Gyro-System for Guidance with Magnetically Suspended Gyroscope, Using Control Laws Based on Dynamic Inversion

Abstract

1. Introduction

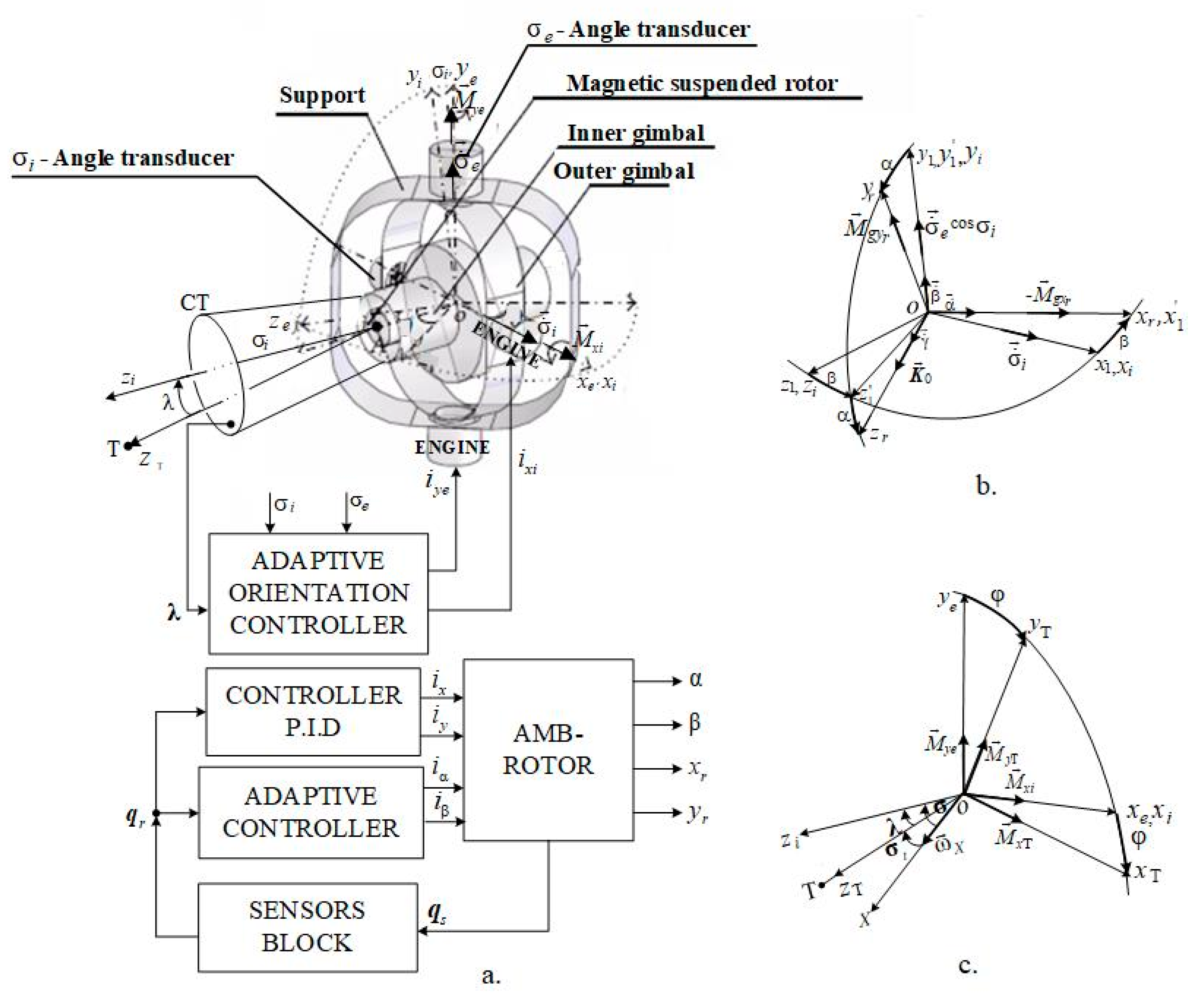

2. The Structure of a DGMSGG, the Reference Frames, and the Defining Angular Parameters

3. Nonlinear Dynamic Models of the Rotor and Gimbals

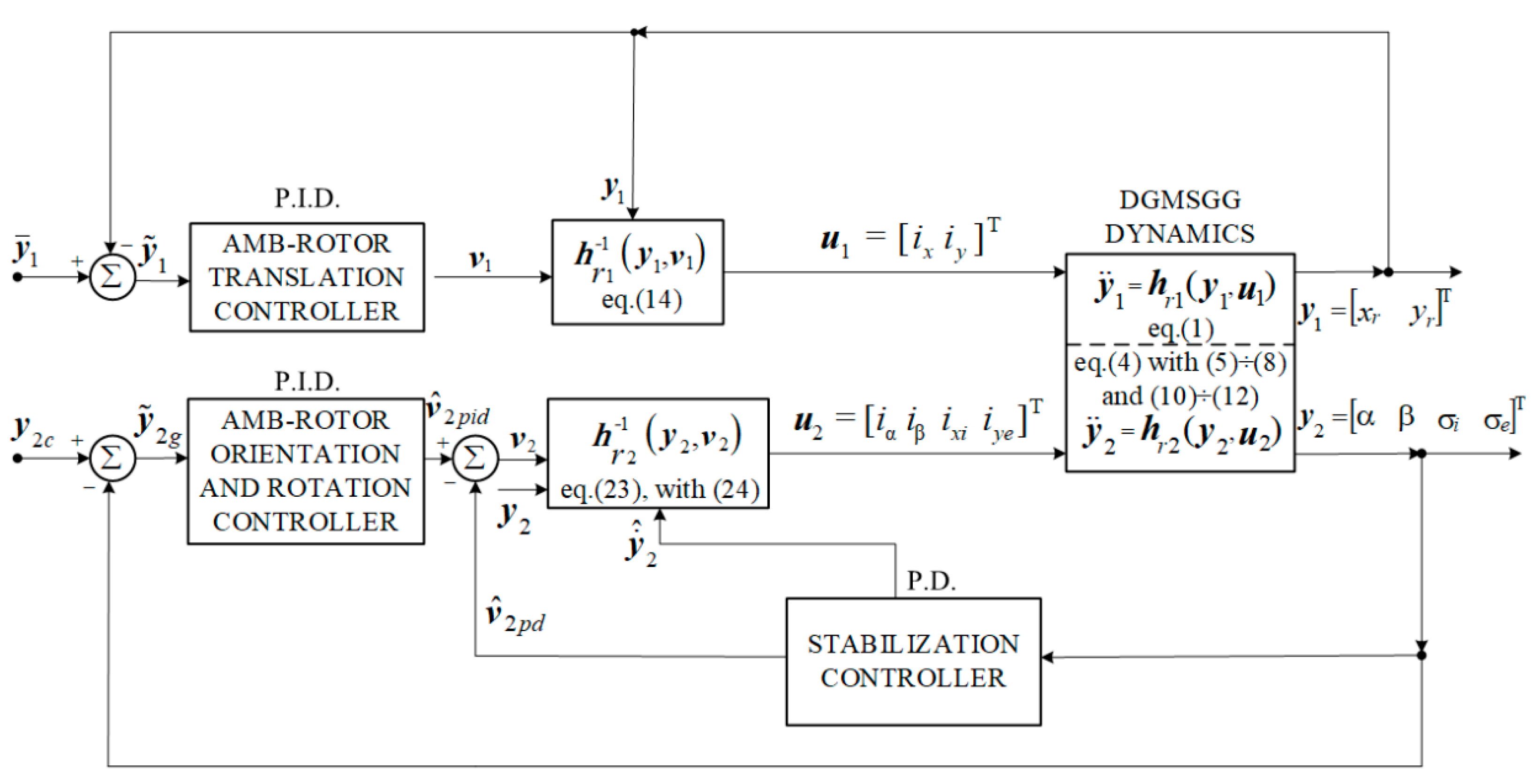

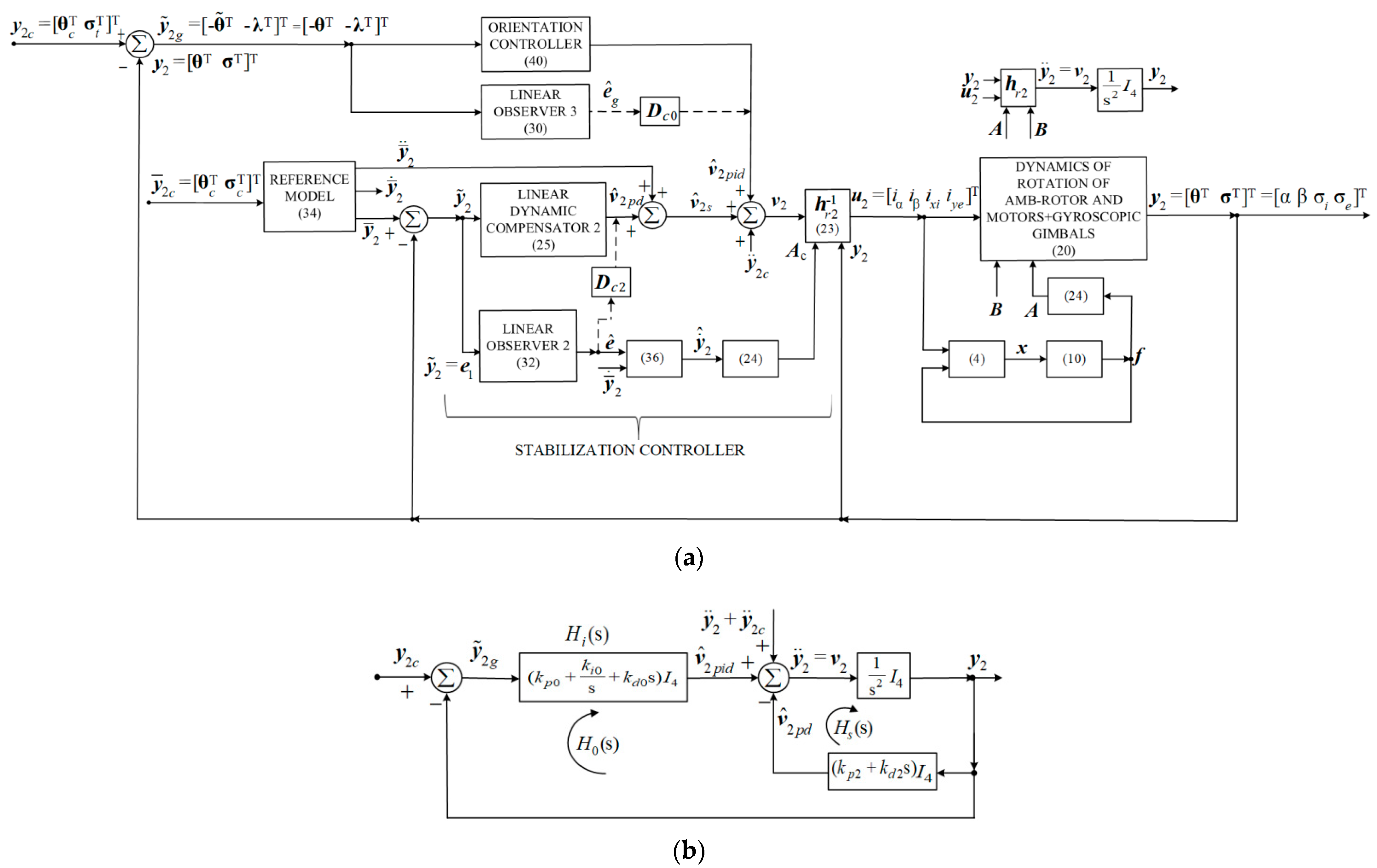

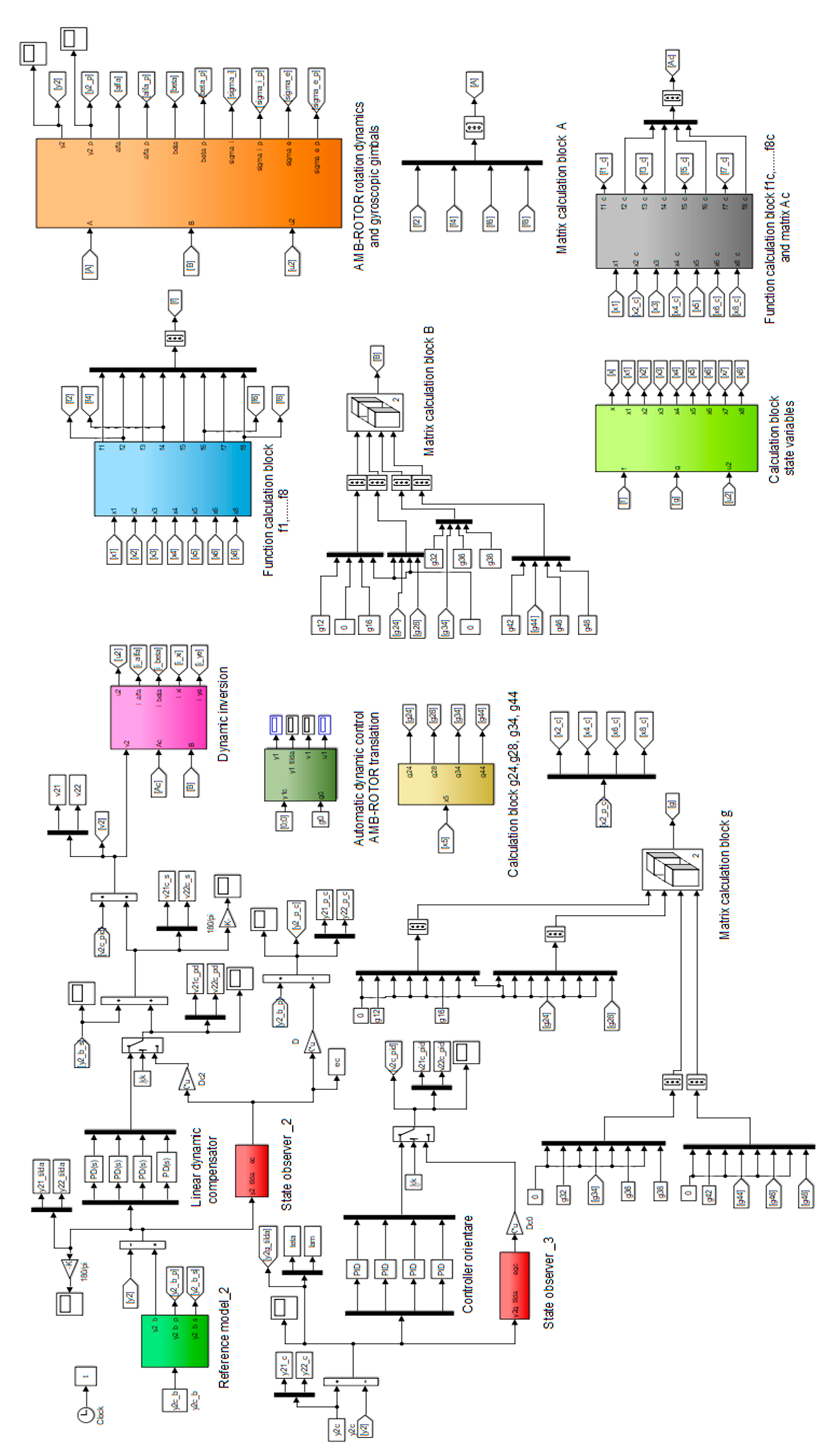

4. Structure of the DGMSGG’s Automatic Control System Based on the Dynamic Inversion Concept

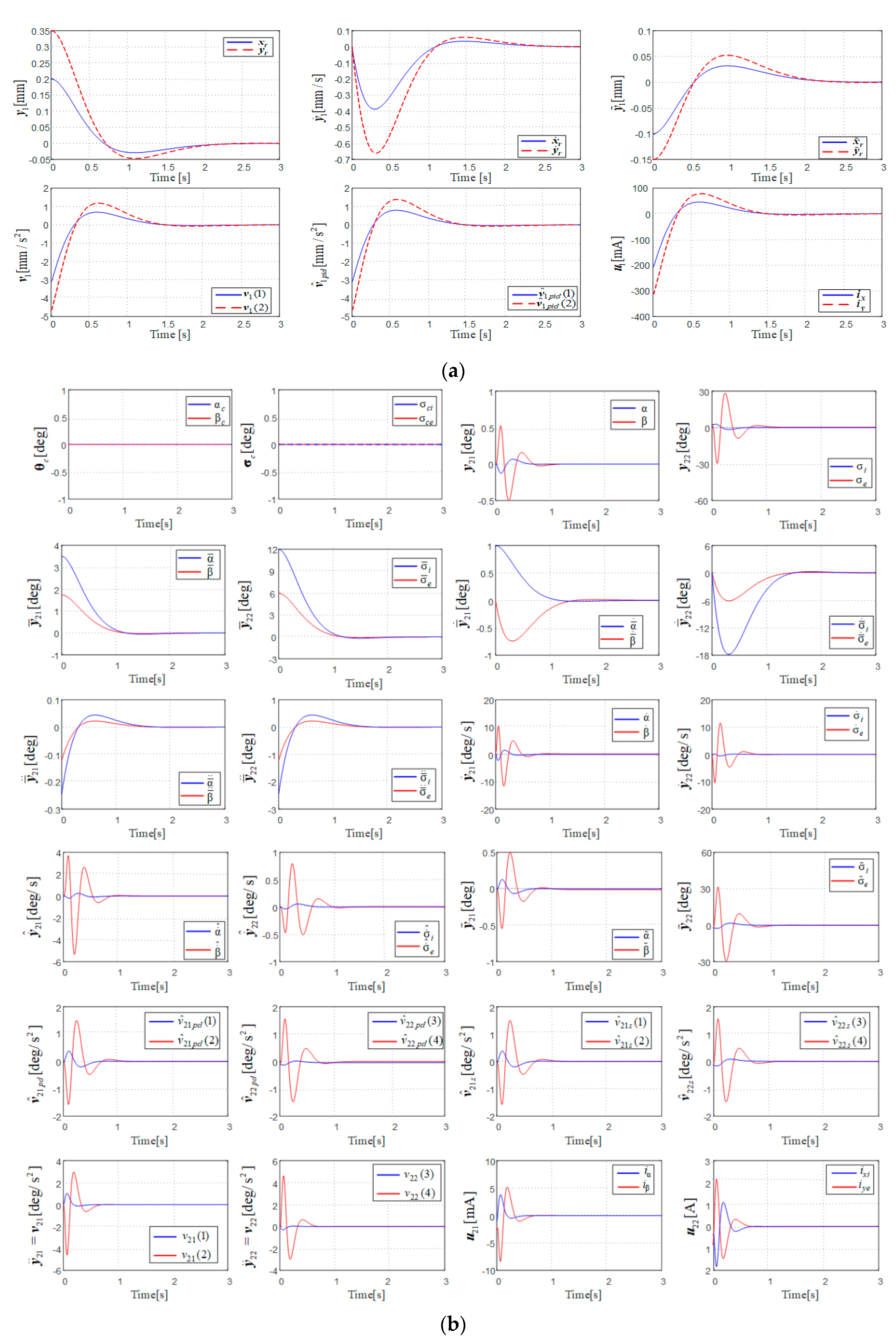

