1. Introduction

In comparison to serial robots, parallel robots offer significant advantages, including enhanced stiffness and improved repeatability. Delta robots, as a highly successful configuration of parallel robots, have found extensive applications in various fields such as Pick-and-Place [

1], 3D printing [

2], medical fields [

3], and machining [

4]. For machining applications, Delta robots demand exceptional motion precision. Precision in robotic systems is typically achieved through two approaches: precise analysis during the design stage and error compensation following assembly. Error calibration and compensation, facilitated using algorithms and software, substantially enhance the precision of deployed robots [

5,

6].

Kinematic modeling serves as the cornerstone of robot error calibration. Various methods are employed, including the Denavit–Hartenberg (DH) method [

7], exponential product [

8], and vector loop method [

9]. The vector loop method formulates closed-loop motion equations through position vectors at the link ends or joints within kinematic chains and is highly suitable for parallel robots. Vischer et al. [

10] utilized the vector loop method to construct two kinematic models, “Model 54” and “Model 24”, for the 3-R(2-SS) configuration. “Model 54” considers geometric errors in all mechanical components except for the spherical joints; if the spatial parallelogram is assumed to remain perfect, “Model 54” can be simplified to “Model 24”. In “Model 24”, the direction of the Delta robot’s moving platform is assumed to be constant. Li et al. [

11], also focusing on the 3-R(2-SS) configuration, demonstrated a significant influence of parallel mechanism errors on motion precision, especially in the Z-direction, with an increase in the tilt angle of the moving platform. Shen et al. [

12], utilizing the variational method, studied the effect of error components (including the parallelogram mechanism) on the motion precision of Delta-RU robots, significantly enhancing the accuracy of the end effector through compensation. While scholars have recently introduced data-driven approaches for kinematic calibration, the model-based method continues to be predominant. This preference stems from its clear physical significance and the extensive measurement data demanded by the former [

13].

Kinematic parameter identification is typically based on redundant equations formed using kinematic models and multiple measurement points. Considering noises in measurement data, the final parameter solution is obtained through nonlinear least squares solutions, with the Levenberg–Marquardt algorithm being the most commonly used algorithm [

14]. Other probabilistic methods, such as maximum likelihood estimation and Kalman filtering, are less commonly used. Different parameter error components have varying degrees of influence on the total pose error, typically characterized using sensitivity analysis [

15,

16]. A local parameter sensitivity can be defined as the ratio of the sensitivity coefficient of a single error component to the combined one of all errors at a measurement point. A global sensitivity can be defined as the integration of local sensitivity over the robot workspace. Sensitivity analysis can identify the dominant error components of the robot. In addition to the calibration for link dimensions and assembly errors, scholars have also investigated the calibration of joint clearance. Kim et al. [

17] discussed the relationship between the end effector pose error of the Stewart platform and the tolerance limits of its joints. Tannous et al. [

18] conducted a sensitivity analysis on joint clearance using interval analysis methods, taking three manipulators as examples.

The problem of identifying dynamic parameters of robots involves several aspects, including specific identification parameters, dynamic models, excitation trajectories, and solution algorithms. Jan et al. [

19] proposed a statistical framework for the dynamic parameter identification of multi-joint serial robots. The excitation trajectories were defined as finite Fourier series on each joint, with the optimal criterion being the uncertainty on the estimated parameters or a lower bound for it. The parameters identified included mass, inertia parameters, and friction parameters. In another study, the coefficients of the Fourier series were optimized to minimize the sensitivity of the identification to measurement disturbances [

20]. Zafer et al. [

21] used the least squares (LS) method and particle swarm optimization (PSO) technique to estimate distinct inertia parameters of the Staubli RX-60 robot, showing that the PSO method had a smaller identification error. Grotjahn et al. [

22] investigated the identification of friction and rigid-body dynamics in parallel kinematic structures, achieving their separation via point-to-point motions. Han et al. [

