1. Introduction

According to some references, by 2030, 18.2% of Chinese people will be over 65 years old [

1]. Additionally, the number of people with physical disabilities will reach 24.12 million, accounting for 29.07% of the total number of disabled individuals, among which there are approximately 1.58 million people with lower limb paralysis [

2]. Currently, China is becoming an aging society, and with the growth of the elderly population and the occurrence of various accidents, the number of people who have difficulty in walking is increasing year by year. However, due to various reasons, only a small portion of the population can receive timely and effective rehabilitation treatment [

3]. This can cause significant potential harm to the lives of the patients and their families [

4]. At this point, the emergence of lower limb exoskeletons brings significant help to patients and their families. Lower limb exoskeletons can assist patients in effective rehabilitation training, improve their lower limb motor function, and alleviate the burden on the patients’ caregivers. The emergence of lower limb exoskeletons brings new hope to patients and improves their quality of life [

5]. Generally speaking, lower limb exoskeletons have two different objectives: assisting patients in rehabilitation training, and assisting in human working activities [

6]. Robotic technologies that assist physical health and provide support for the elderly are rapidly developing. In the past three decades, lower limb exoskeleton robotics and assistive technologies have been a focus of attention in the industry [

7]. As a typical application of human–machine interaction devices, the perception and control of lower limb exoskeleton robots will significantly affect the actual wearing effects of users in lower limb assistance or augmentation [

8]. Therefore, in order to achieve the swinging control of the lower limb exoskeleton, it is essential to design an appropriate swing controller during the development stage [

9].

Currently, an increasing number of researchers aim to enhance the development and improvement of lower limb exoskeletons through control, thereby improving their performance [

10]. With the rise of model-based control techniques, knowledge of the precise dynamic mathematical model of lower limb exoskeletons is required. However, in practical systems, various uncertainties exist that have a significant impact on the model-based controllers, thereby severely affecting their performance. Therefore, designing a reasonable control algorithm to address the uncertainties in lower limb exoskeleton systems has become a research hotspot [

11]. Currently, optimization control strategies for lower limb exoskeletons need to meet the criteria of safety, stability, effective rehabilitation, assistance, and efficient control simultaneously [

12]. Furthermore, for lower limb exoskeletons, controllers need to demonstrate good tracking performance and stability while minimizing tracking errors [

13]. Therefore, appropriate control algorithms are required to ensure the stability and robustness of lower limb exoskeletons during motion [

14]. Currently, the main control strategies for lower limb exoskeletons include position tracking control, force impedance control, biological signal control, and more. Among them, position tracking control serves as the foundation for other control methods [

15]. Additionally, the control modes of exoskeletons primarily involve active control and passive control. In active control, the exoskeleton provides necessary assistance and closely follows human motion. In passive control, the human body acts as the load for the exoskeleton, and the exoskeleton is entirely driven by external forces. The key aspect of passive control lies in studying the dynamic model of the exoskeleton [

16]. From this perspective, the development of control systems is one of the most critical parts of exoskeleton systems. RBF neural networks are chosen due to their excellent generalization ability, simple structure, and the ability to approximate any nonlinear function with arbitrary precision. They can be used to estimate the unknown parts of the hyper-local model [

17]. Reference [

18] considers the exoskeleton as a nonlinear motion system and applies RBF neural networks for real-time identification of the system. The current hip and ankle joint angles of the exoskeleton, along with the previous knee joint angle, are defined as the network inputs at the current time. A general error function is defined, which includes tracking errors of the exoskeleton and interaction torques between the pilot and the exoskeleton to ensure convergence. Subsequently, a mathematical model of the human–machine system is established. It can be seen that the RBF neural network controller performs well in controlling the lower limb exoskeleton robot through simulation experiments.

Furthermore, through extensive literature review, it is evident that determining the inertial parameters of the robot is necessary to develop advanced control algorithms. The design of nonlinear robot controllers typically relies on the robot model, and their performance directly depends on accurate inertial parameters. Due to the complexity of certain robot structures and the nonlinear nature of loads, determining dynamic parameters can be challenging, and parameter identification is the only effective method to obtain precise inertial parameters [

19]. As model-based control is crucial, the identification of inertial parameters has gained extensive attention from researchers [

20]. Identifying the inertial parameters first requires establishing a mathematical model and linearizing it to obtain a coefficient matrix for parameter identification [

21]. In the offline dynamic identification stage the coefficient matrix is utilized, and the parameters are calculated using the least squares method [

22].

