1. Introduction

An integrated electromechanical actuator mainly comprises a motor, a reducer, a driver, a controller, and a position sensor. Actuators are mainly used in aviation, aerospace, robotics, guided weapons, medical devices, precision instruments, and other fields [

1,

2,

3,

4,

5]. Reducers used in EMAs mainly include the parallel shaft gear reducer, planetary gear reducer, harmonic reducer, and rotary vector reducer. Harmonic reducers are commonly employed for actuators with high reduction ratios and medium power. The main factors that affect the transmission accuracy of harmonic reducers are clearance, friction, and stiffness. Spong et al. [

6] proposed a dynamic modeling method for flexible joints. Based on the friction characteristics of harmonic reducers, Gandhi [

7] associated friction with speed and position in the transmission system and used friction identification and nonlinear compensation methods to improve transmission accuracy. Taghirad et al. [

8] established a dynamic model of a harmonic reducer, modeled friction losses at high and low speeds, and studied the characteristics of the model through simulation analysis. In the literature [

9,

10,

11,

12], the influence of temperature and load on friction has been deeply studied. Maré J. C. [

9] proposed a generic framework for introducing load and temperature effects in the system-level friction model. Studies [

10,

11,

12] have analyzed the effects of temperature and load on the friction torque of the harmonic reducer.

High-performance permanent magnet synchronous motors (PMSMs) are used in EMAs. Commonly employed in the control process of PMSM are PID control and state feedback control methods. However, PID control has the drawbacks of slow response speed and weak disturbance rejection. Advanced intelligent algorithms have been incorporated into PID controllers to improve PID control effects, such as genetic algorithm PID, self-tuning PID, artificial intelligence algorithm, and neural network PID [

13,

14,

15,

16]. Intelligent control algorithms have complex algorithms, high computational complexity, and pose challenges in engineering applications. Active disturbance rejection control (ADRC) operates independently of precise mathematical modeling of the controlled object. Contrary to traditional methods, it accounts for uncertain and complex factors, including unmodeled system components, external disturbances, nonlinear factors, and time-varying elements, by classifying these as the “total disturbance” of the system. ADRC utilizes a constructed extended state observer to estimate this “total disturbance” online and employs a control law for compensation [

17]. Applications of ADRC in motor control have shown varying degrees of improvement in motor control efficacy [

18,

19,

20]. Jin et al. [

21] implemented a novel type of linear ADRC, replacing the PID controller, to effectively control a hydraulic cylinder servo system, acknowledging the characteristics of high-order coupling in the electrohydraulic system. Hu et al. [

22] established an ADRC control method based on LuGre friction compensation to study the effect of nonlinear friction on the transmission accuracy of the photoelectric stabilization platform. Sira-Ramírez et al. [

23] employed ADRC based on high gain generalized proportional integral observers for PMSM large disturbance trajectory tracking systems. Li et al. [

24] used second-order ADRC to improve the disturbance rejection and transmission accuracy in the PMSM position control process. Research has been conducted on built-in PMSM control by using ADRC for position sensorless control [

25].

To mitigate the impact of nonlinear friction on the precision of EMA transmission, this study proposes an improved ADRC method based on the magnetic field-oriented control (FOC) method. The EMA friction model was added to the IADRC through feedforward compensation to improve the transmission accuracy. First, a mathematical model of the PMSM is presented. Based on this model, combined with the ADRC control principle, an EMA speed loop/position loop composite second-order ADRC is constructed. In the nonlinear error feedback link, a fuzzy control algorithm is incorporated to achieve the adaptive functionality of the EMA control algorithm. The relationship between the no-load friction torque and torque current is derived based on the transmission model of a harmonic reducer. The friction model was established through experimental methods and added to the ADRC control model through feedforward compensation. Based on the above research, an EMA drive control system was developed using STM32F4 as the main control chip, and the aforementioned control strategies were experimentally verified. The experimental results were evaluated and analyzed using the integral of time absolute error (ITAE) and the root mean square error (RMSE).

