Review of Thrust Regulation and System Control Methods of Variable-Thrust Liquid Rocket Engines in Space Drones

Abstract

1. Introduction

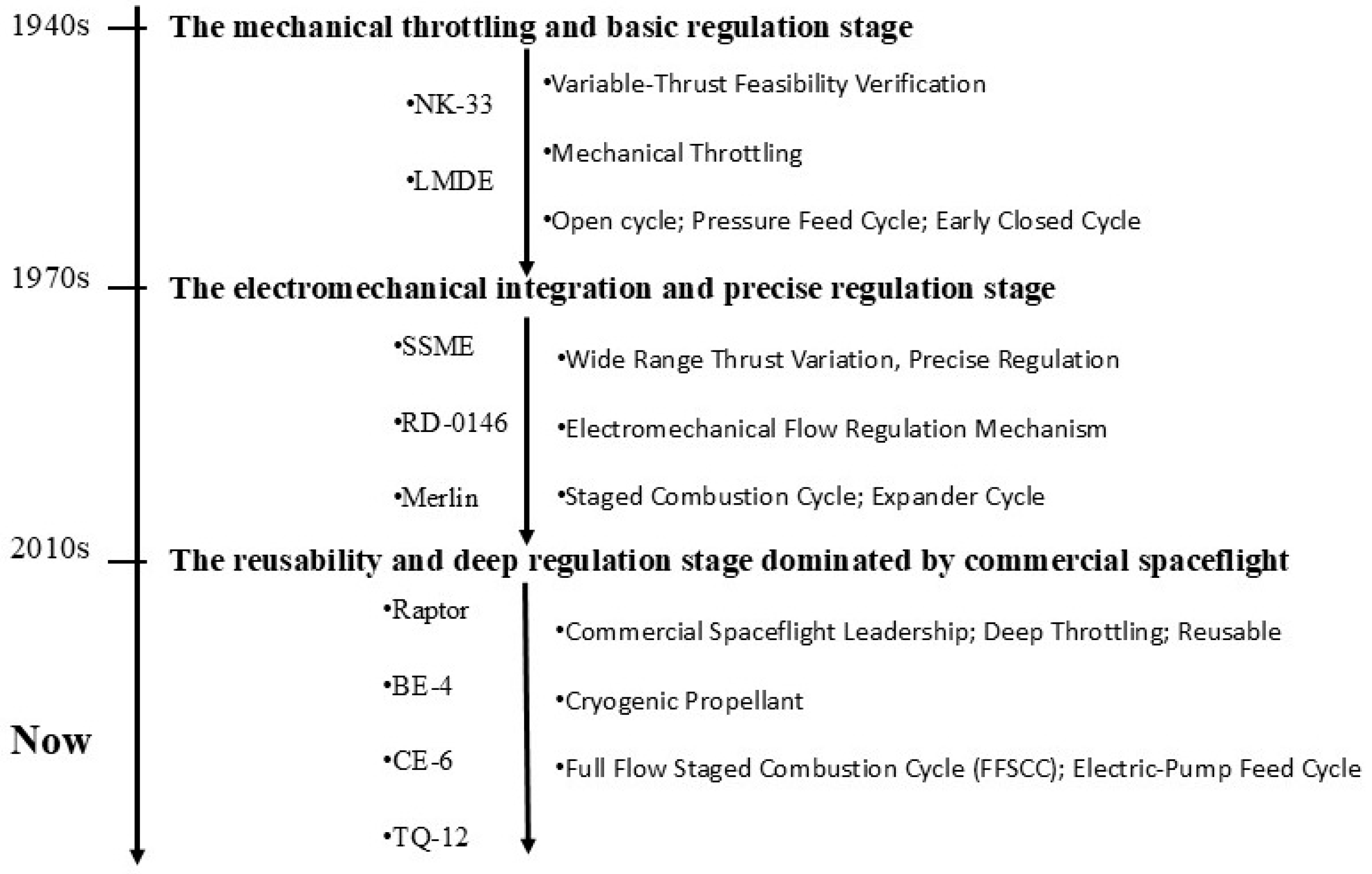

2. Development Stages and Technical Characteristics

2.1. Stage 1: The Mechanical Throttling and Basic Regulation

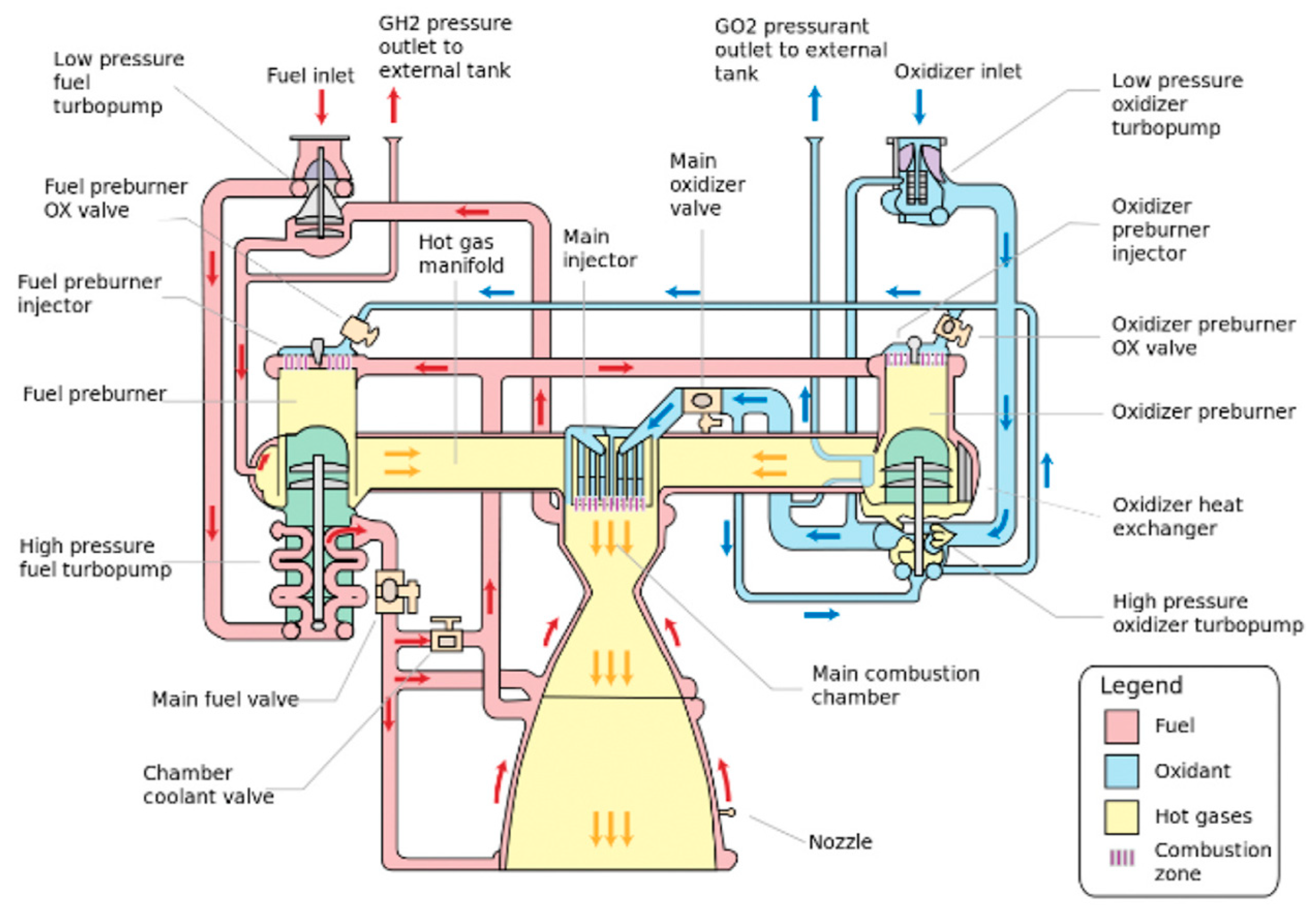

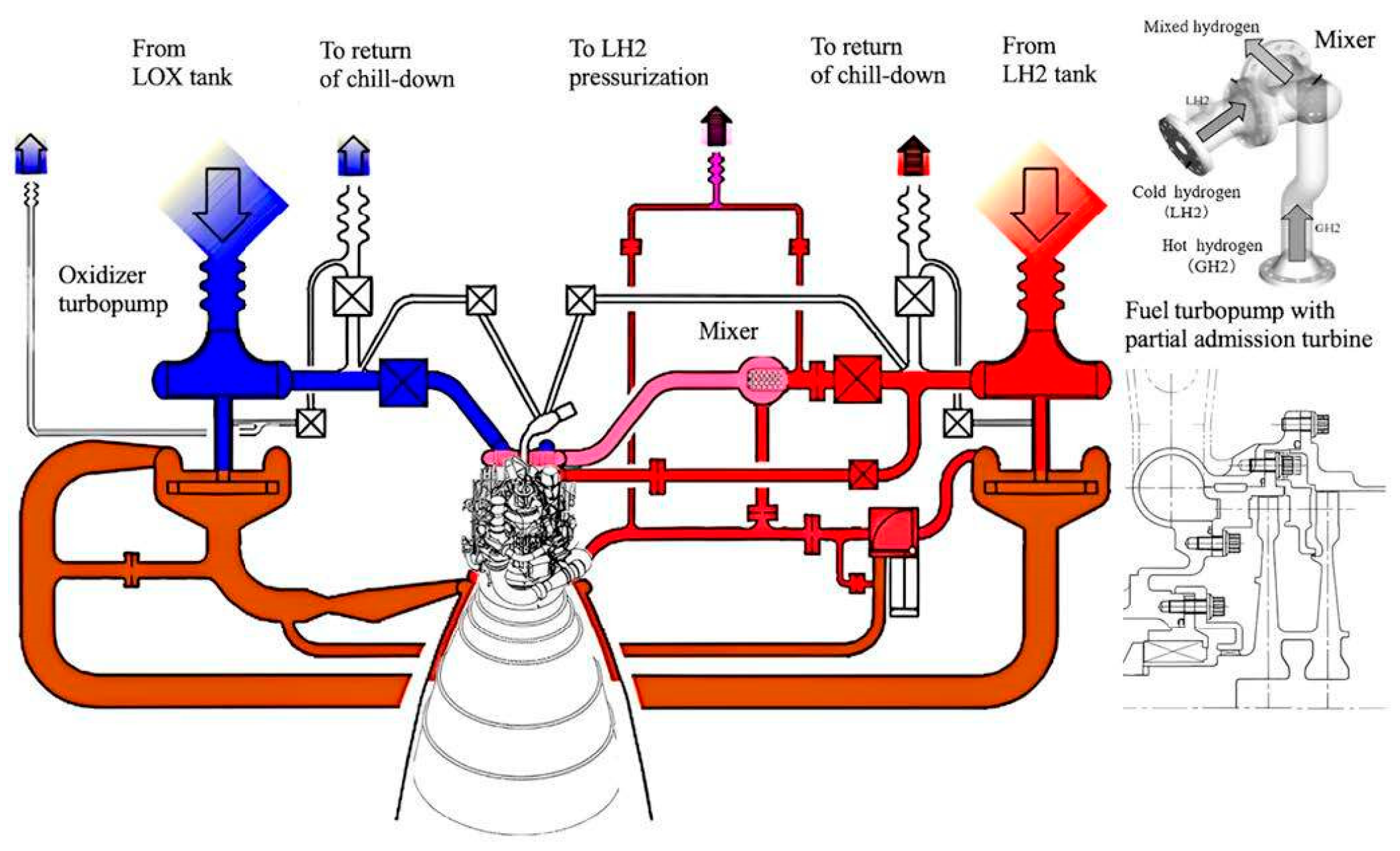

2.2. Stage 2: The Electromechanical Integration and Precise Regulation

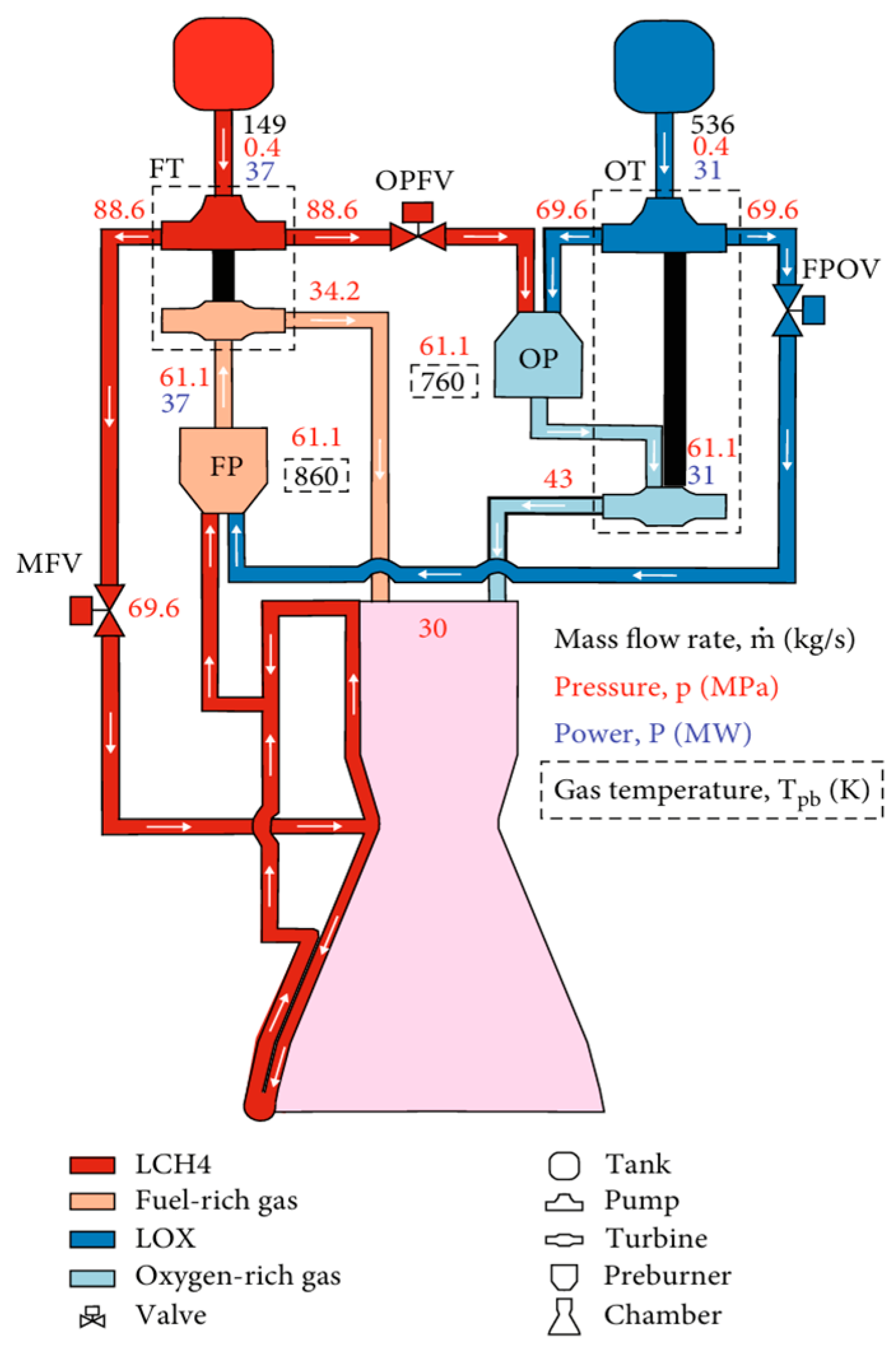

2.3. Stage 3: The Reusability and Deep Regulation Stage Dominated by Commercial Spaceflight

3. Thrust Regulation Technology of Variable-Thrust LRE

3.1. Propellant Flow Regulator

3.1.1. Throttle Valves

3.1.2. Adjustable Cavitating Venturi Tubes

- Under the rapid mode-switching demanded by deep-throttling variable-thrust engines, the coupled mechanism between cavitation and turbulent fluctuations remains poorly quantified, leaving the dynamic response to thrust step changes without a rigorous mathematical description. This gap severely limits the robustness of high-precision control-law design.

