Abstract

In this paper, a novel asymmetrical bistable short mover permanent magnet actuator is presented. The comparisons between the presented machine and the asymmetrical structure bistable permanent magnet actuator are introduced. The static and dynamic characteristics of the high-voltage circuit breaker with the presented machine are calculated and discussed. The influences of the length of the mover and the initial mover position in the presented machine are studied and researched. The merits of the presented machine, such as less permanent magnet volume, low cost, small mover mass, and high starting speed, are researched and discussed. The Genetic Algorithm is used to optimize the presented machine. Finally, a conventional permanent magnet actuator prototype is created and tested on account of the limited experimental conditions. The characteristic curves of position versus retaining force are acquired to confirm the proposed design.

1. Introduction

A number of studies have shown that the troubles in high-voltage circuit breaker (HVCB) are largely caused by the fault of the operating mechanism [1]. The operating mechanism with the permanent magnet actuator (PMA) is widely adapted in a vacuum circuit breaker. Hence, the reliability and security of the PMA is highly affecting the reliability and security of the HVCB. The PMA has many virtues, such as small volume, low maintenance cost, simple construction, and long life-cycle, which prompted many interests in engineers and researchers [2]. The permanent magnet actuator can be classified as monostable permanent magnet actuator, bistable permanent magnet actuator and multi-magnetic circuit permanent magnet actuator [3].

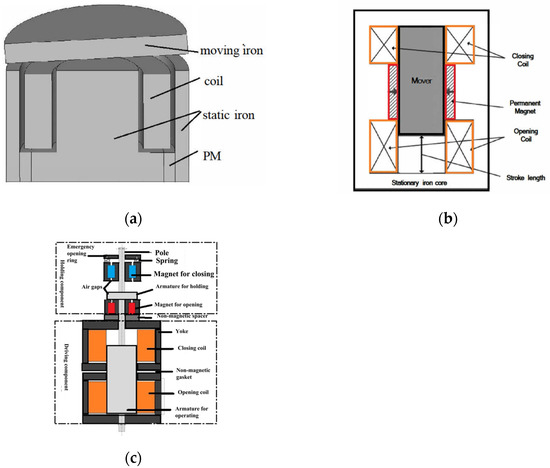

The monostable permanent magnet actuator only has a closing coil, and has holding force in closing state, as shown in Figure 1a. Thus, the opening force depends on the external agency. The bistable permanent magnet actuator owns holding forces in closing and opening states, as shown in Figure 1b. However, the holding force in two states is same. The multi-magnetic circuit permanent magnet actuator has different magnetic circuit for holding force magnetic circuit and electromagnetic force magnetic circuit, as shown in Figure 1c.

Figure 1.

The structure of permanent magnet actuator. (a) Monostable permanent magnet actuator. (b) Bistable permanent magnet actuator. (c) Multi-magnetic circuit permanent magnet actuator.

First, two types have a lot of good points, such as the simple structure, high dependability and steerability, long life-cycle, and low maintenance cost [4,5,6,7,8,9,10,11]. For example, in [12,13], the authors were presented the E-core and C-core monostable permanent magnet actuator. However, these structures of the monostable permanent magnet actuator also have some disadvantages, such as big retention in the close state and large opening current. On other hand, in [14], the topology of symmetrical bistable permanent magnet actuator is presented to solve the problem of big retention in the close state and to improve the efficiency. However, the starting time and wastage will increase for the symmetrical structure bistable permanent magnet actuator, which is caused by the large retention forces in the opening stage [15,16,17,18,19,20,21,22,23,24,25,26]. Thus, the asymmetrical structure bistable permanent magnet actuator (ASBPMA) is presented in [27,28,29,30,31,32] to improve HVBC with symmetrical bistable permanent magnet actuator. However, the ASBPMA is not faultless, e.g., lower starting speed.

Thus, the multi-magnetic circuit permanent magnet actuator is proposed to improve starting speed, which commonly combines with two structures, such as monostable permanent magnet actuator, bistable permanent magnet actuator, and Thomson coil actuator [33,34,35,36,37,38,39]. The multi-magnetic circuit permanent magnet actuator currently inherits the merits of two structures. However, the disadvantages of two structures are also present. An asymmetrical bistable multimagnetic circuit permanent magnet actuator was present in [40]. This permanent magnet actuator improves its preferment by using novel magnetic circuit technology. In [41], bionic soft multimodal actuators were presented to solve the challenging problem of triggering strong and fast actuating performances with an extremely weak magnetic field. This soft actuator was not researched in high-voltage circuit breaker application.

In this paper, a novel asymmetrical bistable short mover permanent magnet actuator (ABSMPMA) is proposed, which has little mover mass, higher starting speed, less permanent magnet, and low cost. The successful numerical finite element analysis methods (FEAM), such as Maxwell Circuit Editor and Ansoft Maxwell, are used to gain more accurate and correct results of the ABSMPMA. In this study, two-dimensional finite element analysis (2-DFEA) was used to confirm the validity and correctness of the calculated characteristics. A conventional permanent magnet actuator prototype was made and tested to confirm the proposed permanent magnet actuator. To certify the contribution and credibility in this paper, the closing and opening dynamic characteristics of the prototype are tested in this paper.

The structures of this paper are as follows. Section 2 describes the novel structure of ABSMPMA, and Section 3 analyzes the working principle of ABSMPMA. Section 4 addresses the dynamic and static preferment, and the Section 5 optimize the ABSMPMA using Genetic Algorithm (GA). Section 6 contrasts the experimental results and simulation results. Finally, Section 7 outlines and discusses this paper.