2. Mathematical Model of the PMSM Established Using the FOC Method

The PMSM is frequently utilized as a torque source in high-performance EMA applications. The PMSM mathematical model mainly includes the voltage equation, magnetic linkage equation, torque equation, and mechanical equation. To simplify the analysis without affecting the control, the winding current is assumed to be a symmetrical three-phase sinusoidal current, motor core saturation is ignored, and the eddy current and hysteresis losses of the motor are not considered. The PMSM adopts the FOC method, which offers the advantages of fast dynamic response, smooth torque, and stable low-speed control. By using FOC, the voltage equation in the d-q coordinate system is

The d-q axis magnetic linkage equation is

The electromagnetic torque equation is

The second Newton law applied to the motor rotor is

In Equations (1)–(4),

Rs is the phase resistance,

id and

iq are the d-axis and q-axis currents,

ud and

uq are the d-axis and q-axis voltages,

Ld and

Lq are the d-axis and q-axis inductances,

ψd and

ψq are, respectively, the d-axis and q-axis magnetic linkages,

pn is the number of pole pairs,

Te is the electromagnetic torque, J is the rotational inertia,

TL is the load torque, B is the damping coefficient,

ψf is the permanent magnet magnetic flux,

ω is to the electrical angular velocity, and

ωr is the mechanical angular velocity.

For surface-mounted PMSM,

Ld =

Lq. When

id = 0 or

Ld =

Lq, Equation (3) can be simplified as

3. Transmission Model of the Harmonic Reducer

The harmonic reducer comprises a circular spine, a flexspline, and a wave generator, as shown in

Figure 1. In the EMA, the circular spine is fixed and connects the rotor to the wave generator, whereas the flexspline is connected to the load end. During EMA operation, the wave generator acts as an active component; when the wave generator rotates, the flexspline generates controllable elastic deformation to transmit power. Approximately 30% of the teeth of the flexspline’s outer ring and the circular spline’s inner ring are in mesh, providing benefits such as a high transmission ratio and substantial load-bearing capacity.

During the operation of the harmonic reducer, friction arises between the tooth surfaces of the flexspline and the circular spine, between the balls of the flexible bearing and the inner and outer rings, and between the wave generator and the contact surface of the flexspline. When the EMA reciprocates motion, the friction torque affects the transmission accuracy of the system. Friction disturbances in harmonic reducers cannot be ignored in high-performance control processes. High-precision control situations rely on friction compensation. Considering the flexspline as a torsion spring structure; considering the friction between the wave generator, flexspline, and circular spine; and considering the friction between the flexspline and the load, we established a nonlinear friction transmission model of the harmonic reducer based on the friction links in the transmission process, as shown in

Figure 2.

In

Figure 2,

Tf1 is the friction generated by the wave generator,

Tf2 refers to the friction between the flexspline and the circular spine,

Tf3 refers to the friction generated by the flexspline,

θm and

Tm are, respectively, the rotor position and torque,

θng and

Tng are, respectively, the output positions and moments of the wave generator,

θnin and

Tnin are, respectively, the input angle and input torque of the flexspline torsion spring model,

θnout and

Tnout are, respectively, the displacement and output torque of the flexspline, Tk and Ts are, respectively, the torsion spring force and damping force of the flexspline torsion spring model,

TL is the output torque of the flexspline, and

θL is the position of the flexspline.

The equilibrium equation of angular displacement and frictional torque between the wave generator and the flexspline is

The equilibrium equation for the angular displacement and friction moment between the flexspline and the circular spine is

The friction torque

Tf acting on the harmonic reducer is

Tf =

Tf1 +

Tf2 +

Tf3. The friction torque

Tf3 acting on the load end under low speeds and heavy loads is much smaller than the friction torque

Tf1 acting on the motor and wave generator end under high speeds and light loads and can be ignored; that is,

Tf3 ≈ 0.

TL =

Tnout =

Tk +

Ts, and

Tnout =

f(Δθ,

KL).

f(Δθ,

KL) =

Tk +

Ts =

TL.

k is the stiffness coefficient of the harmonic drive. Thus, the relationship between the input torque, friction torque, and output torque of the harmonic reducer can be expressed as follows:

where

KL is the equivalent stiffness coefficient of the harmonic reducer, neglecting the rotational inertia of the reducer,

J is the rotational inertia of the motor rotor,

JL is the rotational inertia of the load end, and

f(Δθ,

KL) =

TL. The relationship between the motor torque

Te and the wave generator torque

Tm is

The nonlinear friction torque obtained from Equations (9) can be expressed as

Here, it is assumed that the load is purely inertial. The nonlinear friction force

Tf of the harmonic reducer can be expressed as

When unloaded and running at a constant speed, Equation (12) can be simplified as

As can be seen from Equation (13), the friction torque is related to the torque current iq. During no-load and constant speed operation, the change rule of friction torque can be obtained by measuring the torque current iq at different speeds and fitting the iq change curve.

