Abstract

Current trends in the development of technology are linked inextricably to the increasing level of automation in technological processes and production systems. In this regard, the development of systems for supplying working fluids with adjustable pumps that have high performance characteristics, an increased service life and low operating costs is an important scientific and technical task. A primary challenge in the development of such systems lies in achieving low fluid flow rates while maintaining stable operating characteristics. This challenge stems from the fact that currently available controlled hydraulic pumps exhibit either a high cost or suboptimal life and efficiency parameters. This work focuses on the development of a plunger hydraulic pump with a small working volume. A mathematical model has been developed to investigate the characteristics, optimize the design of this pump and further expand the size range of such pumps. The solution was implemented on a computer using the dynamic modelling environment MATLAB/Simulink. In order to verify the mathematical model’s adequacy, a plunger pump prototype was built and integrated with a test bench featuring a measurement system. The test results showed higher pump efficiency and a significant reduction in hydraulic losses. An analysis of the obtained data shows that the pump is characterized by increased efficiency due to optimal flow distribution and reduced internal leakage, which makes it promising for use in hydraulic systems requiring improved operating characteristics. The developed pump has more rational characteristics compared to existing alternatives for use in water supply systems for induction superheaters. The experimental external characteristics of the developed pump are 10% higher than the external characteristics of the ULKA EX5 pump selected as an analogue, and the pressure characteristics are 65% higher. It offers production costs that are several times lower compared to existing cam-type plunger or diaphragm pumps with oil sumps and precision valve mechanisms. Additionally, it has significantly better operating characteristics and a longer service life compared to vibrating plunger pumps.

1. Introduction

Hydraulic pumps are an important element of hydraulic systems that are widely used in various fields of industry and technology. The most promising types are radial plunger pumps, which, due to the simplicity of their design, allow achieving high efficiency and safety indicators with relatively small dimensions. Plunger pumps are positive displacement pumps, where the delivery is determined by the geometry of the working elements and the frequency of their movement. In contrast to dynamic pumps such as centrifugal pumps, the delivery of plunger pumps remains almost constant and does not depend on the head [1,2].

The available hydraulic pumps with small displacement have either high cost, short life or poor external characteristics. Due to their small displacement and internal leakage, these pumps are not able to provide sufficient flow stability during pressure boosts [3,4,5,6].

The development of a small-displacement radial plunger pump is driven by the need to improve the efficiency and accuracy of hydraulic systems, an imperative in the context of contemporary requirements for energy conservation and environmental sustainability in equipment. These pumps are used in specialized applications, such as precision machine control, mobile technology, automation systems and robotics [7,8]. Low pumping flow is also used in superheaters and steam plasma power systems, where the power fluid is water at temperatures up to 80 °C [9]. The possibility of operation with different power fluids, compactness, the accuracy of liquid supply and high performance are the most important parameters for these units.

The main problem with existing plunger pumps is the valve mechanism [10,11]. In [12], the problems of fluid flow distribution are solved, but this solution is not applicable to small-displacement pumps.

The main objective of this development is to create a radial plunger pump with an eccentric shaft and a spool-type distributor mechanism to achieve an optimal ratio between operating costs and performance curve.

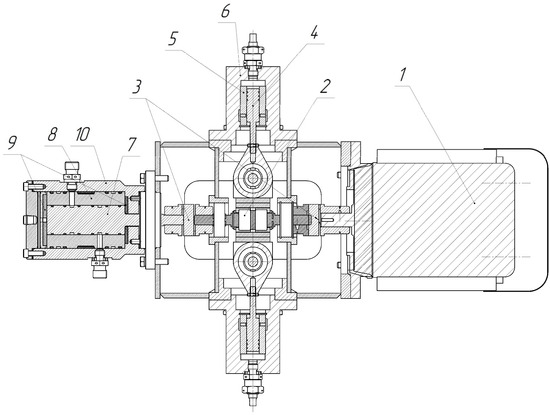

To solve these problems, the design of a low-flow plunger pump was developed (Figure 1) and its dynamic characteristics were investigated using the developed mathematical model and full-scale experiment [13,14,15,16,17,18,19,20,21,22,23,24,25,26,27].

Figure 1.

Construction of a low-flow plunger pump: 1—asynchronous electric motor, 2—cam mechanism, 3—shaft coupling, 4—plunger, 5—fluid liner, 6—pump cylinder, 7—valve spool, 8—control valve sleeve, 9—end plates, 10—hydraulic control valve.

The plungers (4) are moved by converting the rotation of the motor shaft (1) by means of the cam mechanism (2). At the moment of direct movement of the lower plunger, the spool (7) of the control valve (10) is rotated so that the piston cavity channel of the lower plunger connects with the discharge channel and the cavity of the other cylinder with the suction channel of the control valve (10).

Article [28] points out that micro plunger pumps are widely used in the field of deep-sea hydraulic equipment with modern intelligent technology due to their high power density, high output pressure and many other advantages. This paper conducts a hydraulic process simulation using the AMESim engineering software.

In [29], an electric plunger hydraulic pump is considered, which combines an electric motor and a hydraulic pump. The advantages of such devices are increasing efficiency, achieving miniaturization and promoting environmental sustainability. This paper presents a speed control strategy for an electric hydraulic pump that operates over the entire speed range without using position sensor feedback.

This review shows that there are significant gaps in the methodological and design support in this area of knowledge. Most pumps of this type have valve or membrane design schemes, which limit their productivity. The purpose of this work is to develop a new basic scheme of a low-volume hydraulic pump with improved performance characteristics by creating a spool valve distribution mechanism, constructing a mathematical model of a low-volume pump that allows maximum efficiency to be achieved and manufacturing a prototype for experimental confirmation of the proposed scientific proposals.

2. Materials and Methods

The mathematical model was solved using an electronic computer in the Matlab/Simulink (version R2021A) dynamic modelling environment. The validity of the computational experiment was confirmed by the high repeatability of the various solutions to the system of equations and the results of the tests on the bench equipment. The best modelling result was obtained by the ode15s method proposed by Geer [30,31].