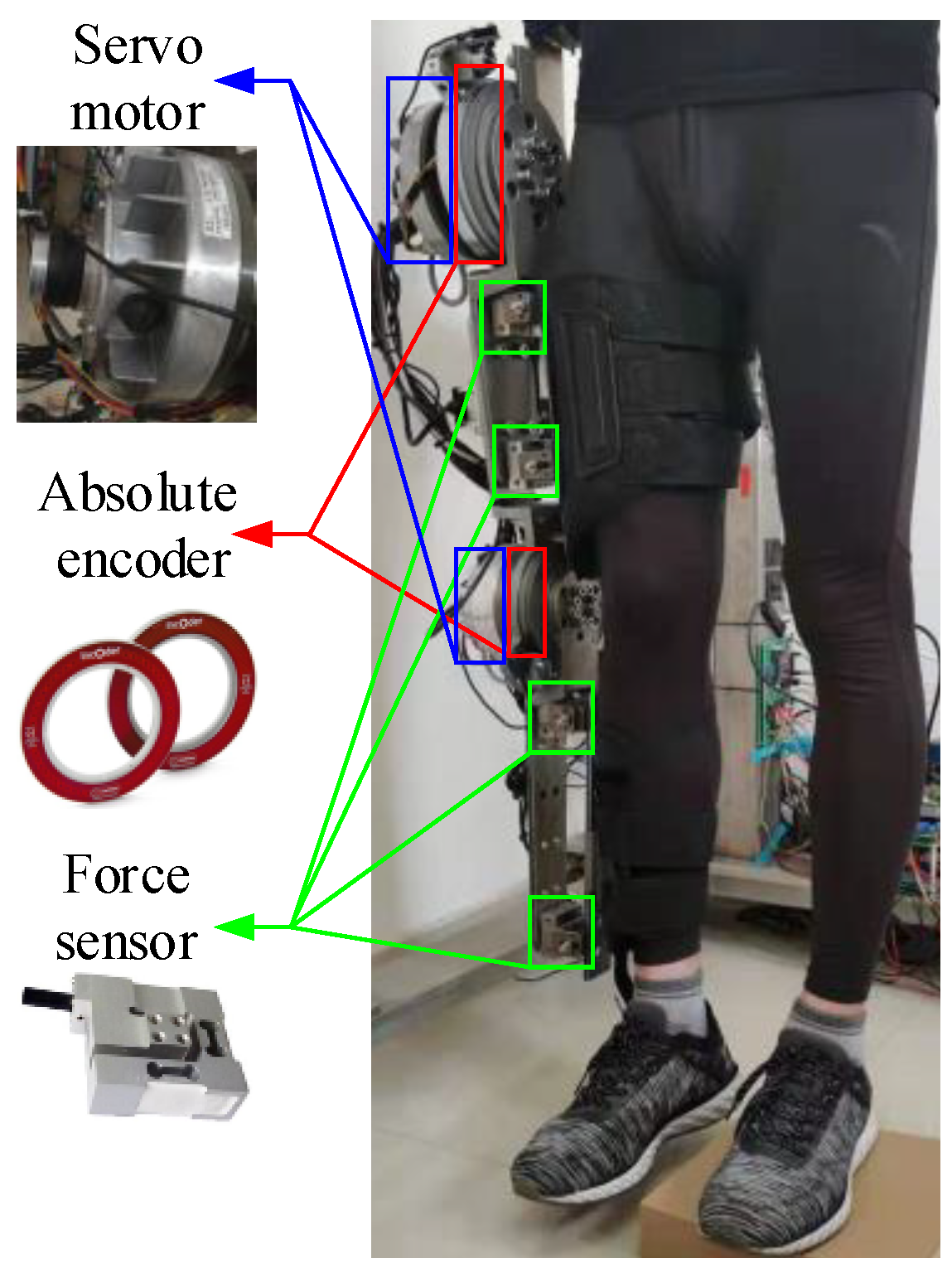

It can be seen that the control of lower limb exoskeletons is crucial in their research. Model-based control methods have been used to achieve a desirable control performance. This study focuses on lower limb exoskeleton robots. Considering the individual differences among people, this work firstly determines the inertial parameters of the human–machine coupling model through experiments to establish a foundation for control simulations, rather than using average anatomical values as the model’s inertial parameters. In the control simulation stage, assuming the exoskeleton operates in passive control mode, an adaptive controller based on RBF neural network approximation is designed to track the desired trajectory. Simulations are conducted using MATLAB to indicate the control effects of the RBF neural network controller.