- Existing achievements are almost exclusively based on room-temperature propellants; systematic investigations for cryogenic propellants such as LOX/methane are conspicuously absent. Foundational questions—ranging from how cryogenic cavitation dynamics influence flow-modulation characteristics to the establishment of discharge-coefficient calibration, dynamic-response characterization, and model construction under cryogenic conditions—remain open. Consequently, three critical voids must be filled: (i) a transient cryogenic cavitation–turbulence coupling model for variable Venturis, (ii) a dynamic calibration methodology for discharge coefficients under variable operating conditions, and (iii) a cryogenic-adaptive control architecture.

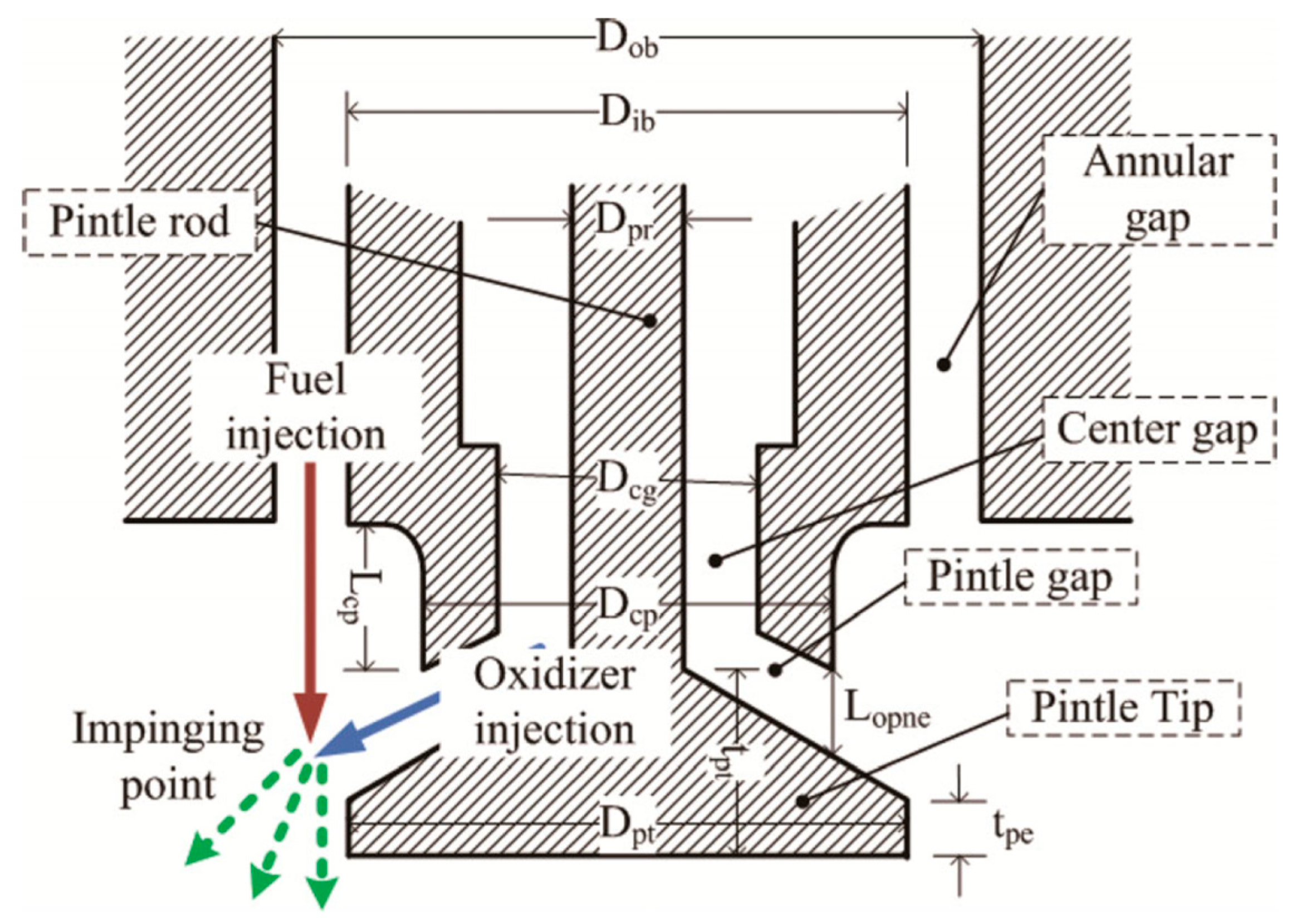

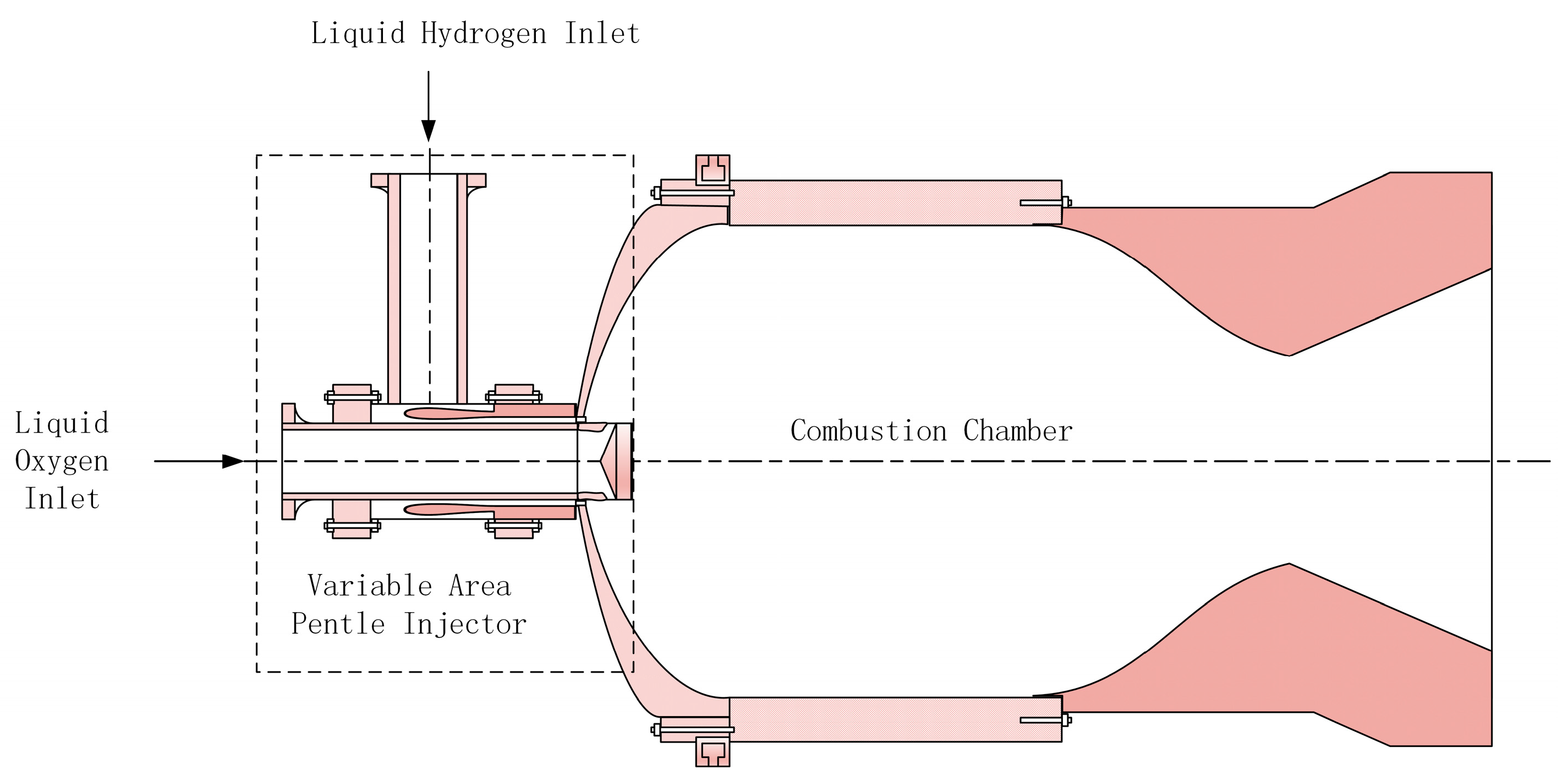

3.2. Injector Dynamic Pressure Drop Matching Technology

3.2.1. Combustion Organization Challenges of Traditional Injectors at Low Operating Conditions

3.2.2. Dynamic Pressure Drop Matching of Adjustable Pintle Injectors

4. Variable-Thrust LRE System Control Technology

4.1. Difficulties in System Control of Variable-Thrust LRE

- Multivariable coupling

- 2.

- Control signal and response delays

- 3.

- Harsh operating environment with strong disturbances

- 4.

- Strong nonlinear characteristics

4.2. Control Strategies for Variable-Thrust LRE

- Open-loop control

- 2.

- Feedback control based on linear models

- 3.

- Robust control

4.3. Engineering Challenges in Advanced Control Strategy Implementation

- Sensor reliability bottlenecks

- 2.

- Nonlinear model-based controller design and application

- 3.

- Control-structure coupled vibrations

5. Conclusions and Prospects

5.1. Conclusions

5.2. Prospects

- Application prospects and challenges of cryogenic propellants: Cryogenic propellants, with their high specific impulse, clean combustion characteristics, and potential as core fuels for in situ resource utilization on Mars, have become a key option for high-frequency reusable commercial space missions and deep-space exploration tasks. However, their application in variable-thrust engines faces severe challenges: the effectiveness and robustness of existing design criteria and control systems based on room-temperature propellants under cryogenic and wide-range variable operating conditions need urgent verification, and the problem of unsteady flow fields caused by cavitation and flashing has not been fundamentally solved. Future efforts should focus on breaking through cryogenic wide-range flow regulation technologies, reducing the model’s dependence on empirical parameters based on the phase change characteristics of propellants, and developing new types of cryogenic throttling devices and rapid-response control systems.

- Combustion stability during deep throttling: Deep thrust regulation relies on the wide-range flow adjustment capability of propellant regulating devices. However, issues such as nonlinear fluctuations in combustion chamber pressure, decreased combustion efficiency, and deteriorated atomization and mixing caused by extreme throttling conditions urgently require breakthroughs through dynamic coupling design. The core to solving these problems lies in establishing a real-time matching mechanism among injection pressure drop, flow rate, and pintle stroke. Through the collaborative design of profiles and injection orifices, the imbalance of gas–liquid momentum ratio caused by injection area adjustment can be eliminated, ensuring the stability of spray cone angle and Sauter Mean Diameter (SMD) under wide operating conditions. Meanwhile, transient CFD simulations should be used to reconstruct the processes of liquid film shear and gas–liquid collision, quantifying the dynamic laws of spray cone angle deviation and SMD deterioration during thrust steps. Reinforcement learning algorithms can be employed to dynamically regulate the pintle stroke and annular gap area, achieving stable combustion control under pressure drop fluctuations. Ultimately, it is necessary to verify through ground and flight tests covering all operating conditions and construct a highly robust injector design system integrating dynamic pressure drop compensation, multi-parameter coupling optimization, and transient atomization control so as to fundamentally solve the combustion instability under deep throttling.