2. Novel Structure of ABSMPMA

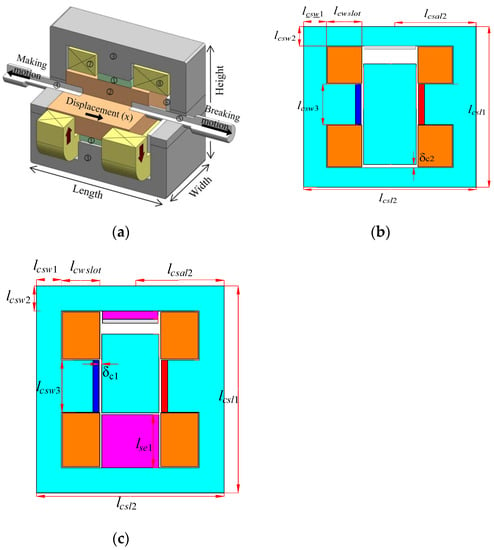

The conventional asymmetrical structure bistable permanent magnet actuator and ABSMPMA are shown in Figure 2. From Figure 2, it is evident that the ASBPMA and the proposed machine have two pieces PM in the middle of the stator. The red part and the blue part are permanent magnet in Figure 2b,c. The purple parts are the differences between ASBPMA and ABSMPMA, which have the same material with the stator. In the closing state, the field of the ASBPMA enters the mover along radial vertical direction from the middle of the stator and then moves back to the end of the stator along the axial axis of the mover, which is same with ABSMPMA. However, the different between ABSMPMA and ASBPMA are the length of the mover, and that the ABSMPMA has the stator embossing. The mover length of the ABSMPMA is shorter than the tooth width plus the stroke. Under the circumstances, the mover mass of the novel machine is lesser than the ASBPMA, which will increase the speed of the ABSMPMA.

Figure 2.

The structures of the asymmetrical bistable permanent magnet actuator. (a) Three-dimensional drawing of the ASBPMA [19]. (b) Two-dimensional drawing of the ASBPMA. (c) Two-dimensional drawing of the ABSMPMA. [Note: the purple parts are the differences between ASBPMA and ABSMPMA].

The novel ABSMPMA offers many merits, such as low mover mass, high starting speed, less permanent magnet, improving dynamic performance, and low cost. The reasons for its merits are shown in the following.

3. Working Principle of ABSMPMA

For convenient to analyze, the following hypotheses are accepted:

- The leakage flux of the end is negligible;

- The magnetic circuit in the stator and mover are not saturated.

Assuming the flux density in work air gap is , effective area in the end of the mover is , the force of the ABSMPMA and ASBPMA can be expressed as [42]

where is the space permeability; is the magnetic flux in work air gap; is the force of the conventional ASBPMA and ABSMPMA. The main magnetic circuits of the PMA are shown in Figure 3. The field in the gap of the opening state position is negligible when the mover starts in closing state position.

Figure 3.

The main magnetic circuit. (a) The ASBPMA [19]. (b). The ABSMPMA.

The magnetic resistance can be expressed as Equation (2) [43]

where is the permeability; is the length of magnetic path; and is the effective area in the magnetic path.

The total magnetic resistance of the ASBPMA in the main magnetic circuit can be expressed as Equation (3).

where .

In the work gap, the magnetic flow of ASBPMA can be expressed as Equation (4) [44].

where .

In another situation, the mover covers the tooth in the closing state, as shown in Figure 3b. The magnetic flow of the ABSMPMA in gap can be expressed as Equation (5).

where .

The iron magnetic permeability is far higher than air magnetic permeability for reasonable machine design. In this case, the magnetic resistance is bigger than the other magnetic resistance according to Equations (2) and (3). Therefore, , and then . Hence, in the closing state, the retaining force of the ASBPMA is smaller than the ABSMPMA with the same sizes. In other words, the permanent magnet volume of the ASBPMA needs more than that of the ABSMPMA with the same closing retaining force. Then, the cost of the ABSMPMA is lower than that of the ASBPMA.

The speed of the HVCB with the PMA can be expressed as Equation (6).

where is the force of HVCB; is the motion part mass of the HVCB.

From Equation (6), it is obvious that the speed of the HVCB with ABSMPMA is faster than the HVCB with ASBPMA, when the electromagnetic forces are same due to the mover mass of the ASBPMA larger than the ABSMPMA.

4. Numerical Analysis and Simulation Results

The characteristics of the HVCB with the presented ABSMPMA are analyzed and estimated using Ansoft Maxwell. In other words, all simulation results in this paper are derived using the Ansoft Maxwell. In this paper, the voltage level of circuit breaker is 40.5 kV. The specification of the 40.5 kV vacuum circuit breaker is given in the Table 1 [19,40]. The parameters of the ASBPMA and ABSMPMA are shown in Table 2. Initial mover position is defined as the length that the radial central axis of the mover diverges the radial central axis of the PM. is the positive value near the opening state position.

Table 1.

Specification of 40.5 kv vacuum circuit breaker.

Table 2.

Parameters of machine.

