1. Introduction

Bearings, as critical components in rotating machinery, play a crucial role in determining the performance and reliability of the entire mechanical system [

1,

2,

3]. In practical industrial applications, due to various factors such as design, manufacturing, installation, and operating conditions, bearings are among the most prone components to failure [

4]. Therefore, timely diagnosis of bearing faults is essential for the overall safety and efficient operation of the equipment [

5].

Vibration signal-based analysis is the most commonly used and reliable method for rolling bearing fault diagnosis [

6,

7,

8]. This method combines signal decomposition techniques with envelope analysis to reduce noise and extract fault characteristic frequencies. These extracted frequencies are then compared with the theoretical fault characteristic frequencies of different bearing components, allowing for the identification of faults at various positions within the bearing. In reference [

9], linear frequency cepstral coefficients are introduced as features from vibration sensor data to enhance the performance of rolling bearing anomaly detection. Reference [

10] proposes a novel sparse time–frequency analysis method that integrates the frequency adaptability of the S-transform and the iterative computation of the multi-synchronous compression algorithm, overcoming the limitations of the fixed sliding window in short-time Fourier transform. This approach enables a time–frequency representation with higher energy concentration. However, when diagnosing faults through bearing vibration signal analysis, manual expertise is required for feature extraction, leading to lower diagnostic efficiency. Additionally, this method demands that the operator possess certain professional knowledge and a good understanding of the bearing’s structural parameters [

11].

Fault diagnosis is essentially a pattern recognition process, and shallow machine learning methods are typical approaches for pattern recognition [

12,

13]. By combining fault feature extraction with shallow machine learning methods, signal denoising and fault feature extraction are first performed using time-domain, frequency–domain, and time–frequency domain signal processing techniques. The extracted features are then input into shallow machine learning algorithms for fault classification. Reference [

14] proposes a bearing fault diagnosis model based on the Circular Entropy Spectrum (CCES) and Least Squares Support Vector Machine (LSSVM) under impulse noise conditions. First, CCES is used to extract narrowband kurtosis vector features, which are then classified using the LSSVM model. This model demonstrates good experimental results and exhibits strong adaptive capability. Furthermore, Reference [

15] introduces a model that combines artificial neural networks with dimensional analysis for bearing fault size diagnosis. The results show that the diagnostic efficiency of the artificial neural network outperforms dimensional analysis, with the error band performance and actual error being approximately 97.79% and 5.49%, respectively. This highlights the performance of artificial neural networks and the simplicity of data preprocessing. However, due to the shallow structure typically used in machine learning algorithms, their ability to extract nonlinear features from complex datasets is limited, and they heavily rely on carefully selected fault features [

16].

Deep learning methods have been widely applied in bearing fault diagnosis due to their ability to automatically extract features and uncover hidden nonlinear relationships within large datasets [

17,

18]. Reference [

19] aims to enhance the accuracy of rolling bearing fault recognition by utilizing cyclic spectral analysis to estimate the two-dimensional cyclic spectral coherence diagram of vibration signals, thereby generating bearing classification patterns that can distinguish different fault types. Reference [

20] investigates three time–frequency transformation methods—Short-Time Fourier Transform (STFT), Continuous Wavelet Transform (CWT), and S-transform—for converting one-dimensional vibration signals into two-dimensional time–frequency images, and their application in convolutional neural network (CNN)-based rolling bearing fault diagnosis. Reference [

21] proposes a bearing fault diagnosis method based on spectral image information fusion and CNN. This method analyzes multi-channel vibration signals using STFT to obtain frequency–domain information, which is then fused into two-dimensional images and input into a CNN for training, resulting in a fault diagnosis model. The model’s diagnostic performance is validated using an existing dataset to achieve intelligent and efficient fault diagnosis. Reference [

22] introduces a multi-scale recursive fusion strategy guided by an attention mechanism. This strategy effectively allocates attention, allowing deep neural networks (DNNs) to focus more on useful information in adjacent layers, thereby accurately representing potential features related to changes in working conditions.

Although deep learning methods have achieved good diagnostic results in the aforementioned literature, there are still limitations in addressing time series data. When handling sequential tasks, Recurrent Neural Networks (RNNs) are more effective but are prone to issues such as vanishing or exploding gradients. To address this problem, Reference [

23] proposes a data-driven bearing performance degradation assessment method based on Long Short-Term Memory Recurrent Neural Networks (LSTM-RNNs), which improves the ability to handle long-term dependencies, a common limitation in traditional RNNs. Reference [

24] introduces a deep learning framework combining LSTM-RNN, Stacked Autoencoders (SAEs), and Particle Swarm Optimization (PSO), focusing on fault detection by utilizing unlabeled historical data and unknown abnormal features.

