Dynamics and Computed-Muscle-Force Control of a Planar Muscle-Driven Snake Robot

Abstract

:1. Introduction

2. Materials and Methods

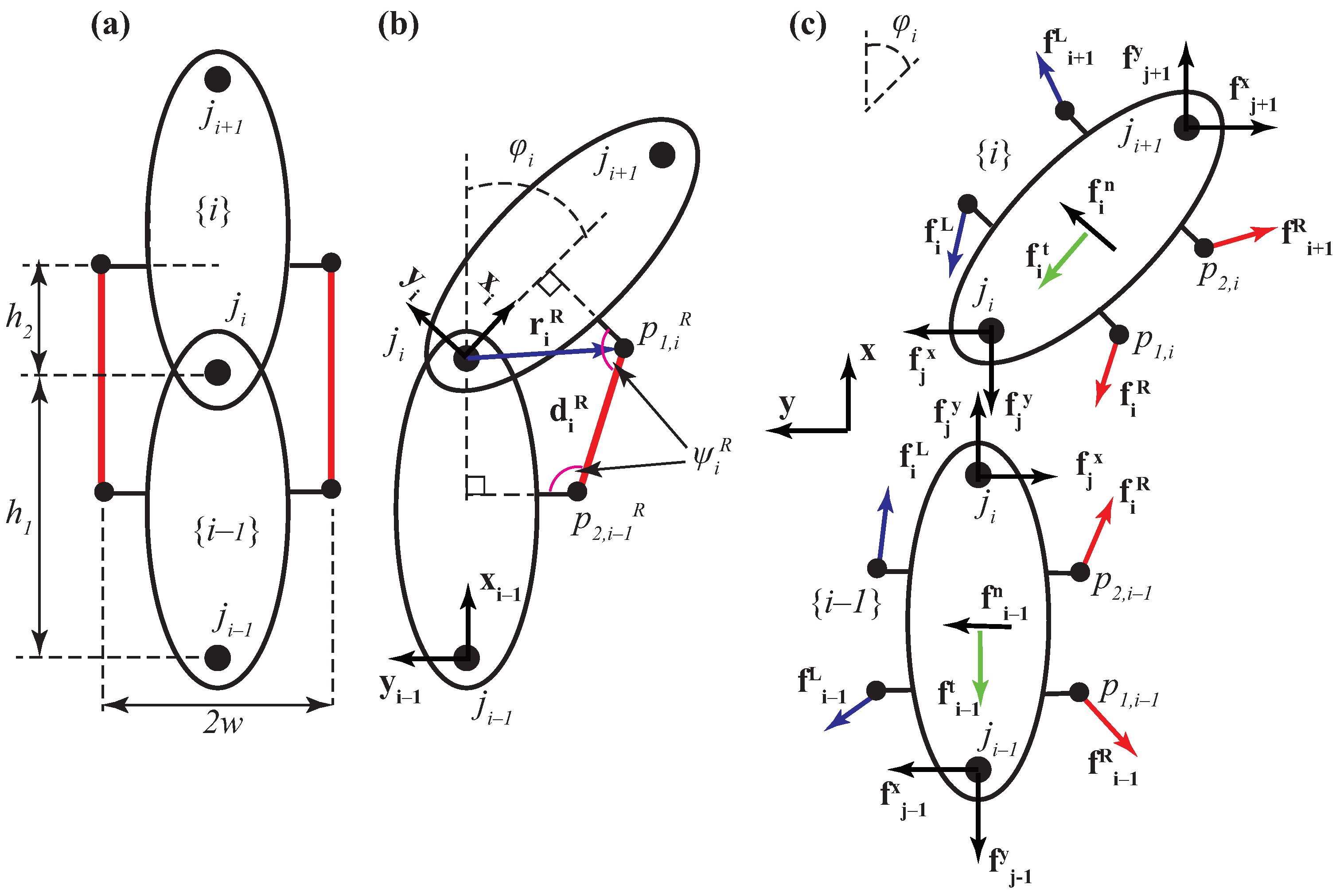

2.1. Kinematics of Artificial-Muscle-Driven Snake Robot

2.1.1. Joint Position–Muscle Vector Relationship

2.1.2. Joint Space to Cartesian Space

2.2. Dynamics

2.2.1. Lagrangian of the Artificial-Muscle-Driven Snake Robot

2.2.2. Generalized Forces

2.2.3. Equations of Motion

2.3. Computed Muscle–Force Control

- Follow the desired path in Cartesian space based on the line-of-sight concept, which adjust the heading direction of the overall movement of the snake robot;

- Generate the lateral undulation gate, which means the joints’ motion of the snake robot must follow the desired sinusoidal function [1];

- Achieve the desired average linear velocity in the direction of the movement while keeping the velocity zero in the perpendicular direction (virtually generating the non-holonomic constraints).

