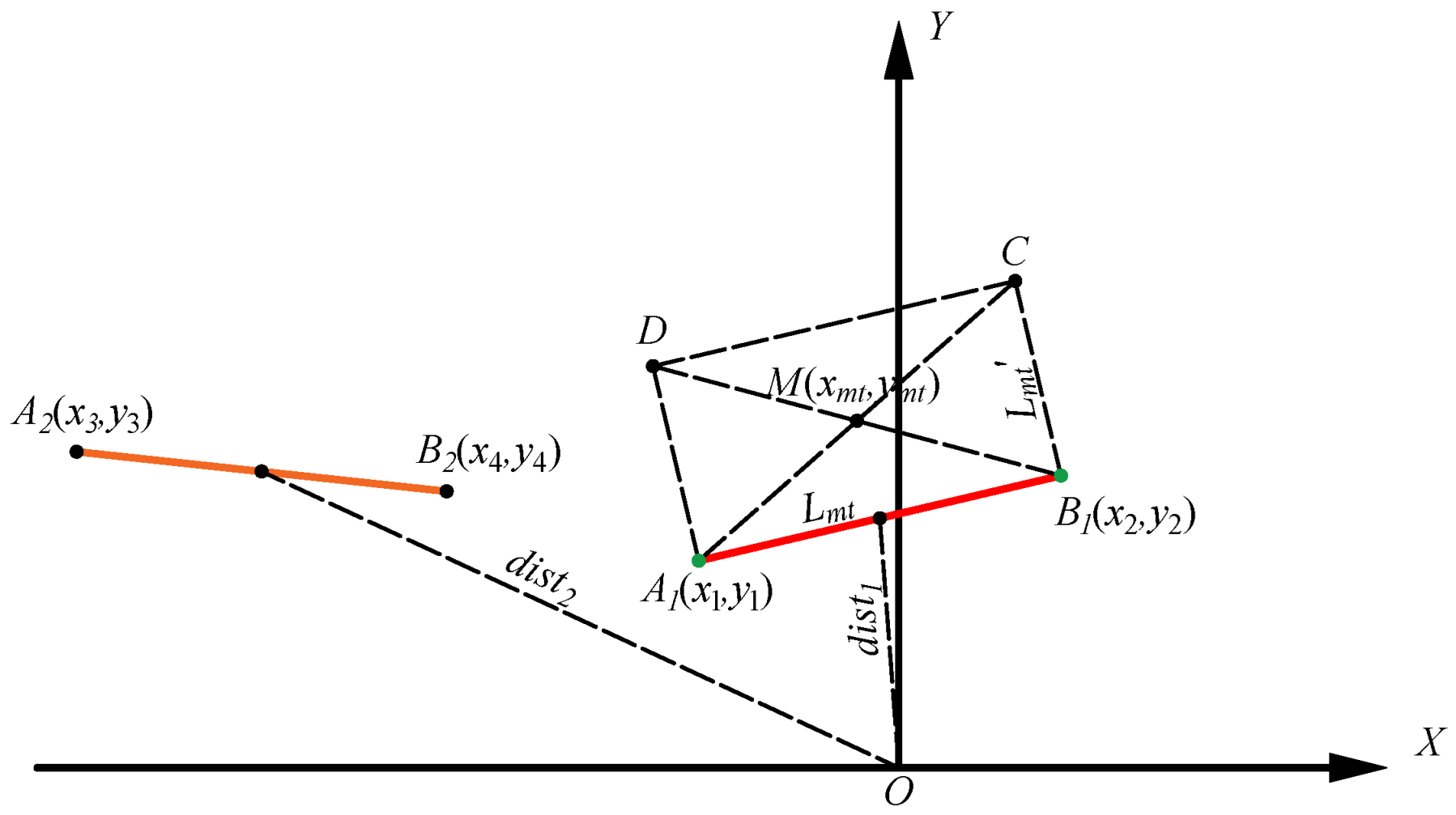

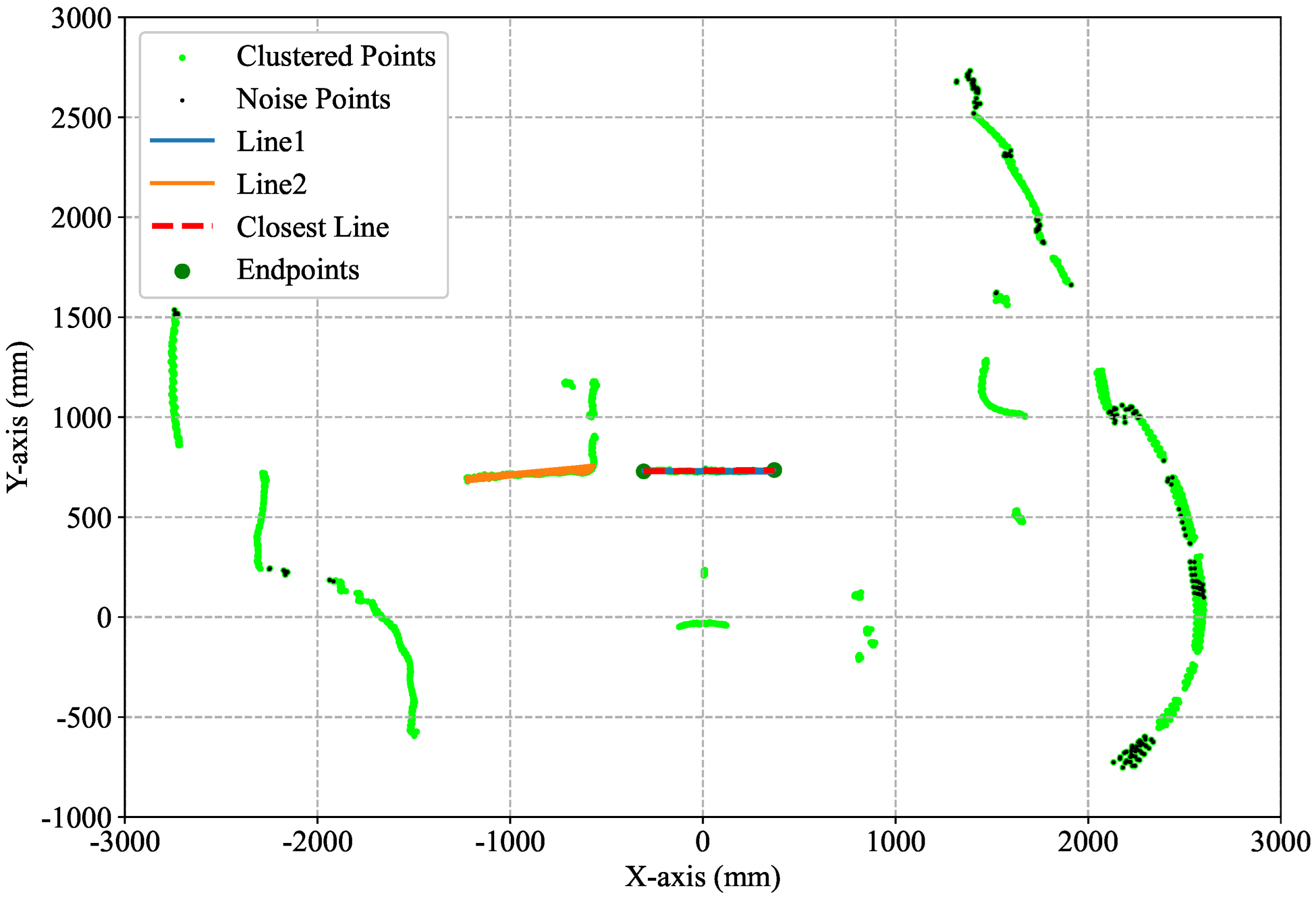

The LiDAR positioning results are shown in

Figure 12. Using the dynamic DBSCAN algorithm, the points are classified into noise points (black) and valid points (green).