23] considered measurement errors in the process of optimizing excitation trajectories, integrating weighted least squares (WLS) and nonlinear error models, and iteratively reweighted least squares to unify the modeling process of friction and rigid-body dynamics. Dong et al. [

24] first identified the friction parameters in the nonlinear Tustin friction model using the LS method during forward and reverse rotations, then estimated the remaining dynamic parameters of the Stäubli TX-90 robot using the symbiotic organisms search (SOS) algorithm. Song et al. [

25] implemented the load parameter identification of parallel robots based on the Extended Kalman Filter. Ohno et al. [

26] designed target trajectories for the detection of joint clearances based on actuation torque fluctuation. Diaz-Rodriguez et al. [

27] developed a simplified dynamic model for a 3-DOF prismatic-revolute-spherical parallel manipulator to improve trajectory tracking precision and reduce the real-time computational burden. Abed Azad et al. [

28] obtained the base inertial parameters through singular value decomposition, constructing an optimized path containing several harmonics within the desired bandwidth, achieving offline–online identification of the base inertial parameters.

Measurement processes can be categorized into two types: with or without external measurement devices. Without external measurement device support, the end effector of the robot is virtually constrained to a point, line, or surface [

29,

30], commonly applied in serial robots. The calibration process of parallel robots often employs external measurement devices, including laser trackers, laser interferometers, coordinate measurement machines (CMMs), vision-based measurement systems, ball-bar systems, etc. [

10,

31,

32,

33]. The selection of measurement points directly affects the quality of error parameter identification, leading to an optimization problem, typically aiming for an observation metric as the optimization objective along with constraints. Specific solving methods include local search methods represented by gradient descent and global search algorithms represented by meta-heuristic algorithms. Daney et al. [

34] proposed a constrained optimization method for iteratively selecting measurement poses to minimize indicators based on the Jacobi matrix, utilizing the tabu search metaheuristic algorithm to avoid local optima.

This study tackles the relatively unexplored challenge of kinematic error modeling and dynamic calibration for the 3-R(RPaR) configuration Delta robot integrated into a self-built five-axis blade grinding device. It specifically investigates how geometric errors affect the poses of parallelogram mechanism while considering the constraints imposed by the robot’s DoF. Departing from conventional measurement point selection methods, this research reframes the issue as an optimization problem aimed at shaping the measurement workpiece surface, under the assumption that pose errors can be inferred from surface machining errors. Given the complexity of existing parameter sensitivity approaches, the paper seeks to establish criteria for parameter identifiability through the singular value decomposition (SVD) of the LMCM. For machining tasks with smooth and uniform motion, a simplified dynamic model with friction coefficients and other dynamic parameters is established and identified. The objective of this study is to devise a Delta robot calibration methodology tailored for machining environments.

The structure of the subsequent sections is as follows:

Section 2 provides an introduction to the blade grinding device and details the kinematic and dynamic models of the Delta robot.

Section 3 examines the influence of geometric errors on the parallel mechanism and describes the development of the kinematic error model tailored for the 3-

R(RPaR) configuration. In

Section 4, the identifiability criteria for error components are proposed, along with the definition of periodic error measurement surfaces and the optimization models under constraints.

Section 5 delves into solution algorithms for the optimization problem and validates the kinematic calibration process through simulation.

Section 6 validates the dynamic calibration method through experiments. The paper concludes with a summary of the findings and final remarks.

2. Kinematic and Dynamic Modeling

The blade grinding equipment, depicted in

Figure 1, includes an optical platform, an aluminum alloy frame, a grinding head unit with a C and B axis, and a Delta robot unit suspended at the top of the frame. The Delta robot’s static platform is secured to the frame’s top, while a six-axis force sensor is mounted on its moving platform and connected to the workpiece. The C axis rotates vertically on the optical platform, and the B axis is perpendicular to its rotation axis. A spindle, mounted perpendicular to the B axis, holds an abrasive flap wheel via an extension rod. In this paper, only the Delta robot unit of the equipment is addressed, with the angular positions of the C and B axis held fixed during the calibration process.