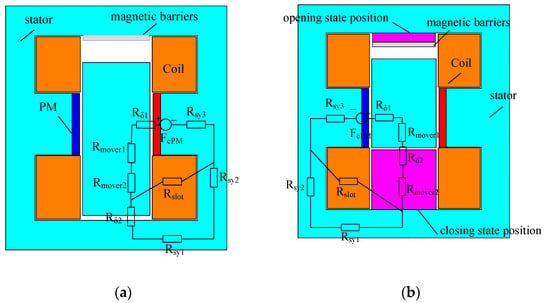

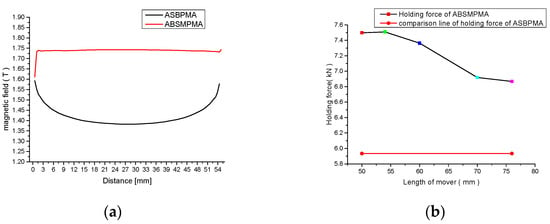

4.1. The Static Characteristics

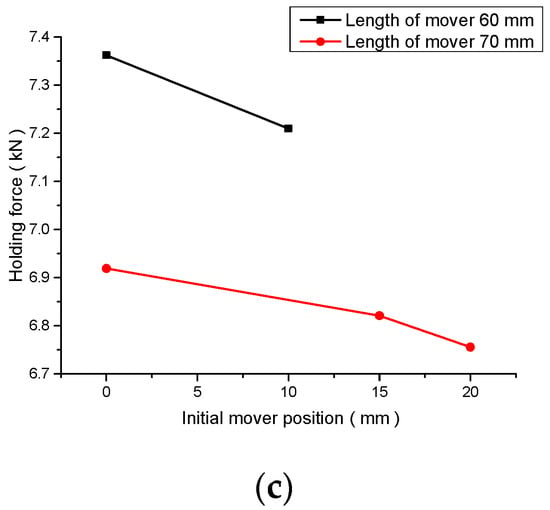

Based on Ansoft Maxwell, the characteristics of the retaining force and magnetic field in the gap are shown in Figure 4. It is evident that the magnetic field in the ABSMPMA is larger than the ASBPMA with the same sizes. In other words, the above analytical results are right and correct for the ABSMPMA, such as large retaining force, less permanent magnet volume, and low cost. It is also obvious that the retaining force in closing state is decreasing with the initial mover position increasing, which is caused by the effect of the leakage flux.

Figure 4.

The results of 2-D FE are shown. (a) The magnetic field in gap. (b) The characteristic of the mover length vs. retaining force. (c) The influences of the initial mover position for retaining force.

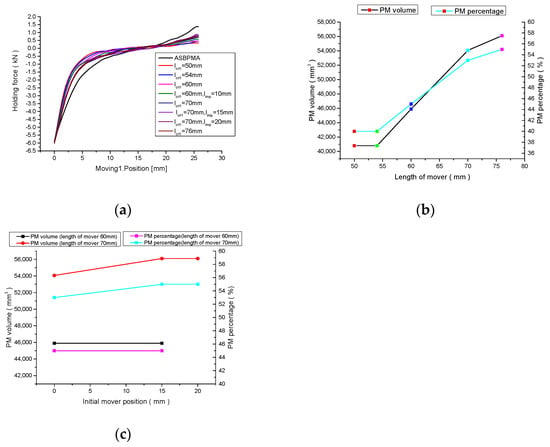

The calculation of the retaining forces, in the ASBPMA and ABSMPMA, are analyzed by 2-D FEA, as shown in Figure 5. The permanent magnet size of ABSMPMA was resized to obtain same retaining force, as shown in Figure 5a. In Figure 5a, the retaining force in closing state of ASBPMA is 5.9335 kN. The retaining forces in closing state of ABSMPMA are 5.941 kN, 5.899 kN, 5.996 kN, 5.906 kN, and 5.954 kN, for lengths of the mover: 50 mm, 54 mm, 60 mm, 70 mm, and 76 mm, respectively. Therefore, with same retaining force in closing state, the permanent magnet volume ratios of ABSMPMA vs. ASBPMA are 40%, 40%, 45%, 53%, and 55%, for lengths of the mover: 50 mm, 54 mm, 60 mm, 70 mm, and 76 mm, respectively. These results prove that the presented ABSMPMA needs less permanent magnet volume and low cost. It is also distinct that the permanent magnet volumes of the ABSMPMA have little difference with mover initial position increasing.

Figure 5.

The characteristics curve of the presented ABSMPMA. (a) The characteristic of the moving position vs. retaining force. (b) The characteristic of the length of mover vs. PM volume. (c) The characteristic of the initial mover position vs. PM volume.

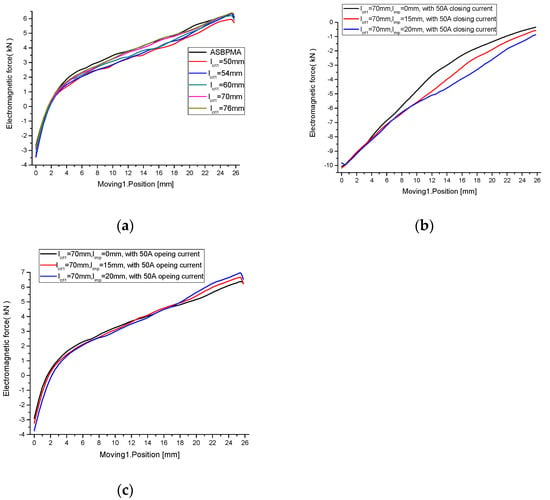

The calculation of the electromagnetic force, in the ASBPMA and ABSMPMA, are analyzed by 2-D FEA, as shown in Figure 6.

Figure 6.

The characteristics curve of the presented ABSMPMA. (a) The characteristic of the electromagnetic force vs. moving position with 50 A opening current. (b) The characteristic of the electromagnetic force vs. moving position with 50 A closing current for ABSMPMA with different initial mover position. (c) The characteristic of the electromagnetic force vs. moving position with 50 A opening current for ABSMPMA with different initial mover position.

