Reduced Kinematic Error for Position Accuracy in a High-Torque, Lightweight Actuator

Abstract

1. Introduction

- (a)

- The design and fabrication of a lightweight, high-torque actuator with improved performance while minimizing mass.

- (b)

- Kinematic error modeling as the research delved into modeling the kinematic errors associated with the proposed actuator. Understanding and quantifying these errors was crucial for optimizing the performance and accuracy of the actuator in practical applications.

- (c)

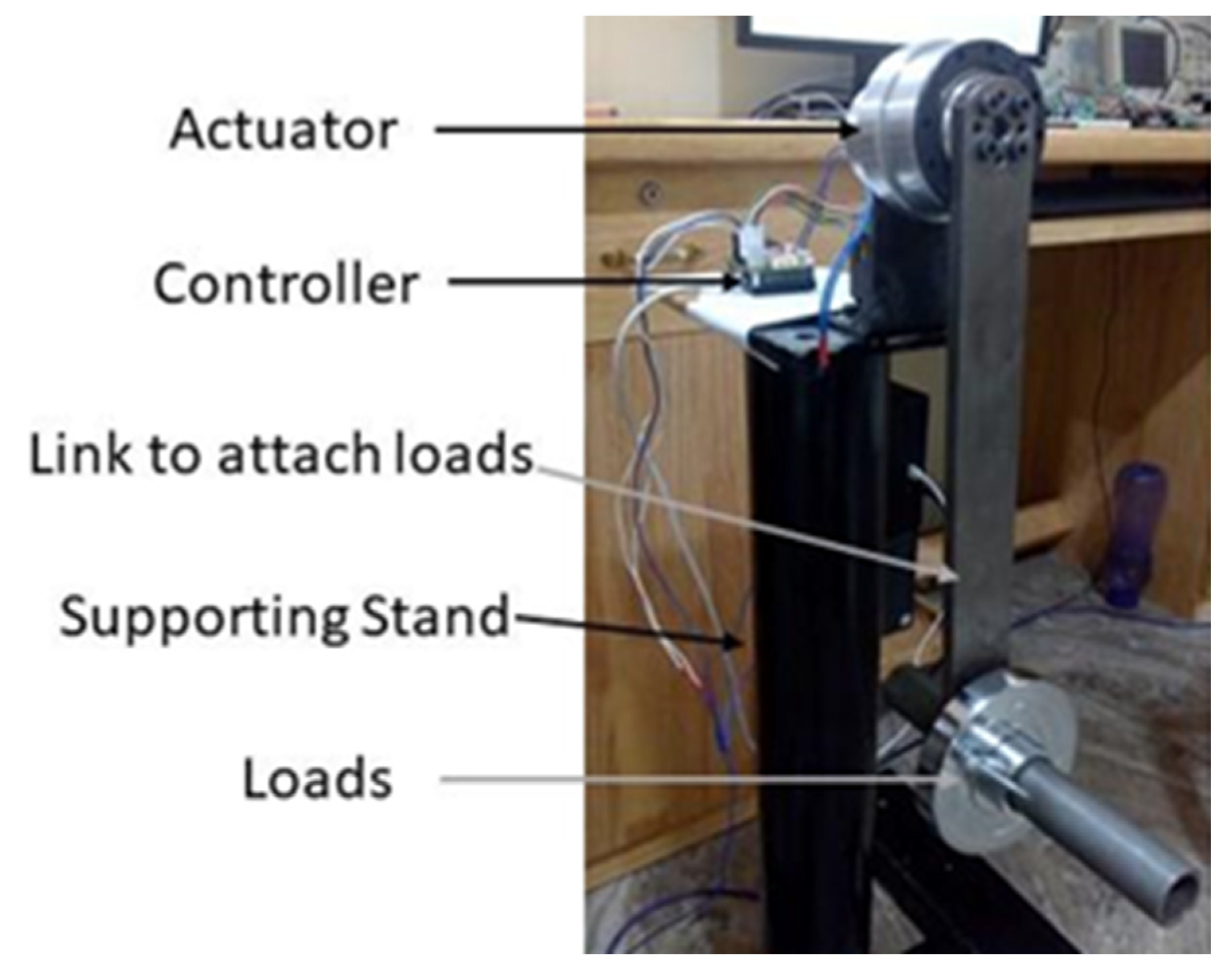

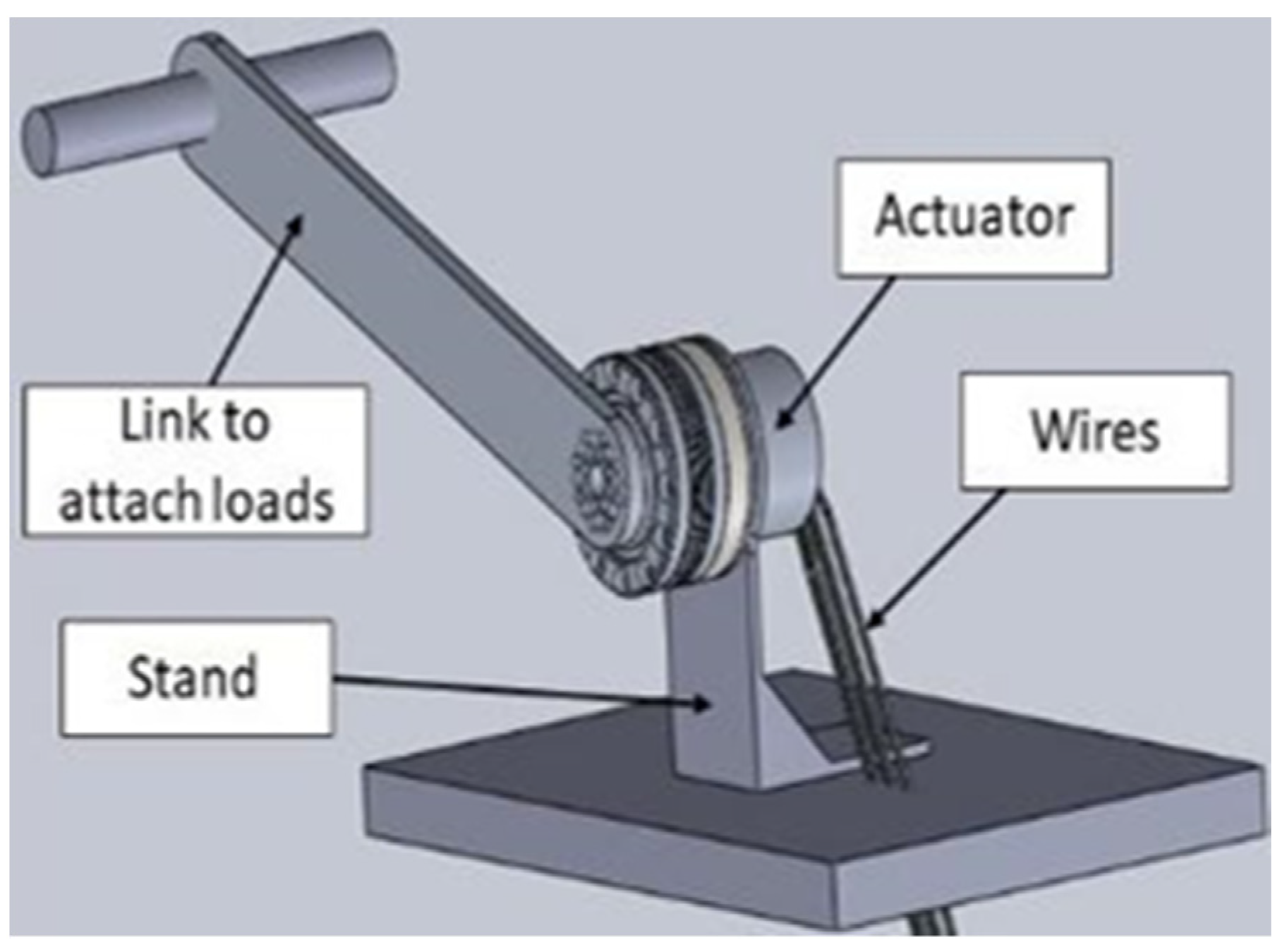

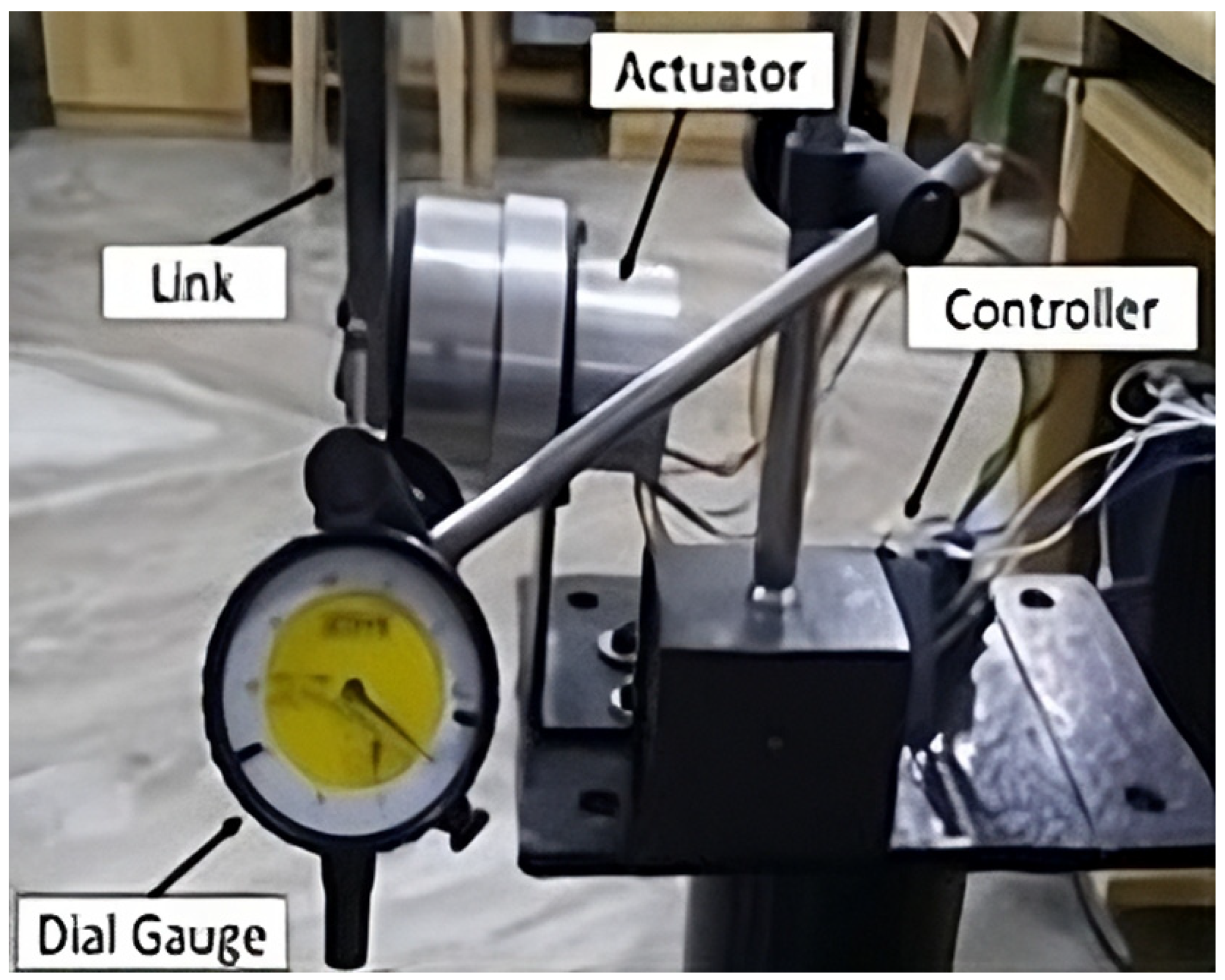

- The design and fabrication of a test setup, as a dedicated test setup was designed and fabricated to validate the functionality and performance of the proposed actuator. This setup provided a controlled environment for conducting the experiments and gathering empirical data to assess the actuator’s capabilities.

- (d)

- Performance evaluation and validation, as the research conducted comprehensive performance evaluations and validation tests on the fabricated actuator. Through rigorous testing and analysis, the team aimed to verify the effectiveness and reliability of the proposed model in real-world scenarios, ensuring its suitability for practical applications.