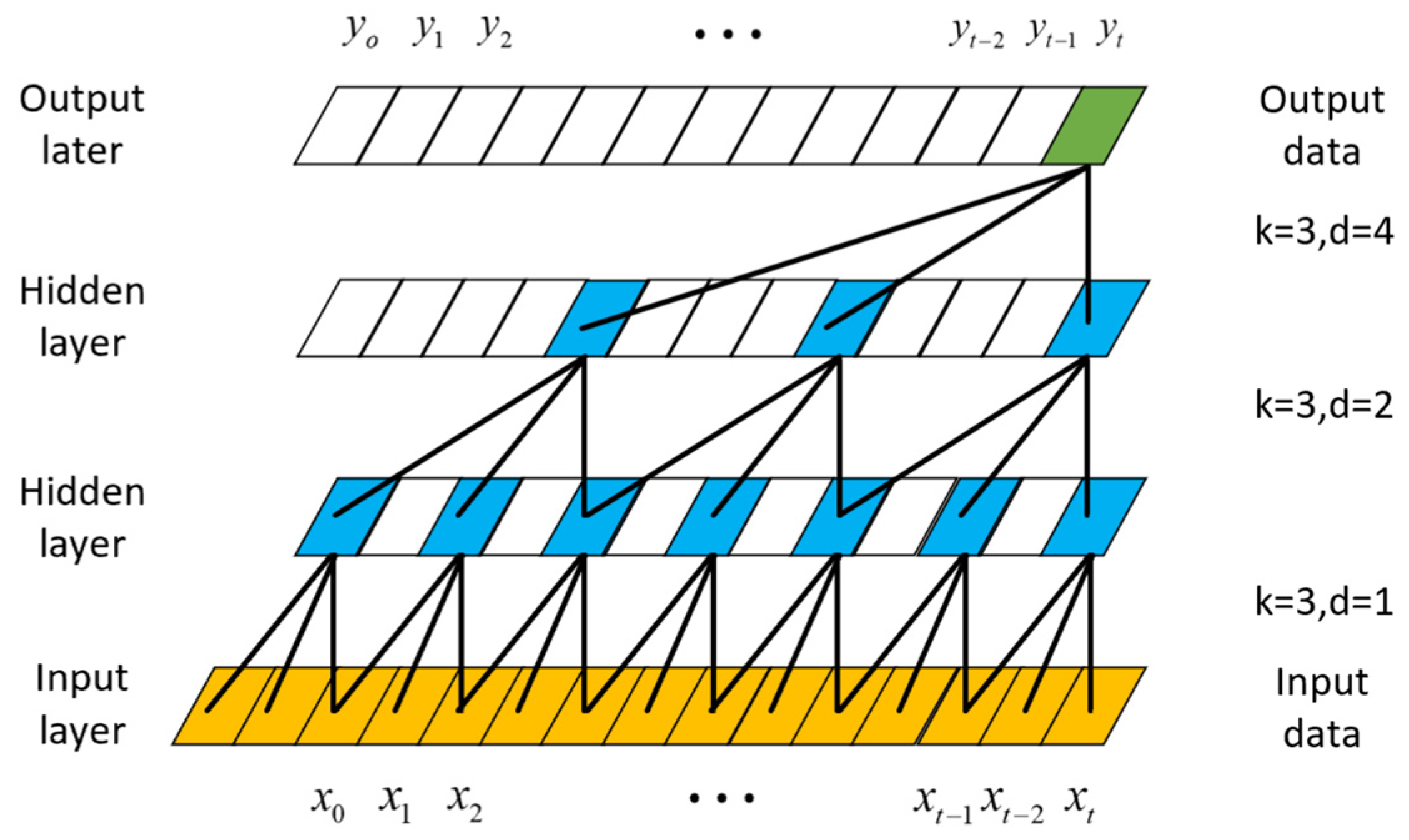

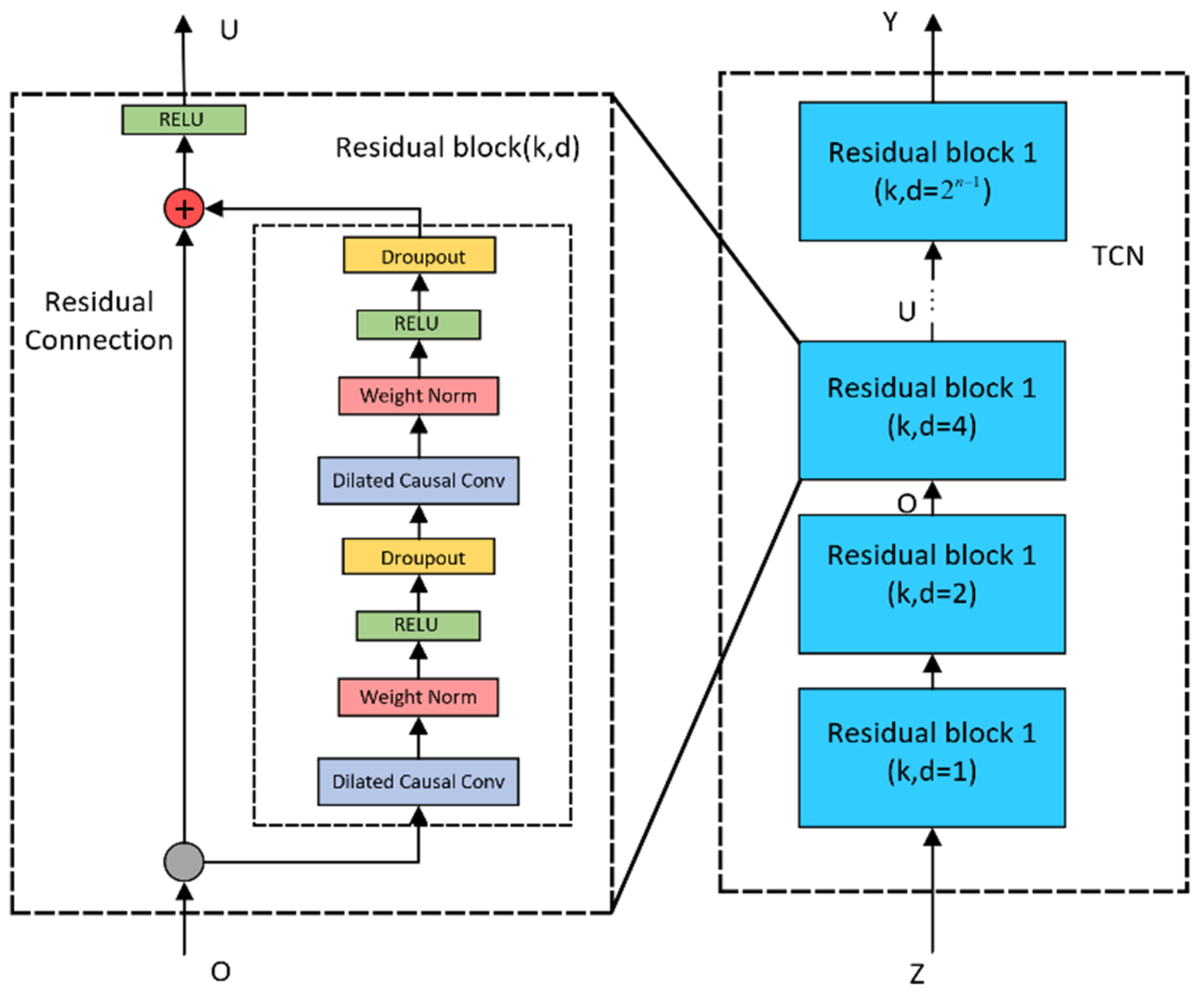

In recent years, Temporal Convolutional Networks (TCNs) have been shown to outperform CNNs and LSTMs in handling sequence data problems [

25], and significant progress has been made in fault diagnosis research. Reference [

26] combines TCN with an attention mechanism for remaining useful life (RUL) prediction of rolling bearings, demonstrating that TCN is effective in predicting vibration trends and RUL for rolling bearings. Reference [

27] proposes a bearing fault diagnosis model based on an attention-based Temporal Convolutional Network and Bidirectional Gated Recurrent Units (Bi-GRU), with results indicating that this method outperforms 1D Convolutional Neural Networks, Bidirectional Long Short-Term Memory Networks, and Bidirectional Recurrent Neural Networks in terms of identification accuracy. Numerous studies have shown that TCN, with its simple convolutional architecture, performs better than classical recurrent networks across different tasks and datasets. Moreover, TCNs offer advantages such as large effective memory, parallelizable convolution, flexible receptive fields, and stable gradients.

Traditional Temporal Convolutional Networks (TCNs) for fault diagnosis typically use a Softmax classifier for fault classification. Although the Softmax classifier effectively integrates with the network during the training phase and facilitates weight updates for the TCN model, it has several drawbacks, including poor performance on nonlinear problems, insufficient model generalization, a large number of parameters that increase computational time, and susceptibility to overfitting. On the other hand, Support Vector Machines (SVMs) perform well in handling small sample sizes and nonlinear issues [

28], with stronger generalization capabilities. Therefore, this paper replaces the fully connected Softmax classifier with an SVM.

The Fast Fourier Transform (FFT) is an efficient algorithm used to compute the Discrete Fourier Transform (DFT) and its inverse transform [

29]. In signal processing, by exploiting symmetry and periodicity, a set of data with a time duration of T can be transformed into a T/2-point DFT, which is then further reduced to T/4-point, T/8-point DFTs, and so on, significantly reducing the computational load. As the number of FFT points increases, the computation speed approaches linear growth, making FFT highly efficient for period calculations. In rolling bearing fault diagnosis, FFT can convert time-domain signals into frequency–domain signals, enabling the extraction of fault characteristic frequencies and their harmonics. The advantage of this method lies in its ability to effectively reduce noise interference, highlight fault features, and provide clearer data support for subsequent feature extraction and classification [

30].

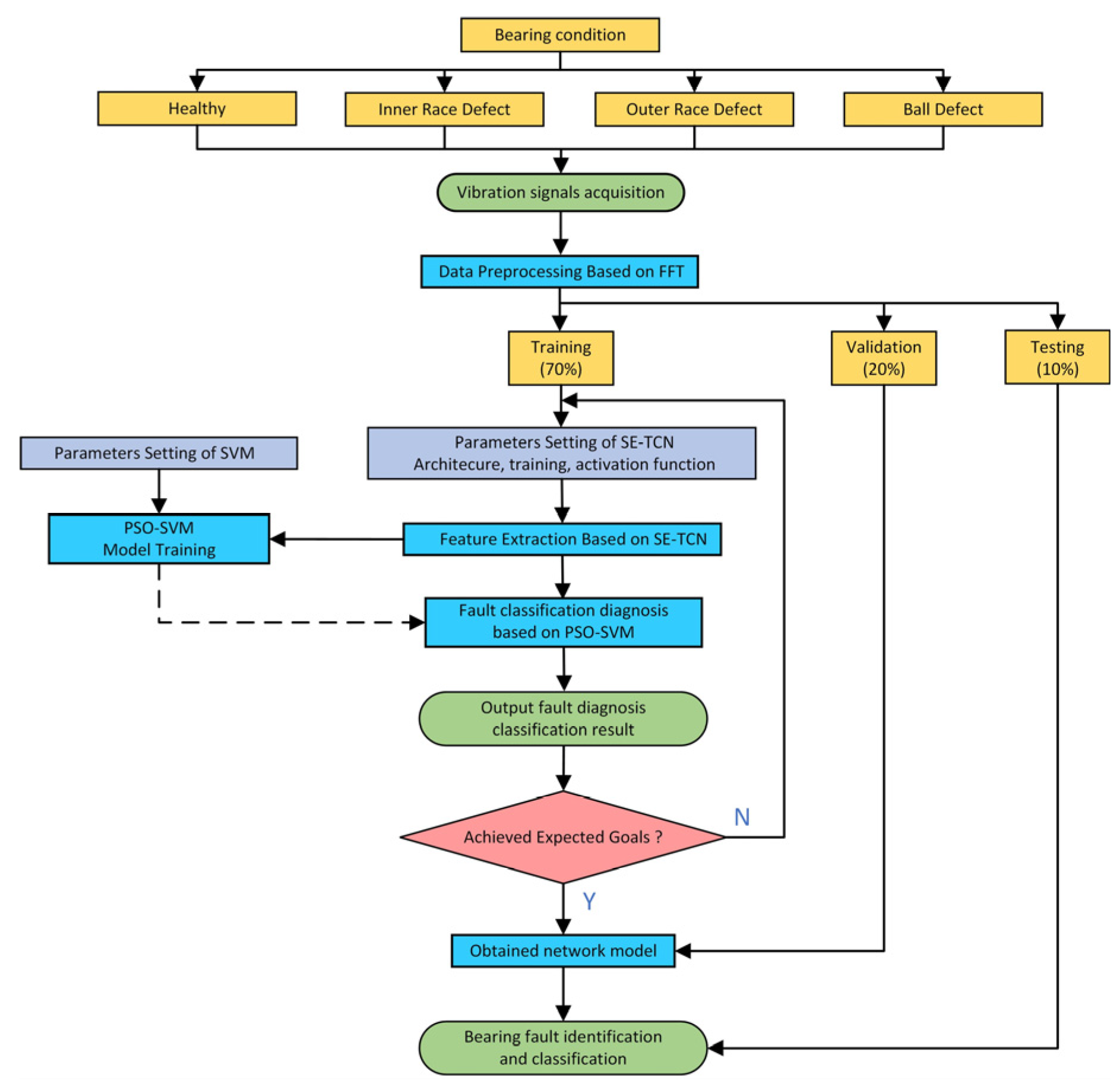

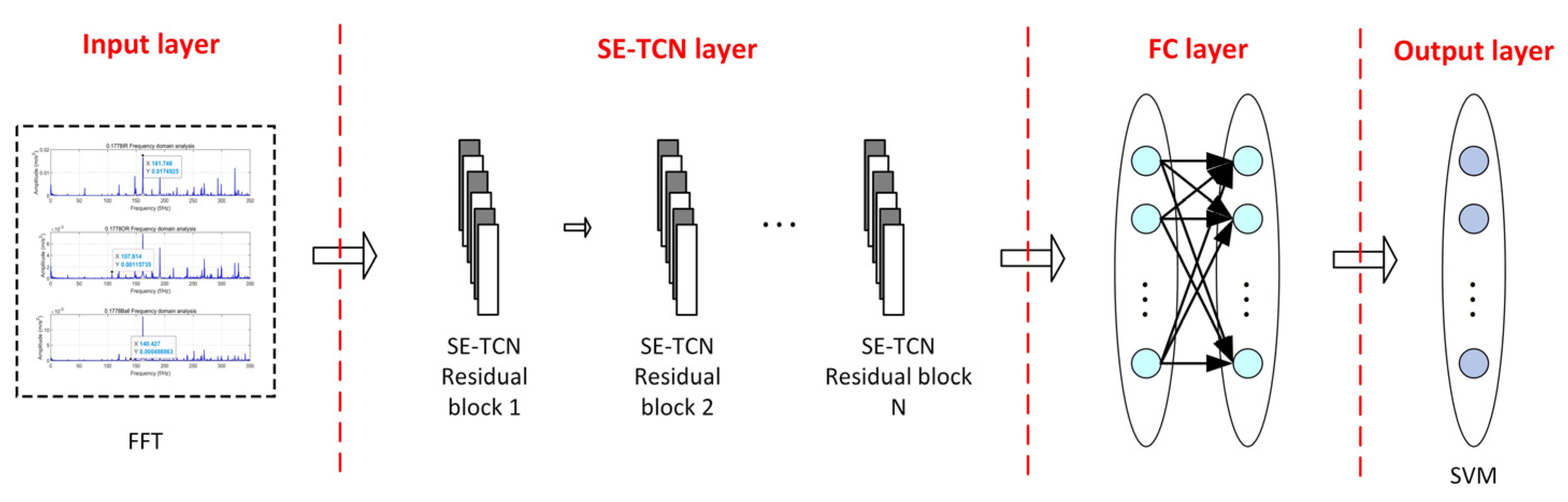

In order to fully leverage the advantages of different models, this paper proposes a rolling bearing fault diagnosis method that combines Fast Fourier Transform (FFT), a Time Convolutional Network (TCN) with an integrated attention mechanism (SE-TCN), and Support Vector Machine (SVM) (hereinafter referred to as FFT-SE-TCN-SVM). The basic idea is as follows:

- (1)

Use FFT as a preprocessing step for the bearing fault vibration signal to reduce dimensionality and denoise the original signal, highlighting the key frequency components. This makes it easier for the TCN to capture the critical features, thereby improving diagnostic accuracy;

- (2)

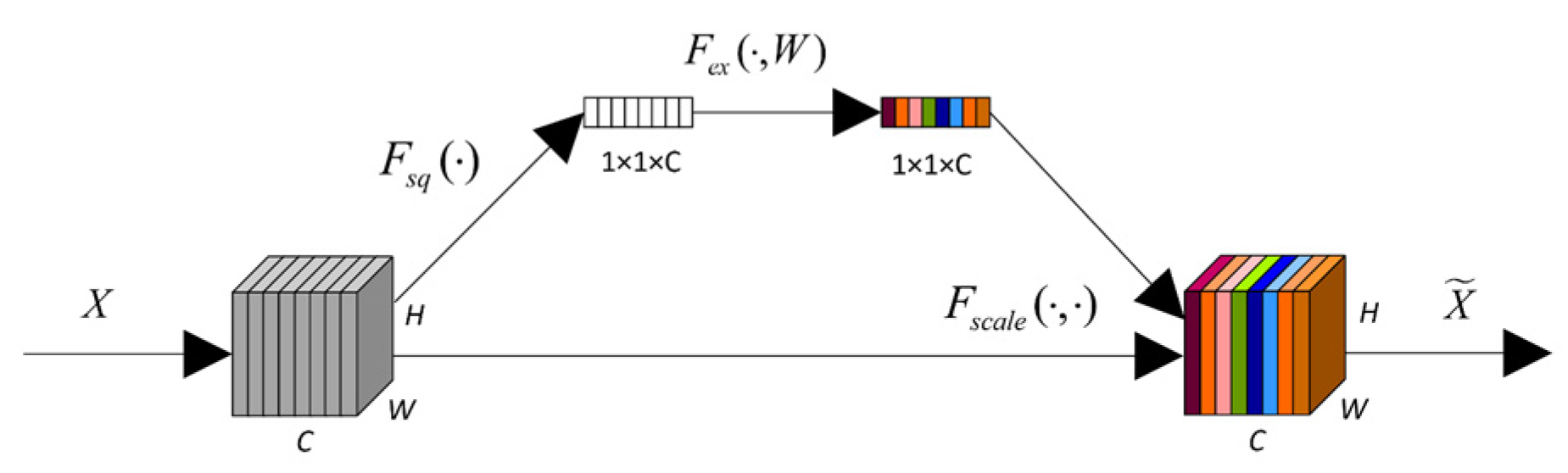

Process the data using the TCN model and enhance it with the attention mechanism from SENet to improve the feature extraction capability of the TCN network. This enables the model to selectively focus on channels with key information, especially in regions where the signal shape undergoes significant changes, thus strengthening the model’s feature representation ability;

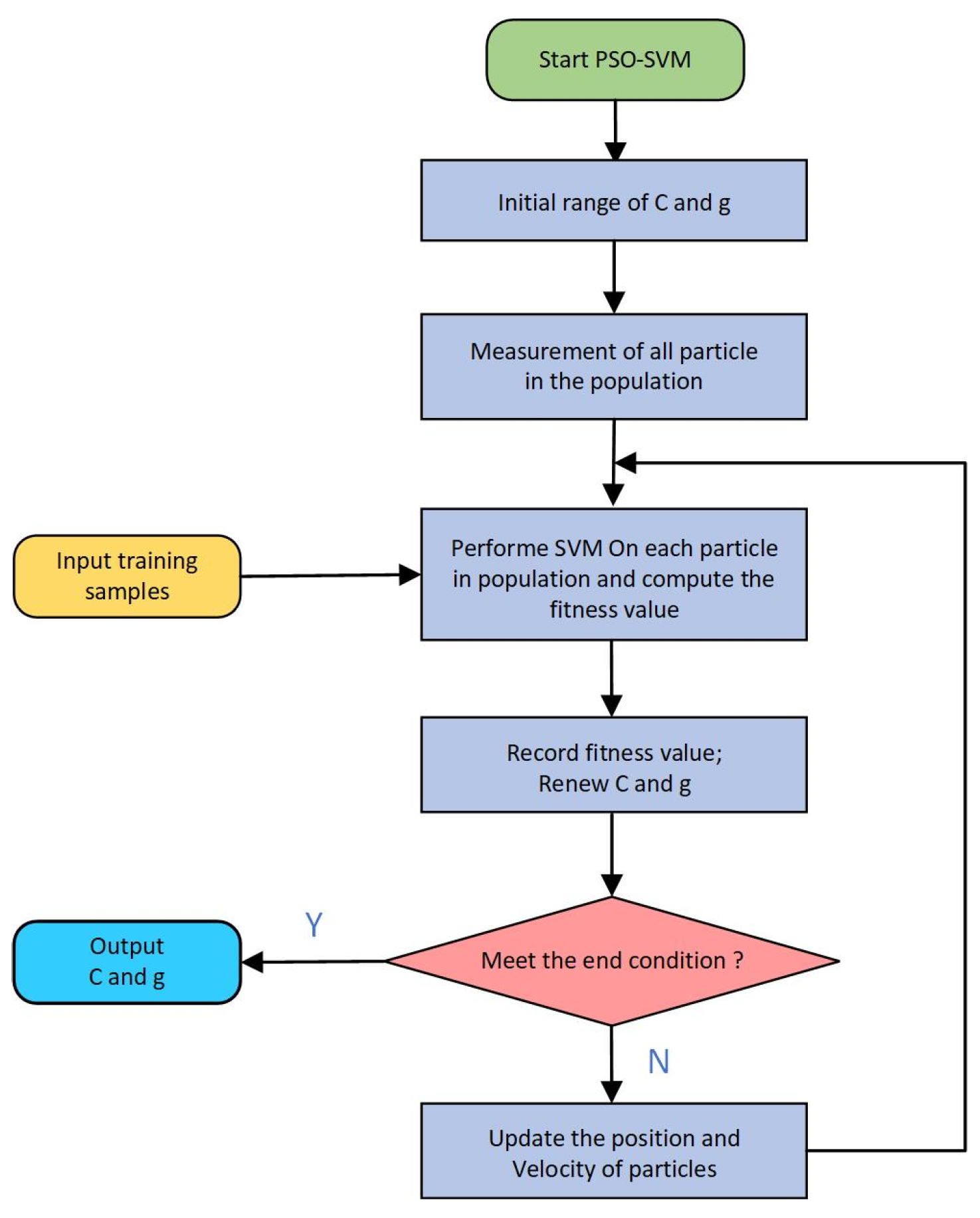

- (3)

Replace the original Softmax classifier with a classic SVM classifier and optimize the parameters using Particle Swarm Optimization (PSO) to further improve the classification capability of the network.

The structure of the article is as follows:

Section 2 introduces the principles of FFT, SE-TCN network, and SVM, and provides a detailed description of the flowchart of the proposed method.

Section 3 conducts a case study using the CWRU and laboratory-collected bearing fault datasets to validate the effectiveness of the proposed method. Finally,

Section 4 offers the concluding remarks of the paper.

3. Case Study

This section will use two bearing fault datasets: the CWRU dataset and the laboratory-collected dataset. Vibration signals of rolling bearings under normal operation and nine fault conditions, based on different damage locations and diameters, are collected, totaling 10 sets of data. The proposed method will be trained, tested, and validated.

Section 3.1 uses the CWRU dataset, with 500 experimental samples selected for each fault state. The data are split into training (70%), validation (20%), and test (10%) sets, with training and testing conducted, followed by a comparison of the results.

Section 3.2 evaluates the diagnostic performance when handling small sample data. A total of 500 samples, with 50 samples selected from each fault mode in the CWRU dataset, will be used for model training and testing to verify the model’s effectiveness.

Section 3.3 uses the laboratory data to assess the model’s generalization ability. Fifty samples from each fault mode will be selected for testing.

The experiments are conducted on a computer with an Intel Core i7-10750H CPU, and the data analysis software used is MATLAB 2023b.