- Integration of high-fidelity variable-thrust engine system modeling with advanced control strategies: The strong nonlinear characteristics of variable-thrust liquid rocket engine systems make accurate modeling challenging. Issues of data noise and model mismatch are particularly prominent in extreme environments, which not only affect control performance and reliability but also exacerbate the contradiction between computational resource requirements and real-time correction. Future research should integrate high-fidelity system models with advanced control strategies, improve parameter identification accuracy through experimental calibration and data-driven modeling, and develop adaptive control algorithms under environmental uncertainties. The development of intelligent engine control technologies based on artificial intelligence and digital twin technologies will provide more effective solutions to the aforementioned problems of data noise and model mismatch. Meanwhile, it is necessary to balance computational efficiency and model fidelity using methods such as model order reduction, thereby forming an intelligent control system oriented toward engineering applications.

Author Contributions

Funding

Conflicts of Interest

References

- Roma, A. Drones and popularisation of space. Space Policy 2017, 41, 65–67. [Google Scholar] [CrossRef]

- Medina, F.N.; Sande, C.U.; Rey, G.; García, J.P.; Pérez-Tavernier, D. Drones for Space Exploration. In Applying Drones to Current Societal and Industrial Challenges; Carou, D., Sartal, A., Davim, J.P., Eds.; Springer: Cham, Switzerland, 2024; pp. 181–218. [Google Scholar] [CrossRef]

- Zhao, P.; Li, R.; Wu, P.; Liu, H.; Gao, X.; Deng, Z. Review of Key Technologies of Rotary-Wing Mars UAVs for Mars Exploration. Inventions 2023, 8, 151. [Google Scholar] [CrossRef]

- Gong, Y.; Guo, Y.; Lyu, Y.; Ma, G.; Guo, M. Multi-constrained feedback guidance for mars pinpoint soft landing using time-varying sliding mode. Adv. Space Res. 2022, 70, 2240–2253. [Google Scholar] [CrossRef]

- Yuan, J.; Huang, Y.; Li, P.; Zhang, Z.; Ma, Y.; Yang, P.; Huang, Y. Orbit determination for Chang’e-6 mission during the lunar orbit phase. In Advances in Space Research; Elsevier: Amsterdam, The Netherlands, 2025. [Google Scholar] [CrossRef]

- Betts, E.; Frederick, R. A Historical Systems Study of Liquid Rocket Engine Throttling Capabilities. In Proceedings of the 46th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Salt Lake City, UT, USA, 8–11 July 2001; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2010. [Google Scholar] [CrossRef]

- Zhang, Y.-L. State-space analysis of the dynamic characteristics of a variable thrust liquid propellant rocket engine. Acta Astronaut. 1984, 11, 535–541. [Google Scholar] [CrossRef]

- Cheng, P.; Li, Q.; Kang, Z.; Zhang, X. Combustion Dynamics of an Extreme Fuel-Rich Throttleable Rocket Engine During Continuously Throttling Process. Combust. Sci. Technol. 2016, 189, 717–731. [Google Scholar] [CrossRef]

- Dressler, G. Summary of Deep Throttling Rocket Engines with Emphasis on Apollo LMDE. In Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Sacramento, CA, USA, 9–12 July 2006. [Google Scholar] [CrossRef]

- Selle, L.; Blouquin, R.; Théron, M.; Dorey, L.-H.; Schmid, M.; Anderson, W. Prediction and Analysis of Combustion Instabilities in a Model Rocket Engine. J. Propuls. Power 2014, 30, 978–990. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z.; Zhou, J. Nonlinear theory of combustion stability in liquid rocket engine based on chemistry dynamics. Sci. China Ser. B Chem. 2002, 45, 373–383. [Google Scholar] [CrossRef]

