Abstract

To achieve optimal controllability in a dual steering tractor (a four-wheel, iso-diametric tractor equipped with a dual-hydraulic steering system), this study proposes a coordinated approach that combines experimental testing (using a special agricultural tractor) with numerical analysis of the entire vehicle, developed in Bond Graph-3D. For certain crops, a dual steering vehicle is used to meet the needs of professionals who require easy maneuverability in narrow spaces and/or reduced steering time. This study aims to explore the reasons behind the need for dual steering tractors, highlighting the advantages and disadvantages of these two different configurations and ultimately focusing on the combined benefits of both. Based on an extensive review of the literature and drawing from previous studies, this paper analyzes aspects such as the variation in noise levels (or comfort level) experienced at the steering wheel when switching from Ackermann steering to a dual steering system. After outlining the theoretical methodology used to describe the model, both experimental and numerical analyses of a vineyard tractor in operation are presented. The goal of this work is to provide guidance on design methods and, through the Bond Graph-3D model, suggest the best control algorithms to minimize steering noise and enhance driving comfort. This research aims to pave the way for future control strategies in electrohydraulic steering systems.

1. Introduction

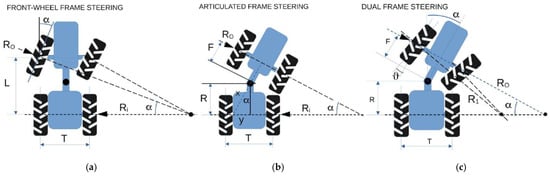

The main goal of this research is to identify an optimal control algorithm that enhances maneuverability at low speeds, with a reduced tractor turning radius, while maintaining stability and comfort at high speeds, similar to a classic Ackermann vehicle. Dual steering systems integrate both front and articulated steering methods, aiming to improve stability and optimize operational efficiency by reducing cycle times. Among early studies, researchers such as Horton and Crolla [1] have investigated lateral stability using planar linearized three-degree-of-freedom (3-DOF) models, yielding results consistent with the issues reported by manufacturers. For articulated vehicles, they used a torsional spring and damper at the articulation joint to model the hydraulic cylinders between the front and rear sections. Other researchers have taken a different approach by integrating 3-DOF vehicle models with the inclusion of normalized equations of the steering valve and hydraulic cylinder, as proposed by Merritt [2] and proved by Azad [3]. Figure 1 shows various configurations, along with simplified expressions, that allow for the estimation of the inner and outer radii for each configuration. The vehicle being analyzed is a tractor designed for agricultural use, specifically in vineyards. The tractor’s ultra-compact design requires an independent steering system for both the front axle and central articulation to ensure consistent chassis behavior at high speeds and to enhance steering capabilities during maneuvers. With specific reference to Figure 1, Table 1 presents the main geometric data of the tractor used in the experimental tests.

Figure 1.

Schematics of front steering (a), articulated steering (b), and dual steering systems (c).

Table 1.

Comparative analysis for one specific tractor (based on geometric layouts).

Equations (1) and (2) refer to Figure 1a. Equations (3) and (5) refer to Figure 1b, and Equation (6) refers to Figure 1c. Equation (4) is the same for Figure 1b,c. It is noteworthy that the turning radius of the system with central articulation is greater than the corresponding turning radius of a front-wheel steering system, such as the Ackermann. However, it is important to mention that tractors come in various widths (median roadway), and in this case, the smallest value has been used. This study primarily focuses on enhancing the driver’s steering experience to minimize unnecessary corrections during operation (as clearly highlighted in Section 2) and, secondarily, on a numerical model that encompasses all of the vehicle’s components and systems. To achieve the main goal, it was necessary to highlight the advantages and disadvantages of these different steering architectures, first, by reviewing the literature on similar problems and conditions studied by other researchers, and second, by employing a technical approach. To describe the vehicle behavior in each part (or sub-system), a numerical approach is used. Using a bond graph methodology, the system demonstrates a thorough integration and understanding of the physical principles governing it. This process allows researchers to “read” and conceptualize the system holistically, fostering a detailed understanding of its internal interactions. Multidomain simulation tools offer preprogrammed libraries for mechanical and hydraulic systems, simplifying the modeling process. However, they abstract key physical phenomena within prebuilt components, which can limit users’ insights into the underlying physics. This approach prioritizes convenience over a deeper, conceptual understanding, with users typically focusing on assembling predefined modules rather than fully engaging with system interactions. A bond graph is a graphical language that allows researchers to systematically derive the state equations of the system from the diagram itself. Using bond graphs ensures that no aspects of the system’s dynamics are overlooked, providing a solid foundation for implementing control strategies and regulatory systems. For these reasons, in this work, 20-Sim software was used. An overview of important software tools specifically designed for multibody and multiphysics simulations is presented in Table 2.

Table 2.

Main software for multibody and multiphysics simulations.

The literature concerns off-road machinery simulation. This study identified two trends in this field: the first includes systems such as the MODELICA Multibody library with HyLib (Otther P. and Beather M., 2003 [4]; Patil A. and Radle M., 2021 [5]), AMESim with the Planar Mechanical library (Altare G., 2009 [6] and Altare et al. 2012 [7]; Casoli P. and Alvin A., 2011 [8]), and MATLAB/Simulink with SimMechanics (Simscape) (Prabhu S.M., 2007 [9]; Jhala H.S., 2023 [10]; Hong T.D. et al., 2024 [11]); the second encompasses systems that require specialized interfaces to exchange variables across domains during simulation. Examples include co-simulations such as ADAMS and AMESim (Roccatello et al., 2007 [12]), ADAMS and MATLAB (Sapietova A. et al., 2012 [13]), and AMESim and Virtual Lab Motion (Prescott, 2009 [14]).

