An Origami Flexiball-Inspired Metamaterial Actuator and Its In-Pipe Robot Prototype

Abstract

1. Introduction

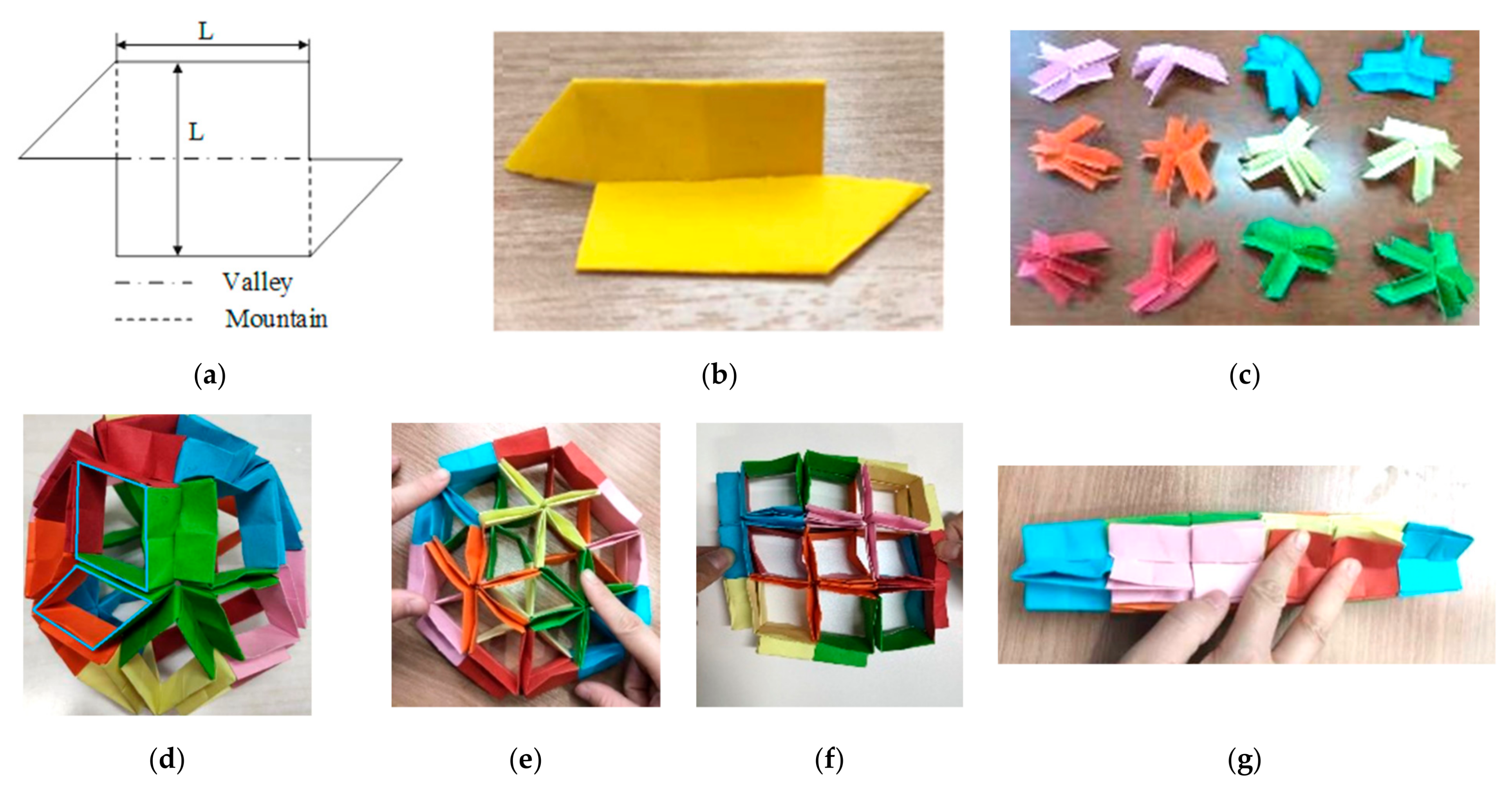

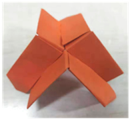

