Abstract

In this overview of recent developments in the field of biorobotics we cover the developments in materials such as the use of polyester fabric being used as artificial skin and the start of whole new ways to actuate artificial muscles as a whole. In this, we discuss all of the relevant innovations from the fields of nano and microtechnology, as well as in the field of soft robotics to summarize what has been over the last 4 years and what could be improved for artificial muscles in the future. The goal of this paper will be to gain a better understanding of where the current field of biorobotics is at and what its current trends in manufacturing and its techniques are within the last several years.

1. Introduction

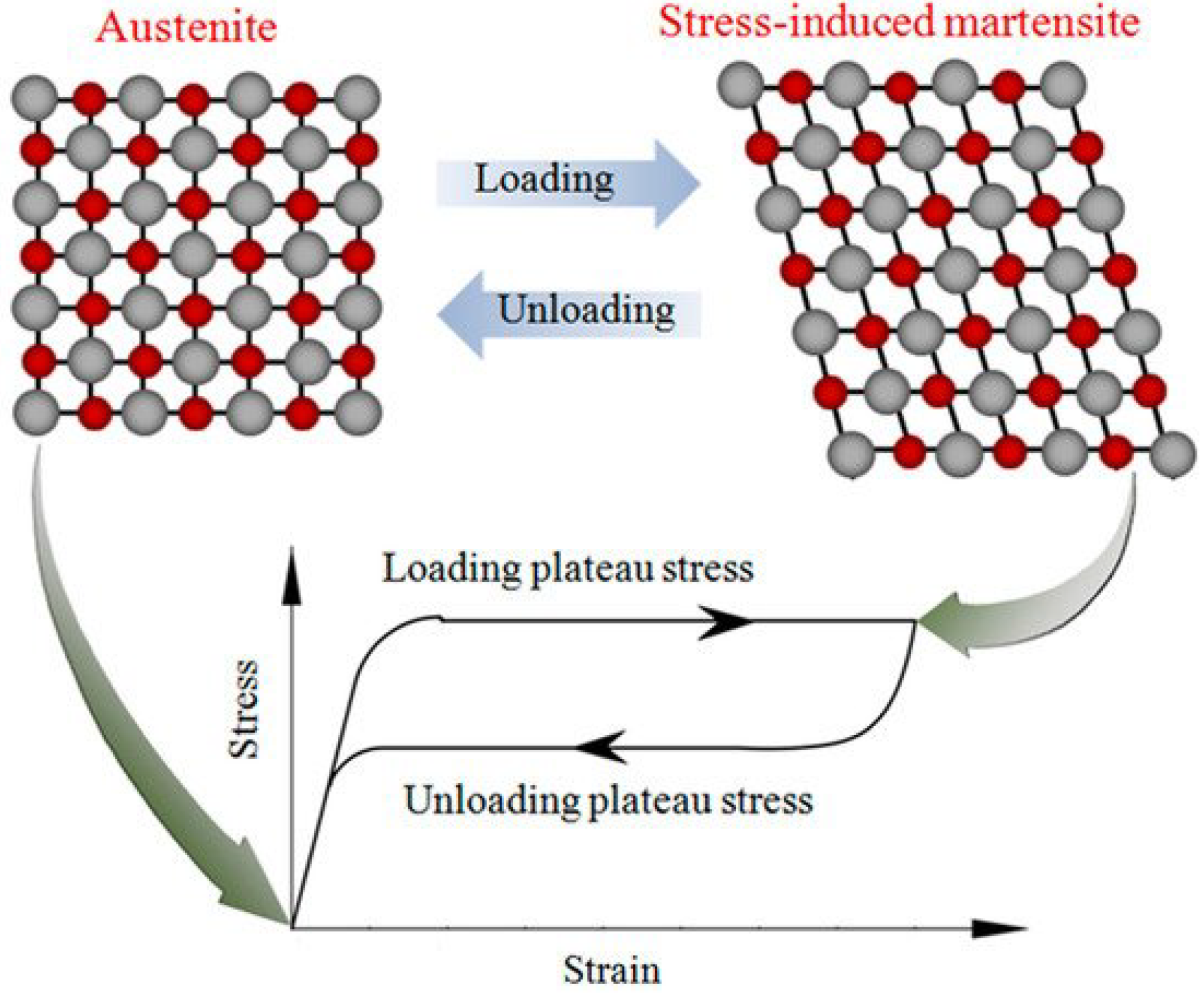

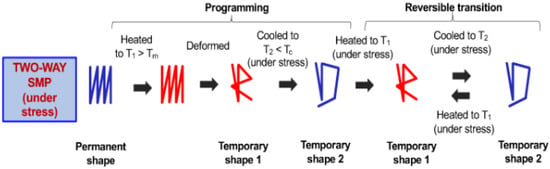

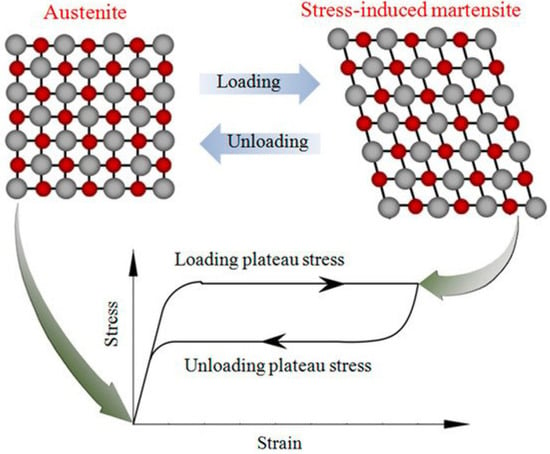

In this up-to-date overview, we will give a general summary of up-and-coming developments within the field of biorobotics, that lend themselves to innovating the manufacturing and research for artificial muscles. Biorobotics is an interdisciplinary form of science that combines the fields of biomedical cybernetics, macro, micro, and nanotechnological materials, and techniques to replicate human biological movement. Soft robotics is the specific science within biorobotics that utilizes soft materials and techniques to achieve its goals, these are generally much more lightweight and usually more elastic. Artificial muscles are comprised of actuators and other components that try to replicate the use of a natural muscle to try and mimic an organic muscle’s movement. Such as replicating its expansion, contraction, and rotation, and when used in tandem with one another can allow for other forms of movement from the device such as bending [1,2,3]. The recent work on artificial muscle components shows that these artificial muscles can range from the actuators that drive the muscles themselves being reiterated, to the carbon nanotubes (CNTs) and wires becoming easier to manufacture, allowing for more contributions within the field of artificial muscles. In recent years, artificial muscles have been compared to soft actuators but have many differences from conventional rigid actuators like pneumatic pistons and electric motors [3]. These comparisons to soft actuators are substantiated due to artificial muscles’ capability of generating actuation within a small device in response to external stimuli [3,4]. These external stimuli can take the form of electrical signals, magnetic fields, thermal energy, as well as pressure-based stimuli [3]. Artificial muscles have been attributed features such as the possibility of small-scale components such as the aforementioned CNTS and wires, and also having low stiffness to allow for greater flexibility [1,3,4]. Due to these features the soft robotics components and manufacturing naturally lend themselves well to the construction of artificial muscles, they also both generally require soft actuators and sensors [5,6]. In recent years though, we have had different takes on the individual actuators within artificial muscles such as ones based on pneumatic, ionic polymeric, dielectric elastomer (DE), micro piezoelectric, magnetic, shape memory alloys (SMAs), and shape memory polymers (SMPS) [3,7,8].

The goal of this overview of recent discoveries within the field of artificial muscles is to discuss and compare the previously used material and techniques in the manufacturing and design of the components within different forms of artificial muscles. In this overview, there will be an analysis and comparison of the preexisting manufacturing materials and techniques that will be compared to the most prevalent innovations in the field of artificial muscles by set criteria laid out systematically. The criteria used to identify what literature would be added and discussed within this paper was done so with two things in mind, the first was whether it was published within the last 4 years, and what its relevance to the main means of actuating, manufacturing, or design of artificial muscles was. More specific and emerging techniques for manufacturing, actuation, and design, while still discussed in this paper, were added to better explain the emerging innovations to the most well-known means of actuating artificial muscles. However, as a whole, this paper is more of an introductory look over the most popular means of actuation within the field of artificial muscle development, with a few examples of more nuanced and specific attempts at pushing this industry further.

2. Criteria to Compare

From the information researched, the reported criteria will be compared from previous iterations of components whether this is the thermal resistivity to the modulus of elasticity of the material and its manufacturing processes. Parameters that will be compared will not be limited to the output strain, output stress, output work, power density, catch state, actuation directionality, cycle life, efficiency, and finally bandwidth. The output strain (ε) is the length of excitation when normalized to the initial length. The output stress (σ) is then created force upon the excitation of the normalized initial cross-sectional area of the muscle at rest (σE) or when in its excited state (σT). Output work (W) is created when the muscle on actuation is normalized to the mass or volume of the artificial muscle. The power density (P) is the energy density normalized to the period of actuation. The catch state (or lock-up state) is when the actuator holds its actuation state without consuming energy. Actuation directionality is unidirectional and is the ability to continuously contract or expand in length, whereas bidirectionality is the ability to actively contract and expand such as Lorentz force actuators. Cycle life measures the number of cycles that an artificial muscle can actuate properly before failing. The efficiency (η) is the ratio of outwork work divided by the input energy, which can be things like the formation of electricity, thermal energy, or radiation accumulation. Finally, bandwidth is the range of frequencies that the actuator can actuate continuously. The comparisons of not only the materials but also the designs will be done to compare what benefits have been made to the components and designs of components within artificial muscles [9].

3. Innovation of Components

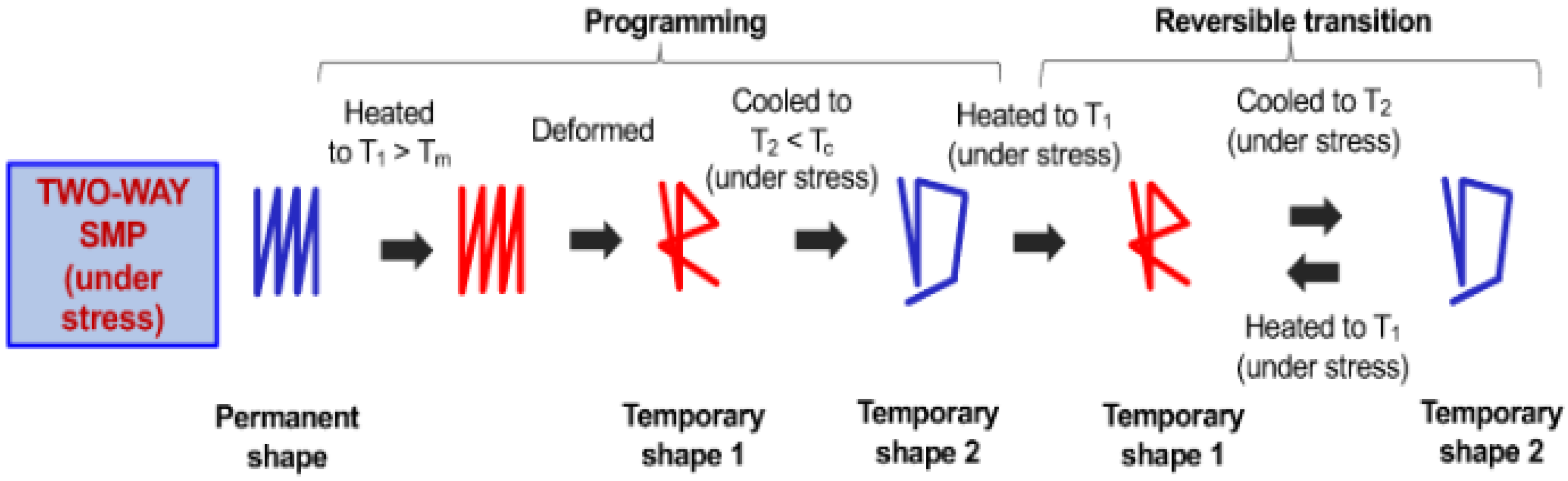

Within the 30 years of the artificial muscle industry booming, there has been an accumulation of many forms of actuation within artificial muscles, these are not limited to pneumatic, ionic polymeric, dielectric elastomer (DE), micro piezoelectric, magnetic, shape memory alloys (SMAs), and shape memory polymers (SMPS) [7,10]. The form of artificial muscles that use the means of pneumatic actuation uses many applications in the field of soft robotics, the materials for which are made of many different forms of elastomers such as polydimethylsiloxane (PDMS). PDMS is used in many forms of prototypes from academic to commercial use, due to its ease to mold as well as seal, and it has a shelf life of 3 years. However, in manufacturing for commercial use, there is a mixture of multiple structures that incorporate a number of separate elastomers with different mechanical properties that, while still flexible, are inextensible similar to paper or glass fiber as they would rip or break. These forms of materials have been increasingly used not only in the field of artificial muscles but used more generally within the entirety of soft robotics [10].