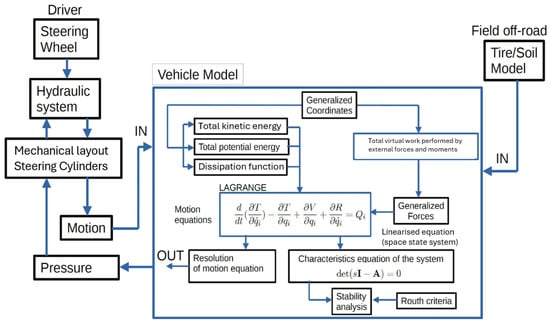

On the introduction of the tractor virtual model in 3D-BG, Xu and others [15] advocate for the incorporation of cylinder speeds as inputs, yet they subsequently employ algorithms based on the principle of minimum resistance within the Lagrangian framework. Figure 2 presents a block diagram representing the Lagrange approach. It is important to note a discrepancy: while the depicted inputs are forces, this contradicts the physical principle that the input variables from the hydraulic actuators, applied to the multibody model, should be velocities rather than forces. Similarly, the inputs from the tire/wheel interaction are forces exerted by the ground, and they impose a certain kinematic constraint dictated by the cylinders. Specifically, the mechanical domain is modeled using a 3D-BG vectorial domain, while the hydraulic domain is represented through a 1D-BG scalar domain. De las Heras and Codina [16] have a proven track record and extensive experience employing this methodology. This article focuses on the structural baseline part, consisting of a finite number of rigid bodies and joints. Several modules of this toolbox have demonstrated successful application in vehicle modeling to predict dynamic behavior, as shown by Filippini [17,18], and have been effectively employed in another project related to vehicle fault diagnosis by Silva L. et al. [19]. The spatial motion of the rigid bodies is determined using the well-established Euler equations. Moreover, it is highly capable of interacting with multiple energy domains, as indicated by Borutzky [20] and Thoma J. [21]. Regarding multibody systems, a variety of bond graph techniques have been introduced: Karnopp and Rosenberg [22] have outlined a strategy for generating bond graphs using Lagrange’s equations, and Bos [23] has presented a modular strategy rooted in Newton–Euler equations. Various experimental and numerical tests have been conducted by the authors to establish a clear path for investigating the optimal approach to achieving controllability in travel and drivability in dual steering mode. The first technical experiment, carried out using a tractor prototype, aimed to transition from an Ackermann steering system to a dual steering system. This was followed by a model of the entire tractor, created using 20SIM v5.1. [24]. This article demonstrated a possible control strategy for a steering system.

Figure 2.

Block diagram schematizing the Lagrange approach [6].

2. Methodologies

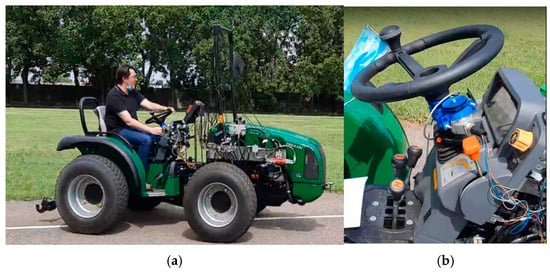

Initially, an experimental design was produced to highlight the differences in instability between the Ackermann steering mode and the dual steering mode. The differences are discussed in Section 4. Following this, a numerical analysis with a 3D simulation was performed to compare the experimental results with all available (and unavailable) data introduced into the simulation. The tractor used in the field experiments is an isodiametric tractor (a tractor with all wheels of the same diameter), equipped with a 73 kW engine and a new electrohydraulic dual steering system. Figure 3 shows the prototype. The chassis used for the experiments is based on a common dual steering system tractor (with mechanical links), which was modified to incorporate the aforementioned hydraulic system. Due to confidentiality, detailed descriptions of the hydraulic components used cannot be disclosed in this article.

Figure 3.

(a) Prototype tractor with a new ECU and new hydraulic system under analysis; (b) roto transducer installed under the steering wheel to log the steering movement in the two working conditions under investigation: traveling in dual steering mode and traveling in Ackermann mode.

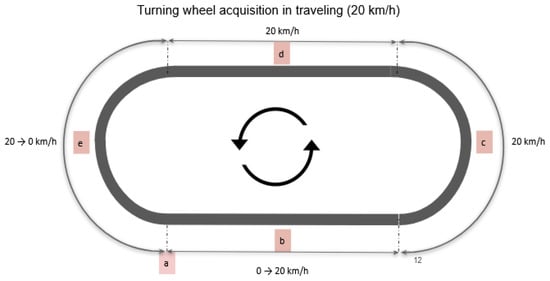

Figure 4 depicts the specific track used for conducting field tests and evaluating both stability and vehicle trajectories. The letters a–e depicts the speed trend. The track was asphalted (not tarmac), dry (on a sunny day at 28 °C), and in a test area closed track in northern Italy. The test track consisted of multiple segments, starting at point “a”, which marks the beginning of the trial. Prior to the start of the experiment, a briefing session was held, involving full steering maneuvers to the left and right. This was carried out to demonstrate the functionality of each sensor and the data-logging equipment. No ground experiment was performed during this period. The main sensors used for the experiment are described in Table 3.

Figure 4.

Circuit for the stability experiment in dual steering and Ackermann mode.

Table 3.

Main sensors used in tractor experiments.

The experiments were conducted using a portable HYDAC HMG 4000 data recorder, a powerful mobile handheld measuring device with a 5.7″ color touchscreen, designed for recording and storing measurement data. The J1939 CAN protocol was used for the experiment, connecting to the ECU for central steering control and the WDGA encoder. This model aims to encompass the specifications of both steering systems, whether synchronized or not, in conjunction with a dynamic model of the articulated vehicle. The proposed methodology, which considers cylinder velocities as inputs, provides a more straightforward and clear approach for dynamic modeling.

