Media-Free and Contactless Micro-Positioning System Using Ultrasonic Levitation and Magnetic Actuators

Abstract

1. Introduction

2. Concepts and Structures of Actuators

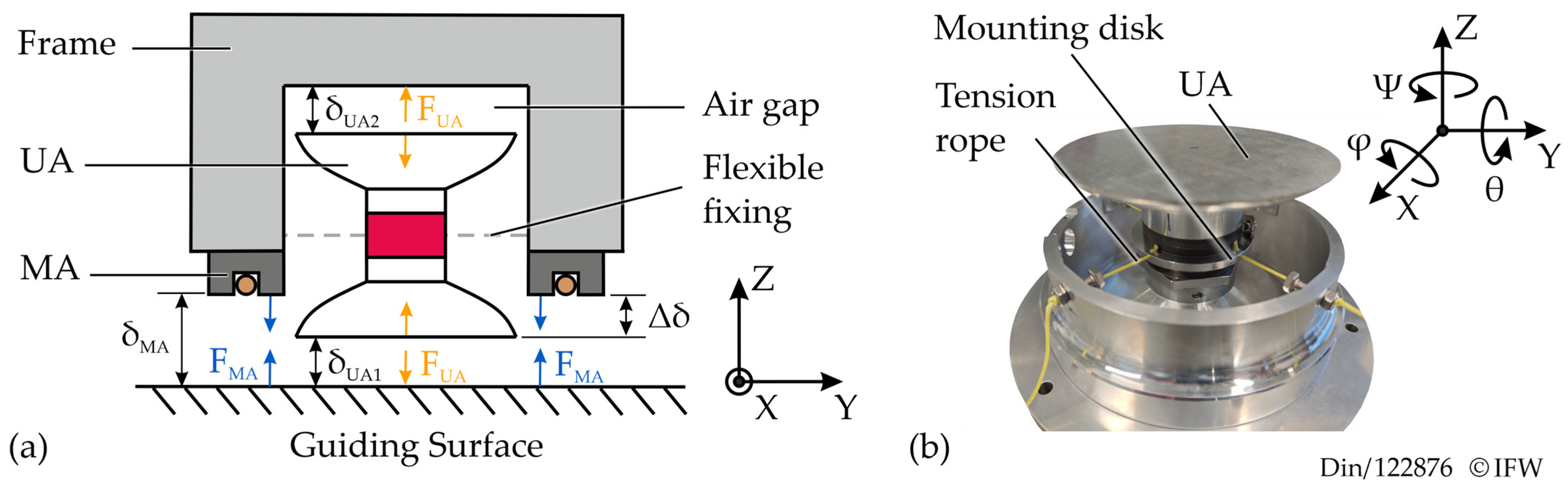

2.1. Concept of Hybrid Actuator

2.2. Structure of Ultrasonic Actuator

2.3. Structure of Magnetic Actuator

2.4. Structure of Overall Positioning System

3. Control of the Positioning System

3.1. Control of the Ultrasonic Actuator for Levitation

3.2. Control of the Magnetic Actuator for Positioning

3.3. Experimental Setup

4. Results and Discussion

5. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DOF | Degree of Freedom |

| MA | Magnetic actuator |

| MEMS | Micro-electro-mechanical system |

| MPT | Micro-production technology |

| PLL | Phase-locked loop |

| RCP | Rapid-control-prototyping |

| UA | Ultrasonic actuator |

References

- Riemer, O. Advances in ultraprecision manufacturing. In Proceedings of the Japan Society of Precision Engineering, Kanazawa, Japan, 20–22 September 2011; pp. 1–6. [Google Scholar]

- YOLE Group. MEMS Market Regains Momentum. Leading Companies Bosch, STMicroelectronics and TDK Navigate the Post Inventory Growth Era. Available online: https://www.yolegroup.com/press-release/mems-market-regains-momentum-leading-companies-bosch-stmicroelectronics-and-tdk-navigate-the-post-inventory-growth-era (accessed on 16 November 2025).

