3.4.1. Temperature Distribution Rule

Due to the different thermal conductivities of the materials within the motor, the temperature distribution within the motor is not uniform. In this paper, Fluent software is used to calculate the temperature of the motor, and the thermal conductivity of the materials used in this paper for each part of the motor is shown in

Table 6 [

20,

21,

22].

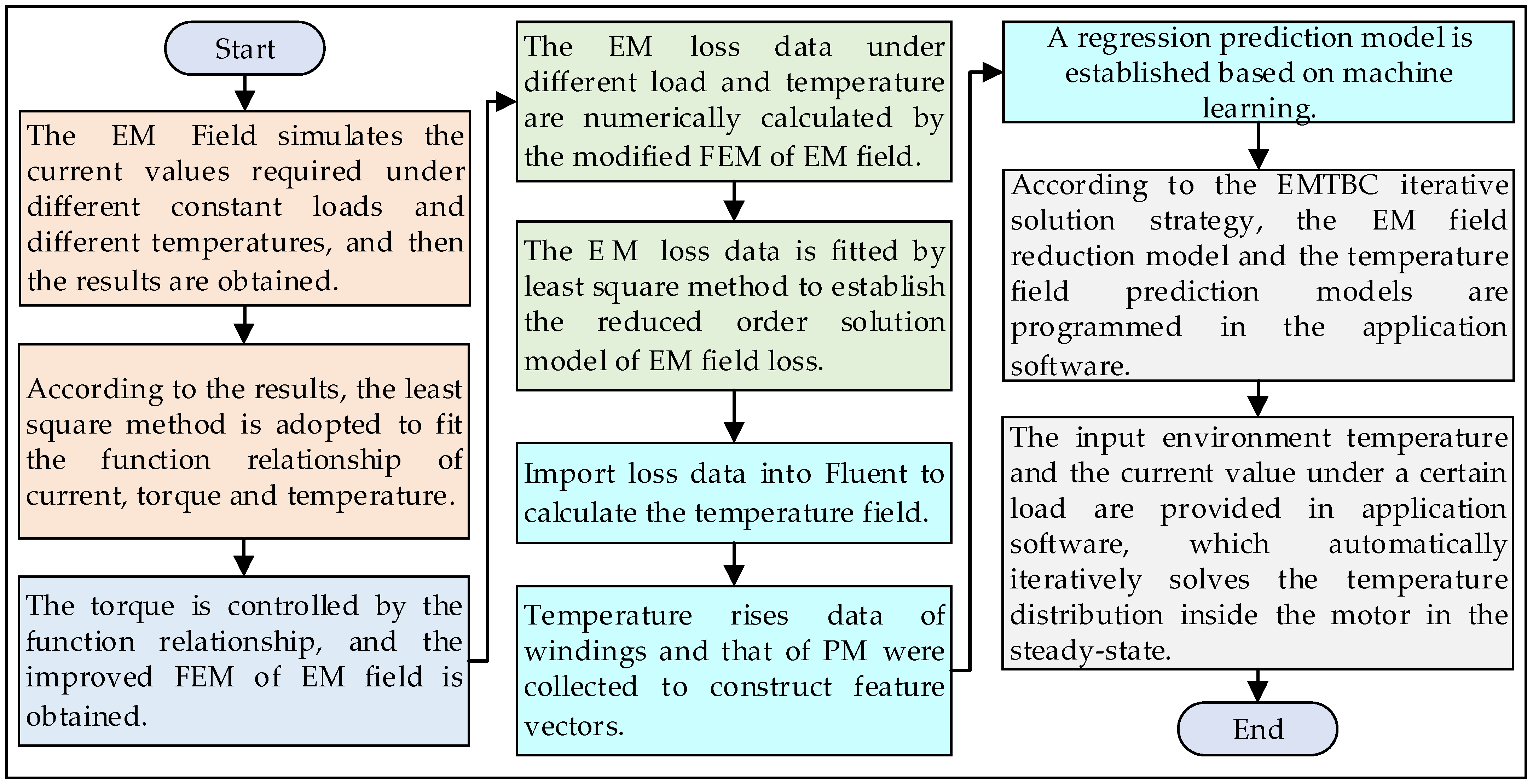

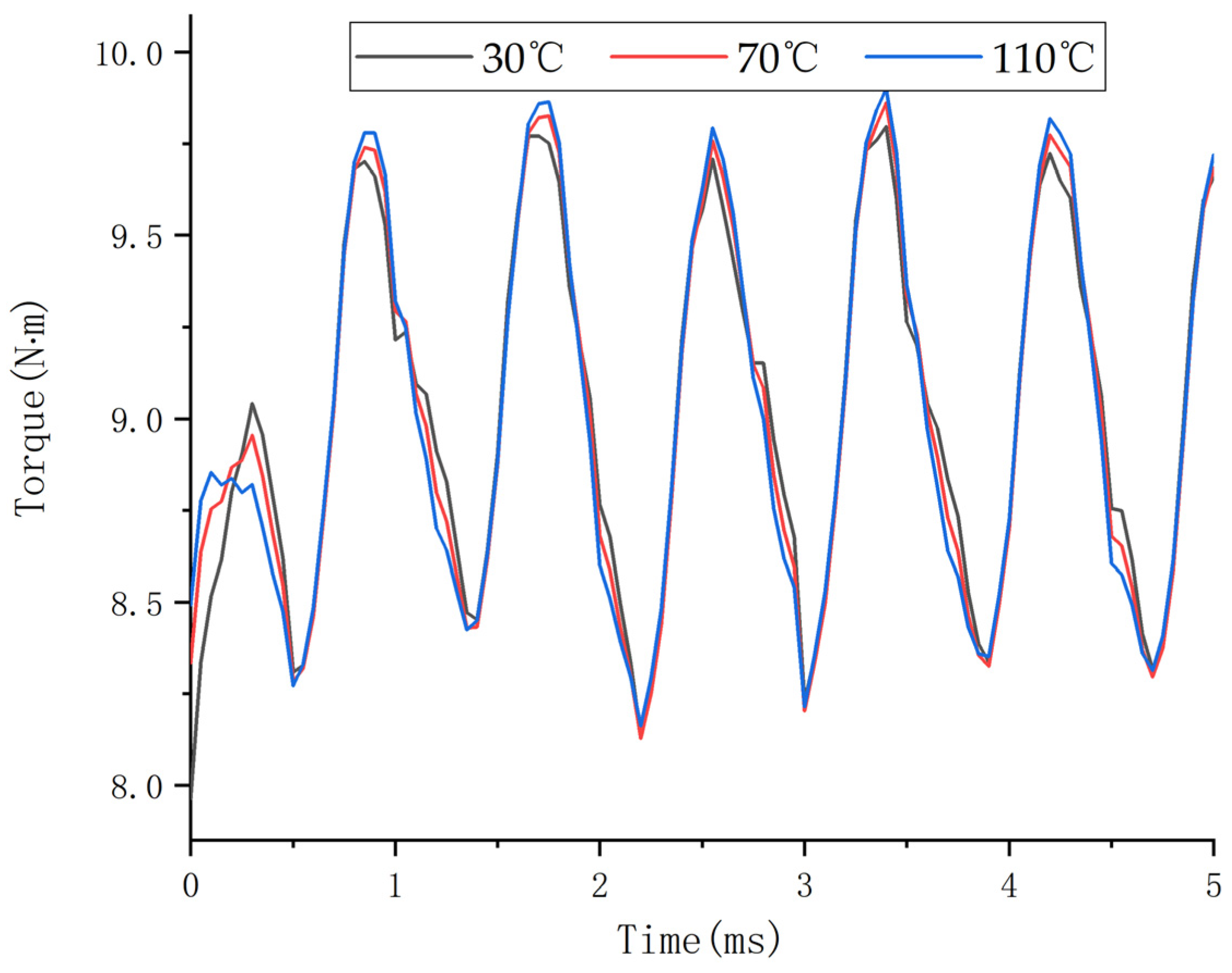

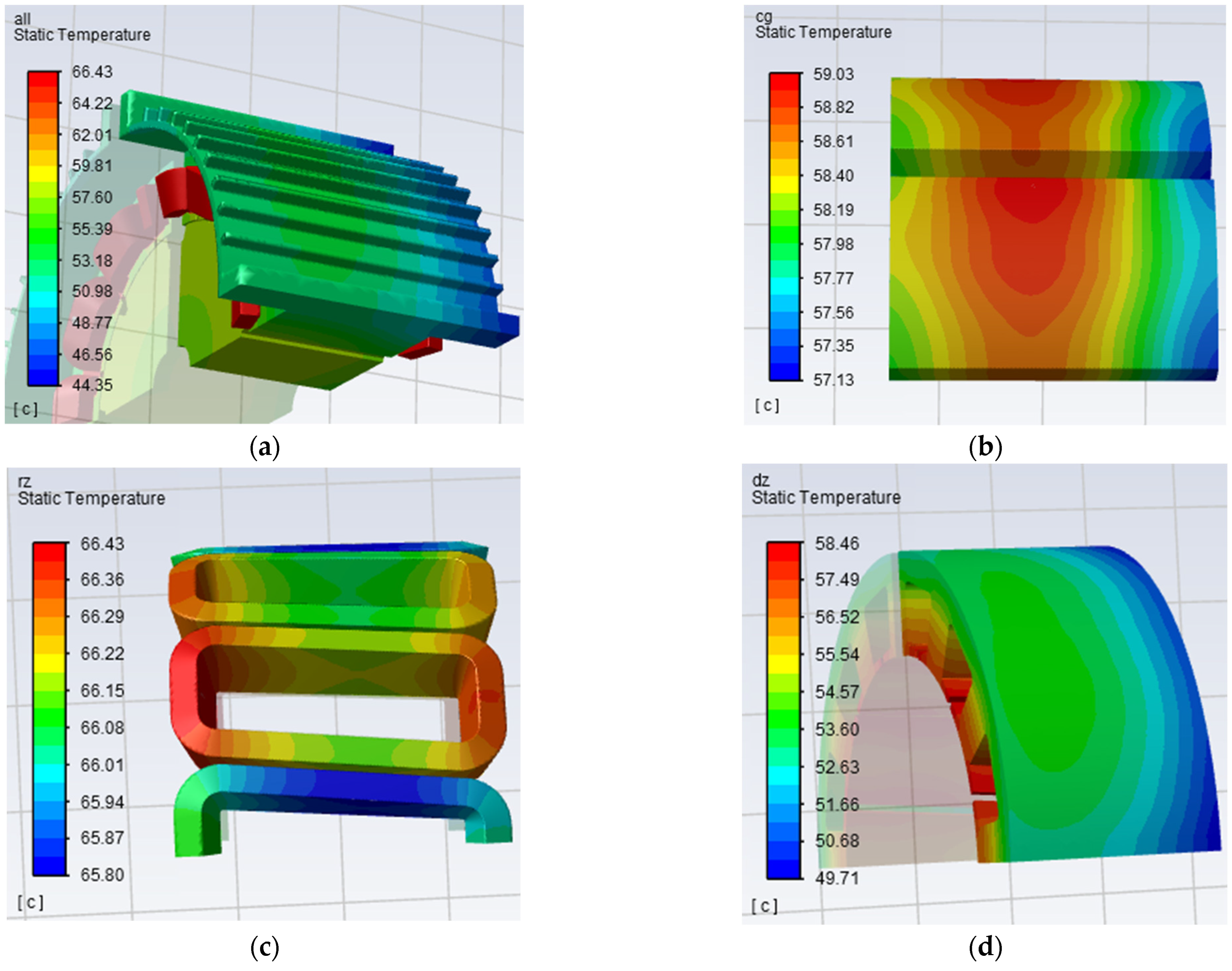

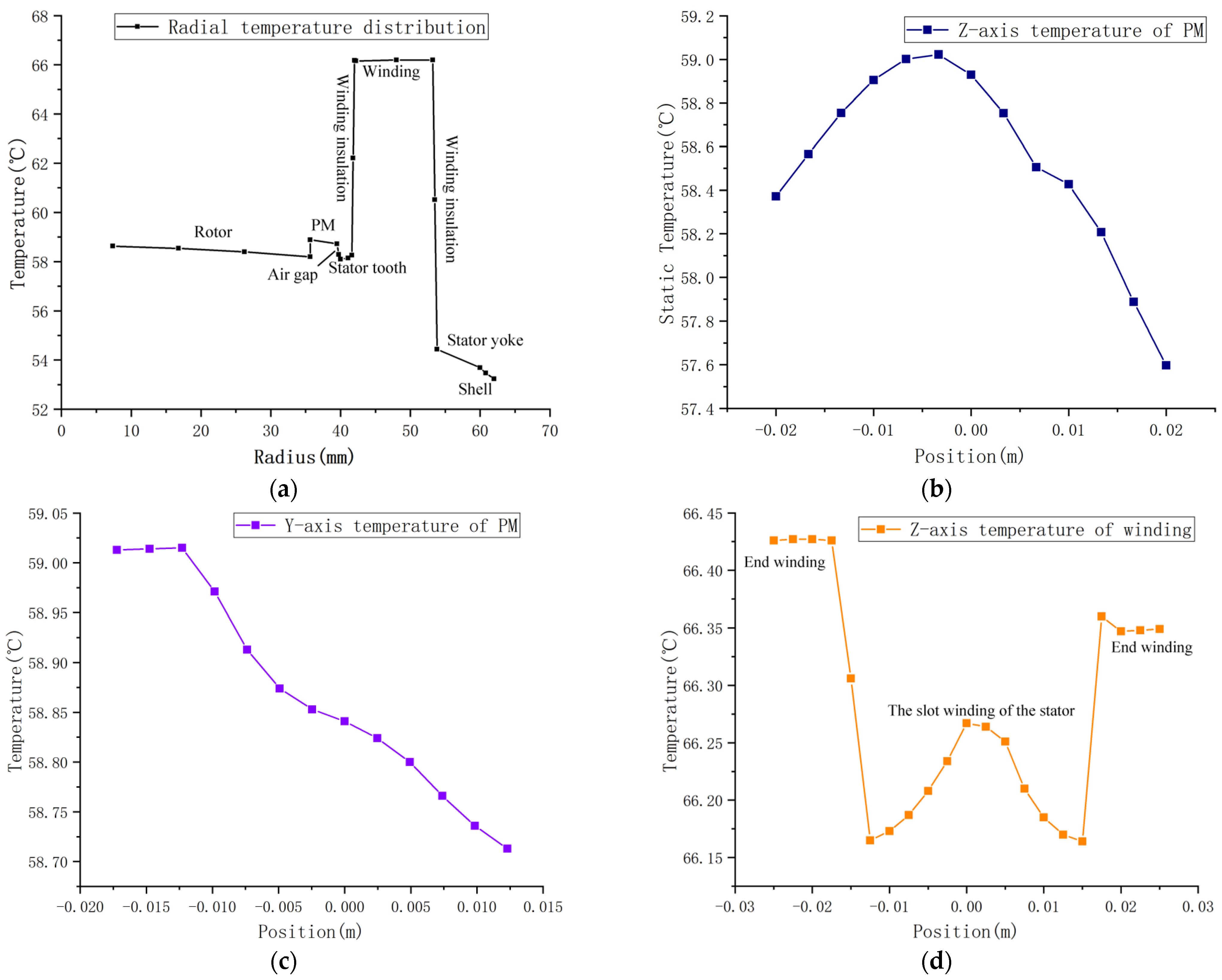

Figure 8 depicts the results of the EMTBC numerical calculation of the PMSM used to determine the temperature distribution field inside the motor.

To derive the specific temperature distribution rule within the motor, the temperatures of various components in