3.1. Paper-Thin Materials and Techniques for Them

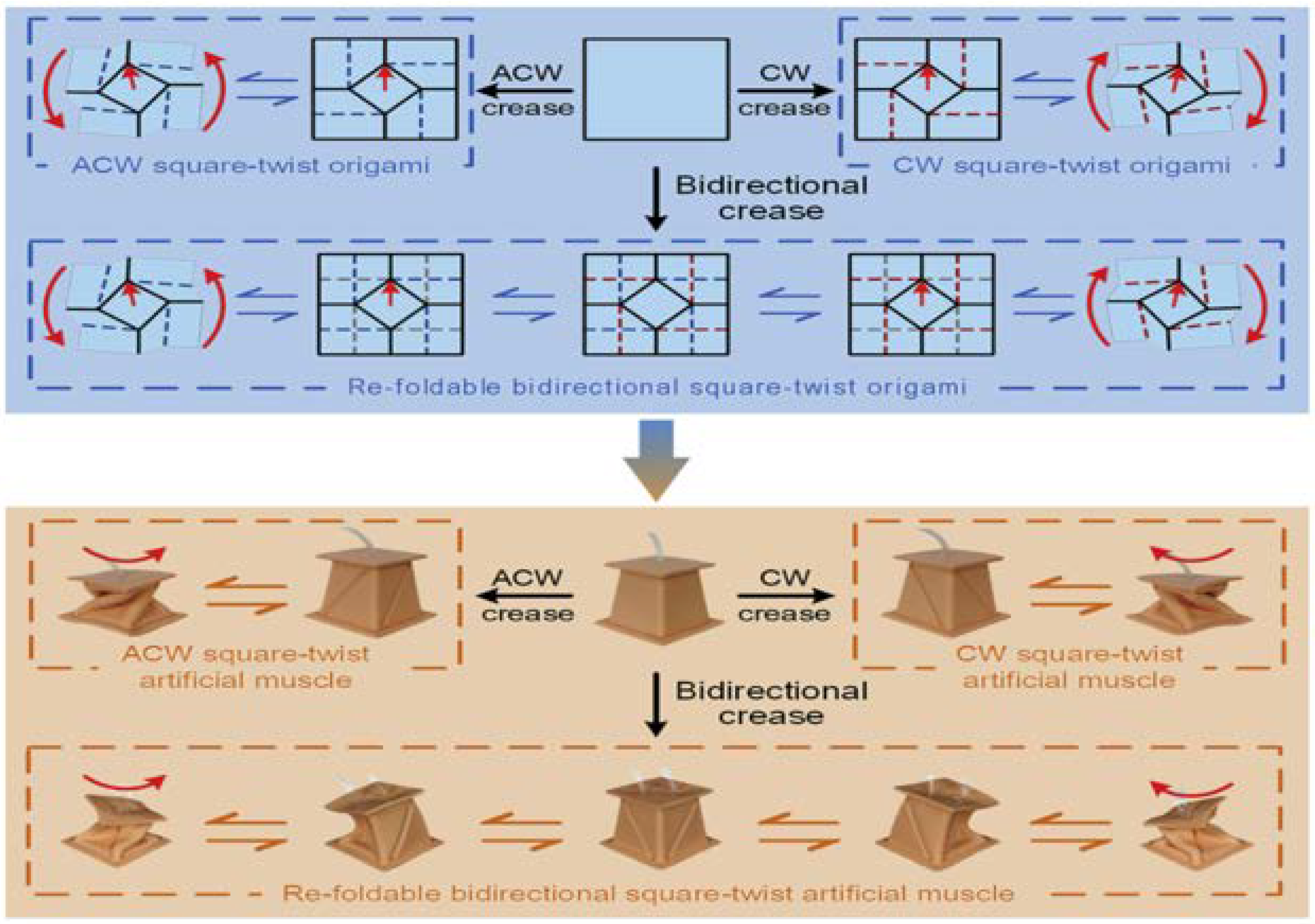

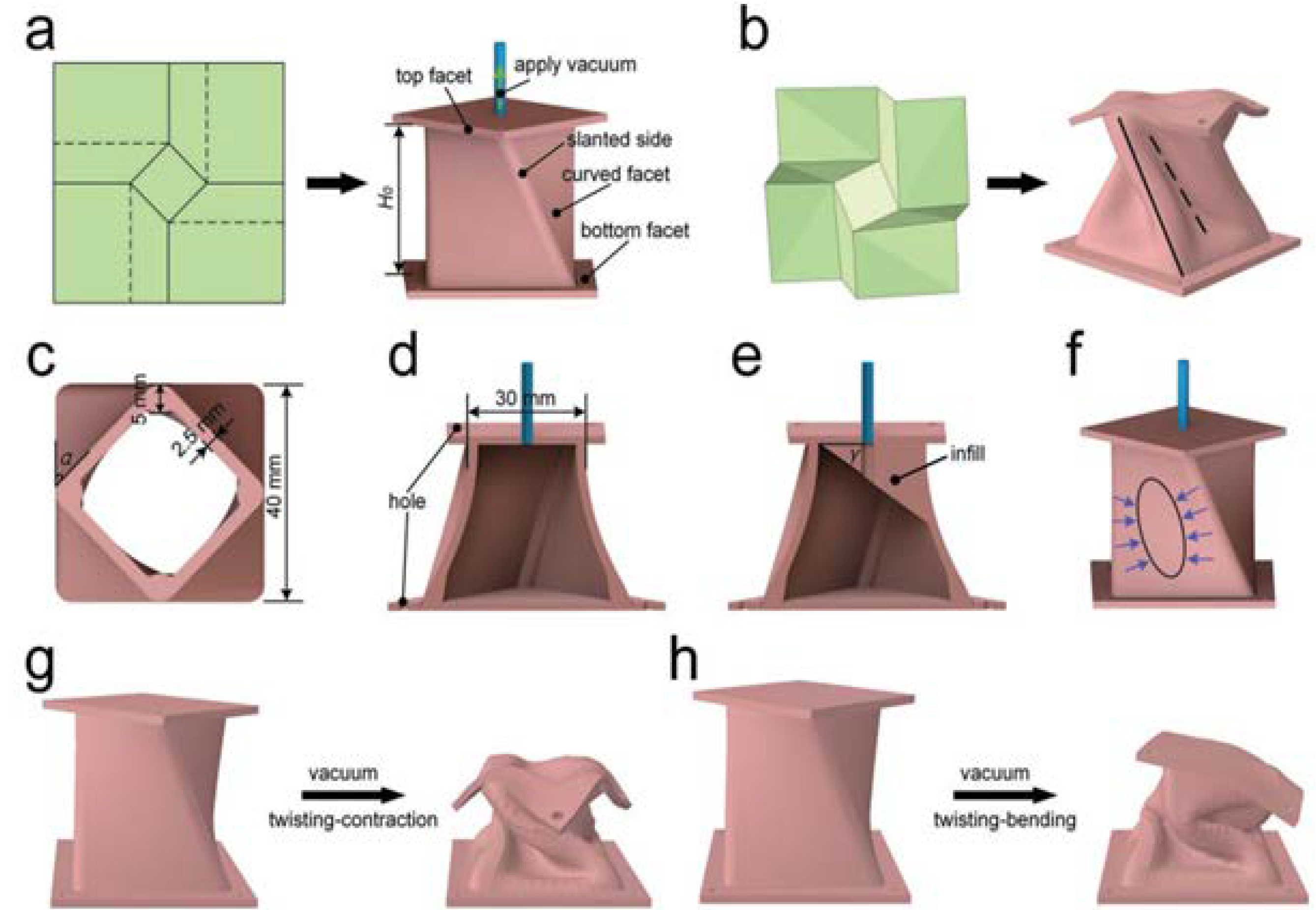

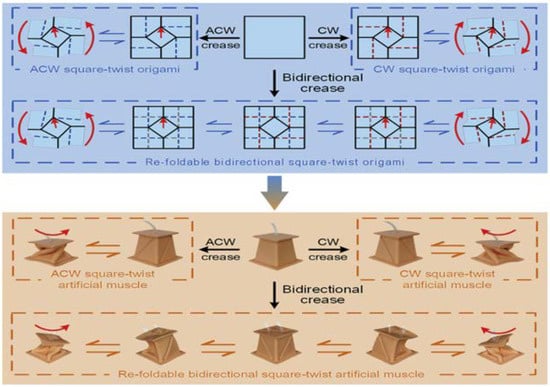

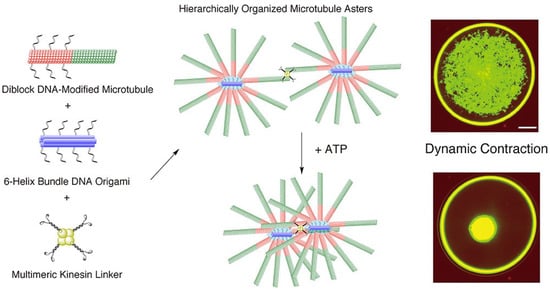

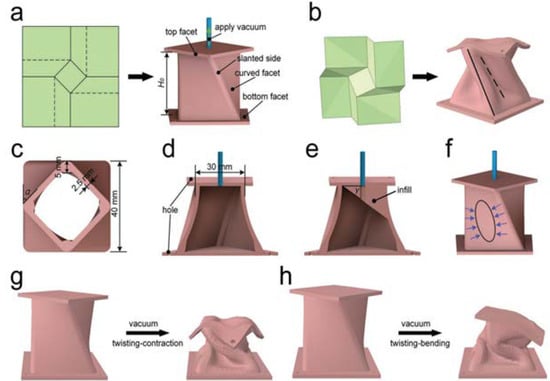

The major components within the soft systems of soft robotics are soft materials, things such as the aforementioned elastomers, and paper-thin materials, there are also fabrics, granules, foams, gels, liquids, and liquid crystals [10]. Paper-thin materials are considered any solid material that is between 0.05 and 0.10 mm (50,000 nm to 100,000 nm), this makes it comparable to the thickness of normal everyday paper. With the materials of flexible sheets and fabrics, it is important to note that for the future of soft robotics design in general that manufacturers will have stronger and more durable products if they have a better understanding of techniques such as origami and kirigami to allow for greater structural rigidity. The importance of structural rigidity will play an integral part in the future designs of artificial muscles, as it will allow for stronger and lighter exoskeletons and more importantly endoskeletons for protecting the internal components of actuation [10,11]. Even now there are advancements that allow for re-foldable square-twist artificial muscles, which were inspired by re-foldable square-twist origami. These can be demonstrated by using a pneumatic means of actuation by creating a vacuum on two chambers within a series sequence. When doing this it will allow for different twisting movements from the square-twisted artificial muscle and can allow for complex levels of motion such as twisting, bending, and contraction; the flexibility and fluidity allow for a greater mimicry of biological motion. They are able to emulate the movement of a hand grasping, bicep stretching and retracting, and bidirectional twisting of a wrist, neck, and ankle [12]. To better illustrate the range of movement, see Figure 1 below.

Figure 1.

The counterclockwise ACW and clockwise CW square twist are actuated by a vacuum. The section is an overhead view of what direction the vacuum is actuating on the example piece, whereas the orange section is an isometric view of what happened on the example piece as a result of the vacuum’s actuation (Reprinted with permission from Jiao et al. [12]. Copyright 2021, CC BY NC ND 4.0 International).

This same origami-inspired, collapsing deformation design was used in a study that demonstrated its use as a modular building block from which multiple classes of soft robotics can be assembled. Using a twisting-collapsing design and a twisting-bending design, Jiao’s team was able to assemble a quadruped robot, a soft gripper, a pipe-climbing robot, and a flexible robot wrist. All of these devices were created with different configurations of the same two collapsing origami designs, using different methods of attachment and arrangements to achieve each of the fully capable designs [13]. The purpose of this modularity is for soft robots being used in real-world situations to be able to easily adapt to various tasks that a robot may be needed for [8,13,14,15]. Other attempts utilizing origami and kirigami techniques went an external thermal stimuli route of actuating their assembly, they used a fiber that when actuated in its heat channels would create reversible movement of that emulating human fingers. The fiber used would expand and contract reversibly when exposed to thermal stimuli and the transmitted movement from these guiding fibers would act like tendons within a hand to guide their hand assembly [11].

These materials go hand in hand with previously discussed manufacturing techniques such as PDMS elastomers which are structural materials that make the fabrication of prototyping for more than just structural integrity but other useful enduring attributes as well. These include things such as being transparent, PDMS is easy to sterilize, as well biocompatibility with many components. Other important techniques that have not been previously discussed are the use of soft lithography and microfluidics, which allow for greater stability and freedom for creating pneumatic and hydraulic channels within the field of microtechnology, and soft robotics. There are also soft material composites that generate and allow for control anisotropically during the actuation of soft robotics [10].

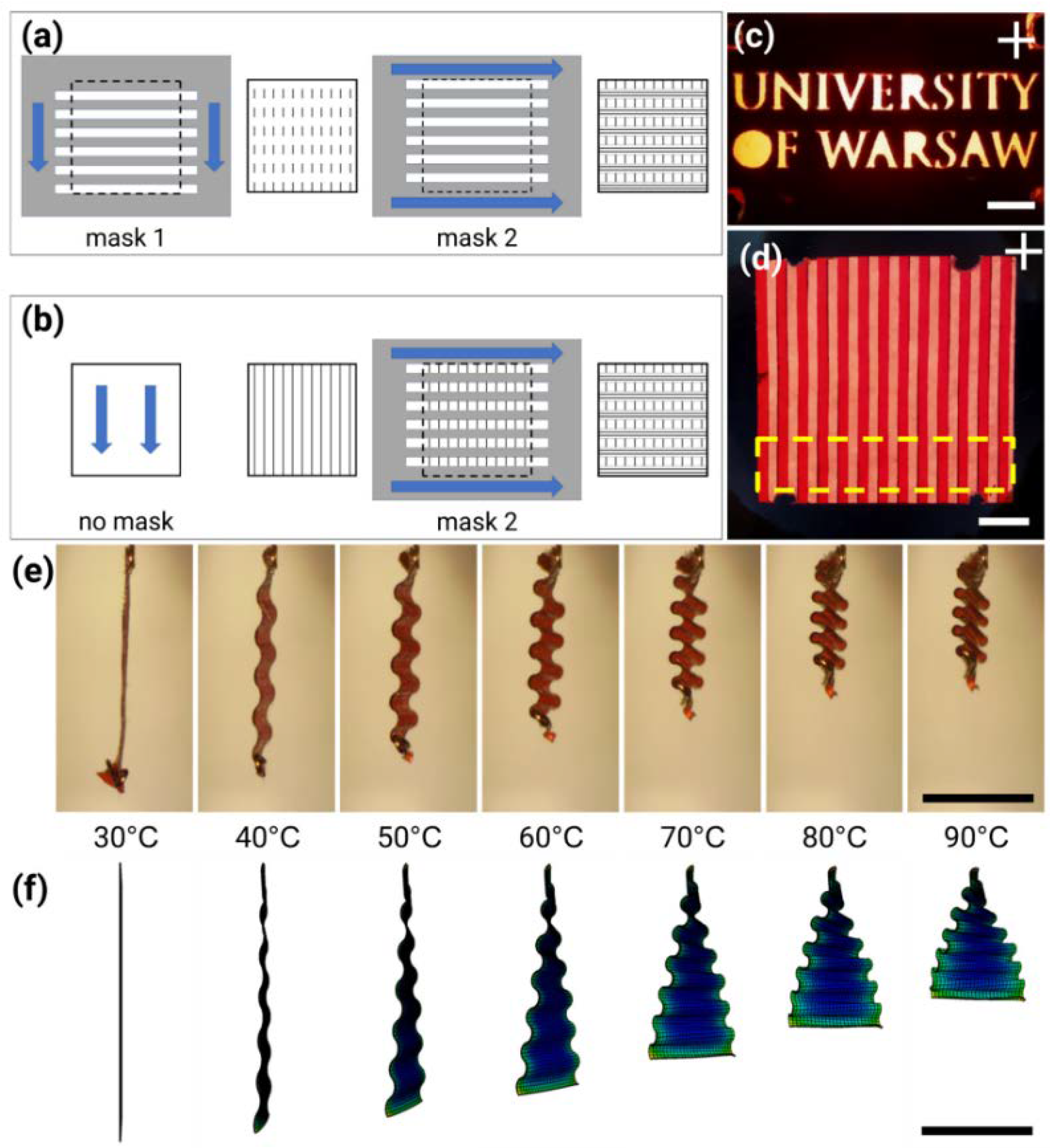

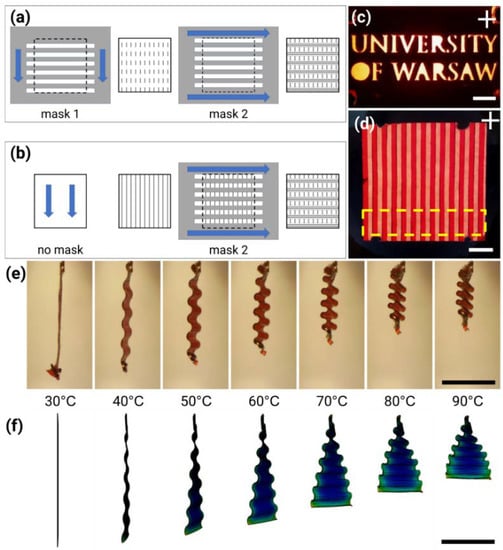

3.2. Liquid Crystal Polymers and Elastomers

The other mentioned forms of elastomers are liquid and liquid crystal materials, these are used to create materials like liquid crystal polymers (LCPs), and liquid crystal elastomers (LCEs). LCPs are a material choice for artificial muscle assemblies as they exhibit macroscopic shape change as a result of liquid crystal-isotropic and order-disorder phase transition of mesogens. The phase transitions of these mesogens are a part of the polymer structure within either main or side groups, actuators that utilize LCP are applied in the form of cross-linked networks, which can be triggered by various stimuli such as thermally, change in humidity, can be actuated by light, and can be electrically actuated as well [16]. The LCEs instead allow for reversible shape changing when cycled above and below their nematic-to-isotropic transition temperature (). This actuated shape can be locked in from high-temperature UV exposure, and by synthesizing LCE-based inks in tandem with light-triggerable dynamic bonds, the printing of which can be controlled locally to program their directing alignment and UV light intensity [17,18]. This control of UV light and alignment will enable control over network configurations without an imposed mechanical field stimulus [17]. There have been recent efforts to apply infrared dye on one side of a cross-linked monodomain, the other object is a cross-linked polydomain, along the thicknesses would have these behave like a photo actuator without the need for support. This would be accomplished by having a flat strip with two ends affixed to the substrate surface, which forms a moving bump under laser scanning, this would allow for a light-powered converter to transport objects. Curing off the bump and putting it under the laser scanner will show that it created a soft, flexible, millimeter-scale crawler that can only move straight back and forward and can allow for climbing along an inclined surface. However, this can also undergo light-guided turning left or right when combined with out-of-plane and in-plane actuation [19]. Other LCEs recently are looking at using electricity for their external stimuli, things such as traditional tubular actuators can help exhibit their capability for multidirectional bending [20].

3.3. Artificial Skin and Fabrics

When talking about artificial muscles something that may go overlooked is the artificial skin used to help add even more durability to the assembly itself. Now there are tubular biomimetic skins that are intended for use on biorobotics. Their compliant skin is constructed from iron rings and water-resistant, polyester fabric. The final product is a flexible skin tube that can bend up to 90° in any direction. The structural integrity of the skin comes from the iron rings of descending radii. These rigid iron rings have partial overlap, completely protecting whatever robotic device could be inside. Even during bending and movement, the rings never allow any significant gaps. With the hard, protective properties of the iron rings, the water, and debris-tight nature of the polyester wrap, and the unbound structure of the rings, this skin can provide incredible protection for a biorobotic device while still allowing functional deformation [21].