In order to conduct a full-scale experiment, as well as to assess the influence of various factors on the pumping flow and pressure, bench equipment was developed, which allowed a multi-factor experiment to be conducted. Distilled water at 25 °C was used as the power fluid in this work [32]. To collect and process the information, a measuring complex was developed, essentially including a manometer, a vacuum manometer, a tachometer TX-01 (Moscow, Russia) [33], a vacuum pressure sensor with a measuring range −1–5 bar and a full-scale accuracy ±0.5%, a gauge pressure sensor with a measuring range 0–60 bar and a full-scale accuracy ±0.5%, a measuring tank for measuring feed, and an E20-10 (Moscow, Russia) fast analogue-to-digital converter module with 4 ADC channels (14 bit/10 MHz).

3. Results and Discussion

3.1. Mathematical Model of the Pump

Due to the fact that the developed pump is a batch-type pump, during its operation there are pressure fluctuations with different frequencies and amplitudes, depending mainly on the load at the outlet and shaft speed. Ignoring this fact will not give an opportunity to assess the influence of the power fluid supply system characteristics on the water conversion processes in the induction superheater. Therefore, the aim of this work was to develop a mathematical model that allows the dynamic characteristics of the pump to be taken into account when studying the working processes in induction superheaters [9].

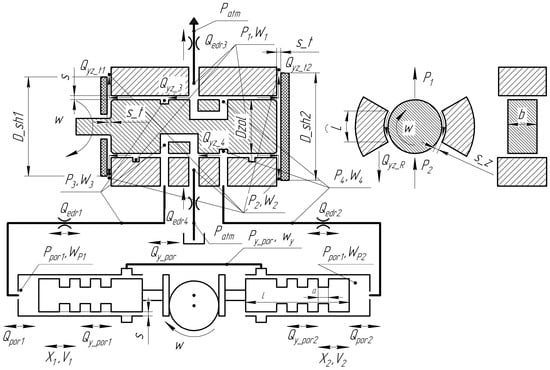

When developing the calculation scheme of the mathematical model (Figure 2), allowing us to estimate the dynamic characteristics of the pumping unit of the plunger pump, the hydro-mechanical system of the pump was taken into account without taking into account the mechanical characteristics of the drive part of the whole unit.

Figure 2.

Pump calculation diagram.

In addition, the modelling of processes occurring in real pump operation is complicated by the non-stationarity of power fluid flows and the instability of real influences on the system; for the simplification of the mathematical model, the following assumptions were accepted: the power fluid characteristics (density, viscosity, Reynolds’ number, flow coefficient [1], etc.) are constant in all pump operating modes; the flow coefficients and volumetric modulus of elasticity of the fluid are constant; the pipelines and hydraulic channels of the pump are absolutely rigid; the pressure and flow rate of the liquid are values concentrated in volumes defined by the design scheme; pressure losses due to short and over-diameter local and linear hydraulic resistances are not taken into account; temperature effects and related changes in material and liquid properties are not considered; and hydro-impact phenomena and related dynamic effects are not considered. The model does not take into account the phenomenon of cavitation, since the suction lines of a given pump are usually under the head of the liquid column. Absolute pressures were used in the calculations [34].

Taking these assumptions, it is possible to determine the pressures in the concentrated volumes of the hydraulic system using the equations of the balance of flow rates (1) in a general form [1,11,13]:

where —the sum of flow rates from power fluid inflows into the concentrated volume, m3/s; —the sum of flow rates from fluid outflows from the concentrated volume, m3/s; and —the fluid flow rate during fluid compression (expansion), m3/s.

Let us determine the pressure change in time from the flow balance in Equation (1):

where E—the fluid bulk modulus, Pa; and W—the fluid volume between inlet and outlet flows, m3.

In the calculation scheme (Figure 2), six concentrated volumes can be conditionally distinguished: W1, W2, W3, W4, WP1, and WP2.

Then, the pressure in each concentrated volume can be determined by Equation (3):

The equations for the balance of flow rates in concentrated volumes of the hydraulic system are shown below (4):

where —expenses at compression (expansion) of power fluid in concentrated volumes, m3/s.

The suction and discharge lines of the power fluid supply system, consisting of the sum of the linear and local hydraulic resistances, can be conventionally represented as equivalent throttles. The flow rate through the equivalent throttles of the hydraulic system is determined by Formulas (5)–(8) [35]:

where —the discharge coefficient of the equivalent throttle; —the discharge area of the equivalent throttle, m2; —the discharge area of the equivalent throttle in the discharge line, m2; —the discharge area of the equivalent throttle in the suction line, m2; —the head end pressures, Pa; —the discharge pressure, Pa; —the suction pressure, Pa; —the pressure at the inlets of the rotary control valve, Pa; and —the atmospheric pressure, Pa.

The power fluid flow rate at the openings of the discharge and suction channels is determined by the following Formulas (9)–(12):

where —the valve discharge coefficient; —the discharge areas of the discharge channels, m2; and —the discharge areas of the suction channels, m2.

The discharge areas of the suction and discharge channels are described by Equations (13)–(19):

where x—the angular coordinate of spool movement, rad.; Rotv—the channel radius in the spool, m; Rzol—the spool radius, m; and α—the channel opening angle in the spool, rad.

The plunger flow rate is described by Equations (20) and (21):

where V1, V2—plunger velocity, m/s.; and Spor—plunger cross-sectional area, m2.

The throttle flow rate of the equivalent cross-sectional area between the plunger and the sleeve at the leakage of power fluid from the piston head end is determined by Formulas (22) and (23):

where Dpor—plunger diameter, m; s—plunger-to-liner clearance, m; and L—plunger length, m.

From the flow balance shown in Equation (1), the pressure in the concentrated volumes can be distinguished as W1, W2, W3, W4, WP1, and WP2, which can be determined by Formulas (24)–(27):

The pressure in the suction and discharge lines can be obtained as follows:

The volume of the plunger chamber depends on the plunger movement and is determined by Equations (28) and (29):

where W0—maximum plunger chamber volume, m3; and X1, X2—plunger movement, m.

