Characteristics of Hydraulic and Electric Servo Motors

Abstract

:1. Introduction

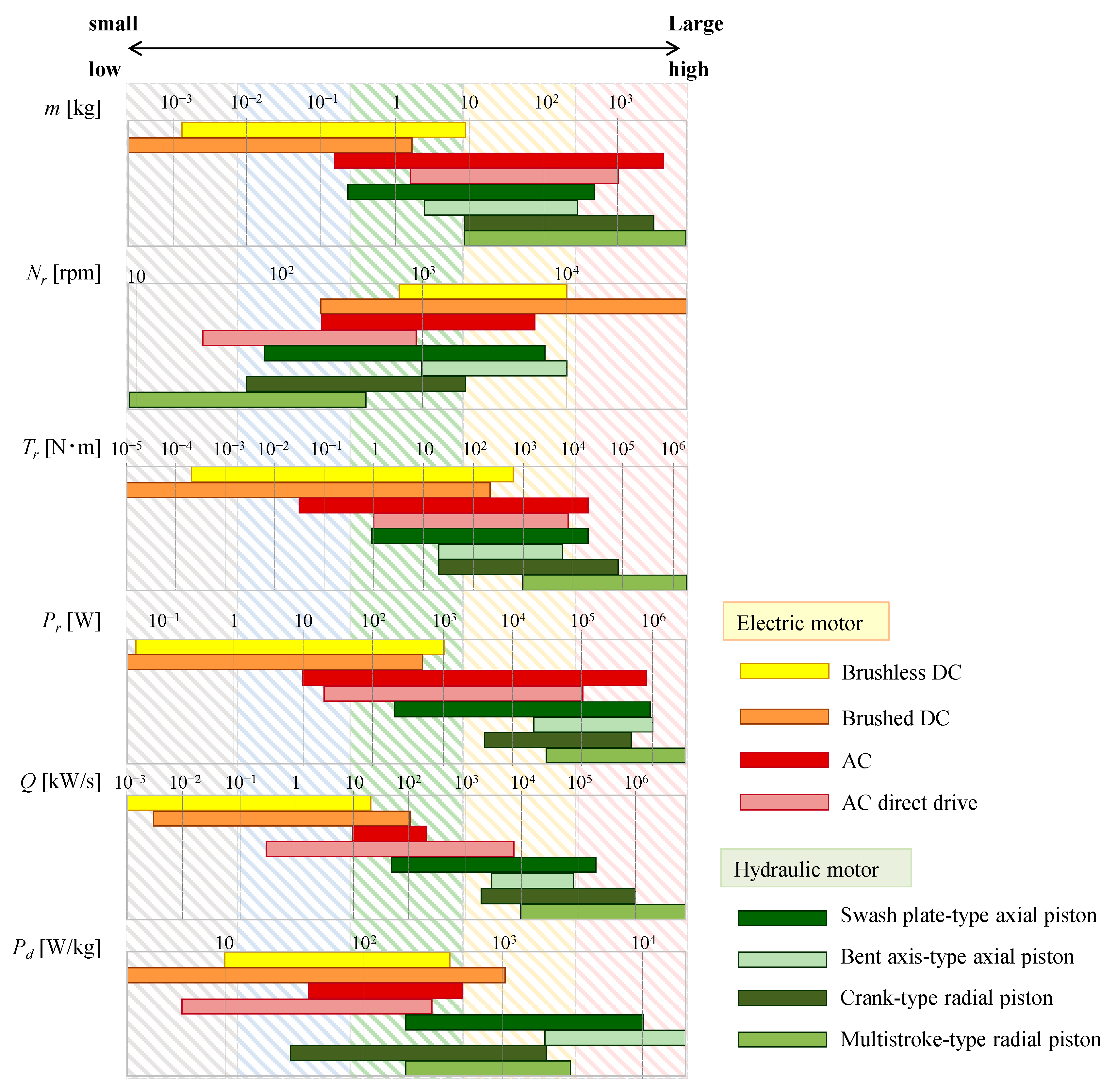

2. Survey Target

3. Performance Indexes

4. Trends of Motor Characteristics

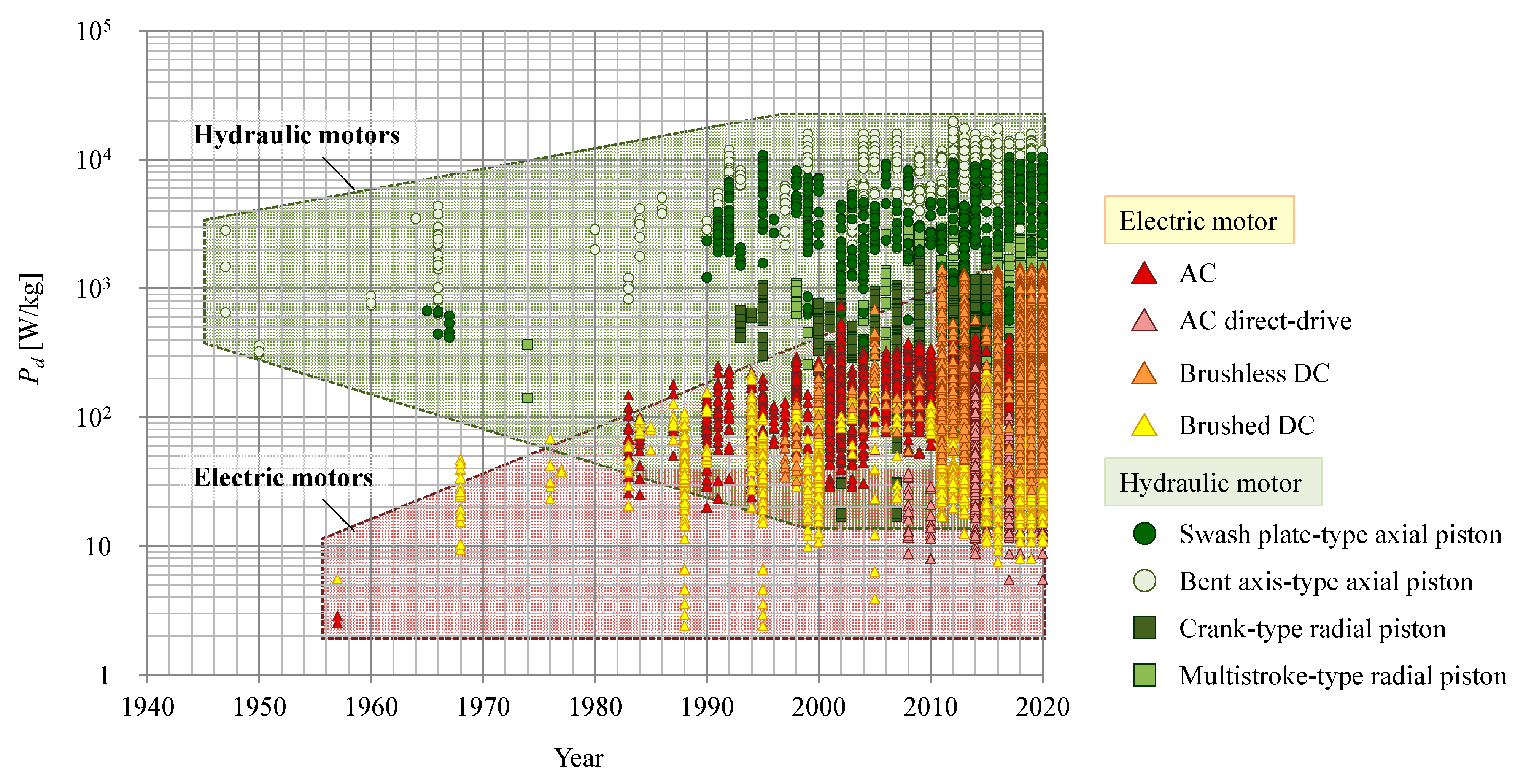

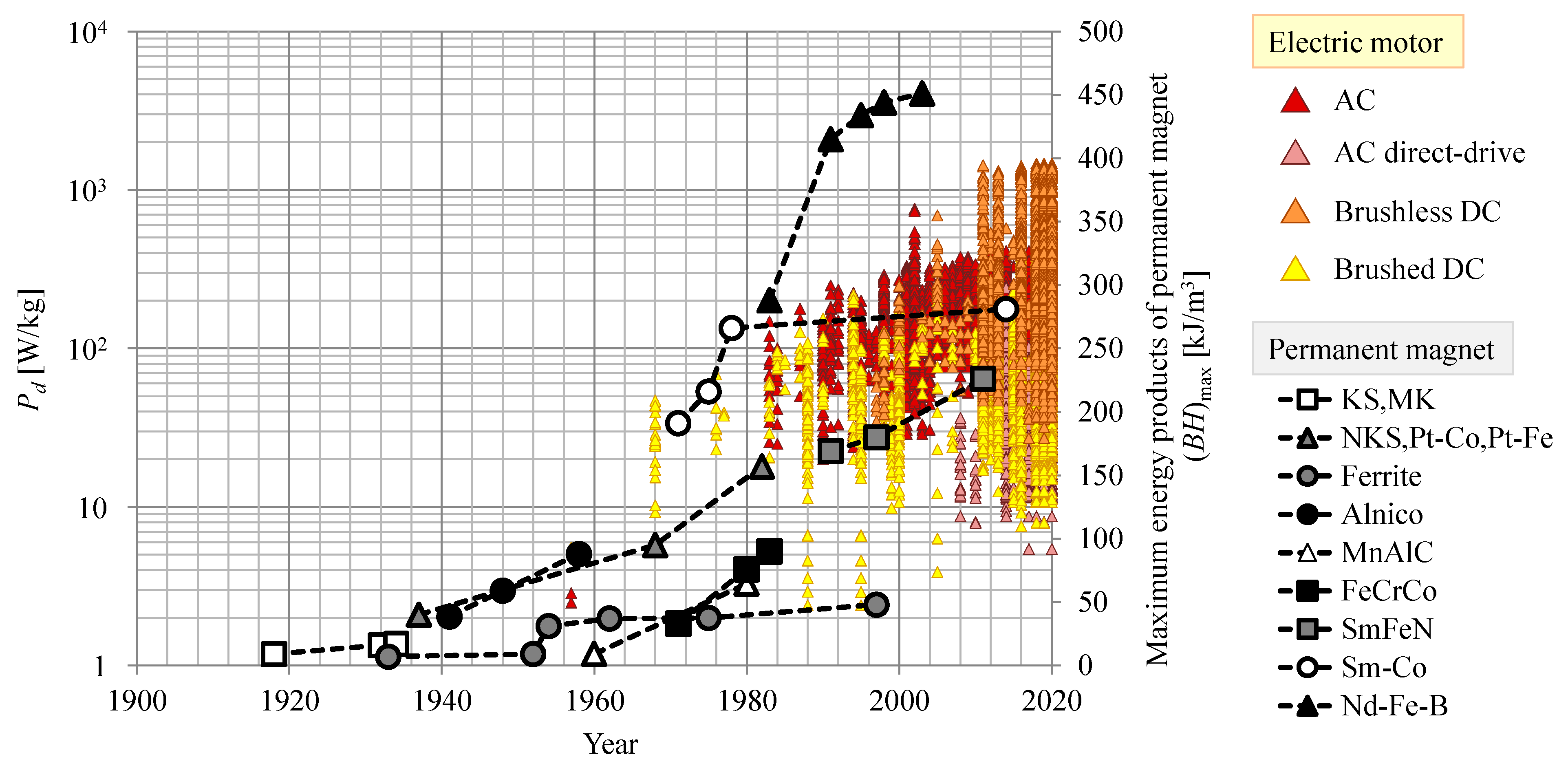

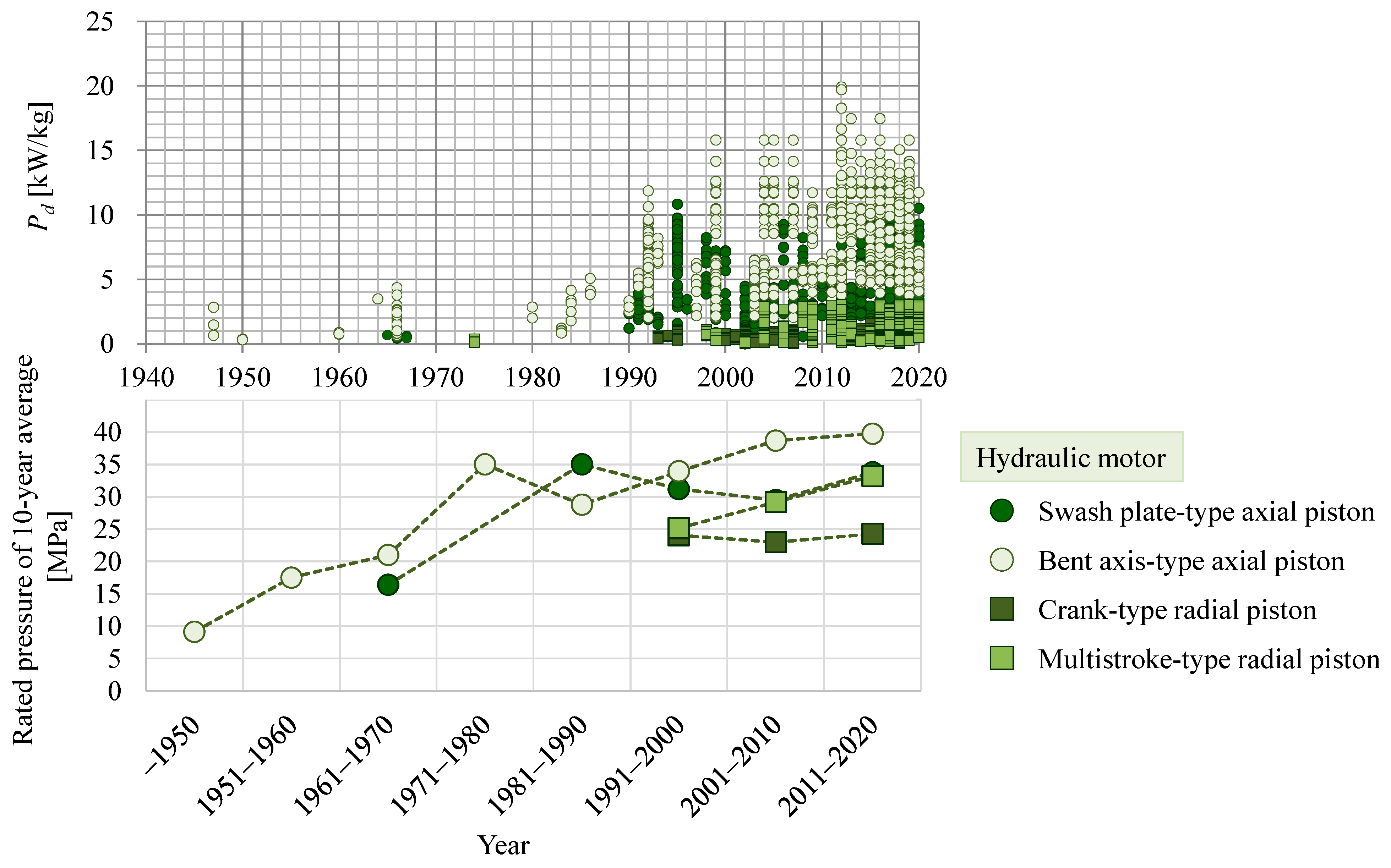

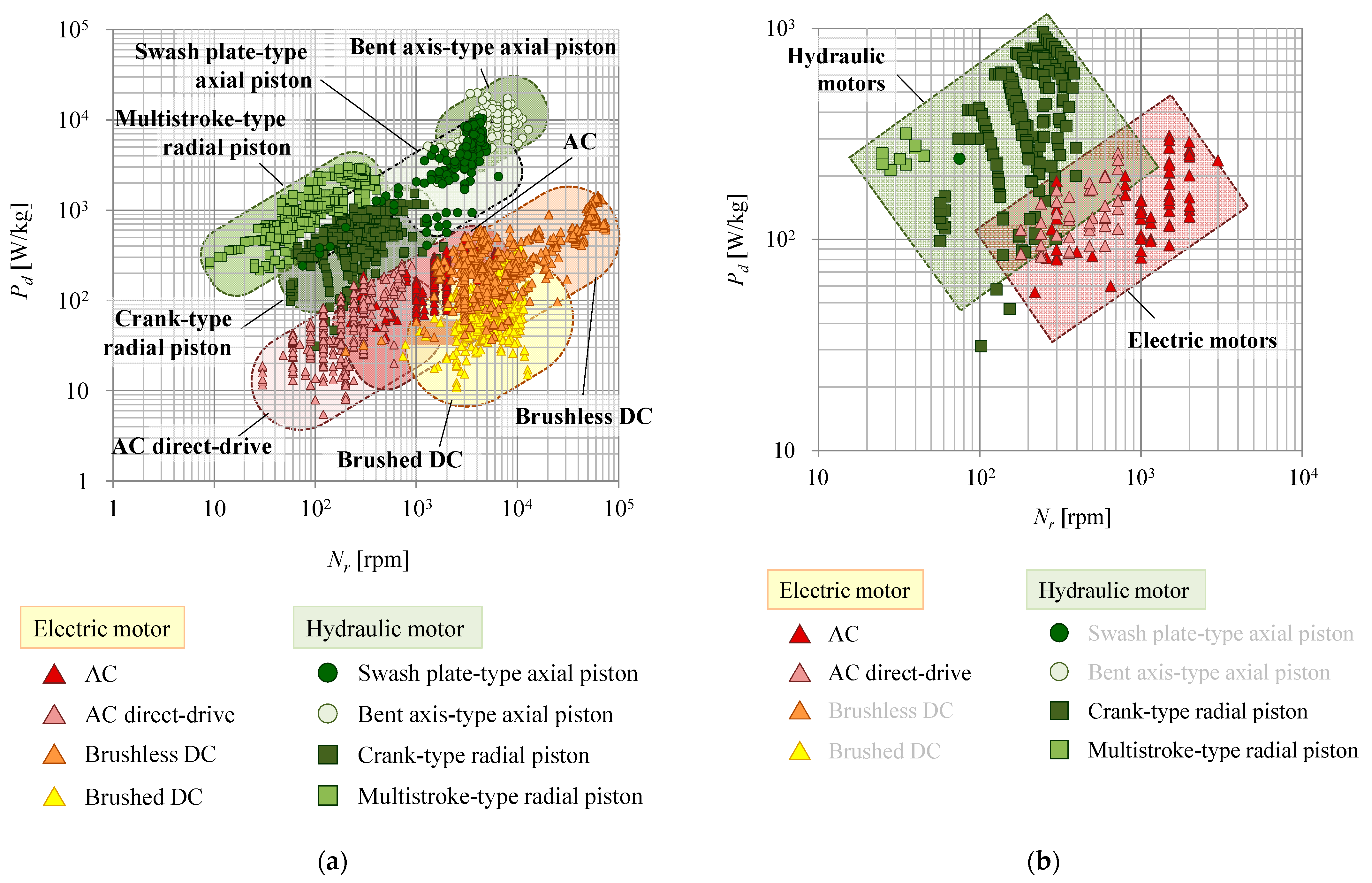

4.1. Power Density

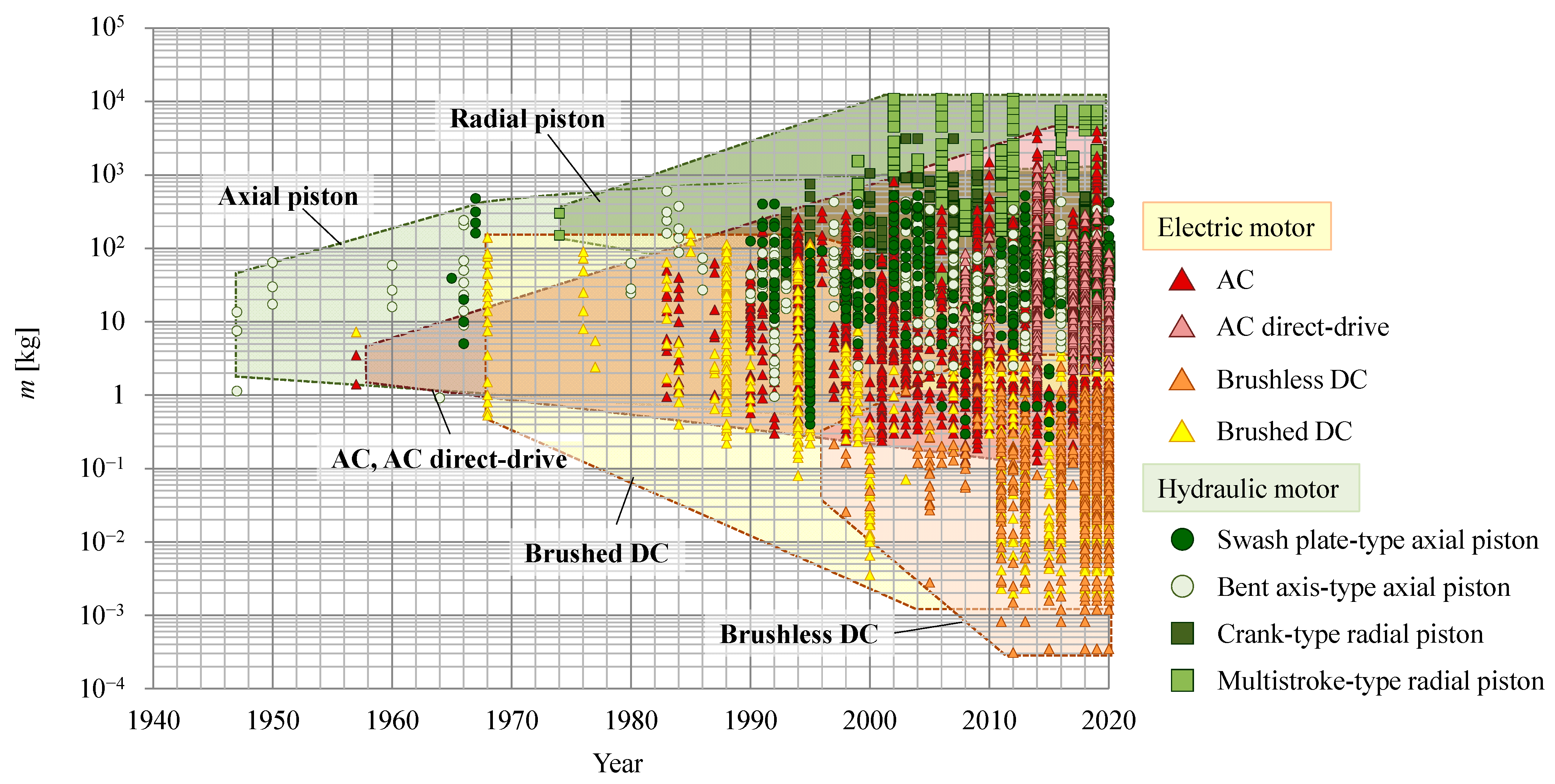