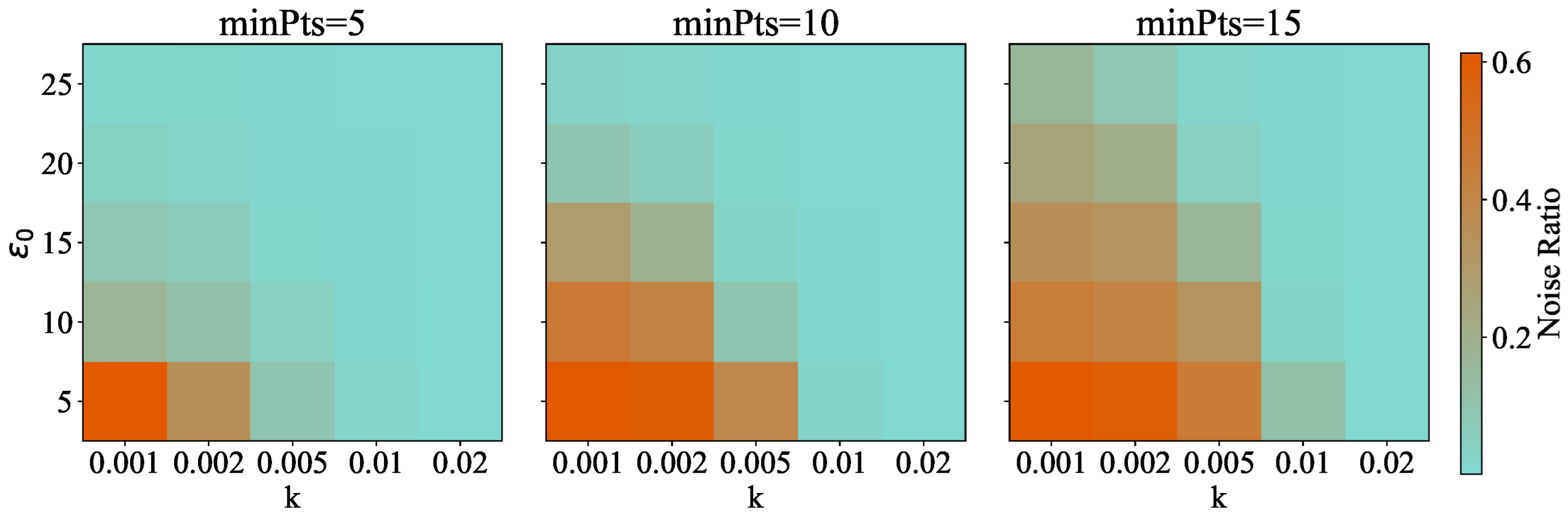

To determine appropriate clustering parameters, we performed a sensitivity analysis by varying

,

k, and

across a range of values. For each parameter combination, the proportion of points classified as noise was computed, as illustrated in

Figure 13.

This analysis reveals a trade-off between removing noisy outliers and preserving sufficient valid data for reliable line detection. A small or k tends to over-segment the point cloud, while a large value may include spurious points into valid clusters. Based on the balance between noise suppression and data retention, we selected (, , ) as the final configuration, which yields a reasonable noise ratio and ensures cluster continuity for subsequent geometric analysis.

The RANSAC algorithm (

,

) is then applied to fit straight-line segments and identify the nearest one to the electric shovel (highlighted in red) along with its two endpoints. The actual measured values are shown in

Figure 12. We then changed the truck’s position and conducted two more positioning experiments, as shown in

Figure 14. The results are shown in

Table 4, with five repeated measurements conducted at each position. The reported X and Y values represent the coordinates of the geometric center of the simulated mining truck. As summarized in

Table 5, the mean absolute errors (MAEs) in the X and Y directions are 10.85 mm and 20.0 mm, respectively, with corresponding root mean square errors (RMSEs) of 13.04 mm and 20.67 mm. The maximum absolute errors are 21.1 mm in X and 27.0 mm in Y.

It is important to note that the LiDAR used in the scaled experiment is a full-function sensor with fixed resolution and ranging accuracy. As such, the observed positioning errors are not subject to scaling by the physical model ratio [

39,

40]. In other words, the measured error values reflect the actual performance expected in full-scale deployment. Given that these errors are significantly smaller than the physical dimensions of the mining truck, the proposed method is sufficiently accurate for localization and automated truck loading tasks.