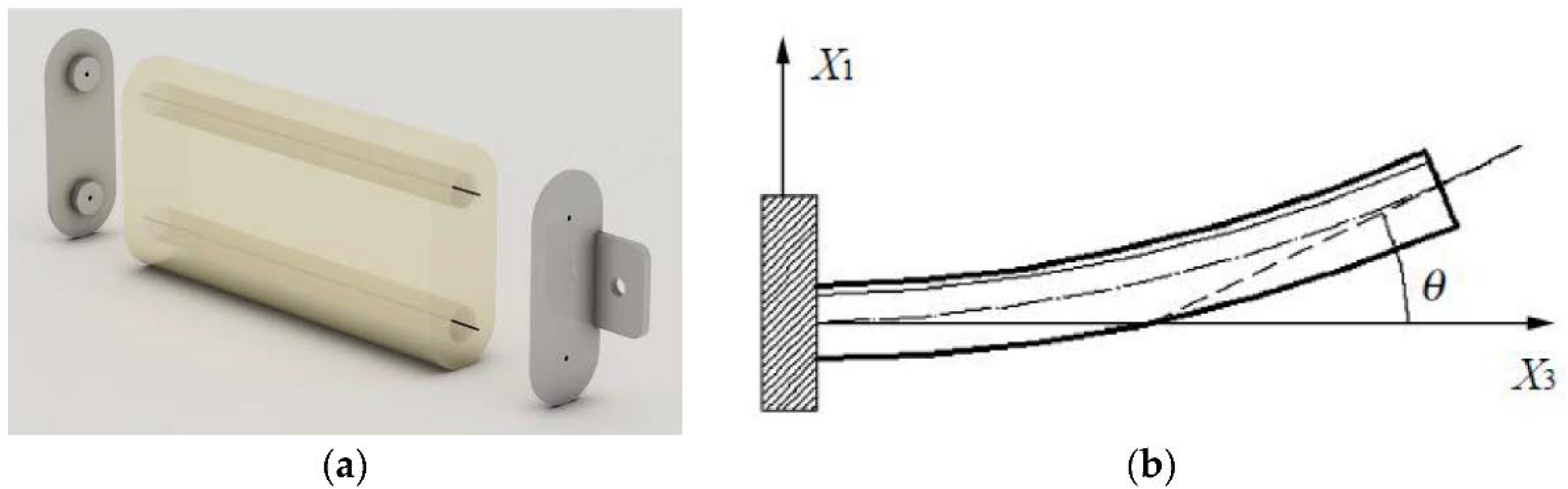

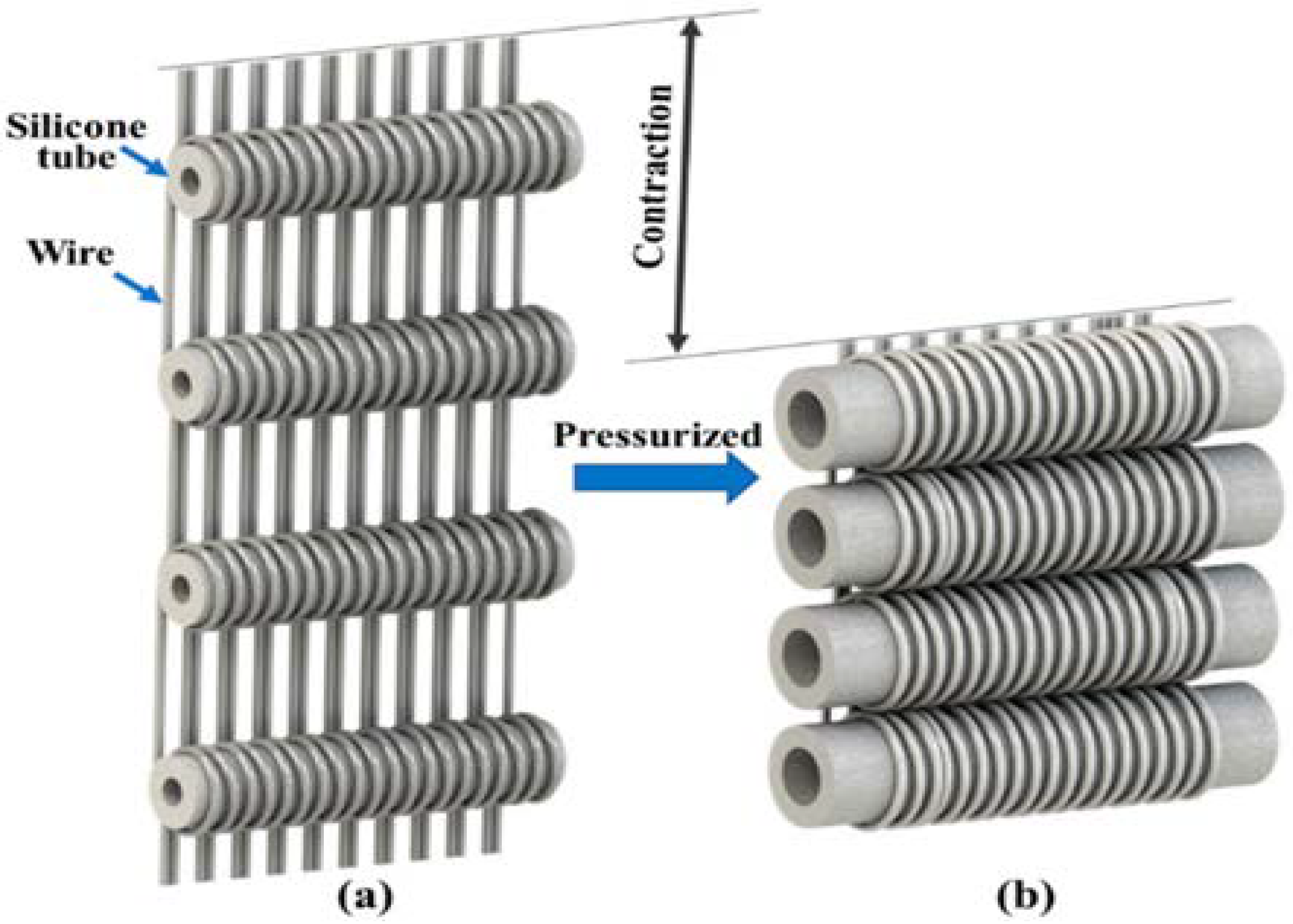

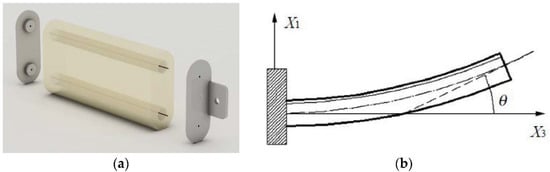

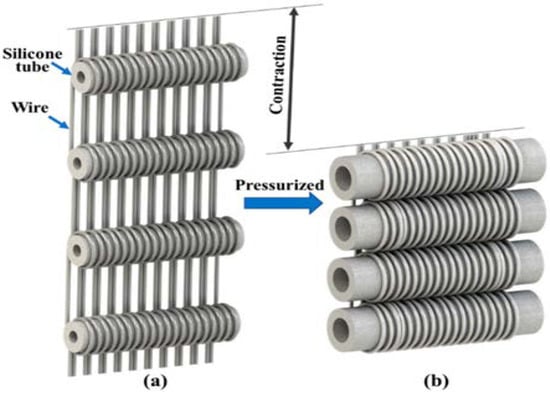

Another branch of artificial muscles that has been developing in recent years is the use of robotic fabrics, these allow for reconfigurable tools that can change passive structures into active robotics from surface-induced deformations. Due to this flexibility of actuation and reconfiguration capability, there has not been a proper time to create empirical models for every single possible configuration, as well as materials that could be used within these robotic fabrics. Robotic fabrics in greater detail allow for sensing and actuating elements within a fabric substrate, these can be wrapped around soft passive bodies such as elastomers, foams, and tensegrity structures. From these soft passive bodies, the fabric substrate surrounds allow for the robotic fabric to impart motion onto the bodies it encompasses. Many of the later topics within this paper refer to both sensors and actuation for artificial muscles, and yet there have been those who have created fabrics to do it in one small package [22,23]. When searching for different means of actuation from these robotic fabrics, you can reorient the fabric on different surfaces and bodies that have different properties, which will allow for a different range of motions [11]. Previous attempts for this were sleeves that had sensing capabilities, others were things such as variable stiffness actuating fibers, which is similar to the goal of fibers and rigid materials for helping with actuating artificial muscles [22,23,24]. Recently, there have been past attempts for this sensing and actuating robotic fabric, but past attempts would not suffice as they were unable to quantitatively estimate the system state [22,23]. The current iteration of this robotic fabric present is one that has conductive composite-based capacitive sensors with pneumatic McKibben actuators [9]. As previously mentioned in this section, the robotic fabric is surrounding a passive cylindrical body that will create continuum joints, they also allow for the estimation of the current state and stiffness of the cylinder body while the fabric is actuating. The significance of the robotic fabric being able to sense and transmit that data is important as finding out which form of soft passive body to house the robotic fabric requires countless amounts of trial and error. This is due to this technology being so new and a lack of information on how it will react to many soft bodies, so the ability to know as soon as you put it on the housing body saves much more time and effort in between trials. They propose that this can one day allow for system models that benefit from feedforward soft-bodied controlled approaches as well. Their robotic fabric system consists of the robotic fabric with parallel actuators and sensors which are wrapped around a deformable cylindrical body, when the actuator contracts it causes the cylindrical body to curve and deform [22]. An example of their work in action can be seen in Figure 2.

Figure 2.

(a) is an example of the sensor placement along the soft cylindrical body, these sensors are placed at even intervals to align with the x and y axes. The locations of the sensors would be on the opposite side of other sensors in this example, which would have them all around the cylinder. (b) is a schematic of a constant curvature beam on the cylindrical body itself (Reprinted with permission from Liu, M. et al. [25]. Copyright 2021, CC BY 4.0 International).

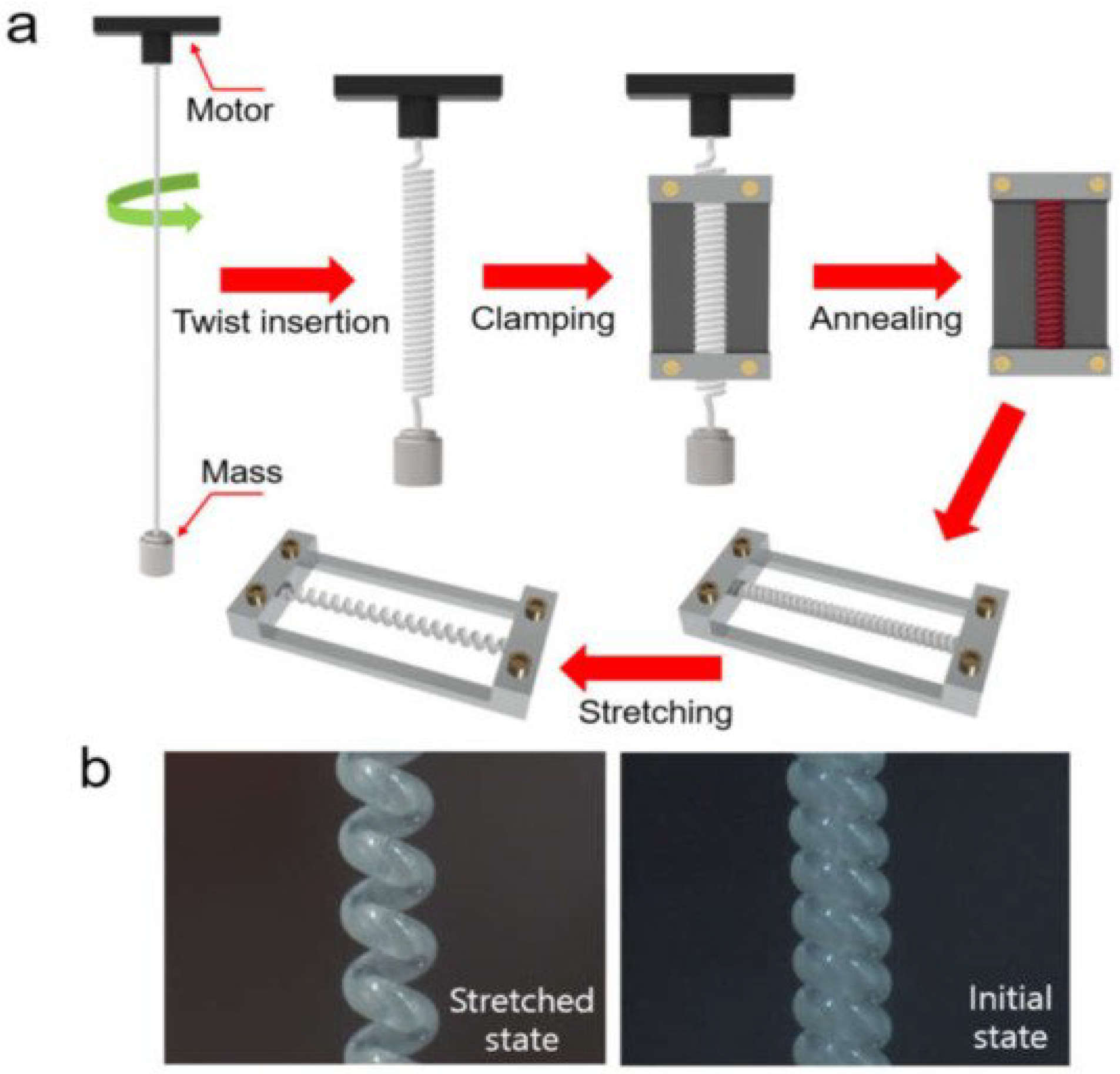

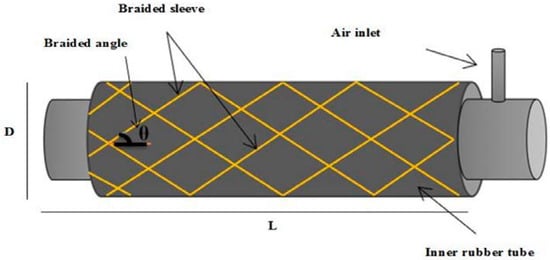

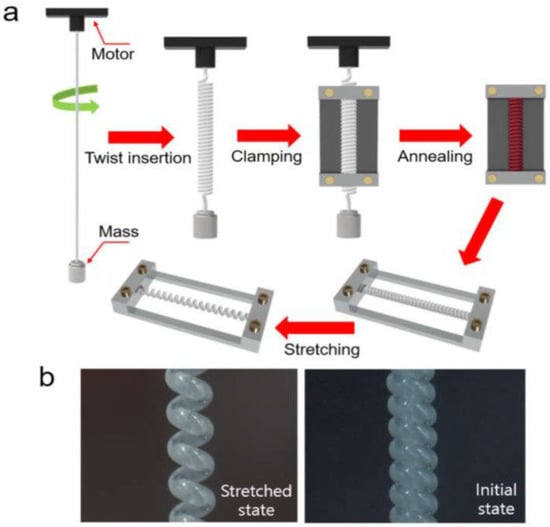

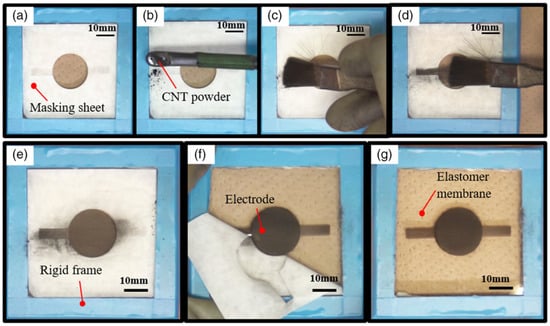

More prominently, fibers are twisted to the point that their polymer chain morphology is altered to set the fiber in a permanent spiral. From this state, they can be actuated to cause a variety of movements including, but not limited to, expansion, contraction, rotation, and bending. Using this as the basic foundation, many new innovations and developments have ensued. On the materials and components side, fibers being used include nylon, PVA, PE, carbon nanotube yarns, graphene, NiTi, graphene oxide, and silk. On the actuating side, researchers have had success with thermal, electro-chemical, electro-chemical with solvent, solvent-based, and photo-responsive actuation methods [26]. One type of twisted fiber that has found much interest within the field of biorobotics is carbon nanotubes (CNTs) which are used within hybrid yarn artificial muscles (HYAMs) [27,28]. These involve the twisting and coiling of a CNT yarn made with filler non-CNT fibers inserted into it, the end state is described as being “guest-filled” [28]. Then, the method of actuation can be changed depending on what the guest material is, and as a result, this is believed to reduce the amount of input voltage for things like dielectric elastomer’s high-voltage actuation requirements [27,28]. One team sought to find a new method of yarn creation that could yield competitive results without using CNT at all, as CNT is expensive. Instead of a guest-host structure, the central yarn is encased in a polymer, similar to how electrical wires have their insulation. The dimensional and modulus changes of this coating, or “sheath” as they call it, are what cause actuation. They named this model sheath-run artificial muscles (SRAM) [28].

Other recent applications of CNTs have been taking steps forward in eliminating humans from workspaces that have microwave radiation waves (MRW), which are electromagnetic radiofrequency waves. These MRW affect humans’ long-term health with issues such as central nervous system issues, sleep disorders, as well as learning capability, and can impair memory. Replacing people with controlled or automated robotics in these MRW avoids these inherent complications for these professionals and helps to save money and lives. There are issues overcoming these MRW environments, things such as traditional motors and linear metal actuators do not work effectively within them, this is because the metal materials have a highly reflective property with microwaves which can cause serious fire hazards. The field of biorobotics applies well to this issue as there are many alternative materials for actuating these motors without the use of purely metallic properties, and instead have a myriad of polymer-based soft actuators to choose from. The MWR and artificial muscle framework blend together well as the MWR has powered passive heating which the artificial muscle actuators can take advantage of as their external stimuli to actuate their assemblies. This detail will allow for a large amount of freedom for the types of applications artificial muscles can have in MWR-affected areas, from things like pre-programmed to autonomous repetitious applications. There are also inherent advantages when using artificial muscles in combination with MWR-affected areas, things such as better energy efficiency, longer penetration depths from heat into materials, and can also lower power costs overall. The way to specifically actuate an artificial muscle with an MWR external stimuli is that the heat produced from the MWR can be triggered with unshielded zones within the affected area. This can be concentrated and controlled with a waveguide which is powered by a solid-state microwave source, the issue with this is that many conventional polymers cannot properly shield this MWR effectively. This is where the CNT comes into play, these are exceptional at MWR absorption, so many of the polymers attempting this use a mixture of CNTs within their specific polymer’s composites, the reason is that their MWR reflection is a much smaller proportion to many other materials [29].