- Guangxu Wang, B.L.; Yonghua, T.; Yushan, G. High frequency combustion instability in liquid rocket engines: Review. Acta Aeronaut. Et Astronaut. Sin. 2024, 45, 529450. [Google Scholar] [CrossRef]

- Hossain, M.A.; Morse, A.; Hernandez, I.; Quintana, J.; Choudhuri, A. Liquid Rocket Engine Performance Characterization Using Computational Modeling: Preliminary Analysis and Validation. Aerospace 2024, 11, 824. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, Y.; Yang, S.; Liu, X.; Wu, J. Dynamics modeling and simulation analysis of a reusable high-pressure staged combustion LOX/kerosene variable thrust rocket engine. Acta Astronaut. 2025, 233, 17–29. [Google Scholar] [CrossRef]

- Casiano, M.J.; Hulka, J.R.; Yang, V. Liquid-Propellant Rocket Engine Throttling: A Comprehensive Review. J. Propuls. Power 2010, 26, 897. [Google Scholar] [CrossRef]

- Haeseler, D.; Haidn, O.J. Russian Engine Technologies. In Chemical Rocket Propulsion: A Comprehensive Survey of Energetic Materials; De Luca, L.T., Shimada, T., Sinditskii, V.P., Calabro, M., Eds.; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Sutton, G.P. History of Liquid-Propellant Rocket Engines in Russia, Formerly the Soviet Union. J. Propuls. Power 2003, 19, 1008–1037. [Google Scholar] [CrossRef]

- Kang, S.H.; Moon, I.; Lee, S.Y. Experiments on an Oxidizer-Rich Preburner for Staged Combustion Cycle Rocket Engines. J. Propuls. Power 2014, 30, 1098–1103. [Google Scholar] [CrossRef]

- Kuznetsov, N. Closed-cycle liquid propellant rocket engines. In Proceedings of the 29th Joint Propulsion Conference and Exhibit, Monterey, CA, USA, 28–30 June 1993; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1993. [Google Scholar] [CrossRef]

- Norris, J.; Vernon, D. Apollo propulsion-system performance evaluation. In Proceedings of the 4th Propulsion Joint Specialist Conference, Cleveland, OH, USA, 10–14 June 1968; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1968. [Google Scholar] [CrossRef]

- Elverum, J.G.; Hoffman, A.; Miller, J.; Rockow, R. The descent engine for the lunar module. In Proceedings of the 3rd Propulsion Joint Specialist Conference, Washington, DC, USA, 17–21 July 1967; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1967. [Google Scholar] [CrossRef]

- Gilroy, R.; Sackheim, R. The Lunar Module descent engine–A historical summary. In Proceedings of the 25th Joint Propulsion Conference, Monterey, CA, USA, 12–16 July 1989; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1989. [Google Scholar] [CrossRef]

- Bradley, D.; Hooser, K.V. Space Shuttle Main Engine–The Relentless Pursuit of Improvement. In Proceedings of the AIAA SPACE 2011 Conference & Exposition, Long Beach, CA, USA, 27–29 September 2011. [Google Scholar]

- Furst, R. Space Shuttle Main Engine turbopump design and development. In Proceedings of the 11th Propulsion Conference, Anaheim, CA, USA, 29 September–1 October 1975; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1975. [Google Scholar] [CrossRef]

- Naderi, M.; Karimi, H.; Liang, G. Modeling the effect of reusability on the performance of an existing LPRE. Acta Astronaut. 2021, 181, 201–216. [Google Scholar] [CrossRef]

- Anderson, B.; Bradley, M.; Ives, J.; Anderson, B.; Bradley, M.; Ives, J. SSME key operations demonstration. In Proceedings of the 33rd Joint Propulsion Conference and Exhibit, Seattle, WA, USA, 6–9 July 1997. [Google Scholar] [CrossRef]

- Glover, R.C.; Kelley, B.A.; Tischer, A.E. Studies and Analyses of the Space Shuttle Main Engine: SSME Failure Data Review, Diagnostic Survey and SSME Diagnostic Evaluation; NTRS–NASA Technical Reports Server: Chicago, IL, USA, 1986. [Google Scholar][Green Version]

- Dunbar, D.; Waterman, R.; White, R.; Henley, M. The Atlas family–Evolving and growing to meet communications satellite needs. In Proceedings of the 14th International Communication Satellite Systems Conference and Exhibit, Washington, DC, USA, 22–26 March 1992. [Google Scholar] [CrossRef]

- Katorgin, B.; Chelkis, F.; Limerick, C. The RD-170, a different approach to launch vehicle propulsion. In Proceedings of the 29th Joint Propulsion Conference and Exhibit, Monterey, CA, USA, 28–30 June 1993; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1993. [Google Scholar] [CrossRef]

- Rachuk, V.; Goncharov, N.; Martynenko, Y.; Barinshtejn, B.; Sciorelli, F. Design, development, and history of the oxygen/hydrogen engine RD-0120. In Proceedings of the 31st Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 10–12 July 1995. [Google Scholar] [CrossRef]

- Dressler, G.; Bauer, J. TRW pintle engine heritage and performance characteristics. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000. [Google Scholar] [CrossRef]

- Giuliano, V.; Leonard, T.; Adamski, W.; Kim, T. CECE: A Deep Throttling Demonstrator Cryogenic Engine for NASA’s Lunar Lander. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, OH, USA, 8–11 July 2007; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2007. [Google Scholar] [CrossRef]

- Giuliano, V.; Leonard, T.; Lyda, R.; Kim, T. CECE: Expanding the Envelope of Deep Throttling in Liquid Oxygen/Liquid Hydrogen Rocket Engines For NASA Exploration Missions. In Proceedings of the 46th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Nashville, TN, USA, 25–28 July 2010; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2010. [Google Scholar] [CrossRef]

- Belousov, A.I.; Ponomarev, Y.K. Spatial vibration protection in a turbopump of hydrogen rocket engines. Russ. Aeronaut. (Iz VUZ) 2016, 59, 388–394. [Google Scholar] [CrossRef]

- Gulczyński, M.T.; Hahn, R.H.S.; Deeken, J.C.; Oschwald, M. Turbopump Parametric Modelling and Reliability Assessment for Reusable Rocket Engine Applications. Aerospace 2024, 11, 808. [Google Scholar] [CrossRef]

- Sippel, M.; Wilken, J. Selection of propulsion characteristics for systematic assessment of future European RLV-options. CEAS Space J. 2025, 17, 89–111. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, Q.; Bin, F.; Qiu, Y.; Yang, Z.; Zhao, Y.; Wei, X. Fundamental research progress in regenerative cooling for methane engine thrust chambers. Appl. Therm. Eng. 2025, 258, 124572. [Google Scholar] [CrossRef]

- Melcher, J.C.; Morehead, R.L. Combustion Stability Characteristics of the Project Morpheus Liquid Oxygen / Liquid Methane Main Engine. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2014. [Google Scholar] [CrossRef]

- Morehead, R. Project Morpheus Main Engine Development and Preliminary Flight Testing. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2011. [Google Scholar] [CrossRef]

- Baiocco, P. Overview of reusable space systems with a look to technology aspects. Acta Astronaut. 2021, 189, 10–25. [Google Scholar] [CrossRef]

- Nikitaeva, D.; Dale Thomas, L. Propulsion Alternatives for Mars Transportation Architectures. J. Spacecr. Rocket. 2023, 60, 520–532. [Google Scholar] [CrossRef]