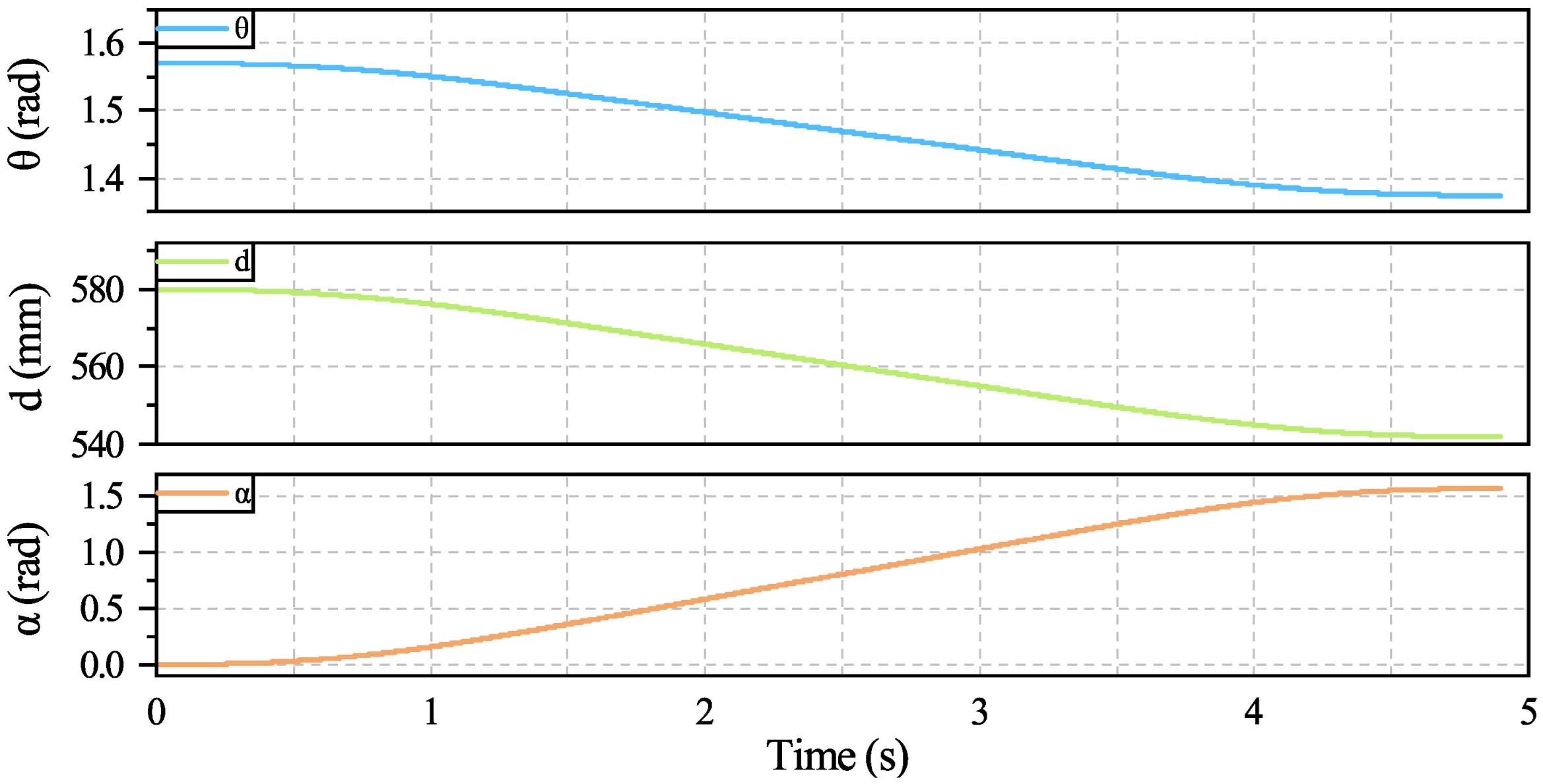

Based on the previously established excavator motion model, the calculated swing unloading point, which is the endpoint of the trajectory, is

. Consider the case where no obstacle avoidance is required (Condition 1, assumed starting point

