Metal Thickness Measurement Using an Ultrasonic Probe with a Linear Actuator for a Magnet-Type Climbing Robot: Design and Development

Abstract

1. Introduction

2. Materials and Methods

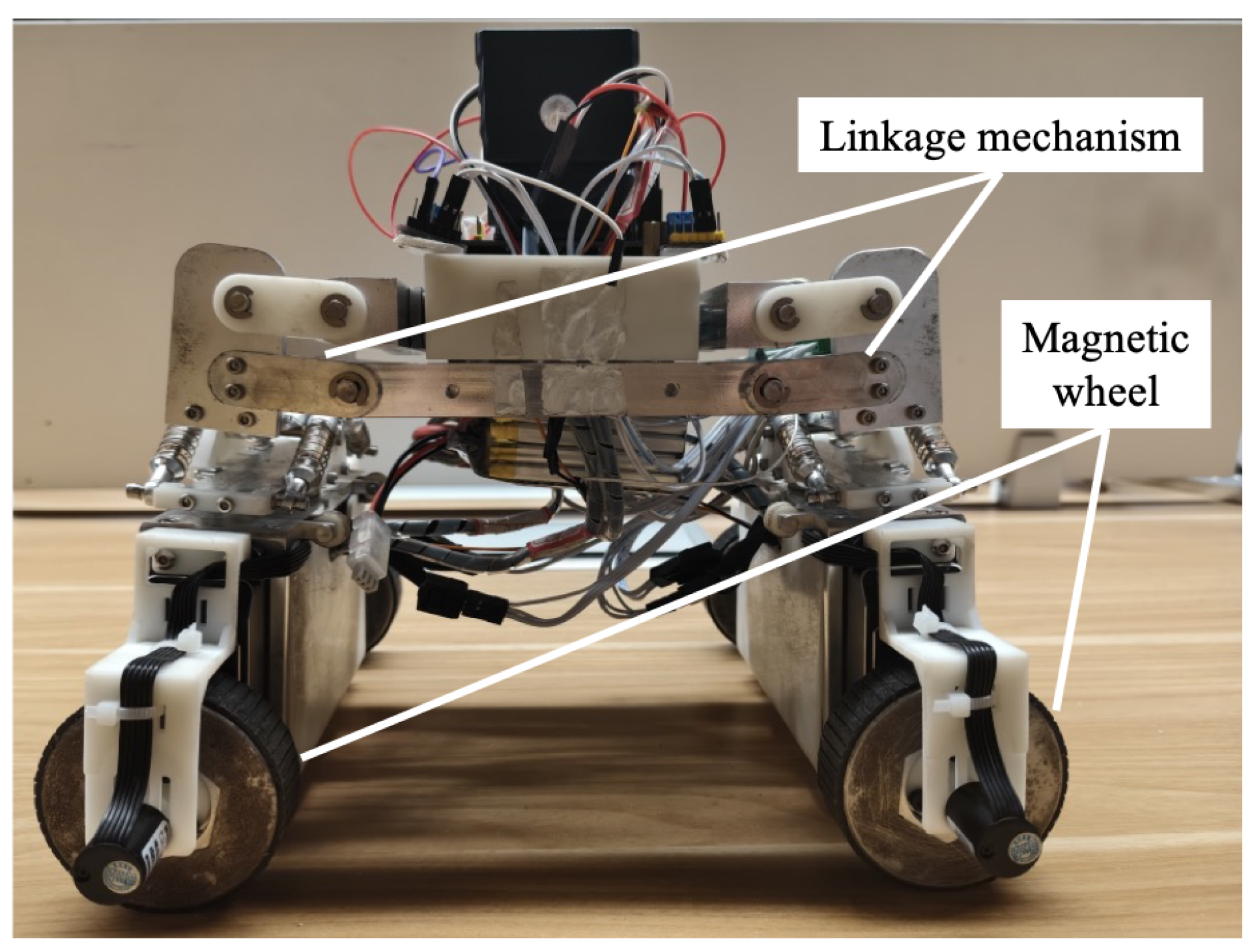

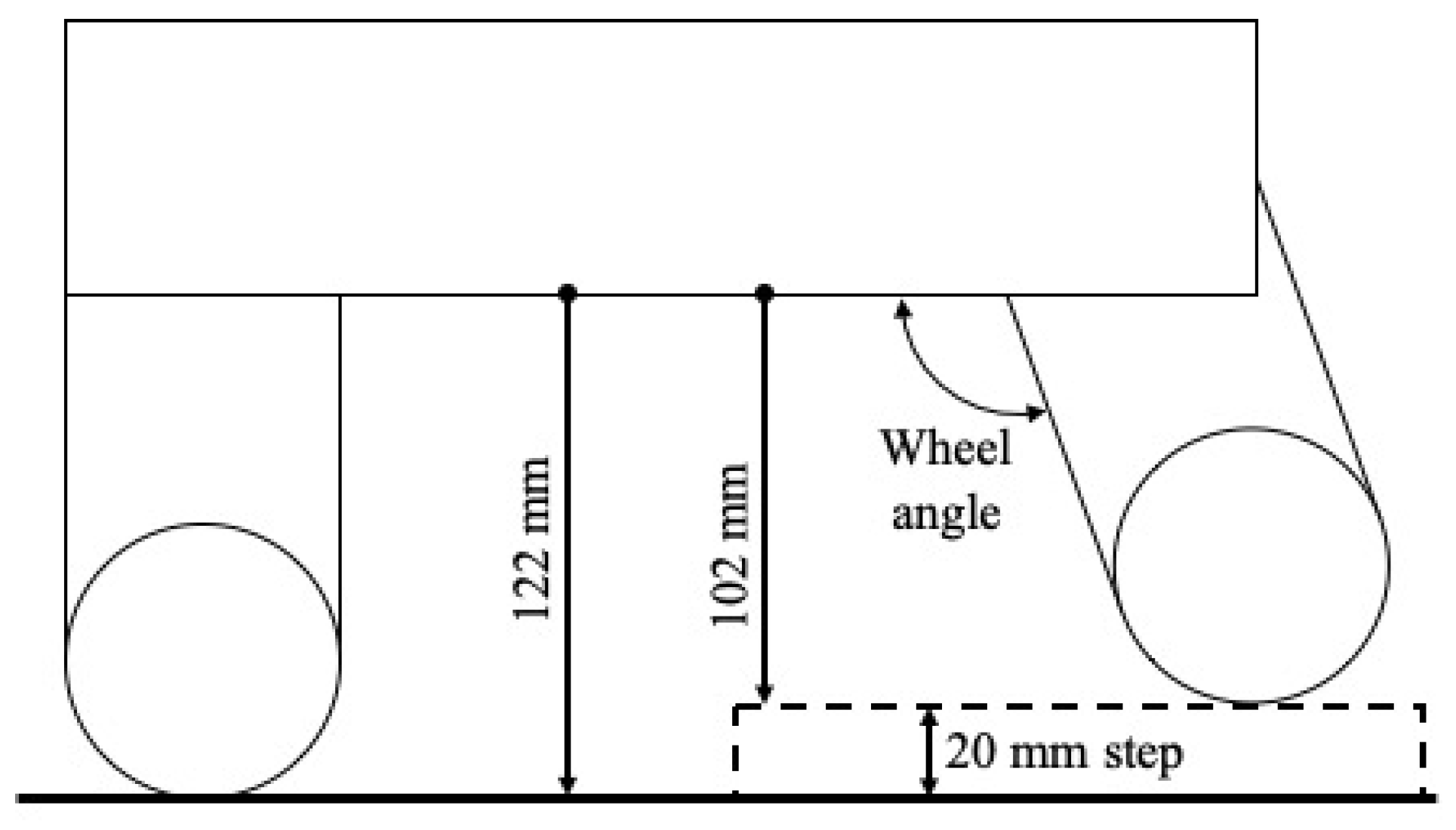

2.1. Magnet-Type Climbing Robot

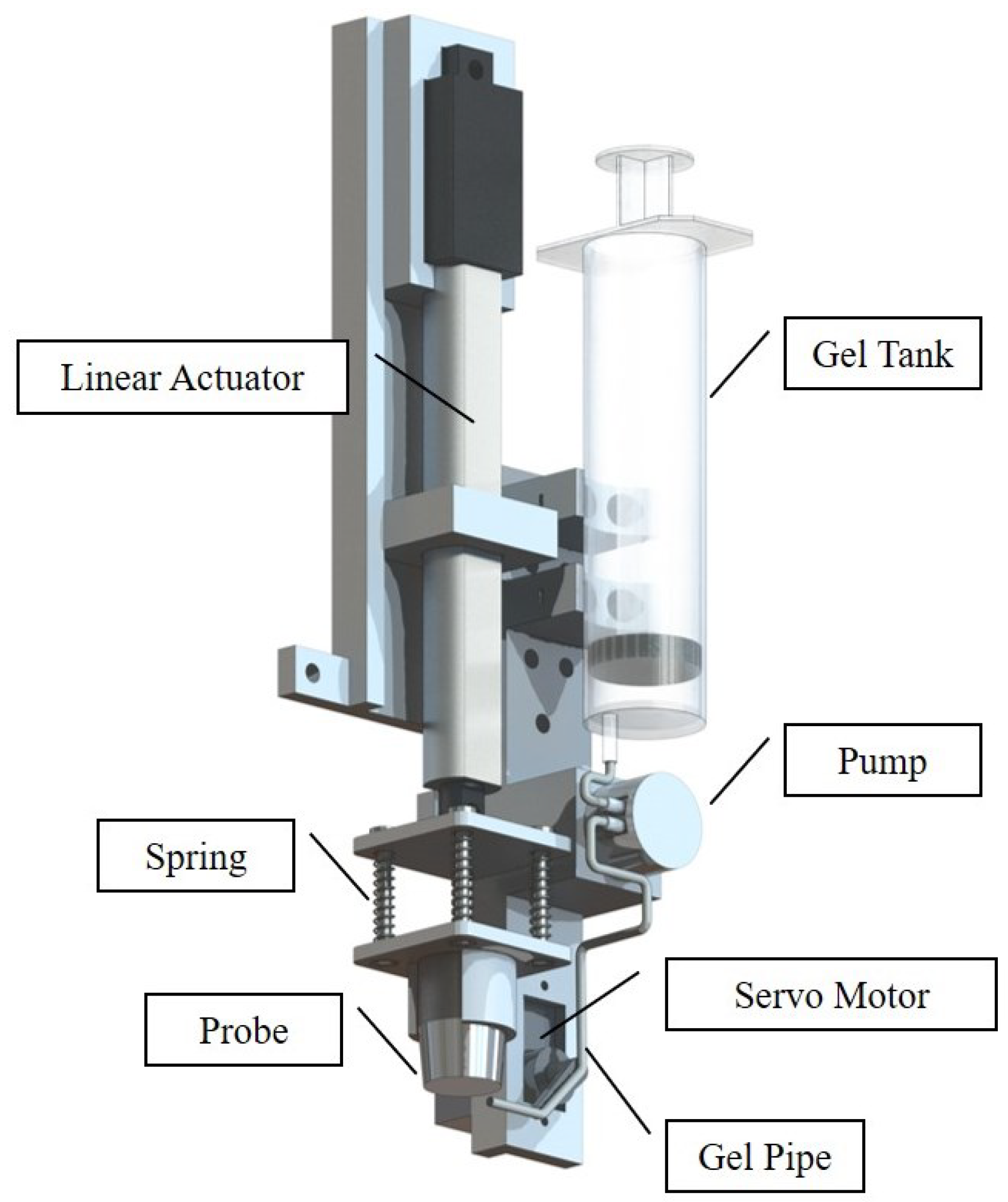