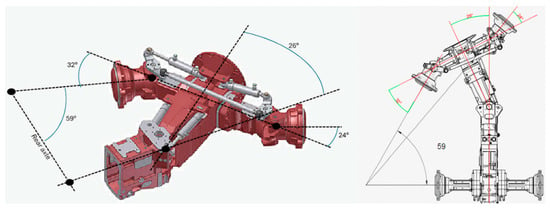

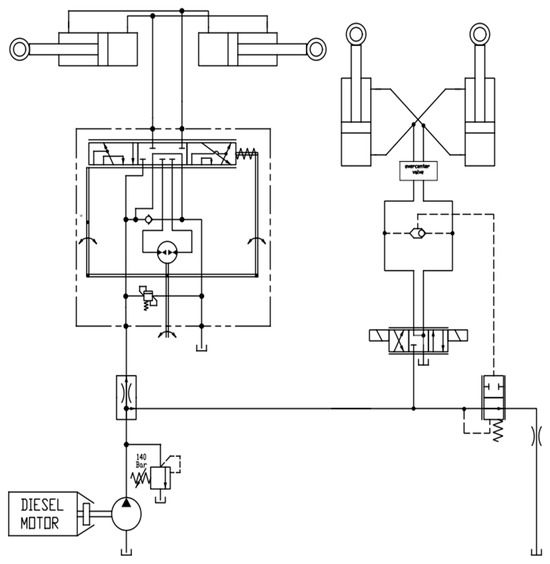

Before analyzing the dynamic model, it is important to provide an overview of the hydraulic circuit used to control the dual steering system in the tractor under analysis. The vehicle under study is a tractor with isodiametric wheels, central articulation, and directional front wheels, as depicted in Figure 5. Additionally, Figure 6 presents a simplified diagram of the hydraulic circuit with a description for each component shown in Table 4. The approach encompasses two primary modules: the hydraulic domain model and the mechanical domain model. Firstly, this study addresses the actuators for the implements, which include both the steering system and its associated hydraulic drive system. These systems are treated as one-dimensional (1D) systems in our modeling approach, utilizing fundamental 1D bond graph elements. Finally, the validity of this approach will be confirmed by comparing its numerical results with a series of experimental data obtained from field tests.

Figure 5.

Three-dimensional view of tractor chassis and top view with steering angles.

Figure 6.

Simplified diagram of hydraulic circuit.

Table 4.

Hydraulic components.

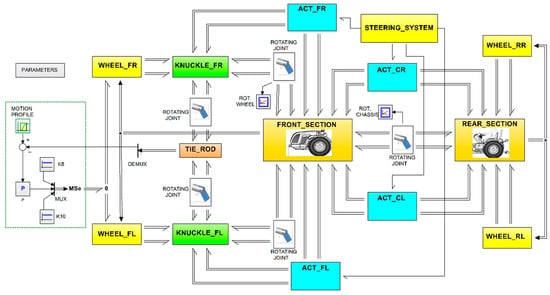

The dual steering tractor model, depicted in Figure 7, was designed to emulate a tractor with its two rigidly joined bodies (rear and front sections), with the pivot point located near the geometric center of the vehicle. Alongside the pivot point system, the vehicle’s two bodies are connected by hydraulic actuators integrated into the central steering system. It is worth noting that this type of vehicle is not equipped with suspensions, and the cantilever engine is mounted in a forward position, affecting the center of gravity (CoG) and the distribution of mass. More than 50% of the tractor’s weight is supported by the front axle, mainly due to the weight of the diesel engine. The vehicle’s sections are modeled as rigid bodies, with a local coordinate system (x, y, z) attached to their center of mass and aligned with their principal axes. Each section has a mass mmm, and moments of inertia JrJ_rJr (roll) about the x-axis, JpJ_pJp (pitch) about the y-axis, and JyJ_yJy (yaw) about the z-axis. To determine the motion of a rigid body in space, a set of relations known as Euler equations is used. Additionally, it is necessary to model the interconnections between rigid bodies (joints) and the actions of the external environment on them. In the model, a joint represents the force relationship between the rigid bodies it connects, depending on their position and relative orientation. In summary, the dual steering tractor is composed of multiple interconnected rigid bodies, including the rear- and front-section bodies (orange box), tie rod (red box), knuckles (green box), and wheels and wheel/tire assemblies (yellow box), as can be seen in the 3D-BG of Figure 7.

Figure 7.

Bond graph virtual model of articulated tractor (3D-GB upper layer).

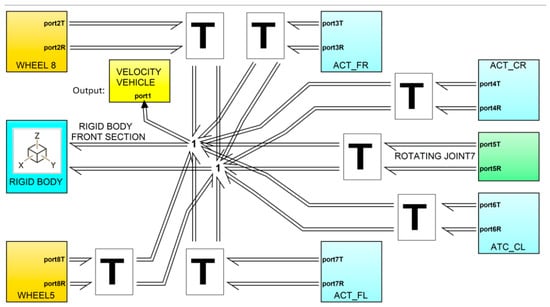

Given the hierarchical structure—model, submodels, BG basic elements, and constitutive equations—Figure 7 presents the bond graph submodel schematic implicit in the front-section icon. To establish the connection between the rigid body of the front section and the central rotating joint (white box), a translation is required. Additionally, a series of translations (T elements) are necessary to facilitate the interconnections between this rigid body and its interactions with external environmental forces, linking them to the steering hydraulic actuators (blue box) and the wheels (orange box).

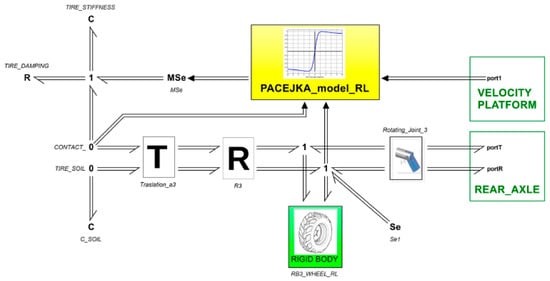

Next, this study will focus specifically on the wheel submodule, which, as shown in Figure 8, incorporates the behavior of the wheel as a rigid solid (green box) and the tire/soil interaction (yellow box).