), as shown in

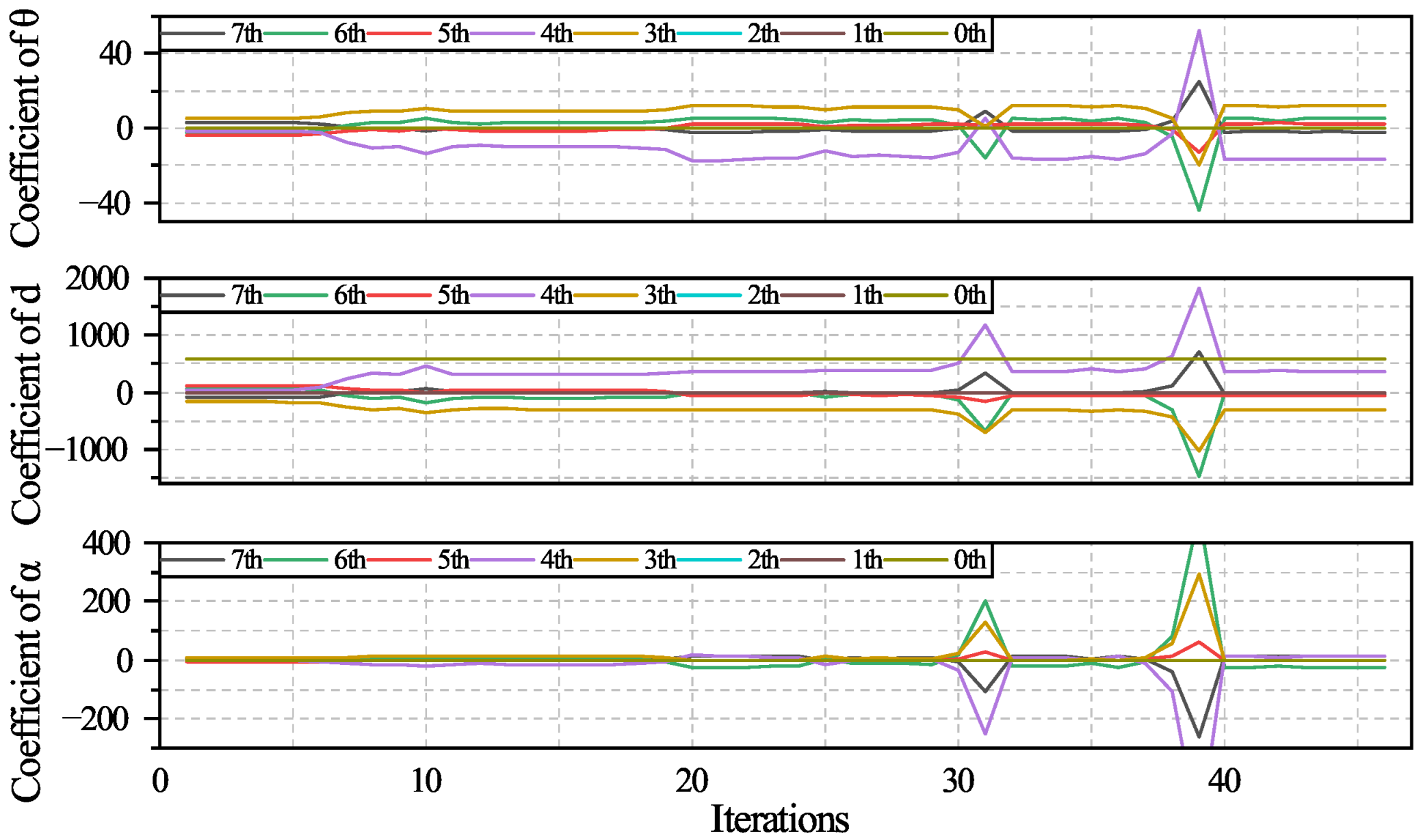

Figure 15. Based on the obtained relative position information of the mining truck, a time-optimal trajectory is planned using the method described in

Section 4, with

,

,

. The polynomial coefficient optimization process is shown in

Figure 16. Since the swing motion has the largest amplitude during the unloading process, the maximum acceleration and velocity constraints of the swing determine the value of

. Considering the mechanical structure and drive capability, we set

and

. When

,

, and

, resulting in

. Thus, the optimized trajectory time is

, and the curves of

,

d and

are shown in

Figure 17.

In certain operating conditions (Condition 2, starting point

), as shown in

Figure 18, the endpoint of the excavation trajectory is lower than the unloading point. Direct swing trajectory planning in such cases may result in a collision between the bucket and the mining truck. Therefore, obstacle avoidance is considered by setting a safety distance of

mm and a penalty weight of

. The choice of

takes into account the bucket dimensions and the structural clearance required for the bottom gate mechanism of the prototype, ensuring that sufficient clearance is maintained to prevent collisions during the autonomous swing operation. The coefficient optimization process and the final trajectory are shown in

Figure 19 and

Figure 20 with

s. To avoid obstacles, the trajectory planner generates a motion path that maintains a greater distance from the obstacle points. As a result, the planned trajectory exhibits an earlier lifting action compared to the nominal curve, enabling the bucket to gain sufficient height in advance to avoid potential collisions with the mining truck during the subsequent swing.

To evaluate the computational performance of the full autonomous operation pipeline, we measured the time consumption of three key steps: LiDAR scanning, DBSCAN+RANSAC-based truck localization, and SLSQP-based trajectory planning. Each step was executed 20 times under identical conditions. The tests were conducted on a laptop with Intel i7-10750H and 16GB RAM. The time cost of each step is shown in

Table 6.

These results confirm that the total processing time from sensing to trajectory generation remains under 8 s, which is acceptable for real-time deployment.

Considering the operational characteristics of the ERS, the unloading point can be determined as soon as the mining truck arrives. Likewise, once the bucket begins excavating the pile surface, the starting point of the swing trajectory becomes known. Since the excavation phase typically lasts 10–20 s, there is sufficient time to complete the planning process within the same operation cycle. Therefore, the proposed planning method is suitable for enabling continuous and uninterrupted autonomous operation. Further acceleration is possible by reducing problem dimensionality or leveraging parallel hardware in future implementations.

The final coefficients of the trajectories of condition 1 and 2 are shown in

Table 7.