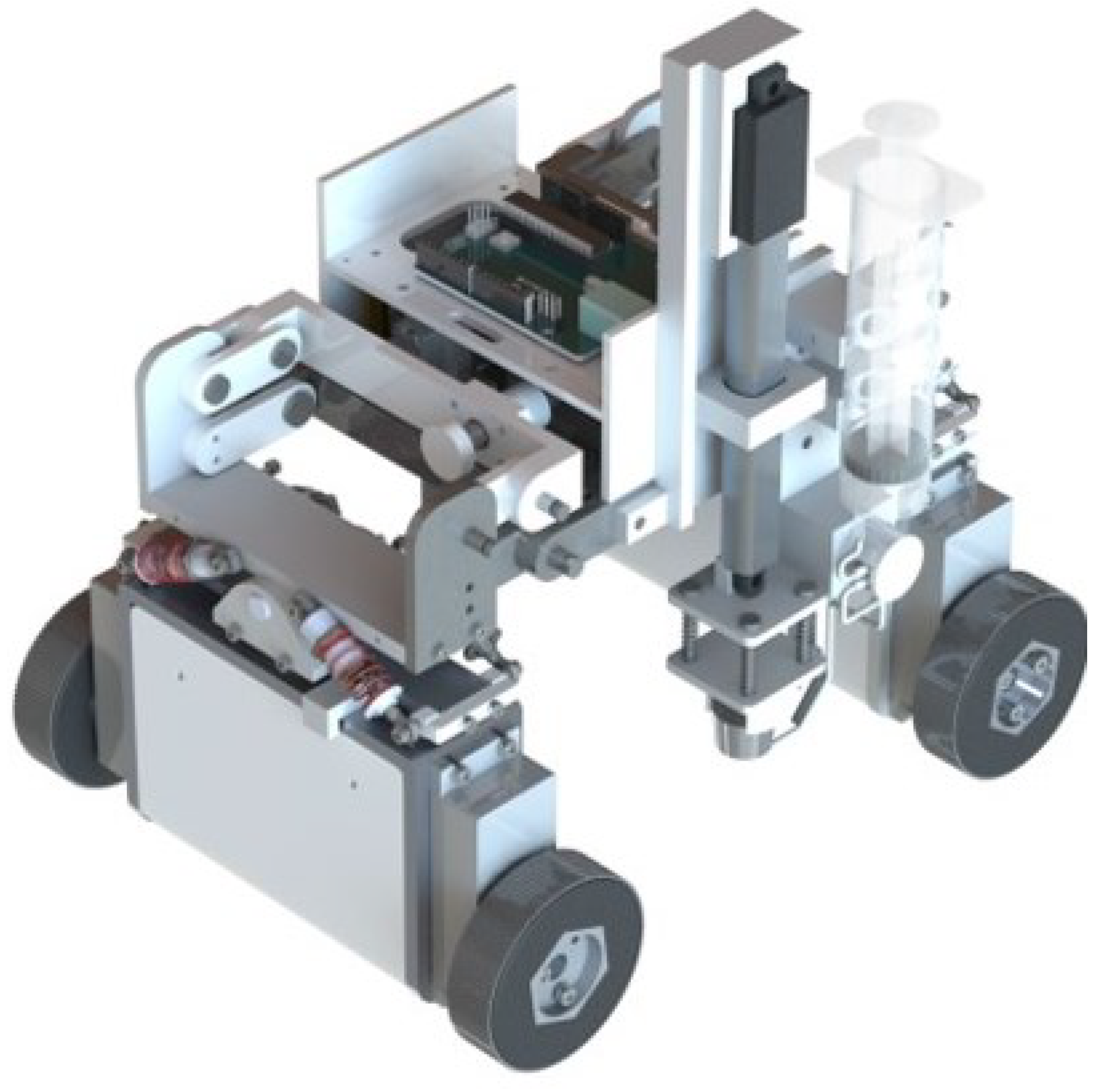

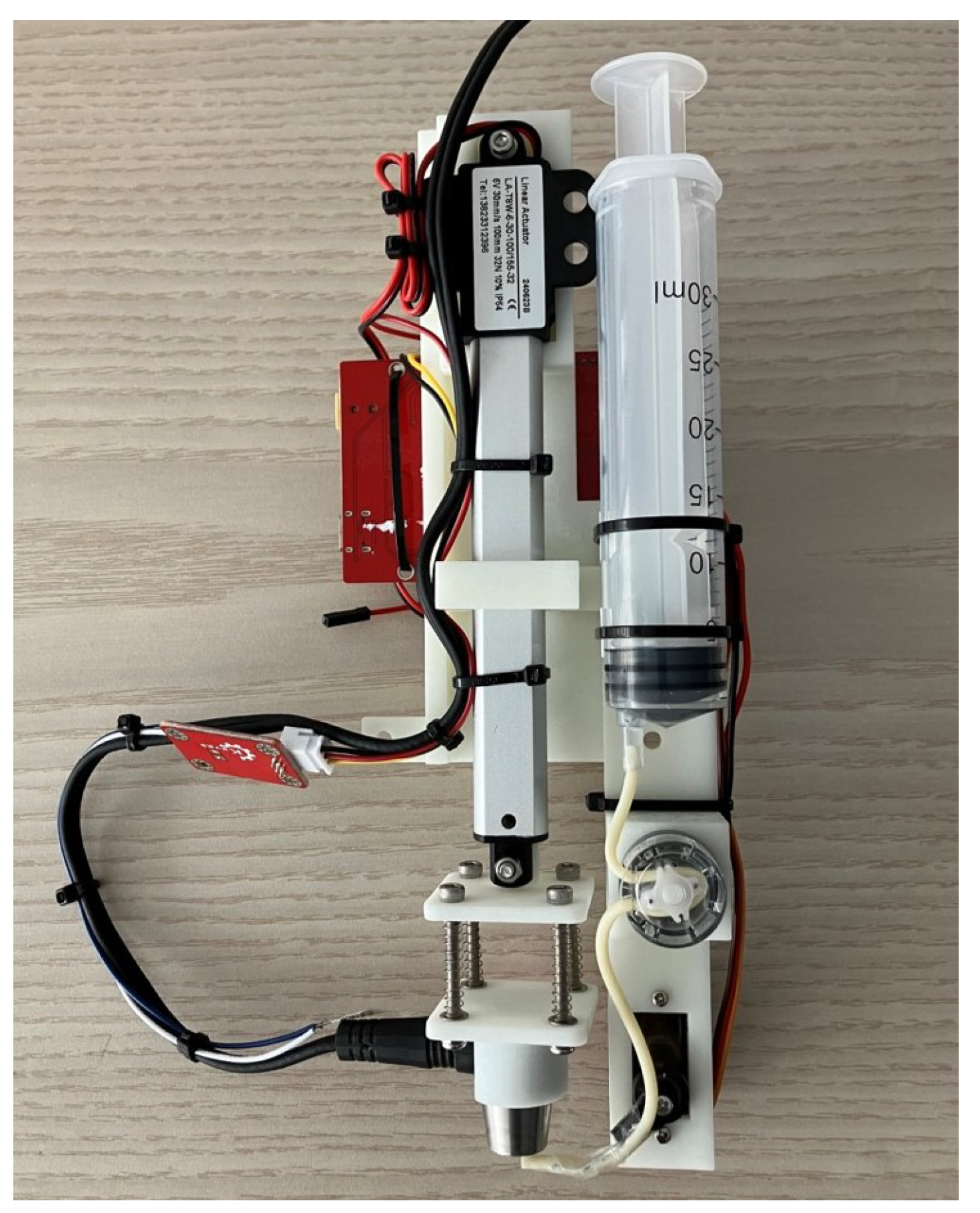

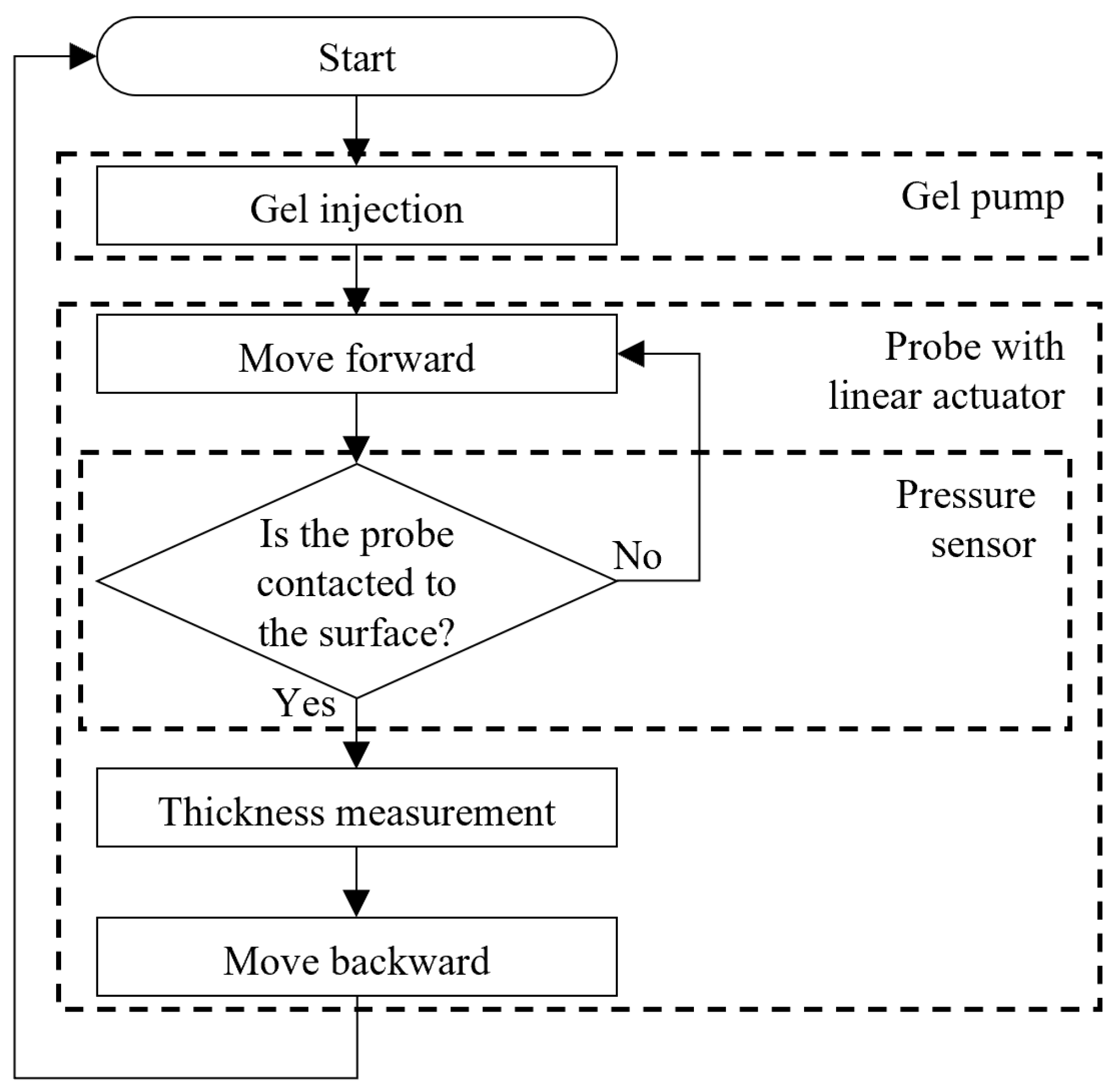

2.2. Design of the Probe with Linear Actuator