3.4. Rigid Materials and Techniques for Variability

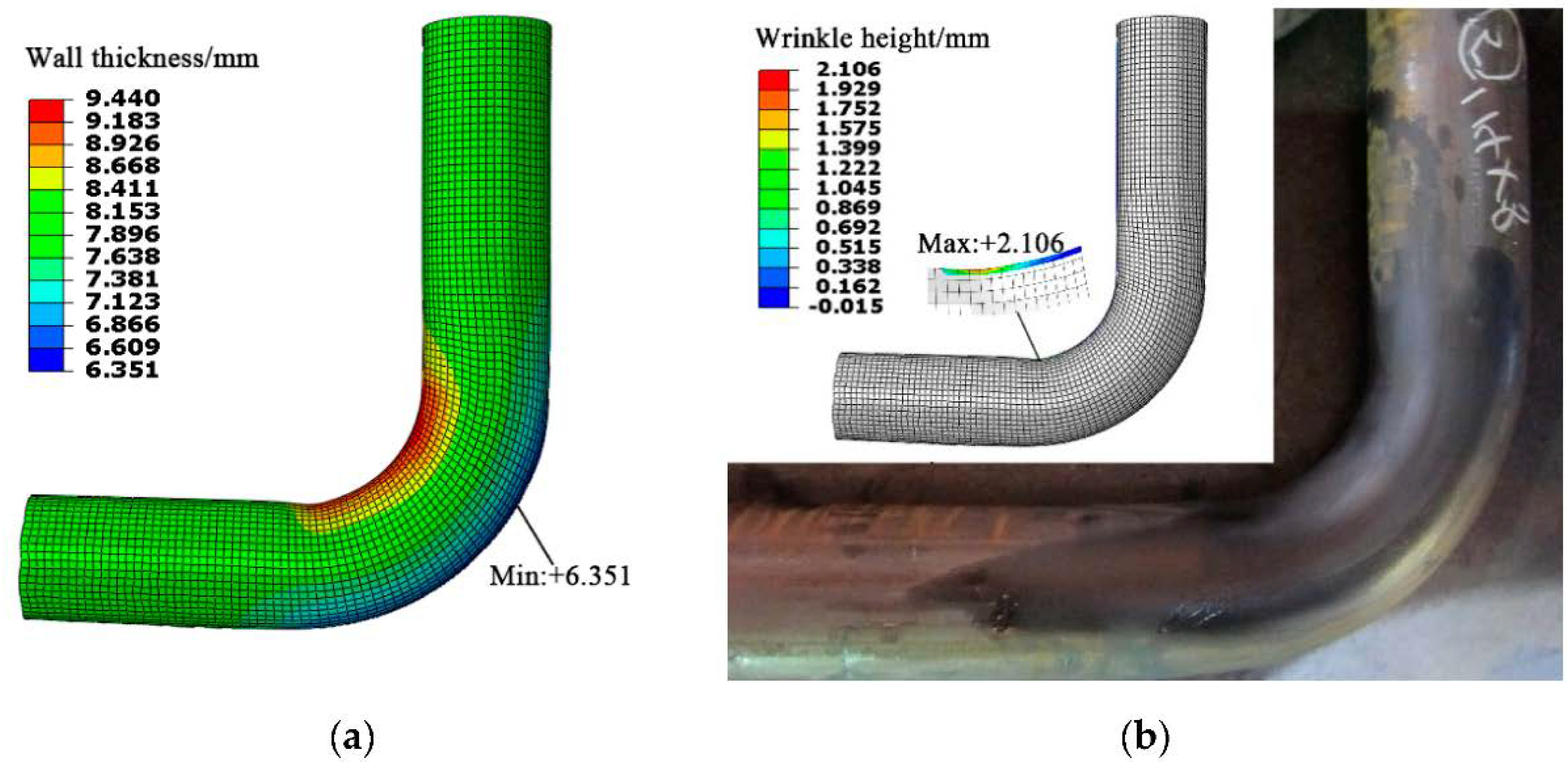

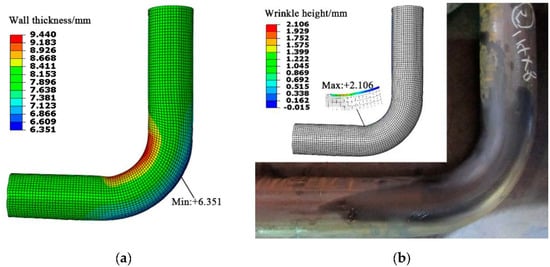

An important type of component within artificial muscles is the rigid materials that can help support the linear displacement of most actuators, these, while accurate and stable, also allow for rigid members to be connected with joints [30]. In recent years research has shown that soft and deformable support structures outperform these rigid joint-based assemblies, as there is a challenge to maintain flexibility while keeping durability within soft robotic assemblies [4,14,30]. As a result of this discovery, engineers have been inspired to design more compliant components that can have better control over actuation and have varied stiffness [14,30]. This varied stiffness can be invaluable to such assemblies utilizing joints to help actively soften and adapt to a wide range of tasks [2,8,15,30]. Other benefits of variable stiffness can allow for adaptive vibration damping, and mechanical modulation of cell growth, and are universally useful for things such as orthopedic casts, customized seats, and adaptive aerodynamic surfaces [15,24,30,31]. There have been attempts at variable stiffness already with such efforts as jamming granular materials which are thin sheets, this is activated when a vacuum is applied. This in turn increases the relative shear stress experienced by the particles within the elastic membranes, which increases the stiffness without a large volume change. The problem with this approach is the sheer volume of granular material needed to achieve this higher stiffness, so while not really applicable for the tiny compact designs of actuators within artificial muscles, this is highly useful for large-surface robots. There have been other attempts such as continuum flexible manipulators (CFMs), which utilize a rigid translational tube that partially restricts the bending of the flexible section. The issue with the CFM approach is that it will only allow for bending at one single position along this assembly and will require an additional actuator for the tube to move properly. This paper [30] proposes that to solve all of these issues, they will create a method that is cost-effective, compact, and can exploit the inherent thermoplastic property. They also want to take advantage of the Joule heating capability for the printed material without additional elements for stiffness variability and help with the application of shape modulation for soft actuators. This approach they present uses the conductive polylactic acid (CPLA) material, which can be readily printed with a fused deposition modeling (FDM) 3D printer. The naturally conductive attribute of CPLA lends itself to thermal activation through the aforementioned Joule heating, as a result, the CPLA shows a 98.6% reduction of young’s modulus, which dropped from 1 GPa (at 25 °C) to 13.6 MPa (at 80 °C). This result can be completely reversed back to its initial rest state by being cooled back to room temperature (25 °C). CPLA has a glass transition temperature of 55 °C, which is 60% of the value at its rest state at 25 °C. An example is shown how CPLA can be used to modulate and control stiffness as well as the bending shape for a soft pneumatic actuator is started when the CPLA layer is bonded to the flat side of a soft pneumatic actuator. At room temperature due to the stiffness at the rest state for CPLA the soft pneumatic actuator will not bend when pressure is applied, then when Joule heating activates at a specific place on the CPLA the material around that area softens and begins to bend, this allows for that area eventually can be controlled with the Joule heating to create an effective joint or hinge. This overall bending shape from the actuator can be controlled by tuning the CPLA temperature at different locations, but the soft pneumatic actuator can only bend at these determined heated zones due to their now lower stiffness [30]. This is all illustrated in Figure 3.

Figure 3.

(a) represents a render of the CPLA component undergoing thermal application measuring its specific levels of thermal energy at different points along it. Where there is a higher thermal measurement at a specific point along the CPLA is represented by the lighter color with red being the hottest, at the point seen it has created a bend in this CPLA material. (b) is what the material actually looks like now as a result of the thermal application due to the concentration of Joule heating (Reprinted with permission from Bai, L. et al. [32]. Copyright 2021, CC BY 4.0 International).

3.5. Soft Robotic Grippers

In the field of biorobotics, all of the previously mentioned soft, adaptive, and durable materials allow for the creation of soft robots that have a higher level of flexibility and compliance than traditional rigid robots [15,33,34]. Recent research has shown that due to these innovations in materials and actuators, soft robotic grippers will be able to handle objects of various shapes and dimensions that could be incredibly fragile [33]. From this research, more and more have tried to create a soft robotic gripper that can allow for adaptive grasping, that could mimic the level of control and speed of a human hand, and due to this goal, it has been incredibly beneficial to the artificial muscle industry. Before these innovations, the issue was that with rigid grippers there were very few clues to figure out the contact forces without adding sensors, which could heavily increase the weight and cost of these incredibly small biorobotic assemblies. Another issue that lends itself to the rigid robotic model was that compliance and stiffness control of these rigid grippers require other increasingly heavy and complex elastic-actuation element arrangements [33,34]. The soft robotic gripper, in contrast to the rigid robotics alternative, is that the soft robotic grippers are naturally compliant and adaptive to their environments [15,33]. These soft robotic grippers distribute contact forces and can allow for grasping without the need for an actuator’s control-based sensor assemblies, which reduces complexity and weight and directly affects the overall efficiency and cost of the artificial muscle [4,33]. Due to all these attributes, the soft robotic grippers are capable of compliant grasping, and due to the finger’s conformity, it increases the grip quality while the stiffness control is activated to help lock and maintain the finger’s given deformation [33].

The previous attempts of these innovative soft robotic grippers throughout the last several years have employed things such as SMAs and variable fluid viscosity to help achieve variable stiffness. These creators used DE in combination with low-melting-point alloy to allow for the creation of a variable stiffness gripper. Similar attempts of the aforementioned proposed a way to achieve a variable stiffness gripper that had a built-in position feedback system, the issue though was that there was little bandwidth for these thermally activated materials, and these grippers had a limited amount of dynamic stiffness control performance. On top of that, the previously proposed DE example required too high of an operating voltage and would have low efficiency due to needing heating and cooling for the associated energy gain and losses. Other attempts included a layer jamming that would be induced to allow for an active vacuum adhesion gripper, this would be able to lift flat and concave or convex-shaped objects. This would have a particle pack that would act like a stiffness-changeable gripper but would be susceptible to membrane damages. One other attempt was done to create a 3D printed soft gripper that combined negative and positive pressures to help control and vary its stiffness. An intriguing attempt was done where a soft robotic gripper had allowed for portions of its soft fingers to inflate to help maintain and vary its stiffness control. Due to being monolithic, their force output made them suitable for small-scale applications which could prove to be incredibly useful in the future innovations to come in the field of biorobotics [33]. One attempt at these soft robotic grippers uses something that is discussed later in this paper, is that there is a design that utilizes antagonistic pneumatic muscle actuators to help achieve a dissociated shape as well as the stiffness variation [33,35]. An important attempt within the field of biorobotics is those of the pneumatic actuated soft robotic grippers, as they lend themselves well to the adaptive and decoupled stiffness variability needed to control artificial muscles [31,33,35]. This would also allow the soft fingers of said pneumatic actuated gripper to utilize their length constraining mechanisms to allow for structural integrity and maintain stiffness control. The key, as mentioned briefly from other attempts at this soft robotic gripper, is that it is important to maintain as monolithic-like design as possible, the less complex the gripper’s assembly is, the more weight it reduces and the cost it saves. These pneumatic actuated soft grippers have fingers that combine articulated length constraining mechanisms and pneumatic actuated muscles to create and maintain stiffness control which can be used for stronger grips without losing on its gripper’s compliance. The length constraining mechanisms have been described as that of the highly compliant tails of the spider monkey, this is because their tails can function as a gripper as itself grasping from branch to branch. The spider monkey tail has a muscular lining that allows for the actuation of its skeletal structure which includes the backbone. The spider monkey’s backbone is similar to our length constraining mechanism, which when actuates its muscular lining underneath its backbone to help comply with its desired structural shape and stiffness. This is how the length constrained mechanism allows for compliance, this is where the pneumatic actuated muscle activates the length constrained mechanism to maintain and manipulate itself into whatever desired orientation may be needed at a given moment and maintain its stiffness for a strong grasp on the object [33].

From this prototype, there were two main components, the articulated length constraining mechanism, as well as the pneumatic actuated muscles. The particular length constraining mechanism from this prototype’s muscles that had been used were ones that had high individual tensile strength plastic units that were assembled to form an articulated kinematic chain. These individual plastic units were connected with ball-and-socket links that allowed for free movement in many directions; they 3D printed these same units for the purposes of testing. However, after creating them time and time again, they resorted to going for the official product instead as it was too complex for them to 3D print over and over again. After this decision, they anchored pneumatic actuated muscles to the ends of the length constrainer using the 3D printed anchors. They custom-made extension-mode pneumatic-actuated muscles that were able to sustain pressure up to 700 kPa and extend by up to 50% [33].

The proposed soft robotic gripper has three soft fingers that were in a symmetrical tri-fingered configuration to offer much more flexibility as well as versatility when handling variable-sized and shaped objects. These fingers were attached to the CAD 3D printed base unit. In the individual fingers, there are three pneumatic actuated muscles, two of the three would be actuated simultaneously which resulted in two effective degrees of freedom per finger. Due to these two degrees of freedom, this allowed for bidirectional bending using pneumatic actuated muscles in an antagonistic arrangement. It also allowed for a stronger gripper force generation from the simultaneous actuation of the two pneumatic actuated muscles, which would create twice as much torque as a result. Then all of this would culminate to achieve control over the stiffness from the remaining pneumatic actuated muscle in the unused finger [33].

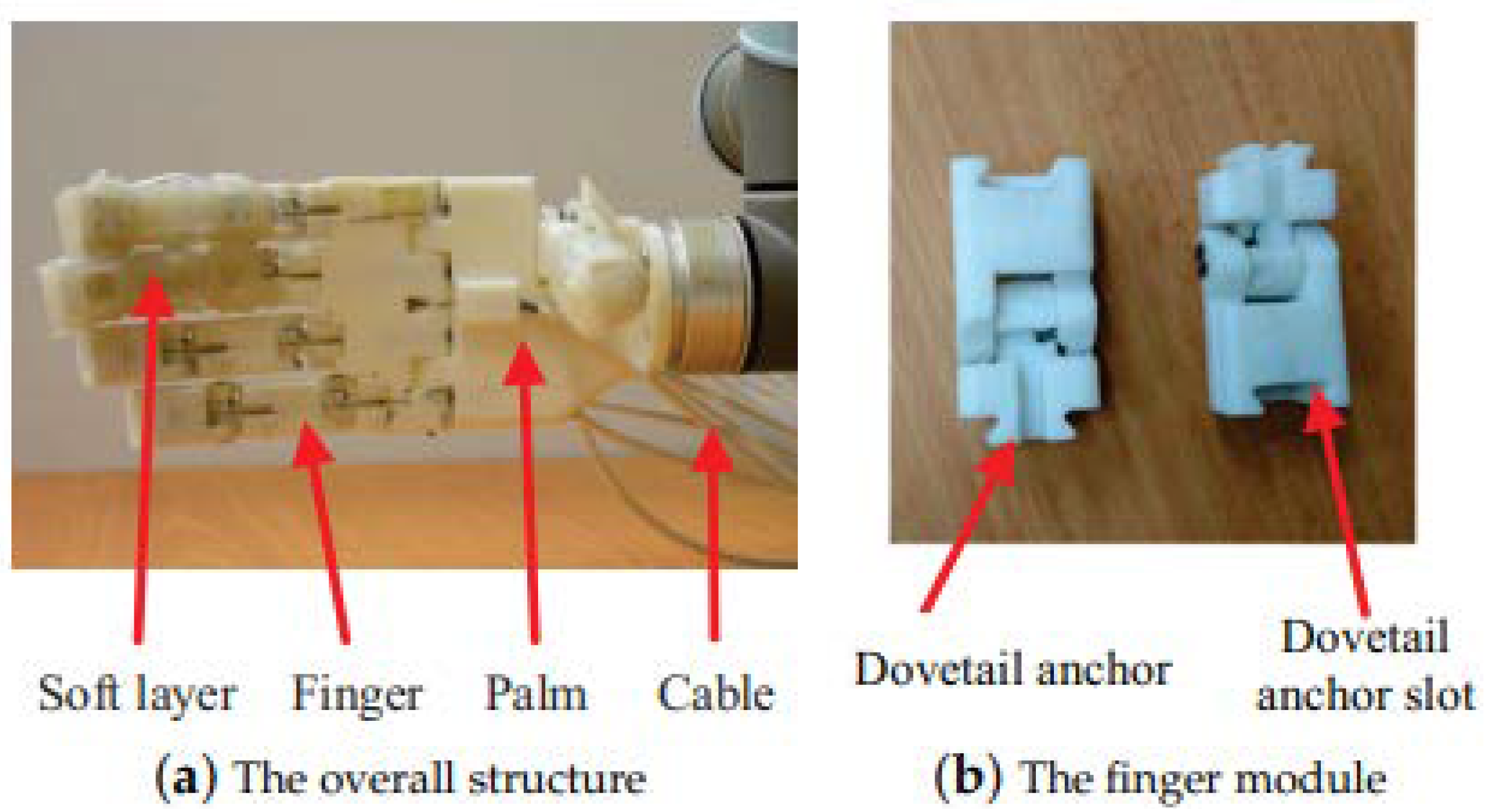

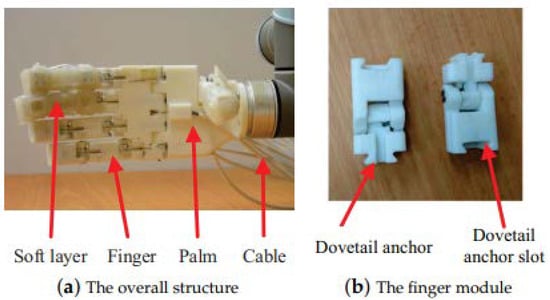

Going even further into the examples of soft robotic grippers is the work in [36], which is a bimanual teleoperated pair of full robotic arms and five-fingered grippers. This can be seen in Figure 4.

Figure 4.

(a) shows the composition of the hand assembly, which is comprised of a soft layer for the index, thumb, and middle finger. (b) shows the way that the interconnected joints of the finger assembly connect to one another with dovetail anchor plugs and sockets (Reprinted with permission from Zhu, G. et al. [36]. Copyright 2020, CC BY 4.0 International).

Teleoperation is composed of a human operator with master devices that utilize and control communication channels and slave robots. This master device physically connects with a human operator, and the control commands are generated from this master device and through the communication channels are sent to the slave robots which ultimately carry out the desired movement and command. There is an interaction force between the slave robot’s perception of its environment which is then sent back to the master device. The slave robot would have its position and orientation acquired rather from the visual perception of the human operator [36].

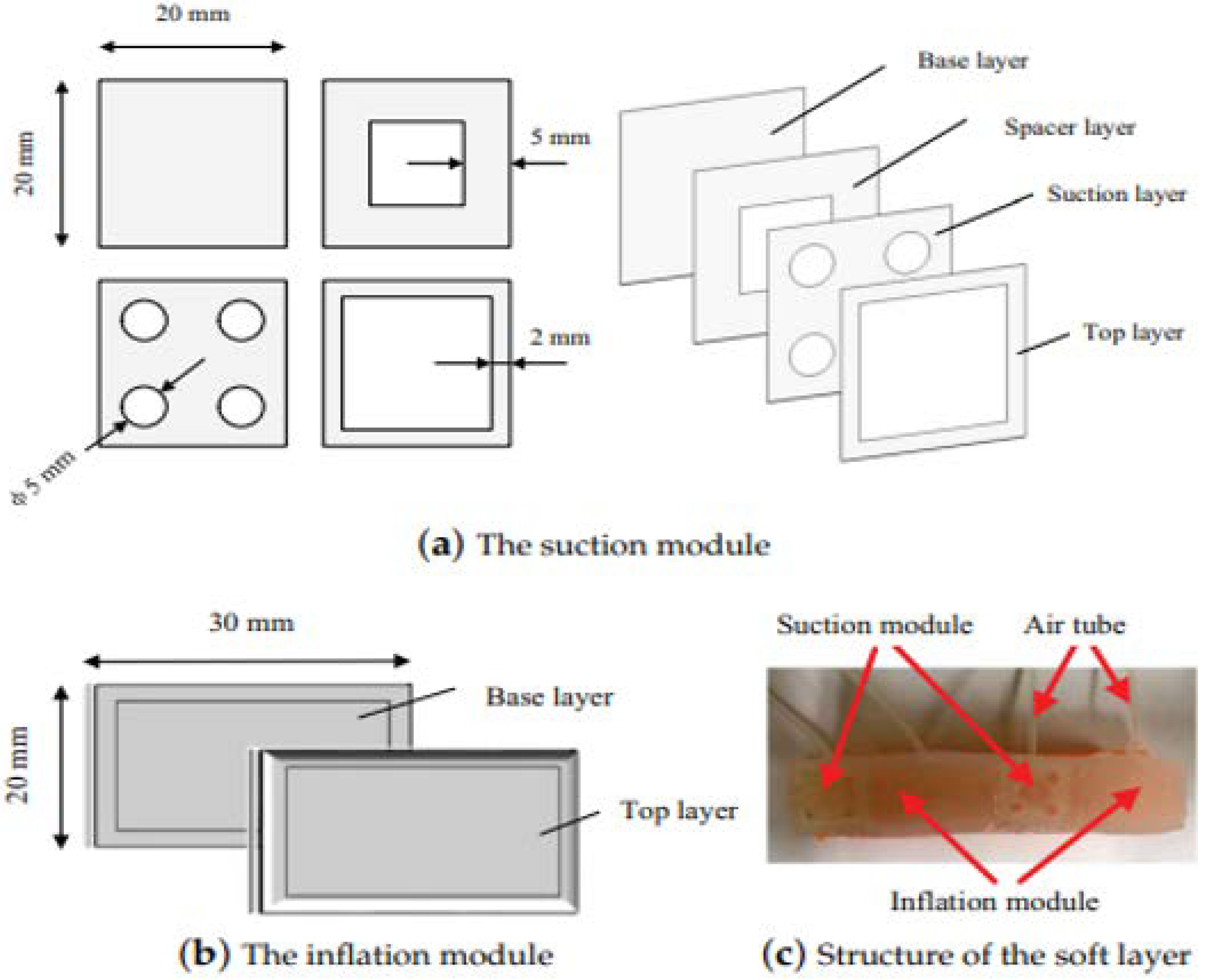

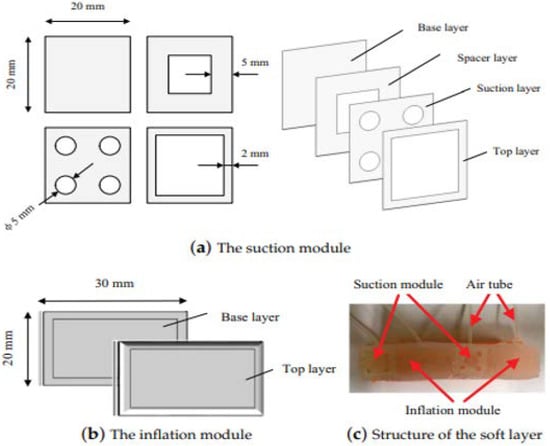

The two-arm approach, also referred to as being operated bimanually, from this assembly allows for much more complex and challenging tasks for the assembly to handle and endure. It is also using rigid gripper construction for the grippers, which have soft augmented layers of a stretchable and malleable material called EcoflexTM. The intriguing part of this whole assembly is the customization and variability for all of the applications of pieces, since all of the fingers and palm can have EcoflexTM adhered to the hand and help with the incredibly strong grip that these grippers have from the palm with a suction and inflation modules which comprise the soft layer in tandem with the EcoflexTM. This increases grip strength and increases the cushion for objects as the grippers’ bare assembly themselves is rather hard and rigid. An example of this soft layer can be seen in Figure 5 and Figure 6, showing the teleoperated bimanual assembly operating with a human operator [36].