The pressures in the piston chambers are determined by Equations (30) and (31):

The total fluid flow through the clearance between the spool and the control valve sleeve to its transfer by the rotating surface and squeezing through the clearance is determined by Equation (32):

where w—the spool valve speed, rpm; s—the clearance between the spool and control valve sleeve, m; and b—the groove width control valve sleeve, m.

The total fluid flow rate in the ring clearance formed by the stationary valve sleeve and the rotating spool is determined by Equations (33) and (34):

where φ—spool valve rotation angle, rad.

The total fluid flow rate in the end clearances between parallel end plates is determined by Formulas (35) and (36):

where st—the clearance between the spool valve end and end plate, m; and Dsh1, Dsh2—end plate diameters, m.

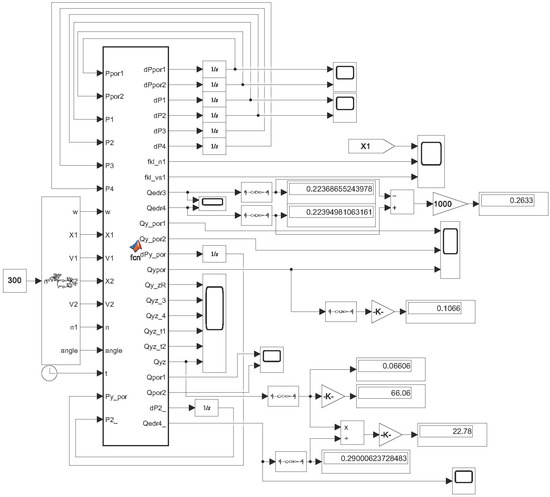

3.2. Computational Experiment

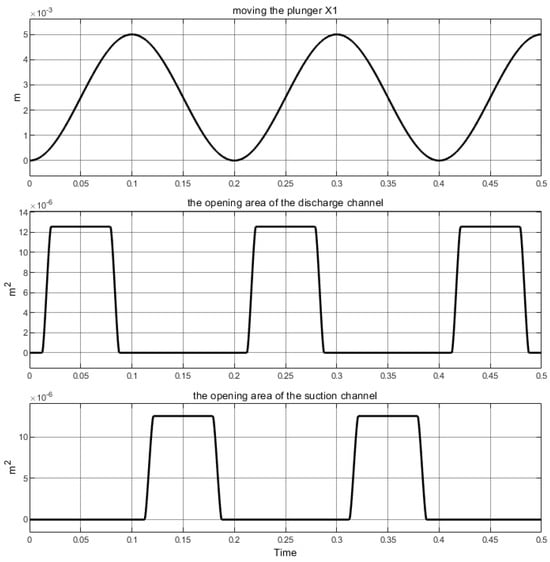

Substituting the initial data (Table 1) into the mathematical model (Figure 3), we obtained the dependences of pressures, flow rates, displacement and velocity of plungers in time (Figure 4, Figure 5, Figure 6, Figure 7, Figure 8, Figure 9, Figure 10 and Figure 11).

Table 1.

Model input data.

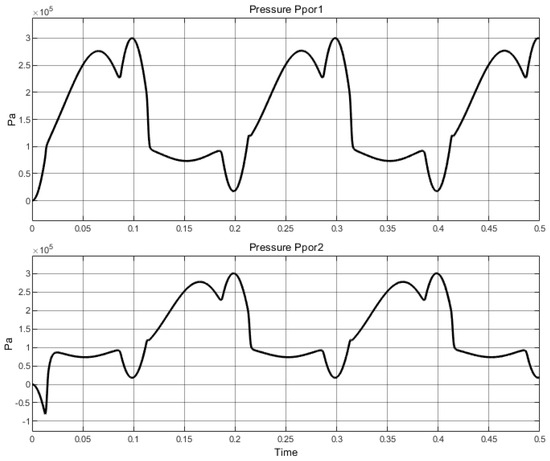

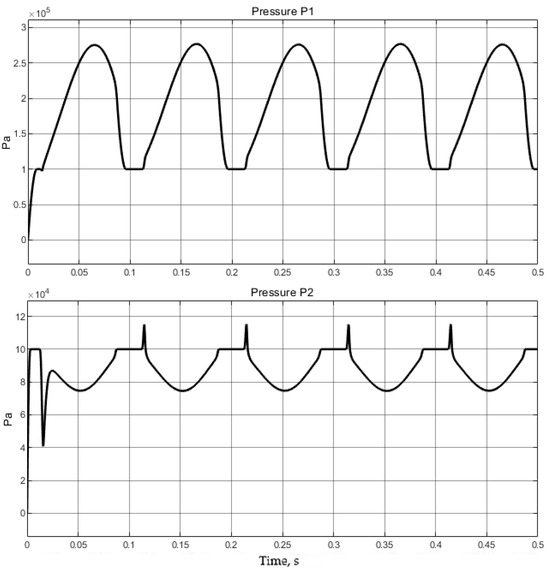

Figure 4 shows the time dependences of pressure in the head end. At the initial moment of time (interval from 0.015 to 0.06 s) in the first head end, Ppor1, there is a discharge cycle, and in the second head end, Ppor2, there is a suction cycle. In the time interval 0.06–0.08 s, the injection cycle of the first plunger ends, the injection channel is closed and the pressure drops from 0.27 MPa to 0.23 MPa (Figure 4) according to the flow balance equation (Equation (4)) because the flow rate from the inflow of power fluid (Equations (20) and (21)) does not compensate for its leakage (Figure 11) when the piston speed decreases (Figure 6). In the time interval 0.08–0.1 s, the discharge channel is closed (Figure 7) and the pressure rises to 0.3 MPa (Figure 4) because the plunger velocity is positive (Figure 6). In the time interval 0.1–0.12 s, the position of the spool is in the ‘dead’ zone; when the suction and discharge channels are simultaneously closed, there is a decrease in pressure to atmospheric (0.1 MPa) (Figure 4) due to the leakage of power fluid through the gaps of the plunger and spool pairs. In the time interval 0.12–0.18 s, a suction cycle occurs in the first chamber, and the pressure decreases from atmospheric to 0.07 MPa (Figure 4 and Figure 5). In the time interval 0.18–0.2 s, the suction channel is closed (Figure 7), the plunger continues to move in the negative direction (Figure 6) and the pressure decreases to 0.02 MPa (Figure 4). In the time interval 0.2–0.22 s, the pressure, due to internal overflows, rises to atmospheric pressure (Figure 4), at 0.22 s the injection channel starts to open (Figure 7) and the cycle repeats.