- He, H.; Yu, N.; Di, S.; Cai, G.; Zhou, C.; Zheng, L. Static Equilibrium Characteristics of Full-Flow Staged Combustion Cycle Engine Under Different Propellants. Int. J. Aerosp. Eng. 2024, 2024, 7114250. [Google Scholar] [CrossRef]

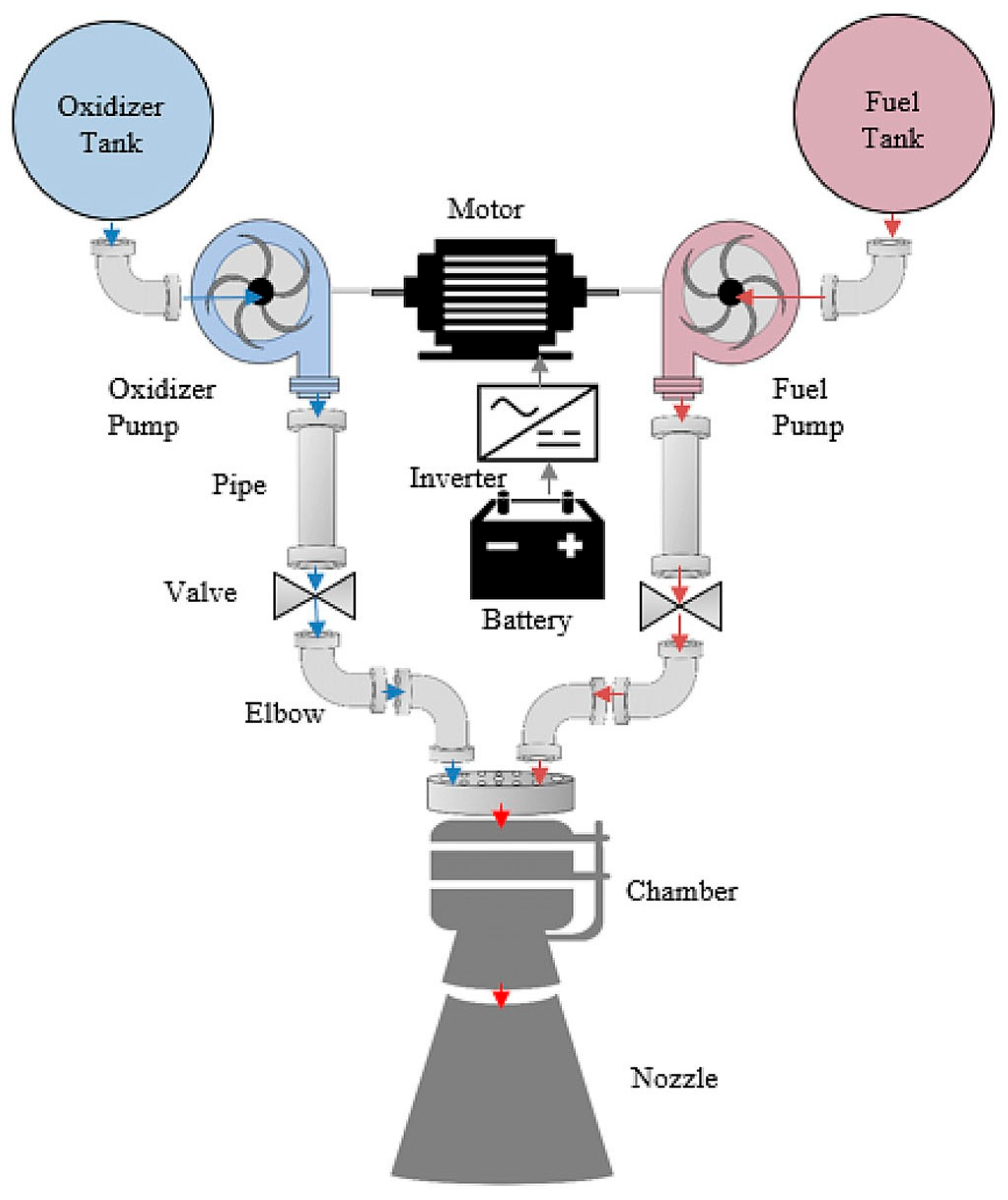

- Cui, P.; Li, Q.; Cheng, P.; Chen, L. System scheme design for LOX/LCH4 variable thrust liquid rocket engines using motor pump. Acta Astronaut. 2020, 171, 139–150. [Google Scholar] [CrossRef]

- Juanping, L.; Xiaohui, L.; Rongjun, Z.; Wei, C. The development of 7500 N variable thrust engine for Chang’E-3. Sci. China Technol. Sci. 2014, 44, 569–575. (In Chinese) [Google Scholar] [CrossRef]

- Wan, W.X.; Wang, C.; Li, C.L.; Wei, Y. China’s first mission to Mars. Nat. Astron. 2020, 4, 721. [Google Scholar] [CrossRef]

- Li, C.; Zuo, W.; Wen, W.; Zeng, X.; Gao, X.; Liu, Y.; Fu, Q.; Zhang, Z.; Su, Y.; Ren, X.; et al. Overview of the Chang’e-4 Mission: Opening the Frontier of Scientific Exploration of the Lunar Far Side. Space Sci. Rev. 2021, 217, 35. [Google Scholar] [CrossRef]

- Xin, H.; Shangqun, G.; Quandong, H.; Zhenxing, P. Development and Flight Performance of Chang’e5 Probe Propulsion System. J. Propuls. Technol. 2022, 43, 1–14. (In Chinese) [Google Scholar] [CrossRef]

- Yu, P.; Zhang, H.; Li, J.; Guan, Y.; Wang, L.; Zhao, Y.; Chen, Y.; Yang, W.; Yu, J.; Wang, H.; et al. Design and implementation of GNC system of lander and ascender module of Chang’e-5 spacecraft. Sci. Sin. Technol. 2021, 51, 763–777. (In Chinese) [Google Scholar] [CrossRef]

- Dong, L.; Yu, W.; Shiqiang, C. Key Technology Analysis of CZ-5 Launch Vehicle Propulsion System. J. Propuls. Technol. 2021, 42. (In Chinese) [Google Scholar] [CrossRef]

- Tan, Y. Research progress in high thrust liquid oxygen methane rocket engine technology. Acta Aeronaut. Et Astronaut. Sin. 2024, 45, 529690. (In Chinese) [Google Scholar] [CrossRef]

- Lee, J.; Roh, T.-S.; Huh, H.; Lee, H.J. Performance Analysis and Mass Estimation of a Small-Sized Liquid Rocket Engine with Electric-Pump Cycle. Int. J. Aeronaut. Space Sci. 2021, 22, 94–107. [Google Scholar] [CrossRef]

- Chen, F.; Xue, W.; Tang, Y.; Wang, T. A Comparative Research of Control System Design Based on H-Infinity and ALQR for the Liquid Rocket Engine of Variable Thrust. Int. J. Aerosp. Eng. 2023, 2023, 2155528. [Google Scholar] [CrossRef]

- Yao, Z.; Qi, Y.; Bao, W.; Zhang, T. Thrust Control Method and Technology of Variable-Thrust Liquid Engine for Reusable Launch Rocket. Aerospace 2023, 10, 32. [Google Scholar] [CrossRef]

- Witrant, E.; Landau, I.D.; Vaillant, M.-P. A data-driven control methodology applied to throttle valves. Control. Eng. Pract. 2023, 139, 105634. [Google Scholar] [CrossRef]

- Feng, Y.; Long, Y.; Yao, C.; Song, E. Adaptive Second-Order Fixed-Time Sliding Mode Controller with a Disturbance Observer for Electronic Throttle Valves. Sensors 2023, 23, 7676. [Google Scholar] [CrossRef]

- Zhou, X.; Zhi, X.-q.; Gao, X.; Chen, H.; Zhu, S.-l.; Wang, K.; Qiu, L.-m.; Zhang, X.-b. Cavitation evolution and damage by liquid nitrogen in a globe valve. J. Zhejiang Univ.-Sci. A 2022, 23, 101–117. [Google Scholar] [CrossRef]