2. Method

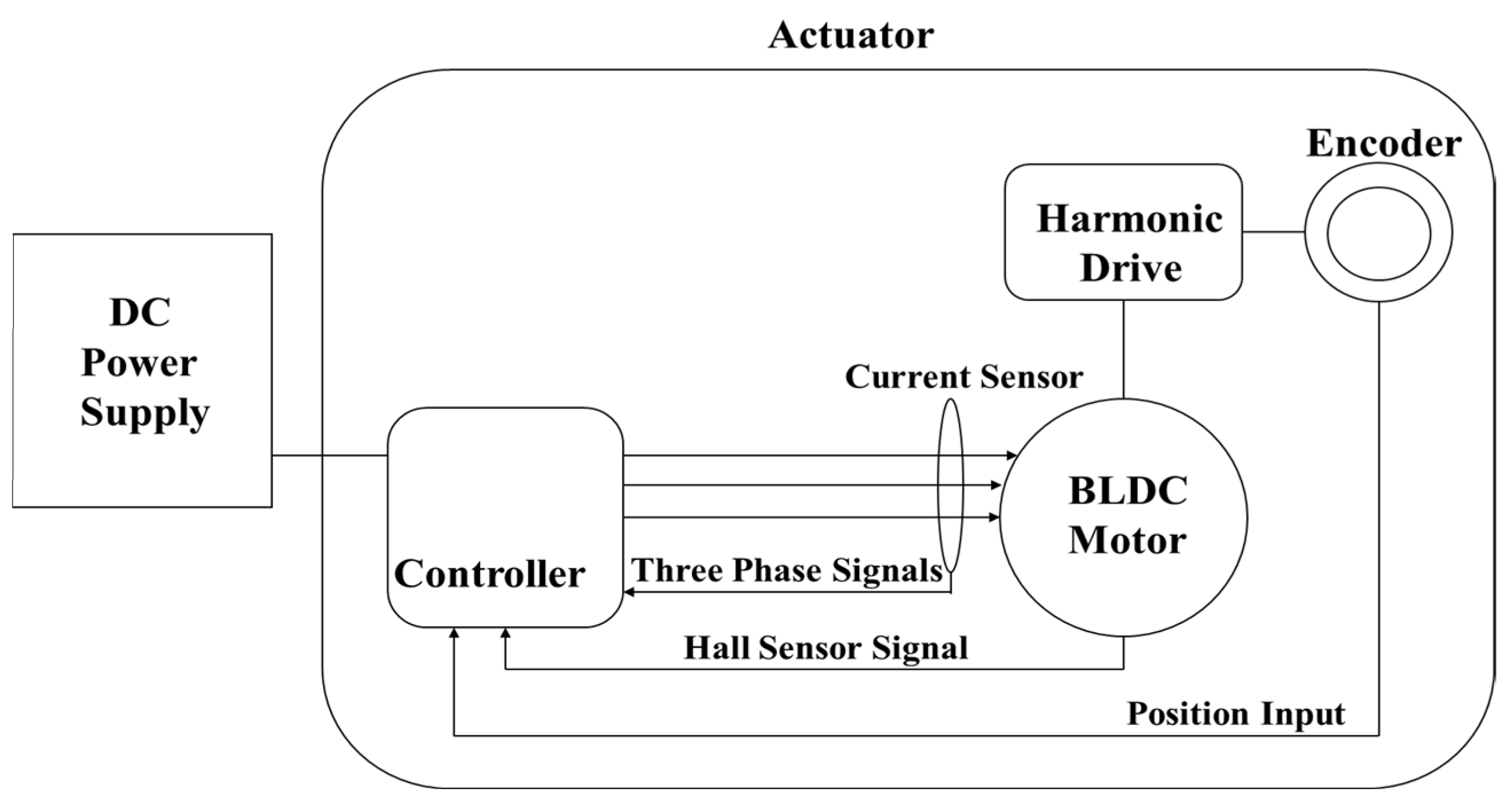

2.1. System Architecture

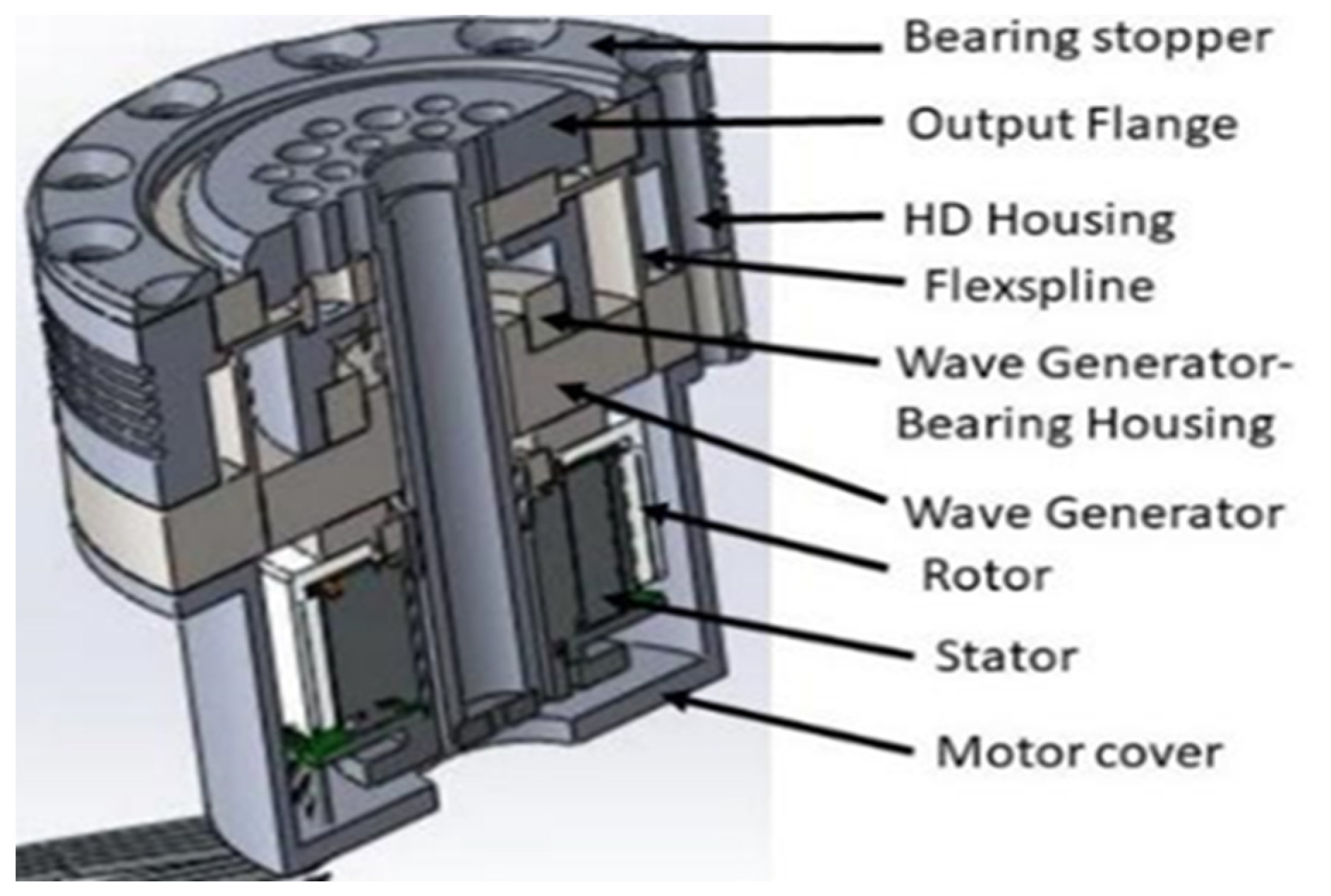

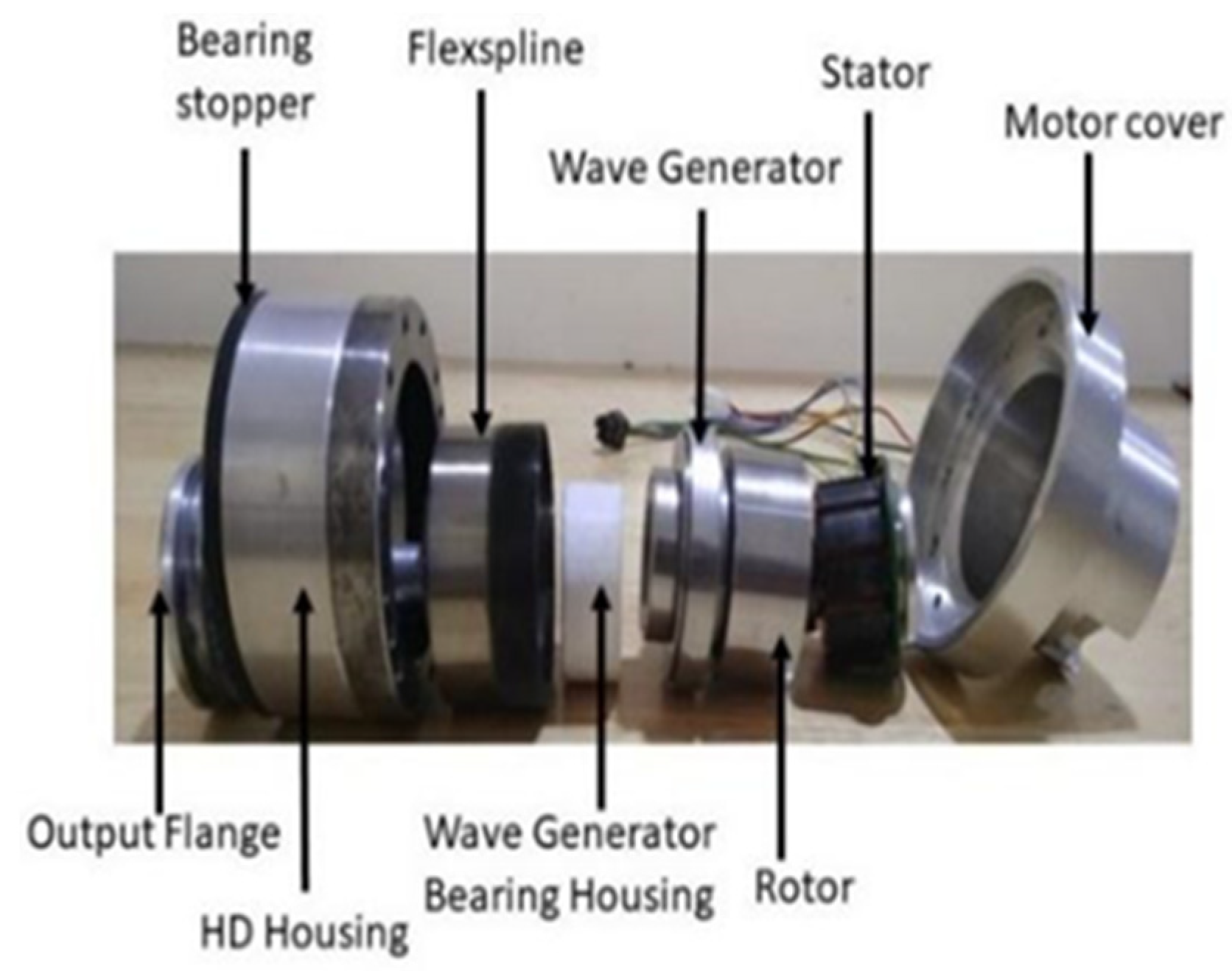

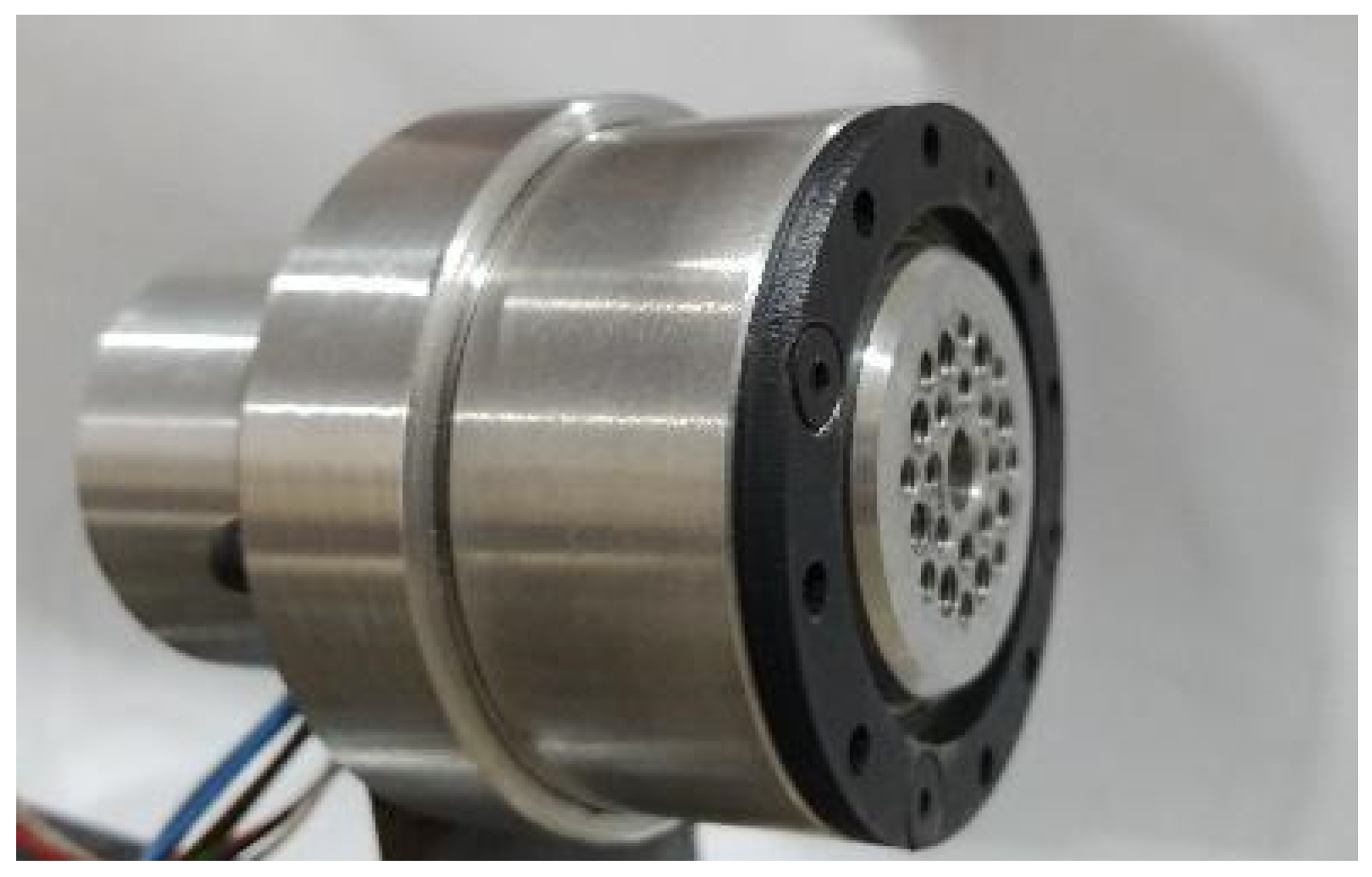

2.2. Actuator Module