Figure 3.

Pump model fragment in Matlab/Simulink programme.

Figure 4.

Time dependence of pressures in plunger chambers.

Figure 5.

Time dependence of pressures in the discharge and suction lines.

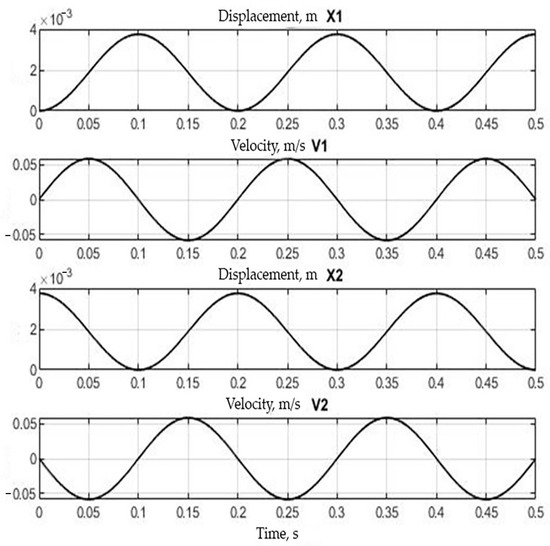

Figure 6.

Time dependence of plunger displacement and velocity.

Figure 7.

Time dependence of the displacement of the first plunger and the discharge areas of the first discharge channel and the first suction channel.

The plunger moves at a frequency of 5 Hz, which corresponds to a pump shaft rotation of 300 rpm (Figure 6).

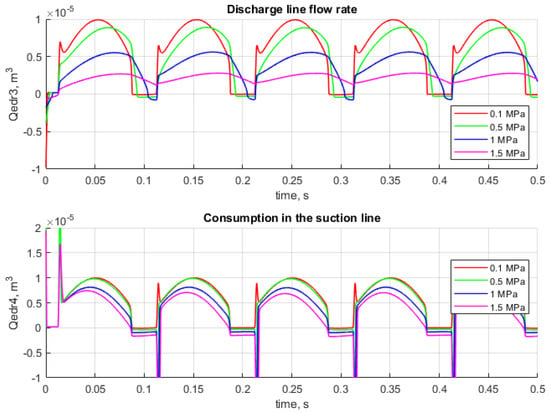

- (1)

- At an outlet pressure of 0.1 MPa, the maximum momentary flow rate in the pressure line is 9.9201 × 10−6 m3, and the maximum momentary flow rate in the suction line is 9.953 × 10−6 m3 (Figure 8).

- (2)

- At a pressure of 0.5 MPa, the maximum momentary flow rate in the discharge line is 8.9006 × 10−6 m3, and the maximum momentary flow rate in the suction line is 9.796 × 10−6 m3.

- (3)

- At a pressure of 1 MPa, the maximum momentary flow rate in the discharge line is 5.6096 × 10−6 m3, and the maximum momentary flow rate in the suction line is 8.104 × 10−6 m3.

- (4)

- At a pressure of 1.5 MPa, the maximum momentary flow rate in the discharge line is 2.7976 × 10−6 m3, and the maximum momentary flow rate in the suction line is 7.418 × 10−6 m3.

Figure 8.

Calculated momentary flow rates at different pressures.

Figure 8 shows that as the pressure increases, the flow rate in the discharge line decreases due to leakage, which is described by Equation (4).

The theoretical pump displacement is determined by Formula (37):

where n is the rotational speed of the pump shaft.

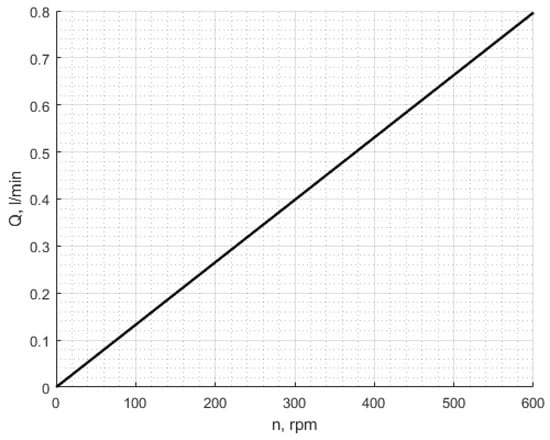

As can be seen from Figure 9, the theoretical flow rate is adjustable between 0 and 0.8 l/min as the pumping rotational speed is varied from 0 to 600 rpm; however, this dependence is simplified for engineering calculations (Equation (37)), while in reality the instantaneous feed rate depends on many parameters (Equation (4)) and varies in time (Figure 8).

Figure 9.

Theoretical flow rate from pump rotation speed.