3.1. Data Experiment Analysis

3.1.1. Dataset Introduction

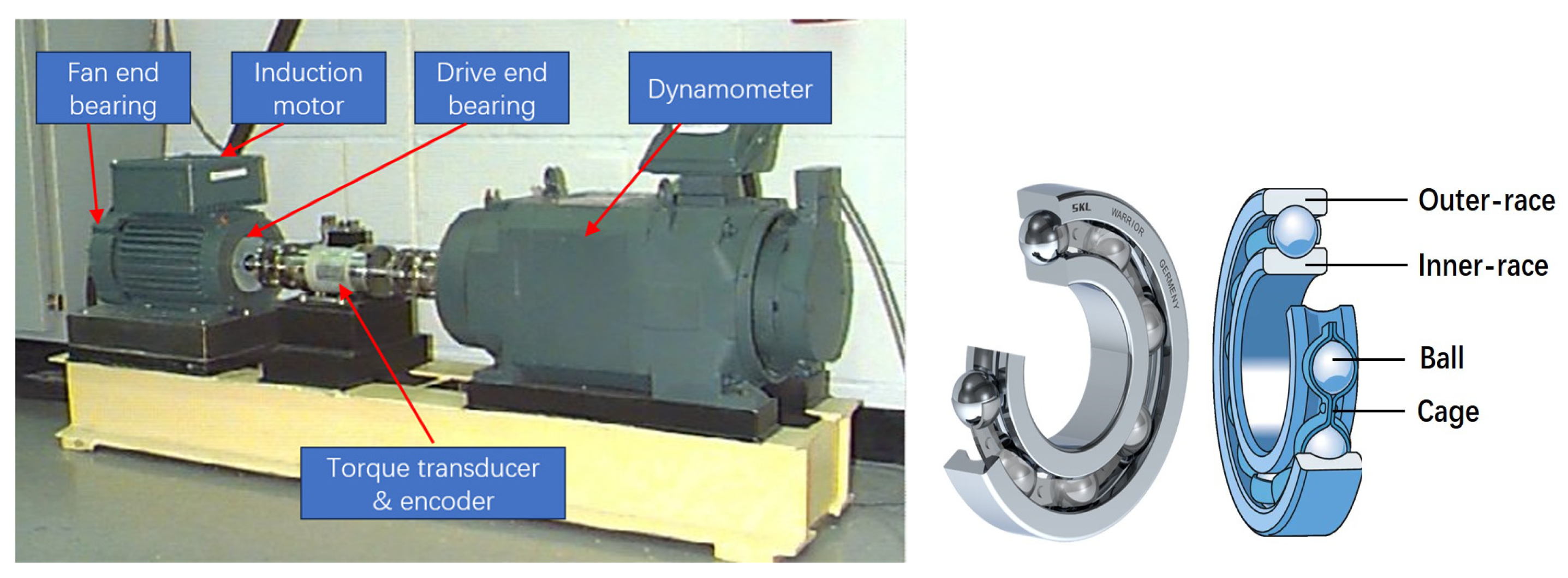

The Case Western Reserve University (CWRU) bearing fault dataset is widely used in the field of fault diagnosis for comparing the performance of different algorithms. As shown in

Figure 8, the experimental setup consists of four components: a 1.5 kW (2 horsepower) electric motor, a torque sensor, a power meter, and an electronic controller.

The experimental motor operates with a load of 0 horsepower and an approximate speed of 1792 rpm, with a sampling frequency of 48 kHz. The vibration signals collected from the drive-end bearing housing are categorized into 10 fault modes: normal, inner race, outer race, and rolling element, with fault diameters of 0.1778 mm, 0.3556 mm, and 0.5334 mm, and a fault depth of 0.2794 mm. The fault data are represented as N, I1, I2, I3, O1, O2, O3, B1, B2, and B3. Among them, N represents normal; I denotes inner race surface faults; O indicates outer race surface faults; B represents rolling element faults; and 1, 2, and 3 correspond to fault diameters of 0.1778 mm, 0.3556 mm, and 0.5334 mm, respectively. The bearing fault data sample information is shown in

Table 1.

The bearing model used for the drive-end in the experiment is the 6205-2RS JEM SKF deep groove ball bearing, with parameters shown in

Table 2. The fault characteristic frequencies of the bearing are calculated and presented in

Table 3.

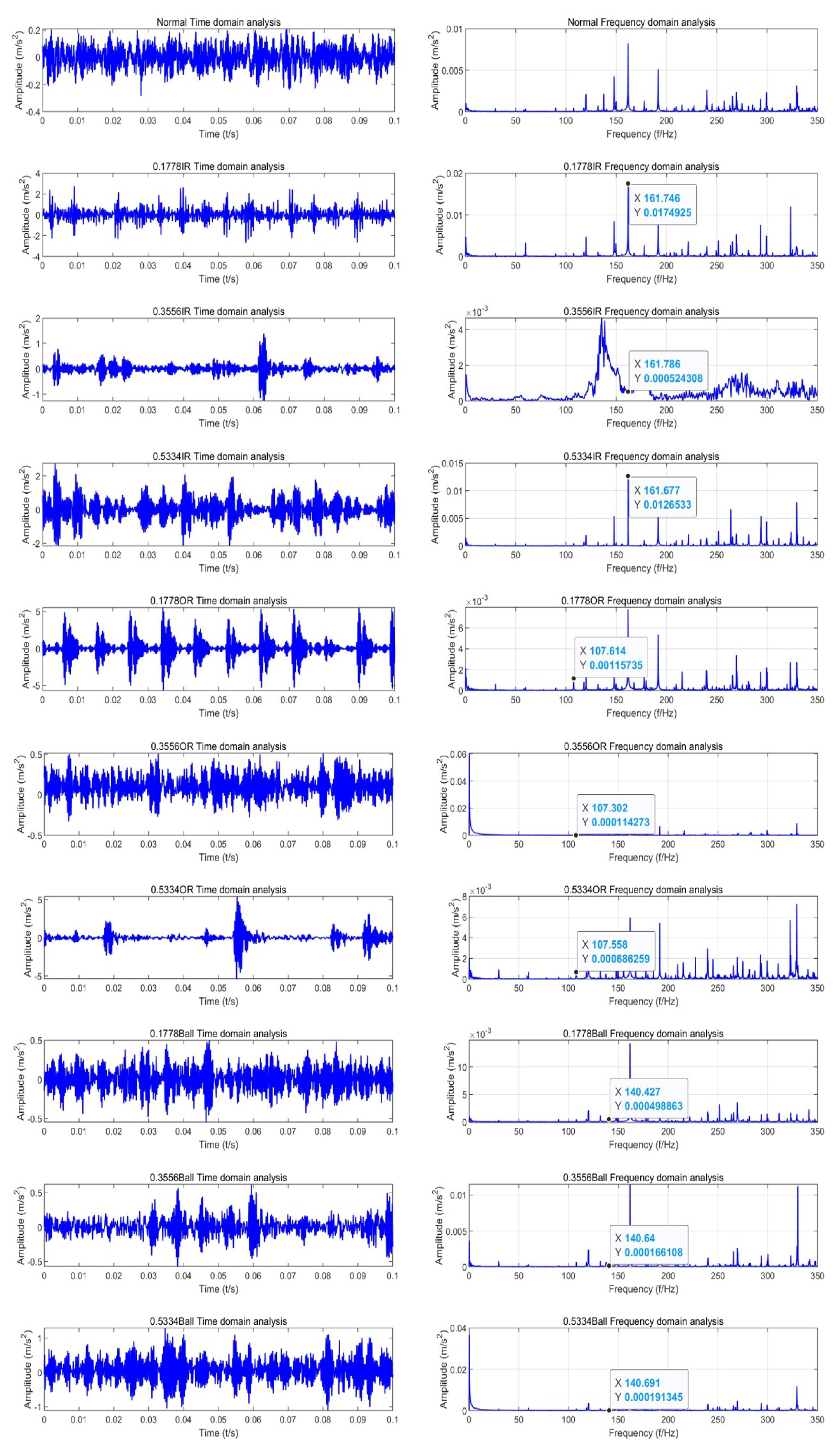

3.1.2. FFT Result

Figure 9 shows the time-domain waveforms of the bearing vibration signals collected under normal and nine fault conditions, along with the corresponding frequency spectra obtained after signal preprocessing using FFT.

On the left, the time-domain waveforms represent the bearing signals over a 0.1 s interval. Compared to the normal condition, when a fault occurs in a specific component, the time-domain waveform exhibits noticeable periodic variations. By observing for abnormal impacts or vibrations, it is possible to indicate the presence of a fault in the bearing. However, the time-domain signal is prone to noise interference, which can distort the waveform and affect the accuracy of fault diagnosis. On the right, the frequency spectrum after FFT processing is presented. In the normal condition, the characteristic frequencies of each component can be identified. When a fault occurs in a component, the fault can be determined based on the frequency value. Additionally, the magnitude of the signal at each frequency can help further assess the extent of the damage to the component. Noise in the time-domain signal is converted to low-value components in the frequency domain, which helps to suppress the noise.

As shown on the right, fault characteristic frequencies of 161 Hz, 107 Hz, and 140 Hz are identified in the frequency domain, corresponding to faults in the bearing’s inner race, outer race, and rolling elements. Based on the amplitude values of the frequency domain signals at 161 Hz—0.0174, 0.0005, and 0.0126, the fault diameters can be determined as 0.1778 mm, 0.3556 mm, and 0.5334 mm, respectively. Compared to the time-domain waveform, the frequency spectrum makes it easier to identify the fault location and severity and facilitates the extraction of sequence features.

3.1.3. Model Analysis

To verify the effectiveness and diagnostic performance of the proposed FFT-SE-TCN-SVM method, it is compared with FFT-TCN and FFT-SE-TCN in the experiments. CWRU bearing fault data are used, with each sample consisting of 1024 data points. For each type of fault, 500 experimental samples are randomly selected for model testing and comparison.

Faults in the diagnostic model involve numerous hyperparameters, but experiments show that fine-tuning these hyperparameters has little effect on the overall diagnostic performance of the model. Therefore, this paper does not analyze the impact of hyperparameters.