2.3. Torque, Power, and Error Modeling

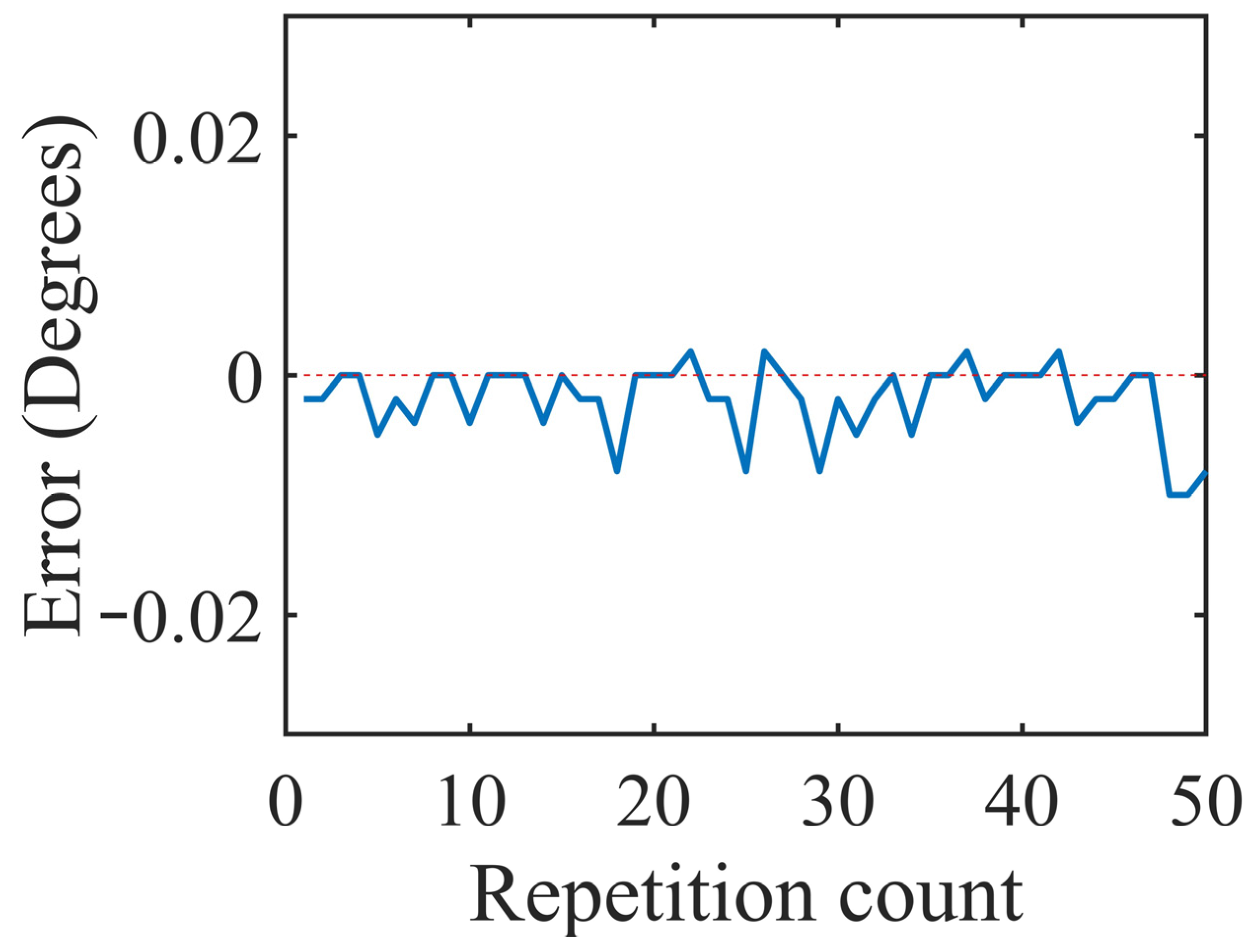

3. Experiments and Results

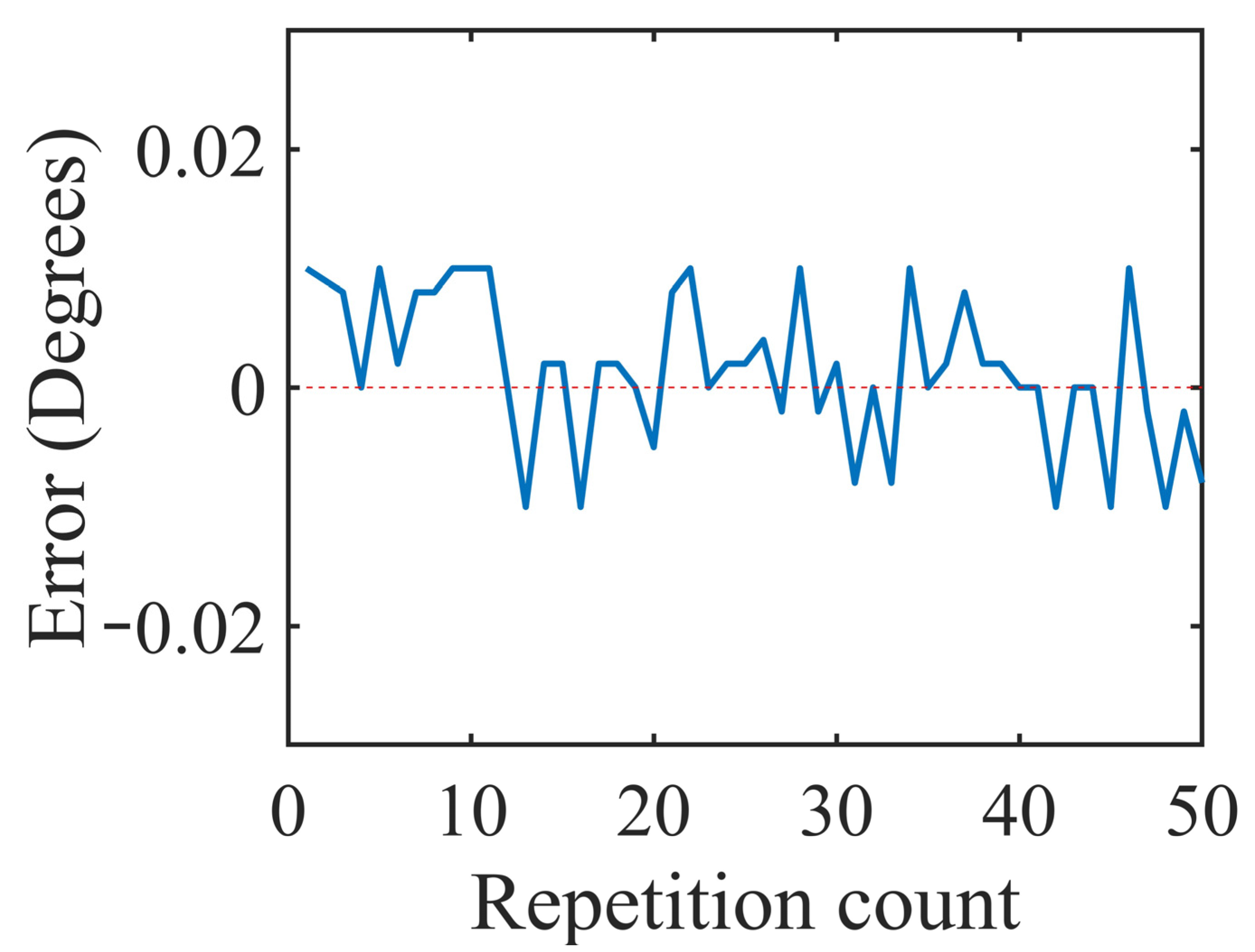

3.1. Position Repeatability Test

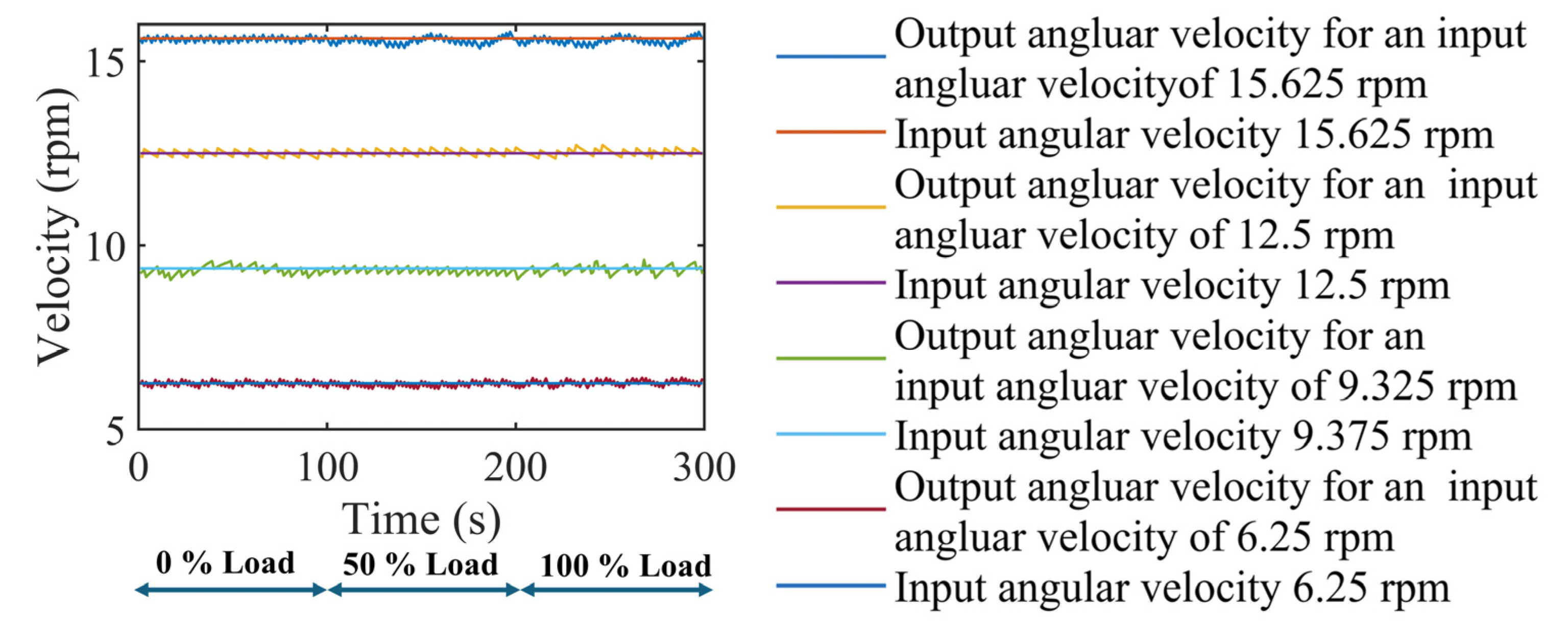