The Delta robot is composed of a stationary platform (base), a moving platform, and three interconnected kinematic chains. This study focuses on the 3-

R(RPaR) configuration, illustrated in

Figure 2. Each chain connects the base to an active arm via an active revolute joint denoted as

Ai (

i = 1, 2, 3). The active arm is linked to a parallelogram mechanism, consisting of four revolute joints (

Di,

Ei,

Fi,

Gi) and four links, through another passive revolute joint labeled as

Bi. The moving platform connects to the parallel mechanism through a passive revolute joint denoted as

Ci. The three chains are evenly distributed around the stationary platform, spaced 120° apart, with the

Z0 axis defined as the central axis. The origin

S of the stationary coordinate system {

W0} is at the intersection of the plane containing

A1A2A3 with the

X0 axis, and

Y0 =

Z0 ×

X0. Coordinate systems {

Wi,1} and {

Wi,2} are established at

Ai, fixed to the stationary platform and the active arm, respectively.

Zi,1 is oriented along the rotation axis of joint

Ai, while

Yi,1 is parallel to

Z0 but in the opposite direction.

Zi,2 is aligned with

Zi,1, and

Xi,2 is oriented along the vector

AiBi. The angle between

Xi,2 and

Xi,1 is denoted as

θi, representing the rotation angle of the active arm. The unit vector of

DiEi is denoted as

Zi,3, and the unit vector of

CiGi is denoted as

Zi,4.

Zi,4 also serves as the

Z-axis in {

Wi,4}, fixed to point

Ci and the moving platform. The direction of

Yi,4 is consistent with

Z0. The lengths

SAi and

TCi represent the radius

r1 of the stationary platform and the radius

r2 of the moving platform, respectively.

lp and

ln denote the lengths of active arm

AiBi and the vector

BiCi, respectively, defining the four basic parameters of the Delta robot.

Φ1 = 0°,

Φ2 = 120°, and

Φ3 = 240° indicate the angles between the three active arm rotation planes and

Z0X0 plane for chains 1, 2, and 3, respectively. Under ideal conditions, the moving platform only undergoes translation, maintaining a fixed orientation. A local coordinate system {

W5} is established with

T as the origin, aligned with {

W0}. {

W7}, {

W8} and {

W9} in

Figure 2 are, respectively, associated with the C axis, B axis, and the grinding tool, which are not involved in the subsequent sections.

T is the center of

C1,

C2 and

C3 and is denoted as

0T (

xt,

yt,

zt) and

i,1T(

i,1xt,

i,1yt,

i,1zt) in {

W0} and {

Wi,1}, respectively. In {

Wi,1},

where

,

,

. Substituted into Equation (1),

The relationship of

T coordinates in {

W0} and {

Wi,1} can be represented as the following:

where

Rot(

axis,

angle) represents the rotation matrix around

axis by

angle. The fundamental kinematic equations of the Delta robot are formed by substituting Equation (3) for

i = 1,2,3, respectively. Given

θ1,

θ2, and

θ3, if the goal is to determine

xt,

yt,

zt, it constitutes a forward kinematics problem. Conversely, it represents an inverse kinematics problem. By substituting Equation (2) into Equation (3),

Beginning with the inverse kinematics, Equation (5) yields the following:

where

,

,

. Solving Equation (6),

Proceeding to obtain the forward solution, similarly derived from Equation (5),

where

,

,

,

, and Δ

r =

r1 − r2. The solutions for

xt,

yt and

zt are obtained through the resolution of quadratic equations, the details of which are omitted here for brevity. In both forward and inverse solutions, the selection among multiple solutions is necessary. The viable solution must adhere to inequality (9).

where the left superscript “0” denotes the vector value in {

W0}, and

,

,

,

.