2. Materials and Methods

2.1. Coupled Dynamics Model of 2-DOF Lower Extremity Exoskeleton and Human Body

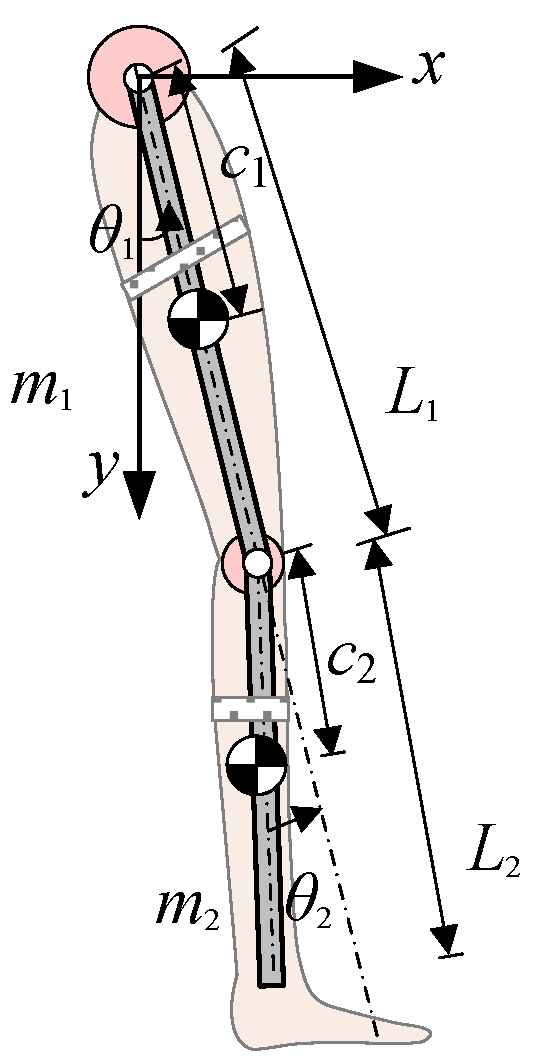

In this paper, a Lagrange modelling approach is utilized to research the dynamics of a lower limb exoskeleton robot and the human body. The Lagrange method firstly finds the total kinetic energy and the potential energy of the model, and then puts and into the Lagrange function to get . Then, the Lagrange function equation can be derived from its partial derivation to find out the magnitude of the actuating torque needed to rotate the corresponding joints in the model.

Figure 1 shows the schematic diagram of a 2-DOF lower extremity exoskeleton coupled with the human body. The corresponding symbols for the physical parameters in the figure are shown in

Table 1. We treat the human body and lower limb exoskeleton as a whole in this section.

According to the kinetic energy formula, the translational kinetic energy and the rotational kinetic energy of the center of mass, respectively, make up the kinetic energy of the thigh

and the shank

:

From the potential energy equation, the potential energy of the thigh

and the shank

can be obtained:

where gravitational acceleration

.

Then the Lagrange function

can be written as:

Lagrange dynamic method is used to solve the system’s equations, and the Lagrange equation is:

where

represents the dual angle vector representing the coupled model,

represents the joint generalized vector.

According to the above derivation, the dynamic model of the coupled human lower extremity exoskeleton can be represented as:

In Equation (7), , and represent the Inertia matrix, Coriolis matrix and Gravity matrix, represent the dual joint friction torque, represent the dual joint control torque.

Convert the dynamic model into a linear form:

In Equation (8),

represents the parameter vector to be identified,

represents the regression matrix composed of the angle, angular velocity, and angular acceleration of the hip and knee joints. The specific forms of the parameter vector to be identified and the regression matrix are provided in

Appendix A.

Assuming that there are

N sets of sampling points in the experiment, the sampling regression matrix

and the sampling torque vector

can be represented as:

The parameter vector to be identified can be obtained using the least square method:

Due to the presence of signification noise in the sampled data, designing a suitable excitation trajectory can help suppress the noise and thereby improve the accuracy of the parameter vector to be identified.