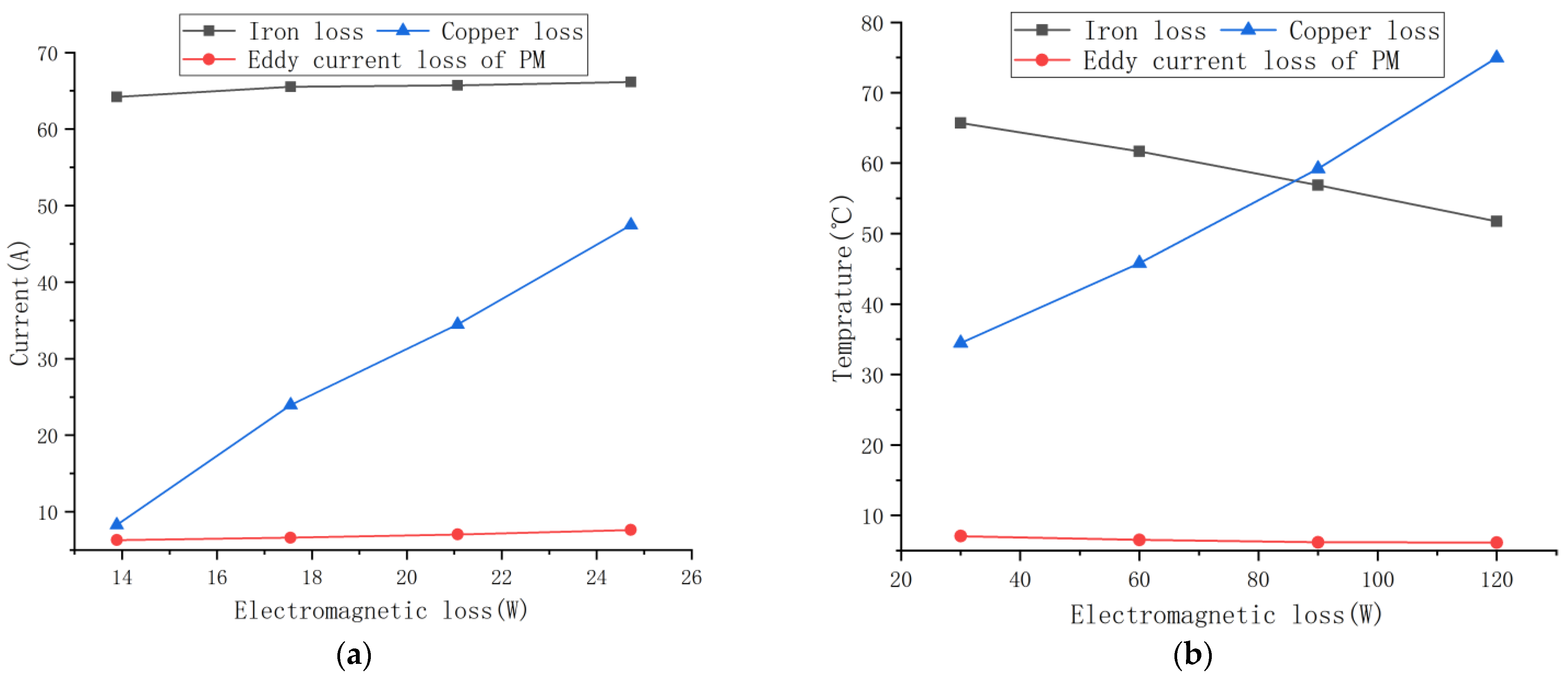

Figure 8 were extracted, and the temperature gradients of the various components within the motor are depicted in

Figure 9a. Because the high temperature of the permanent magnet (PM) causes demagnetization and the high insulation temperature of the winding causes a short-circuit defect, the temperature rise distribution of the PM and winding should be analyzed within a suitable range, as depicted in

Figure 9b–d.