In accordance with the principle of virtual work, the virtual work carried out using all non-inertial forces should equal the virtual work carried out using inertial forces. This principle is applied to driving integrated joints:

where

Γ represents the motor torque,

Γc represents frictional torque,

I denotes the moment of inertia of the integrated joints (including active arms),

J signifies the Jacobian matrix,

FA stands for the inertial force generated by the moving platform mass (

me),

FG represents the gravitational force acting on

me,

ΓCM accounts for the gravitational moment produced by the unbalanced mass of the integrated joints (including active arms), δ

Θ represents virtual displacement, and

denotes joint acceleration. Here, it is assumed that the mass of the parallelogram linkage segment is negligible, or it can be separately accounted for at either end of integrated joints or the moving platform.

5. Simulation

This section validates the proposed kinematic calibration method for the Delta robot with 3-R(RPaR) configuration through computational cases. Initially, nominal geometric parameters are specified: r1 = 0.127 m, r2 = 0.046 m, lp = 0.22751 m, ln = 0.55361 m, and = 0.1 m. Eliminating Δlbi, the other 51-dimensional (or positional) error terms are set to 1 × 10−4 m, and angular (or orientation) error terms are set to 0.01° (1.745 × 10−4 rad). For instance, Δxai = 1 × 10−4 m and Δθi = 0.01°.

1. Verification of parameter identifiability. A total of 50 points are randomly selected in the Delta robot’s workspace, as detailed in

Section 4.1 with

n = 50.

Figure 6 illustrates the singular values of the LMCM

M from Equation (51), plotted in descending order on a log10 scale. The singular values of

M form three distinct tiers, labeled I, II, and III, with magnitudes of approximately 10

0, 10

−7, and 10

−15, respectively. Given that position and angle errors are on the order of 10

−4, the magnitude of

is also 10

−4. According to inequality (55), parameters can be ignored when

λi < 10

−4. Therefore, parameters corresponding to tiers other than tier I will be ignored. The lowest point in tier I corresponds to the singular value

λ24.

Rewriting Equation (52) yields the following:

where

v denotes the 51-component error vector excluding Δ

lb1, Δ

lb2, and Δ

lb3.

Figure 7 displays a scatter plot of the components of the column vectors

wi, with each color corresponding to the same

i value. The

jth component of

wi also serves as the coefficient for the

jth error component of

v. The horizontal axis in

Figure 7 represents each of the 17 error components in each chain, ordered as chains 1, 2, and 3. Notably, the component values in

wi have been preprocessed based on the error scale; specifically, if the absolute value of a component in

wi is less than 10

−4, it is set to zero.

From

Figure 7, it is evident that the coefficients corresponding to components 8, 9, 11, 12, 13, and 14 in the error vectors within each chain consistently evaluate to zero. Consequently, these parameters are deemed unidentifiable. Furthermore, the coefficients of components 1, 2, and 3 within each chain exhibit sign symmetry in relation to the coefficients of components 15, 16, and 17, respectively. This indicates that either the error components 1, 2, and 3, or the error components 15, 16, and 17, cannot be individually discerned. What can be discerned are

vci(1)–

vci(15),

vci(2)–

vci(16), and

vci(3)–

vci(17), where

vci(

j) represents the

jth component of the

vci vector. In subsequent optimization,

vci(1),

vci(2) and

vci(3) will be utilized to denote

vci(1)–

vci(15),

vci(2)–

vci(16), and

vci(3)–

vci(17), respectively. The remaining identifiable parameters for each chain are as follows:

2. Determining the optimal measurement surface. The cylindrical workspace of the Delta robot is characterized by a maximum radius Rwmax = 0.265 m, a given minimum radius Rwmin = 0.100 m, and a height Hwm = 0.2 m, with its zero point in {W0} along the Z axis positioned at Zhome = 0.3795 m. When evaluating in Problem (61), the surface coefficients in Equations (59) and (60) are considered given, and a point acquisition method on the surface needs to be specified. Here, , , and s and t are uniformly divided into 36 and 12 parts, respectively, generating a grid of points. Since the s direction forms a closed curve, it is iterated from i = 0 to 35 and j = 0 to 12, yielding a total of 36 × 13 non-repeating grid points in space. While more points theoretically enhance the accuracy of the grid, an excessive number would escalate measurement and computation times. In this study, the choice of points is balanced; even for trigonometric components with m, and n = 3 in Equations (59) and (60), a minimum of four sampling points per cycle is ensured.