Figure 8.

Front-section platform submodel (3D-BG scheme—sublayer n°1).

In Figure 9, which shows a part of the scheme from Figure 6 in the bottom left corner, the icons of the hydraulic actuators (blue box) responsible for the kinematics of the operator-imposed steering are visible. These submodels are connected to the hydraulic system submodel (yellow box in Figure 6). Additionally, Figure 9 illustrates the hierarchical structure of the hydraulic cylinder, highlighting the connection between the mechanical domain and the hydraulic domain.

Figure 9.

Wheel submodel tire/soil interaction (3D-BG scheme—sublayer n°1).

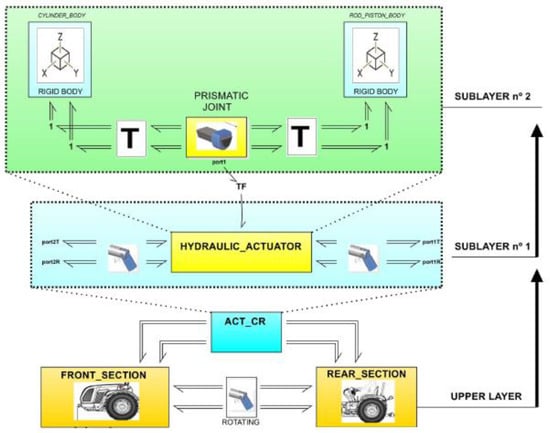

The four hydraulic actuator submodels (RL, RR, FL, FR), which are responsible for the dual steering system, are configured by combining the mechanical domain (a hydraulic cylinder consisting of two mechanical elements, the housing or cylinder, and the piston/rod assembly that slides inside the former) and the hydraulic domain (which, powered by energy from the ICE engine to the hydraulic group, generates relative motion between the two mechanical parts). In other words, the flow provided by the hydraulic group is transformed into rod velocity, which in turn serves as input for the multibody system. This motion is then returned to the hydraulic system as resistive force and working pressure, ultimately requiring a certain torque from the ICE engine.

Hydraulic Domain

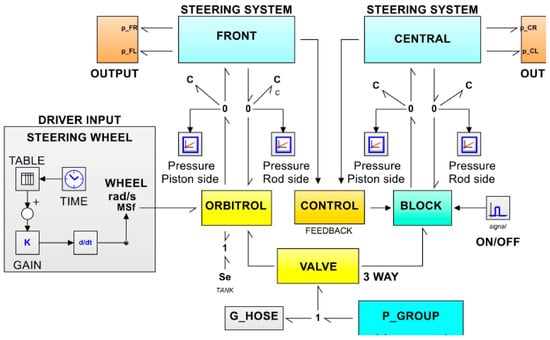

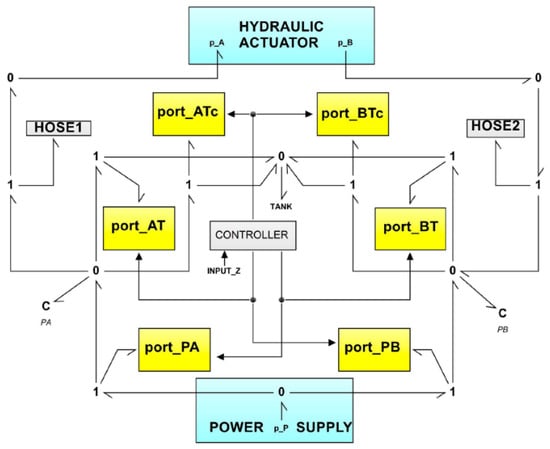

As described in the previous section and outlined in Figure 6, the four hydraulic actuators are responsible for the dual steering system implemented in the tractor. Building on this, using the hydraulic domain as a reference point, Figure 10 presents the scalar bond graph structure developed for the proposed hydraulic circuit to simulate the dual steering system (front and central steering). Additionally, the 3D prismatic joint is connected to a 1D bond graph diagram corresponding to the fluid mechanics domain, incorporating equations of mass conservation (including oil compressibility) and the conservation of momentum.

Figure 10.

Hierarchical structure (by layer) of the hydraulic cylinder.

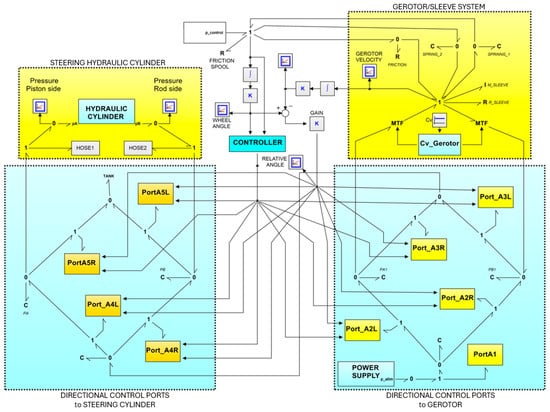

Other submodels worth mentioning in Figure 10 are those corresponding to the hydraulic block (green box), called orbitrol, and the 3-way valve (yellow boxes). The scalar bond graph diagrams for these two components (orbitrol) are shown in Figure 11 and Figure 12. The 3-way valve is shown in Figure 13.

Figure 11.

Steering hydraulic system (1D-BG scheme—sublayer n°1).

Figure 12.

HSU orbitrol hydraulic component (1D-BG scheme—sublayer n°2).