To enable adaptive learning rates and parameter updates in the negative gradient direction for faster network convergence, the TCN model employs the Adam optimizer. Additionally, to better capture the nonlinear features in the data, the Leaky ReLU activation function is selected. The maximum number of iterations is set to 50. The hyperparameter settings for the TCN model are listed in

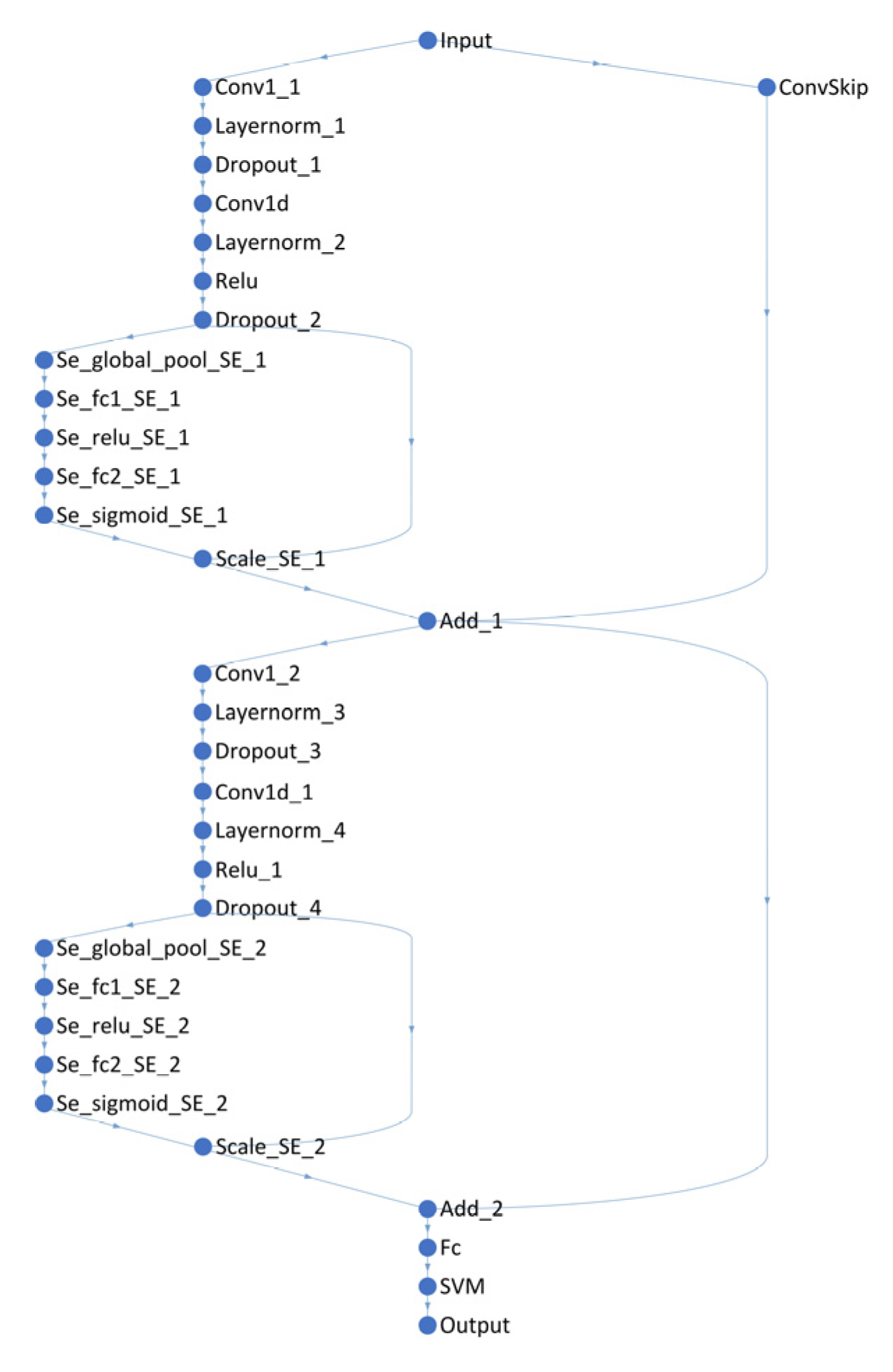

Table 4. The article sets up 2 SE-TCN modules, and the network structure is shown in

Figure 10.

After determining the structure of the SE-TCN model, TCN is combined with SVM. The RBF (radial basis function) kernel is chosen for the SVM, as it can model nonlinear responses and has fewer parameters than polynomial functions, significantly reducing the algorithm’s dependence on computational resources and providing a foundation for the algorithm’s real-time performance. The SVM parameters, including the penalty factor C and kernel parameter g, are optimized using the Particle Swarm Optimization (PSO) algorithm to obtain the optimal fault classifier.

Three models—FFT-TCN, FFT-SE-TCN, and FFT-SE-TCN-SVM—were constructed for testing and comparative analysis. To enhance the reliability of the experimental results, each method was tested 10 times, and the average of the 10 trials was used as the performance metric for classification evaluation, as shown in

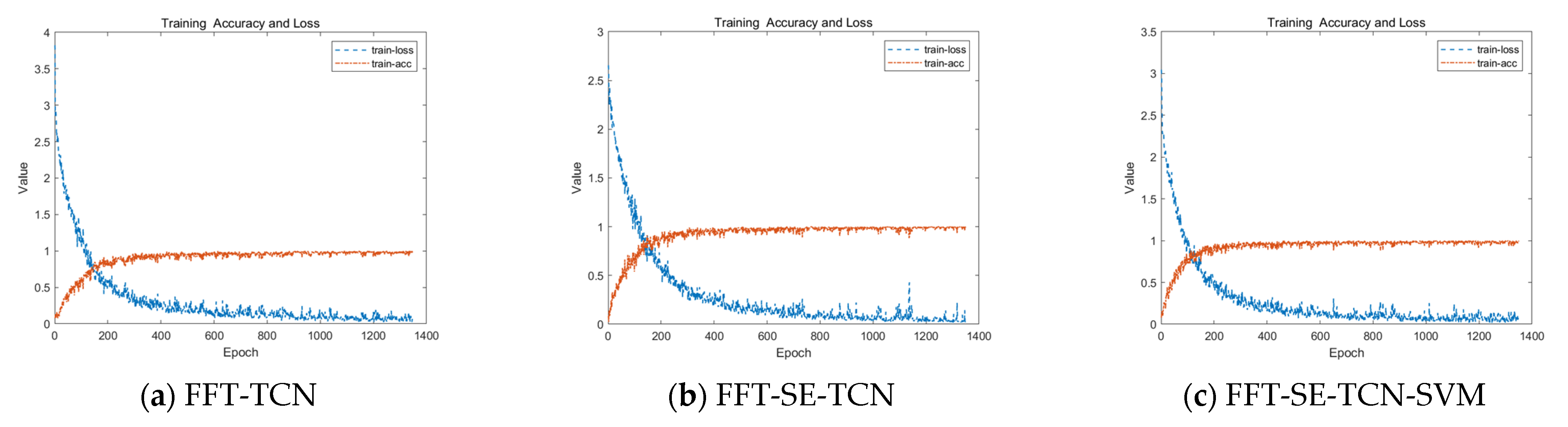

Table 5. The results of a particular training session are depicted in

Figure 11 and

Figure 12.

From

Figure 11, it can be observed that as the algorithm continues to train, all three methods gradually stabilize, and their classification accuracy improves accordingly. This indicates that the TCN-based architecture exhibits strong stability in fault detection, highlighting the scientific significance of research focused on improving this foundational module. With the introduction of the attention mechanism, there is more fluctuation in classification accuracy during the early stages of training compared to the previous methods. This is because the attention mechanism is designed to mitigate the computational resource consumption associated with exhaustive search strategies based on sliding windows. In the early stages of training, the algorithm may lack sufficient knowledge accumulation, leading to missed signals in regions that should have been prioritized, resulting in false negatives.

However, as shown in the latter part of the waveform, after complete data training, the stability of the classification accuracy, particularly with the attention mechanism-based training strategy, is significantly improved. In comparison, the specific data in

Figure 12 demonstrate that the FFT-SE-TCN-SVM network structure proposed in this paper has a substantial advantage in terms of classification accuracy.

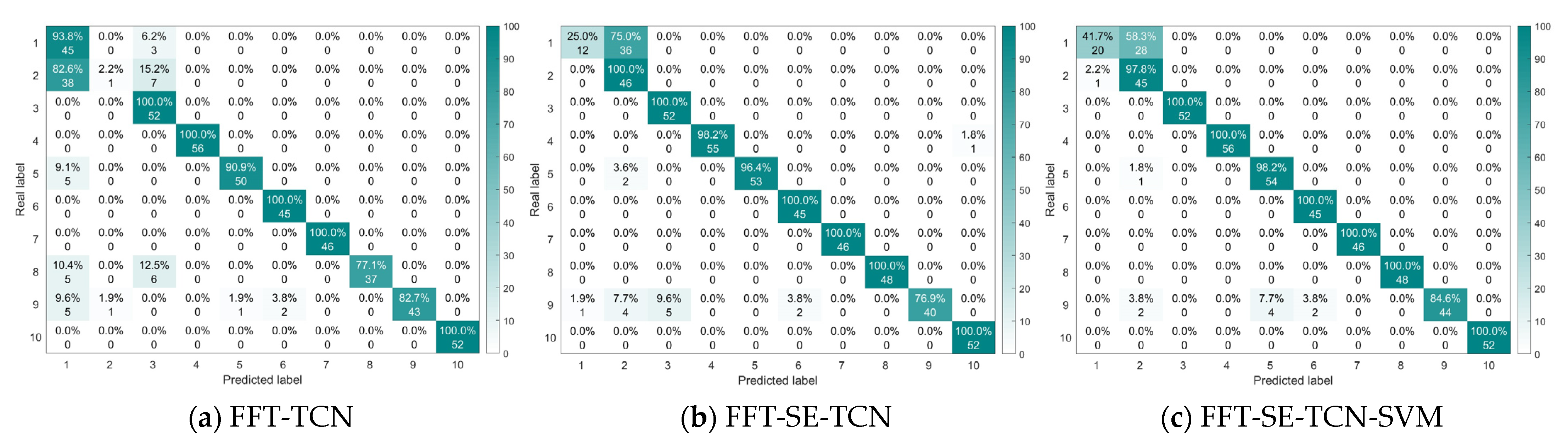

The test results were analyzed in detail using confusion matrices, which provide a more intuitive view of the fault detection performance for various bearing faults in the test set. (a) The FFT-TCN model achieved a diagnostic accuracy of 97.4%, with a misclassification rate of 22.9% for normal bearing data being incorrectly identified as a 0.1778mm inner race fault. (b) The FFT-SE-TCN model achieved a diagnostic accuracy of 98.6%, with the primary misclassification occurring when a 0.1778mm inner race fault was incorrectly classified as a normal state, with a fault rate of 13%. (c) The FFT-SE-TCN-SVM model correctly classified both the normal state and the 0.1778mm inner race fault. All three models showed varying degrees of misclassification for the 0.3556mm rolling element fault, with no significant differences observed.

In addition to the confusion matrix, the models were compared using training time, F1 score, recall, and accuracy metrics, as shown in

Table 5. The table reveals that the classification accuracy of all three models reached over 97%, with overall good performance. However, the FFT-SE-TCN-SVM network showed improvements in F1 score, recall, and accuracy compared to the FFT-TCN and FFT-SE-TCN models. Specifically, the accuracy reached 99.8%, an increase of 2.4% and 1.2% over the other two networks, indicating the best overall model performance. The recall was 0.8911, improving by 2.15% and 1.07%, which indicates a stronger ability to correctly identify positive samples and a lower false negative rate. The F1 score was 0.9073, improving by 2.18% and 1.09%, suggesting that the model performs well in both precision and recall, effectively identifying positive samples while minimizing false positives.