This paper employs a hybrid solving algorithm that combines the Hook–Jeeves Direct Search Algorithm (DSA) with the Inner Point Method (IPM) for the optimization problem outlined in Problem (61). Initially, the constrained optimization problem is converted into an unconstrained one through the application of the interior point method. Here, the constraints refer to “<” and “>” constraints, while equality constraints can be ensured through the definition of the measurement surface. The augmented objective function needed for the interior point method is formulated as follows:

where

τ > 0 is the penalty factor.

The essence of the interior point method is to transform a constrained optimization problem into a sequence of unconstrained optimization problems

, where

, as shown in “IPM” part of

Figure 8. In the simulation process,

ρ = 0.5,

τ0 = 1. The barrier function

is defined as follows:

where

Rq is achieved by separately solving the maximum value of

and

, i.e.,

. As

k increases,

will gradually decrease. The termination criterion for the iterative process is

. In simulation process,

.

Each

undergoes optimization using the Hook–Jeeves DSA to determine the minimum value. While DSAs may not converge as rapidly as derivative-based methods like gradient descent or Newton’s method, the latter are susceptible to local optima. The DSA, being derivative-free, offers global optimality and requires fewer parameters than heuristic algorithms, making it well-suited for engineering applications. The Hook–Jeeves algorithm comprises two key components: Descent Direction Search (DDS) and Step Acceleration (SA), depicted in the “DSA” section of

Figure 8. In DDS, the search progresses along the positive and negative directions of each unit component

ej of the

vcoff vector sequentially, with a step size of

d. The initial value of

vcoff is denoted as

. Upon identifying a direction of function reduction, the SA phase is initiated. During SA, the step length is accelerated using the acceleration factor

to update

vcoff and commence a new cycle of DDS. In the simulation process,

α= 4. If a direction of function reduction is not detected,

d =

d/2, and DDS continues. The termination criterion for the Hook–Jeeves DSA is d <

εDS. In simulations, the initial value of

d is set to 0.005, with

εDS = 10

−6.

Figure 9 illustrates the iterative convergence process of the augmented objective function. The horizontal axis represents the number of iterations of the Hook–Jeeves DSA, which is the ordinal of the sequence min

fa(

vcoff,

τk). The convergence process is very rapid, with the augmented objective function entering a bottom plateau phase after approximately five iterations. The value of the augmented objective function decreases from 1239.6853 to 236.8953, a decrease of more than five times.

Figure 10a and 10b, respectively, depict the iterative convergence process of the surface coefficients

as0,

as1,

as3,

bs1,

bs2,

bs3 and

at0,

at1,

at2,

at3,

bt1,

bt2,

bt3 with the same horizontal axis as

Figure 9. From

Figure 10, it can be observed that the amplitudes of

as0 and

bs0 are significantly larger compared to other trigonometric coefficients, and their initial values change noticeably during the initial iterations.

Figure 11 depicts the optimized surface profile. In the 3D representation shown in

Figure 11a, the surface demonstrates pronounced periodicity along both the

s and

t directions. Moreover, the surface’s position and height in the

Z direction align with the specified values. As illustrated in

Figure 11b, the optimized surface profile adheres to the “<” and “>” constraints outlined in Problem (60), with both constraint boundaries being attained.

Table 2 presents the conditions used in the optimization process, the values of the surface coefficients before and after optimization, and the values of the augmented objective function before and after optimization.