The excitation trajectory can be represented using a second-order Fourier series:

In Equation (11),

,

,

and

T represents the duration of the data collection experiment for design,

represents the set base frequency,

k represents the set sampling parameter,

represents the initial bias angle of the exoskeleton hip and knee joints, and

and

represent the parameters to be optimized. Considering the joint angle limitation range during human movement [

23] as well as our hardware device restriction, the constraint intervals for the excitation trajectory are shown in

Table 2.

In MATLAB, the Equation (11) is sampled to obtain a sampled regression matrix. By using the particle swarm algorithm to optimize the obtained matrix, the parameters

and

to be optimized can be obtained. The condition number of the sampling regression matrix is selected as the fitness function (

) for the optimization process. Meanwhile, the set excitation trajectory should follow the constraint conditions shown in

Table 2. Based on the final set, the excitation trajectory is as follows:

2.2. Adaptive Control of Exoskeleton Based on RBF Neural Network Approximation

The most classic control algorithms for exoskeletons include PID control, neural network control, fuzzy control, iterative learning control, and robot inversion control [

24]. The PD controller is the most widely used control algorithm, especially in a nonlinear control system. The PD controller’s leading characteristics can be utilized to enhance the dynamic performance and robustness of the control system [

25]. RBF neural networks, due to their good performance and simple structure, can avoid unnecessary and complex calculations that are commonly used in a nonlinear system [

26]. Compared to the PD controller, the RBF neural network can eliminate the error caused by disturbance and accelerate convergence speed [

27].

In practical application engineering, there may be unknown external disturbance acting on the torque

applied to the exoskeleton [

28]. When an unknown external disturbance is added to system, the mathematical expression for the model of the limb exoskeleton is:

The M, C, G matrices represent the inertia matrix, Coriolis acceleration, and gravity matric of the identified exoskeleton and human body system.

The input of the system

is the desired angle vector for the exoskeleton’s hip and knee joints, and the output

is the actual tracked angle vector for the exoskeleton’s hip and knee joints. Therefore, the error of the system is given by:

In order to achieve a better control performance, it is necessary to compensate for the unknown disturbances. Because the RBF neural network has a good error compensate capability, it is used to compensate for the unknown external disturbances in the exoskeleton. The error function is defined as:

In Equation (15)

, which represents the magnification. By combining Equations (14) and (15), we obtain:

Taking the derivative of Equation (16) with regards to time and left-multiplying by the matrix

, we obtain:

Substituting Equations (13) to (17) into the previous equation, we obtain:

The expression for

f in Equation (18) is:

The unknown

represents the model uncertainty in practical engineering applications, and it needs to be approximated. Equation (19) indicates that this uncertainty is a nonlinear function, which can be approximated using an RBF neural network. The chosen RBF neural network is a three-layer feedforward network with a single hidden layer, which is more straightforward and computationally straightforward than higher level neural networks, while still satisfying our model’s control requirements. The transformation from the input layer to the hidden layer is nonlinear. The input signals of the network are denoted as

. The transformation function in the hidden layer is the radial basis function, represented as

hj,

j = 1, 2, …, m. The radial basis function is used in the Gaussian kernel function, and its expression is:

In Equation (20), represents the center of the j-th radial basis function, and represents the width of the j-th radial basis function.

The transformation from the hidden layer to the output layer in the RBF neural network is a linear transformation. The output expression is as follows:

In Equation (22), and represent the weight matrix of the RBF neural network, while represents the output matrix of the radial basis functions.

Since the role of the neural network is to compensate for the model uncertainty, the control law of the designed RBF neural network controller is as follows:

In Equation (23), represents the amplification coefficient of the error, while represents the robust term used to overcome approximation errors in the neural network.

2.3. Adaptive Analysis of Neural Network Stablility and Converagence

By substituting the control law (23) into Equation (18) and simplifying, we obtain:

where

.

Designing the robust term

as follows:

In Equation (25), and represent the upper bounds of and .

The expression for the Lyapunov function is defined as:

In Equation (26),

is a positive definite matrix, and taking the derivative of Equation (26), we obtain:

By substituting Equation (22) into the previous equation, we obtain:

Taking into account the characteristics of the exoskeleton, we choose the adaptive law of the neural network as:

Based on the above analysis, we can conclude that: . When , , according to LaSalle’s invariance principle, the closed-loop system is asymptotically stable, when , and the tracking error corresponds to zero.