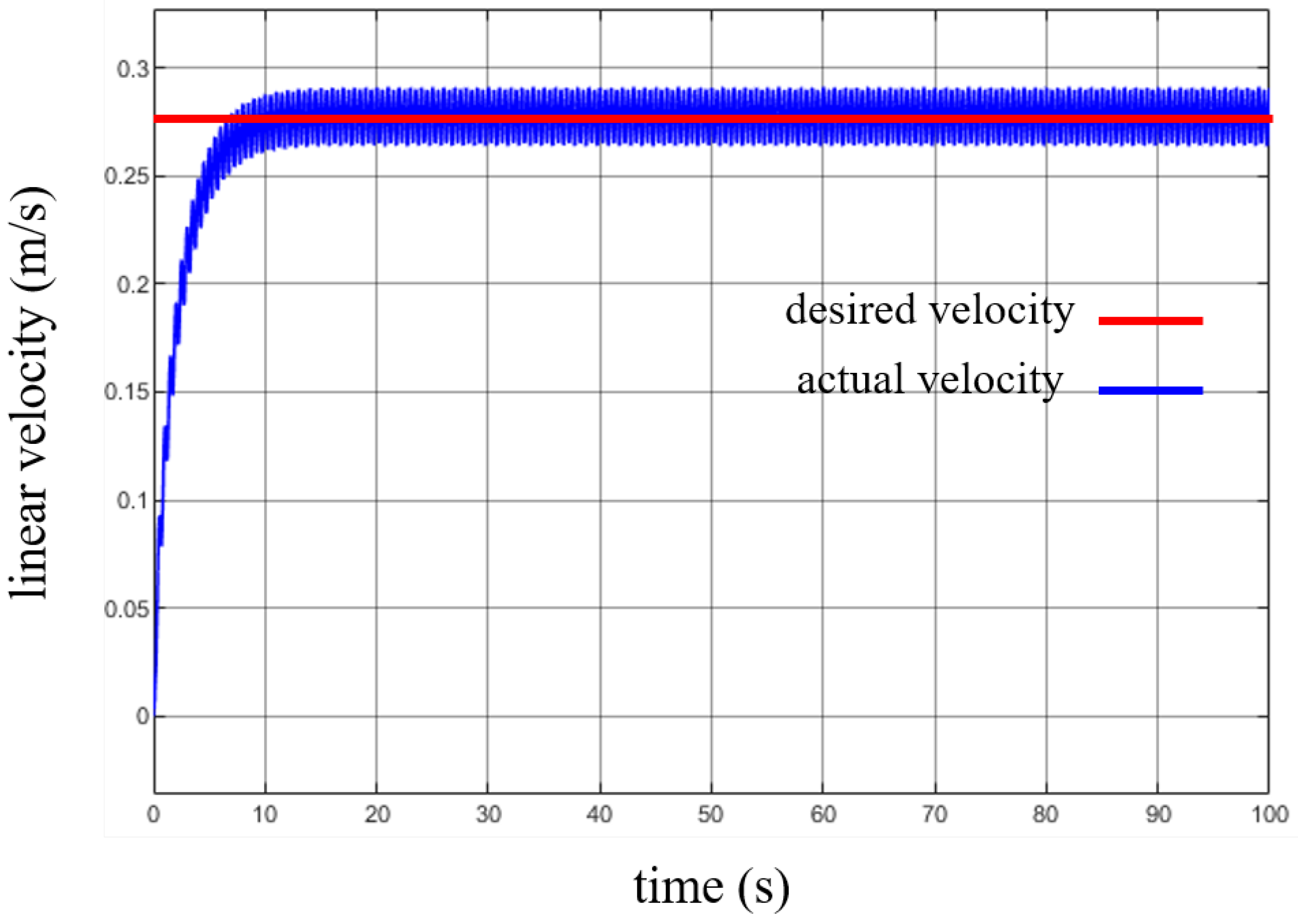

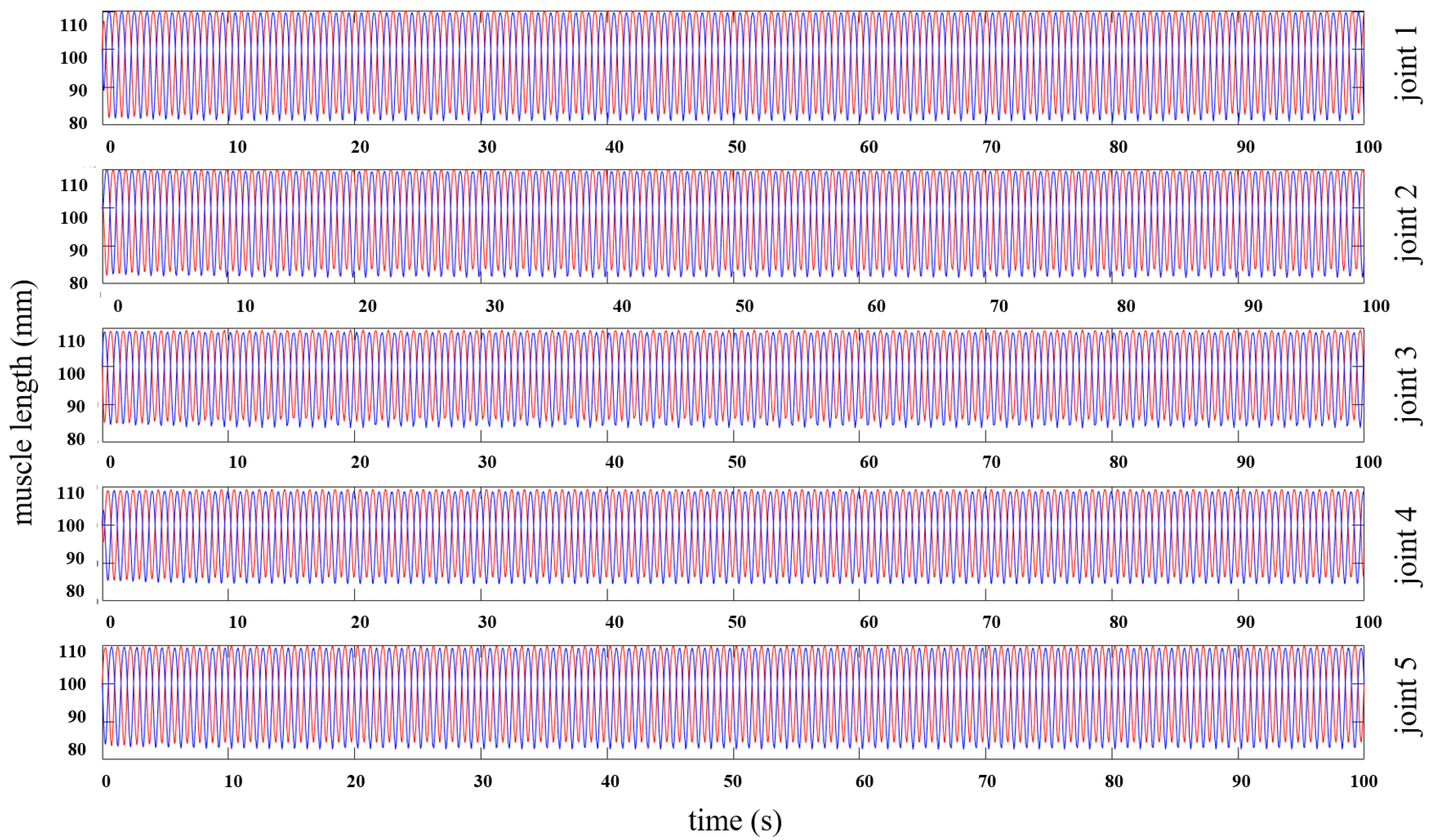

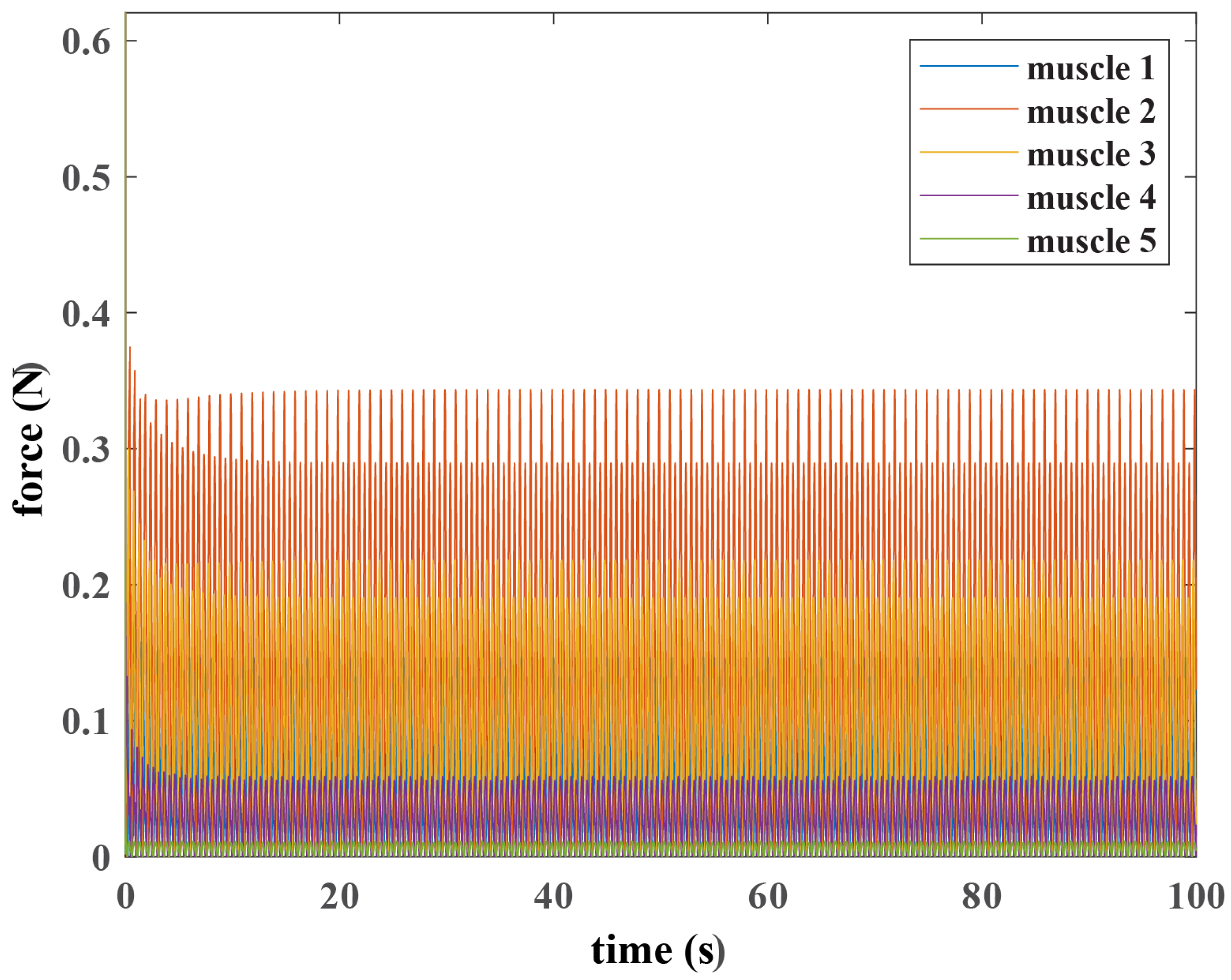

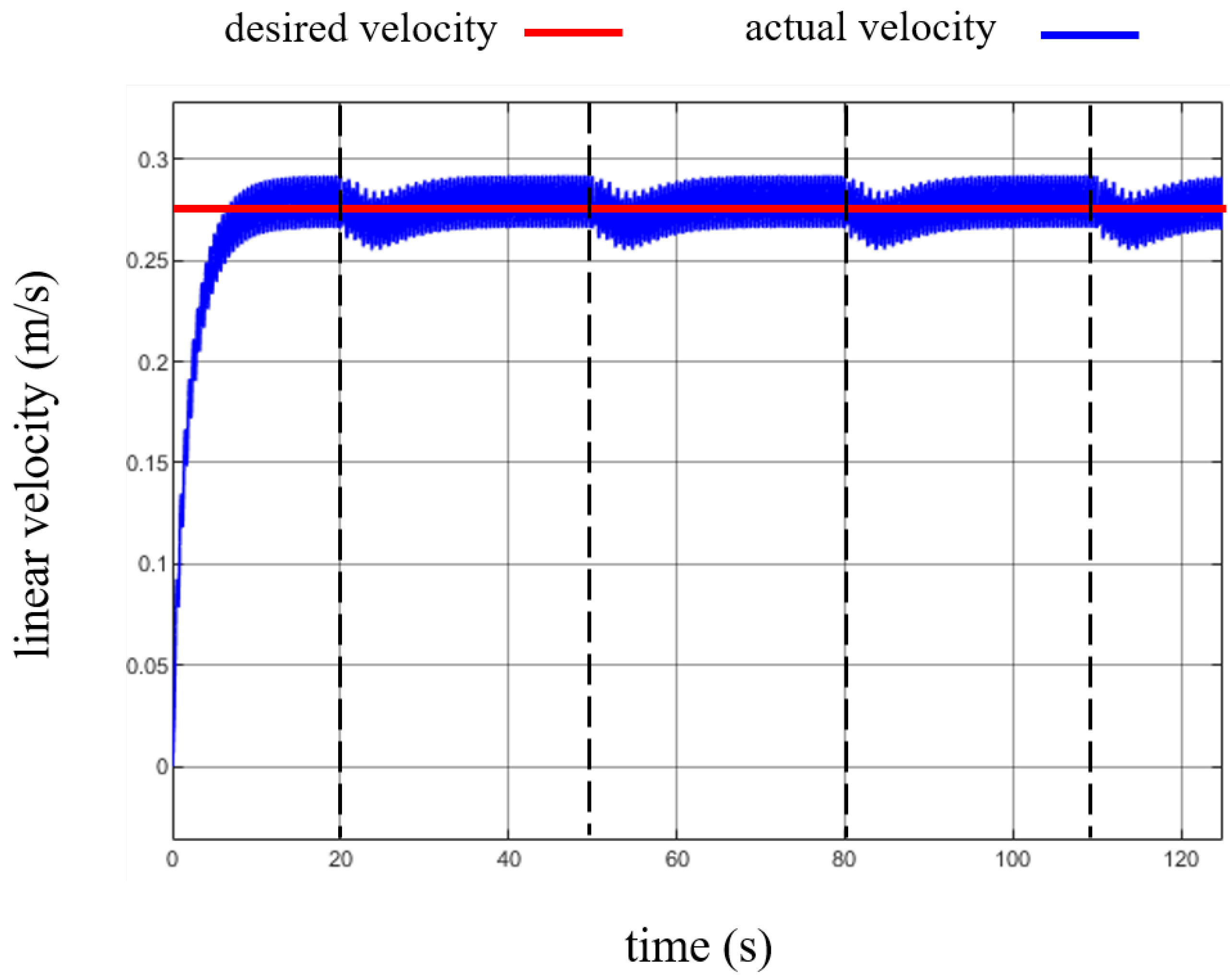

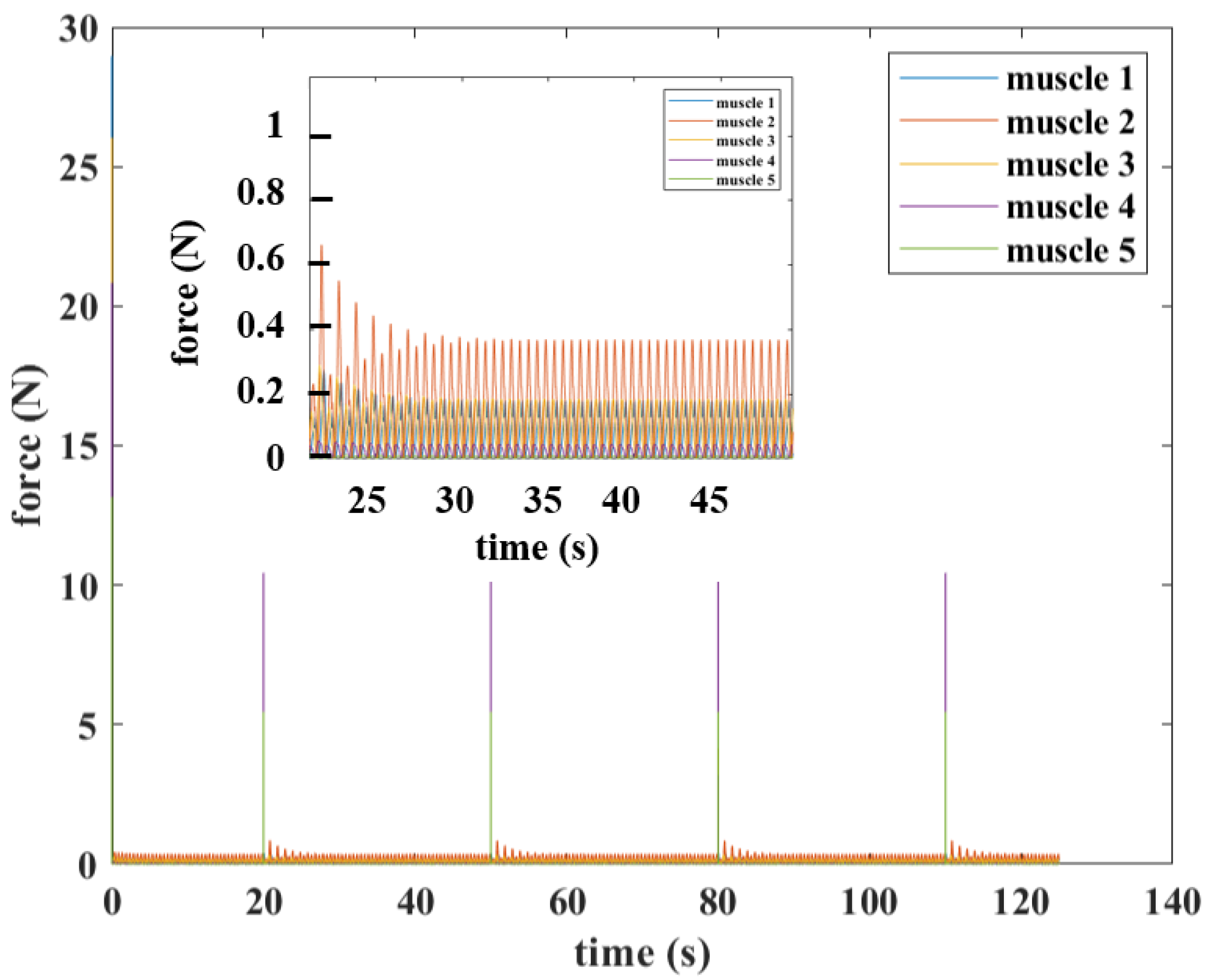

3. Results and Discussion

3.1. Circle Path

3.2. Square Path

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCW | Counterclockwise |

| DOF | Degrees of freedom |

| LoS | Line of sight |

| PAMs | Pneumatic artificial muscles |

| PEA | Parallel elastic actuators |

| 2D | Two dimensional |

| 3D | Three dimensional |

Appendix A

References

- Hirose, S. Biologically Inspired Robots: Snake-like Locomotors and Manipulators; Oxford Science Publications; Oxford University Press: Oxford, UK, 1993; Volume 1093. [Google Scholar]

- Pettersen, K.Y. Snake robots. Annu. Rev. Control 2017, 44, 19–44. [Google Scholar] [CrossRef]

- Dowling, K. Limbless locomotion: Learning to crawl. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation (Cat. No. 99CH36288C), Detroit, MI, USA, 10–15 May 1999; IEEE: Piscataway, NJ, USA, 1999; Volume 4, pp. 3001–3006. [Google Scholar]