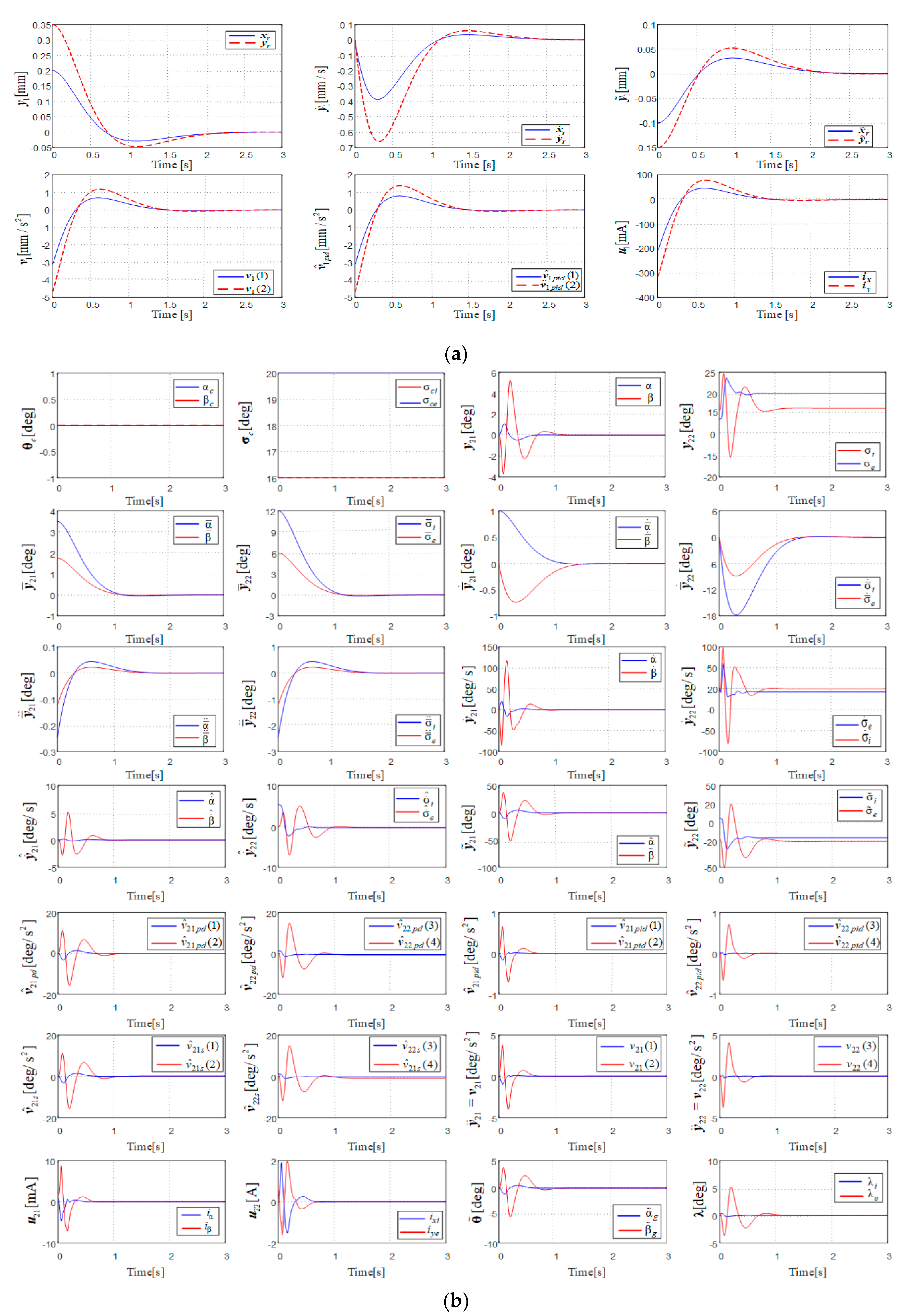

5. The Design of DGMSGG’s Automatic Control Subsystems

6. Results and Discussions

7. Conclusions

- A new form of nonlinear dynamic model described by equations of state for the interconnected dynamics of AMB–rotor’s rotations and of gyroscopic gimbals’ rotations;

- Decoupling the dynamics of the AMB–rotor’s translations from the dynamics of its rotations and of the gimbals’ rotations;

- Determination of the nonlinear input–output vector equation, which highlights the relative degrees of the model in relation to the variables of the output