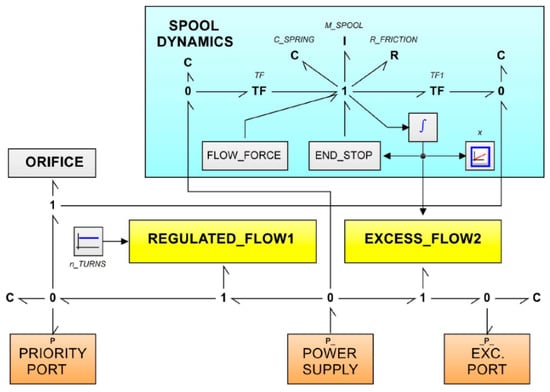

Figure 13.

Three-way valve (priority concept) (1D-BG scheme—sublayer n°2).

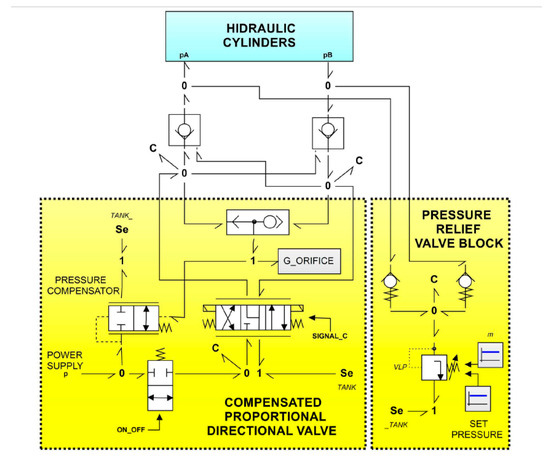

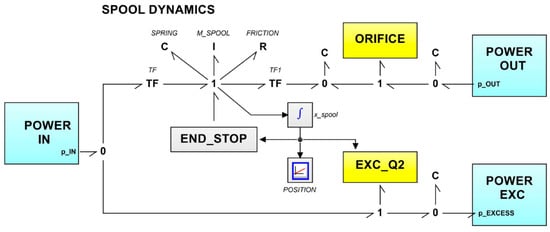

The key submodels in these two bond graph diagrams correspond to the icons labeled “Port_iii”, which physically represent the nine variable orifices of the rotary valve (spool/sleeve assembly) in the case of the orbitrol element, and the corresponding orifices of the directional control valve in the case of the three-way valve. To conclude this section, it is necessary to describe the submodel referred to as the block (green box in Figure 10). In this submodel, it is important to highlight the presence of the proportional valve with pressure compensation, for which the corresponding bond graph diagrams are illustrated in Figure 14 and Figure 15.

Figure 14.

Central steering system hydraulic circuit (submodel n°2).

Figure 15.

Proportional directional control valve (1D-BG scheme—sublayer n°3).

In these diagrams, the presence of variable-section throttles, also known as metering, is once again emphasized; they control the flow of oil feeding the hydraulic actuators of the steering systems. For this reason, it is pertinent to briefly explain how they have been simulated and the basic equations required for their modeling. On the other hand, it is unnecessary to investigate the description of the other hydraulic elements, as they are more conventional and well known to those familiar with fluid power technology and scalar bond graph diagrams. Table 5 provides a summary of the most significant parameters of the modeled hydraulic components, offering a comprehensive overview of their key characteristics and attributes.

Table 5.

Main simulation factors used in the numerical analysis.

This structure model and its characteristics started with the modelization of all information available (experimental data and bibliography) when this study started. The first improvement aims to make it easier to structure each submodel in order to reduce the simulation time. The identification of minor aspects that do not aid the quality of the results is the right way to proceed.

3. Numerical Results and Validation Procedure

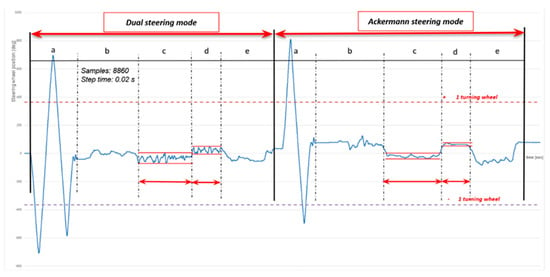

The trends displayed in Figure 16 represent the steering displacement logged by the rotary sensor, as reported in Table 2. Sector “a” corresponds to the warm-up phase, where the tractor is stopped and a full steering displacement is applied. This action is used to identify any issues before the tests. Sectors “c” and “d” highlight a significant shift in the tractor’s behavior. A noticeable trend can be observed at the corners, where the external forces are higher. The tendency is an increase in steering noise, especially in dual steering mode. Finally, sector “e” represents the last corner before the finish line. As shown in Figure 16 (8860 samples every 0.02 s as the logging time), the variability between the maximum and minimum values changes as the system switches from dual steering mode to Ackermann mode.

Figure 16.

Hydraulic pressure compensator (1D-BG scheme—sublayer n°3).

Parameter uncertainties are the main source of error in the simulation (real viscous friction coefficients, etc.). Inertial and geometrical parameters of the mechanical system, including the hydraulic actuator components, can be easily obtained from the CAD model. However, other parameters are more elusive, such as the elastic-damping parameters of the tires and, in particular, those related to verifying specific parameters of the hydraulic system and its components. In some cases, confidence has been placed in the technical expertise and professional experience of the laboratory technicians involved in this work, particularly in the art of simulating components and estimating more subjective parameters. Nonetheless, this result represents a starting point.