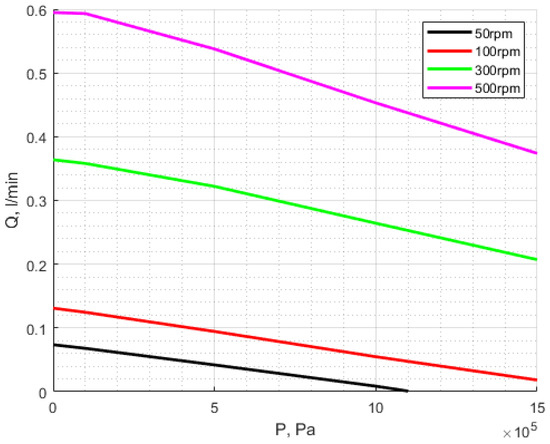

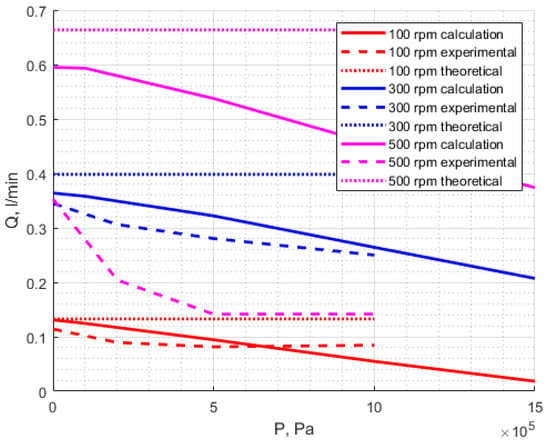

Figure 10 shows the dependence of power fluid delivery on differential pressure at fixed shaft speeds. Here, this pump was investigated at rotational speeds of 50, 100, 300 and 500 rpm at manometric pressures from 0 to 1.5 MPa.

Figure 10.

Calculated pump performance curves.

At 50 rpm, with a pressure boost from 0 to 1.1 MPa, the flow rate changed by 87%. At 100 rpm, with a pressure boost from 0 to 1.5 MPa, the flow rate changed by 86%. At 300 rpm, with a pressure boost from 0 to 1.5 MPa, the flow rate changed by 43%. At 500 rpm, with a pressure boost from 0 to 1.5 MPa, the flow rate changed by 37%. As a result, it can be seen that increasing the nominal frequency improves the external characteristic of the pump, but according to the results of the field experiment, the pump characteristic drops sharply after 400 rpm. This is due to the fact that a number of assumptions are introduced in the model due to the averaging of power fluid characteristics and unaccounted cavitation processes in the power fluid flow and flow discontinuity boundaries.

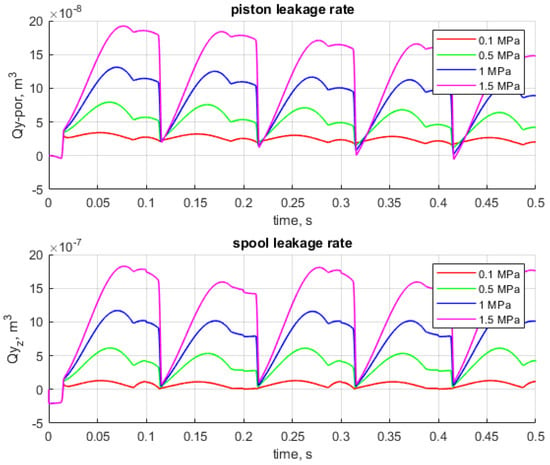

As seen from Figure 11, the momentary leakage flow rate in the plunger group at a pressure of 0.1 MPa is 0.01% of the design pumping flow, at 0.05 MPa—0.7%, at 1 MPa—1.6% and at 1.5 MPa—0.25%. The momentary flow rate of the spool valve at 0.1 MPa is 1.5% of the calculated pumping flow, at 0.5 MPa—7.1%, at 1 MPa—15.8% and at 1.5 MPa—25%. This all illustrates the extent to which leakage at higher pressures affects the external characteristic of the pump.

Figure 11.

Calculated momentary leakage rates at 300 rpm and different pressures.

3.3. Full-Scale Experiment

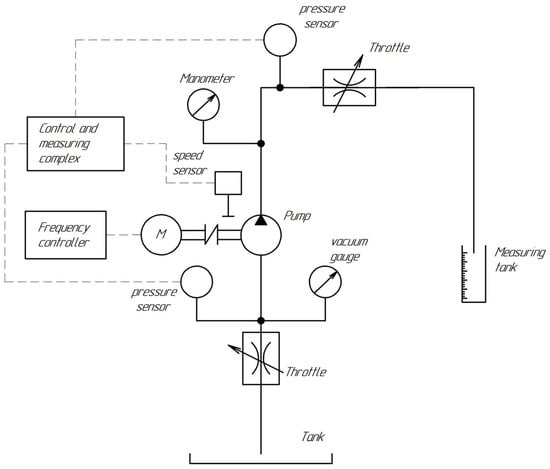

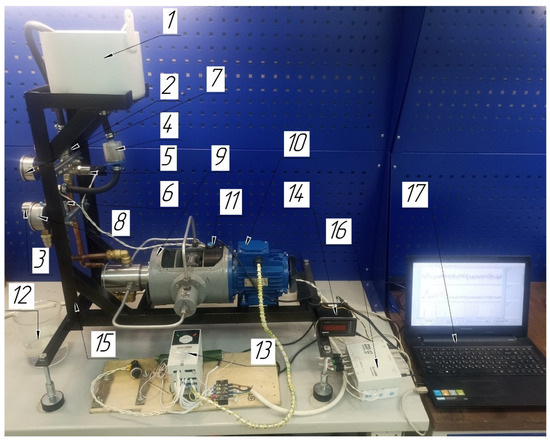

To conduct a full-scale experiment, a stand (Figure 12 and Figure 13) was created to determine the static and dynamic characteristics of the prototype plunger pump of low pumping flow and to confirm the adequacy of the developed mathematical model.

Figure 12.

Hydraulic circuit diagram of the test bench.

Figure 13.

Static and dynamic pump performance test bench: 1—tank, 2—discharge line throttle, 3—suction line throttle, 4—filter, 5—manometric pressure sensor, 6—vacuum pressure sensor, 7—manometer, 8—vacuum meter, 9—pump prototype, 10—induction motor, 11—rotation speed sensor, 12—measuring tank, 13—frequency converter, 14—tachometer, 15—base box, 16—DAC/ADC E20-10, 17—laptop.

The asynchronous motor of the bench, controlled by a frequency converter, made it possible to adjust the pump shaft speed to change its capacity. The discharge line throttle was designed to simulate the hydraulic resistance of the system. The suction line throttle was designed to simulate the hydraulic resistance of the line. The pressure gauge and vacuum gauge monitored the pressure in the discharge and suction lines, respectively. The pump performance was determined volumetrically by means of a measuring vessel and a stopwatch. The pressure and speed sensors were connected to an E20-10 fast analogue-to-digital converter module, the data from which, in turn, were transmitted to a laptop computer.