- Liljeback, P.; Pettersen, K.Y.; Stavdahl, Ø.; Gravdahl, J.T. Experimental Investigation of Obstacle-Aided Locomotion With a Snake Robot. IEEE Trans. Robot. 2011, 27, 792–800. [Google Scholar] [CrossRef] [Green Version]

- Onal, C.D.; Rus, D. Autonomous undulatory serpentine locomotion utilizing body dynamics of a fluidic soft robot. Bioinspir. Biomim. 2013, 8, 026003. [Google Scholar] [CrossRef] [PubMed]

- Luo, M.; Agheli, M.; Onal, C.D. Theoretical modeling and experimental analysis of a pressure-operated soft robotic snake. Soft Robot. 2014, 1, 136–146. [Google Scholar] [CrossRef]

- Luo, M.; Pan, Y.; Skorina, E.H.; Tao, W.; Chen, F.; Ozel, S.; Onal, C.D. Slithering towards autonomy: A self-contained soft robotic snake platform with integrated curvature sensing. Bioinspir. Biomim. 2015, 10, 055001. [Google Scholar] [CrossRef] [PubMed]

- Branyan, C.; Fleming, C.; Remaley, J.; Kothari, A.; Tumer, K.; Hatton, R.L.; Mengüç, Y. Soft snake robots: Mechanical design and geometric gait implementation. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, China, 5–8 December 2017; pp. 282–289. [Google Scholar] [CrossRef]