5. EMA Control System Design

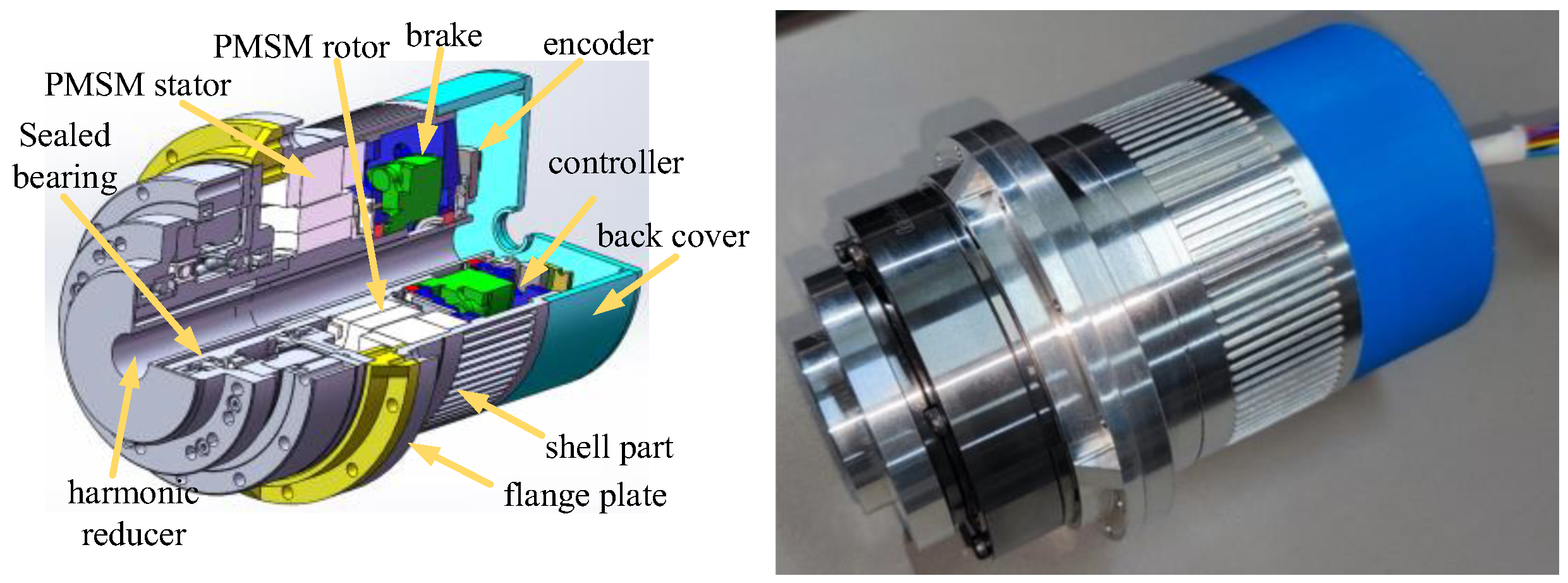

The three-dimensional cross-sectional and physical views of the EMA developed with an integrated hollow shaft harmonic reducer are depicted in

Figure 7. The incremental encoder disk is fixed on the hollow shaft of the spindle by using an adhesive that has high aging resistance, impact resistance, and shear strength. To ensure the reliability of bonding, the viscosity is 750–1750 cps, and the shear strength is greater than 19 MPa. The main parameters of the harmonic reducer in

Table 2. The main parameters of the PMSM in

Table 3.