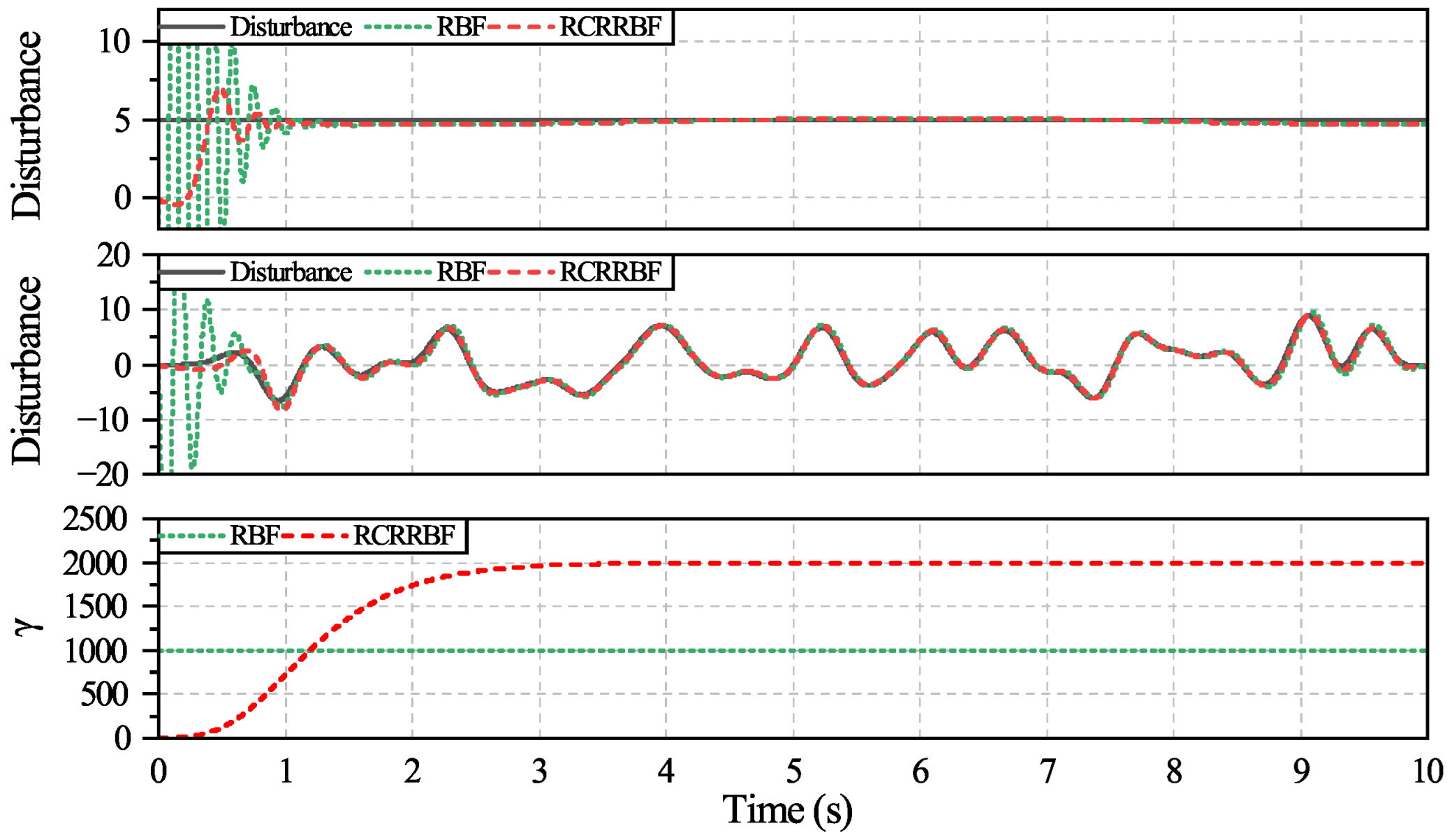

6.3. Simulation of RCRRBF Network

In real-world heavy-duty construction machinery applications, it is often difficult to directly measure shaft torque. Similarly, in the scaled-down experimental platform, the external disturbance acting on the motor cannot be directly obtained. As a result, it is not possible to obtain an accurate reference value for the disturbance in real experiments to validate the accuracy of the RCRRBF network estimation. To address this limitation, we construct a training dataset using a simulation model and, after offline training, apply the trained RCRRBF network to the actual control system.

However, due to experimental constraints, the error between the RCRRBF-estimated disturbance and the actual disturbance cannot be directly compared in real experiments. Therefore, we have included a simulation experiment section in the paper to verify the RCRRBF network’s disturbance estimation capability using simulation data and to analyze its error characteristics. This simulation experiment supports the effectiveness of the RCRRBF network in real systems, compensating for the lack of a real disturbance reference in physical experiments. As shown in

Figure 21, the results demonstrate that the RCRRBF network (

,

,

,

) improves initial stability and maintains comparable tracking performance to the traditional RBF network under both constant and random disturbances. The gradual increase in

effectively reduces initial divergence, making the RCRRBF network more robust and adaptive to system variations.