- Branyan, C.; Menğüç, Y. Soft Snake Robots: Investigating the Effects of Gait Parameters on Locomotion in Complex Terrains. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 1–9. [Google Scholar]

- Luo, M.; Wan, Z.; Sun, Y.; Skorina, E.H.; Tao, W.; Chen, F.; Gopalka, L.; Yang, H.; Onal, C.D. Motion Planning and Iterative Learning Control of a Modular Soft Robotic Snake. Front. Robot. AI 2020, 7, 599242. [Google Scholar] [CrossRef]

- Godage, I.S. Swimming locomotion of Soft Robotic Snakes. arXiv 2019, arXiv:1908.05250. [Google Scholar]

- Chirikjian, G.S.; Burdick, J.W. The kinematics of hyper-redundant robot locomotion. IEEE Trans. Robot. Autom. 1995, 11, 781–793. [Google Scholar] [CrossRef] [Green Version]

- Wright, C.; Johnson, A.; Peck, A.; McCord, Z.; Naaktgeboren, A.; Gianfortoni, P.; Gonzalez-Rivero, M.; Hatton, R.; Choset, H. Design of a modular snake robot. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 2609–2614. [Google Scholar] [CrossRef]

- Ma, S. Analysis of snake movement forms for realization of snake-like robots. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation (Cat. No. 99CH36288C), Detroit, MI, USA, 10–15 May 1999; IEEE: Piscataway, NJ, USA, 1999; Volume 4, pp. 3007–3013. [Google Scholar]

- Saito, M.; Fukaya, M.; Iwasaki, T. Modeling, analysis, and synthesis of serpentine locomotion with a multilink robotic snake. IEEE Control Syst. Mag. 2002, 22, 64–81. [Google Scholar]

- Tanaka, M.; Matsuno, F. Control of snake robots with switching constraints: Trajectory tracking with moving obstacle. Adv. Robot. 2014, 28, 415–429. [Google Scholar] [CrossRef]

- Liljebäck, P.; Pettersen, K.Y.; Stavdahl, Ø.; Gravdahl, J.T. Snake Robots: Modelling, Mechatronics, and Control; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Haghshenas-Jaryani, M.; Vossoughi, G. Modeling and sliding mode control of a snake-like robot with holonomic constraints. In Proceedings of the 2008 IEEE International Conference on Robotics and Biomimetics, Bangkok, Thailand, 22–25 February 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 454–461. [Google Scholar]