Figure 5.

(a) shows the dimensions as well as a breakdown of this soft layer’s composition. It is comprised of a basic layer, then a spacing layer, followed by the suction layer, and ends with a soft top layer. (b) shows the inflation module in greater detail and with its dimensions, it has a simpler composition of a base and then layers. (c) shows the structure in real time, breaking down where what the suction and inflation modules look like, as well as pointing out the air tubes to allow for the inflation modules’ actuation (Reprinted with permission from Zhu, G. et al. [36]. Copyright 2020, CC BY 4.0 International).

Figure 6.

This shows the teleoperated bimanual assembly carrying a large assortment of different shapes and sizes to show how well it can grip with its soft layer and cumulative hand strength (Reprinted with permission from Zhu, G. et al. [36]. Copyright 2020, CC BY 4.0 International).

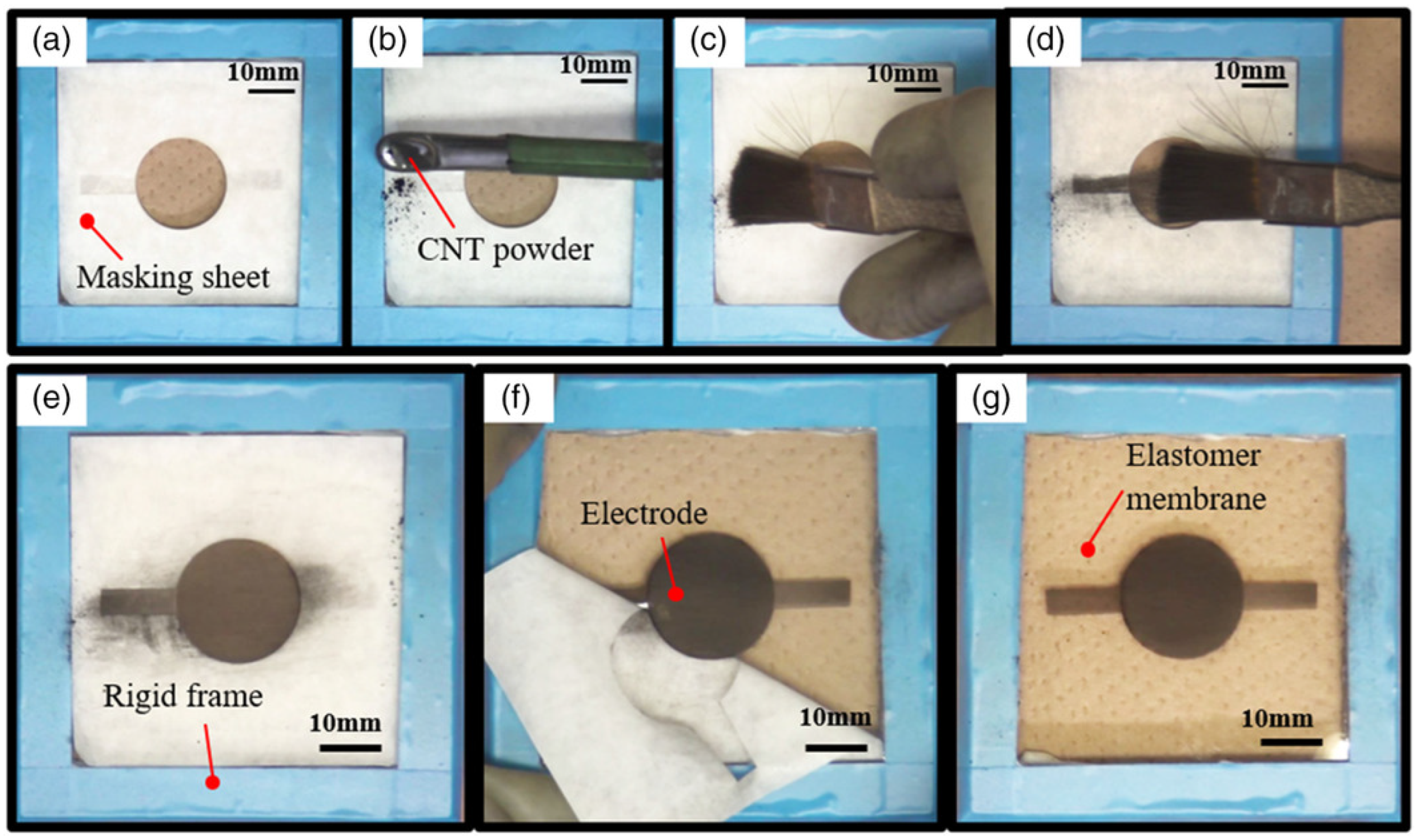

3.6. Soft Robotic Sensors

Many of the examples presented so far have been implied to be for macro-scale applications of artificial muscles, but in many new cases, the applications can be incredibly small with a high level of precision. Things like surgery have been embracing this high level of adaptability from artificial muscles, and due to many means of actuating these artificial muscles, these can be produced small enough to fit into many different circumstances. The issue is that while these artificial muscle assemblies can fit within these incredibly precise, small, and delicate areas within those going through a surgery, they have trouble actuating and properly being controlled within these situations [37,38]. The way to integrate greater control and lessen the complexity of the overall assembly sensing for these delicate areas has become paramount to many incredibly accurate and sensitive external hazardous situations [37]. These sensors require signaling functions within a single element to help form a feedback loop, the issue with all of this is that these current artificial muscle actuators require external stimuli [39]. On top of the external stimuli required to actuate the artificial muscle, they also require a control and signal transmission system, as a result, this increases the complexity of the overall artificial muscle assembly [16,36]. So, the current trend for creating greater sensors for incredibly small, fragile, and precise applications requires flexible, compact, and adaptive artificial muscles that have a large strain for advanced applications [31,39]. There have been attempts that, while they have their merits, still rely on traditional micro-electro-mechanical systems (MEMS) force sensors that are embedded into the soft layers, which increases the stiffness of the actuator. More recent attempts make use of carbon-based composites, which allow for flexible and elastic sensors, these sensors, while carbon-based, had conductive media that included multi-walled carbon nanotubes (MWCNTs). The carbon-based composites were prepared with EcoflexTM, which is an elastomer matrix, the reason for which is that it has the desired mechanical properties for large tensile strain ranges. In the application of this proposed MWCNT-based actuator, there were different applications of its sensing capability, such as measuring strain, force, and pressure. With this in mind, there was an example created that was a compressive force sensor that aimed to eliminate the effect of capacitance-induced impedance variation that could arise from the large, agglomerated zones of conductive phases within the MWCNT-based composite. They used a very low stiffness and viscosity elastomer within the insulting phase of the composite. With various concentrations of the conductive phase within the composite, it demonstrated their fabrication of embedded piezoresistive pillars. Due to these piezoresistive pillars’ small surface area, they allow for the implementation of high-density pillar arrays, as a result, these can push toward the development of high-resolution, highly elastic, and conformal load sensing fabric [37]. Other sensors use fibers such as in [40], which created an optical fiber Bragg grating (FBG) shape sensor for soft robotics, that had flexible morphing similar to a wing’s structure. This optical FBG was then embedded inside a polyimide film and fixed into the body of a soft robot and a morphing wing, through their research they determined that the FBG sensor inside this polyimide film held up to continued use over time [40].

Another proposed sensor used for these incredibly strict, small-scale, high-stake applications is one that aims to emulate the way that a signal from the human brain travels through the central neuron systems. This sensor uses electrical signals for sensing and signal transmission, as a result, the information for bending and contraction deformation can be gained from actuating. From the aforementioned aspect of these assemblies being incredibly adaptable and flexible due to their components, the particular compact fibers used in this were made of rubber, which was used to thermally drive tensile artificial muscles with entropic elasticity. Up to this point within the research on these highly sensitive small, scaled sensors, no one had created an artificial muscle that integrated both tensile and torsional actuation from a single electrical signal as its external stimuli. Specifically, it could self-control, allowing for the turning on and off of actuation due to the feedback loop, by sensing the muscle deformation. This was fully realized as there was a sensor on an actuator that was in a single elastomer fiber artificial muscle, from this artificial muscle they had designed a bisheath buckled CNT skin on an elastomer fiber core. This was activated and sensed from the single electrical stimuli, the reason this works is due to the elastomer fiber acting as a thermally driven artificial muscle, which would contract due to the entropic elasticity by electro heating of the CNT later. The overall entropy of the stretched elastomer would be lower than that of the non-stretched at rest elastomer, and when heating the at rest rubber fiber, it would increase its elastic modulus. Due to this increase of elastic modulus within the at rest rubber fiber, then it would isobarically load the elastomer fiber to contract. The area in contact between the CNT buckles would increase during the thermally driven contraction from the elastomer fiber, which results in nearly linear resistance change as a function of the strain during the electrothermal actuation. The muscle length can be measured and monitored by looking at the resistance of the CNT sheath, which, calling back to the analogy of the mission statement for this sensor, is similar to human muscle fibers from muscle spindles. The torsional actuation can also be measured and monitored from the thermo-piezoresistive changes of the CNT layer. This torsional artificial muscle was prepared by connecting an elastomer fiber muscle to a return spring followed by a twist insertion. As previously mentioned, a feedback loop was designed and created to allow for self-control of the actuation, by sensing the muscle deformation [39].

When talking about artificial muscles, the obvious application is for victims missing or unable to move their limbs to finally have a means of moving their damaged or missing appendages. An example of consumers looking for near neural replication of an artificial muscle is stroke victims, as some may lose control over their limbs which artificial muscle aims to fix. The paper [41], seeks to create a pneumatically actuated soft robotics-based bilateral therapy system for hand-specific rehabilitation in stroke victims. They propose a paretic hand by using a healthy hand to guide the motion of the sensor integrated glove in tandem with a robotic exoskeleton, this glove will track the motion of the healthy hand and provide inputs for the soft robotic exoskeleton on the damaged hand [41]. Similar to that post-stroke victim sensor, in the field of all robotics, biorobotics seeks innovation for those the light-based sensors which can detect movement within macro and even micro-scale applications [42]. There are researchers such as those within [42] who are looking into molecular photo switches which are composed of photochromic molecules. The main structure or backbone of these photochromic molecules can comprise many things, but from their research they used spiropyrans, and on these backbones can be applied various substituents that better fit these materials into their given applications. There are also multi-responsive photochromic molecule-based materials that display more than one isomerization mode, these are often created by covalently linking one or more photo switches. The main idea between these applications of photochromic molecule assemblies is that it could allow for the switching between many isomeric states that have distinct spectral features, such as their colors, and could be used to help organize and define these attributes into a data storage system. This data system could even surpass binary notions and mimic advanced logic operations, other uses to discern different isomeric states and their distinct features could be based on things such as their concomitant structural changes and differences. An example of this is that of photophamacology, which is when photoactive molecules are designed to interface with biomolecules of particular interest only after being exposed to an external light stimulus. This changes the structure of this from its passive form to its active form, though in many of these cases they utilize azobenzene derivatives in tandem with diarylethene as well as the aforementioned spiropyrans [42]. Any of these attempts at utilizing these materials to allow for machines to operate in a passive and active state from their light stimuli could one day allow for the use of these techniques and assemblies in artificial muscle sensors. One day the user may be able to set the parameters for a particular hue or shade of color in an application to set movement limits for applications with incredibly high levels of accuracy.