In Figure 6, the electromagnetic force of the ASBPMA is larger than that of the ABSMPMA with the same sizes and current. However, the mover mass of the ABSMPMA is also lesser than the ASBPMA, which is the key improving the dynamic characteristic of the ABSMPMA. This is a Game problem between reducing mass and reducing electromagnetic force with the same sizes and current in ABSMPMA. However, the simulation shows that short mover can speed up actuator’s action, as shown follow. With 50 A opening current, the electromagnetic force of the ABSMPMA increases with mover initial position increasing near closing state position, while it decreases near opening state position. However, with 50 A closing current, the electromagnetic force of the ABSMPMA is increasing with increasing initial mover position near opening state position. This will improve the closing performance.

4.2. The Dynamic Characteristic

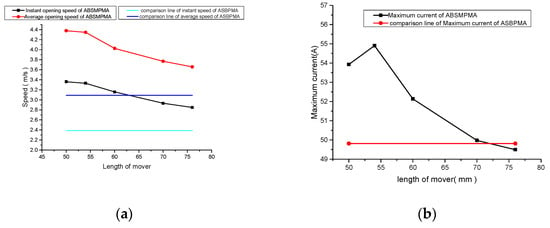

The opening performances of the ASBPMA and ABSMPMA are shown in Figure 7 according to the results of the FEAM.

Figure 7.

The opening characteristics are shown. (a) The characteristic of length of mover vs. opening speed. (b) The characteristic of length of mover vs. maximum opening current.

In the simulation model, there is a fixed voltage for the ASBPMA and ABSMPMA (150 V). At instant contact separating, the opening speed of the ASBPMA is 2.385 m/s. However, at instant contact separating, the opening speeds of the ABSMPMA are approximately 3.361 m/s, 3.329 m/s, 3.157 m/s, 2.931 m/s, and 2.848 m/s for lengths of the mover: 50 mm, 54 mm, 60 mm, 70 mm, and 76 mm, respectively. At scope of the two-thirds distance after the instant of contact separating, the average opening speed of the ASBPMA is 3.089 m/s. At scope of two-thirds distance after the instant of contact separating, the average opening speeds of the ABSMPMA are 4.377 m/s, 4.346 m/s, 4.025 m/s, 3.769 m/s, and 3.657 m/s, for lengths of the mover: 50 mm, 54 mm, 60 mm, 70 mm, and 76 mm, respectively. It is obvious that the opening dynamic characteristic of HVCB with the ABSMPMA is better than the HVCB with ASBPMA. The opening speed of the 40.5 kV vacuum circuit breaker needs more than 2.5 m/s. It is seeing that the average opening speeds of the ABSMPMA are more than 2.5 m/s, which meet the potential applications.

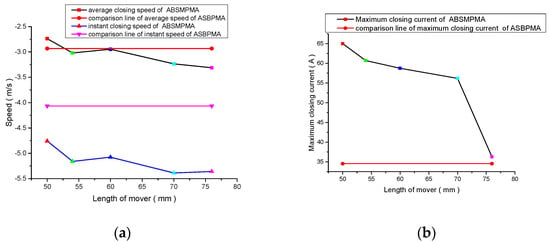

The closing characteristics of the ABSMPMA and ASBPMA are shown in Figure 8.

Figure 8.

The closing characteristics are shown. (a) The characteristics of the length of mover vs. closing speed. (b) The characteristics of the length of mover vs. maximum closing current.

At instant of contact touching, the closing speed of the traditional ASBPMA is −4.066 m/s. However, at instant of contact touching, the closing speeds of the ABSMPMA are approximately −4.758 m/s, −5.161 m/s, −5.077 m/s, −5.388 m/s, and −5.358 m/s for lengths of the mover: 50 mm, 54 mm, 60 mm, 70 mm, and 76 mm, respectively. At the scope of two-thirds distance before instant of contact touching, the average closing speed of the ASBPMA is −2.934 m/s. At the scope of two-thirds distance before instant of contact touching, the average closing speeds of the ABSMPMA are −2.738 m/s, −3.021 m/s, −2.946 m/s, −3.235 m/s, and −3.313 m/s for lengths of the mover: 50 mm, 54 mm, 60 mm, 70 mm, and 76 mm, respectively. It is obvious that the closing dynamic characteristic of the HVCB with the ABSMPMA is also better than the HVCB with ASBPMA in some cases. However, the maximum closing current for ABSMPMA is larger than the ASBPMA, which is undesirable. Hence, this problem is addressed in the following. The closing speed of the 40.5 kV vacuum circuit breaker needs more than 0.8 m/s. It is seeing that the average closing speeds of the ABSMPMA are more than 0.8 m/s, which meet the potential applications.

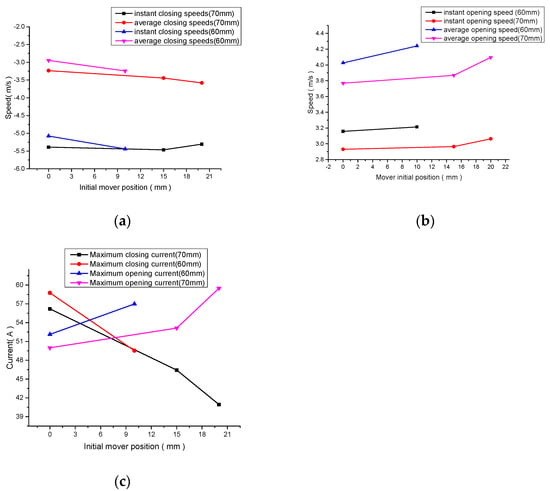

The opening and closing characteristics of the HVCB with the ABSMPMA, in different initial mover positions, are shown in Figure 9.

Figure 9.

The opening and closing characteristics are shown when the length of the mover are 60 mm and 70 mm. (a) The characteristic of the initial mover position vs. closing speed. (b) The characteristic of the initial mover position vs. opening speed. (c) The characteristic of the initial mover position vs. maximum current.