- Haghshenas-Jaryani, M.; Vossoughi, G. Trajectory Control of Snake-Like Robots in Operational Space Using a Double Layer Sliding Mode Controller. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015. [Google Scholar]

- Sevil, L.F.H.; Haghshenas-Jaryani, M. Anomaly Detection in Joint Angle Sensor of a Snake Robot. In Proceedings of the 33rd Florida Conference on Recent Advances in Robotics (FCRAR), Melbourne, FL, USA, 14–16 May 2020. [Google Scholar]

- Haghshenas-Jaryani, M.; Sevil, H.E.; Sun, L. Navigation and Obstacle Avoidance of Snake-Robot Guided by a Co-Robot UAV Visual Servoing. In Proceedings of the ASME 2020 Dynamic Systems and Control Conference, Virtual, 5–7 October 2020. [Google Scholar] [CrossRef]

- Haghshenas-Jaryani, M.; Sevil, H.E. Autonomous Navigation and Obstacle Avoidance of a Snake Robot with Combined Velocity-Heading Control. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 10 February 2020; pp. 7507–7512. [Google Scholar] [CrossRef]

- Haghshenas-Jaryani, M. Maneuvering Control of a Planar Snake Robot Locomotion using a Combined Heading-Velocity-Shape Strategy. In Proceedings of the ASME 2022 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC/CIE), 46th Mechanisms and Robotics Conference, St. Louis, MO, USA, 14–17 August 2022. [Google Scholar]

- Guo, Z.; Mahadevan, L. Limbless undulatory propulsion on land. Proc. Natl. Acad. Sci. USA 2008, 105, 3179–3184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, X.; Zhu, W.; Fang, Y. Guided Motion Planning for Snake-like Robots Based on Geometry Mechanics and HJB Equation. IEEE Trans. Ind. Electron. 2019, 66, 7120–7130. [Google Scholar] [CrossRef]

- Ma, S.; Araya, H.; Li, L. Development of a creeping snake-robot. In Proceedings of the 2001 IEEE International Symposium on Computational Intelligence in Robotics and Automation (Cat. No. 01EX515), Banff, AB, Canada, 29 July–1 August 2001; IEEE: Piscataway, NJ, USA, 2001; pp. 77–82. [Google Scholar]

- Xiao, X.; Cappo, E.; Zhen, W.; Dai, J.; Sun, K.; Gong, C.; Travers, M.J.; Choset, H. Locomotive reduction for snake robots. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 3735–3740. [Google Scholar] [CrossRef]

- Hatton, R.L.; Choset, H. Generating gaits for snake robots: Annealed chain fitting and keyframe wave extraction. Auton. Robot. 2010, 28, 271–281. [Google Scholar] [CrossRef]

- Ostrowski, J.; Burdick, J. Gait kinematics for a serpentine robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; IEEE: Piscataway, NJ, USA, 1996; Volume 2, pp. 1294–1299. [Google Scholar]

- Ishikawa, M. Iterative feedback control of snake-like robot based on principal fibre bundle modelling. Int. J. Adv. Mechatron. Syst. 2009, 1, 175–182. [Google Scholar] [CrossRef]

- Hicks, G.; Ito, K. A method for determination of optimal gaits with application to a snake-like serial-link structure. IEEE Trans. Autom. Control 2005, 50, 1291–1306. [Google Scholar] [CrossRef]

- Matsuno, F.; Suenaga, K. Control of redundant 3D snake robot based on kinematic model. In Proceedings of the 2003 IEEE International Conference on Robotics and Automation (Cat. No. 03CH37422), Taipei, Taiwan, 14–19 September 2003; IEEE: Piscataway, NJ, USA, 2003; Volume 2, pp. 2061–2066. [Google Scholar]

- Mohammadi, A.; Rezapour, E.; Maggiore, M.; Pettersen, K.Y. Maneuvering control of planar snake robots using virtual holonomic constraints. IEEE Trans. Control Syst. Technol. 2015, 24, 884–899. [Google Scholar] [CrossRef] [Green Version]

- Kohl, A.M.; Kelasidi, E.; Mohammadi, A.; Maggiore, M.; Pettersen, K.Y. Planar maneuvering control of underwater snake robots using virtual holonomic constraints. Bioinspir. Biomim. 2016, 11, 065005. [Google Scholar] [CrossRef]

- Chang, A.H.; Hyun, N.P.; Verriest, E.I.; Vela, P.A. Optimal Trajectory Planning and Feedback Control of Lateral Undulation in Snake-Like Robots. In Proceedings of the 2018 Annual American Control Conference (ACC), Milwaukee, WI, USA, 27–29 June 2018; pp. 2114–2120. [Google Scholar] [CrossRef]

- Mazzolai, B.; Laschi, C. A vision for future bioinspired and biohybrid robots. Sci. Robot. 2020, 5, eaba6893. [Google Scholar] [CrossRef]

- Morimoto, Y.; Onoe, H.; Takeuchi, S. Biohybrid robot powered by an antagonistic pair of skeletal muscle tissues. Sci. Robot. 2018, 3, eaat4440. [Google Scholar] [CrossRef] [Green Version]

- Davis, S.; Tsagarakis, N.; Canderle, J.; Caldwell, D.G. Enhanced modelling and performance in braided pneumatic muscle actuators. Int. J. Robot. Res. 2003, 22, 213–227. [Google Scholar] [CrossRef]