vector , using a theory of differential geometry (based on the Lie derivative calculus);

- Design of the output vector control structure using the dynamic inversion concept, comprising two subsystems: one for stabilization (with reference model and stabilization controller, consisting of a linear dynamic compensator of P.D.-type and linear state observer); another one for orientation (with P.I.D-type orientation controller and linear state observer);

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Bai, J.G.; Zhang, X.Z.; Wang, L.M. A Flywheel Energy Storage System with Active Magnetic Bearings. In Proceedings of the 2012 International Conference on Future Energy, Environment and Material, Hong Kong, China, 12–13 April 2012; pp. 1124–1128. [Google Scholar]

- Li, H.; Ning, X.; Han, B. Speed Tracking Control for Gimbal System Harmonic Drive. In Control Engineering Practice, no.58; Elsevier: Amsterdam, The Netherlands, 2017; pp. 204–213. [Google Scholar]

- Sasaki, T.; Shimomura, T.; Schaub, H. Robust attitude control using a double-gimbal variable-speed control moment gyroscope. J. Spacecr. Rocket. 2018, 55, 1235–1247. [Google Scholar] [CrossRef]

- Zheng, S.; Han, B. Investigations of an Integrated Angular Velocity Measurement and Attitude Control System for Spacecraft Using Magnetically Suspended Double-Gimbal CMGs. Adv. Space Res. 2013, 51, 2216–2228. [Google Scholar] [CrossRef]

- Leeghim, H.; Kim, D. Singularity-robust control moment gyro allocation strategy for spacecraft attitude control in the presence. of disturbances. Aerosp. Sci. Technol. 2021, 119, 107178. [Google Scholar] [CrossRef]

- Lungu, R.; Lungu, M.; Ioan, M. Determination and control of the satellites’ attitude by using a pyramidal configuration of four control moment gyros. In Proceedings of the 12th IEEE International Conference on Informatics in Control, Automation and Robotics, Colmar, France, 21–23 July 2015; pp. 448–456. [Google Scholar]

- Ma, Z.Q.; Huang, P.F. Discrete-time sliding mode control for deployment of tethered space robot with only length and angle measurement. IEEE Trans. Aerosp. Electron. Syst. 2020, 56, 585–596. [Google Scholar] [CrossRef]

- Schweitzer, G. Active Magnetic Bearings—Chances and Limitations. In International Center for Magnetic Bearings; EHT Zurich: Zürich, Switzerland, 2002. [Google Scholar]