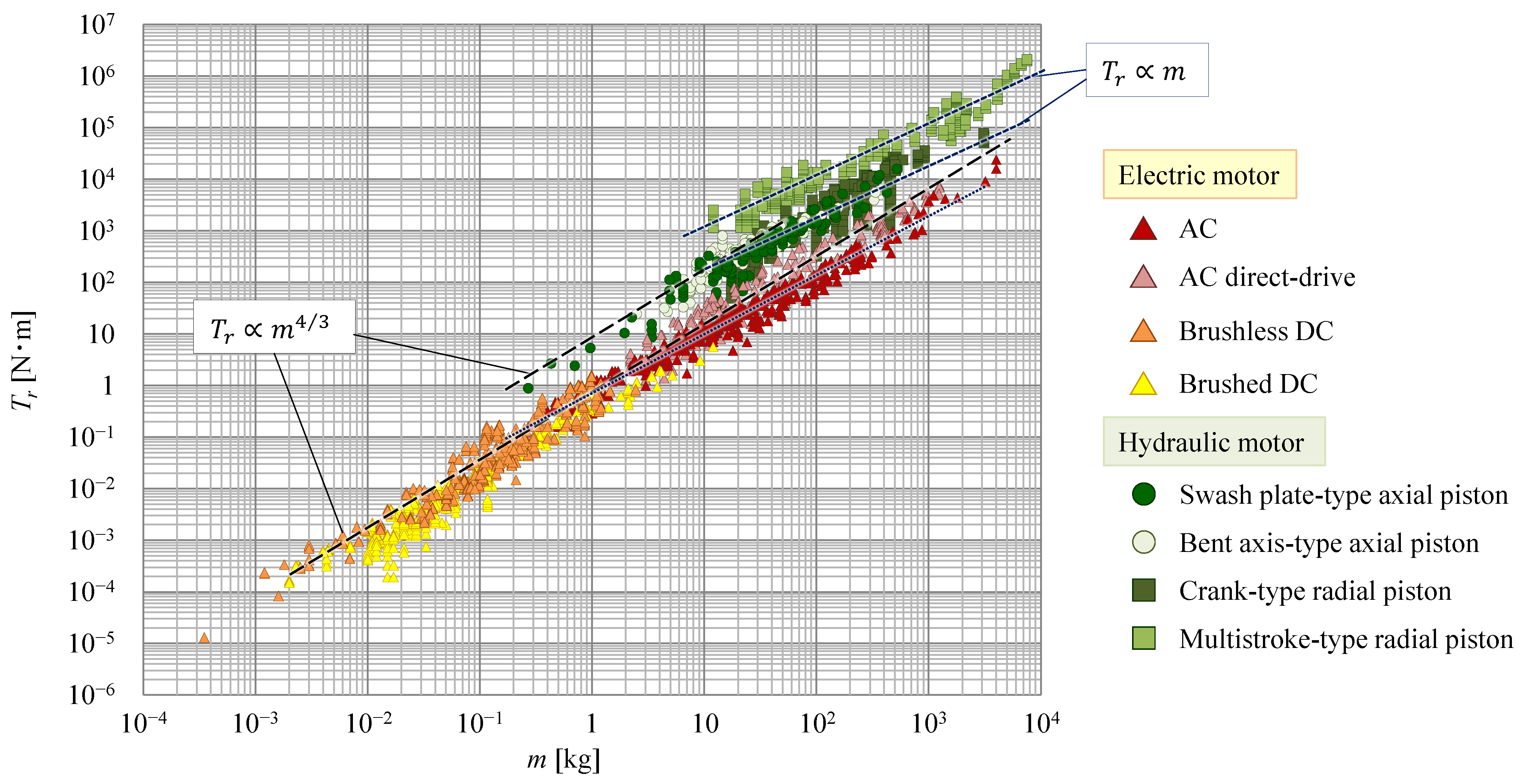

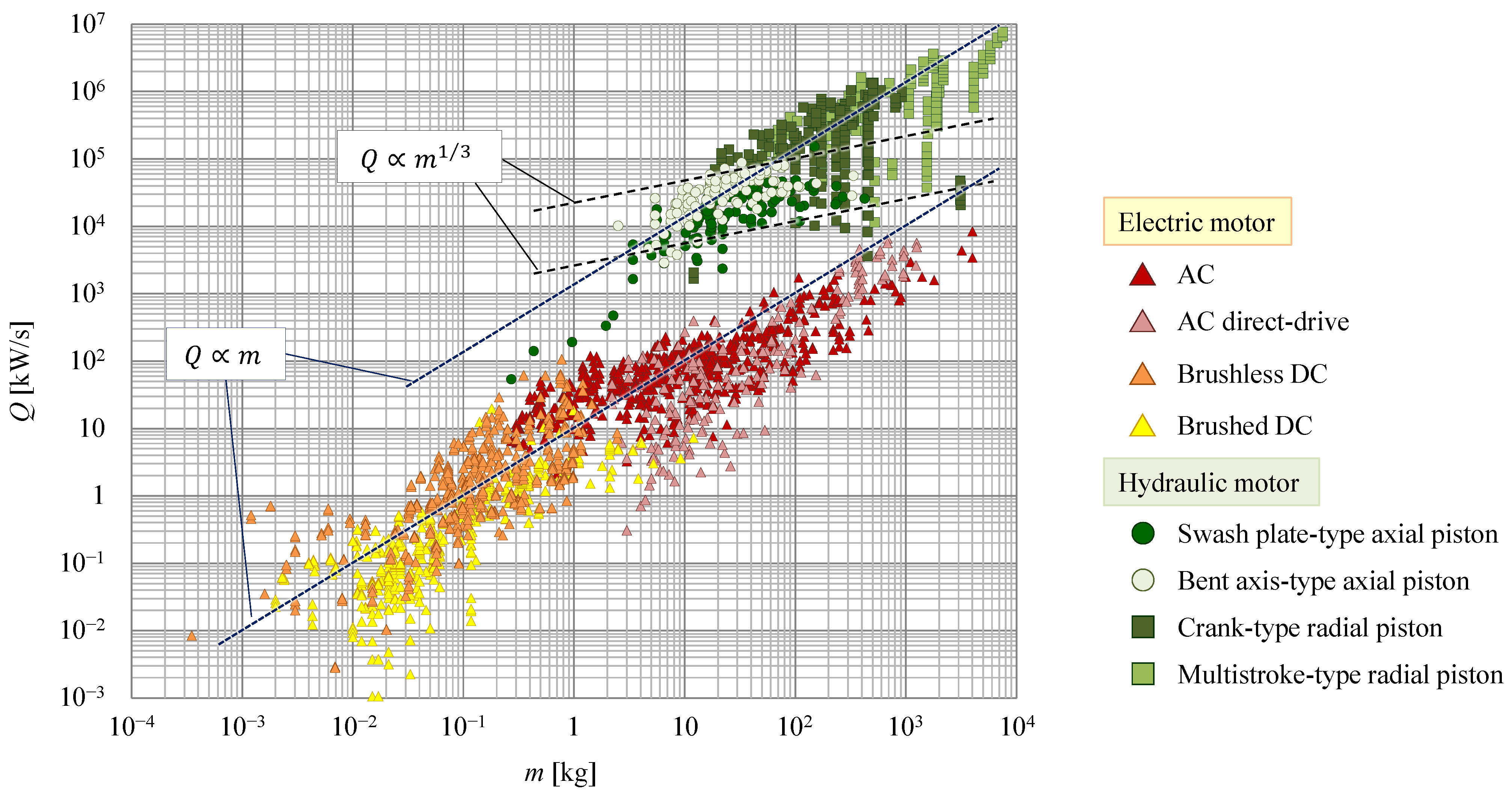

4.2. Weight and Torque

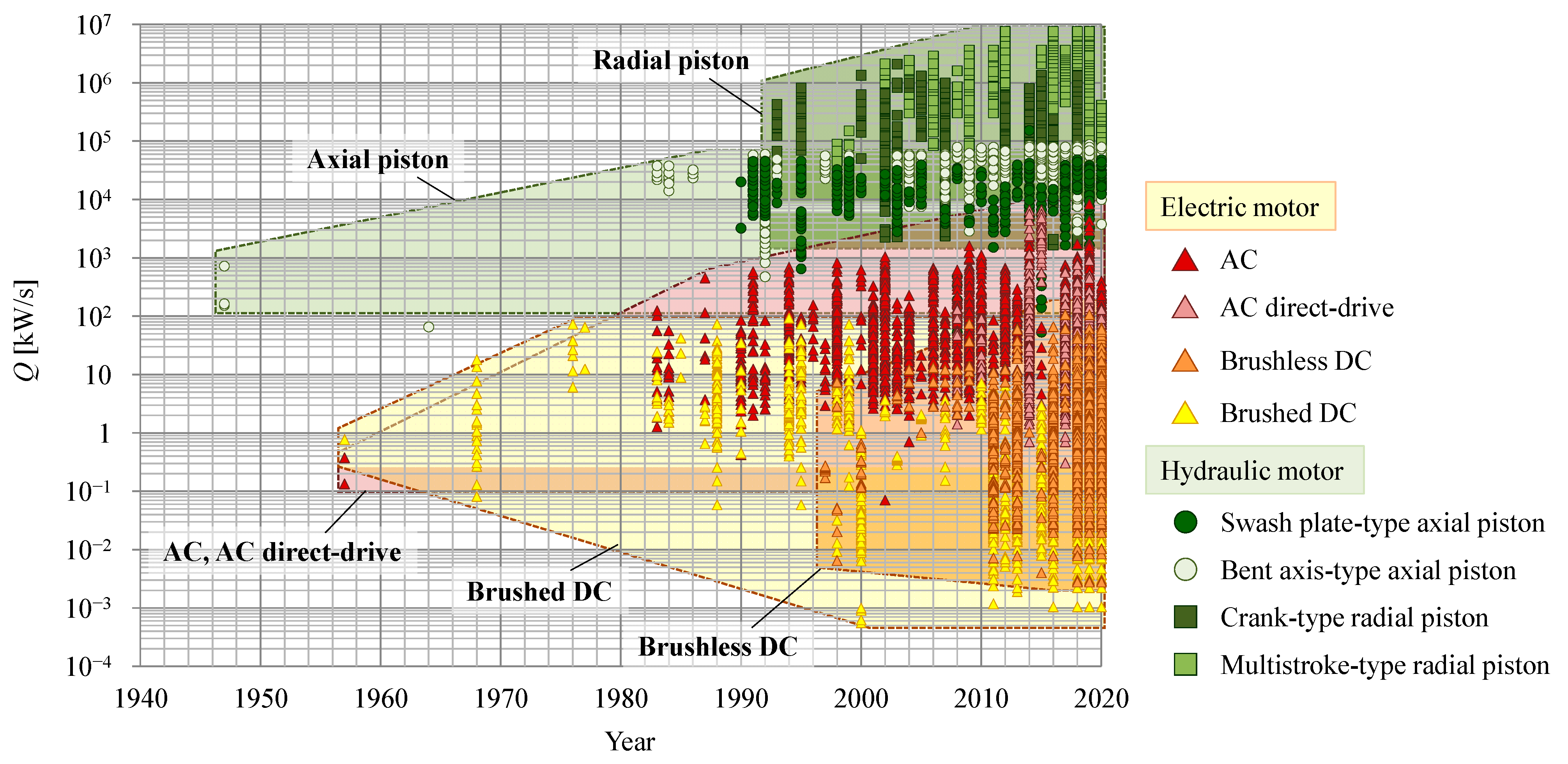

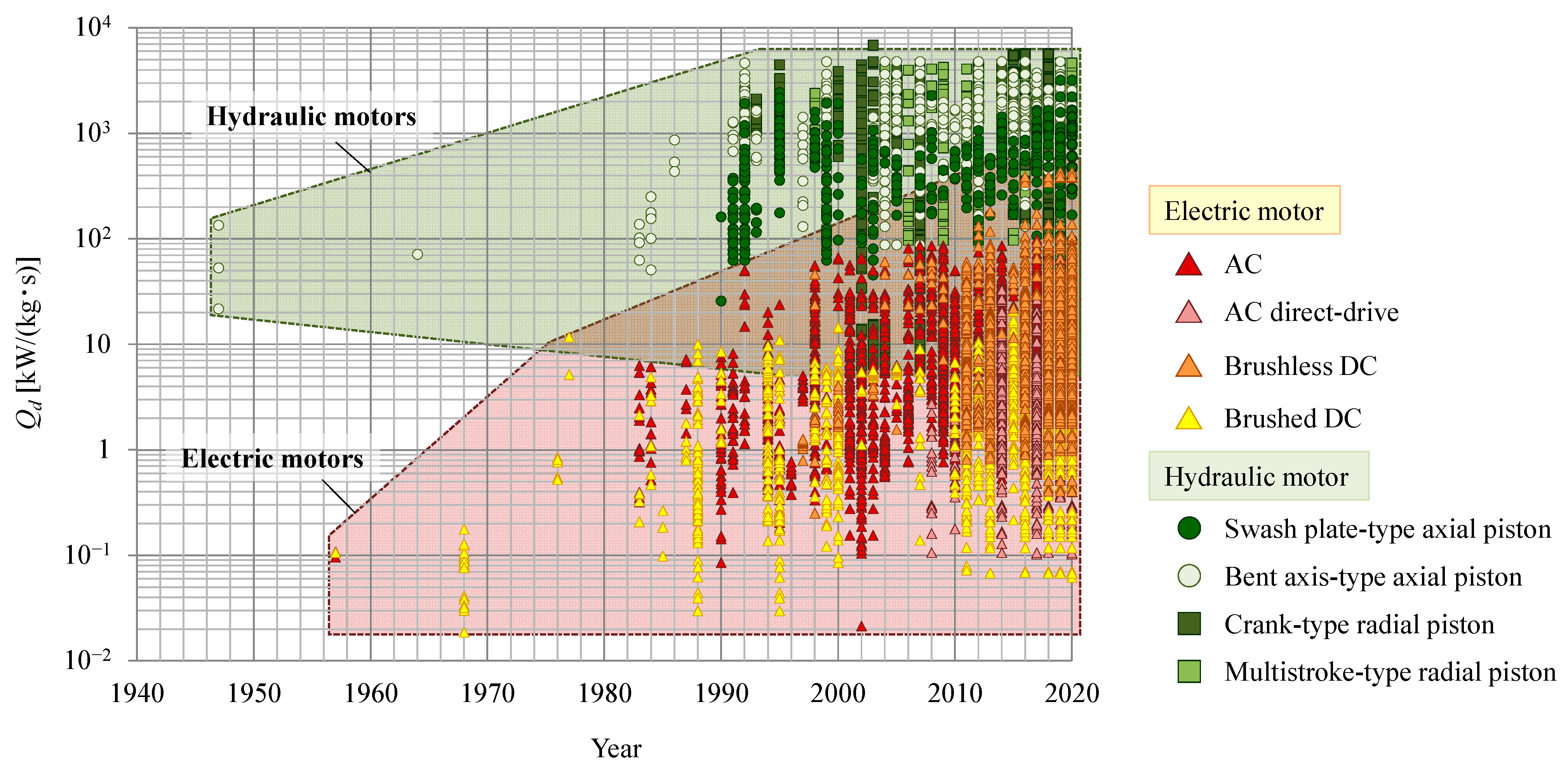

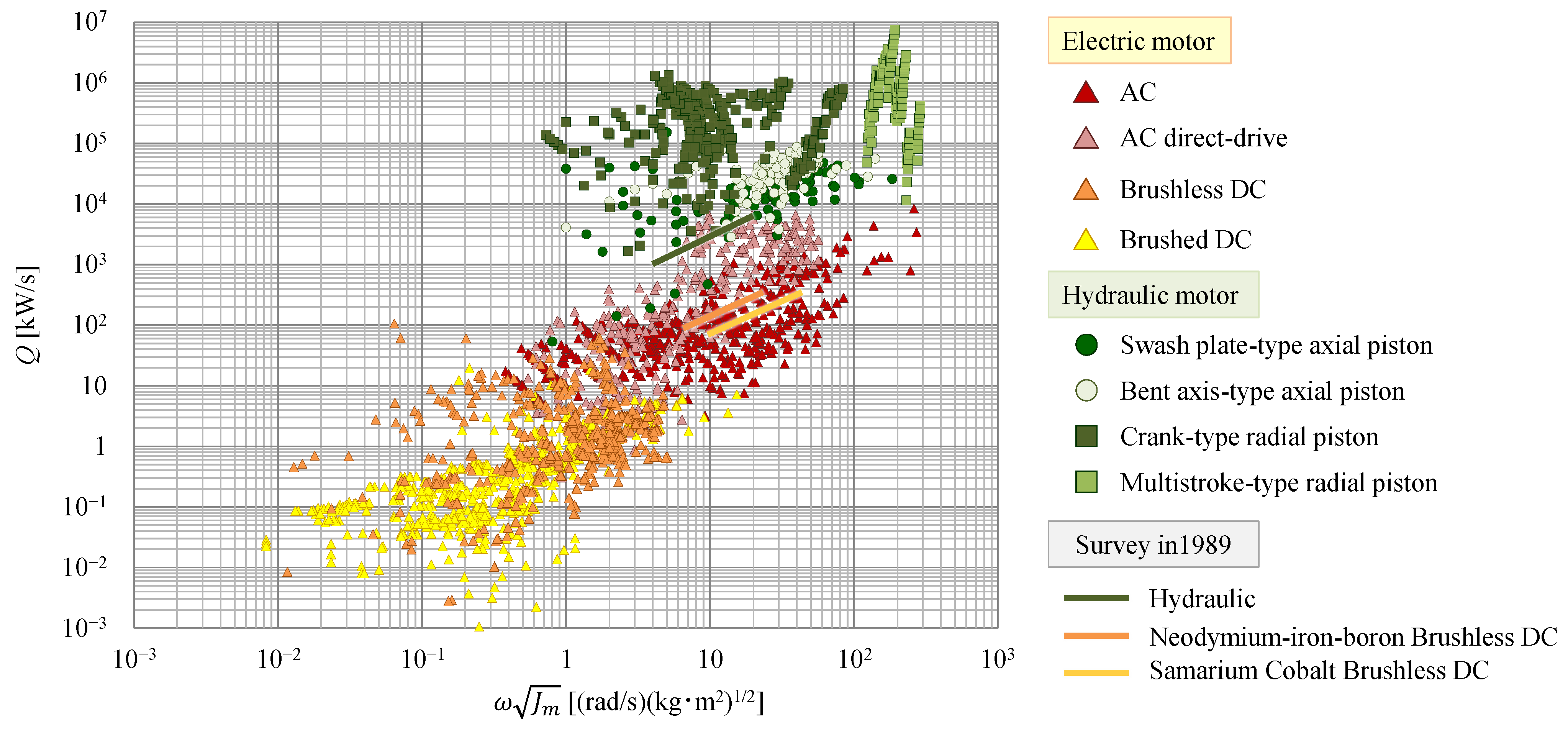

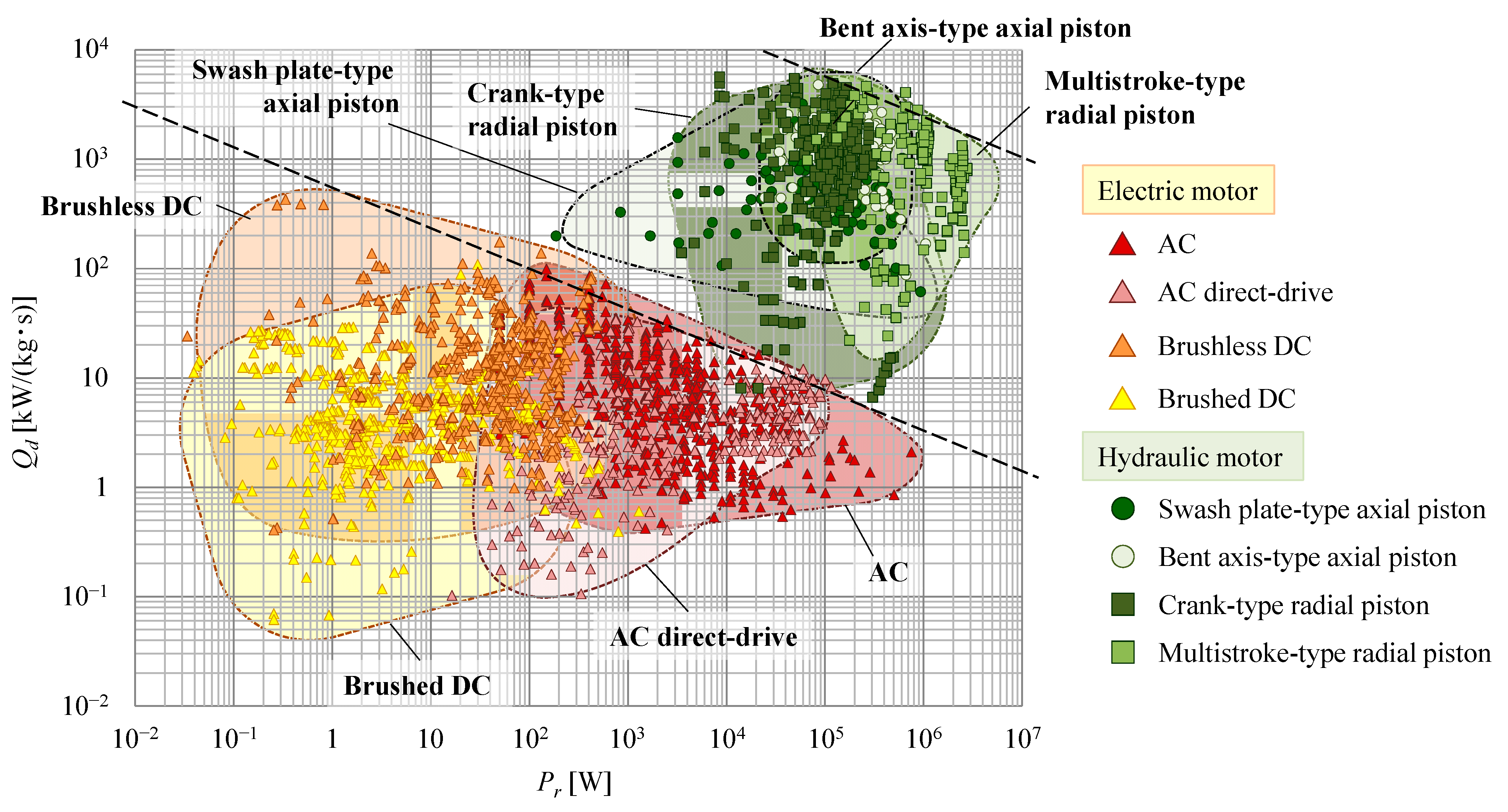

4.3. Power Rate and Power Rate Density

5. Trends of Motor Characteristics

5.1. Weight–Torque

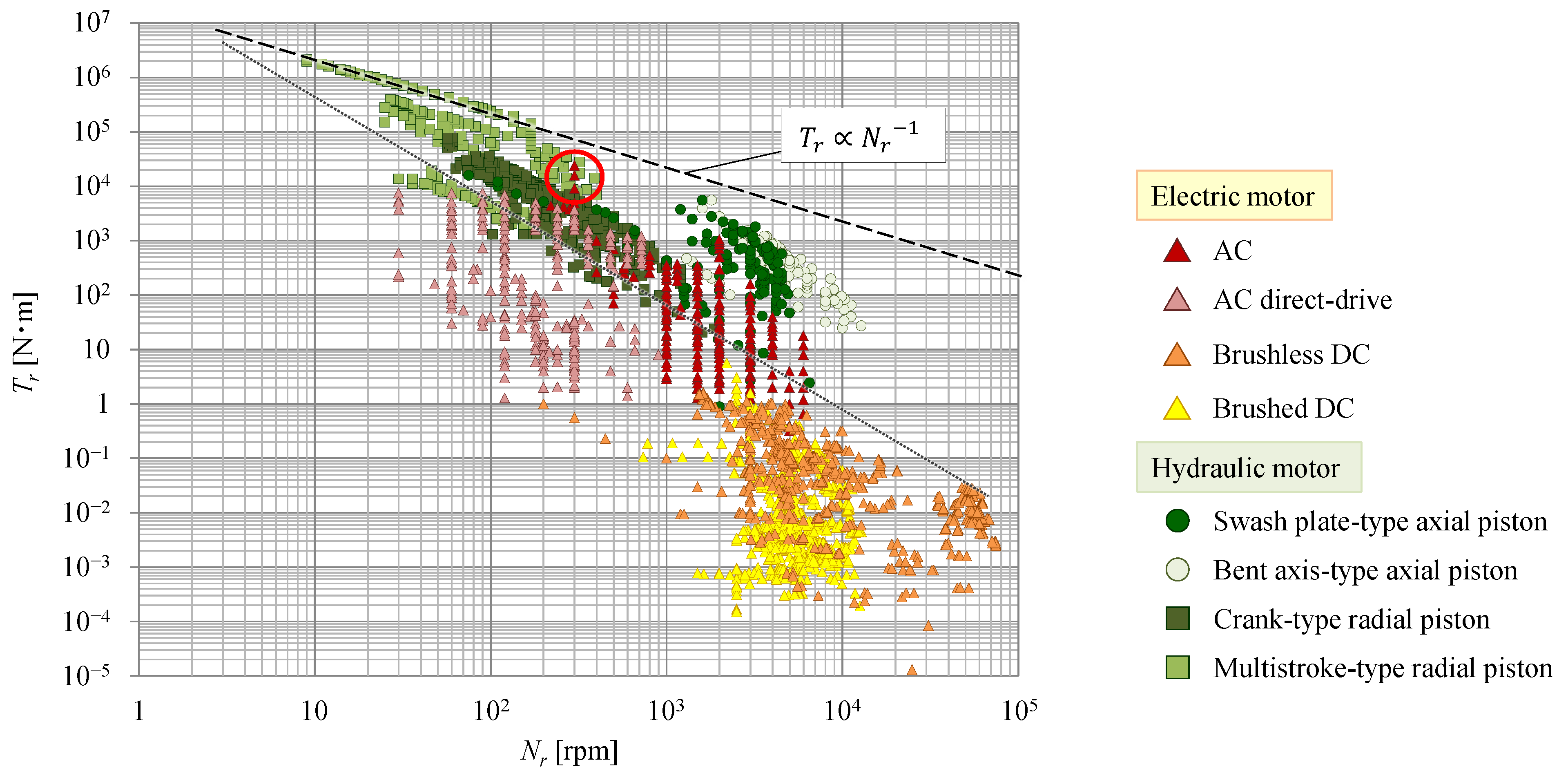