2.3. Development of the Prototype Device

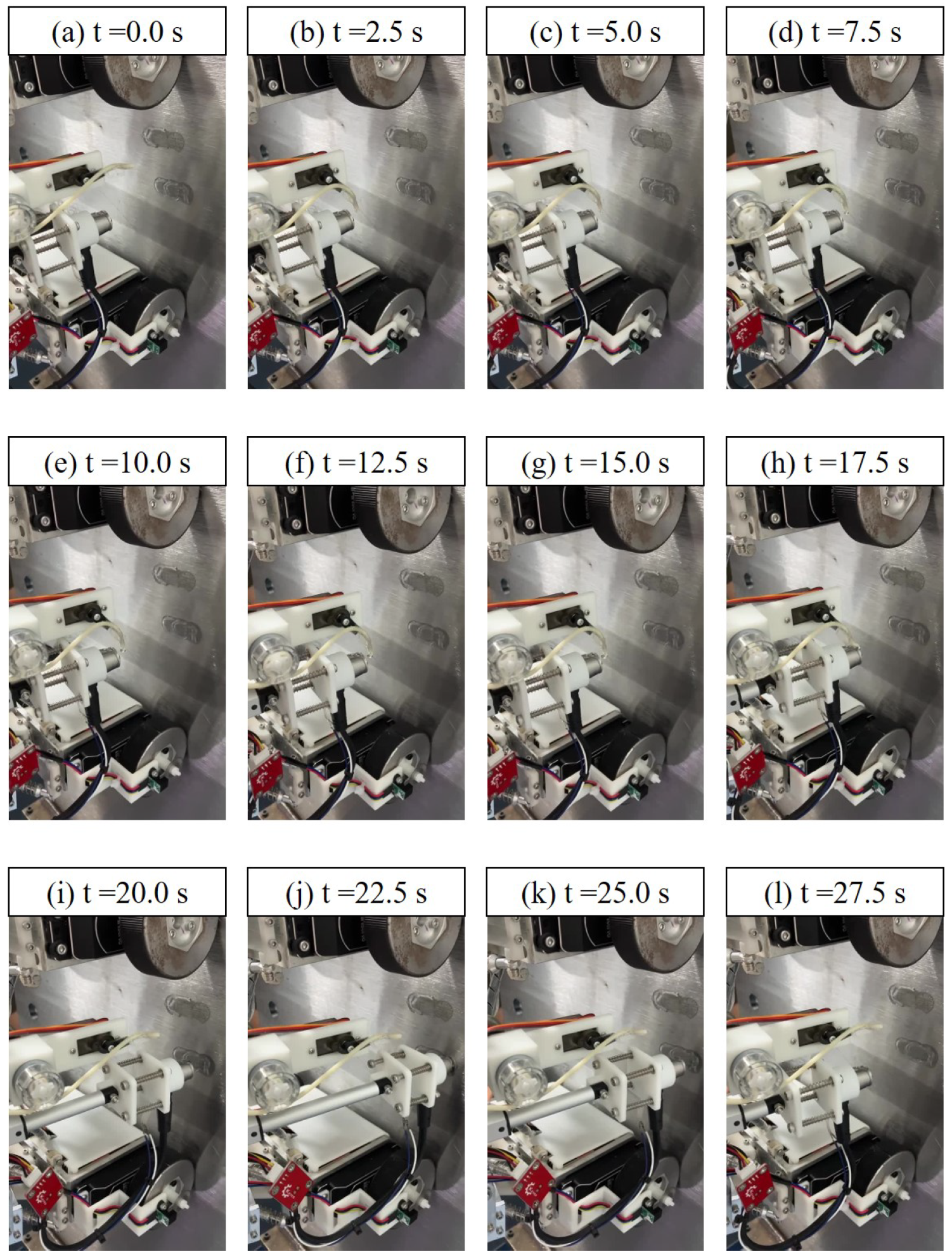

2.4. Fundamental Experiment

3. Results

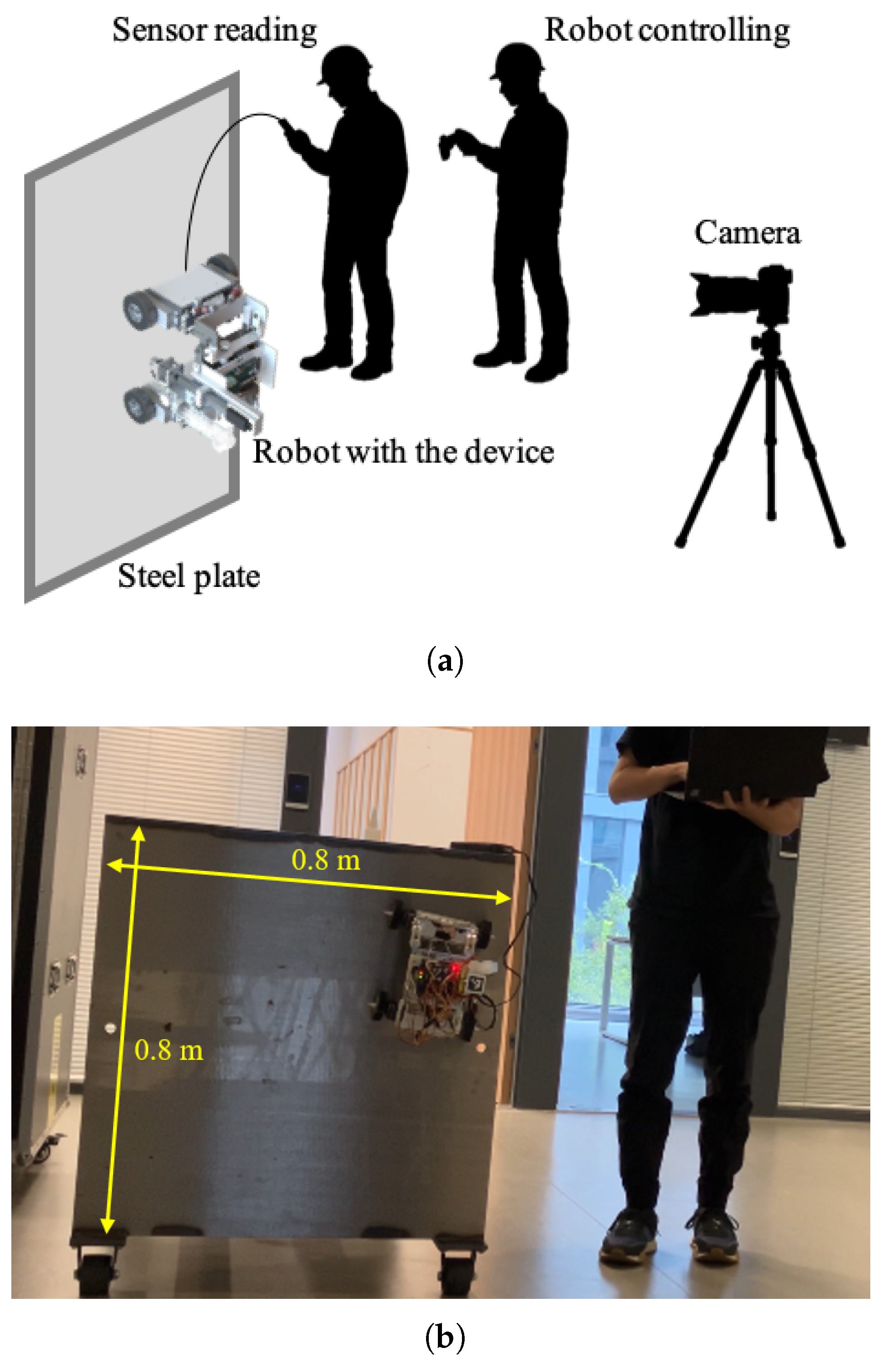

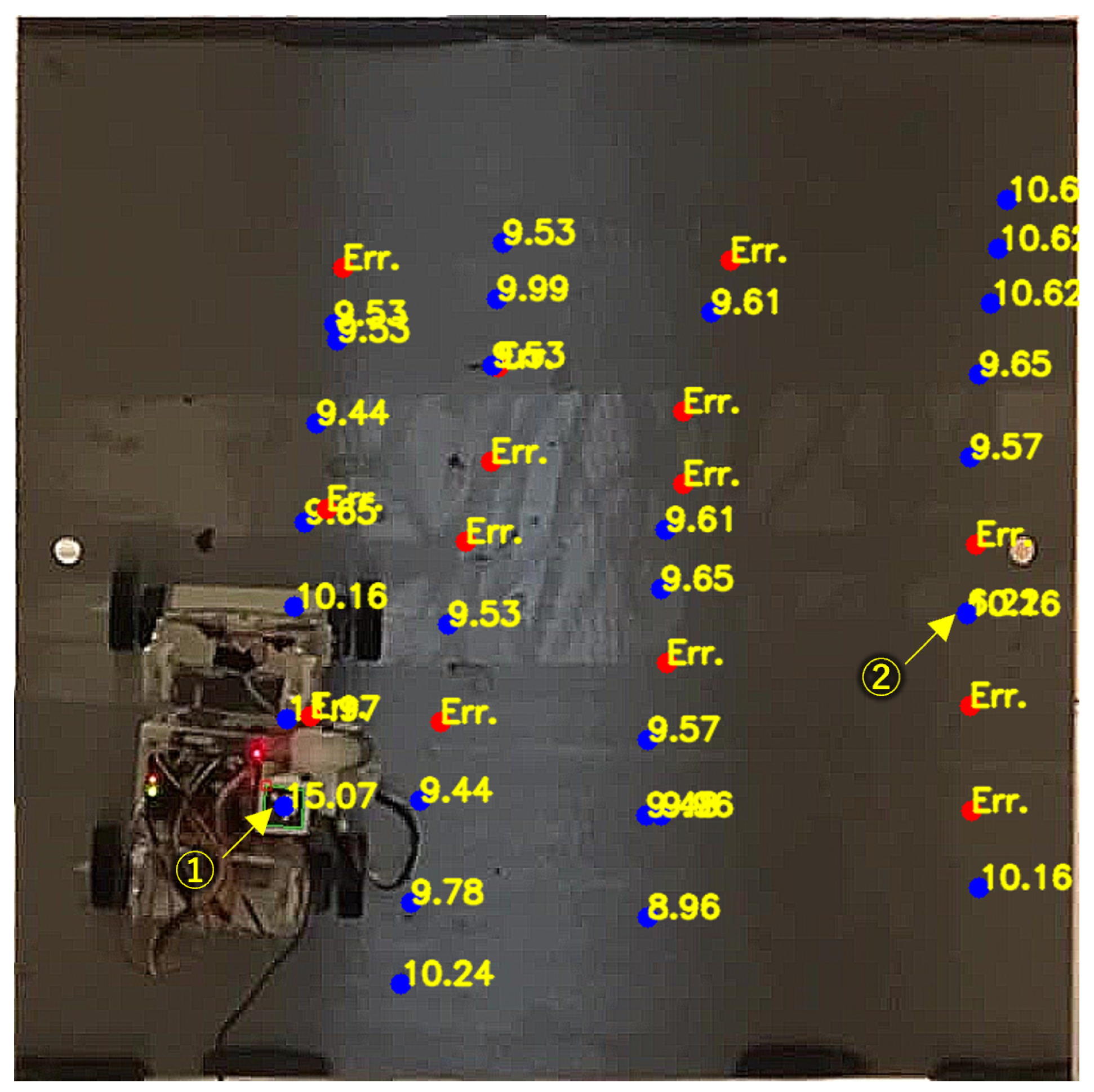