4. Discussion

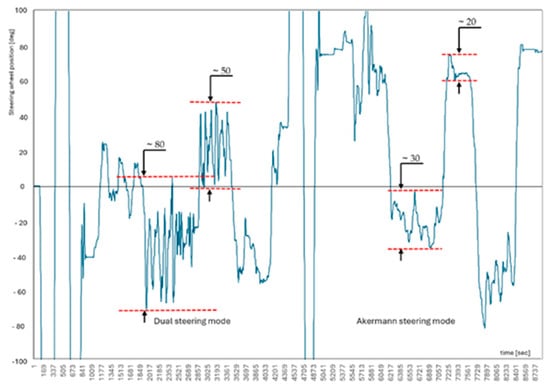

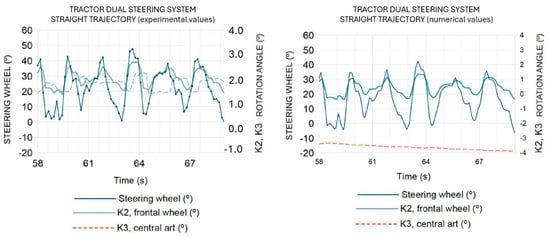

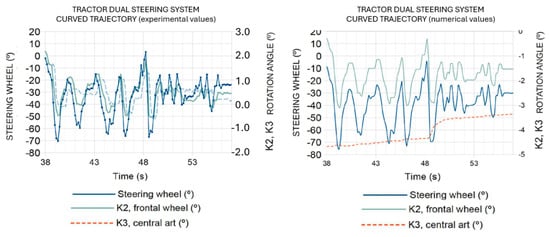

The tractor accelerates from 0 to 20 km/h while operating in dual steering mode. During the turn, the tractor maintains a constant speed of 20 km/h, a pattern that continues through sector d. Upon entering sector e, the tractor decelerates until it reaches a speed of zero. Once it reaches point a, there is a switch to Ackermann mode, and another turn is executed under the same acceleration and speed conditions. As described in the following data acquisition process, the first turn is performed in dual steering mode, followed by the second turn in Ackermann mode. When traversing the circuit at the same speed and vehicle condition in Ackermann mode, the steering noise lower, and the feeling of controllability is improved. According to the experimental data, it is evident that steering ability improves by 37.5% during cornering and by 40% in a straight-line direction, passing through the Ackermann configuration to dual steering configuration. This can be explained by the low impact of the tractor’s dynamics, and consequently, a smaller number of driving factors. In dual steering mode, the tendency difference is more pronounced. This can be attributed to both the vehicle’s dynamics (where some damping parameters have been hypothesized) and the metering devices (flow control valve and orbitrol model), where the metering function was not fully known, as indicated by the hysteresis in the experimental graph. This supports the conclusion that the concept of having a vehicle capable of switching between an Ackermann configuration and dual steering mode makes sense, as it can be adapted to the different tasks required by the tractor (maneuvers in tight spaces vs. high-speed transport operations). The primary focus was to maintain tractor stability and ensure as linear a trajectory as possible. Due to the significant gain associated with even a small movement of the steering wheel in dual mode, corrective counter-steering was required whenever snaking behavior occurred to realign the tractor. The results from simulations conducted using 20-SIM reveal differences in offset values. The input in the tractor model was the steering wheel acquisition (Figure 17 and Figure 18) performed during the experiment with the tractor. Practically, in running the model, the goal was to achieve the same trend shown by the sensor acquisition on the tractor. These variations are due to the zero value assumed by the position transducers located at the rotation points near the wheels/articulation. Due to space constraints, the sensors could not be oriented identically along the tractor’s axis due to the bulk of electrical connections and the space needed for cables (right/left steering). The values and trends in the graph shown in Figure 19 suggest that the numerical results closely follow the experimental trend in the Ackermann configuration and in a straight-line direction. However, the results differ for the dual steering system. Despite using the same control algorithm for both the front steering system and the central system, there is evidence of a lack of synchronization in the control system. A specific point worth mentioning is the difference observed in the central articulation (Figure 19, right), where a significant disparity is visible between the experimental trend and the numerical analysis. The input for the numerical analysis is the movement of the steering wheel, and the trends in the experimental and numerical data align for this aspect. However, the experimental data reveal a slight lag between the steering wheel movement and the movement of the front wheels, indicating elastic effects along the control chain (e.g., flexible hydraulic pipes, clearances between mechanical parts). The lag in the movement of the central articulation is more noticeable due to the combination of elastic elements (similar to the front steering) and the time required for the front steering variation detection, which is measured by the rotary sensor on the front wheels. The calculation took several hours (four) for just 10 s of simulation. The issues with the match between numerical and experimental data can be attributed to the absence of the central actuator in the numerical model. This could be identified as a delay in the actuation due to a restriction or an element that stiffens either the hydraulic model or the mechanical model. The data then undergo processing by the ECU before the hydraulic actuation reaches the cylinders. This results in a “congenital” actuation delay, which can only be reduced with a more rigid system (hydromechanical) and a faster electronic system. Analyzing the data further, the numerical model’s complexity arises from the large number of operations and the time required to obtain numerical results. The four-wheel submodels (RL, RR, FL, FR in Figure 7) play a crucial role in determining the vehicle’s behavior, as they are the only components directly interacting with the ground. In agricultural research, understanding the interaction between implements and unpaved soft soil is critical. Due to the soil’s low tensile strength, it deforms permanently, making any modeling effort involving soil interaction nonlinear and subject to significant material variability. Empirical approaches and field tests have been the primary methods for analyzing tire/soil interaction. The Pacejka tire models [25] are commonly used in professional vehicle dynamics simulations due to their reasonable accuracy, ease of implementation, and quick solution times. In this study, while the wheel is typically modeled as a rigid body, dynamic effects such as friction between the tire and the ground and the tire’s response to compression are also considered. The tire’s response to compression is modeled using a spring and damper mechanism operating vertically with respect to the global coordinate system, with parameters derived from relevant references [26,27]. To analyze the forces along the axes (Fx for longitudinal and Fy for lateral) and moments about these axes (Mx for overturning, My for rolling resistance, and Mz for aligning torque), the general form of the Magic Formula, introduced by Pacejka, is adopted. This formula uses empirical approaches to model force or moment as functions of a carefully selected “slip” variable representing the interaction between the tire and the ground. This issue, common in articulated vehicles [28,29,30,31,32,33], is largely mitigated when the Ackermann configuration is activated [34]. It offers a valuable perspective for discussing the need to analytically describe the physical model in each part and provide crucial information regarding driving strategy.