- Wulfsberg, J.; Redlich, T.; Kohrs, P. Square Foot Manufacturing a new production concept for micro manufacturing. Prod. Eng. 2010, 1, 75–84. [Google Scholar] [CrossRef]

- Lei, P.; Wang, Z.; Shi, C.; Peng, Y.; Lu, F. Simulation, Modeling and Experimental Research on the Thermal Effect of the Motion Error of Hydrostatic Guideways. Micromachines 2021, 12, 1445. [Google Scholar] [CrossRef] [PubMed]

- Kayapinar, H. Lineardirekt Mehrkoordinatenantrieb für Werkzeugmaschinen. Doctoral Dissertation, TEWISS Verlag, Garbsen, Germany, 2015. [Google Scholar]

- Zhao, Q.; Qiang, M.; Hou, Y.; Chen, S.; Lai, T. Research Developments of Aerostatic Thrust Bearings: A Review. Appl. Sci. 2022, 12, 11887. [Google Scholar] [CrossRef]

- Andres, L. Notes 12(b): Hydrostatic Journal Bearings; Texas A&M University: College Station, TX, USA, 2010. [Google Scholar]

- Zha, J.; Cheng, K.; Xue, F.; Wu, D.; Liu, X. Hydrostatic guideways for precision machines: The state-of-the-art and future perspectives. Tribol. Int. 2024, 200, 110060. [Google Scholar] [CrossRef]

- Denkena, B.; Dahlmann, D.; Krueger, R. Electromagnetic Levitation Guide for Use in Ultra-Precision Milling Centres. Procedia CIRP 2015, 37, 199–204. [Google Scholar] [CrossRef]

- Denkena, B.; Reiners, J.; Wallaschek, J.; Twiefel, J.; Ille, I. Application of Combined Ultrasonic-Levitation-Magnetic-Actuatos for Machine Guideways. In Proceedings of the ACTUATOR 2016—15th International Conference on New Actuators, Bremen, Germany, 13–15 June 2016; pp. 236–240. [Google Scholar]

- Reiners, J.; Denkena, B. Investigation on the Dynamic Behaviour of an Ultrasonic-Levitation Magnetic Guiding System. Adv. Mater. Res. 2016, 1140, 377–383. [Google Scholar] [CrossRef]

- Mojrzisch, S.; Ille, I.; Wallaschek, J.; Denkena, B. A Hybrid Ultrasonic Squeeze Film and Magnetic Levitation Actuator for Machine Guideways. In Proceedings of the IEEE International Ultrasonics Symposium, Prague, Czech Republic, 21–25 July 2013; pp. 485–487. [Google Scholar]

- Reiners, J. Kombinierte Ultraschall-Levitations-Magnetführung. Doctoral Dissertation, TEWISS Verlag, Garbsen, Germany, 2022. [Google Scholar]

- Chen, Z.; Twiefel, J.; Ding, C.; Buhl, H.; Denkena, B.; Wallaschek, J. Novel Design and Control of Ultrasonic Transducers for a Media-Free Contractless Micro-Positioning System. Actuators 2025, 14, 547. [Google Scholar] [CrossRef]

| Material | PIC181 (from PI Ceramic GmbH, Lederhose, Germany) | |

|---|---|---|

| Density | 7800 kg/m3 | |

| d33 | 2.65 × 10−10 C/N | |

| Quality factor | 2000 | |

| Dielectric loss factor | 3 × 10−3 | Chen © IDS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Denkena, B.; Wallaschek, J.; Buhl, H.; Twiefel, J.; Ding, C.; Chen, Z. Media-Free and Contactless Micro-Positioning System Using Ultrasonic Levitation and Magnetic Actuators. Actuators 2025, 14, 563. https://doi.org/10.3390/act14110563

Denkena B, Wallaschek J, Buhl H, Twiefel J, Ding C, Chen Z. Media-Free and Contactless Micro-Positioning System Using Ultrasonic Levitation and Magnetic Actuators. Actuators. 2025; 14(11):563. https://doi.org/10.3390/act14110563

Chicago/Turabian StyleDenkena, Berend, Jörg Wallaschek, Henning Buhl, Jens Twiefel, Chenglong Ding, and Zijian Chen. 2025. "Media-Free and Contactless Micro-Positioning System Using Ultrasonic Levitation and Magnetic Actuators" Actuators 14, no. 11: 563. https://doi.org/10.3390/act14110563

APA StyleDenkena, B., Wallaschek, J., Buhl, H., Twiefel, J., Ding, C., & Chen, Z. (2025). Media-Free and Contactless Micro-Positioning System Using Ultrasonic Levitation and Magnetic Actuators. Actuators, 14(11), 563. https://doi.org/10.3390/act14110563