3. Identify the parameter errors. Firstly, simulation error data are generated for the measurement surface. Assuming a uniform error distribution, Δlbi, Δxci, Δyci and Δzci are set to zero, and the remaining 42 positional and angular errors are set to 1 × 10−4 m and 0.01°, respectively. These errors are then added to the nominal parameter values accordingly. Utilizing the actual parameter values, the pose vectors for the points Q(si, tj) on the measurement surface are computed directly by Equations (30), (34), and (35), without introducing linearization errors. This method ensures a more precise assessment of the comprehensive error magnitude. Additionally, besides acquiring the pose components of the moving platform control point T, the non-planar deformation angles for the three parallelogram mechanisms are also calculated. Notably, in the linearized Equation (50), , and have been eliminated as intermediate variables.

Subsequently, parameter identification is performed based on the simulated error data. By employing the linearized Equation (51) and the identifiable error vector in Equation (63), a set of linear over-constrained equations is established. The identifiable error components in Equation (63) are then resolved using the least squares method, and the outcomes are presented in

Table 3. In

Table 3, “GV” denotes the error values provided during the construction of the simulation data, “CV” represents the error components computed based on Equations (51) and (63), and “Error” indicates the relative deviation between the two. Notably,

Table 3 illustrates that the maximum absolute relative deviation is 0.9%, thereby affirming the efficacy of the proposed method for parameter error identification. This also corroborates the parameter identifiability judgment. Furthermore, it suggests that the error components not listed in

Table 3 have a negligible impact on the overall error.

In Ref. [

12],

Table 3 presented the simulation results of kinematic parameter identification for a Delta robot. It showed that the accuracy of the identification results varied with different spatial distributions of measurement points, with Set 1 achieving the best accuracy. The maximum deviation between the identified and given errors in Ref. [

12] is 1.6%, which is larger than 0.9%. In our research, the measurement surface or the distribution of measurement points is optimized, allowing the algorithm to determine a unique set of measurement points.

To verify the parameter identification performance of the algorithm under error conditions, random errors of ±5% Δ

Ti,jare added to the pose error vector Δ

Ti,j, and the error components are recalculated.

Table 4 presents a typical result of parameter identification under random measurement errors. The maximum identification error in the identification results is −10.36%. Although this is considerably larger than the results in

Table 3, it is still sufficient for engineering applications.

6. Experiments

The dynamic calibration method is validated by experiments. The nominal geometric parameters are specified:

r1 = 0.065 m,

r2 = 0.035 m,

lp = 0.1042 m,

ln = 0.1650 m. The motor used has a rated current of 3.47 A, a torque constant of 25.9 mNm/A, a no-load speed of 8810 rpm at 24 V voltage, and a reduction ratio of 12. In contrast to the top-mounted configuration illustrated in

Figure 1, in the experiment, the Delta robot is laterally installed, and a preloaded spring in the upper kinematic chain compensates for the torque of the integrated joint. The spring torque is defined as follows:

where

ks and

τs0 are the proportional coefficient and initial torque of the spring, respectively. During the grinding task, the robot usually follows a smooth and slow curve with very small acceleration and deceleration. Therefore, the parameters in the simplified dynamic model in this paper mainly include friction and mass, and the inertia parameters closely related to acceleration are not reflected, i.e.,

,

JTFA, and

ΓCM are negligible. Consequently, these three factors will be disregarded in the identification process. Additionally, accounting for the frictional forces of integrated joints, the motor torque

Γ will be adjusted to incorporate the effect of the frictional torque

Γc. The Coulomb model is employed as the friction model,

where

Γc = [

τc1,

τc2,

τc3]

T. Therefore, the dynamic equation can be re-defined as follows:

The excitation trajectory adopts a uniform synchronous curve in joint space, i.e., θ1(t) = θ2(t) = θ3(t) = vt + θmin, where v is the moving speed, with a motion range of θmin = −32° and θmax = 72°. A suitable velocity, such as 5°/s, is selected. Under the servo driver’s CSP mode, the system moves from the starting point to the ending point at a constant speed. The joint angle is obtained through the encoder at the rear of the motor, and the torque is acquired by reading the motor’s current value and combining it with the torque constant and reduction ratio. Both the encoder values and current values are read in real-time at a 1 ms cycle from the corresponding variables inside the driver using the TwinCAT software (v3.1.4024.11). The same procedure is repeated from the ending point back to the starting point. The joint angle is obtained through the encoder at the rear of the motor, and the torque is acquired by reading the motor’s current value and combining it with the torque constant and reduction ratio. Both the encoder values and current values are read in real-time at a 1 ms cycle from the corresponding variables inside the driver using the TwinCAT software.