Figure 17.

Circuit path for the stability experiment in dual steering and Ackermann mode where a–e are the speed segments of the Figure 4 (time vs. steering grade displacement).

Figure 18.

Zoomed-in view of the variations in the experiment stability in dual steering mode and Ackermann mode (time vs. steering grade displacement).

Figure 19.

Experimental and numerical results regarding the dual steering systems (involving corrective counter of steering wheel movement in dual-mode steering) during curved and straight trajectory at 20 km/h.

5. Conclusions

This work has demonstrated a difference in terms of lateral stability between Ackermann and dual steering architectures under the same operating conditions, quantifying the variation between them. The results validate the large body of data available in the literature, which is only partially referenced in this work. The difference in terms of operator sensitivity lies in the increased attention required when using the tractor at a speed of 20 km/h, as the recall and correction operations are greater in terms of amplitude. The numerical analysis has highlighted the inherent difficulty of fully describing all aspects present in the dynamic field, noting that control in dual steering mode is complex and challenging to implement. The acquisition data presented above show a difference in terms of the vehicle’s steering ability, with the Ackermann mode being considered the most effective at high speeds. For this reason, the Ackermann mode can be switched automatically once a certain speed threshold is exceeded. This speed threshold can be chosen based on the maximum speed usable in dual steering mode, which typically corresponds to the end-field maneuverer speed. In the near future, the time response between the front and central steering systems will be investigated to identify delays in electronic and hydraulic signals within the “master and slave” dual steering system. A threshold can be set, relative to the vehicle speed, to disable dual steering mode when a certain speed is exceeded. Based on experimental data from experienced operators, this threshold is set to around 8.5 km/h. This value is specific to the case in question (type of soil, type of tractor wheelbase and length, type of tires and diameters, hydraulic circuit setup, etc.), should be based on expert opinions, and should not be generalized to other applications. The switch speed must be taken into account in different environmental conditions, and this aspect is under study in relation to the tractor model. For future work, different terrains will also be investigated to evaluate the repeatability regarding comfortability under each condition.

6. Patents

The system analyzed in this work has been patented as EP3871950A1-HIGH-MANEUVERABILITY VARIABLE-STEERING TRACTOR.

Author Contributions

The investigation was led and supervised by E.C.M. Experimental works and data processing were completed by G.P.M.; bond graph simulation models and illustrations were finalized by G.F., G.R.A., P.J.G.-M., G.P.M. and E.C.M. The manuscript was finalized by G.P.M. and P.J.G.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data in this study are available on request from the corresponding author. The data are not publicly available due to privacy reasons.

Acknowledgments

The authors would like to express their heartfelt thanks to Technical Director of BCS S.p.A. (BCS Group), for the exceptional development work carried out by him and his team on the tractor steering system. We also extend our gratitude to Albert Porta Forradelles for his significant contributions to the development of the numerical model at the beginning of this project.

Conflicts of Interest

The funding sponsor had no role in the design of this study; in the collection, analysis, or interpretation of data; or in the writing of the conclusions and in the decision to publish the results. The authors declare no conflicts of interest.

References

- Horton, D.N.L.; Crolla, D.A. Theoretical Analysis of the Steering Behaviour of Articulated Frame Steer Vehicles. Veh. Syst. Dyn. 1986, 15, 211–234. [Google Scholar] [CrossRef]

- Merrit, H.E. Hydraulic Control Systems; Wiley: New York, NY, USA, 1967; 358p. [Google Scholar]

- Lashgarian Azad, N. Dynamic Modelling and Stability Controller Development for Articulated Steer Vehicles [Internet]. University of Waterloo. 2007. Available online: http://hdl.handle.net/10012/2633 (accessed on 26 November 2024).

- Beater, P.; Otter, M. Multi domain simulation: Mechanics and hydraulics of an excavator. In Proceedings of the Conference: 3rd International Modelica Conference, Linkoping, Sweden, 3–4 November 2003; The Modelica Association: Linkoping, Sweden, 2003. [Google Scholar]

- Patil, A.; Radle, M. Hydraulic and multibody combined simulations for electric forklift design using modelica. Int. J. Eng. Sci. Technol. 2022, 10, 27–35. [Google Scholar]

- Altare, G. Analisi e Modellazione del Circuito Idraulico di un Miniescavatore. Master’s Thesis, Politecnico di Torino, Torino, Italy, 2009. [Google Scholar]

- Altare, G.; Lovuolo, F.; Nervegna, N.; Rundo, M. Coupled Simulation of a Telehandler Forks Handling Hydraulics. Int. J. Fluid Power 2012, 13, 15–28. [Google Scholar] [CrossRef]

- Casoli, P.; Alvin, A. Modelling of an Excavator Pump Nonlinear Model and Structural Linkage/Mechanical Model. In Proceedings of the 12th Scandinavian International Conference on Fluid Power, Tampere, Finland, 18–20 May 2011; pp. 25–40. [Google Scholar]

- Prabhu, S.M. Model-Based Design for Off-Highway Machine Systems Development; SAE: Warrendale, PA, USA, 2007. [Google Scholar]

- Jhala, H.S. A Multibody Simulation Approach to Identify Critical Instability Scenarios of a Forklift Truck. Master Automotive Technology. Master’s Thesis, Eindhoven University Technology, Eindhoven, The Netherlands, 2023. [Google Scholar]

- Hong, T.D.; Pham, M.Q.; Tram, S.C.; Tram, L.Q.; Nguyen, T.T. A comparative study on kinetics and dynamics of two dump truck lifting mechanisms using Matlab Simscape. Theor. Appl. Mech. Lett. 2024, 14, 100502. [Google Scholar] [CrossRef]