5.2. Rated Rotating Speed–Torque

5.3. Weight, Rotating Speed–Power, Power Density

5.4. Power Rate and Power Rate Density

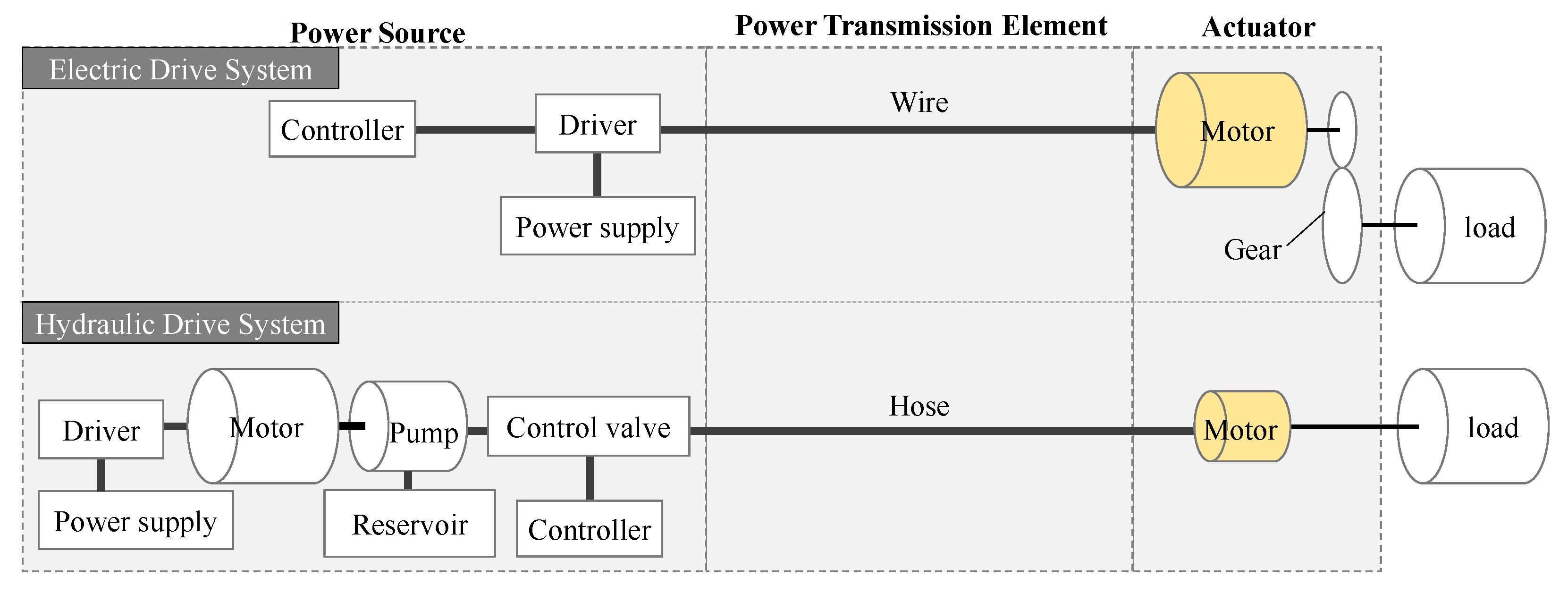

6. Comparison of Electric and Hydraulic Drive Systems

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Brinkman, N.; Eberle, U.; Formanski, V.; Grebe, U.-D.; Matthe, R. Vehicle Electrification—Quo Vadis?