In Figure 9, the opening speed of the ABSMPMA increases with mover initial position increasing. However, the characteristics of the maximum opening current and opening starting time are worse. The closing maximum current of the ABSMPMA decreases with initial mover position increasing, which is a good way to solve large maximum closing current for ABSMPMA. It is obvious that the dynamic closing characteristics and dynamic opening characteristics of ABSMPMA are a pair of contradictory factors with different initial mover position. Based on the adjustment of the initial mover position, the maximum closing current can be limited to reasonable rage.

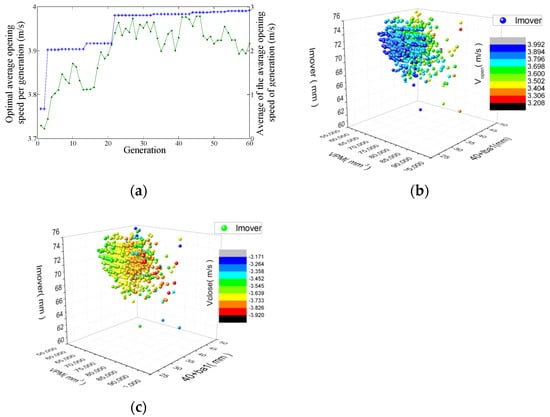

5. Optimization by Genetic Algorithm

In this paper, the Genetic Algorithm (GA) is used to optimize the ABSMPMA [45]. In this paper, we use the GA Toolbox of MATLAB, which is successful business software. The convergence of optimization is verified by some researcher [46]. The objective in the optimization is the average opening speed within constraint conditions. The value ranges of parameters can be expressed as

To ensure that the mover is not intersecting in the stator in simulation model, the constraint condition can be expressed as

To ensure that the bottom side of the mover is lower than the bottom side of the permanent magnets at closing state, the constraint condition can be expressed as

To ensure that the upper side of the mover is higher than the upper side of the permanent magnet at closing state, the constraint condition needs to meet

Therefore, constraint functions of parameters can be expressed as

The constraint functions of the closing retaining force and maximum current can be expressed as

The object function can be expressed as

where is the average opening speed.

The optimized results are shown in Figure 10. The average opening speed would converge on 4 m/s. It is obvious that the dynamic opening speed and dynamic closing speed of the ABSMPMA is a pair of contradictory factors. In the design process, the two factors need to balance.

Figure 10.

The optimized results. (a) The optimal average opening speed per generation and the average value of the average opening speed per generation. (b) The average opening speed characteristics within constraint conditions. (c) The average closing speed characteristics within constraint conditions.

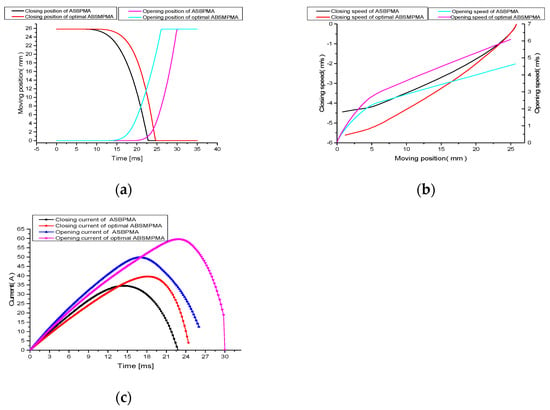

The closing and opening characteristics of the optimal ASBPMA are shown in Figure 11. It is obvious that the dynamic speed characteristics of the ABSMPMA are better than the ASBPMA. The maximum closing and opening current are limited in reasonable rage. In Figure 11, we can find the dynamic characteristics of the ASBPMA in this paper using FEA simulations agree with the experimental and simulation results of the ASBPMA in [19]. The difference between the dynamic characteristics of the ASBPMA in this paper and experimental and simulation results in [19] is mainly caused by different voltage. In this paper, we use the DC voltage source, while capacitance is used as the voltage source in [19].

Figure 11.

The closing and opening characteristics of the ASBPMA and optimal ABSMPMA are shown. (a) The closing and opening moving position characteristics. (b) The closing and opening speed characteristics. (c) The closing and opening armature current characteristics.

6. Experimental Results

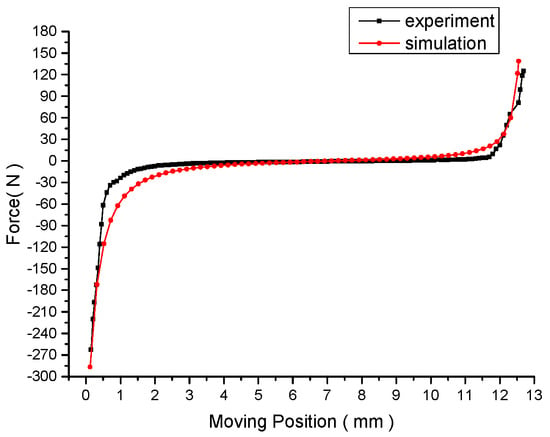

To further research and certify the above results, a prototype of the traditional permanent magnet actuator is created and tested in our research work on account of the limited experimental conditions, which is shown in Figure 12.

Figure 12.

The measurement results and simulation results are shown.

For example, testing stroke of the testing platform is 180 mm, maximum load force is 1000 N, and level of sensitivity is ±1%. However, the parameters used in FEM simulations have 6000 N retaining force. That is why the parameters of prototype and the parameters in Table 1 are different. The simulation result in Figure 12 is derived using the Ansoft Maxwell, which is finite element method software. The principal sizes of the prototype are shown in Table 3. The prototype parameters listed in Table 3 are very different from the simulation model parameters, because our experimental conditions very limit. For example, testing stroke of the testing platform is 180 mm; maximum load force is 1000 N; and level of sensitivity is ±1%.