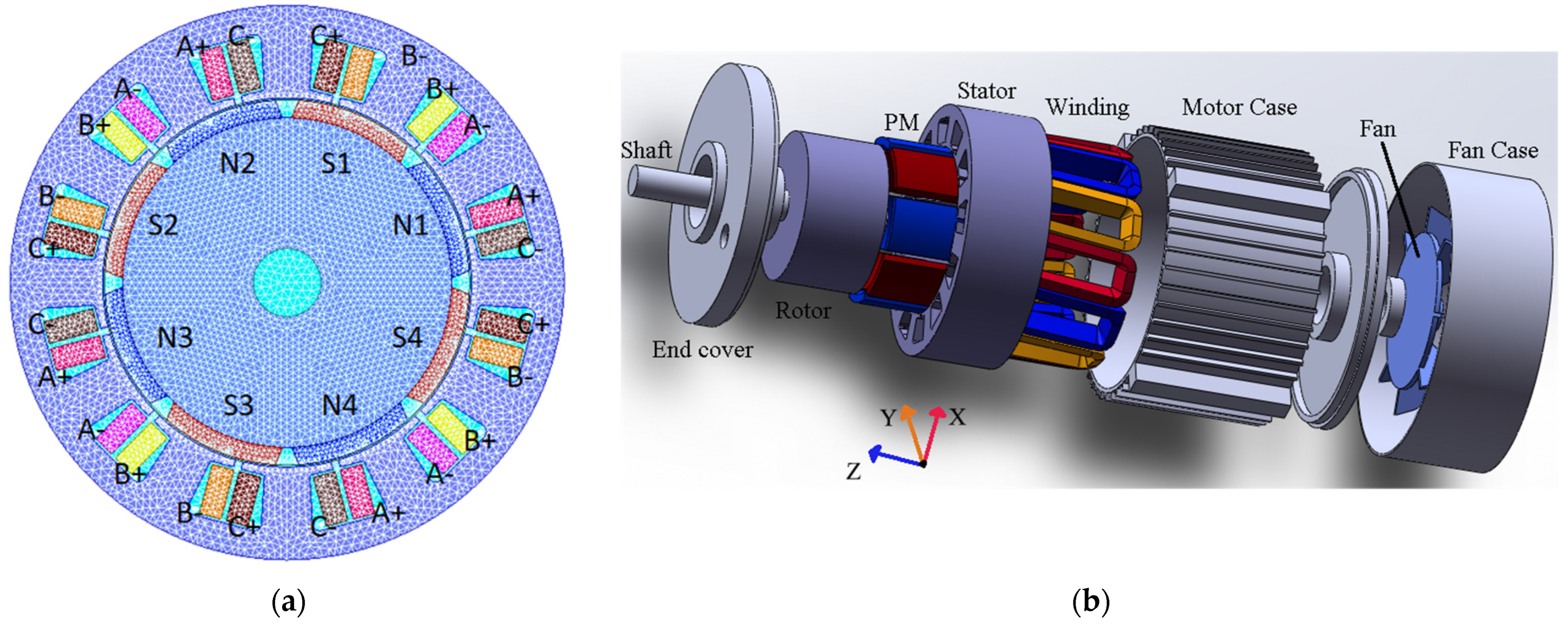

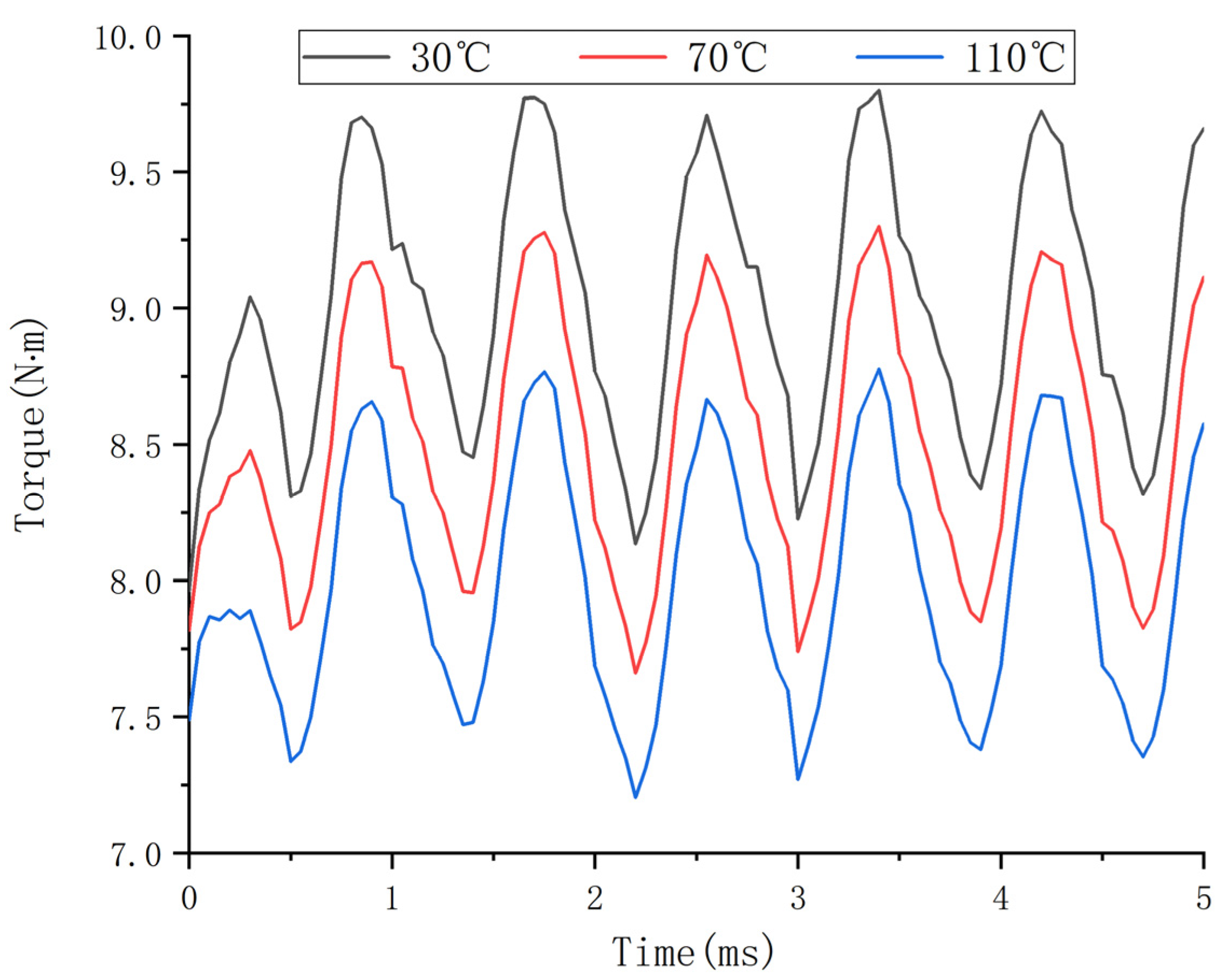

Figure 9a depicts the temperature gradient changes of the various motor components (where the orientation of the specific coordinate system is shown in

Figure 2b). It indicates that the winding temperature is the highest, and the motor case temperature is the lowest. There are two protrusions: the temperature distribution of the PM and the temperature distribution of the winding. Since both the PM and the winding are heat sources, their temperatures are slightly higher than those of the surrounding contact portions.

Figure 9b depicts the PM’s axial temperature distribution diagram. The PM temperature rise is higher in the middle and lower at both extremities, with the temperature on the right being lower than the temperature on the left. The following are the factors for this change:

The temperature near the middle border of the PM is the highest. The highest temperature of the PM is located in the axial middle of the PM and marginally near the edge of the middle of the two PMs, whereas the lowest temperature is located near the fan’s axial end.

Figure 9d depicts the distribution of the winding’s axial temperature rise. Due to inadequate heat dissipation at the end of the winding, the temperature is the highest at both ends of the winding, and the temperature is the lowest near the fan and connected to the end of the winding.