3.7. Miscellaneous Techniques for Materials Used in Actuation

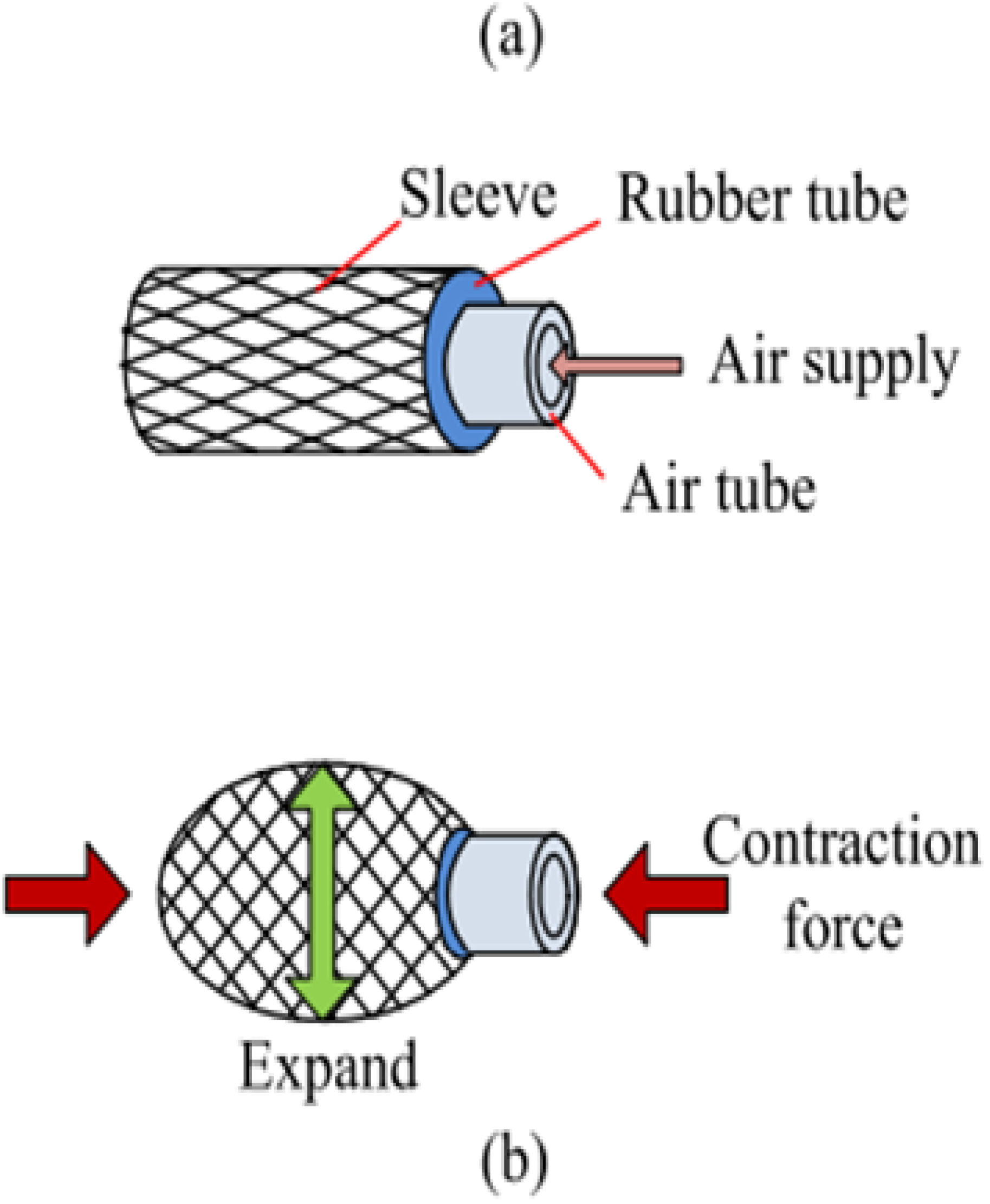

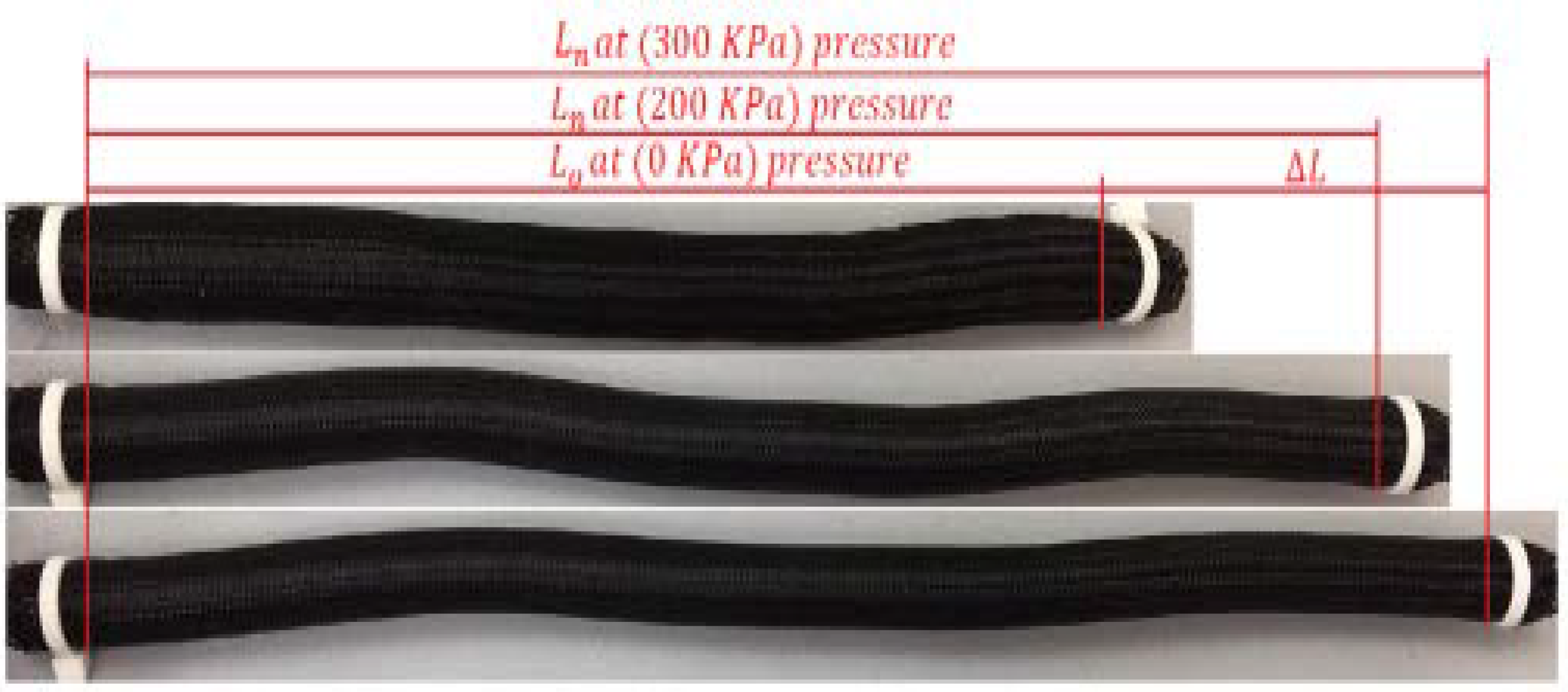

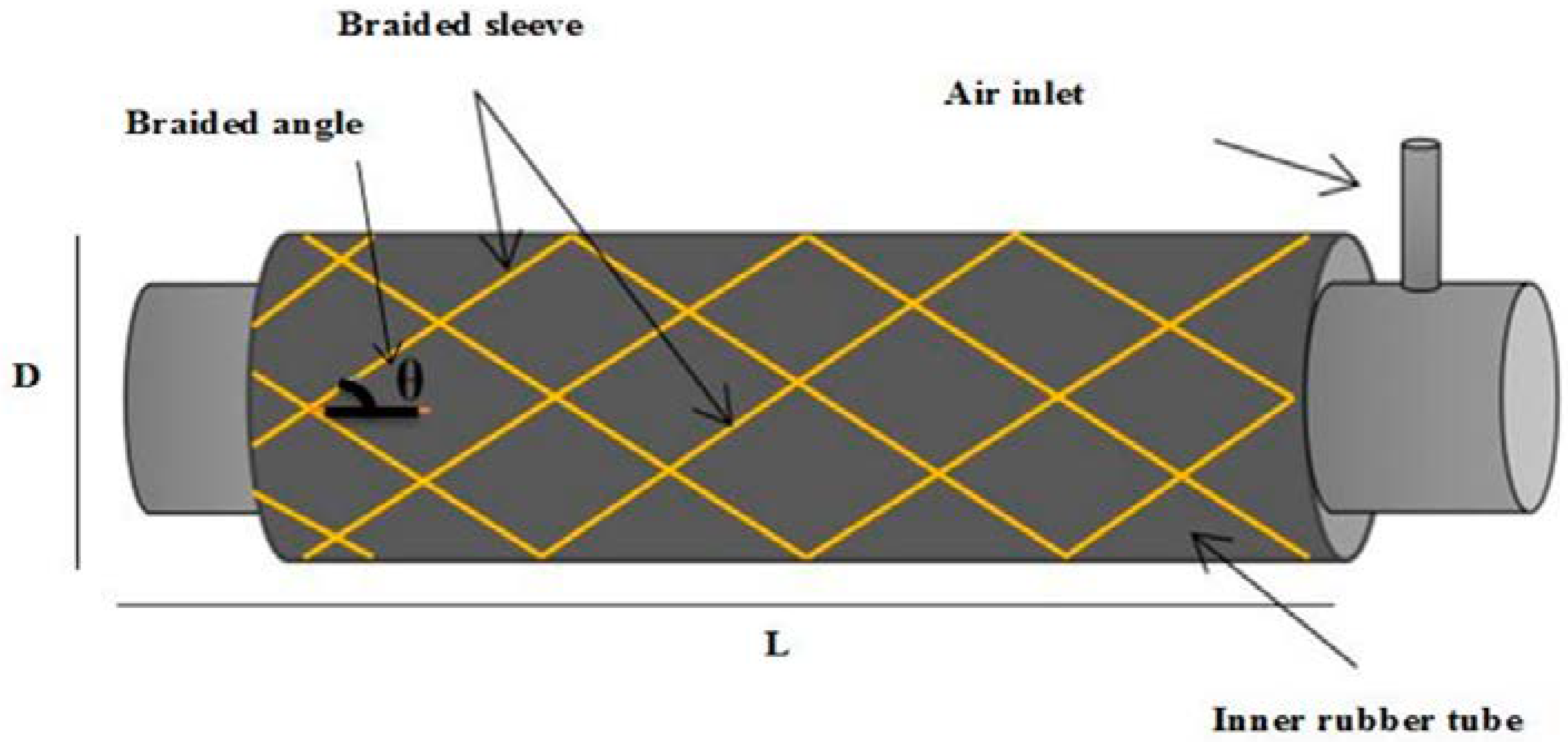

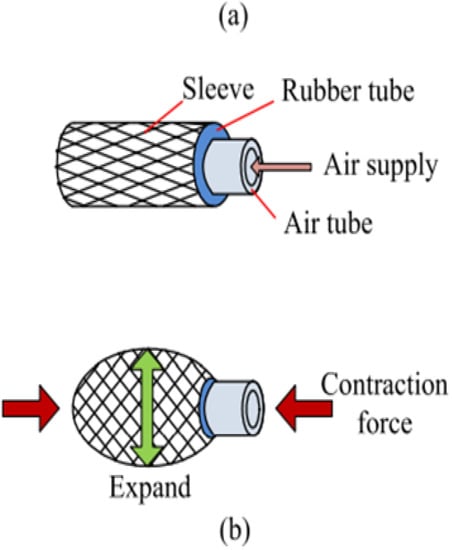

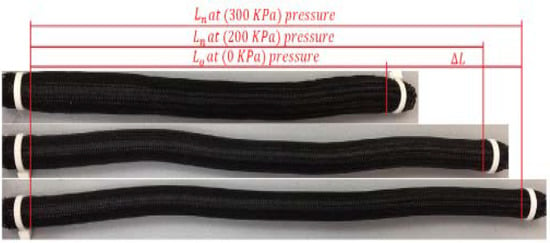

A topic that is discussed in the next section which is incredibly influential within the field of artificial muscles, if not all biorobotics, is the use of pneumatics within artificial muscle assemblies. An innovation done to these soft pneumatic actuators is within their air-bladder region, researchers have searched out the effect of cutting slits in these bladders to see how they could help with their commonplace reliance on their elasticity. These actuators are called slit-in-tube (SLiT) actuators, these patterned slits are within a fabricated tube that is composed of an inextensible or compressible polymer composite [43]. When the pneumatic actuator actuates and pressurizes the air bladder, it expands inside region which has patterned slits, this is similar to pleated pneumatic artificial muscles (pleated PAMs). These pleated PAMs are like pneumatic actuated muscles, which are a subclass of McKibben-like actuators, a number of pleats are created along the direction of actuation, and as the actuator expands and displaces it unfolds these pleats [43,44]. Other similar attempts before SLiT, were things like the strategy of an elastomeric soft actuator, which had parallel slits that were cut on a roll of paper, and that paper was embedded within a layer of elastomer. When this was pressurized, the center of the roll opened the slits and would expand like a Japanese Toro, which is their form of traditional lantern. Similar offshoot attempts of this pneumatic actuated elastomeric soft actuator had utilized a plastic braid around an elastomeric tube, which would amplify motion. This SLiT attempt with the pneumatic soft actuators used similar to the last attempt with plastic tubes to create braids outside of the elastomeric structure, which when expanded and pressurized would have a range of motions [43].

Another specific innovation for a particular form of actuating artificial muscles is the piezoelectric actuators. Piezoelectric actuators allow for the production of tension or compression in thickness direction under the external stimuli of electric fields. When these piezoelectric actuators are subjected to the electric field, they exhibit a converse piezoelectric effect, this effect creates mechanical stress within the microscopic structural lattices of the particular piezoelectric material. The stress produced from this process can be translated into force change or displacement. While piezoelectric actuators are far from perfect, they allow for high speed, high-stress manipulation, high energy efficiency, and high positioning precision. The disadvantages are just as relevant when considering this means of actuating an artificial muscle, such as the high-voltage requirement, low robustness, low strain, and rather low power density. For example, a material used with a thickness of 100 μm will require 100 volts, and, furthermore, these piezoceramic materials are, in general, brittle and have small fracture toughness. The inherent applications for these piezoelectric actuators are most useful for more micro-scale applications but also allow for macroscopic and hybrid style applications as more common uses for them. The means of controlling this are two means, both feedforward control as well as feedback control. Feedforward control is used most often for compensation of nonlinear and vibrational dynamics, and by modeling the inverse mapping of this nonlinear relationship the inverse model can be used as a feedforward controller. To further improve accuracy and robustness, feedback control can be utilized instead, things like proportional-integral-derivative (PID) controllers were widely adopted due to their simplicity and great performance. PID control eliminates steady state errors and can be especially effective when under a static or low-frequency operation. Some more advanced applications with proposed higher bandwidth control are things such as sliding mode, which can achieve rather strong robustness by rejecting input uncertainties, hysteresis, and other disturbances. Keeping a greater control over robustness allows for the minimization of effects of disturbances within all of these means of actuation within piezoelectric actuators [45]. All of these components with their advantages and disadvantages can be seen in Table 1.

Table 1.

Summary of each category of components and their advantages and disadvantages.

4. Nanocomponents in Artificial Muscles

For the last few decades, all fields of technology are trending towards miniaturization, and artificial muscles are no different [10,45,46,47,49]. Artificial muscles have developed to the point where nanotechnology is being more incorporated into new developments in the field. Nanotechnology refers to the manipulation of matter on the 1–100 nm scale. The recent advance in nanotechnology allows the once theorized properties of some nanoparticles to be confirmed through testing [10]. The integration of nanotechnology and artificial muscles will lead to the creation of small yet powerful artificial muscle systems. There are four classifications for commonly used nanosized artificial muscle components that will be addressed in the paper: graphene, carbon nanotubes, fullerene, and motor proteins.

4.1. Graphene

Carbon-based materials come in many forms, but the backbone of many carbon-based nano components is graphene. Graphene is a single layer of carbon atoms arranged in a hexagonal crystalline structure with sp2 bonds. Graphene is an allotrope of carbon with the simplest form having a carbon-to-carbon covalent bond distance of 0.0142 nm. This carbon-based material is held in such high regard because graphene can be used in a wide variety of applications not only in artificial muscles but in most scientific fields. Graphene has been held as “one of the most wonderful achievements in science” since 2004 [50]. Graphene is thin, light, flexible, and transparent. Graphene has various advantages in the artificial muscle field. Graphene is one of the mechanically strongest materials known and is a great conductor thermally and electrically [51]. Graphene can be stacked to enhance its properties. While graphene is a great material on its own, it can also be used in conjunction with other materials to enhance its properties.

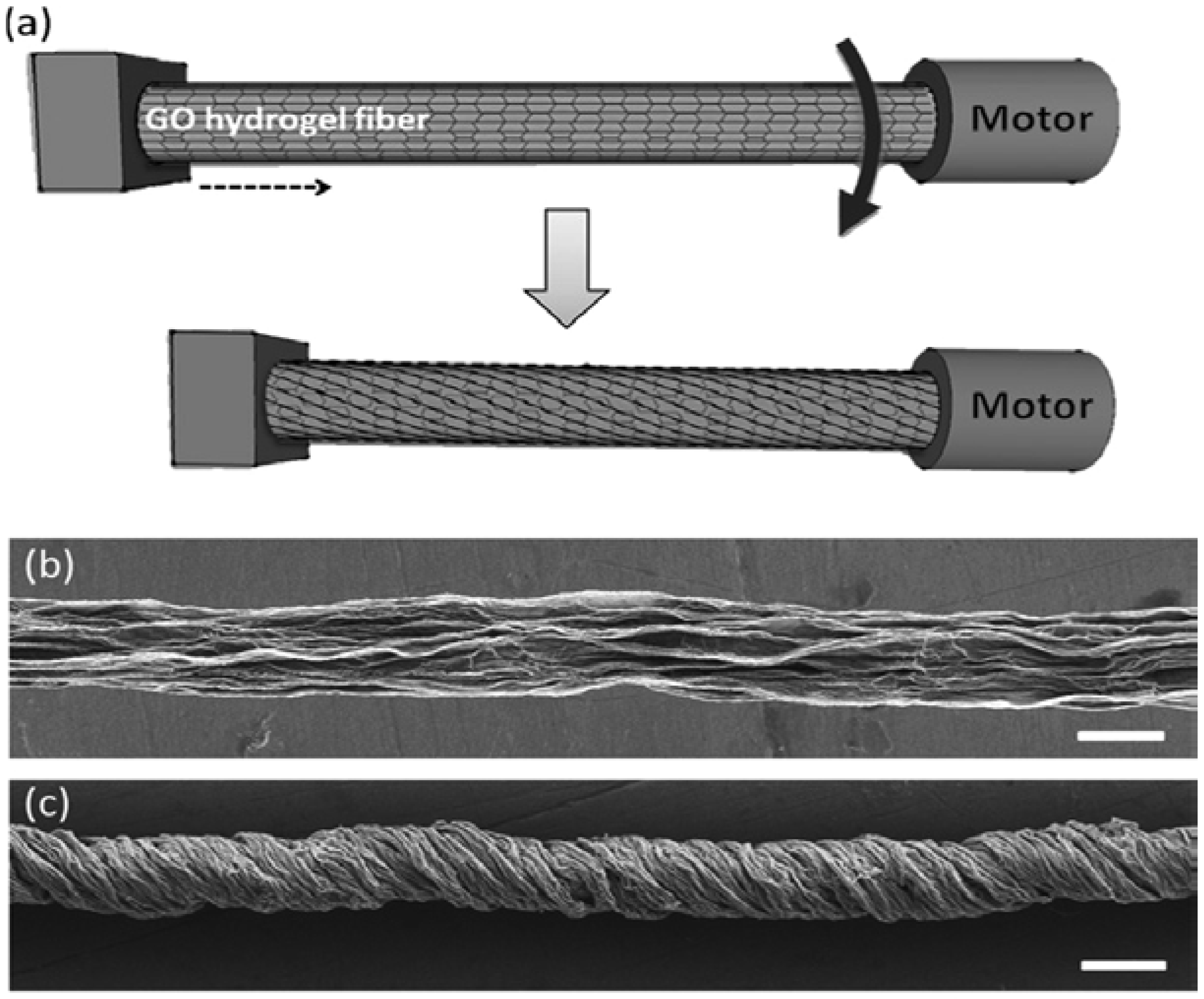

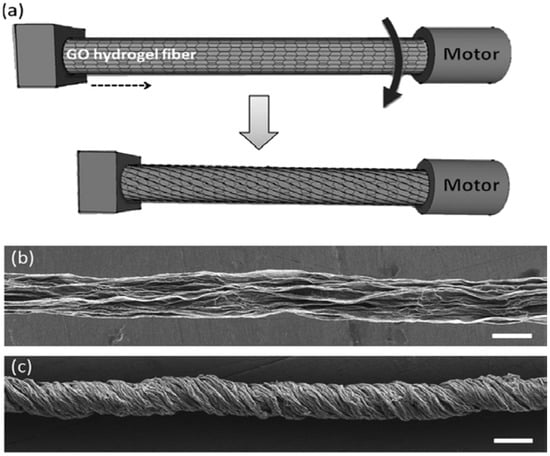

Graphene’s most distinct property is its high mechanical strength. With a single layer of graphene, young’s modulus ranges from about 0.8 TPa up to 1.1 TPa [52]. For comparison’s sake, a diamond can yield a young’s modulus of about 1.2 TPa. The same study documented an experiment with graphene where it yielded a tensile strength test ranging between 100 and 120 GPa [50]. A fractional stress of 97.54 GPa and shear strength of 60 GPa were reported, however, more tests on shear strength and fractional stress must be conducted to formulate a more conclusive result [50,52]. While more research needs to be conducted on the mechanical properties of graphene, the values currently known show that one layer of graphene has a mechanical strength comparable to diamond. The study conducted by Hyeon et al. investigates how a carbon nanotube coated in graphene operates as an actuator [53]. Carbon nanotubes are placed in a solution of graphene and then twisted to roughly 800 turns/meter. After the carbon nanotubes are removed from the solution, they are twisted roughly 3500 turns/meter [54]. Once fully formed, the twisted carbon nanotube will appear as seen in Figure 7, with a yarn-like twist pattern. The carbon nanotube twist yarn actuators actuated by applying a voltage of −3, this causes the material to compress itself. The material experiences a large tensile actuation of 19%, more than twice as strong as the bare carbon nanotube muscle [54,55]. A similar study was conducted by Foroughi et al., where a tensile actuation of 4.7% was recorded for standalone graphene fiber, four times weaker than graphene fiber [55].