- Yue, C.; Kuman, K.D.; Shen, Q.; Gogh, C.H.; Lee, T.H. Attitude Stabilization Using Two Parallel Single-Gimbal Control Moment Gyroscopes. J. Guid. Control Dyn. 2019, 42, 1353–1364. [Google Scholar] [CrossRef]

- Kim, H.Y.; Lee, C.W. Design and Control of Active Magnetic Bearings System with Lorentz Force-Type Axial Actuator. Mechatronics 2006, 16, 13–20. [Google Scholar] [CrossRef]

- Yoon, H. Spacecraft Attitudne and Power Control Using Variable Control Moment Gyros. Ph.D. Thesis, Georgia Insitute of Technology, Atlanta, GA, USA, 2004. [Google Scholar]

- Shelke, S. Controllability of Radial Magnetic Bearing. In Proceedings of the 3rd International Conference of Innovation Automation and Mechatronics Engineering, ICIAME, Vallabh Vidhyanagar, India, 5–6 February 2016; pp. 106–113. [Google Scholar]

- Fang, J.; Sheng, S.; Han, B. AMB Vibration Control for Double-Gimbal Control Moment Gyro With High-Speed Magnetically Suspended Rotor. IEEE Trans. Mechatron. 2013, 18, 32–43. [Google Scholar] [CrossRef]

- Lungu, R.; Ioan, M.; Lungu, M. Control of Satellites’ Attitude; Sitech Publisher: Craiova, Romania, 2017. [Google Scholar]

- Lungu, R.; Lungu, M.; Efrim, C. Adaptive Control of DGMSCMG Using Dynamic Inversion and Neural Networks. Adv. Space Res. 2021, 68, 3478–3494. [Google Scholar] [CrossRef]

- Su, D.; Xu, S. The Precise Control of a Double Gimbal MSCMG Based on Modal Separation and Feedback Linearization. In Proceedings of the 2013 International Conference on Electrical Machines and Systems, Busan, Republic of Korea, 26–29 October 2013; pp. 1355–1360. [Google Scholar]

- Peng, C.; Fang, J.; Xu, S. Composite Anti-Disturbance Controller for Magnetically Suspended Control Moment Gyro Subject to Mismatched Disturbances. Nonlinear Dyn. 2015, 79, 1563–1573. [Google Scholar] [CrossRef]

- Chen, X.; Chen, M. Precise Control of Magnetically Suspended Doble-Gimbal Control Moment Gyroscope Using Differential Geometric Decoupling Method. Chin. J. Aeronaut. 2013, 26, 1017–1028. [Google Scholar] [CrossRef]

- Lungu, R.; Efrim, C.; Zheng, Z.; Lungu, M. Dynamic Inversion Based on Control of DGMSCMGs. Part 2: Control Arhitecture Design and Validation. In Proceedings of the IEEE International Conference on Applied and Theroretical Electricity (ICATE 2021), Craiova, Romania, 27–29 May 2021; pp. 7–12. [Google Scholar]

- Bunryo, Y.; Satoh, S.; Shoji, Y.; Yamada, K. Feedback Attitude Control of Spacecraft Using Two Single Gimbal Control Moment Gyros. Adv. Space Res. 2021, 68, 2713–2726. [Google Scholar] [CrossRef]

- Ahmed, J.; Bernstein, D.S. Adaptive Control of Double-Gimbal Control Moment Gyro with Unbalanced Rotor. J. Guid. Control Dyn. 2002, 25, 105–115. [Google Scholar] [CrossRef]

- Fang, J.; Ren, Y. Decoupling Control of Magnetically Suspended Rotor in a Control Moment Gyro Based on Inverse System Method. IEEE ASME Trans. Mechatron. 2012, 17, 1133–1144. [Google Scholar] [CrossRef]

- Lungu, M.; Lungu, R. Full-Order Observer Design for Linear Systems with Unknown Inputs. Int. J. Control 2012, 85, 1602–1615. [Google Scholar] [CrossRef]

- Lungu, R.; Tudosie, A.-N.; Lungu, M.-A.; Crăciunoiu, N.-C. Actuators with Two Double Gimbal Magnetically Suspended Control Moment Gyros for the Attitude Control of the Satellites. Micromachines 2024, 15, 1159. [Google Scholar] [CrossRef] [PubMed]

- Lungu, R.; Efrim, C.; Lungu, M. Gyroscopic Actuators; Sitech Publisher: Craiova, Romania, 2024. [Google Scholar]