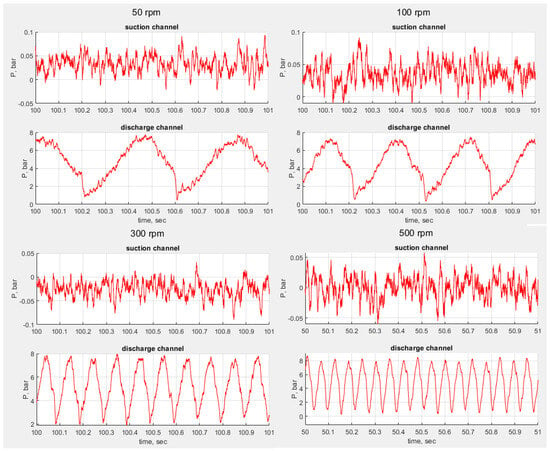

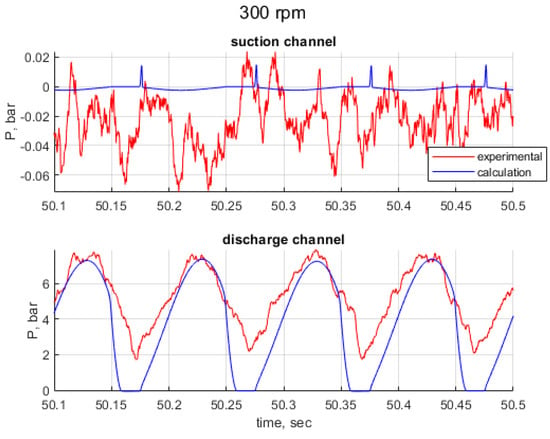

Figure 14 shows the pressure curves in the suction and discharge lines at an average pressure of 5 bar at different pump speeds. The pressure curves in Figure 15 show that in the suction line, the overpressure is close to atmospheric pressure (−0.06 bar), which is within the measurement error of the vacuum pressure sensor. In the discharge line of the computational experiment, the pressure drops to atmospheric pressure in the dead zones of the distributor. This is explained by the fact that in the mathematical model, the flow coefficient is assumed to be averaged, but must take into account the characteristics of the power fluid, which includes dynamic viscosity. The curves of the computational experiment demonstrate close correspondence with the pressure curves of the full-scale experiment (Figure 15).

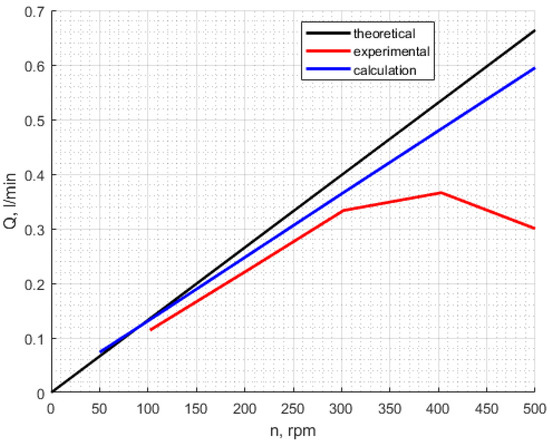

Figure 16 shows the theoretical pumping flow calculated from the pump displacement; the computational flow obtained by solving the mathematical model; and the experimental flow obtained by the volumetric method during the test bench experiment. The experiment showed that the operating rotational speed of the pump did not exceed 400 rpm. When the revolutions increased to more than 400, there was a decrease in power fluid supply due to the observed rupture at the outlet of the power fluid flow due to the imperfect manufacturing technology of the elements of the distributor and pumping units of the prototype pump, namely, a large and uneven gap between the plungers and sleeves, spool and distributor bushing up to 20 microns, which increased the leakage rate.

Figure 14.

Time dependence of pressures in suction and discharge lines at different rotational speeds.

Figure 15.

Time dependence of measured and calculated pressures in suction and discharge lines at different rotational speeds.

Figure 16.

Dependences of theoretical, computational and experimental pumping flows on pump rotational speed.

Figure 17 shows the dependence of the theoretical, calculated and experimental pumping flows on pressure at different pump rotational speeds. The calculated flow varies within 7–20% of the maximum at different pumping rotational speeds, which corresponds to the calculated values. The discrepancies between the design and experimental flow rates are not more than 15% for speeds up to 400 rpm (Figure 16).

Figure 17.

Pressure dependencies of pumping flow at different pump rotational speeds.

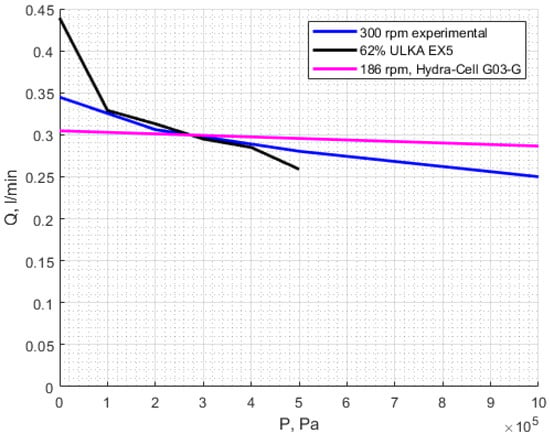

Figure 18 shows the comparative characteristics of pumping flow from the pressure of the prototype small-displacement plunger pump, ULKA EX5 vibrating plunger pump and Hydra-Cell G03-G diaphragm pump that were selected as analogues [5,6]. The performance discrepancy between the prototype pump and the ULKA EX5 at pressures between 1 and 4 bar is <1%. The volumetric efficiency factor of the prototype plunger pump at 5 bar is 70%, the ULKA EX5 efficiency factor at 5 bar is 64% and the ULKA EX5 efficiency factor tends to 0% when the pressure increases above 5 bar. However, despite the low cost (less than USD 30), the ULKA EX5 pump was not able to operate at pressures above 4 bar for a long time because the electromagnetic winding was heated and the power fluid flow was reduced, which does not meet the requirements of many technological processes in the operation of induction steam superheaters. The Hydra-Cell G03-G diaphragm pump has a good performance curve and can work continuously for a long time, but has a high cost of more than USD 7000.