For the proposed IADRC control algorithm, STM32F4 is used as the main control chip for verification. The controller possesses abundant built-in resources, supports floating-point operations, and encompasses various communication interfaces, including two advanced timers, TIM1 and TIM8, dedicated to motor control. Functions such as position detection, current detection, USART, CAN, and RS485 can be performed using this chip. The hardware circuit structure of the EMA is illustrated in

Figure 8.

The N-type IRFS3607 MOSFET is used as the power device in the inverter circuit, and IR2101S is used as the power driver chip. The driving circuits for the V and W phases in a three-phase system are consistent. Using the U-phase as an example, the inverter circuit is briefly explained. The U-phase drive circuit for three-phase current is illustrated in

Figure 9.

The IO ports corresponding to advanced timer 1 and advanced timer 8 in STM32F4 can output six complementary and symmetrical PWM waves. The working voltage of the IR2101S power driver chip is 12V, and IR2101S receives PWM signals from the MCU to drive IRFS3607. IRFS3607 is an N-type MOSFET.

Rotor position data constitutes crucial information in the FOC process. Current resistance sampling methods encompass single, double, and triple resistance sampling. The single resistance sampling method, while structurally simple, complicates software processing. Conversely, double resistance sampling may induce three-phase asymmetry. Triple resistance sampling requires an operational amplifier, which is costly; however, it offers the advantages of accurate sampling and relatively simple program processing. For the convenience of software processing, the triple resistance sampling method is adopted in the control system. The U, V, and W three-phase control circuits are the same. Here, the U-phase is taken as an example; the U-phase sampling circuit is shown in

Figure 10.

MCP6024 has a large magnification. According to the virtual shorting of the amplifier, there is no current flowing through both ends of the operational amplifier. The current flowing through R2 and R7 is equal, and the current flowing through R10 and R14 is equal:

Let a = R6 + R7 = R9 + R10 and b = R2 = R14, Substituting these into Equation (21), we obtain

Solving Equation (22) yields

Under virtual shorting, V+ = V−, Can be obtained

As can be seen from Equation (24), the voltage at both ends of the sampling resistor is biased by 1.65 V and amplified by 5.1 times. The sampling resistor is selected as a high-precision resistor of 10 m Ω and 2 W, with a theoretical maximum sampling current of 14.14 A. If the maximum amplitude of the sinusoidal current of the motor is 10 A, the voltage range input to the amplifier end is −0.1–0.1 V. According to Equation (24), the output voltage of the amplifier is calculated as 1.14–2.16 V, which can be directly inputted into the ADC sampling pin of the motor, providing a large safety margin.

6. Experimental Analysis

According to Equation (13), friction torque can be determined by measuring the torque current

iq at a constant speed without load. This article performed experimental analysis on frictional forces in the counter-clockwise rotation direction. The inertia of the reducer was disregarded, and it was assumed that the torque during no-load operation equals the friction torque during uniform motion. A friction model was developed by measuring torque values at various speeds and fitting the data. This model was incorporated into the control system through feedforward compensation, effectively eliminating friction disturbances. Friction torque testing was performed on the RT-Cube platform, which is capable of achieving a minimum control cycle for the motor within 100 µs. Moreover, this platform allows for the online modification of any control parameter and the online monitoring of any system variable during the control process. The tests were made at a room temperature of approximately 25 °C and a relative humidity ranging from 40% to 70%RH. The experimental platform and the test results obtained using the Gaussian fitting method are shown in

Figure 11 and

Figure 12, respectively.

According to the fitting equation, the friction force at different speeds was obtained. The friction force, corresponding to the torque current, was compensated for and attenuated by adjusting the torque current at various speeds. The IADRC controller was constructed by integrating the frictional torque current into the second-order fuzzy ADRC control model through feedforward compensation, as shown in

Figure 13.