3.2. Velocity Test for Variable Load

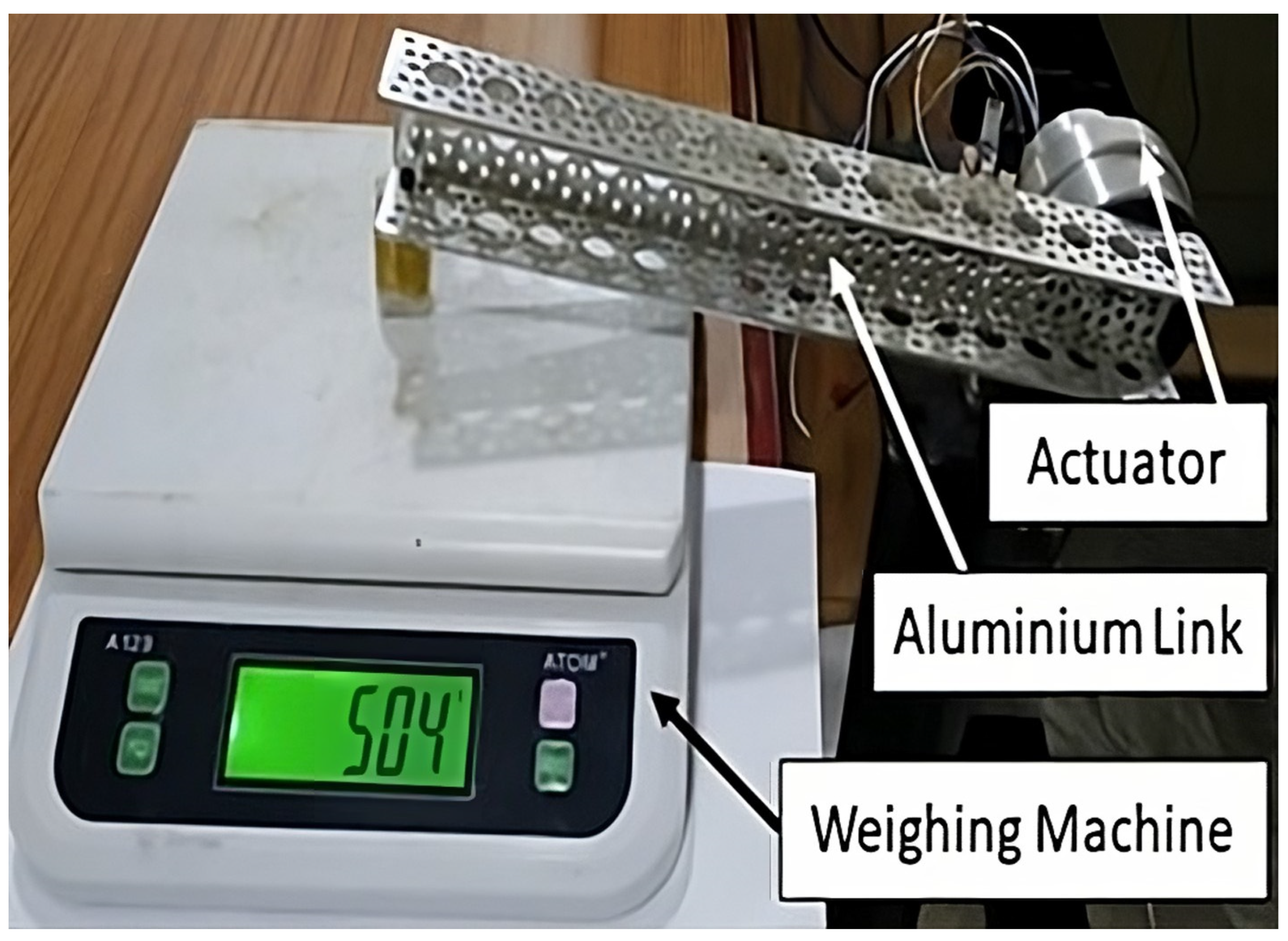

3.3. Torque Analysis for the Variable Applied Current

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Megalingam, R.K.; Manoharan, S.K.; Mohan, S.M.; Vadivel, S.R.R.; Gangireddy, R.; Ghanta, S.; Kotte, S.; Perugupally, S.T.; Sivanantham, V. Amaran: An Unmanned Robotic Coconut Tree Climber and Harvester. IEEE/ASME Trans. Mechatron. 2021, 26, 288–299. [Google Scholar] [CrossRef]