Figure 7.

Fabrication and characterization of graphene fiber artificial muscles, (a) is the scheme of the graphene fiber fabrication; the arrow indicates the direction of rotation; (b) SEM images of the directly dried graphene fiber, and (c) twisted graphene fiber (Reprinted with permission from Foroughi, J. et al. [55]. Copyright 2020, CC BY 4.0 International).

Along with graphene’s mechanical properties, it is also the best-known conductor. Graphene’s high electrical properties come from the two pi-electrons found in every hexagonal ring in graphene sheets. At room temperature, single-layer graphene is theorized to show a thermal conductivity range of 3000–5000 Wm−1 K−1 [56]. Graphene’s electrical conductivity can be modulated by applying an electrical field; this effect is possible due to graphene’s two-dimensional shape. With three-dimensional metals, the abundance of free electrons in the metal dampens the electric field [55].

On its own, graphene is a very useful material with strong properties, but graphene can also be used to enhance the properties of other materials as a coating [53,57,58]. Using graphene as a material in a nanocomposite, the mechanical and conductive properties are increased. Hwang et al. investigated electroactive plasticized PVC gel as a soft actuator in artificial muscle applications [54]. The PVC gel is placed between an anode and cathode attached to a function generator. The function generator applies a square wave of ±0.5 kV, ±1.0 kV, and ±1.5 kV to the PVC gel. As a response to the electrical pulse, the gel contracts, and the displacement is measured. The study reports that the inclusion of graphene oxide (GO) at 0.1 wt. increases the overall performance of the PVC gel. The PVC/GO gel shows a 20% increase in displacement at all tested voltages compared to the PVC gel. The PVC/GO also showcased a significant increase in the blocking force by 41% and power output by 36%. The study by Hwang et al. utilizes graphene’s conductivity to increase the efficiency of the PVC gel [59].

Graphene, with its high mechanical strength and conductivity, is the thinnest material in existence. Graphene is a two-dimensional structure of carbon molecules, so it yields a thickness of one carbon atom [60]. While one atom is thin, graphene keeps its highly flexible and transparent features. A unique feature that graphene has is its ability to stack upon itself. By creating a stack of graphene material, the mechanical and conductivity of the material increases to the detriment of its thickness and transparency. Hwang et al. created a transparent actuator using a few layers of graphene [59]. The actuator was composed of a silicone elastomer with electrodes on each side. The electrodes were made of graphene dispersed in N-methyl-pyrrolidone stacked upon itself. The transparent actuator recorded a displacement ranging from 29 to 946 μm. When the stacked actuator was exposed to a wavenumber of 600 nm, it had optical transparency of over 57%. This is a significant decrease in transparency compared to a single layer of graphene’s transmittance at 97.7% and silicon’s transmittance of 75–85%, as the study recorded. The actuator demonstrated that graphene loses its transparent property while retaining its actuation capabilities as graphene is stacked [59].

Along with its mechanical, conductive, and physical properties, graphene is biocompatible. Jia et al. conducted a study that promotes the biocompatible application of graphene [61]. The study compares two actuator films: Ti3C2TX MXene and Ti3C2TX MXene-graphene oxide (MGO). MXene films are weak, brittle, and prone to oxidation. The addition of graphene oxide into the film made the actuator response time faster, more conducive, and more stable, with a larger bending angle. The MGO has higher cycling stability, after 50 cycles MXene film began to deform while the MGO film remained unchanged. In another test, the films were constantly exposed to water vapor for 10 days. On the tenth day, MGO was able to maintain the same bending angle as the first day, where the MXene film reverted to its original shape. The study points out that MGO is a promising material for biomimetic soft actuators. To showcase some of the MGO applications, the study created three actuators. The first actuator the study created was a simulated flower with six petals. When the flower is exposed to water vapor, the flower blooms, reaching its maximum expansion in 16 s. When the water vapor has been removed the flower then slowly reverts to its original shape. The second MGO film application was by Jia et al., in which their team created a robotic arm triggered by moisture capable of lifting objects several times its strength [61]. A non-contact switch with MGO was fabricated. The switch is activated by placing a finger near, but not touching, the MGO film. The water vapor that is passively released from a finger activates the MGO until it actuates enough to close the circuit, activating the lamp. The study continues by suggesting that MGO film should be used in various applications [61].

Graphene has many great properties, but no material is without its flaws. There is one major aspect of graphene that was affecting its prevalence today: production. There were two main problems with the current production methods of graphene. One is the lack of consistency in using all methods of production [62,63]. The other problem is that it is very costly to produce even a small amount of graphene [62]. The production of graphene struggled with consistency, harmful byproducts, and excessive cost. Over the years, the production of graphene has gone through dramatic changes to the point where mass production is possible. Omoriyekomwan et al. proposed a process of converting biomass into graphene [63]. The process heats the biomass via microwave to create graphene and graphene fiber. The study concludes that microwave-assisted pyrolysis of biomass can be an effective method of fabrication, capable of the production of graphene in large quantities and consistently. However, more research must be conducted to prove the method is more efficient. The production of graphene suffers from inconsistency and is cost-ineffective, but microwave-assisted pyrolysis leads to a promising future for the fabrication of graphene.

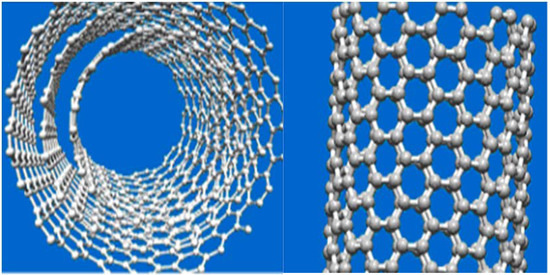

4.2. Carbon Nanotubes

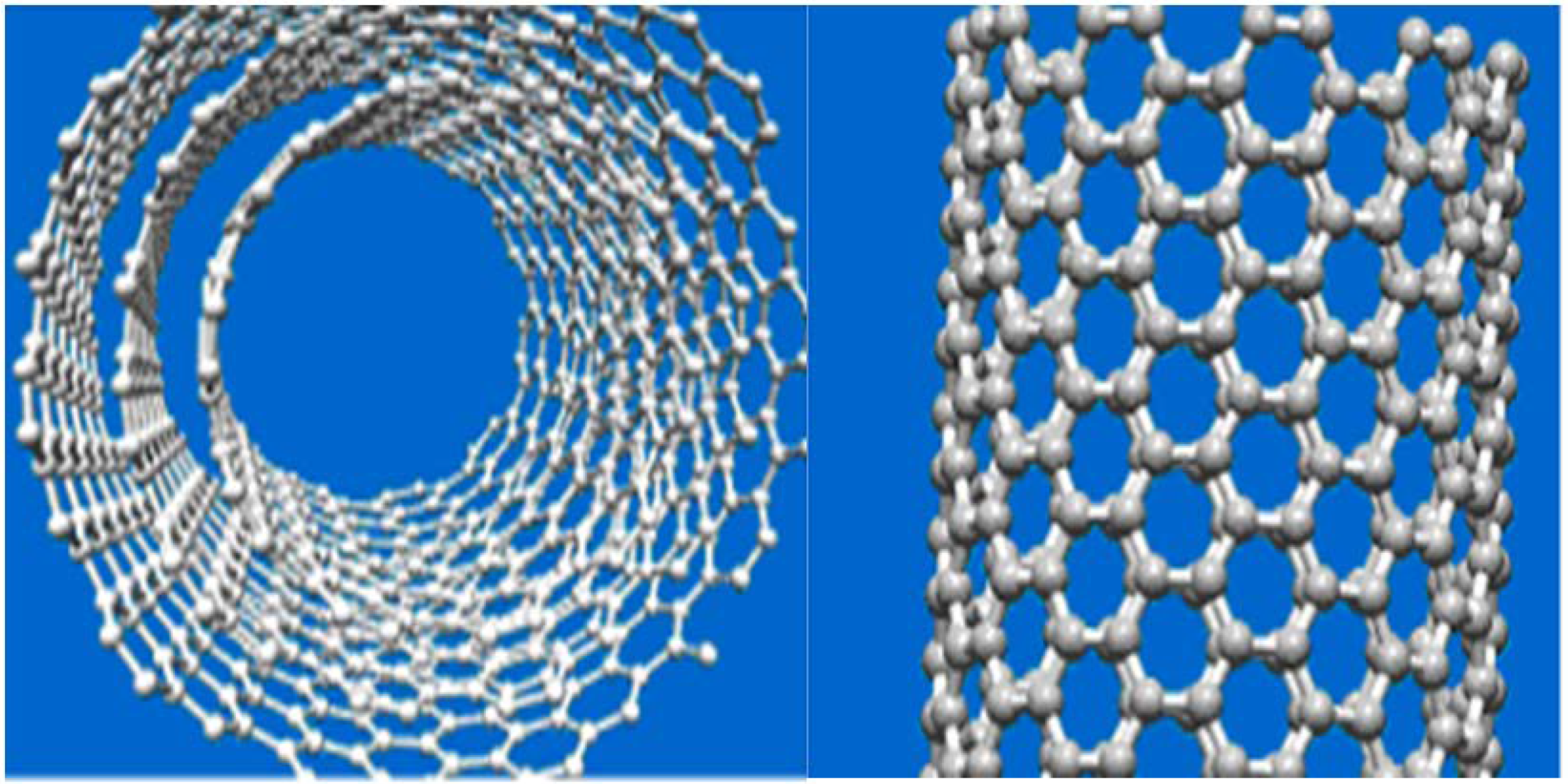

Carbon nanotubes (CNTs) are another common nanosized component in artificial muscle applications. CNTs are another allotrope of carbon that is the intermediary position between the flat two-dimensional structure of graphene and the three-dimensional ball-like shape of fullerene. There are two types of carbon nanotubes: single-wall carbon nanotubes and multi-wall carbon nanotubes. Single-walled carbon nanotubes (SWCNTs) are a single layer of carbon atoms in a hexagonal structure rolled to create a hollow cylinder. Pure SWCNTs are known for their ability to conduct heat and electricity at a high rate. Like graphene, CNT can be stacked to enhance its properties. SWCNTs can be arranged concentrically to form multi-walled carbon nanotubes (MWCNTs). Multiple SWCNTs are bound together through weak intermolecular forces. The MWCNT is mechanically strong to the detriment of its conductivity capabilities [62].

Carbon nanotubes share many similarities to another allotrope of carbon, graphene. Structurally, carbon nanotubes and graphene are the same, both are composed of carbon molecules arranged in a hexagon pattern. Graphene’s and CNTs’ compositions of carbon makes them a thin, light, and flexible material [63]. CNT and graphene share the trait of having a delocalized electron, making them excellent conductors [64]. Graphene and CNT also can stack upon themselves to enhance their mechanical strength [62]. Similarly, to graphene, SWCNT is difficult to produce efficiently and consistently [28]. This affects not only the application but also impedes the amount of testing that can be done on the materials.

The actuation system for any artificial muscles is important. A popular method of manipulating artificial muscles is by embedding polymer composites inside the would-be hollow section of the nanotube. The embedded polymers can be activated through hydrothermal, infrared, or Joule heating [65]. When the polymer is heated, the nanotube will actuate in one direction, axially along the tube [66]. Another method of actuating carbon nanotubes that was proposed was using microwave radiation. By applying electromagnetic radiofrequency radiation waves with frequencies from 300 MHz to 300 GHZ, the polymer composites will heat up. The electromagnetic waves have long wavelengths, this allows the polymers to heat up volumetrically and subsequently faster actuation compared to hydrothermal, infrared, or Joule heating. Actuation by microwave works best when the CNTs are aligned in an orderly fashion. CNTs placed in a random orientation in the polymer matrix could result in a non-uniform orientation [67].

Large quantities of CNTs can be made into a popular form known as fiber, also known as yarn. Carbon nanotube fibers (CNTFs) are formed through a process called wet spinning. Wet spinning is a process in which a polymer is mixed with a solvent and the solution is extruded onto a chemical bath to form the fiber [67]. CNTFs can be used in a variety of applications due to their desirable properties, such as its lightweight, high strength, high conductivity, and long cycle life [29,63]. Liu et al. created a robotic gripper based on the human hand [68]. The gripper uses an all-solid-state CNTF that contracts when electricity is applied. This is to replicate the tendons in a finger, to maximize the properties of all-solid-state CNTF, Liu et al. used twisted fibers with a weight attached to the non-fixed end. CNTFs are a popular form of carbon nanotubes because they bring out a lot of desirable traits. However, the one degree of freedom that the CNTF actuator causes some complications [68,69]. The CNTF’s driving methods limit some of its potential applications [66]. Additionally, CNTFs have a slow response time, low output stress, unpredictable drive deformation, and the inability to self-recover without being exposed to external sources [68,70].

Another study created a biocompatible carbon nanotube fiber. The microfiber is composed of a hyaluronic acid hydrogel (HA) and SWCNTs. The HA gel reduces the surface tension and increases the dispersion of SWCNTs, increasing electrical and mechanical properties. The HA hydrogel also prevents the CNTs from leaking out of the HA/SWCNT composite. The HA/SWCNT enhances the young’s modulus, failure strain, toughness, electric conductivity, and resistance to biodegradability. When a 1 V is applied to HA/SWCNT, the fiber acts by contracting. To test the biocompatibility of HA/SWCNT, the microfiber composite was implanted under the skin of mice and checked after 1 and 3 weeks. The immune response to the introduction of HA/CNT can be measured by the presence of monocytes and macrophages. The experiment shows that after one week, a large number of monocytes and macrophages were still present. However, after three weeks, there is a dramatic decrease in monocyte and macrophages around the fibers. The HA/SWCNT has shown that it is improved mechanical, conductivity, and actuator behavior, and biocompatibility properties to be an effective material in biomedical applications [71].

Due to the CNT’s geometry of a hollow cylinder of graphene, there are many similarities. However, the differences in geometry change a few properties between CNT and graphene. Kumar et al., identify the difference in properties of the two materials. The strength of the materials is drastically different. Although both materials are mechanically strong, pure graphene is superior to a pure SWCNT [72]. Additionally, a CNT is significantly weak when exposed to radial forces [73,74]. Since a CNT is a hollow cylinder, it is also larger and heavier. By contrast, graphene is extremely light and thin because of its two-dimensional shape. While SWCNTs and graphene have difficulty to be produced in a fast and consistent manner, MWCNTs do not suffer the same production issue. MWCNTs have had many improvements to their fabrication process to the point where MWCNTs are available in abundance commercially, an example of its three-dimensional model can be seen in Figure 8 [64].

Figure 8.

The image on the left is a three-dimensional model of a single-walled carbon nanotube (SWCNT). The image on the right is three SWCNTs concentrically aligned on top of one another, also known as a multi-walled carbon nanotube (MWCNT) (Reprinted with permission from Ganesh, E.N. [64]. Copyright 2013, CC BY NC ND 4.0 International).

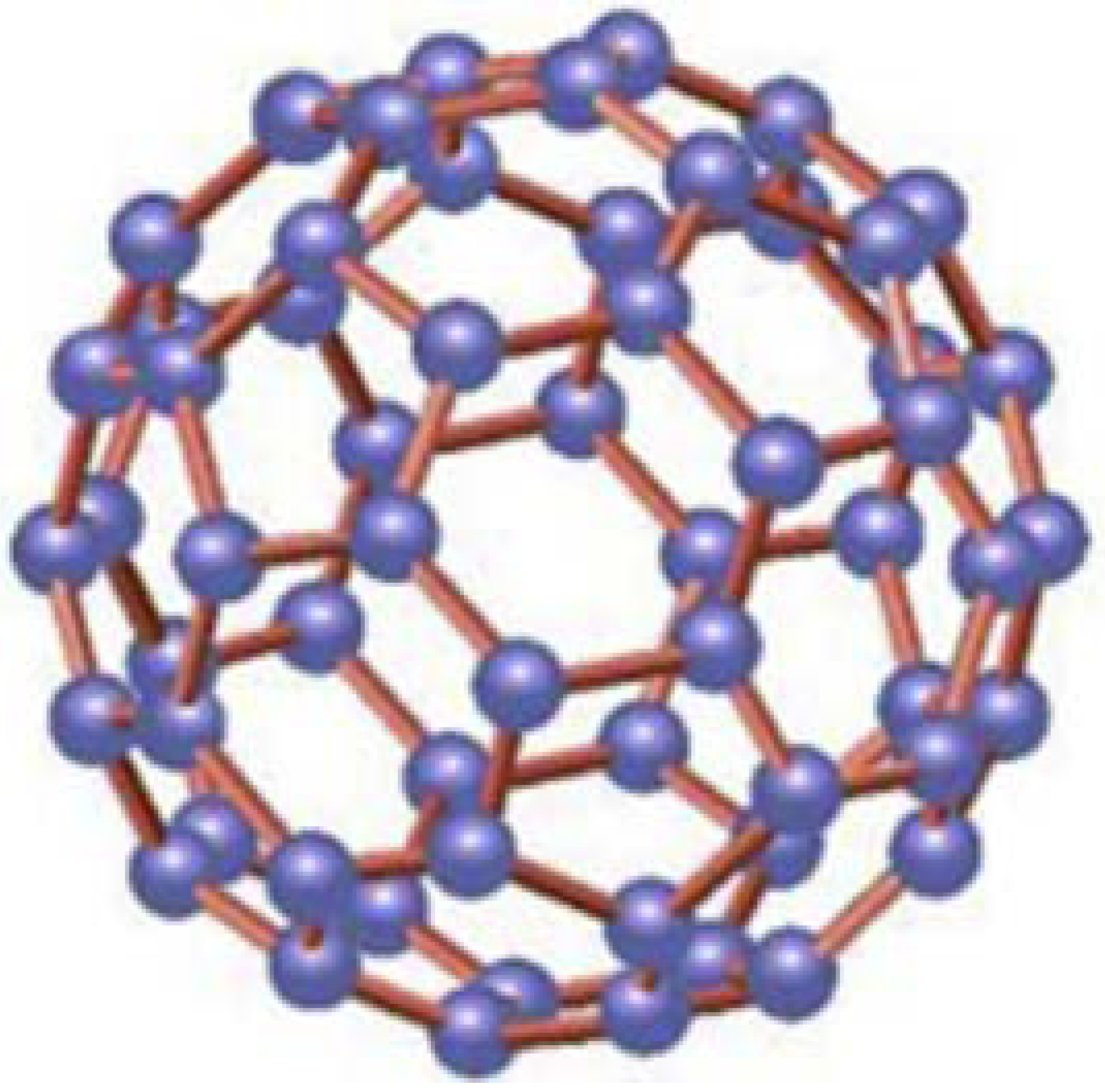

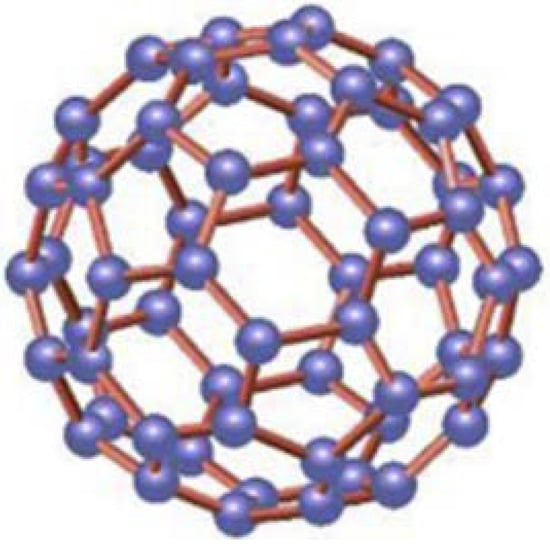

4.3. Fullerene

Fullerene is an allotrope of carbon where a network of carbon atoms joins together to form a pentagon, hexagon, or heptagon ring and multiple rings join to form a hollow spherical shape [75]. Fullerenes are named using the empirical formula, Cn, where n is the number of carbon atoms. The most notable fullerene is C60 and is often referred to as “buckyball” for its soccer ball-like shape, as seen in Figure 9 [50].