In the EMA speed mode, the current loop of all three control methods adopts PI control mode, and the speed loop adopts PI, ADRC, and IADRC, respectively. An IADRC controller with a step speed of 6 rev/min was used. The control parameters for the three controllers were empirically set. The main parameters to be adjusted in the TD are the

r and

h1. The

r affects the tracking effect. A larger

r corresponds to a shorter transition time and thus a faster tracking response. However, very large

r leads to overshoot and oscillation. When the

r is constant and the

h1 is large, the tracking signal error is large; when the

h1 is small, the noise suppression is more prominent. However, when the

h1 is too small, the ability of the TD to suppress noise will be weakened. The disturbance compensation factor

b0 mainly affects the disturbance compensation capacity. If the system disturbance is significant,

b0 should be slightly larger; if the system disturbance is small,

b0 should be marginally lower. Directional adjustment is adopted. When we set α

01 = α

02 = 1,

fal(e,α,δ) can be linearized to

fal(e,α,δ) = e. The values for the parameters

β01,

β02, and

β03 need to be adjusted in practical applications according to the system output. The tuning rules for these parameters are listed in

Table 4. Notably, when one parameter is tuned, the other two remain constant.

The results obtained using PI control method and the enlarged image of the step response are shown in

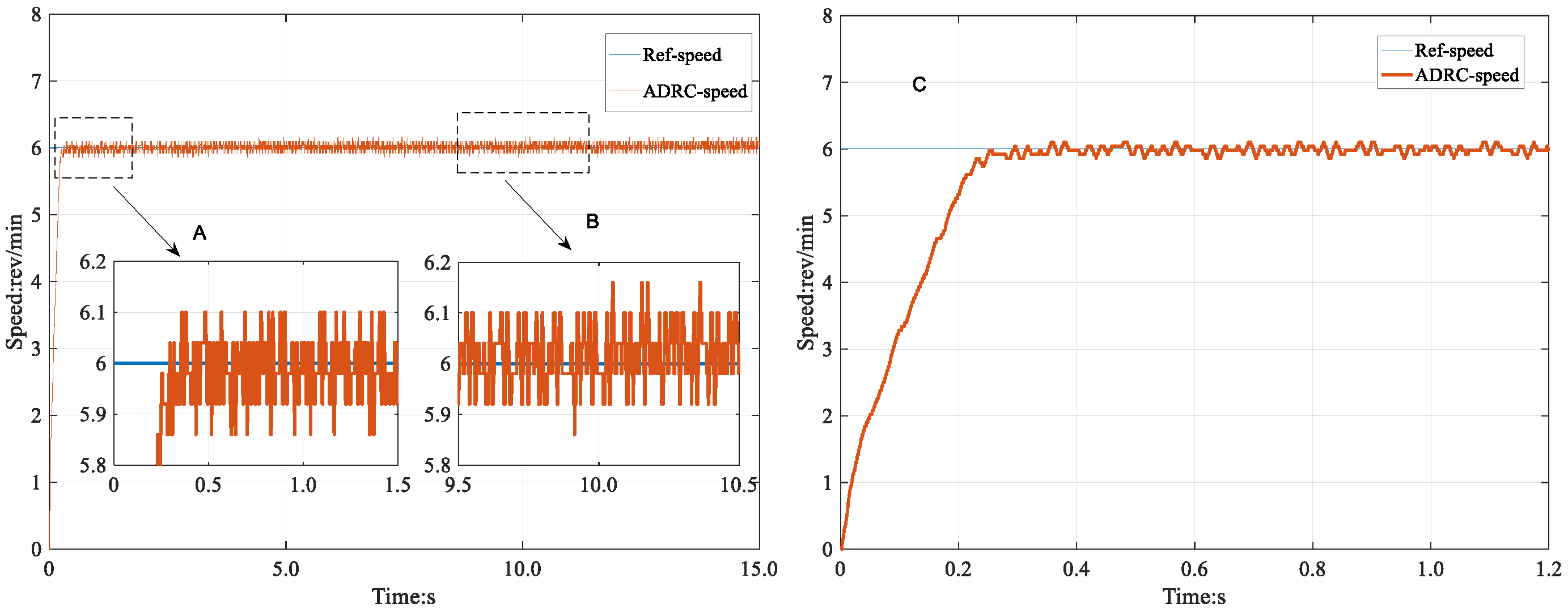

Figure 14. The results obtained using ADRC control method and the enlarged image of the step response are shown in

Figure 15. The results obtained using IADRC control method and the enlarged image of the step response are shown in

Figure 16. As can be seen in the locally enlarged image A, the PI control method, ADRC control method, and feedforward compensation fuzzy IADRC reached a steady state in 0.65, 0.25, and 0.20 s, respectively. The PI control method experienced an overshoot before reaching the steady state, with a maximum speed of 6.2 rev/min and an overshoot of 3.33%. The other two control methods quickly achieved the target speed without overshooting. The steady-state speed error of all three control methods was 0.1 rev/min. By comparing the locally enlarged image B of ADRC and IADRC, it can be concluded that the IADRC control method has a lower speed oscillation frequency in the steady state.