However, the training time increased by 33.49 s when the SE module was added to the TCN network. Given that the SE module enhances the feature extraction ability of the model by selecting key channels through nonlinear transformations, the additional computational cost associated with the SE module is considered acceptable due to the improvement in model performance. The experimental results show that the execution time of FFT-SE-TCN-SVM is shorter than that of FFT-SE-TCN. This can be attributed to two factors. First, TCN requires iterative optimization of all parameters during end-to-end training, and as the input signal length or network depth increases, the complexity of gradient calculation during backpropagation grows exponentially. In contrast, FFT-SE-TCN-SVM separates feature learning (FFT-SE-TCN) from classification decision (SVM), reducing the training complexity. Second, if PSO detects that the fitness fluctuates less than 1% for five consecutive iterations, it terminates early, avoiding redundant calculations. This makes the latter, although more complex, able to perform the optimization process more quickly.

In summary, the proposed method demonstrates significant advantages in terms of F1 score, recall, and accuracy, with a classification accuracy of 99.8%. This is considered a high classification accuracy in the field of AI-based recognition, indicating a clear superiority of the proposed method. It is important to note that compared to the FFT-TCN model, the latter two methods do not offer an advantage in training time. However, this refers to the training time of the algorithm, not the time consumed during its application. The time difference is associated with the computational cost during the model’s training process, rather than the processing time required during actual application. Therefore, the impact on the algorithm’s real-world application is minimal. When mechanical faults occur, the duration of such faults is typically longer, and the accuracy of fault diagnosis is generally more critical than the processing time.

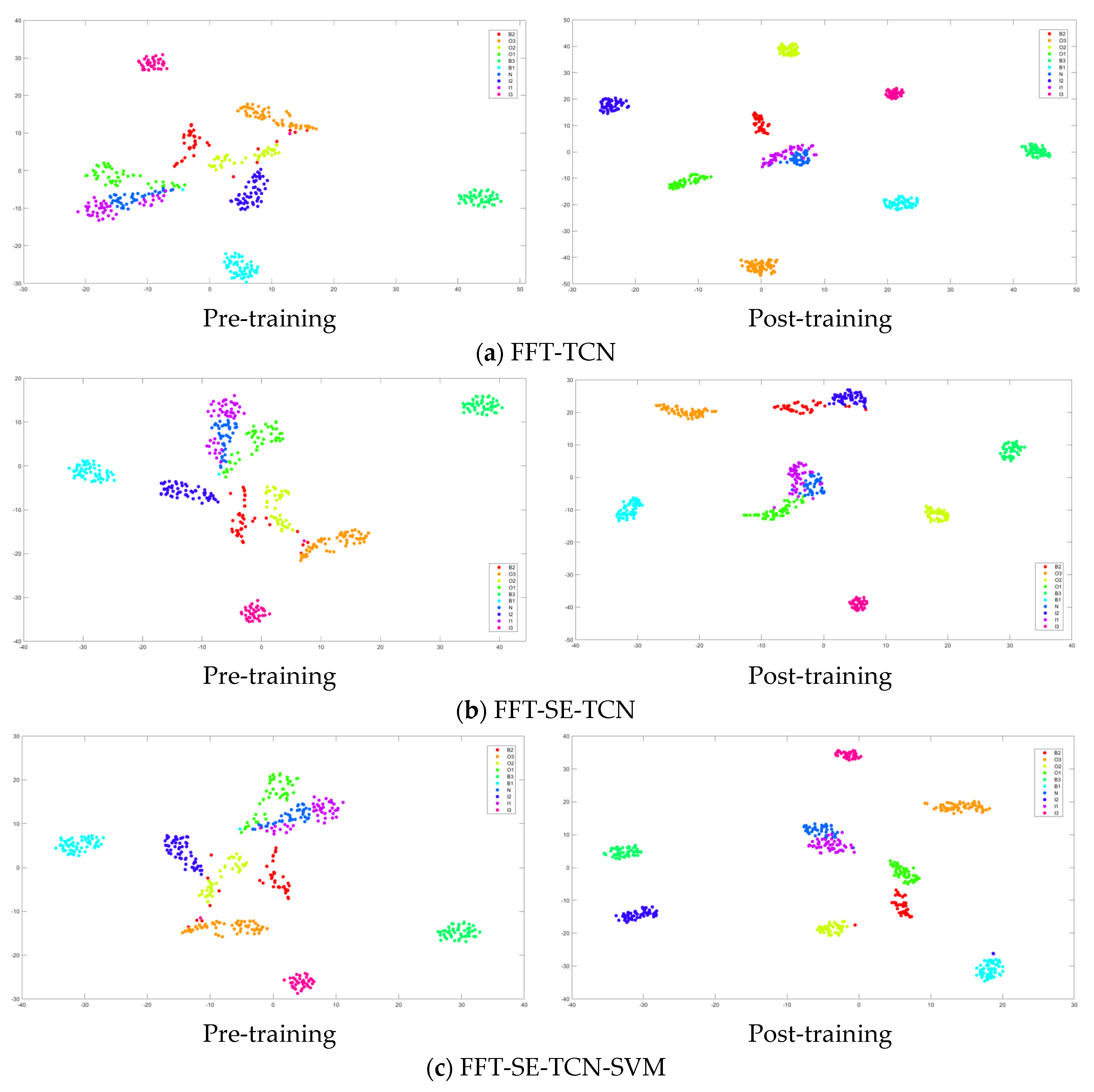

3.1.4. T-SNE Visual Analysis

To further evaluate the feature learning ability of the improved FFT-SE-TCN-SVM model and visually demonstrate its effect on feature extraction from input data, t-Distributed Stochastic Neighbor Embedding (t-SNE) was used to map the high-dimensional feature space onto a two-dimensional plane for visualization. This method effectively preserves local structures, ensuring that similar data points remain close to each other in the low-dimensional space, which is useful for understanding the internal structure of complex datasets.

Figure 13 presents the fault feature visualization results after dimensionality reduction using t-SNE, with a comparison between the outputs before and after applying the three models. As shown in the figure, all three models are able to achieve a certain degree of fault feature separation, but there are significant differences in terms of clarity and clustering performance. The proposed improved model exhibits more distinct fault feature boundaries, with greater distances between different categories, indicating stronger discriminative ability and better generalization performance.

The experimental results demonstrate that the proposed method effectively extracts the raw fault features from the input data and transforms them into more representative features that better capture the essence of the faults, making it highly effective for bearing fault diagnosis and classification.

3.2. Experimental Analysis of Small Sample Data

In practical industrial environments, obtaining a large number of labeled bearing fault samples is often very challenging, making small-sample data testing a highly difficult task. To evaluate the proposed method’s diagnostic performance on small sample data, 50 samples were selected from each fault mode, totaling 500 samples, for training and testing the model to validate its effectiveness.

The model was trained with the same hyperparameter settings as in

Section 3.1. Cross-validation was used to reduce bias caused by randomness. Each method was tested in 10 experiments, and the average results of these 10 trials were taken as the classification performance metric. The results are shown in

Table 6, and

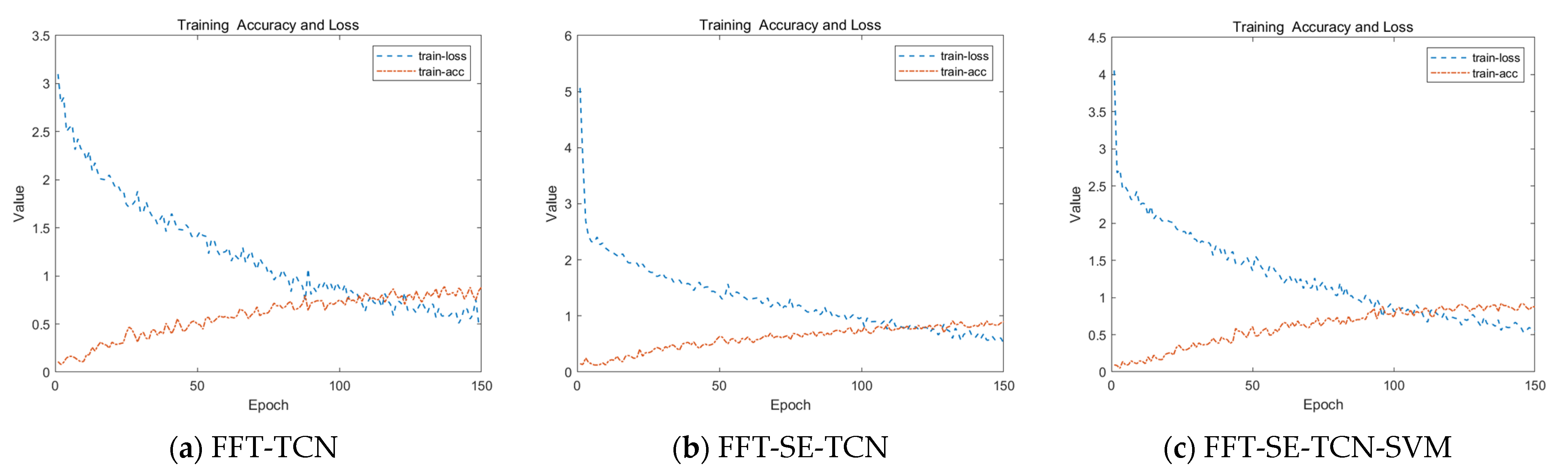

Figure 14 and

Figure 15 illustrate the classification results from a particular training session.

Figure 14 shows the training accuracy and loss curves for the three models. As the number of training epochs increased, the training accuracy gradually improved. The FFT-TCN model’s training loss decreased steadily, while the training losses of the FFT-SE-TCN and FFT-SE-TCN-SVM models dropped rapidly at first and then leveled off. The curves for the latter two models were smoother, indicating that the SE mechanism effectively enhanced the learning efficiency of the models. However, due to the limited data under the small sample condition, the training results had not stabilized after 150 training epochs. Therefore, in small-sample data conditions, adjusting the batch size to make gradient updates more stable could help achieve a more stable training process.