/Fahrzeugelektrifizierung—Quo Vadis? In Proceedings of the 33rd International Vienna Motor Symposium, Vienna, Austria, 26–27 April 2012; pp. 186–215. [Google Scholar]

- Pugi, L.; Delogu, M.; Grasso, F.; Berzi, L.; Pero, F.D.; Savi, R.; Boni, E. Electrification of Directional Drilling Machines for Sustainable Trenchless Excavations. In Proceedings of the 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I &CPS Europe), Genova, Italy, 11–14 June 2019; pp. 1–6. [Google Scholar]

- Lequesne, B. Automotive electrification: The nonhybrid story. IEEE Trans. Transp. Electrif. 2015, 1, 40–53. [Google Scholar] [CrossRef]

- Wenping, C.; Mecrow, B.C.; Atkinson, G.J.; Bennett, J.W.; Atkinson, D.J. Overview of electric motor technologies used for more electric aircraft (MEA). IEEE Trans. Ind. Electron. 2012, 59, 3523–3531. [Google Scholar] [CrossRef]

- Qiao, G.; Liu, G.; Shi, Z.; Wang, Y.; Ma, S.; Lim, T.C. A Review of Electromechanical Actuators for More/All Electric Aircraft Systems. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 4128–4151. [Google Scholar] [CrossRef] [Green Version]

- Sarlioglu, B.; Morris, C.T. More electric aircraft: Review, challenges, and opportunities for commercial transport aircraft. IEEE Trans. Transp. Electr. 2015, 1, 54–64. [Google Scholar] [CrossRef]

- El-Refaie, A.M. Growing Role of Electrical Machines and Drives in Electrification. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 364–370. [Google Scholar]

- Raibert, M.; Blankespoor, K.; Nelson, G.; Playter, R. BigDog, the Rough-Terrain Quadruped Robot. IFAC Proc. Vol. 2008, 41, 10822–10825. [Google Scholar] [CrossRef] [Green Version]

- ATLAS®. Available online: https://www.bostondynamics.com/atlas (accessed on 28 December 2021).