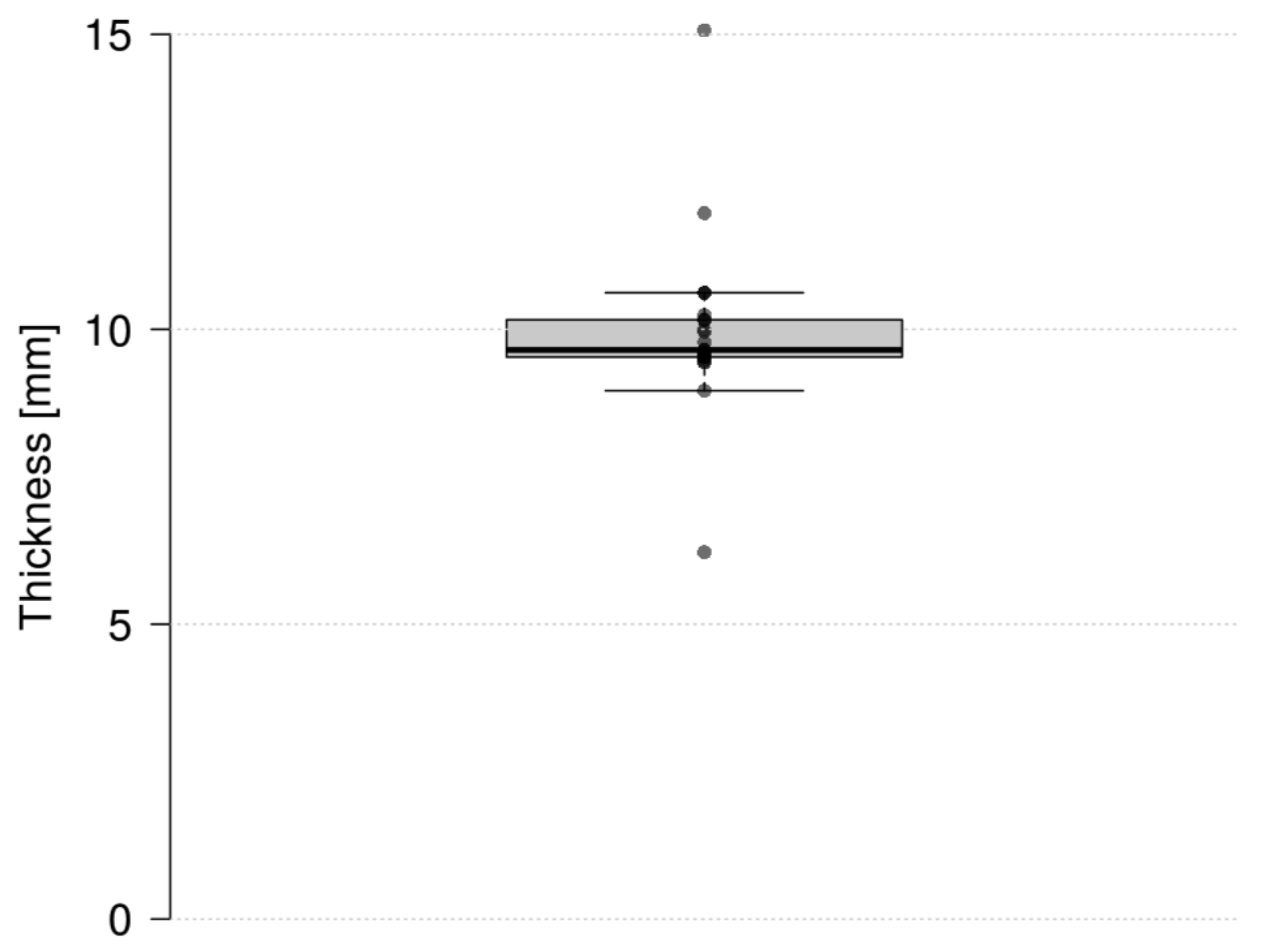

3.1. Experimental Setups

3.2. Results

4. Discussion

Limitation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yaguchi, H.; Kimura, I.; Sakuma, S. A New Type of Rotary Magnetic Actuator System Using Electromagnetic Vibration and Wheel. Actuators 2020, 9, 51. [Google Scholar] [CrossRef]