This simple curve form can fully meet the identification needs of the dynamic model in this paper. Additionally, this curve can be implemented at the early stage of robot controller development, without requiring interpolation in Cartesian space or worrying whether the T point after synthesizing the three joint motions always remains within the robot workspace.

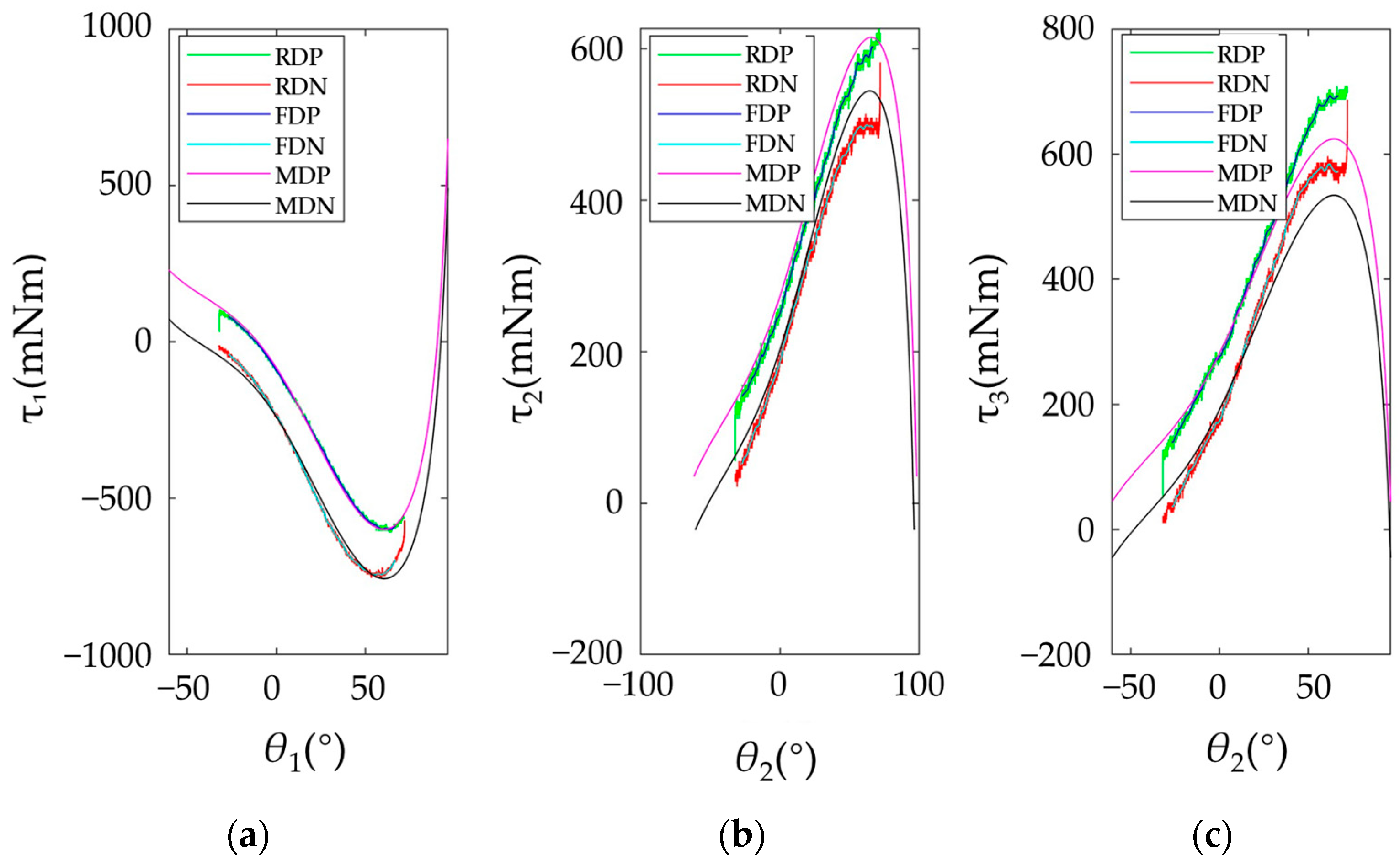

Figure 12 display the raw torque-angle data and the data after applying moving average filtering for positive and negative movements. Based on the filtered data, nonlinear least squares fitting was conducted to obtain the calibration results of the dynamic parameters, as shown in

Table 5.

Figure 12 also depicts the model prediction curves based on the identified dynamic parameters. The torque RMSEs between the filtered data and model-predicted data for the three joints are 14.5529 mNm, 26.2232 mNm, and 31.7745 mNm, which are approximately 1.42%, 2.55%, and 3.09% of the joints’ rated torques, respectively. Apart from slightly larger deviations at the beginning and end, the prediction curves fit the actual curves very well in most regions.

In Ref. [

28], Table 6 provided the simulation results of RMSE between the given torques and the predicted torques of the identified model for a Delta robot. Ref. [

28] did not provide the rated torques of robot joints. To compare with the results in our research, it is assumed that the maximum output torque in Ref. [

28] is 0.7 times the rated torque, making it consistent with the situation our research. Additionally, the units in Ref. [

28] are converted to mNm. First, looking at the offline parameter identification results in Table 6 of Ref. [

28], the RMSE was 632.7 mNm, which is 4.4% of the rated torque. The identification process in our paper is also offline, and the maximum RMSE between the model-predicted torque and the actual torque is 3.09% of the rated torque, which is better than the offline identification results in Ref. [

28]. Additionally, Ref. [

28] provides online identification results, with the corresponding torque RMSE being 31.5 mNm, or 0.22% of the rated torque. It is worth noting that the results in Table 6 of Ref. [

28] are simulation results, while our research provides experimental results. The results in our research include data noise and other unknown factors.