3.4.2. Establishment of Prediction of Regression Temperature Field Model

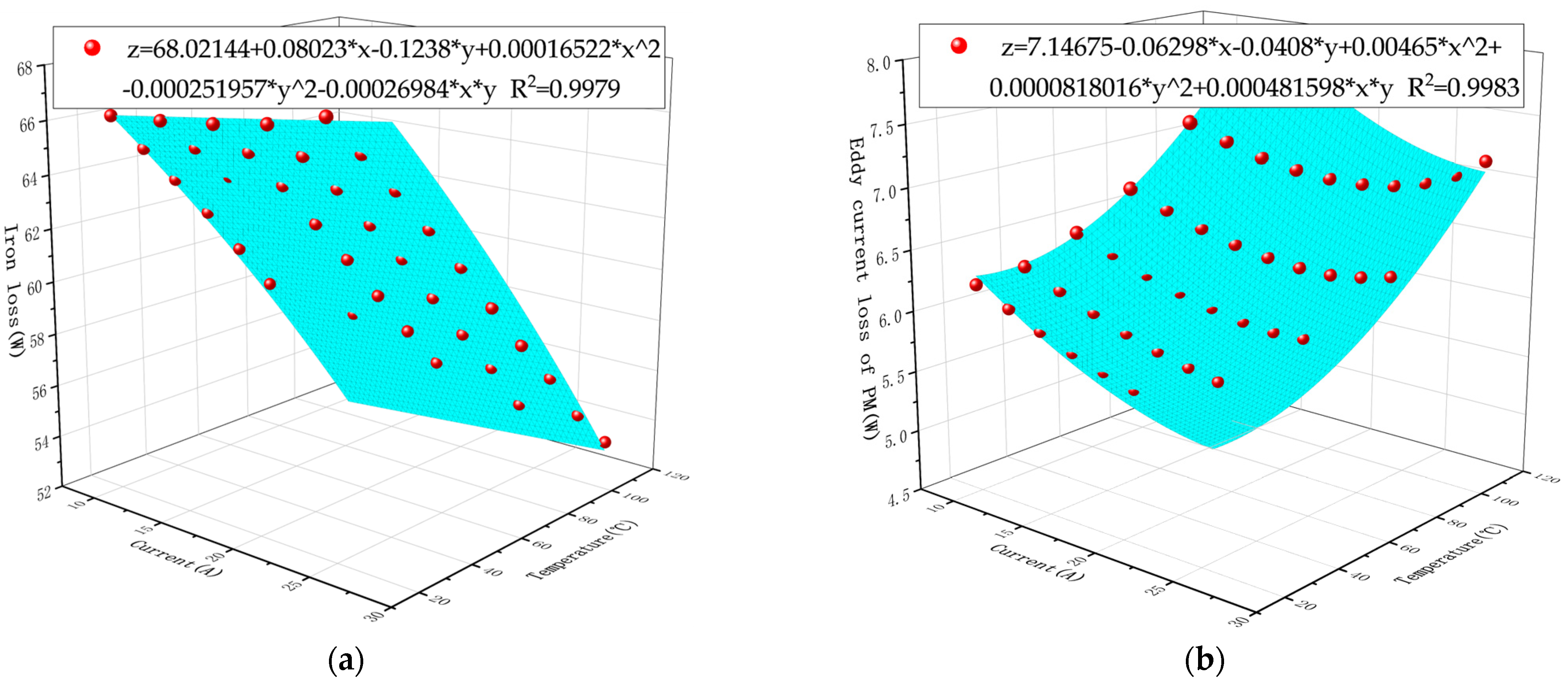

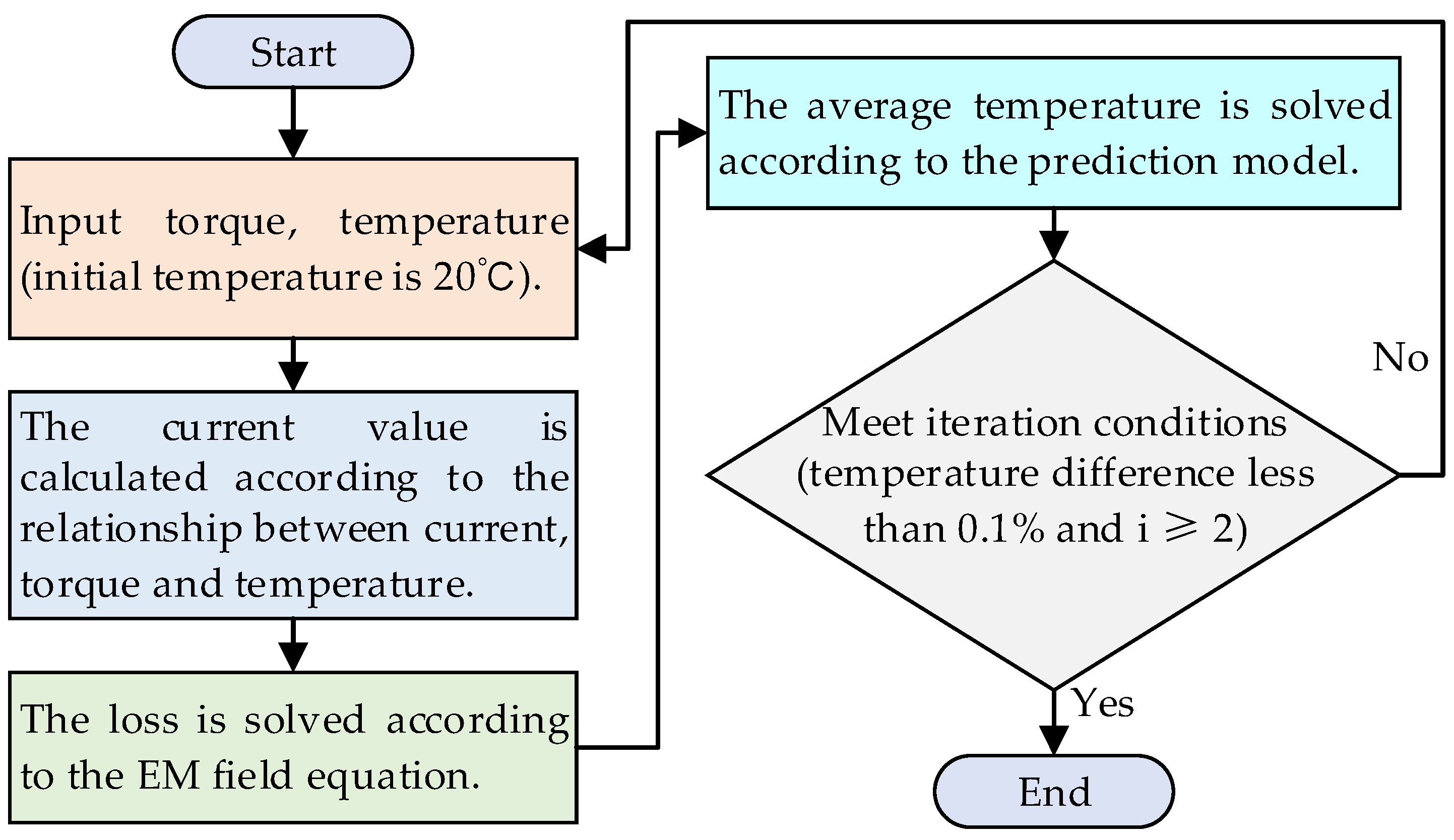

In the process of solving the internal temperature field of the PMSM using FEA, on the one hand, a large number of grids are required to simulate the real heat transfer process inside the PMSM; on the other hand, to account for the influence of temperature on the properties of EM materials, the temperature field and the EM field must constantly reverse iterate in order to achieve a certain level of calculation accuracy. Therefore, the traditional EMTBC method for solving temperature fields requires a great deal of calculation effort. To address this issue, we use the EM field loss data as the input to the temperature field and the highest and lowest winding and PM temperatures as the output. By constructing a high-precision proxy model to fit the mapping relationship between the input and output, it is possible to obtain a high-precision regression prediction model without an excessive amount of data samples, which significantly improves the computational efficiency of the temperature field.