- Roccatello, A.; Manc, S.; Nervegna, N. Modelling a Variable Displacement Axial Piston Pump in a Multibody Simulation Environment. J. Dyn. Sys. Meas. Control 2007, 29, 456–469. [Google Scholar] [CrossRef]

- Sapietova, A.; Saga, M.; Novak, P. Multi software platform for solving of multibody systems synthesis. Commun. Sci. Lett. Univ. Zilina 2012, 14, 43–48. [Google Scholar] [CrossRef]

- Prescot, W. Using multibody dynamics solvers in a Multiphysics environment. Multibody Dynamics. In Proceedings of the ECCOMAS Thematic Conference, Warsaw, Poland, 29 June–2 July 2009. [Google Scholar]

- Xu, T.; Shen, Y.; Huang, Y.; Khajepour, A. Study of Hydraulic Steering Process for Articulated Heavy Vehicles Based on the Principle of the Least Resistance. IEEE/ASME Trans. Mechatronics 2019, 24, 1662–1673. [Google Scholar] [CrossRef]

- de las Heras, S.; Codina, E. Modelización de Sistemas Fluidos Mediante Bondgraph; S. de las Heras: Barcelona, Spain, 1997. [Google Scholar]

- Filippini, G.; Nigro, N.; Junco, S. Estudio del comportamiento dinamico de vehiculos terrestres utilizando la tecnica de bond graphs. Mec. Comput. 2005, XXIV, 1559–1582. [Google Scholar]

- Filippini, G.; Nigro, N.; Junco, S. Vehicle Dynamics Simulation Using Bond Graphs. December 2004. [Google Scholar]

- Silva, L.; Delarmelina, D.; Junco, S.J.; M’Sirdi, N.K.; Noura, H. Bond Graph Based Fault Diagnosis of 4 W-Vehicles Suspension Systems I: Passive Suspensions. Engineering. 2007. Available online: https://www.google.it/url?sa=t&source=web&rct=j&opi=89978449&url=https://bicyt.conicet.gov.ar/fichas/produccion/1038957&ved=2ahUKEwif3Iu53viKAxVF8bsIHY9rCZMQFnoECBkQAQ&usg=AOvVaw0xTVpxpM8ouuZrtodG6tjX (accessed on 26 November 2024).

- Borutzky, W. (Ed.) Bond Graphs for Modelling, Control and Fault Diagnosis of Engineering Systems; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Thoma, J.U. Simulation by Bondgraphs: Introduction to a Graphical Method; Springer: Berlin/Heidelberg, Germany, 1990; p. 1. [Google Scholar]

- Karnopp, D.; Margolis, D.L.; Rosenberg, R.C. System Dynamics: Modeling and Simulation of Mechatronic Systems, 5th ed.; Wiley: Hoboken, NJ, USA, 2012; p. 411. [Google Scholar]

- Bos, A.M. Modelling Multibody Systems in Terms of Multibond Graphs: With Applications to a Motorcycle; Universiteit Twente: Enschede, The Netherlands, 1986. [Google Scholar]

- 20-SIM Software Package for Mechatronic Systems [Internet]. Controllab Products. Available online: https://www.20sim.com/download/ (accessed on 26 November 2024).

- Pacejka, H.B.; Besselink, I. Tire and Vehicle Dynamics, 3rd ed.; Butterworth-Heinemann Elsevier: Waltham, MA, USA, 2012. [Google Scholar]

- Hao, L. Analysis of Off-Road Tire-Soil Interaction through Analytical and Finite Element Methods. Engineering, Environmental Science, Agricultural and Food Sciences. August 2013, p. 33. Available online: https://www.google.it/url?sa=t&source=web&rct=j&opi=89978449&url=https://kluedo.ub.rptu.de/files/3644/_Analysis%2Bof%2BOff-Road%2BTire-Soil%2BInteraction%2Bthrough%2BAnalytical%2Band%2BFinite%2BElement%2BMethods.pdf&ved=2ahUKEwj-1b2p4fiKAxWw3AIHHbmOIYgQFnoECB8QAQ&usg=AOvVaw2qganoqOMonCq3Uuojk2p_ (accessed on 26 November 2024).

- Lines, J.A.; Murphy, K. The stiffness of agricultural tractor tyres. J. Terramech. 1991, 28, 49–64. [Google Scholar] [CrossRef]

- Polotski, V. New reference point for guiding an articulated vehicle. In Proceedings of the 2000 IEEE International Conference on Control Applications Conference Proceedings (Cat No00CH37162), Anchorage, AK, USA, 27 September 2000; pp. 455–460. [Google Scholar]

- Dudziński, P.; Skurjat, A. System for improving directional stability for articulated vehicles. AIP Conf. Proc. 2019, 2078, 020084. [Google Scholar]

- Łopatka, M.J.; Rubiec, A. Concept and Preliminary Simulations of a Driver-Aid System for Transport Tasks of Articulated Vehicles with a Hydrostatic Steering System. Appl. Sci. 2020, 10, 5747. [Google Scholar] [CrossRef]

- Alhimdani, F.F. Dynamic Analysis of Steering Articulated Tracked Vehicles. J. Eng. Sustain. Dev. 2006, 10, 32–44. [Google Scholar]

- Delrobaei, M.; McIsaac, K.A. Design and Steering Control of a Center-Articulated Mobile Robot Module. J. Robot. 2011, 2011, 621879. [Google Scholar] [CrossRef]

- Dudziński, P.; Skurjat, A. Directional dynamics problems of an articulated frame steer wheeled vehicles. J. KONES Powertrain Transp. 2015, 19, 89–98. [Google Scholar] [CrossRef]

- Qiao, Y.; Chen, X.; Yin, D. Coordinated Control for the Trajectory Tracking of Four-Wheel Independent Drive–Four-Wheel Independent Steering Electric Vehicles Based on the Extension Dynamic Stability Domain. Actuators 2024, 13, 77. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).