Common performance indicators of the control system include integrated square error (ISE), integrated time square error (ITSE), integrated absolute error (IAE), and integrated time absolute error (ITAE). Different performance indicators have different priorities.

The

ITAE criterion can better reflect the system’s response speed, oscillation characteristics, and steady-state errors, and has good selectivity for different controllers:

The

ITAE calculation results for the three control methods within 0–1s are presented in

Table 5.

The unit of ITAE is “(rev/min)*s

2”. The ITAE calculation result within 0–1 s of IADRC was 15.445 (rev/min)*s

2, thus indicating the optimal control performance of IADRC. The number of encoder lines is 2880, and after fourfold frequency, it is 11,520. The position input signal is y = 115,200*sin(0.05*pi*t), and the unit of y is the carving line number of the encoder (LNE). The main parameters in the experimental are shown in

Table 6.

In the EMA position mode, three control configurations were implemented: PID (position loop) + PI (speed loop) + PI (current loop); ADRC (position loop) + PI (current loop); and IADRC (position loop) + PI (current loop). Data were recorded after the system stabilized. The position tracking results under no-load conditions for the three control methods are illustrated in

Figure 17. The corresponding position tracking error results are presented in

Figure 18.

The RMSE and peak-to-peak calculation results of tracking error are presented in

Table 7.

As can be seen from

Figure 18 and

Table 7, the ADRC control method yielded higher accuracy than the PID control when under load. After adding friction feedforward compensation, the RMSE and peak-to-peak values of position error improved. The peak-to-peak value of IADRC was 1438 less than that of ADRC. The RMSE of IADRC reduced by approximately 160.6 compared with ADRC.

Record data after the system stabilizes. In the position-mode test under 2.5 Nm load conditions, the position tracking results for the three control methods are depicted in

Figure 19. Correspondingly, the position tracking error results for the three control methods are illustrated in

Figure 20. It is noteworthy that this load (2.5 Nm) represents 6.25% of the rated torque.

The RMSE and peak-to-peak calculation results of PID, ADRC, and friction feedforward compensation fuzzy IADRC control methods under load are presented in

Table 8.

As can be seen from

Figure 20 and

Table 8, the ADRC control method yielded higher accuracy than the PID control when under load. After the addition of friction feedforward compensation, the root mean square and peak-to-peak values of position error improved. The peak-to-peak value of IADRC was 3373 less than that of ADRC. The RMSE of IADRC was reduced by approximately 410.4 compared to ADRC.

7. Conclusions

Aiming at the problem of EMA control accuracy, this paper adopts high-performance IADRC and friction feedforward compensation methods. The PMSM mathematical model was established, and a second-order composite ADRC control strategy was developed for the PMSM speed loop and position loop based on the FOC model. The ADRC controller demonstrates several superior characteristics not present in the PI controller. To address the issue of ADRC controller parameter adaptation, fuzzy control was integrated into the nonlinear state error feedback link, facilitating self-tuning of ADRC parameters. Furthermore, a model for EMA transmission was developed, and the relationship between friction torque and torque current iq was analyzed. Furthermore, on the RT-Cube platform, the torque current iq at different speeds was measured and then added to the current loop control through feedforward compensation, determining controller parameters through empirical methodologies. In addition, speed-mode and position-mode experiments were conducted in the PI control mode, ADRC control mode, and IADRC control mode. Moreover, the experimental results of the speed step response were analyzed using the IATAE criteria. The IADRC control mode yielded the smallest calculation result and the best control performance. Neglecting the inertia of the reducer, assuming that the no-load running torque is equal to the friction torque during uniform motion, the experimental results of sinusoidal position tracking were analyzed, and the results were evaluated using RMSE and peak-to-peak values. Under conditions of pure inertial load, the integration of friction feedforward compensation combined with the implementation of the IADRC control method enhances the accuracy of EMA transmission.