- Esposito, C.; Mendez, M.A.; Steelant, J.; Vetrano, M.R. Spectral and modal analysis of a cavitating flow through an orifice. Exp. Therm. Fluid Sci. 2021, 121, 110251. [Google Scholar] [CrossRef]

- Harada, K.; Murakami, M.; Ishii, T. PIV measurements for flow pattern and void fraction in cavitating flows of He II and He I. Cryogenics 2006, 46, 648–657. [Google Scholar] [CrossRef]

- Esposito, C.; Steelant, J.; Vetrano, M.R. Impact of Cryogenics on Cavitation through an Orifice: A Review. Energies 2021, 14, 8319. [Google Scholar] [CrossRef]

- Tan, G.; Tian, H.; Lv, G. Experimental Study on Flow Coefficient of Variable Area Cavitating Venturi. In Proceedings of the 8th International Conference on Manufacturing, Material and Metallurgical Engineering (ICMMME) 2024, Djerba, Tunisia, 25–27 March 2013; Springer: Cham, Switzerland, 2025; pp. 139–148. [Google Scholar]

- Sekrecki, M. Cavitating Venturi as a Mass Flow Controller in a Deep Throttling Liquid Rocket Engine. Trans. Aerosp. Res. 2023, 2023, 72–86. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, H.; Wu, D.; Chen, H.; Feng, K.; Zhao, C.; Wu, D. Experimental investigation of the dynamic cavitation behavior and wall static pressure characteristics through convergence-divergence venturis with various divergence angles. Sci. Rep. 2020, 10, 14172. [Google Scholar] [CrossRef]

- Hwang, H.J.; Park, J.; Min, J.K. A numerical study on the flow control characteristic of a cavitating venturi with one- and two-stage diffusers. J. Mech. Sci. Technol. 2021, 35, 1463–1472. [Google Scholar] [CrossRef]

- Shi, H.; Li, M.; Nikrityuk, P.; Liu, Q. Experimental and numerical study of cavitation flows in venturi tubes: From CFD to an empirical model. Chem. Eng. Sci. 2019, 207, 672–687. [Google Scholar] [CrossRef]

- Tan, G.; Tian, H.; Gu, X.; Meng, X.; Wei, T.; Zhang, Y.; Cai, G. Flow feedback control based on variable area cavitating venturi and its application in hybrid rocket motors. Acta Astronaut. 2023, 211, 238–248. [Google Scholar] [CrossRef]

- Guang, T.; Hui, T.; Xianzhu, J.; Ruikai, C.; Yudong, L.; Yuanjun, Z. Experimental study on precise thrust control of hydrogen peroxide and polyethylene hybrid rocket motors. Acta Astronaut. 2022, 196, 303–313. [Google Scholar] [CrossRef]

- Tian, H.; Zeng, P.; Yu, N.; Cai, G. Application of variable area cavitating venturi as a dynamic flow controller. Flow Meas. Instrum. 2014, 38, 21–26. [Google Scholar] [CrossRef]

- Apte, D.; Ge, M.; Coutier-Delgosha, O. Investigation of cloud cavitating flow in a venturi using adaptive mesh refinement. J. Hydrodyn. 2024, 36, 898–913. [Google Scholar] [CrossRef]

- Kang, C.; Lee, S.; Ahn, K. Combustion Characteristics of Shear Coaxial Injectors with Different Recess Lengths Under Wide Operating Conditions. Int. J. Aeronaut. Space Sci. 2025, 26, 172–185. [Google Scholar] [CrossRef]

- Long, M.; Bazarov, V.; Anderson, W. Main Chamber Injectors for Advanced Hydrocarbon Booster Engines. In Proceedings of the 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Salt Lake City, UT, USA, 8–11 July 2001; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2003. [Google Scholar] [CrossRef]

- Sharonov, I.V.; Sheikhaliev, S.M.; Popel, S.I.; Sharonov, V.M. Effect of the design parameters of a centrifugal injector on its rate of output and on the particle size of powders. Sov. Powder Metall. Met. Ceram. 1989, 28, 834–836. [Google Scholar] [CrossRef]

- Ninish, S.; Vaidyanathan, A.; Nandakumar, K. Spray characteristics of liquid-liquid Pintle injector. Exp. Therm. Fluid Sci. 2018, 97, 324–340. [Google Scholar] [CrossRef]

- Son, M.; Yu, K.; Koo, J.; Kwon, O.C.; Kim, J.S. Effects of momentum ratio and Weber number on spray half angles of liquid controlled pintle injector. J. Therm. Sci. 2015, 24, 37–43. [Google Scholar] [CrossRef]

- Mueller, T.; Dressler, G. TRW 40 klbf LOX/RP-1 low cost pintle engine test results. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000. [Google Scholar] [CrossRef]

- Gromski, J.; Majamaki, A.; Chianese, S.; Weinstock, V.; Kim, T. Northrop Grumman TR202 LOX/GH2 Deep Throttling Engine Project Status. In Proceedings of the 46th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Nashville, TN, USA, 25–28 July 2010; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2010. [Google Scholar] [CrossRef]

- Cheng, P.; Li, Q.; Xu, S.; Kang, Z. On the prediction of spray angle of liquid-liquid pintle injectors. Acta Astronaut. 2017, 138, 145–151. [Google Scholar] [CrossRef]

- Freeberg, J.; Hogge, J. Spray Cone Formation from Pintle-Type Injector Systems in Liquid Rocket Engines. In AIAA Scitech 2019 Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2019. [Google Scholar] [CrossRef]

- Heo, S.; Jeong, J.; Kim, D.H.; Yoon, Y.; Lee, B.J. Spray angle prediction model for a multi-slit type throttleable gas–liquid pintle injector. Acta Astronaut. 2025, 231, 113–126. [Google Scholar] [CrossRef]

- Nardi, R.; Perez, V.; Pimenta, A. Experiments with Pintle Injector Design and Development. In Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015. [Google Scholar] [CrossRef]

- Rajendran, R.; Prasad, S.; Subhashree, S.; Phutane, T.S.; Saoor, V.S. Design and optimization of pintle injector for liquid rocket engine. Int. J. Eng. Appl. Sci. Technol. 2020, 5, 151–159. [Google Scholar] [CrossRef]

- Mishra, A.; Kavipriya, J. A Technical Review on effect of spray angles and characteristics for a pintle injector. J. Adv. Eng. Technol. 2021, 7, 30–36. [Google Scholar]

- Cha, J.; Andersson, E.; Bohlin, A. A Numerical Approach to Optimize the Design of a Pintle Injector for LOX/GCH4 Liquid-Propellant Rocket Engine. Aerospace 2023, 10, 582. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, Y.; Cheng, P.; Bai, X.; Li, Q. Flow and spray characteristics of a gas–liquid pintle injector under backpressure environment. Phys. Fluids 2024, 36, 4. [Google Scholar] [CrossRef]

- Li, T.; Yu, N.; Zhao, Z.; Zhao, Y. Experimental Investigation on a Throttleable Pintle-Centrifugal Injector. Appl. Sci. 2025, 15, 2696. [Google Scholar] [CrossRef]

- Radhakrishnan, K.; Son, M.; Lee, K.; Koo, J. Effect of injection conditions on mixing performance of pintle injector for liquid rocket engines. Acta Astronaut. 2018, 150, 105–116. [Google Scholar] [CrossRef]

- Tao, L.; Runsheng, H.; Qinglian, L.; Peng, C.; Jie, S.; Lanwei, C. Thrust control scheme for electric expander cycle of variable thrust liquid rocket engine. J. Aerosp. Power 2023, 38, 2957–2972. (In Chinese) [Google Scholar] [CrossRef]