To establish a high-precision regression prediction model, the sample point selection must satisfy the following criteria:

The iron loss, eddy current loss of the PM loss, and copper loss input data have a certain correlation and cannot be combined at random.

The PMSM load torque and operating temperature are two factors that influence the EM loss; consequently, the operating point should be evenly selected within the torque and temperature range of the motor.

Since the solution of the temperature field is time-consuming, a regression prediction model with a higher accuracy should be obtained with fewer sample points than those of a traditional FEM.

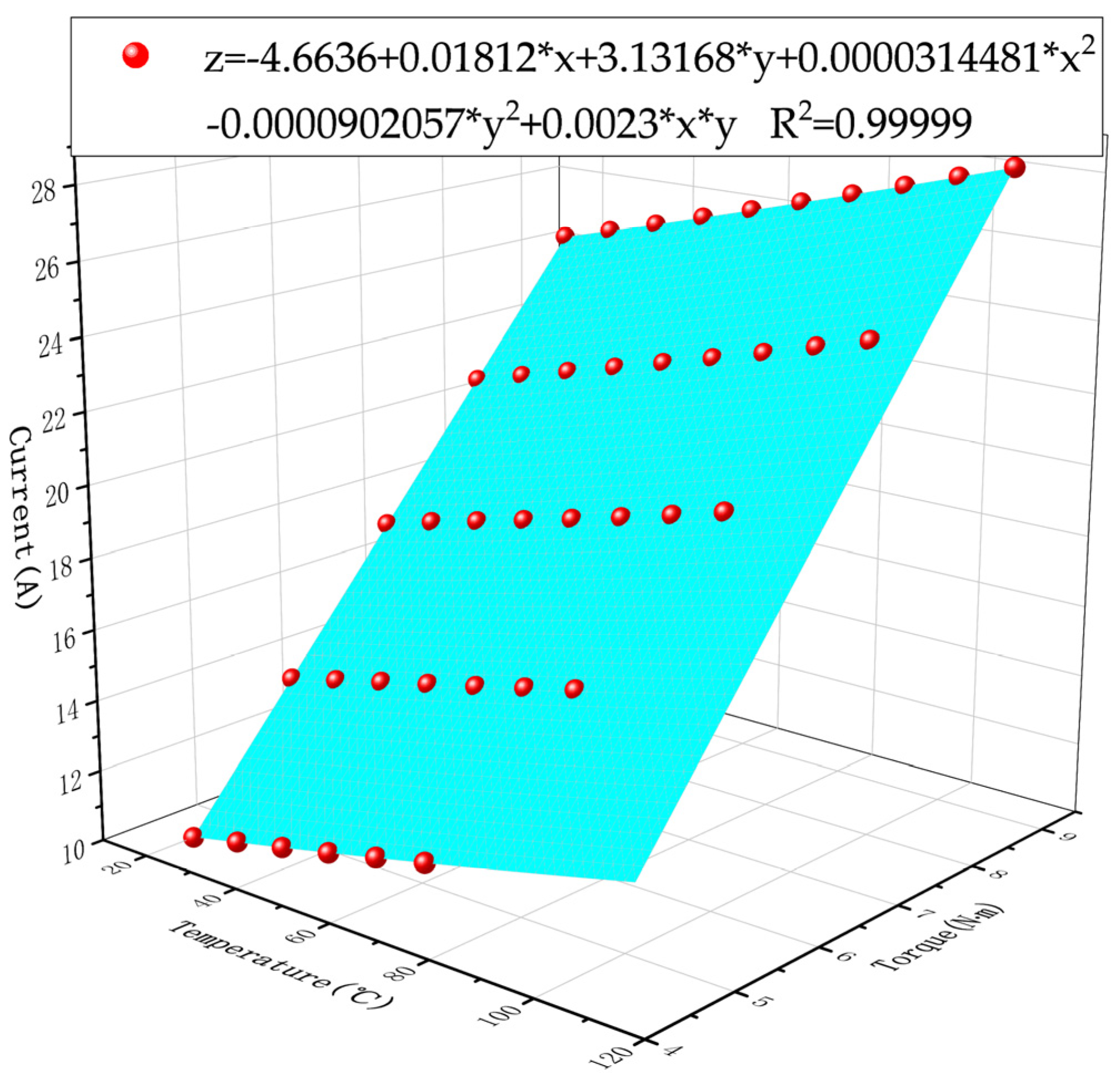

In conclusion, based on the numerical calculation data of the EM field in

Table 5, we selected 20 °C, 40 °C, 60 °C, 70 °C, 80 °C, 90 °C, 100 °C, and 110 °C and the rated EM torque, 1.25 times EM torque, 1.5 times EM torque, 1.75 times EM torque, and 2 times EM torque, and we conducted a numerical calculation of the temperature field at a total of 24 operating points.