- Semini, C.; Barasuol, V.; Focchi, M.; Boelens, C.; Emara, M.; Casella, S.; Villarreal, O.; Orsolino, R.; Fink, G.; Fahmi, S. Brief Introduction to the Quadruped Robot HyQReal. In Proceedings of the Italian Conference on Robotics and Intelligent Machines (I-RIM), Rome, Italy, 18–20 October 2019; pp. 1–2. [Google Scholar]

- Suzumori, K.; Faudzi, A.A. Trends in hydraulic actuators and components in legged and tough robots: A review. Adv. Robot. 2018, 32, 458–476. [Google Scholar] [CrossRef]

- Mattila, J.; Koivumäki, J.; Caldwell, D.G.; Semini, C. A survey on control of hydraulic robotic manipulators with projection to future trends. IEEE/ASME Trans. Mechatron. 2017, 22, 669–680. [Google Scholar] [CrossRef]

- Kaminaga, H.; Ko, T.; Masumura, R.; Komagata, M.; Sato, S.; Yorita, S.; Nakamura, Y. Mechanism and Control of Whole-Body Electro-Hydrostatic Actuator Driven Humanoid Robot Hydra. In International Symposium on Experimental Robotics; Springer: Cham, Switzerland, 2016; pp. 656–665. [Google Scholar]

- Hyon, S.-H.; Taniai, Y.; Hiranuma, K.; Yasunaga, K.; Mizui, H. Overpressure compensation for hydraulic hybrid servo booster applied to hydraulic manipulator. IEEE Robot. Autom. Lett. 2019, 4, 942–949. [Google Scholar] [CrossRef]

- Barasuol, V.; Villarreal-Magaña, O.A.; Sangiah, D.; Frigerio, M.; Baker, M.; Morgan, R.; Medrano-Cerda, G.A.; Caldwell, D.G.; Semini, C. Highly-integrated hydraulic smart actuators and smart manifolds for high-bandwidth force control. Front. Robot. AI 2018, 5, 51. [Google Scholar] [CrossRef] [Green Version]

- Murrenhoff, H. Recent Sustainability Related Research Results in Fluid Power. In Proceedings of the 2011 International Conference on Fluid Power and Mechatronics, Beijing, China, 17–20 August 2011; pp. 991–1001. [Google Scholar]

- Hamzehlouia, S.; Izadian, A. Modeling of Hydraulic Wind Power Transfers. In Proceedings of the 2012 IEEE Power and Energy Conference at Illinois, Champaign, IL, USA, 24–25 February 2012; pp. 1–6. [Google Scholar]

- Cai, M.; Wang, Y.; Jiao, Z.; Shi, Y. Review of fluid and control technology of hydraulic wind turbines. Front. Mech. Eng. 2017, 12, 312–320. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Li, W.; Lin, Y.; Bao, J. An overview of hydraulic systems in wave energy application in China. Renew. Sustain. Energy Rev. 2012, 16, 4522–4526. [Google Scholar] [CrossRef]

- Gaspar, J.F.; Calvário, M.; Kamarlouei, M.; Soares, C.G. Design tradeoffs of an oil-hydraulic power take-off for wave Energy converters. Renew. Energy 2018, 129, 245–259. [Google Scholar] [CrossRef]

- Hansen, R.H.; Kramer, M.M.; Vidal, E. Discrete Displacement Hydraulic Power Take-Off System for the Wavestar Wave Energy Converter. Energies 2013, 6, 4001–4044. [Google Scholar] [CrossRef]

- Gaspar, J.F.; Calvário, M.; Kamarlouei, M.; Guedes Soares, C. Power take-off concept for wave energy converters based on oil-hydraulic transformer units. Renew. Energy 2016, 86, 1232–1246. [Google Scholar] [CrossRef]

- Trautman, W.C.; Middleton, R.E. Comparison of Hydraulic and Electrical Accessory Systems in Aircraft. SAE Trans. 1944, 52, 94–99. [Google Scholar]

- Geyer, M.H.; Treseder, R.C. Weight analysis of aircraft actuators. Trans. Am. Inst. Electr. Eng. Part II Appl. Ind. 1952, 71, 118–126. [Google Scholar]

- Southwell, P.H. Mechanical, Electrical or Hydraulic Transmission? Can. Agric. Eng. 1960, 2, 24–27. [Google Scholar]

- Foster, K.; Fenney, L. Characteristics and Dynamic Performance of Electrical and Hydraulic Servo-Drives. Proc. JFPS Int. Symp. Fluid Power 1989, 1989, 15–22. [Google Scholar] [CrossRef]

- Dransfield, P. Comparing the Responses of Electric, Pneumatic, and Hydraulic Servodrives. IFAC Proc. Vol. 1990, 23, 551–555. [Google Scholar] [CrossRef]

- Backé, W. The Present and Future of Fluid Power. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 1993, 207, 193–212. [Google Scholar] [CrossRef]

- Nakano, K.; Konno, Y. The comparative study on the characteristics of AC, DC Servomotors and hydraulic motors. Hydraul. Pneum. 1997, 28, 466–472. [Google Scholar] [CrossRef]

- Huber, J.E.; Fleck, N.A.; Ashby, M.F. The selection of mechanical actuators based on performance indices. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 1997, 453, 2185–2205. [Google Scholar] [CrossRef]

- Durfee, W.; Xia, J.; Hsiao-Wecksler, E. Tiny Hydraulics for Powered Orthotics. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011; p. 5975473. [Google Scholar]

- Tanaka, Y.; Sakama, S.; Nakano, K.; Kosodo, H. Comparative Study on Dynamic Characteristics of Hydraulic, Pneumatic and Electric Motors. In Proceedings of the ASME/BATH 2013 Symposium on Fluid Power & Motion Control, Sarasota, FL, USA, 6 October 2013; p. V001T001A037. [Google Scholar]

- Kazama, T. Comparison of power density of transmission elements in hydraulic, pneumatic, and electric drive systems. Mech. Eng. Lett. 2019, 5, 19–00139. [Google Scholar] [CrossRef] [Green Version]

- Sagawa, M.; Fujimura, S.; Togawa, N.; Yamamoto, H.; Matsuura, Y. New material for permanent magnets on a base of Nd and Fe (invited). J. Appl. Phys. 1984, 55, 2083–2087. [Google Scholar] [CrossRef]

- Mikami, H.; Ide, K.; Shimizu, Y.; Senoo, M.; Seki, H. Historical evolution of motor technology. Hitachi Rev. 2011, 60, 39. [Google Scholar]

- Kusuda, Y. New generation servomotors. Assem. Autom. 1999, 19, 190–196. [Google Scholar] [CrossRef]

- Kulshreshtha, A.; Charrier, J. Electric Actuation for Flight and Engine Control: Evolution and Challenges. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007. AIAA 2007-1391. [Google Scholar]

| Motor Type | Number of Companies | Total Number of Data | Number of Data Listed in Currently Available Catalogs (as of May 2020) | |

|---|---|---|---|---|

| Electric | AC | 9 | 3844 | 1013 |

| AC direct | 4 | 599 | 308 | |

| Brushless DC | 8 | 3954 | 705 | |

| Brushed DC | 6 | 2333 | 611 | |

| Hydraulic | Swash plate-type axial piston | 12 | 485 | 60 |

| Bent axis-type axial piston | 6 | 726 | 192 | |

| Crank-type radial piston | 4 | 929 | 488 | |

| Multistroke-type radial piston | 3 | 954 | 296 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakama, S.; Tanaka, Y.; Kamimura, A. Characteristics of Hydraulic and Electric Servo Motors. Actuators 2022, 11, 11. https://doi.org/10.3390/act11010011

Sakama S, Tanaka Y, Kamimura A. Characteristics of Hydraulic and Electric Servo Motors. Actuators. 2022; 11(1):11. https://doi.org/10.3390/act11010011

Chicago/Turabian StyleSakama, Sayako, Yutaka Tanaka, and Akiya Kamimura. 2022. "Characteristics of Hydraulic and Electric Servo Motors" Actuators 11, no. 1: 11. https://doi.org/10.3390/act11010011

APA StyleSakama, S., Tanaka, Y., & Kamimura, A. (2022). Characteristics of Hydraulic and Electric Servo Motors. Actuators, 11(1), 11. https://doi.org/10.3390/act11010011