Table 3.

Parameters of prototype.

The difference between the test results and simulation results is mainly caused by the processing technology and the magnetic flux leakage in the stator end. It can be seen that, from Figure 12, the measuring results agree with the simulation results, which confirms the accuracy of the Ansoft Maxwell and the above analysis.

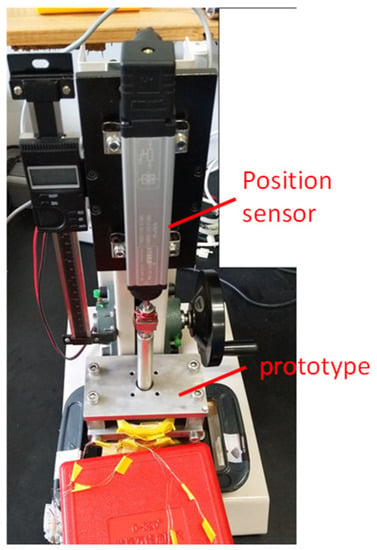

As a transient actuator, dynamic performance is very important. The dynamic characteristics testing platform are shown in Figure 13.

Figure 13.

The dynamic characteristics testing platform.

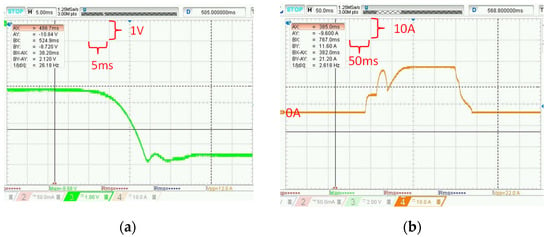

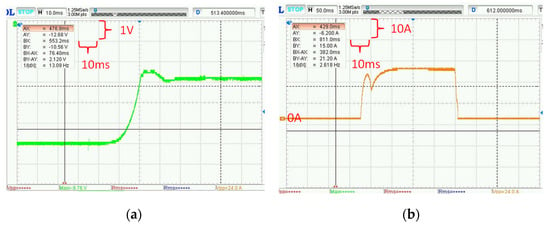

To certify the contribution and credibility in this paper, the closing and opening dynamic characteristics of the prototype are shown in Figure 14 and Figure 15.

Figure 14.

The closing dynamic characteristics of the prototype. (a) The mover position in closing process. (b) The current in closing coil.

Figure 15.

The opening dynamic characteristics of the prototype. (a) The mover position in opening process. (b) The current in opening coil.

In dynamic characteristics, the closing and opening coil is connected to 70 v DC voltage source. In Figure 14a, the mover spent 14 ms from opening position to closing position. The closing current lasts a long time due to limited experimental conditions. We can’t turn off the power right away. However, the closing current does not affect the closing dynamic characteristics of the prototype. The rubber band has added in prototype to obtain the opening dynamic characteristics.

The position sensor output voltage range is from 0 v to 20 v, measuring range is from 0 mm to 75 mm. According to the position sensor output signal in Figure 14a, the mover position can be calculated as dropout voltage. Comparing with Figure 12, Figure 14 and Figure 15, the measuring static performance results agree with the simulation results and dynamic experiments successfully complete the opening and closing process, which confirm the accuracy of dynamic simulation and the above analysis. Therefore, the performances of proposed permanent magnet actuator are sufficient for potential applications. However, the dynamic characteristics of the full-scale ABSMPMA will be studied in the near future owing to limited experimental conditions.

7. Conclusions and Discussion

In this paper, a novel asymmetrical bistable short mover permanent magnet actuator (ABSMPMA) is presented. The operating principle and mathematics models of the proposed ABSMPMA are researched and analyzed. The influences of the mover length for the characteristics of the ABSMPMA are studied. The over maximum closing current problem is researched. A technology, adjusting the initial mover position, is presented to solve this problem. The Genetic Algorithm (GA) is used to optimize the ABSMPMA. To certify the contribution and credibility in this paper, the closing and opening dynamic characteristics of the prototype are tested. The conclusions about the ABSMPMA are drawn as follows.

- The ABSMPMA has a small mover, which is shorter than the width of the tooth plus the stroke. Hence, the mover mass is lesser than that of the ASBPMA, which improves the opening and closing dynamic characteristics of the HVCB with the ABSMPMA;

- The retaining force of the ASBPMA is smaller than the ABSMPMA with the same sizes of permanent magnet;

- The ABSMPMA, with same retaining force, needs approximately half the magnet volumes of the ASBPMA, which is the key to decreasing cost;

- The technology of adjusting the initial mover position can be used to balance maximum closing current and maximum opening current as well as the opening and closing dynamic characteristics.

In short, the results show that the proposed ABSMPMA has some advantages, such as less permanent magnet volume, low cost, small mover mass, and high starting speed. However, the HVCB with the proposed ABSMPMA also has some problems, which will be researched in follow-up work.