- Chen, F.; Wang, L.; Wang, Y.; Zhang, H.; Wang, N.; Ma, P.; Yu, B. Retrieval of dominant methane (CH4) emission sources, the first high-resolution (1–2 m) dataset of storage tanks of China in 2000–2021. Earth Syst. Sci. Data 2024, 16, 3369–3382. [Google Scholar] [CrossRef]

- Ma, S.; Tang, X.; Ma, W.; Liu, J.; Xiao, L. An Unmanned Cleaning Robot for the Inner Wall of Large LNG Tanks. In Proceedings of the 2022 International Conference on Advanced Robotics and Mechatronics (ICARM), Guilin, China, 9–11 July 2022; pp. 562–568. [Google Scholar] [CrossRef]

- Kalra, L.; Shen, W.; Gu, J. A Wall Climbing Robotic System for Non Destructive Inspection of Above Ground Tanks. In Proceedings of the 2006 Canadian Conference on Electrical and Computer Engineering, Ottawa, ON, Canada, 7–10 May 2006; pp. 402–405. [Google Scholar] [CrossRef]

- Mazumdar, A.; Asada, H.H. Mag-Foot: A steel bridge inspection robot. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009. [Google Scholar] [CrossRef]

- Akahori, S.; Higashi, Y.; Masuda, A. Development of an Aerial Inspection Robot with EPM and camera arm for steel structures. In Proceedings of the 2016 IEEE Region 10 Conference (TENCON), Singapore, 22–25 November 2016; pp. 3542–3545. [Google Scholar] [CrossRef]

- Kalra, L.P.; Gu, J.; Meng, M. A Wall Climbing Robot for Oil Tank Inspection. In Proceedings of the 2006 IEEE International Conference on Robotics and Biomimetics, Kunming, China, 17–20 December 2006; pp. 1523–1528. [Google Scholar] [CrossRef]

- Chen, J.; Cao, X.; Xu, H.; Zhang, X.; Deng, Z. Structure Design and Characteristic Analysis of Compound-Driven Unit for Pipeline Robot. In Proceedings of the 2020 5th International Conference on Advanced Robotics and Mechatronics (ICARM), Shenzhen, China, 18–21 December 2020; pp. 353–358. [Google Scholar] [CrossRef]

- Yang, W.; Yang, C.; Zhang, R.; Zhang, W. A Novel Worm-inspired Wall Climbing Robot with Sucker-microspine Composite Structure. In Proceedings of the 2018 3rd International Conference on Advanced Robotics and Mechatronics (ICARM), Singapore, 18–20 July 2018; pp. 744–749. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y. Adaptive Robust Tracking Control of Wall-climbing Robot Based on Constraint Following Theory. In Proceedings of the 2022 International Conference on Advanced Robotics and Mechatronics (ICARM), Guilin, China, 9–11 July 2022; pp. 696–701. [Google Scholar] [CrossRef]

- Amakawa, T.; Yamaguchi, T.; Yamada, Y.; Nakamura, T. Proposing an adhesion unit for a traveling-wave-type, omnidirectional wall-climbing robot in airplane body inspection applications. In Proceedings of the 2017 IEEE International Conference on Mechatronics (ICM), Churchill, VIC, Australia, 13–15 February 2017; pp. 178–183. [Google Scholar] [CrossRef]

- Wang, C.; Gu, J.; Li, Z. Switching Motion Control of the Climbing Robot for Aircraft Skin Inspection. In Proceedings of the 2019 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), New Orleans, LA, USA, 23–26 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Andrikopoulos, G.; Papadimitriou, A.; Brusell, A.; Nikolakopoulos, G. On Model-based Adhesion Control of a Vortex Climbing Robot. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 1460–1465. [Google Scholar] [CrossRef]

- Alkalla, M.G.; Fanni, M.A.; Mohamed, A.M.; Hashimoto, S. Tele-operated propeller-type climbing robot for inspection of petrochemical vessels. Ind. Robot. Int. J. 2017, 44, 166–177. [Google Scholar] [CrossRef]

- Song, W.; Wang, Z.; Wang, T.; Ji, D.; Zhu, S. A Path Tracking Method of a Wall-Climbing Robot towards Autonomous Inspection of Steel Box Girder. Machines 2022, 10, 256. [Google Scholar] [CrossRef]

- Li, J.; Li, B.; Dong, L.; Wang, X.; Tian, M. Weld Seam Identification and Tracking of Inspection Robot Based on Deep Learning Network. Drones 2022, 6, 216. [Google Scholar] [CrossRef]

- Li, J.; Feng, H.; Tu, C.l.; JIN, S.s.; WANG, X.s. Design of Inspection Robot for Spherical Tank Based on Mecanum Wheel. In Proceedings of the 2019 Far East NDT New Technology & Application Forum (FENDT), Qingdao, China, 24–27 June 2019; pp. 218–224. [Google Scholar] [CrossRef]

- Duan, Z.; Fang, G.; Shi, G.; Qian, H.; Cui, J.; Zhang, J. The Design and Performance Investigation of a Split Four-Track Water-Jet Cleaning Robot for Steel Gate Panels. Actuators 2024, 13, 528. [Google Scholar] [CrossRef]

- Zhang, Y.; Dodd, T.; Atallah, K.; Lyne, I. Design and optimization of magnetic wheel for wall and ceiling climbing robot. In Proceedings of the 2010 IEEE International Conference on Mechatronics and Automation, Xi’an, China, 4–7 August 2010; pp. 1393–1398. [Google Scholar] [CrossRef]

- Ji, H.; Li, P.; Wang, Z. Analysis and Simulation of Permanent Magnet Adsorption Performance of Wall-Climbing Robot. Actuators 2024, 13, 337. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, J.; Zhang, Y.; Lin, Y. Research on Foundation Settlement Detection Method of Large Crude Oil Storage Tank. In Proceedings of the 2021 IEEE Far East NDT New Technology & Application Forum (FENDT), Kunming, China, 14–17 December 2021; pp. 134–139. [Google Scholar] [CrossRef]