- Megalingam, R.K.; Vadivel, S.R.R.; Rajendraprasad, A.; Raj, A.; Baskar, S.; Babu, R.B.M. Development and evaluation of a search-and-rescue robot Paripreksya 2.0 for WRS 2020. Adv. Robot. 2022, 36, 1120–1133. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Z.; Ma, Q.; Cheng, A.; Liu, Y.-H.; Kim, S.; Deguet, A.; Reiter, A.; Kazanzides, P.; Taylor, R.H. Vision-Based Calibration of Dual RCM-Based Robot Arms in Human-Robot Collaborative Minimally Invasive Surgery. IEEE Robot. Autom. Lett. 2018, 3, 672–679. [Google Scholar] [CrossRef]

- Megalingam, R.K.; Rajendraprasad, A.; Raj, A.; Raghavan, D.; Teja, C.R.; Sreekanth, S.; Sankaran, R. Self-E: A self-driving wheelchair for elders and physically challenged. Int. J. Intell. Robot. Appl. 2021, 5, 477–493. [Google Scholar] [CrossRef]

- Megalingam, R.K.; Raj, A.; Manoharan, S.K.; Egumadiri, V. App Based Teleoperated UV Disinfectant Robot for COVID Cause. In Proceedings of the 2021 Second International Conference on Electronics and Sustainable Communication Systems (ICESC), Coimbatore, India, 4–6 August 2021; pp. 277–281. [Google Scholar] [CrossRef]

- Megalingam, R.K.; Manoharan, S.K.; Mohandas, S.M.; Reddy, C.P.K.; Vijay, E.; Naveen, P.N.V.K.; Chandrika, D. Wearable Hand Orthotic Device for Rehabilitation: Hand Therapy with Multi-Mode Control and Real-Time Feedback. Appl. Sci. 2023, 13, 3976. [Google Scholar] [CrossRef]

- Li, A.; Ye, L.; Yanqing, J.; Yueming, L.; Jian, C.; Jiayu, H. Soft-Switching Proximate Time Optimal Heading Control for Underactuated Autonomous Underwater Vehicle. IEEE Access 2019, 7, 143233–143249. [Google Scholar] [CrossRef]

- Liu, B.; Fu, W.; Wang, W.; Gao, Z.; Li, R.; Peng, L.; Du, H.; Chen, X. Research on Cobot Action Decision-Making Method Based on Intuitionistic Fuzzy Set and Game Theory. IEEE Access 2022, 10, 103349–103363. [Google Scholar] [CrossRef]

- Van de Perre, G.; Hubert, T.; Verstraten, T.; Vanderborght, B. Investigating the Potential of Flexible Links for Increased Payload to Mass Ratios for Collaborative Robotics. IEEE Access 2023, 11, 15981–15995. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y.; Zhou, G. Research on a Novel Transverse Flux Permanent Magnet Motor with Hybrid Stator Core and Disk-Type Rotor for Industrial Robot Applications. IEEE Trans. Ind. Electron. 2021, 68, 11223–11233. [Google Scholar] [CrossRef]

- Salah, M.; Al-Jarrah, A.; Tatlicioglu, E.; Banihani, S. Robust Backstepping Control for a Four-Bar Linkage Mechanism Driven by a DC Motor. J. Intell. Robot. Syst. 2019, 94, 327–338. [Google Scholar] [CrossRef]

- Lin, N.; Wu, P.; Wang, M.; Wei, J.; Yang, F.; Xu, S.; Ye, Z.; Chen, X. IMU-Based Active Safe Control of a Variable Stiffness Soft Actuator. IEEE Robot. Autom. Lett. 2019, 4, 1247–1254. [Google Scholar] [CrossRef]

- Pan, Y.; Li, X.; Yu, H. Efficient PID Tracking Control of Robotic Manipulators Driven by Compliant Actuators. IEEE Trans. Control Syst. Technol. 2019, 27, 915–922. [Google Scholar] [CrossRef]

- Legrand, J.; Loenders, B.; Vos, A.; Schoevaerdts, L.; Poorten, E.V. Integrated Capacitance Sensing for Miniature Artificial Muscle Actuators. IEEE Sens. J. 2020, 20, 1363–1372. [Google Scholar] [CrossRef]

- Tazaki, Y. Parallel link-based light-weight leg design for bipedal robots. In Proceedings of the IEEE-RAS 19th International Conference on Humanoid Robots (Humanoids), Toronto, ON, Canada, 15–17 October 2019. [Google Scholar] [CrossRef]

- Megalingam, R.K.; Vadivel, S.R.R.; Prem, A.; Avvari, V.S.Y.; Sairam, B.C.S.C.; Konduri, S. Test Setup for Analysis of Torque on DC Motor Shaft and its Possible Applications. In Proceedings of the International Conference on Communication and Signal Processing (ICCSP), Chennai, India, 4–6 April 2019. [Google Scholar]

- Refael, G.; Degani, A. A Single-Actuated Swimming Robot: Design, Modelling, and Experiments. J. Intell. Robot. Syst. 2019, 94, 471–489. [Google Scholar] [CrossRef]

- Tallapragada, P. A swimming robot with an internal rotor as a nonholonomic system. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 657–662. [Google Scholar] [CrossRef]

- Nerat, M.; Vrancic, D. A Novel Fast-Filtering Method for Rotational Speed of the BLDC Motor Drive Applied to Valve Actuator. IEEE/ASME Trans. Mechatron. 2016, 21, 1479–1486. [Google Scholar] [CrossRef]

- Megalingam, R.K.; Vadivel, S.R.R.; Pula, B.T.; Sathi, S.R.; Gupta, U.S.C. Motor Control Design for Position Measurement and Speed Control. In Proceedings of the International Conference on Communication and Signal Processing, Chennai, India, 4–6 April 2019. [Google Scholar]

- Terfurth, J.; Schmid, M.; Parspour, N. Planar Aligned Transverse Flux Machine with Integrated Reduction Gear. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 714–720. [Google Scholar] [CrossRef]

- Terfurth, J.; Waldhof, M.; Schmid, M.; Weber, J.; Keller, M.; Parspour, N. Design and Evaluation of a Spatially Distributed and Gear-Integrated Transverse Flux Machine. IEEE Trans. Ind. Electron. 2023, 70, 5065–5073. [Google Scholar] [CrossRef]