Figure 18.

Pressure dependence of pumping flow of analogue pumps.

The analysis of the static and dynamic characteristics of the pump prototype confirms its operability in the range of rotational speeds 100–400 rpm and a satisfactory coincidence with their calculated values, which allows us to confirm the adequacy of the proposed mathematical model of the pump. However, due to the imperfections of the manufacturing technologies found in the elements of the pumping and distributive unit of the prototype pump, it was not possible to achieve the calculated characteristics of the pump in the whole given range. The obtained mathematical model of the pump will allow us to further optimize the design parameters of the pump and to make changes in the industrial prototype. The accuracy of the mathematical model can be improved by introducing it into an empirical model of flow coefficients depending on many factors, such as the degree of overlap of hydraulic channels, Reynolds numbers, fluid viscosity, etc. For this purpose, a multi-factor experiment is planned in the future after the design and technological deficiencies of the pump identified in this study have been eliminated.

4. Conclusions

A prototype of a small-displacement hydraulic plunger pump was developed. A mathematical model of this pump was developed and its computer implementation was carried out in the well-known interactive modelling tool Matlab/Simulink. Oscillograms of pressure transients in the suction and discharge lines during modelling were obtained. The obtained models allowed us to carry out dynamic analyses of hydraulic systems with plunger pumps of the proposed design. A test bench for static and dynamic characteristics of the pump was developed. The results of the modelling and full-scale tests of the pumping flow, namely, the dependence of pumping flow on pressure, turned out to be consistent with a deviation of less than 15%. The full-scale experiment confirms the adequacy of the mathematical model of the plunger pump. The developed pump has more rational characteristics in comparison with analogues for applications in water supply systems of induction superheaters, as it has a production cost that is several times lower in comparison with existing plungers or cam-type diaphragm pumps with oil sumps and precision valve mechanisms, and also has a much better performance curve and longer service life in comparison with vibrating plunger pumps. The external characteristics of the developed pump are 10% higher than the external characteristics of ULKA EX5, and the pressure characteristics are 65% higher.

Author Contributions

Conceptualization, D.M., V.G. and E.I.; methodology, D.M. and V.G.; software, V.G.; validation, D.M., V.G. and E.I.; formal analysis, D.M., V.G. and E.I.; investigation, D.M., V.G. and E.I.; resources, D.M., V.G. and A.N.B.; data curation, D.M., V.G. and E.I.; writing—original draft preparation, D.M., V.G. and A.N.B.; writing—review and editing, D.M., V.G. and A.N.B.; visualization, D.M., V.G. and E.I.; supervision, A.N.B.; project administration, A.N.B.; funding acquisition, A.N.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to acknowledge the administration of Don State Technical University for their resources and financial support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sidorenko, V.S.; Poleshkin, M.S.; Antonenko, V.I.; Grishchenko, V.I.; Dymochkin, D.D.; Kilina, M.S. Hydromechanical Systems of Stationary and Mobile Technological Machines: Textbook for Students of Higher Educational Institutions in the Field of Mechanical Engineering. Bachelor’s Thesis, INFRA-M, Moscow, Russia, 2019; 281p. [Google Scholar] [CrossRef]

- Myrzakhmet, B. Positive-Displacement Pumps. In Proceedings of the 18th Seifullin Readings: Science of the 21st Century—The Era of Transformation, Astana, Kazakhstan, 6 October 2022; Kazakh Agrotechnical University Named after S. Seifullin: Astana, Kazakhstan, 2022; Volume 1. [Google Scholar]

- Li, K.; Zhou, X.; Zheng, H.; Liu, B.; Chen, S.; Chen, W.; Liu, J. Achieving Full Forward Flow of Valveless Piezoelectric Micro-pump Used for Micro Analysis System. Actuators 2022, 11, 218. [Google Scholar] [CrossRef]

- Procon. Available online: https://www.proconpumps.com/ (accessed on 25 October 2024).

- Ulka. Available online: https://ulkapumps.com/ (accessed on 25 October 2024).

- Heavy-Duty Industrial Pumps. Available online: https://www.hydra-cell.com/ (accessed on 25 October 2024).

- Yu, B.; Li, H.; Ma, G.; Liu, X.; Chen, C.; Zheng, B.; Ba, K.; Kong, X. Design and matching control strategy of electro-hydraulic load-sensitive hydraulic power unit for legged robots. Energy 2024, 313, 133730. [Google Scholar] [CrossRef]

- Pate, K.; Marschand, J.R.; Breidi, F.; Salem, T.; Lumkes, J. Design and Sensitivity Analysis of Mechanically Actuated Digital Radial Piston Pumps. Processes 2024, 12, 504. [Google Scholar] [CrossRef]

- Nikolsky, S.G.; Poleshkin, M.S.; Grishchenko, V.I. Analysis of water supply systems of steam plasma power plants. Actual problems of science and technology. In Proceedings of the All-Russian (National) Scientific and Practical Conference 2022, Rostov-on-Don, Russia, 16–18 March 2022; Volume 1006. Available online: https://ntb.donstu.ru/conference2022 (accessed on 25 October 2024).