Author Contributions

Conceptualization, methodology, software and funding acquisition, G.Z. and X.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Guangdong Natural Science Foundation of China, grant number (No. 2016A030313464).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We would like to express our deepest gratitude to the anonymous reviewers for dedicating their time to reviewing our paper, despite their busy schedules.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wan, S.; Dou, L.; Li, C.; Wu, P.; Liu, R. Study on on-line detection of characteristic parameters in high voltage circuit breaker opening process based on vibration signal. Electr. Power Compon. Syst. 2018, 46, 1969–1978. [Google Scholar] [CrossRef]

- Tseng, K.H.; Shiao, Y.F.; Cheng, P.Y.; Xu, Z.Z. Analysis and improvement of modeling of electromagnetic actuator for medium voltage gas insulated switchgear. Electr. Power Compon. Syst. 2014, 42, 1576–1586. [Google Scholar] [CrossRef]

- Fu, H. Research on Characteristics of Permanent Magnet Operating Mechanism and Its Synchronous Control Technology. Ph.D. Thesis, Central South University, Changsha, China, 2005. [Google Scholar]

- Wang, K.D.; Yi, W.; Ming-Zhi, Z. Design of half bistable permanent magnetic actuator used in 12kV vacuum circuit breaker. Adv. Technol. Electr. Eng. Energy. 2017, 36, 29–36. [Google Scholar]

- Shu, L.; Wu, L.; Wu, G.; Wu, Z. A fully coupled framework of predicting the dynamic characteristics of permanent magnet contactor. IEEE Trans. Magn. 2016, 52, 1–7. [Google Scholar] [CrossRef]

- Bak, H.J.; Ro, J.S.; Chung, T.K.; Jung, H.K. Characteristics analysis and design of a novel magnetic contactor for a 220 V/85 A. IEEE Trans. Magn. 2013, 49, 5498–5506. [Google Scholar] [CrossRef]

- Lin, H.; Wang, X.; Fang, S.; Jin, P.; Ho, S.L. Design, optimization, and intelligent control of permanent-magnet contactor. IEEE Trans. Ind. Electr. 2013, 60, 5148–5159. [Google Scholar] [CrossRef]

- Lin, X.; Shi, K.J.; Xu, J.Y. Influence of permeable property of material on dynamic characteristic of permanent magnetic actuator. High Volt. Appar. 2013, 49, 1–8. [Google Scholar]

- Lim, S.; Jeong, S.; Min, S. Multi-component layout optimization method for the design of a permanent magnet actuator. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Noh, M.D.; Park, Y.W. Topology selection and design optimization for magnetostrictive inertial actuators. J. Appl. Phys. 2012, 111, 07E715-1–07E715-3. [Google Scholar] [CrossRef]

- Shi, X.; Chang, S. Commutation force ripple reduction in a novel linear brushless DC actuator based on predictive current control. Electr. Power Compon. Syst. 2011, 39, 1609–1620. [Google Scholar] [CrossRef]

- Hung, C.Y.; Chi, C.T. A contact de-bounce technique for an AC permanent magnet contactor. WSEAS Trans. Syst. 2010, 9, 476–487. [Google Scholar]

- Fang, S.; Lin, H.; Wang, X.; Jin, P. Design and performance analysis of a vacuum permanent magnet contactor. In Proceedings of the 2010 14th Biennial IEEE Conference on Electromagnetic Field Computation, Chicago, IL, USA, 9–12 May 2010; p. 1. [Google Scholar]

- Dullni, E. A vacuum circuit-breaker with permanent magnetic actuator for frequent operations. In Proceedings of the ISDEIV. 18th International Symposium on Discharges and Electrical Insulation in Vacuum (Cat. No.98CH36073), Eindhoven, The Netherlands, 17–21 August 1998; Volume 2, pp. 688–691. [Google Scholar]

- Chen, X.; Zhu, Z.Q. Analytical determination of optimal split ratio of E-Core permanent magnet linear oscillating actuators. IEEE Trans. Ind. Appl. 2011, 47, 25–33. [Google Scholar] [CrossRef]

- Ahn, H.M.; Chung, T.K.; Oh, Y.H.; Song, K.D.; Kim, Y.I.; Kho, H.R.; Hahn, S.C. Optimal design of permanent magnetic actuator for permanent magnet reduction and dynamic characteristic improvement using response surface methodology. J. Electr. Eng. Technol. 2015, 10, 935–943. [Google Scholar] [CrossRef] [Green Version]

- Hu, J.; Zhao, M.; Zou, J.; Li, Y. Comparative Study of Stator Configurations of a Permanent Magnet Linear Oscillating Actuator for Orbital Friction Vibration Actuator. Appl. Sci. 2017, 7, 630. [Google Scholar] [CrossRef] [Green Version]

- You, J.; Zhang, K.; Zhu, Z.; Liangm, H. Novel design and research for a high-retaining-force, bi-directional, electromagnetic valve actuator with double-layer permanent magnets. J. Magn. 2016, 21, 65–71. [Google Scholar] [CrossRef]

- Lee, C.; Shin, B.H.; Bang, Y. Designing a permanent-magnetic actuator for vacuum circuit breakers using the taguchi method and dynamic characteristic analysis. IEEE Trans. Ind. Electr. 2016, 63, 1655–1664. [Google Scholar] [CrossRef]

- Ahn, H.M.; Lee, J.D.; Lee, B.J.; Hahn, S.C. Optimal design of permanent magnet actuator for vacuum circuit breakers using response surface methodology. Int. J. Appl. Electromagn. Mech. 2014, 45, 503–509. [Google Scholar] [CrossRef]

- Immonen, P.; Ruuskanen, V.; Pyrhonen, J. Moving magnet linear actuator with self-holding functionality. IET Electr. Syst. Transp. 2018, 8, 182–187. [Google Scholar] [CrossRef]

- Abdalla, I.I.; Ibrahim, T.; Nor, N.B.M. Development and optimization of a moving-magnet tubular linear permanent magnet motor for use in a reciprocating compressor of household refrigerators, Int. J. Electr. Power Energy Syst. 2016, 77, 263–270. [Google Scholar] [CrossRef]