Figure 15 shows the confusion matrix for the classification results of the three models. The FFT-TCN model achieved an accuracy of 85.4%, but the classification accuracy for the 0.1778 mm inner race fault was only 2.2%, and the classification results for the 0.1778 mm and 0.3556 mm rolling element faults were relatively poor. The FFT-SE-TCN model achieved an accuracy of 89.8%, but the false positive rate for the bearing’s normal state was as high as 75%, and the classification accuracy for the 0.3556 mm rolling element fault was only 76.9%. The FFT-SE-TCN-SVM model similarly showed lower accuracy for the normal bearing state and the 0.3556 mm rolling element fault, but overall, it outperformed FFT-SE-TCN with an accuracy of 92.4%.

Table 6 compares the training time, F1 score, recall, and accuracy metrics for the three models. The proposed method does not have an advantage in training time but performs better overall in the other three evaluation metrics.

As shown in the fault feature visualization results of

Figure 16, none of the three models could effectively cluster and separate the normal bearing state and the 0.1778 mm inner race fault. The FFT-TCN model performed relatively better.

In summary, the proposed method demonstrates better overall fault classification performance for small sample data. To address the issue of insufficient fault data samples, data augmentation techniques can be applied to generate more diverse training samples, helping the model achieve better generalization.

3.3. Evaluation of the Model Generalization Ability

To evaluate the learning capability of the model proposed in this paper for unseen data, bearing fault data collected in the laboratory were used for testing and validation. This process aims not only to assess whether the model can extract generalizable patterns from the limited training samples but also to ensure that it maintains good predictive performance on previously unseen data.

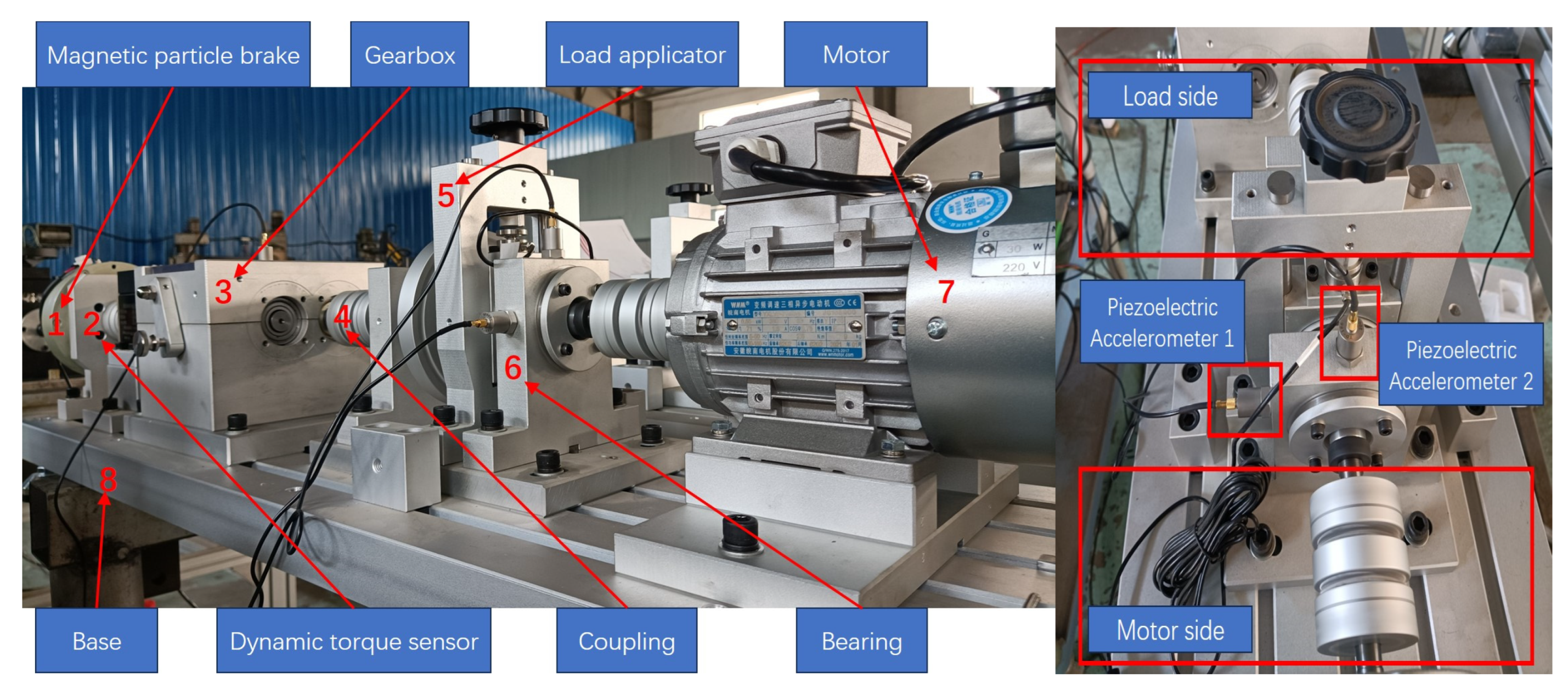

3.3.1. Data Set Introduction

The HFDZ-330 rotating machinery fault implantation experimental platform, built in the laboratory, is shown in

Figure 17. The experiment utilized three YD-186 piezoelectric accelerometers to collect vibration signals, which were installed at the longitudinal direction of the load side gearbox, the horizontal direction of the motor-side bearing, and the longitudinal direction of the bearing, with a sampling frequency of 51,200 Hz. The bearings were tested under operating conditions of 1500 r/min and 2100 r/min, with three different load conditions: no load, medium load of 10 kg, and high load of 20 kg. Additionally, a speed-up process from 0 to 2100 r/min was set up to simulate non-stationary operating conditions with varying speeds.

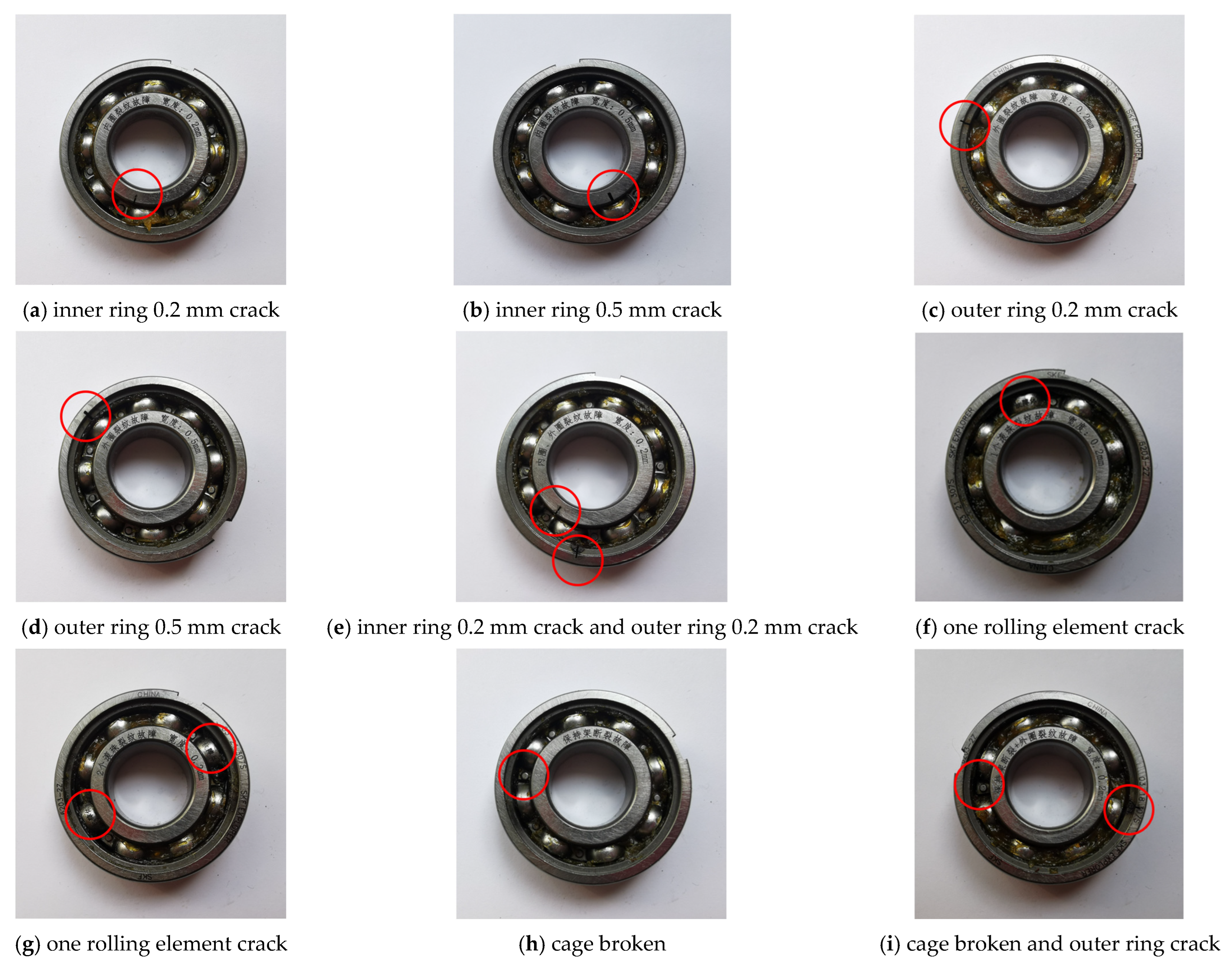

The experimental bearings used were of the model 6203-2Z SKF, with parameters listed in

Table 7. The characteristic frequencies for a rotational speed of 1500 r/min are provided in

Table 8. Prior to the experiment, grooves of varying degrees of damage were machined on the inner ring, outer ring, rolling elements, and cage using wire electrical discharge machining, as shown in

Figure 18. The red circles highlight the fault locations.