- Zhang, J.; Sheng, J.; O’Neill, C.T.; Walsh, C.J.; Wood, R.J.; Ryu, J.H.; Desai, J.P.; Yip, M.C. Robotic Artificial Muscles: Current Progress and Future Perspectives. IEEE Trans. Robot. 2019, 35, 761–781. [Google Scholar] [CrossRef]

- Schroder, J.; Erol, D.; Kawamura, K.; Dillman, R. Dynamic pneumatic actuator model for a model-based torque controller. In Proceedings of the 2003 IEEE International Symposium on Computational Intelligence in Robotics and Automation. Computational Intelligence in Robotics and Automation for the New Millennium (Cat. No. 03EX694), Kobe, Japan, 16–20 July 2003; IEEE: Piscataway, NJ, USA, 2003; Volume 1, pp. 342–347. [Google Scholar]

- József, S.; Gábor, S.; János, G. Investigation and application of pneumatic artificial muscles. Biomech. Hung. 2010, 3, 208–214. [Google Scholar]

- Tondu, B.; Lopez, P. Modeling and control of McKibben artificial muscle robot actuators. IEEE Control Syst. Mag. 2000, 20, 15–38. [Google Scholar]

- Craddock, M.; Augustine, E.; Konerman, S.; Shin, M. Biorobotics: An Overview of Recent Innovations in Artificial Muscles. Actuators 2022, 11, 168. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Beomonte Zobel, P.; Durante, F.; Zeer, M. Modeling-Based EMG Signal (MBES) Classifier for Robotic Remote-Control Purposes. Actuators 2022, 11, 65. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Wei, R.; Perez, M.; Shepard, B.; Koeneman, E.; Koeneman, J.; He, J. RUPERT: An exoskeleton robot for assisting rehabilitation of arm functions. In Proceedings of the 2008 Virtual Rehabilitation, Vancouver, BC, Canada, 25–27 August 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 163–167. [Google Scholar]

- Kobayashi, H.; Hiramatsu, K. Development of muscle suit for upper limb. In Proceedings of the IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 3, pp. 2480–2485. [Google Scholar]

- Koeneman, E.; Schultz, R.; Wolf, S.; Herring, D.; Koeneman, J. A pneumatic muscle hand therapy device. In Proceedings of the 26th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, San Francisco, CA, USA, 1–5 September 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 1, pp. 2711–2713. [Google Scholar]

- Wongsiri, S.; Laksanacharoen, S. Design and construction of an artificial limb driven by artificial muscles for amputees. In Proceedings of the International Conference on Energy and the Environment, Prince of Songkla University, Hat Yai, Songkla, Thailand, 11–12 December 2003; pp. 11–12. [Google Scholar]

- Wehner, M.; Tolley, M.T.; Mengüç, Y.; Park, Y.L.; Mozeika, A.; Ding, Y.; Onal, C.; Shepherd, R.F.; Whitesides, G.M.; Wood, R.J. Pneumatic Energy Sources for Autonomous and Wearable Soft Robotics. Soft Robot. 2014, 1, 263–274. [Google Scholar] [CrossRef] [Green Version]

- Gray, J. The mechanism of locomotion in snakes. J. Exp. Biol. 1946, 23, 101–120. [Google Scholar] [CrossRef]

- Rezaei, S.M.; Barazandeh, F.; Haidarzadeh, M.S.; Sadat, S.M. The effect of snake muscular system on actuators’ torque. J. Intell. Robot. Syst. 2010, 59, 299–318. [Google Scholar] [CrossRef]

- Jayne, B.C. Muscular mechanisms of snake locomotion: An electromyographic study of the sidewinding and concertina modes of Crotalus cerastes, Nerodia fasciata and Elaphe obsoleta. J. Exp. Biol. 1988, 140, 1–33. [Google Scholar] [CrossRef]

- Jayne, B.C. Muscular mechanisms of snake locomotion: An electromyographic study of lateral undulation of the Florida banded water snake (Nerodia fasciata) and the yellow rat snake (Elaphe obsoleta). J. Morphol. 1988, 197, 159–181. [Google Scholar] [CrossRef]

- Moon, B.R.; Gans, C. Kinematics, muscular activity and propulsion in gopher snakes. J. Exp. Biol. 1998, 201, 2669–2684. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Wang, Z.; Wu, G.; Lei, L.; Zhao, B.; Zhang, P.; Shang, P. Design and Analysis of a Snake-like Surgical Robot with Continuum Joints. In Proceedings of the 2020 5th International Conference on Advanced Robotics and Mechatronics (ICARM), Shenzhen, China, 18–21 December 2020. [Google Scholar] [CrossRef]

- Granosik, G.; Borenstein, J. Integrated joint actuator for serpentine robots. IEEE/ASME Trans. Mechatron. 2005, 10, 473–481. [Google Scholar] [CrossRef]

- Kakogawa, A.; Jeon, S.; Ma, S. Stiffness design of a resonance-based planar snake robot with parallel elastic actuators. IEEE Robot. Autom. Lett. 2018, 3, 1284–1291. [Google Scholar] [CrossRef]

- Ute, J.; Ono, K. Fast and efficient locomotion of a snake robot based on self-excitation principle. In Proceedings of the 7th International Workshop on Advanced Motion Control. Proceedings (Cat. No. 02TH8623), Maribor, Slovenia, 3–5 July 2002; IEEE: Piscataway, NJ, USA, 2002; pp. 532–539. [Google Scholar]

- Lopez, M.; Haghshenas-Jaryani, M. A Muscle-Driven Mechanism for Locomotion of Snake-Robots. Automation 2022, 3, 1–26. [Google Scholar] [CrossRef]

- Lanczos, C. The Variational Principles of Mechanics; Courier Corporation: Chelmsford, MA, USA, 2012. [Google Scholar]

- Fossen, T.I. Handbook of Marine Craft Hydrodynamics and Motion Control; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