- Aslam, J.; Li, X.H.; Janjua, F.K. Design of a hybrid magnetomotive force electromechanical valve actuator. Front. Inf. Technol. Electron. Eng. 2017, 18, 1635–1643. [Google Scholar] [CrossRef]

- Yang, S.; Tsai, Y. Design of a thrust actuator for magnetic bearings with low radial attraction force. IEEE Trans. Magn. 2012, 48, 3587–3590. [Google Scholar] [CrossRef]

- Jeong, H.S. Novel torque motor model for performance design and analysis of a servo valve with permanent magnets. J. Mech. Sci. Technol. 2018, 32, 2253–2259. [Google Scholar] [CrossRef]

- Lee, J.; Lee, S.; Kim, K.; Lee, J. Multi-material topology optimization of magnetic actuator with segmented permanent magnets. IEEE Trans. Magn. 2018, 54, 1–6. [Google Scholar] [CrossRef]

- Bae, B.; Kim, M. Electromagnetic actuator with novel electric brake for circuit breaker. J. Magn. 2016, 21, 340–347. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.K.; Ro, J.S.; Jung, H.K. Optimal design of a novel permanent magnetic actuator using evolutionary strategy algorithm and kriging meta-model. J. Electr. Eng. Technol. 2014, 9, 471–477. [Google Scholar] [CrossRef]

- Ro, J.S.; Hong, S.K.; Jung, H.K. Characteristic analysis and design of a novel permanent magnetic actuator for a vacuum circuit breaker. IET Electr. Power Appl. 2013, 7, 87–96. [Google Scholar] [CrossRef]

- Park, H.; Jung, H.; Ro, J. Analysis and design of diverse electromagnet type actuators for moulded case circuit breaker. IET Electr. Power Appl. 2016, 10, 849–857. [Google Scholar] [CrossRef]

- Bi, Y.H.; Dong, E.Y.; Yin, G.X.; Xu, J.Y.; Liu, M.W. Parameter design and dynamic characteristic analysis of magnetic force actuator based on Visual Basic interface programming. Appl. Mech. Mater. 2014, 492, 227–231. [Google Scholar] [CrossRef]

- Ro, J.; Bak, H.; Jung, H. Characteristic analysis and design of a novel lorentz force driving actuator for a molded case circuit breaker. IET Electr. Power Appl. 2015, 9, 1–9. [Google Scholar] [CrossRef]

- Jiang, J.; Lin, H.; Fang, S. Optimization design of a permanent magnet actuator for 126-kV vacuum circuit breaker. IEEE Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.; Li, P.; Wen, H. Comparative studies on two electromagnetic repulsion mechanisms for high-speed vacuum switch. IET Electr. Power Appl. 2018, 12, 247–253. [Google Scholar] [CrossRef]

- Qin, T.; Dong, E.; Wang, Y.; Zou, J. Influence of the contact opening speed on DC vacuum arc. IEEE Trans. Plasma Sci. 2015, 43, 878–883. [Google Scholar]

- Xu, Z.; Fang, S.; Lin, H.; Liu, K.; Kong, Q.; Wu, G.; Chen, Y.; Liu, Q. Analysis of a Permanent Magnetic Actuator with Three Coils for High Voltage Vacuum Circuit Breaker. High Volt Appar. 2016, 52, 111–117. [Google Scholar]

- Wang, Z.; Sun, L.; He, S.; Geng, Y.; Liu, Z. A permanent magnetic actuator for 126 kV vacuum circuit breakers. IEEE Trans. Magn. 2014, 50, 129–135. [Google Scholar] [CrossRef]

- Fang, S.; Xia, M.; Lin, H.; Ho, S. Analysis and design of a high-speed permanent magnet characteristic actuator using eddy current effect for high-voltage vacuum circuit breaker. IET Electr. Power Appl. 2016, 10, 268–275. [Google Scholar] [CrossRef]

- Fang, S.; Liu, Q.; Lin, H.; Ho, S.L. A novel flux-weakening control strategy for permanent-magnet actuator of vacuum circuit breaker. IEEE Trans. Ind. Electron. 2016, 63, 2275–2283. [Google Scholar] [CrossRef]

- Zeng, G.; Xiangyu, Y.; Yin, H.; Jing, Y.; Zhao, S.; Cao, J. Unsymmetrical bistable multimagnetic circuit permanent magnet actuator for high-voltage circuit breaker application: Analysis, design, and dynamic simulation. IET Electr. Power Appl. 2020, 14, 827–836. [Google Scholar] [CrossRef]

- Dai, K.; Zhu, Z.; Jin, H.; Ma, X.; Duan, W.; Wang, J.; Zhang, W. Bionic soft multimodal actuators for fast, large deformation under ultralow magnetic conditions. Adv. Mater. Interfaces 2022, 9, 2200351. [Google Scholar] [CrossRef]

- Zuo, Q.; Hu, S.; Zuo, C. Structural design and performance calculation for flip-flop permanently magnetic operating mechanism(I). Hua Tong Technol. 2002, 2, 13–17. [Google Scholar]

- Tang, Y. Electro Mechanics Fourth Edition; China Machine Press: Beijing, China, 2013. [Google Scholar]

- Tang, R. Modern Permanent Magnet Machines Theory and Design; China Machine Press: Beijing, China, 2015. [Google Scholar]

- Semero, Y.K.; Zhang, J.; Zheng, D.; Wei, D. An accurate very short-term electric load forecasting model with binary genetic algorithm based feature selection for microgrid applications. Electr. Power Compon. Syst. 2018, 46, 1570–1579. [Google Scholar] [CrossRef]

- LI, H.; XU, L.; LI, J. Optimizing circuit breaker temperature control technique based on GA toolbox of Matlab. Comput. Sci. 2017, 44, 557–560. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).