- Crocco, L. Research on combustion instability in liquid propellant rockets. Symp. Int. Combust. 1969, 12, 85–99. [Google Scholar] [CrossRef]

- Zinn, B.T.; Powell, E.A. Nonlinear combustion instability in liquid-propellant rocket engines. Symp. Int. Combust. 1971, 13, 491–503. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, P.; Jin, B.; Ao, W. Nonlinear characteristics of the triggering combustion instabilities in solid rocket motors. Acta Astronaut. 2020, 176, 371–382. [Google Scholar] [CrossRef]

- Rachuk, V.; Goncharov, N.; Martinyenko, Y.; Fanciullo, T. Evolution of the RD-0120 for future launch systems. In Proceedings of the 32nd Joint Propulsion Conference and Exhibit, Lake Buena Vista, FL, USA, 1–3 July 1996; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1996. [Google Scholar] [CrossRef]

- Dai, X.; Ray, A. Damage-Mitigating Control of a Reusable Rocket Engine: Part II—Formulation of an Optimal Policy. J. Dyn. Syst. Meas. Control. 1996, 118, 409–415. [Google Scholar] [CrossRef]

- Kiforenko, B.N.; Kharitonov, A.M. Control of thrust of the liquid rocket engines: Simulation and optimization. J. Autom. Inf. Sci. 2000, 32, 47–63. [Google Scholar]

- Sekita, R.; Yasui, M.; Warashina, S. The LE-5 series development, approach to higher thrust, higher reliability and greater flexibility. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000. [Google Scholar] [CrossRef]

- Sunakawa, H.; Kurosu, A.; Okita, K.; Sakai, W.; Maeda, S.; Ogawara, A. Automatic Thrust and Mixture Ratio Control of LE-X. In Proceedings of the 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Hartford, CT, USA, 21–23 July 2008. [Google Scholar] [CrossRef]

- Hu, R.; Ferrari, R.M.G.; Chen, Z.; Cheng, Y.; Zhu, X.; Cui, X.; Wu, J. System analysis and controller design for the electric pump of a deep-throttling rocket engine. Aerosp. Sci. Technol. 2021, 114, 106729. [Google Scholar] [CrossRef]

- Sopegno, L.; Livreri, P.; Stefanovic, M.; Valavanis, K.P. Thrust Vector Controller Comparison for a Finless Rocket. Machines 2023, 11, 394. [Google Scholar] [CrossRef]

- Santana, A., Jr.; Barbosa, F.; Niwa, M.; Goes, L. Modeling and robust analysis of a liquid rocket engine. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000. [Google Scholar] [CrossRef]

- Kamath, A.G. Robust Thrust Vector Control for Precision Rocket-Landing; University of California: Davis, CA, USA, 2021. [Google Scholar]

- Kurniawan, J.L.; Adi, O.B.; Baylon, P.B.A.; Jenie, Y.I.; Arifianto, O. Robust Controller Design for Planar Rocket with Thrust Vectoring Control. In Proceedings of the 2023 IEEE International Conference on Aerospace Electronics and Remote Sensing Technology (ICARES), Bali, Indonesia, 26–27 October 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Pérez-Roca, S.; Marzat, J.; Piet-Lahanier, H.; Langlois, N.; Galeotta, M.; Farago, F.; Gonidec, S.L. Model-Based Robust Transient Control of Reusable Liquid-Propellant Rocket Engines. IEEE Trans. Aerosp. Electron. Syst. 2021, 57, 129–144. [Google Scholar] [CrossRef]

- Waxenegger-Wilfing, G.; Dresia, K.; Deeken, J.; Oschwald, M. A Reinforcement Learning Approach for Transient Control of Liquid Rocket Engines. IEEE Trans. Aerosp. Electron. Syst. 2021, 57, 2938–2952. [Google Scholar] [CrossRef]

- Bucci, M.A.; Semeraro, O.; Allauzen, A.; Cordier, L.; Mathelin, L. Nonlinear Optimal Control Using Deep Reinforcement Learning. In IUTAM Laminar-Turbulent Transition; IUTAM Bookseries; Springer International Publishing: Cham, Switzerland, 2022; Volume 38, pp. 279–290. [Google Scholar]

- Dresia, K.; Waxenegger-Wilfing, G.; Hahn, R.H.D.S.; Deeken, J.C.; Oschwald, M. Nonlinear Control of an Expander-Bleed Rocket Engine using Reinforcement Learning. In Space Propulsion; German Aerospace Center: Lampoldshausen, Germany, 2021. [Google Scholar]

- Jimenez Mena, D.; Pluchart, S.; Mouvand, S.; Broca, O. Rocket Engine Digital Twin-Modeling and Simulation Benefits. In AIAA Propulsion and Energy 2019 Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2019. [Google Scholar] [CrossRef]

- Ye, Y.; Yang, Q.; Yang, F.; Huo, Y.; Meng, S. Digital twin for the structural health management of reusable spacecraft: A case study. Eng. Fract. Mech. 2020, 234, 107076. [Google Scholar] [CrossRef]

- Pylypenko, O.; Olexiy, N.; Dolgopolov, S.I.; Khoryak, N.V. Evaluation of the scatter of liquid launch vehicle pogo oscillation amplitudes due to the influence of the scatter of internal factors. Space Sci. Technol. 2024, 30, 3–15. [Google Scholar] [CrossRef]

- Yang, X.; Liu, H.; Lu, D.; Zhao, W. Investigation of the dynamic electromechanical coupling due to the thrust harmonics in the linear motor feed system. Mech. Syst. Signal Process. 2018, 111, 492–508. [Google Scholar] [CrossRef]

| Engine | Flow Rate Regulation Schemes | Regulation Range | Injector | Thrust Regulation Schemes |

|---|---|---|---|---|

| LMDE | Adjustable cavitating Venturi tubes | 10~100% | Pintle Injector | Double regulation |

| SSME | Throttle Valve and Turbopump | 50~109% | Coaxial Injector | Single regulation |

| CECE | Bypass Valve and Turbopump | 10~100% | Coaxial Injector | Double regulation |

| TR-202 | Throttle Valve and Turbopump | 18.8~100% | Pintle Injector | Double regulation |

| 7500 N | Adjustable cavitating Venturi tubes | 20~100% | Pintle Injector | Double regulation |

| Morpheus | Electric Motor and Double Ball Valves | 25~100% | Impinging Injector | Single regulation |

| Merlin-1D | Throttle Valve and Turbopump | 75~100% | Pintle Injector | Double regulation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Long, X.; Xu, B.; Ding, H.; Wu, X.; Yang, W.; Zhao, W.; Liu, S. Review of Thrust Regulation and System Control Methods of Variable-Thrust Liquid Rocket Engines in Space Drones. Actuators 2025, 14, 385. https://doi.org/10.3390/act14080385

Sun M, Long X, Xu B, Ding H, Wu X, Yang W, Zhao W, Liu S. Review of Thrust Regulation and System Control Methods of Variable-Thrust Liquid Rocket Engines in Space Drones. Actuators. 2025; 14(8):385. https://doi.org/10.3390/act14080385

Chicago/Turabian StyleSun, Meng, Xiangzhou Long, Bowen Xu, Haixia Ding, Xianyu Wu, Weiqi Yang, Wei Zhao, and Shuangxi Liu. 2025. "Review of Thrust Regulation and System Control Methods of Variable-Thrust Liquid Rocket Engines in Space Drones" Actuators 14, no. 8: 385. https://doi.org/10.3390/act14080385

APA StyleSun, M., Long, X., Xu, B., Ding, H., Wu, X., Yang, W., Zhao, W., & Liu, S. (2025). Review of Thrust Regulation and System Control Methods of Variable-Thrust Liquid Rocket Engines in Space Drones. Actuators, 14(8), 385. https://doi.org/10.3390/act14080385