This paper compares five common regression prediction models, which are as follows: (1) BP (Back Propagation), (2) SVR (support vector regression), (3) CNN (Convolutional Neural Network), (4) RF (Random Forest), and (5) LSTM (Long Short-Term Memory). First, the five regression prediction algorithms were used to build a proxy model for the input variable (loss) and the output target (temperature). Then, the accuracy of the proxy model was compared by calculating the evaluation index of the regression model. Finally, the one with the best evaluation index was selected as the regression prediction model in this paper. Commonly used regression model evaluation indexes include R

2 (the coefficient of determination), among which R

2 is the evaluation index that can best reflect the degree of fitting, and the closer the coefficient is to 1, the better the fitting degree. The calculation of this regression evaluation index can be expressed as follows [

23]:

where

n is the number of samples of the test set,

yi is the actual value of the test set sample,

ŷi is the predicted value of the test set sample, and

ӯ is the average value of the actual value of the test set sample. The specific evaluation indicators of each regression model after training are shown in

Table 7.

In

Table 6, it can be seen that both the BP neural network and LSTM models have a high level of prediction accuracy for the four output targets, but the BP neural network is superior. For each of the four output targets, the model developed by RF has a weak predictive accuracy. For all four output targets, the SVR- and CNN-constructed models provide more precise predictions. In conclusion, we propose the use of a BP neural network to build a regression prediction model.

Since the initial weight and threshold of a BP neural network are arbitrary, the network’s output is unstable [

24]. If the initial weight and threshold are inadequate, the network will reach a local optimal state, resulting in a subpar prediction effect. To enhance the stability of the BP neural network’s prediction effect, we use a genetic algorithm to determine the optimal weight and threshold.

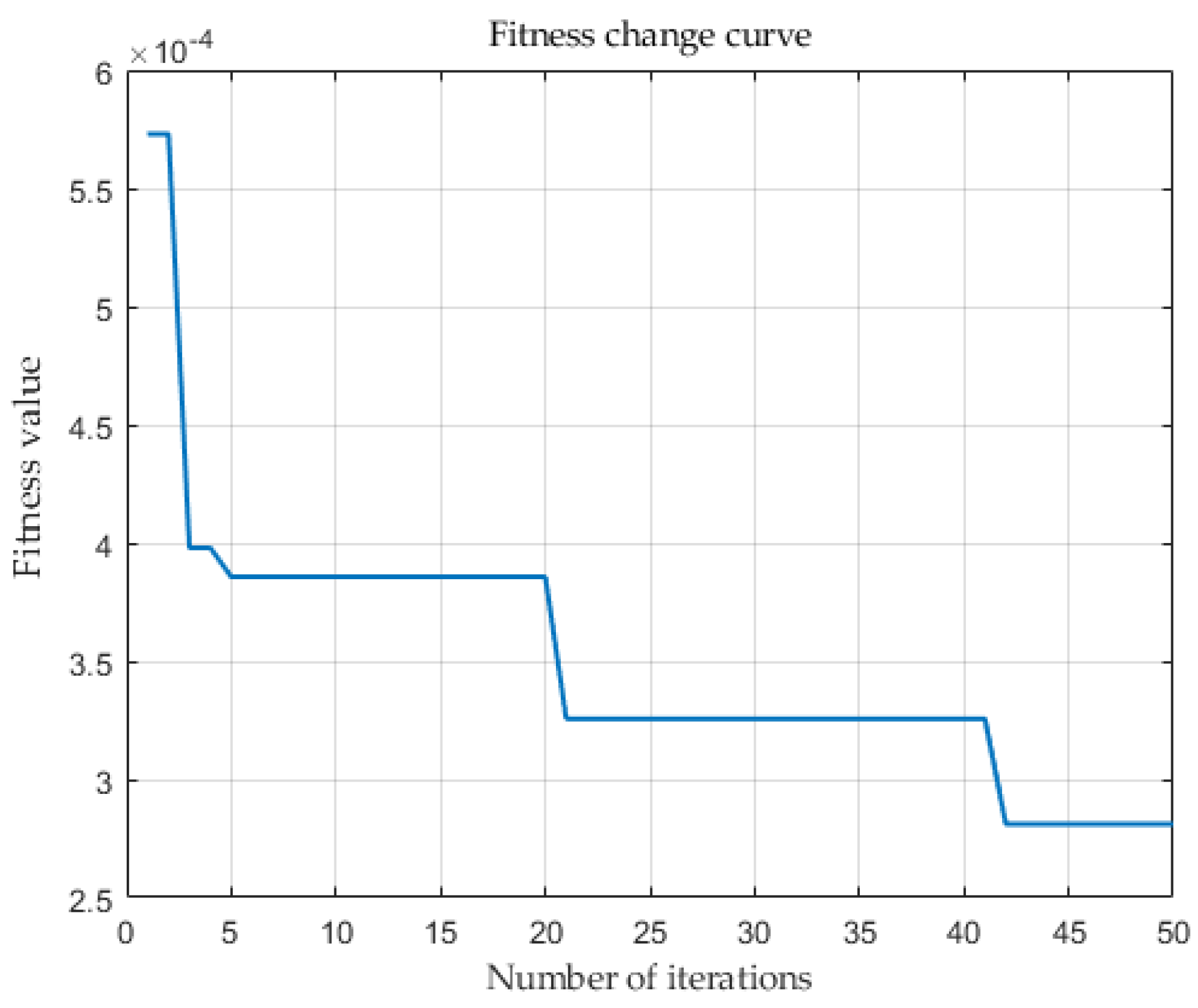

Figure 10 depicts the iterative convergence process, while

Table 6 depicts the final model effect.

Table 8 demonstrates that the genetic algorithm is used to determine the optimal weight and bias for BP, and that the enhanced GA-BP algorithm is more accurate and stable. Therefore, we propose the GA-BP model as the temperature field regression prediction model.