- Lin, F.; Chen, S.; Huang, M. Adaptive Complementary Sliding-Mode Control for Thrust Active Magnetic Bearing System. Control Eng. Pract. 2011, 19, 711–722. [Google Scholar] [CrossRef]

- Lungu, R.; Mihai, C.-A.; Tudosie, A.-N. Guidance Gyro System with Two Gimbals and Magnetic Suspension Gyros Using Adaptive-Type Control Laws. Micromachines 2025, 16, 245. [Google Scholar] [CrossRef] [PubMed]

- Lungu, R.; Efrim, C.; Zheng, Z.; Lungu, M. Dynamic Inversion Based on Control of DGMSCMGs. Part 1: Obtaining Nonlinear Dynamic Model. In Proceedings of the IEEE International Conference on Applied and Theroretical Electricity (ICATE 2021), Craiova, Romania, 27–29 May 2021; pp. 1–6. [Google Scholar]

- Calise, A.J.; Hovakymyan, N.; Idan, M. Adaptive Output Control of Nonlinear Systems Using Neural Networks. Automatica 2001, 37, 1201–1211. [Google Scholar] [CrossRef]

- Isidori, A. Nonlinear Control Systems; Springer: Berlin, Germany, 1995. [Google Scholar]

- Lungu, R.; Lungu, M. Aircraft Landing Automatic Control; Sitech Publisher: Craiova, Romania, 2015. [Google Scholar]

- Lungu, R. Aerospace Guidance Systems; Sitech Publisher: Craiova, Romania, 2002. [Google Scholar]

- Lungu, R.; Mihai, C.A. Dynamic and Adaptive Control of Monoaxial GS with GAR. Part1: Obtaining the Nonlinear Dynamic Model. In Proceedings of the International Conference on Applied and Theoretical Electricity, ICATE 24, Craiova, Romania, 24–26 October 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Lungu, R.; Mihai, C.A. Dynamic and Adaptive Control of Monoaxial GS with GAR. Part 2: Control Architecture Design and Validation. In Proceedings of the International Conference on Applied and Theoretical Electricity, ICATE 24, Craiova, Romania, 24–26 October 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Mihai, C.A.; Lungu, R. Nonlinear Dynamics and Adaptive Control Using The Dynamic Inversion Concept and Neural Networks for a Guidance Gyrosystem (GG) with one Gyroscope and two Suspension Gimbals (GAR). Part 1: Obtaining the Nonlinear Dynamic Model. In Proceedings of the 26th Edition of the International Conference Scientific Research and Education in the Air Force, AFASES, Brasov, Romania, 22–24 May 2025. [Google Scholar] [CrossRef]

- Mihai, C.A. Nonlinear Dynamics and Adaptive Control Using The Dynamic Inversion Concept and Neural Networks for a Guidance Gyrosystem (GG) with one Gyroscope and two Suspension Gimbals (GAR). Part 2: Adaptive Control Arhitecture Design and Validation. In Proceedings of the 26th Edition of the International Conference Scientific Research and Education in the Air Force, AFASES, Brasov, Romania, 22–24 May 2025. [Google Scholar] [CrossRef]

- Lungu, M. Backstepping Control Method in Aerospace Engineering; Academia Greefswald: Rostock, Germany, 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lungu, R.; Mihai, C.-A.; Tudosie, A.-N. Gyro-System for Guidance with Magnetically Suspended Gyroscope, Using Control Laws Based on Dynamic Inversion. Actuators 2025, 14, 316. https://doi.org/10.3390/act14070316

Lungu R, Mihai C-A, Tudosie A-N. Gyro-System for Guidance with Magnetically Suspended Gyroscope, Using Control Laws Based on Dynamic Inversion. Actuators. 2025; 14(7):316. https://doi.org/10.3390/act14070316

Chicago/Turabian StyleLungu, Romulus, Constantin-Adrian Mihai, and Alexandru-Nicolae Tudosie. 2025. "Gyro-System for Guidance with Magnetically Suspended Gyroscope, Using Control Laws Based on Dynamic Inversion" Actuators 14, no. 7: 316. https://doi.org/10.3390/act14070316

APA StyleLungu, R., Mihai, C.-A., & Tudosie, A.-N. (2025). Gyro-System for Guidance with Magnetically Suspended Gyroscope, Using Control Laws Based on Dynamic Inversion. Actuators, 14(7), 316. https://doi.org/10.3390/act14070316