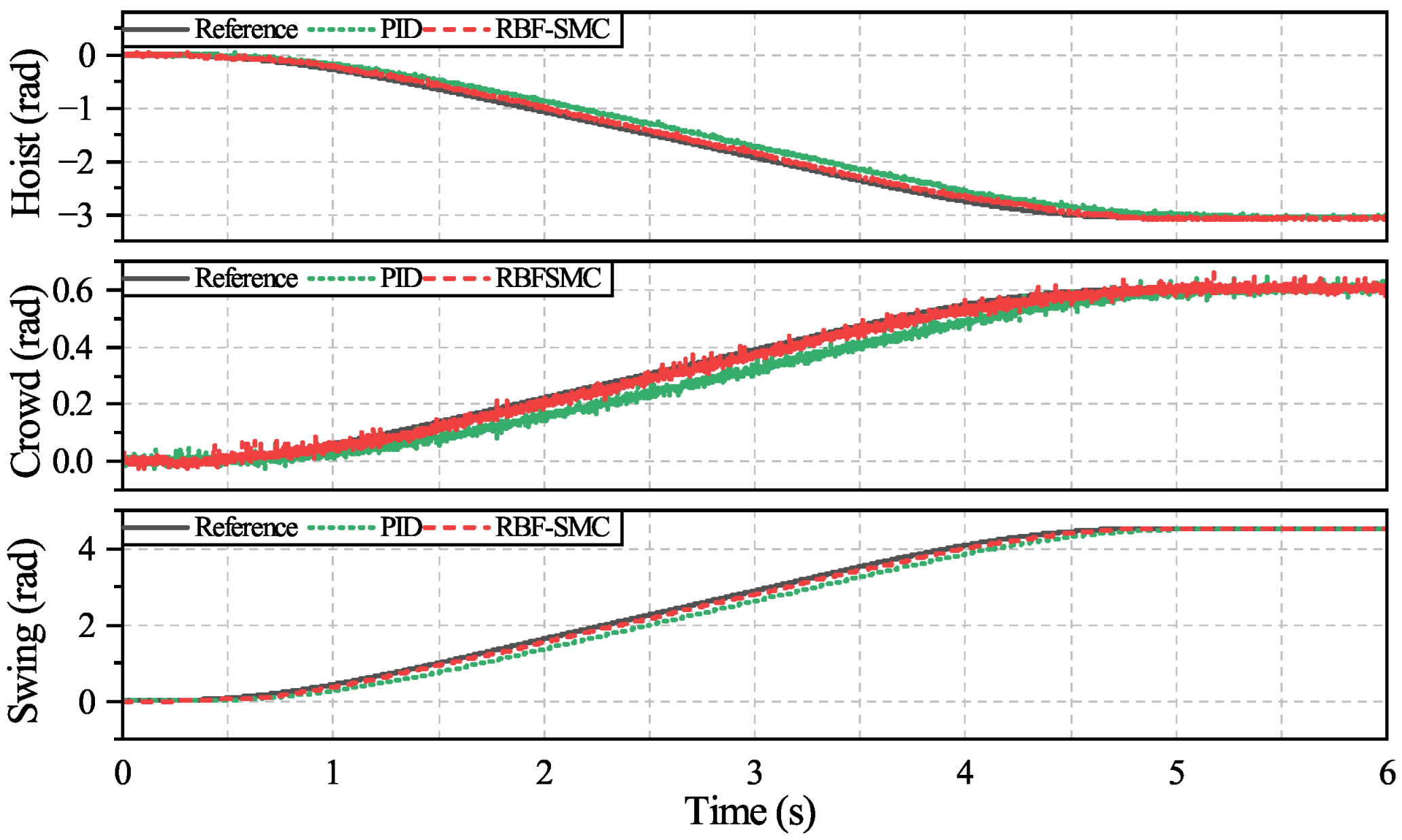

6.4. Preformance Experiment of RBF-SMC

To verify the control performance of the proposed sliding-mode controller, the trajectory planning result of Condition 1 is selected as the reference trajectory for trajectory control experiments on the scaled experimental platform. The control performance is then compared with that of a traditional PID controller, as PID remains the most commonly adopted control strategy in industry owing to its straightforward structure and well-established tuning methods. PID parameters were tuned using the Ziegler–Nichols method and further manually refined for trajectory tracking tasks.The final gains were confirmed to be optimal under the given system dynamics, as further adjustments led to degraded performance or instability. According to the motion model, the values of

,

d,

are converted into the rotation angles of the hoisting, crowding, and swing motors. The trajectory control results are shown in

Figure 22 and

Figure 23 and

Table 8. The control performance is evaluated using a combination of maximum instantaneous error, root mean square error, and time delay, which together provide a more comprehensive assessment of transient deviation, steady-state accuracy, and dynamic responsiveness.

Table 8 shows that the proposed RBF-SMC controller outperforms the traditional PID controller across all three motors. It significantly reduces the maximum instantaneous error, root mean square error, and time delay, indicating improved transient robustness, steady-state accuracy, and dynamic responsiveness. These results confirm that the RBF-SMC achieves more precise and timely trajectory tracking under various operating conditions.