7. Conclusions

This paper focused on the calibration of kinematic errors and dynamic parameters for Delta robots driven by integrated joints with 3-R(RPaR) configuration in machining tasks, including position errors and frictions of integrated joints.

The influence of parallelogram mechanism dimension errors was analyzed based on the vector loop method for the 3-R(RPaR) configuration. The modeling of the in-plane deviation angle of the connecting platform link was conducted. This paper also defined the spatial deformation angle of the parallelogram mechanism constrained by the robot’s DoF, ultimately forming a 54-parameter kinematic error model and its corresponding linearized model.

By employing the SVD of LMCM, this paper established criteria for the identifiability of error component combinations based on the inequality between the singular value and the error vector norm. A measurement surface with Fourier series form containing 14 coefficients was conducted. The condition number of LMCM derived from the measurement surface was defined as the optimization objective. A hybrid algorithm that combines the Hook–Jeeves DSA with IPM was successfully applied to solve the optimal measurement surface under constraints.

The friction coefficients of integrated joints and other dynamic parameters were obtained by fitting the joint torque-angle pairs measured along specific trajectories using nonlinear least squares regression.

The simulation and experiment results validated the proposed kinematic and dynamic calibration methods, providing a foundation for precise control of integrated joints and high-precision motion of robots.

Based on the actual conditions of the grinding process, this study assumed that the motion process is always smooth and uniform, and based on this, the simplified dynamic model was established. If the motion behavior of the robot during the grinding process differs significantly from the assumption, the simplified model proposed in this paper will no longer be applicable, and the calibration accuracy will also be affected.

Our next step is to implement force–position hybrid control during the grinding process, examine the quality of the actual machined surface, and further optimize the dynamic performance through online optimization.