- Zhang, D.; Watson, R.; Dobie, G.; MacLeod, C.; Pierce, G. Autonomous Ultrasonic Inspection Using Unmanned Aerial Vehicle. In Proceedings of the 2018 IEEE International Ultrasonics Symposium (IUS), Kobe, Japan, 22–25 October 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Otsuki, Y.; Nguyen, S.T.; La, H.M.; Wang, Y. Autonomous Ultrasonic Thickness Measurement of Steel Bridge Members Using a Climbing Bicycle Robot. J. Eng. Mech. 2023, 149, 8. [Google Scholar] [CrossRef]

- Ding, Y.; Sun, Z.; Chen, Q. Non-contacted Permanent Magnetic Absorbed Wall-climbing Robot for Ultrasonic Weld Inspection of Spherical Tank. MATEC Web Conf. 2019, 269, 02013. [Google Scholar] [CrossRef]

- Enjikalayil Abdulkader, R.; Veerajagadheswar, P.; Htet Lin, N.; Kumaran, S.; Vishaal, S.R.; Mohan, R.E. Sparrow: A Magnetic Climbing Robot for Autonomous Thickness Measurement in Ship Hull Maintenance. J. Mar. Sci. Eng. 2020, 8, 469. [Google Scholar] [CrossRef]

- Phlernjai, M.; Ratsamee, P. Multi-Legged Inspection Robot with Twist-Based Crouching and Fine Adjustment Mechanism. J. Robot. Mechatron. 2022, 34, 588–598. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, X.; Li, M.; Cao, J.; Huang, Z. Optimization Design and Flexible Detection Method of a Surface Adaptation Wall-Climbing Robot with Multisensor Integration for Petrochemical Tanks. Sensors 2020, 20, 6651. [Google Scholar] [CrossRef] [PubMed]

- Nishimura, Y.; Zheng, T.; Song, W. Metal Thickness Measurement Module with Scotch Yoke Mechanism for Tank Inspections. In Proceedings of the 2024 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Boston, MA, USA, 15–19 July 2024; pp. 734–739. [Google Scholar] [CrossRef]

- Shen, W.; Gu, J.; Shen, Y. Proposed wall climbing robot with permanent magnetic tracks for inspecting oil tanks. In Proceedings of the IEEE International Conference Mechatronics and Automation, Niagara Falls, ON, Canada, 29 July–1 August 2005; pp. 2072–2077. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, S.; Song, W.; Zheng, T.; Ding, H.; Wang, B. Modeling of attractive force of magnetic wheel under different wall structure and attitude used for climbing robot. J. Mech. Sci. Technol. 2024, 38, 411–421. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, S.; Song, W. Design and experiment of climbing robot for steel I-beam girder inspection. Ind. Robot. Int. J. Robot. Res. Appl. 2025, ahead-of-print. [Google Scholar] [CrossRef]

- Garrido-Jurado, S.; Muñoz-Salinas, R.; Madrid-Cuevas, F.; Marín-Jiménez, M. Automatic generation and detection of highly reliable fiducial markers under occlusion. Pattern Recognit. 2014, 47, 2280–2292. [Google Scholar] [CrossRef]

- Ben Hazem, Z.; Guler, N.; Altaif, A.H. A study of advanced mathematical modeling and adaptive control strategies for trajectory tracking in the Mitsubishi RV-2AJ 5-DOF Robotic Arm. Discov. Robot. 2025, 1, 2. [Google Scholar] [CrossRef]

- Hong, K.; Wang, H.; Yuan, B. Inspection-Nerf: Rendering Multi-Type Local Images for Dam Surface Inspection Task Using Climbing Robot and Neural Radiance Field. Buildings 2023, 13, 213. [Google Scholar] [CrossRef]

- Yang, L.; Li, B.; Feng, J.; Yang, G.; Chang, Y.; Jiang, B.; Xiao, J. Automated wall-climbing robot for concrete construction inspection. J. Field Robot. 2022, 40, 110–129. [Google Scholar] [CrossRef]

- Xu, W.; Hou, C.; Li, G.; Cui, C. Path Planning for Wall-Climbing Robots Using an Improved Sparrow Search Algorithm. Actuators 2024, 13, 370. [Google Scholar] [CrossRef]

| Reference | Year | Method | Gel Injection |

|---|---|---|---|

| Ding et al. [24] | 2019 | Electric pusher | N/A |

| Enjikalayil et al. [25] | 2020 | Solenoid | N/A |

| Zhang et al. [27] | 2020 | Four-bar linkage mechanism | Air compressor and diaphragm pump (on-ground) |

| Phlernjai et al. [26] | 2022 | Crouching motion of the legged robot | N/A |

| Otsuki et al. [23] | 2023 | Four-bar linkage mechanism | Peristaltic pump (onboard) |

| Nishimura et al. [28] | 2024 | Scotch Yoke mechanism | N/A |

| Proposed | 2025 | Linear actuator | Peristaltic pump (onboard) |

| Mass [kg] | 3.8 |

| Size [mm × mm × mm] | 280 × 197 × 160 |

| Payload [kg] | 1.2 |

| Climbing mechanism | Magnetic wheel |

| Actuator torque (wheel) [Nm] | 10 |

| Battery life [min] | 50 |

| Applicable obstacle height [mm] | 20 |

| Corner (concave/convex) | 🗸/🗸 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nishimura, Y.; Wang, C.; Song, W. Metal Thickness Measurement Using an Ultrasonic Probe with a Linear Actuator for a Magnet-Type Climbing Robot: Design and Development. Actuators 2025, 14, 299. https://doi.org/10.3390/act14060299

Nishimura Y, Wang C, Song W. Metal Thickness Measurement Using an Ultrasonic Probe with a Linear Actuator for a Magnet-Type Climbing Robot: Design and Development. Actuators. 2025; 14(6):299. https://doi.org/10.3390/act14060299

Chicago/Turabian StyleNishimura, Yuki, Cheng Wang, and Wei Song. 2025. "Metal Thickness Measurement Using an Ultrasonic Probe with a Linear Actuator for a Magnet-Type Climbing Robot: Design and Development" Actuators 14, no. 6: 299. https://doi.org/10.3390/act14060299

APA StyleNishimura, Y., Wang, C., & Song, W. (2025). Metal Thickness Measurement Using an Ultrasonic Probe with a Linear Actuator for a Magnet-Type Climbing Robot: Design and Development. Actuators, 14(6), 299. https://doi.org/10.3390/act14060299