4. Discussion and Conclusions

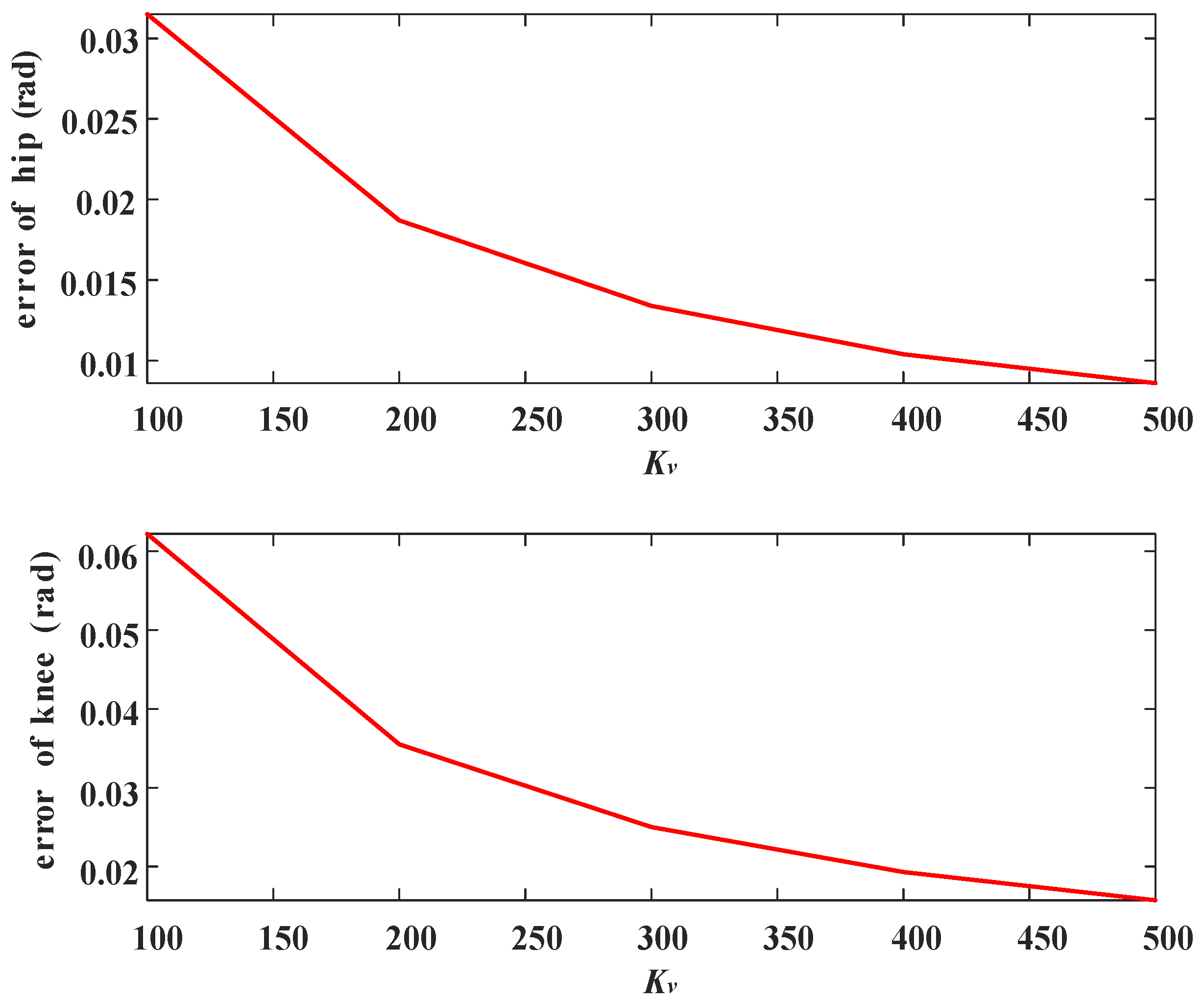

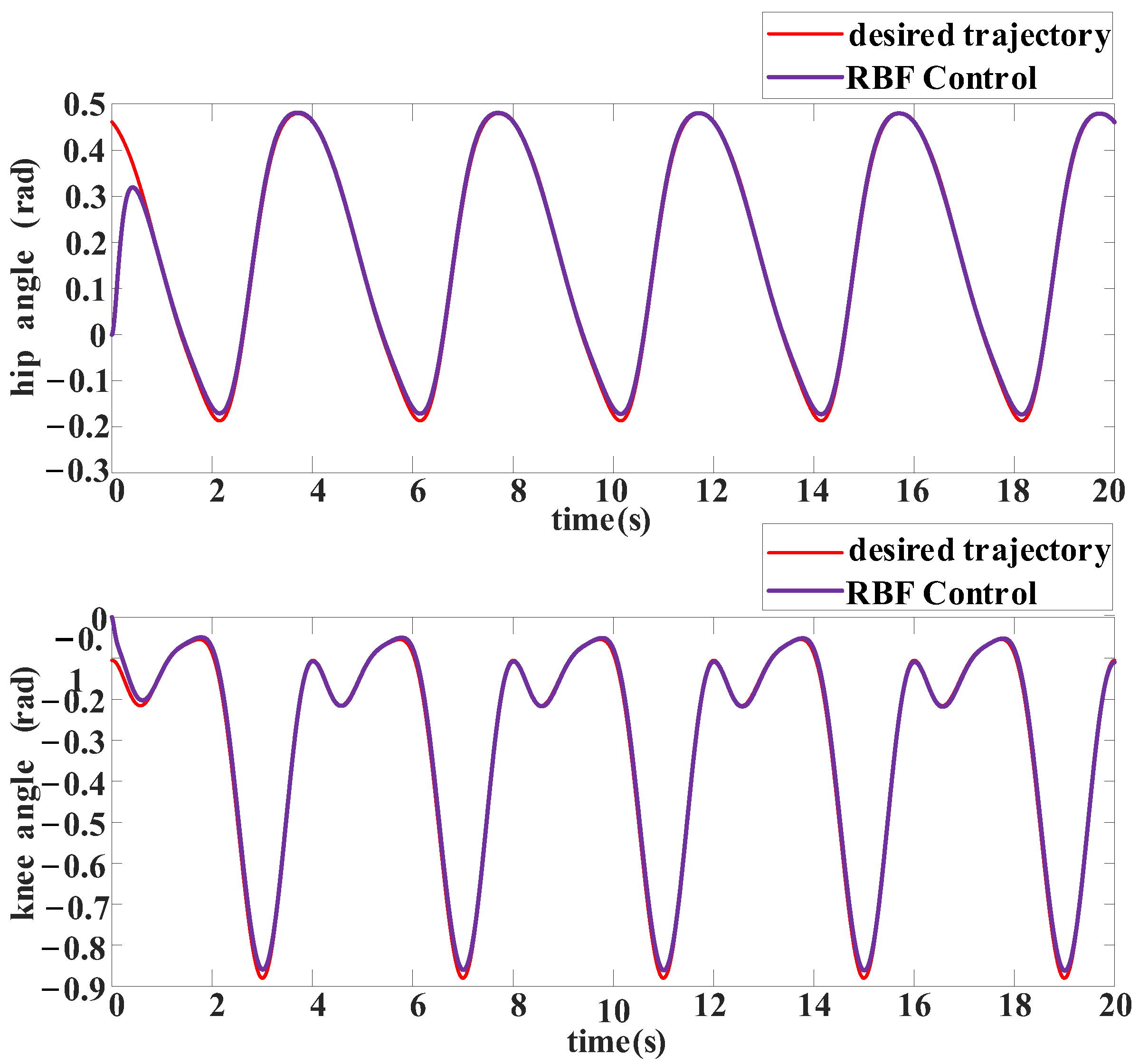

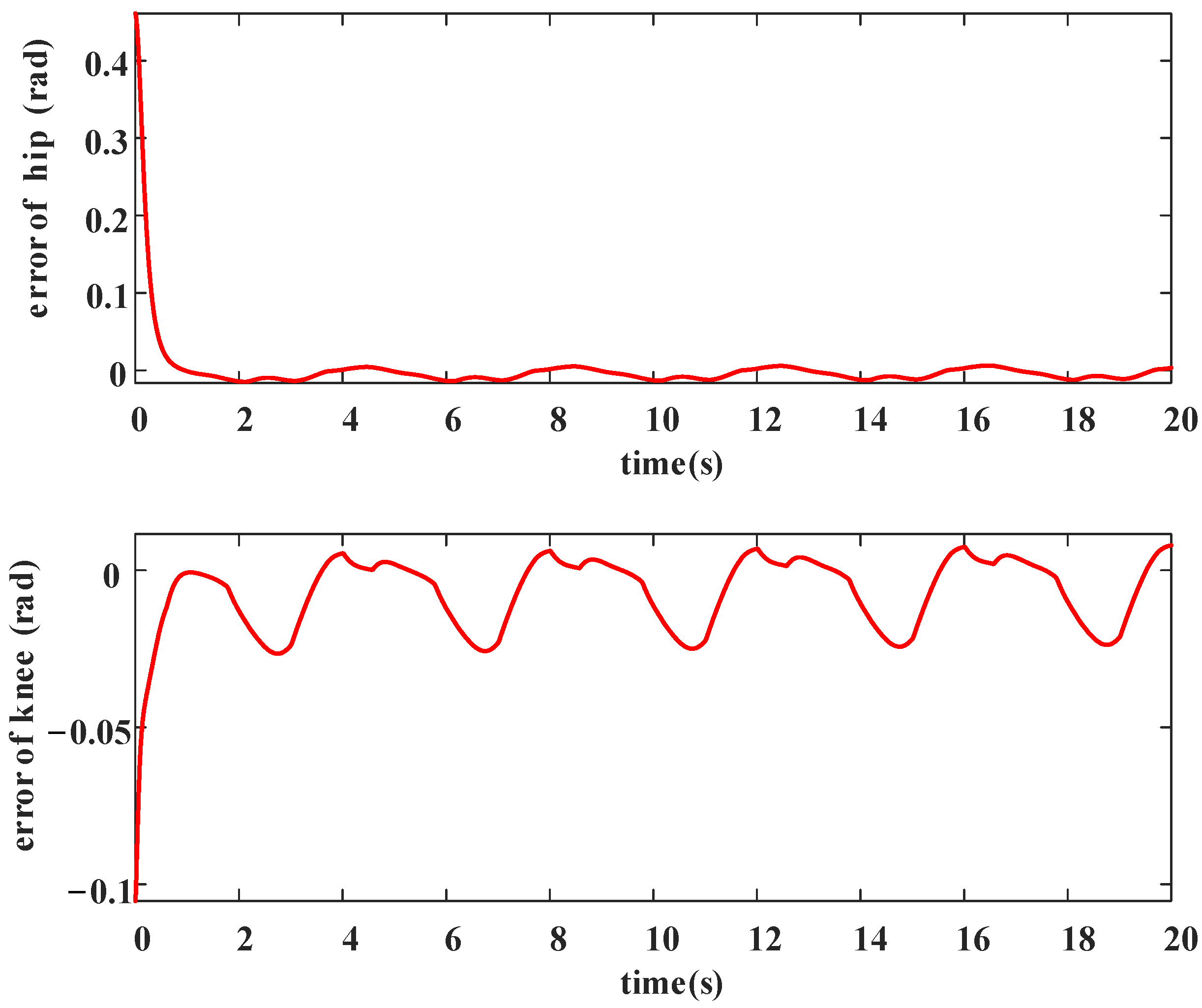

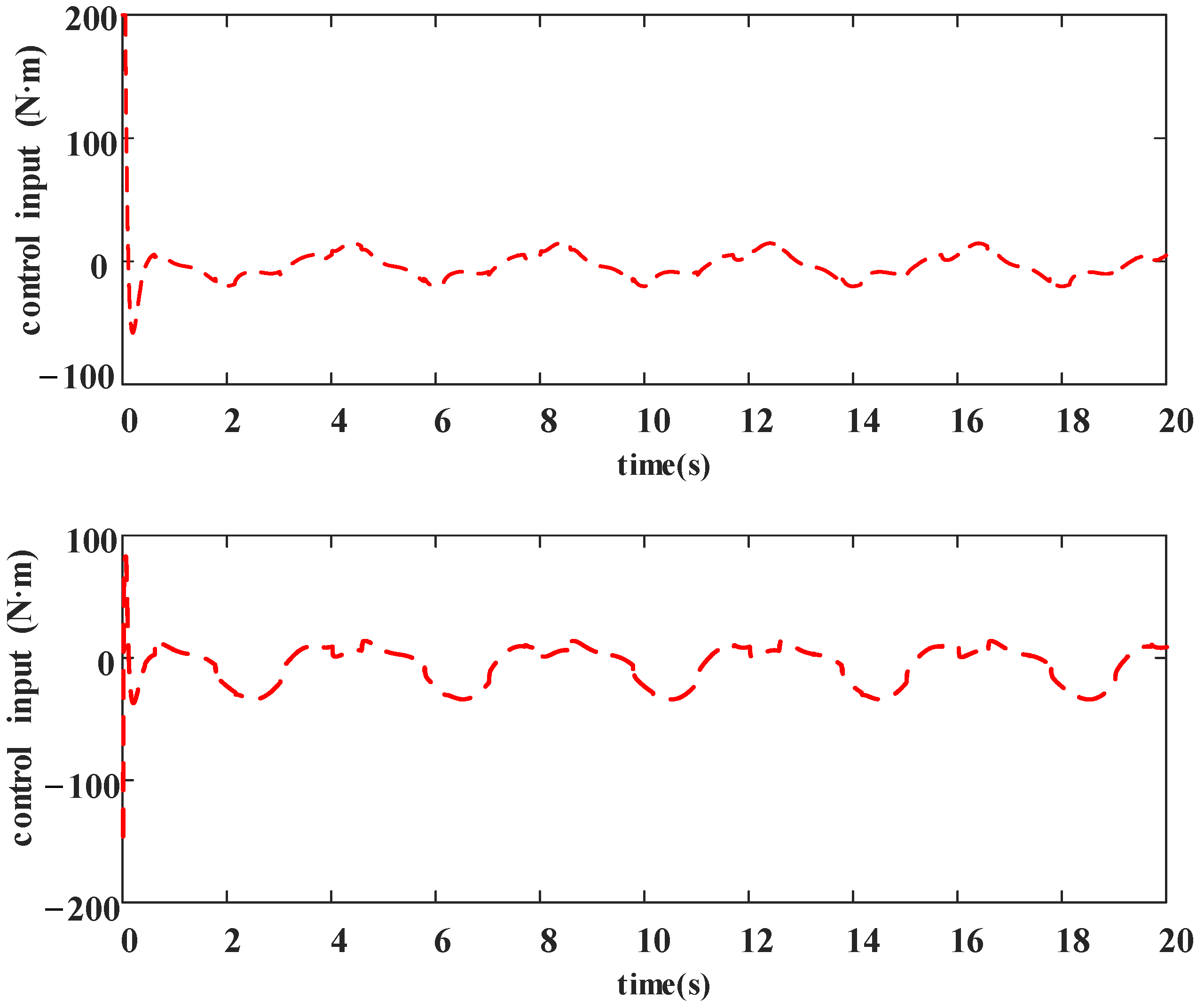

This study focuses on the exoskeleton human–machine system. To enhance the control effectiveness of the model-based control, an identification experiment is used to obtain the inertial parameters of the human–machine system. Based on this, a simulation is made on the control effects of the RBF adaptive control. In the identification stage, firstly, the exoskeleton human–machine mathematical model is linearized and the excitation trajectory is optimized to use the particle swarm optimization algorithm. Secondly, experimental data is collected to obtained the identification parameters