- Kendjouh, T.; Guerroudj, C.; Charpentier, J.-F.; Bracikowski, N.; Hadjout, L.; Bekhouche, L. Contribution to Improve Magnetic Performance and Torque Ripple Reduction of the Low-Speed DSPM Machine. Actuators 2023, 12, 195. [Google Scholar] [CrossRef]

- Varshney, A.; Dwivedi, B. Performance analysis of a BLDC drive under varying load. In Proceedings of the IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems, Delhi, India, 4–6 July 2016. [Google Scholar]

- Schmitt, L.; Conrad, P.; Kopp, A.; Ament, C.; Hoffmann, M. Non-Inchworm Electrostatic Cooperative Micro-Stepper-Actuator Systems with Long Stroke. Actuators 2023, 12, 150. [Google Scholar] [CrossRef]

- Aditya, K.; Udupa, G.; Sreedharan, P. Robotic gripper drive by flexible microactuator based on an innovative technique. In Proceedings of the 2010 IEEE Workshop on Advanced Robotics and its Social Impacts, Seoul, Republic of Korea, 26–28 October 2010. [Google Scholar]

- Taufer, T.; Billet, L. Compact BLDC & stepper motor technology for ultra-slim actuators. In Proceedings of the IKMT 2015; 10. ETG/GMM-Symposium Innovative Small Drives and Micro-Motor Systems, Cologne, Germany, 14–15 September 2015; pp. 1–6. [Google Scholar]

- KinovaActuator. Available online: https://www.kinovarobotics.com/sites/default/files/AS-ACT-KA58-KA75-SP-INT-EN%202018041.2%20%28KINOVA%E2%84%A2%20Actuator%20series%20KA75%2B%20KA-58%20Specifications%29 (accessed on 22 February 2024).

- Hebi-Robotics. Available online: http://docs.hebi.us/resources/datasheets/X-eriesDatasheet.pdf (accessed on 22 February 2024).

| Parameters | Values | Units |

|---|---|---|

| Rated torque | 40 | Nm |

| Limit for average torque | 49 | Nm |

| Limit for repeated peak torque | 92 | Nm |

| Limit for momentary peak torque | 147 | Nm |

| Starting torque | 2.9 | N-cm |

| Back-driving torque | 5.8 | Nm |

| Average input speed | 3500 | rpm |

| Standard accuracy | 1 | Arc min |

| Mass | 0.28 | Kg |

| Gear ratio | 160 | - |

| Parameters | Values |

|---|---|

| No load speed | 38 rpm |

| Nominal torque | 20.480 Nm |

| Nominal speed | 30 rpm |

| Torque gradient | 1.4832 rpm/Nm |

| Position sensor resolution | 16 bits/revolution |

| Operating temperature range | −40 to 100 °C |

| Thermal time constant of the winding | 29.6 s |

| Weight | 0.788 Kg |

| Power supply voltage | 24 V |

| Communication protocol | USB |

| Communication cables | B-type data cable |

| Standard Actuator | Weight (g) | Nominal Torque (Nm) | Angular Resolution |

|---|---|---|---|

| Anydrive [27] | 1090 | 15 | |

| Kinova KA-751 [28] | 570 | 12 | |

| Kinova KA-58 [28] | 357 | 3.6 | |

| Hebi robotics [29] | 500 | 16 | |

| Our actuator | 540 | 20.6 |

| Input Angular Velocity (rpm) | Angular Velocity Deviation Range (rpm) |

|---|---|

| 9.375 | −0.15 to 0.22 |

| 12.5 | −0.31 to 0.23 |

| 15.625 | −0.15 to 0.15 |

| Applied Current (mA) | Measured Torque (Nm) | Theoretical Torque (Nm) | Error (%) |

|---|---|---|---|

| 300 | 1.73 | 1.77 | 2.3 |

| 400 | 2.11 | 2.36 | 10.6 |

| 500 | 2.84 | 2.95 | 3.7 |

| 700 | 4.04 | 4.13 | 2.2 |

| 900 | 5.21 | 5.31 | 1.9 |

| 1200 | 6.92 | 7.08 | 2.3 |

| 1500 | 8.29 | 8.85 | 6.3 |

| 1800 | 10.22 | 10.62 | 3.8 |

| 2000 | 11.13 | 11.80 | 5.7 |

| 2200 | 12.40 | 12.98 | 4.5 |

| 2400 | 13.70 | 14.16 | 3.2 |

| 2600 | 14.50 | 15.35 | 5.5 |

| 2800 | 16.04 | 16.53 | 3.0 |

| 3000 | 16.68 | 17.71 | 5.8 |

| 3200 | 18.16 | 18.89 | 3.9 |

| 3500 | 19.88 | 20.66 | 3.8 |

| Applied Current (mA) | Relative Torque (Nm) | Theoretical Relative Torque (Nm) |

|---|---|---|

| 300 | 0 | 0 |

| 400 | 0.38 | 0.59 |

| 500 | 0.73 | 0.59 |

| 700 | 1.2 | 1.18 |

| 900 | 1.17 | 1.18 |

| 1200 | 1.71 | 1.77 |

| 1500 | 1.37 | 1.77 |

| 1800 | 1.93 | 1.77 |

| 2000 | 0.91 | 1.18 |

| 2200 | 1.27 | 1.18 |

| 2400 | 1.3 | 1.18 |

| 2600 | 0.8 | 1.19 |

| 2800 | 1.54 | 1.18 |

| 3000 | 0.64 | 1.18 |

| 3200 | 1.48 | 1.18 |

| 3500 | 1.72 | 1.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Megalingam, R.K.; Vadivel, S.R.R.; Manoharan, S.K.; Pula, B.T.; Sathi, S.R.; Gupta, U.S.C. Reduced Kinematic Error for Position Accuracy in a High-Torque, Lightweight Actuator. Actuators 2024, 13, 218. https://doi.org/10.3390/act13060218

Megalingam RK, Vadivel SRR, Manoharan SK, Pula BT, Sathi SR, Gupta USC. Reduced Kinematic Error for Position Accuracy in a High-Torque, Lightweight Actuator. Actuators. 2024; 13(6):218. https://doi.org/10.3390/act13060218

Chicago/Turabian StyleMegalingam, Rajesh Kannan, Shree Rajesh Raagul Vadivel, Sakthiprasad Kuttankulangara Manoharan, Bhanu Teja Pula, Sarveswara Reddy Sathi, and Uppala Sai Chaitanya Gupta. 2024. "Reduced Kinematic Error for Position Accuracy in a High-Torque, Lightweight Actuator" Actuators 13, no. 6: 218. https://doi.org/10.3390/act13060218

APA StyleMegalingam, R. K., Vadivel, S. R. R., Manoharan, S. K., Pula, B. T., Sathi, S. R., & Gupta, U. S. C. (2024). Reduced Kinematic Error for Position Accuracy in a High-Torque, Lightweight Actuator. Actuators, 13(6), 218. https://doi.org/10.3390/act13060218