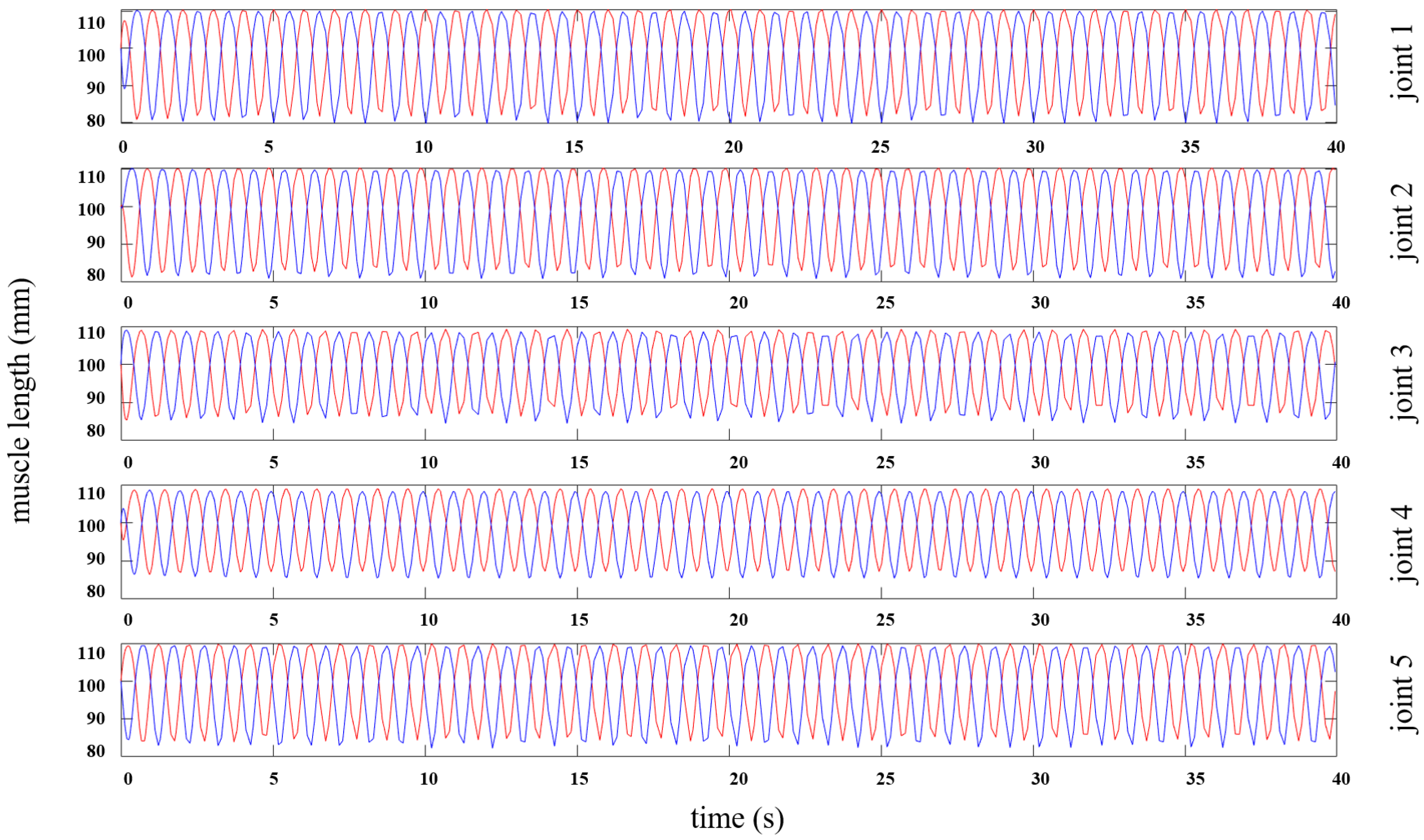

| m1 Right | m1 Left | m2 Right | m2 Left | m3 Right | m3 Left | m4 Right | m4 Left | m5 Right | m5 Left |

|---|---|---|---|---|---|---|---|---|---|

| 82 | 81 | 82.2 | 81.6 | 85 | 83.8 | 85.4 | 84.5 | 83.6 | 82.7 |

| 110.3 | 110 | 110.1 | 109.9 | 109.5 | 109.1 | 109.3 | 109.0 | 109.8 | 109.6 |

| m1 Right | m1 Left | m2 Right | m2 Left | m3 Right | m3 Left | m4 Right | m4 Left | m5 Right | m5 Left |

|---|---|---|---|---|---|---|---|---|---|

| 80.6 | 76 | 81.8 | 75.2 | 85.4 | 79.1 | 86.4 | 80.4 | 83.2 | 77.4 |

| 11.2 | 110.4 | 111.3 | 110.1 | 110.7 | 109.0 | 110.4 | 108.6 | 111 | 109.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haghshenas-Jaryani, M. Dynamics and Computed-Muscle-Force Control of a Planar Muscle-Driven Snake Robot. Actuators 2022, 11, 194. https://doi.org/10.3390/act11070194

Haghshenas-Jaryani M. Dynamics and Computed-Muscle-Force Control of a Planar Muscle-Driven Snake Robot. Actuators. 2022; 11(7):194. https://doi.org/10.3390/act11070194

Chicago/Turabian StyleHaghshenas-Jaryani, Mahdi. 2022. "Dynamics and Computed-Muscle-Force Control of a Planar Muscle-Driven Snake Robot" Actuators 11, no. 7: 194. https://doi.org/10.3390/act11070194

APA StyleHaghshenas-Jaryani, M. (2022). Dynamics and Computed-Muscle-Force Control of a Planar Muscle-Driven Snake Robot. Actuators, 11(7), 194. https://doi.org/10.3390/act11070194