- Zhou, H.; Dong, P.; Zhu, S.; Li, S.; Zhao, S.; Wang, Y. Design and theoretical analysis of a liquid piston hydrogen compressor. J. Energy Storage 2021, 41, 102861. [Google Scholar] [CrossRef]

- Medvedev, D.D.; Grishchenko, V.I.; Ivliev, E.A.; Sidorenko, V.S. Mathematical modeling of a low-flow hydraulic plunger pump. Proc. Tula State Univ. Tech. Sci. 2023, 12, 335–342. [Google Scholar] [CrossRef]

- Guo, T.; Lin, T.; Ren, H.; Miao, C.; Zhao, S. Modeling and Theoretical Study of Relief Chamfer Method for Reducing the Flow Ripple of a Spool Valves Distribution Radial Piston Pump. J. Mech. Eng. Sci. 2021, 235, 3819–3832. [Google Scholar] [CrossRef]

- Medvedev, D.D.; Grishhenko, V.I.; Martynov, V.V. Mathematical model of the pneumatic actuator follower system. E3S Web Conf. 2021, 279, 01009. [Google Scholar] [CrossRef]

- Rybak, A.T.; Ivanovskaya, A.V.; Batura, P.P.; Pelipenko, A.Y. Synchronization in multi-motor hydromechanical systems. Adv. Eng. Res. 2021, 21, 337–345. [Google Scholar] [CrossRef]

- Khinikadze, T.A.; Rybak, A.T.; Popikov, P.I. Simulation of the hydraulic system of a device with self-adaptation for power and kinematic parameters on the working body. Adv. Eng. Res. 2021, 21, 55–61. [Google Scholar] [CrossRef]

- Rybak, A.T.; Shishkarev, M.P.; Demyanov, A.A.; Zharov, V.P. Modeling and calculation of hydromechanical systems dynamics based on the volume rigidity theory. MATEC Web Conf. 2018, 226, 01001. [Google Scholar] [CrossRef]

- Rybak, A.; Meskhi, B.; Rudoy, D.; Olshevskaya, A.; Serdyukova, Y.; Teplyakova, S.; Pelipenko, A. Improving the Efficiency of the Drive of the Test Bench of Rotary Hydraulic Machines. Actuators 2024, 13, 63. [Google Scholar] [CrossRef]

- Ivliev, E.A.; Grishhenko, V.I.; Medvedev, D.D. Mathematical model of an electrohydraulic actuator. Izvestia of Higher educational institutions. The North Caucasus region. Tech. Sci. 2023, 4, 98. [Google Scholar] [CrossRef]

- Bai, X.; Lu, L.; Zhang, T.; Ouyang, X.; Wang, Y. Analysis of the Thermal–Mechanical–Hydraulic Coordination Mechanism of a Constrained Piston Hydraulic Engine. Sustainability 2023, 15, 9341. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, Y.; Wu, D.; Wang, C.; Wang, Z. Theoretical and Experimental Flow Characteristics of a Large-Scale Annular Channel in Terms of Deformation Gradient, Eccentricity, and Water Compressibility. Lubricants 2023, 11, 134. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, H.; Yang, J. The Structure Principle and Dynamic Characteristics of Mechanical-Electric-Hydraulic Dynamic Coupling Drive System and Its Application in Electric Vehicle. Electronics 2022, 11, 1601. [Google Scholar] [CrossRef]

- Yue, D.; Zuo, X.; Liu, Z.; Liu, Y.; Wei, L.; Sun, J.; Gao, H. Simulation Analysis of a Novel Digital Pump with Direct Recycling of Hydraulic Energy. Axioms 2023, 12, 696. [Google Scholar] [CrossRef]

- Yu, C.; Yan, H.; Zhang, X.; Ye, H. A Multi-Model Diagnosis Method for Slowly Varying Faults of Plunger Pump. J. Mar. Sci. Eng. 2022, 10, 1968. [Google Scholar] [CrossRef]

- Qiu, N.; Shang, X.; Liu, R.; Jin, P.; Gao, W. Analysis of the Dynamic Characteristics of the Pump Valve System of an Ultra-High Pressure Liquid Hydrogen Reciprocating Pump. Energies 2022, 15, 4255. [Google Scholar] [CrossRef]

- Lin, J.; Wang, Y.; Zhou, S.; Wu, W.; Ma, H.; Han, Q. Simulation and Experimental Analysis of Pressure Pulsation Characteristics of Pump Source Fluid. Appl. Sci. 2021, 11, 9559. [Google Scholar] [CrossRef]

- Ledvoň, M.; Hružík, L.; Bureček, A.; Dýrr, F.; Polášek, T. Leakage Characteristics of Proportional Directional Valve. Processes 2023, 11, 512. [Google Scholar] [CrossRef]

- Tadano, K.; Ishida, Y.; Takeishi, H. Development of a Four-Way Pinch-Type Servo Valve for Pneumatic Actuator. Appl. Sci. 2020, 10, 1066. [Google Scholar] [CrossRef]

- Cao, W.; Miao, R.; Liu, Y.; Wu, D.; Chen, X. Effects of distribution valve spring stiffness and opening pressure on the volumetric efficiency of micro high-pressure plunger pump. Adv. Mech. Eng. 2024, 16, 10. [Google Scholar] [CrossRef]

- Qiu, X.; Shen, T.; Wang, F.; Jin, X.; Zheng, Y. A position-free control strategy in the full speed domain based on an electro-hydraulic pump. Meas. Control 2024. [Google Scholar] [CrossRef]

- Shampine, L.F.; Reichelt, M.W. The MATLAB ODE Suite. SIAM J. Sci. Comput. 1997, 18, 1–22. [Google Scholar] [CrossRef]

- Shampine, L.F.; Reichelt, M.W.; Kierzenka, J.A. Solving Index-1 DAEs in MATLAB and Simulink. SIAM Rev. 1999, 41, 538–552. [Google Scholar] [CrossRef]

- ISO 3696:1987; Water for Analytical Laboratory Use—Specification and Test Methods (MOD). International Organization for Standardization: Geneva, Switzerland, 1987. Available online: https://www.iso.org/standard/9169.html (accessed on 18 December 2024).

- TX01-RS Tachometer with RS-4. Available online: https://owen.ru/product/tx01rs (accessed on 18 December 2024).

- Tretyakova, E.A. Modeling of Water Hammer in an Axial-Piston Pump. Manag. Large Syst. Proc. 2023, 101, 86–96. [Google Scholar] [CrossRef]

- Popov, D.N.; Panaiotti, S.S.; Ryabinin, M.V. Hydromechanics, 3rd ed.; Moscow State Technical University Named after N.E. Bauman: Moscow, Russia, 2014; 320p, ISBN 978-5-7038-3920-1. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).