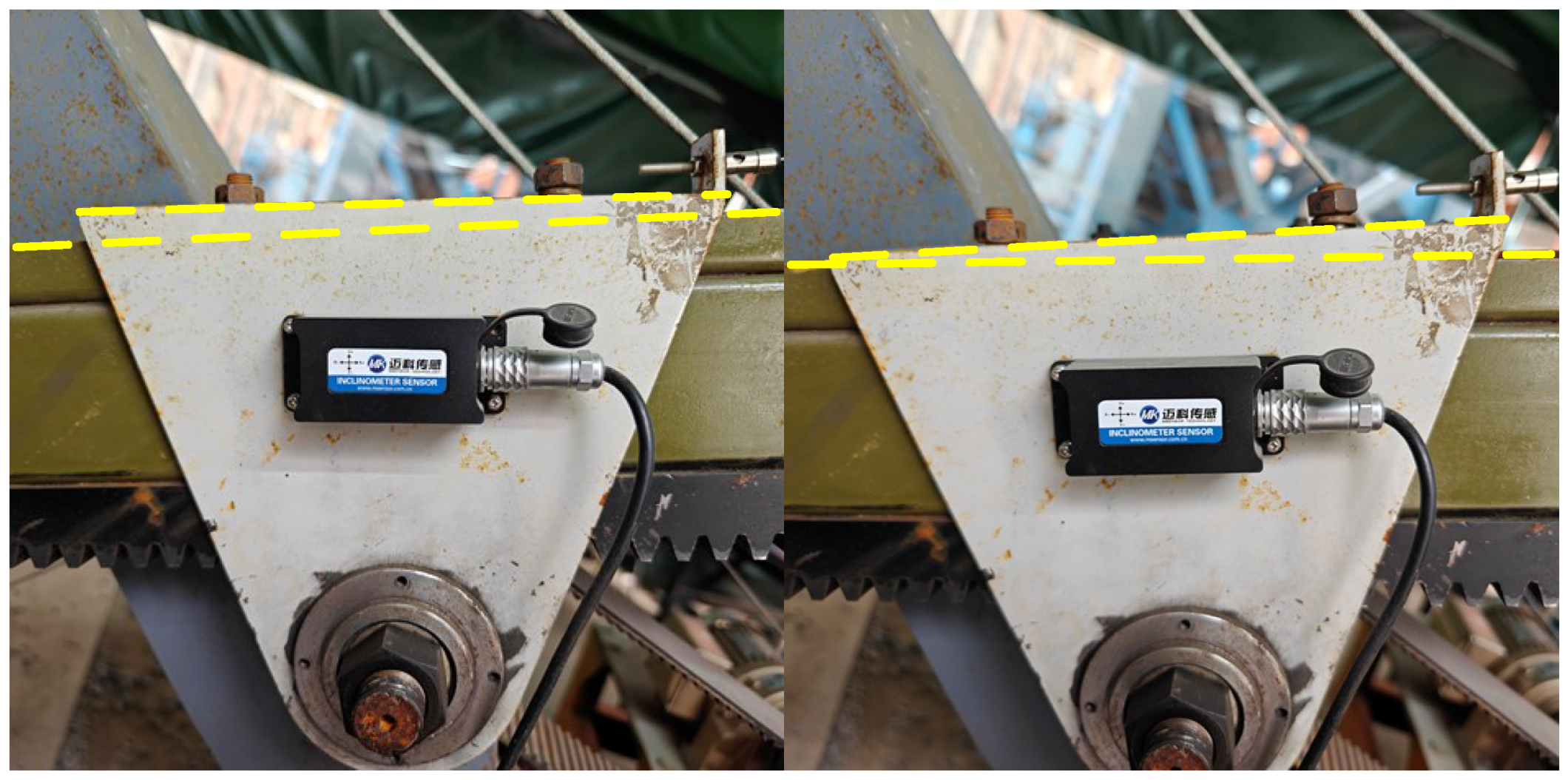

The disturbance observation results are shown in

Figure 24 aligns with expectations. As the disturbance torque on the motor shaft is difficult to measure directly, we computed the theoretical disturbance under ideal conditions based on the reference trajectory of the motor motion, allowing a rough comparison with the observed values. It is important to note that for the estimated disturbance force in the crowding motion, manufacturing errors in the scaled-down test rig led to gear jamming between the crowding gear and rack, rather than simple misalignment. As illustrated in

Figure 25, the jamming caused the crowding motor to stall intermittently and forced it to move in a stepwise manner by overcoming the resistance of each tooth. This resulted in a gradual increase in the overall estimated resistance force, along with localized fluctuations, particularly noticeable around 2 s and 5 s. This abnormal mechanical interaction ultimately resulted leading to discrepancies between the observed disturbance of the crowding motor and its ideal value.

The main parameters of RBF-SMC and the PID controller are shown in

Table 9.

In general, the results demonstrate that the proposed RBF-SMC significantly improves system robustness against external disturbances. By effectively estimating and compensating for unknown input torques, the RBF network enables the controller to maintain higher tracking accuracy with reduced steady-state error and shorter time delay, even under varying load conditions. Compared to conventional control methods, the combined RBF-SMC strategy achieves smoother response and better disturbance rejection.

In addition, we observed that the controller also performs well under unexpected mechanical interferences, such as the backlash and resistance fluctuations caused by the rack and pinion. These observations further support the robustness of the proposed method in practical scenarios.