required for the mathematical model. Then, the inertial parameters of the human–machine model are obtained through the least square method, which helps determine the parameters for subsequent simulation experiments. Subsequently, MATLAB is used to simulate and compare the exoskeleton human–machine model. The relationship between the maximum error after stabilization and the control parameters are analyzed to select to the control gain parameters for RBF neural network control, optimizing the control for the control method. The simulation is conducted using MATLAB’s S-function, and the comparative graphs of the desired and actual trajectories of the exoskeleton’s hip and knee joints, error comparison, and torque comparison are obtained. Based on the dynamic compensation ability of RBF in handing system uncertainties, where control is based on the system error and its derivative, comprehensive analysis of the simulation results indicates that RBF provides desirable trajectory tracking control for the exoskeleton when an appropriate parameter is selected. The error decreases when increasing the RBF parameter Kv within a specified range. However, this reducing impact becomes smaller as the parameter values rise. From the results, we can judge that RBF achieve controlling consequences with fast convergence as well as small errors. In addition, the control performance of the hip joint is superior to that of the knee joint.

Substantial progress has been made in the research of lower limb exoskeleton robot control over the past few decades. However, whether the control strategies of lower limb exoskeletons can more effectively stimulate the functional recovery of patients remains an unresolved question. Future research should focus on structured and standardized studies aimed at identifying the relationship between control strategies and a set of core clinical outcome measures, taking into account the impact of participants’ initial impairment level and training intensity [

30]. In this study, we assumed that the patient does not exert any force and is completely driven by the exoskeleton, without considering the patient’s intentions. In future research, we will take the patient’s intentions into account and conduct in-depth investigations into the influencing factors. We plan to carry out further research on active control in the future.