The experiment was arranged under a rotational speed of 1500 r/min and a load of 10 kg, with 10 fault modes, including normal state, inner ring crack with a width of 0.2 mm, inner ring crack with a width of 0.5 mm, outer ring crack with a width of 0.2 mm, outer ring crack with a width of 0.5 mm, inner and outer ring cracks with a width of 0.2 mm, one ball crack with a width of 0.2 mm, two ball cracks with a width of 0.2 mm, cage fracture fault, and composite outer ring crack fault with a width of 0.2 mm. The bearing fault data sample information is presented in

Table 9, which includes not only single fault types but also data on various compound fault types. By using a high-quality and diverse dataset, this allows for a more accurate evaluation of the model’s performance when faced with complex and variable real-world application scenarios.

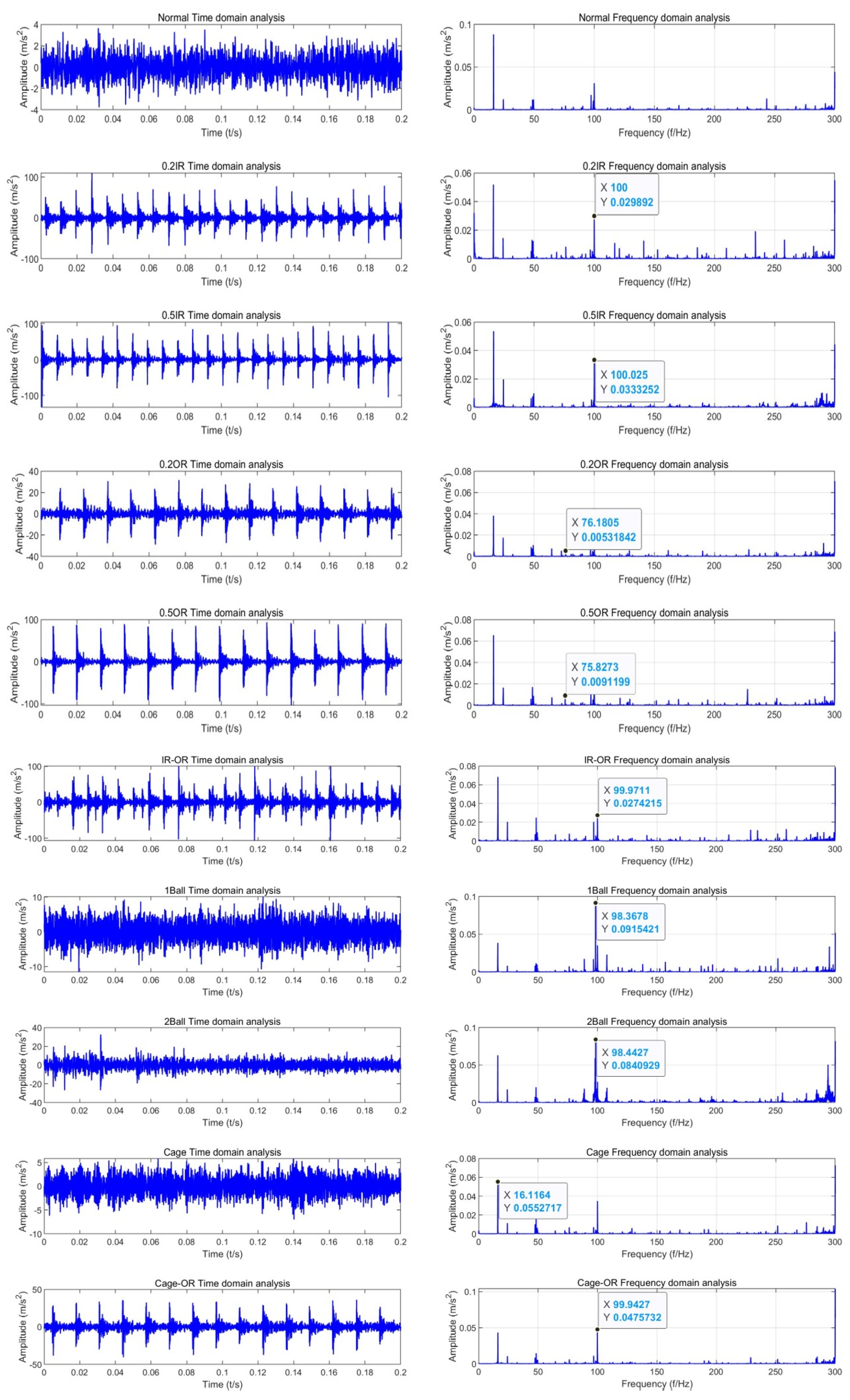

3.3.2. FFT Result of Laboratory Data

Figure 19 shows the time-domain and frequency–domain analysis results of normal and faulty bearing data collected in the laboratory.

In the normal state, the time-domain signal of the bearing vibration is relatively stable, with no obvious periodic fluctuations or abnormal peaks. The frequency spectrum is smooth, with the main energy concentrated in the low-frequency range. In the faulty state, the time-domain signal exhibits periodic pulse signals, indicating the presence of some periodic impact or vibration. For different faults, the amplitude and pulse interval of the pulse signal change. After applying FFT to process the signal, specific frequency components caused by the fault appear as prominent peaks in the frequency–domain plot. The inner race fault is found around 100 Hz, with fault diameters of 0.2 mm and 0.5 mm corresponding to amplitudes of 0.0298 and 0.0333 m/s2, respectively. The outer race fault frequency peak appears at 76 Hz, with fault diameters of 0.2 mm and 0.5 mm corresponding to amplitudes of 0.0053 and 0.0091 m/s2, respectively. Therefore, the frequency–domain data obtained from the FFT processing of the collected signal are more conducive to extracting sequential information and assisting in subsequent analysis.

3.3.3. Model Analysis of Laboratory Data

To verify the generalization ability of the proposed FFT-SE-TCN-SVM method for bearing fault data collected on the laboratory platform, the network model trained on the CWRU bearing fault dataset is tested on the laboratory-collected bearing fault data. This is to examine whether the model can maintain good predictive performance on unseen new data.

The laboratory data are organized with 2048 points as one sample, and 50 samples are randomly selected for each type of fault to form the test set. The fault data sample information is shown in

Table 9. The classification and diagnostic performance of the model based on the original sample data in

Section 3.1 and the small sample data model in

Section 3.2 are evaluated.

In this experiment, the model parameters are strictly frozen: the SE-TCN network weights and PSO-SVM hyperparameters are determined based on the CWRU dataset. The laboratory data are used only for forward inference testing and do not participate in any gradient updates or parameter optimization. Cross-validation is used to reduce bias caused by randomness. Ten experiments are conducted, and the average result of the ten trials is used as the performance metric for classification evaluation.

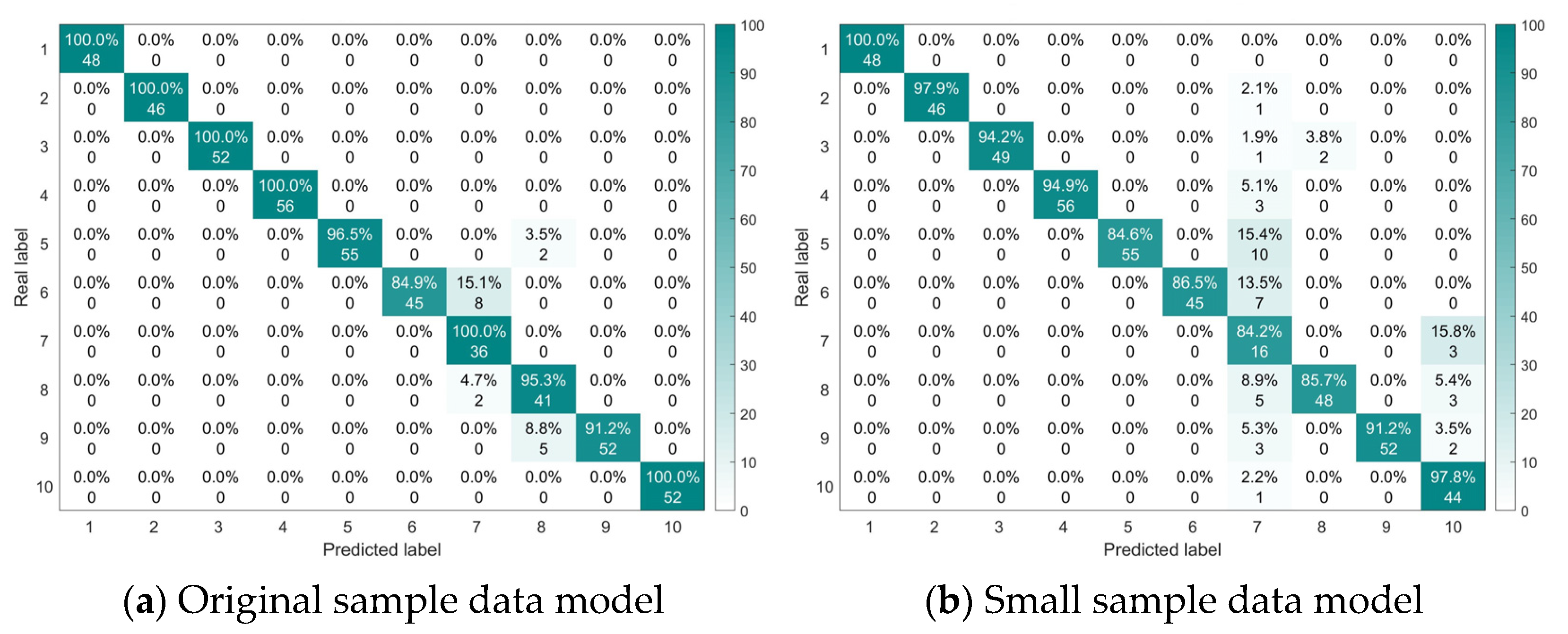

Figure 20 shows the confusion matrix of the classification results for the original sample data model and the small sample data model for a specific trial. In

Figure 20a, the accuracy of the test set for the original samples reached 96.6%, with a small number of classification errors for the bearing faults including a 0.5 mm outer ring crack, 0.2 mm inner and outer ring cracks, 0.2 mm cracks in two rolling elements, and cage fracture. All other faults were classified correctly. In

Figure 20b, the accuracy for the small sample test set reached 91.8%, with correct classification only for the normal bearing state, and varying degrees of classification errors for all fault states.

The test results show that the proposed model achieves good diagnostic performance on laboratory bearing fault data, with a high average fault classification accuracy, demonstrating strong generalization ability.