Figure 9.

Fullerene C60 (Reprinted with permission from Mohan, V.B. et al. [50]. Copyright 2018, with permission from Elsevier).

Like the previously mentioned allotropes of carbon, many of the properties of fullerenes were already theorized before its synthesis in 1985. Compared to the other carbon allotropes mentioned in the earlier section, fullerene has been extensively investigated. While graphene and carbon nanotubes are formed of carbon molecules bonded and arranged in a hexagonal pattern, fullerene’s carbon molecules are arranged in the shapes of a pentagon, hexagon, and sometimes a heptagon. The arrangement of the carbons of the first discovered fullerene, C60, is akin to a soccer ball, with a pentagon with hexagons touching each side. The other fullerenes follow a pattern of a pentagon, hexagon, or heptagon connected to a hexagon on each side; the pattern continues until a sphere-like object is formed [76]. The difference in form results in fullerene’s different properties, one such property is conductivity. The well-known allotropes of carbon like graphene, diamonds, and carbon nanotubes are excellent conductors of heat and electricity. Pure fullerene, on the other hand, is a poor conductor of electricity and heat, which makes fullerene a good insulator. There are two reasons for fullerene’s poor conductivity: one is its sphere-like structure, and the other is the charge of the molecule.

Fullerene sphere-like structure makes the electron jumping from one molecule to another difficult. A fullerene molecule has delocalized electrons to allow for conductivity, but the electrons are only delocalized within an individual molecule. So, a single molecule is conductive but fullerene in bulk does not allow for the electrons to transfer from one molecule to another. A pure molecule of fullerene, C60, has no unpaired electrons, making it a good insulator [77].

Jung et al. created a fullerene-Nafion actuator that emphasizes the properties of fullerene as a composite material. The study analyzes the effectiveness of the inclusion of fullerene in a Nafion composite actuator. There are three samples: pure Nafion, 0.1 wt% fullerene-Nafion, and 0.5 wt% fullerene-Nafion. As the concentration of fullerene increased, the tensile strength and young’s modulus of the composite increased tremendously. Pure Nafion has a young’s modulus of 9.8775 MPa while 0.5 wt% fullerene-Nafion has over double the young’s modulus at 20.6573 MPa. As seen in Figure 3, the higher fullerene concentration composite actuator performs significantly better compared to the composite actuator performing better than the pure Nafion actuator. While fullerene is not electron conductive, the study indicates that the proton conductivity of the composite increases as the weight percentage of fullerene increases [78].

The study by Rajagopalan et al. created a fullerenol-based biocompatible artificial muscle. The artificial muscle was composed of sulfonated polyetherimide (SPEI) with a homogenous dispersion of polyhydroxylated fullerene (PHF) particles. Compared to a pure SPEI, the PHF-SPEI artificial muscle has more favorable properties. The PHF-SPEI displayed a high-water uptake and proton conductivity, which are essential properties for high-performance ionic polymer actuators. PHF-SPEI was proven to be a more flexible actuator with three times the range of motion as the pure SPEI. PHF-SPEI is also much stronger as an actuator than pure SPEI. Rajagopalan created three PHF-SPEI artificial muscles of different concentrations of PHF: 0.1 wt%, 0.3 wt%, and 0.5 wt%. The study observes that as the concentration of PHF increases, the water uptake, proton conductivity, and blocking force also increase. The SPEI and low concentration of PHF make the actuator biocompatible with many potential applications in artificial muscle [79].

The most significant difference between fullerene and the other two allotropes mentioned is the amount of research done [21], even though fullerene was discovered not too long before CNT and graphene, 6 and 19 years respectively. The current level of understanding of fullerene is significantly ahead of graphene and CNT, the reason for such a discrepancy is the difficulty in production. Fullerene is a much easier material to fabricate, and this ease of production allows for more research to be done to gain insight into the material. The rapid production of graphene and carbon nanotubes was only another difference between fullerene and the other carbon allotropes used in artificial muscles is that fullerene alone is rarely used. Artificial muscles that use fullerene use fullerene as a composite with other materials. While fullerene is not mechanically strong, it can enhance the mechanical strength and conductivity of other materials [21,80,81,82].

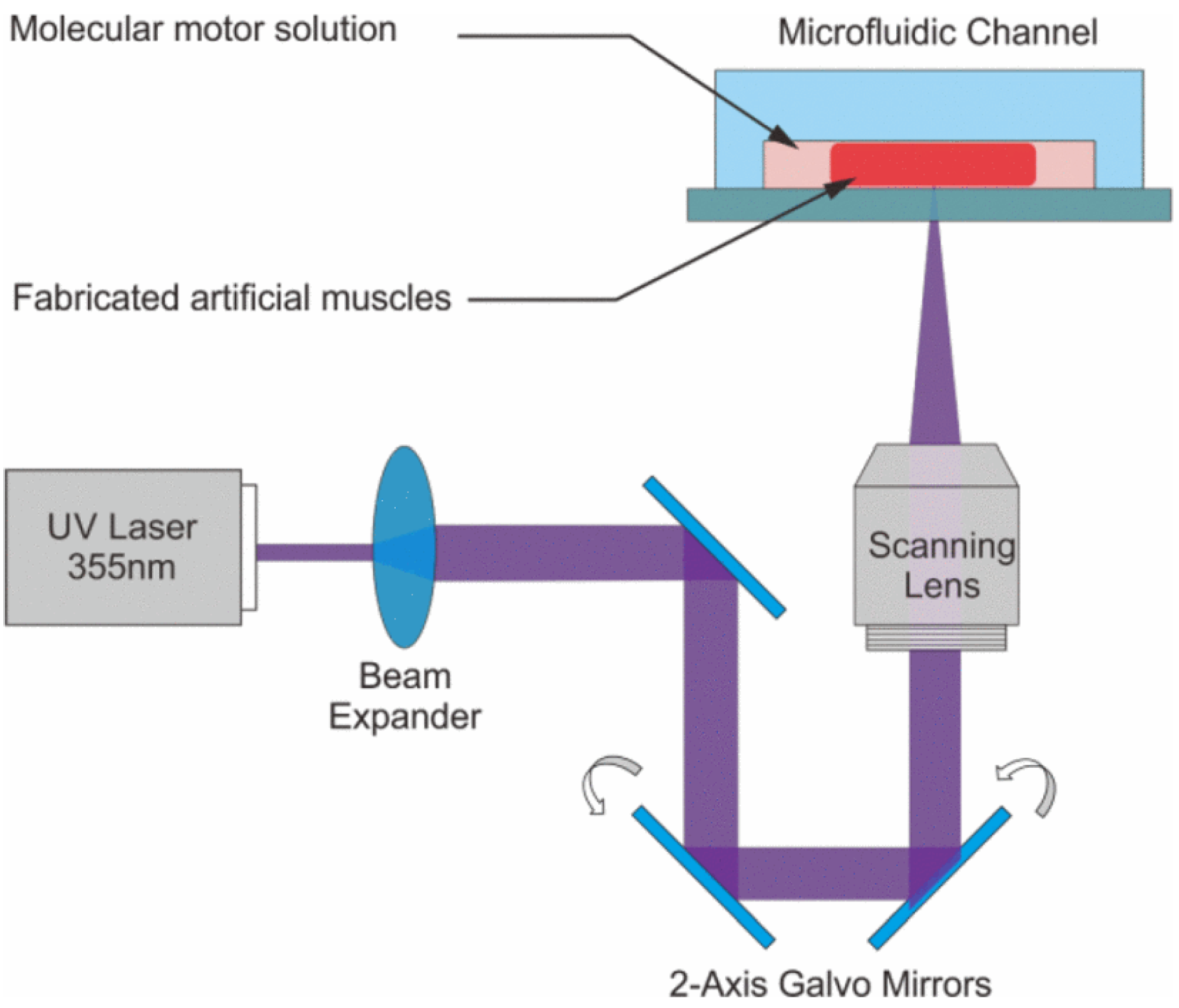

4.4. Molecular Motors

Motor proteins are a category of molecular motors that move along a cytoskeleton filament. Three motor proteins are found in molecular motors: kinesins dynein and myosin. The most studied protein motor is kinesins [83]. When observed, kinesin can be seen “walking” across the surface of a microtubule. This particular mechanical motor can chemically bond to a substance to transport it. While the motor is actuating, the kinesins act as the legs and can be observed chemically binding and unbinding to the surface of the microtubule [83,84,85,86,87]. Another type of molecular motor is dynein. Dynein operates very similarly to kinesis, as the protein bonds to the microtubes for actuation. The difference between the two is that kinesin moves in a “walking” movement from the negative end towards the microtubules’ positive end. Dynein travels in the opposite direction, positive to negative, in a sliding movement. Within the body, dynein motors propel bacteria and other cells [83]. The proteins’ ability to move towards the cell negative end is known as retrograde transport. The last protein motor is myosin. A myosin is a group of motor proteins that plays a significant role in the contraction of muscles throughout the body [83,86]. These protein motors actuate the same way as kinesins, by binding and unbinding to the cytoskeleton.

Two cytoskeleton filaments are used in molecular motors: actin and microtubules. The filament that is commonly used in experiments is microtubules. Microtubules are a polymer made of tubulin, formed by the cytoskeleton, and given structure and shape to eukaryotic cells. Microtubules are hollow tubes that keep the shape of the organelles [79]. The other cytoskeleton filament is the actin filament. The actin filament is a multifunctional protein that is found in all eukaryotic cells. While the actin filament is hollow, thin, and flexible, microtubules are comparatively thicker, and stiffer [2]. The filament is the main method of control for artificial muscles with motor protein components. The motor proteins operate on the filament that acts as the track for the motor proteins as they travel from end to end of the filament [83]. The filament is constantly changing, through reactions, materials are added and subtracted from either end. One end grows at a more rapid rate is known as the plus end while the other end is known as the minus end [79,85]. Microtubules are known as the largest type of filament. Actin is made up of a long spiral chain of identical actin proteins. Actin also has a plus and minus side. Actin is also the smallest type of filament measured at about 10 nm [84].

A desirable quality of molecular motors is their ability to convert chemical energy into mechanical energy. Molecular motors are often used in organic materials. As long as the motors are hosted in organic material, there is no need for an external power source. Since the components that make up the molecular motor are organelles, they can gain the necessary power the same way other organelles do. The molecular motor and other organelles draw energy through ATP hydrolysis, so the organism that the molecular motor inhabits will supply the energy for the motor function. All three motor proteins, kinesins, dynein, and myosin convert ATP hydrolysis into a directed, non-random, motion [83]. The proteins continue in that motion until the end of the cytoskeleton.

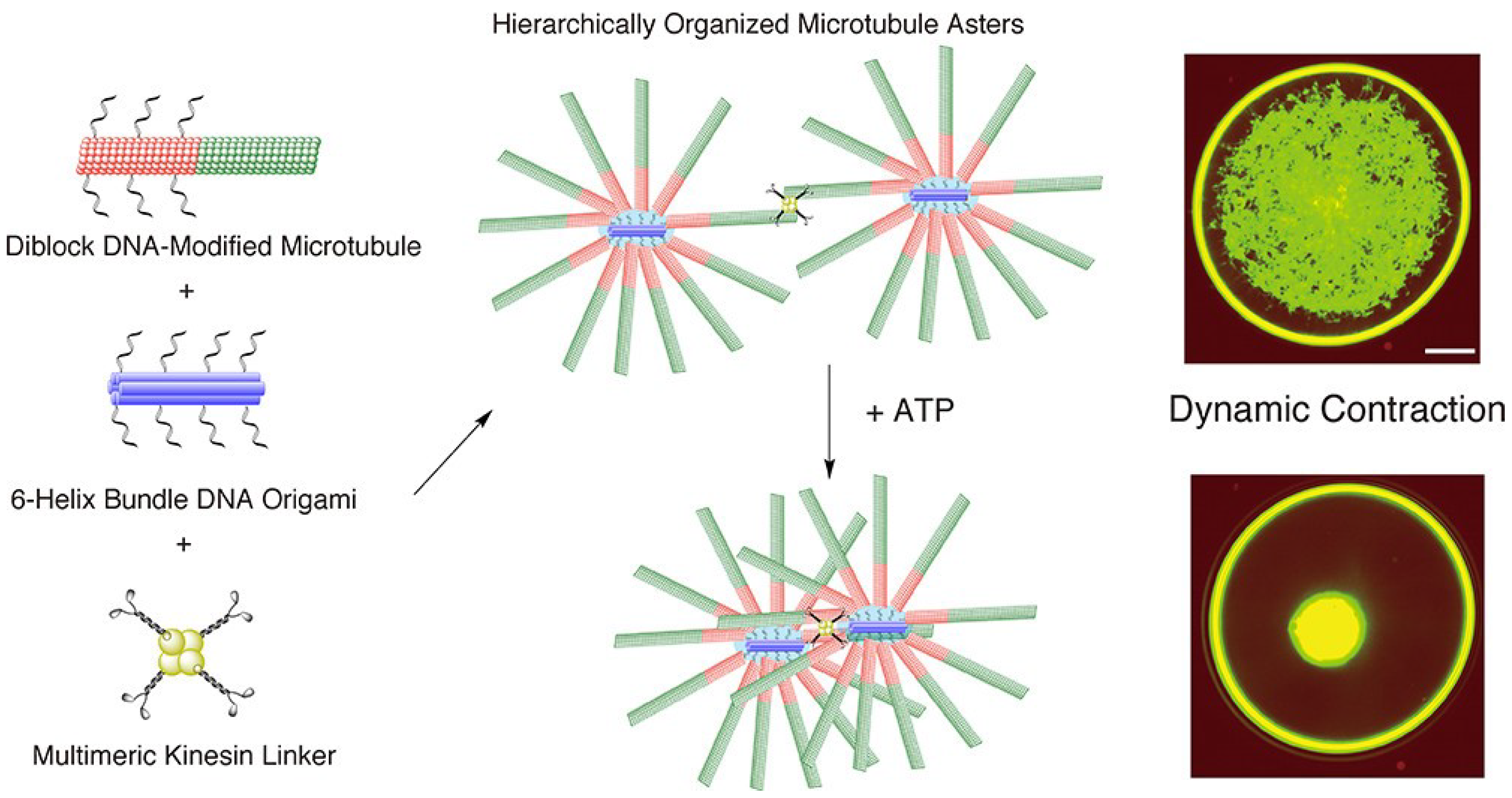

Kinesins are the most commonly used motor protein due to their advantageous properties in the application of artificial muscles. One of the more recent advances in molecular motors in artificial muscles was a study conducted by Matsuda et al. [85]. The study was modeled after macroscopic and mechanical swarm robots. The “robot” was composed of three parts: DNA, a microtubule, and kinesin. The DNA is composed of six DNA helices bundled together in a hexagonal cross-section. The DNA acts as a sensor and a processor. From the DNA, 12 microtubules extrude. The microtubule was modified with single-strand DNA to act as the bridge for each molecular swarm robot. The final piece of this molecular robot is the kinesin. The kinesin is the actuator of the robot. The kinesins are multimeric that attach themselves to the bridges of each robot. When ATP hydrolysis begins, the kinesin pulls the bridges together until it reaches the end of the microtubules. As all the kinesin pulls the bridges together, the swarm robots’ contract into themselves. Although the process is a simple contraction, the programmability of DNA will allow the robots to perform a more complex task. Matsuda et al. speculate that the combination of DNA nanotechnology and biomolecular motor systems will open a new dimension for programmable molecular robots, a simplified diagram of each molecular robot’s components is shown in Figure 10 [84,85].

Figure 10.

This is a simplified diagram with brief explanations of each of the molecular robot’s components and how each “robot” interacts with one another (Reprinted with permission from Matsuda, K. et al. [85]. Copyright 2019 American Chemical Society).

4.5. Metallic Nanoparticles

Nanoparticles are matter that ranges from 1 to 100 nm in diameter. At that scale, particles begin to exhibit different properties than their larger counterparts. Nanoparticles are not subject to the same laws of physics as larger objects; at the same time, they are too big to be subjected to the laws of atomic and molecular matter. One reason that nanoparticles are effective is because of their surface area Despite their small size, nanoparticles have more surface area than material made up of bigger particles. The greater surface area allows more particles to come into contact with surrounding material, making it more reactive. The common nanoparticles used are made up of pure metals or metal oxides [75,88].