2. Intrinsic Metamaterial Mechanisms of Origami Flexiball

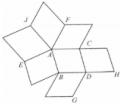

2.1. Topology and Geometry of Origami Flexiball

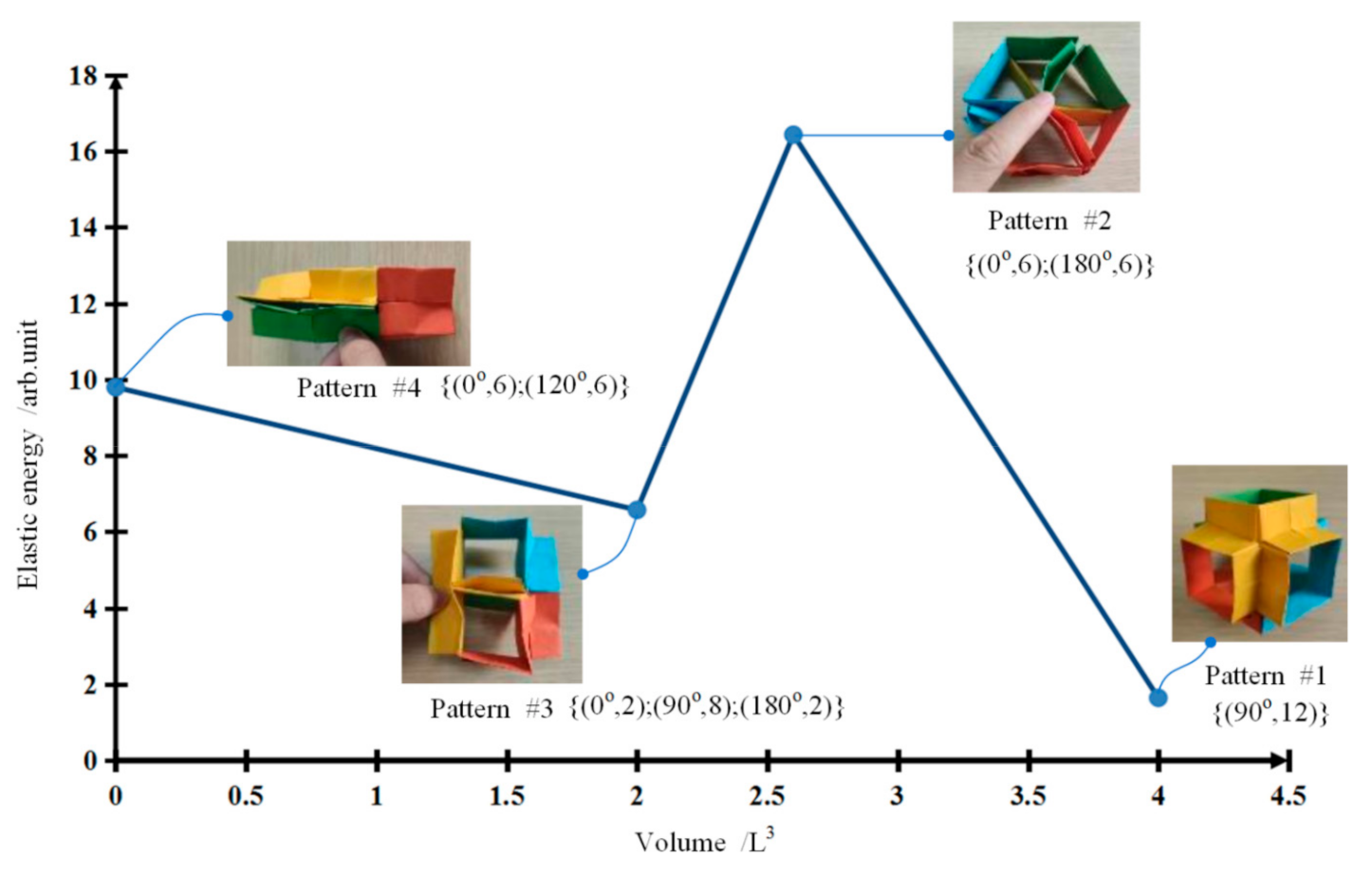

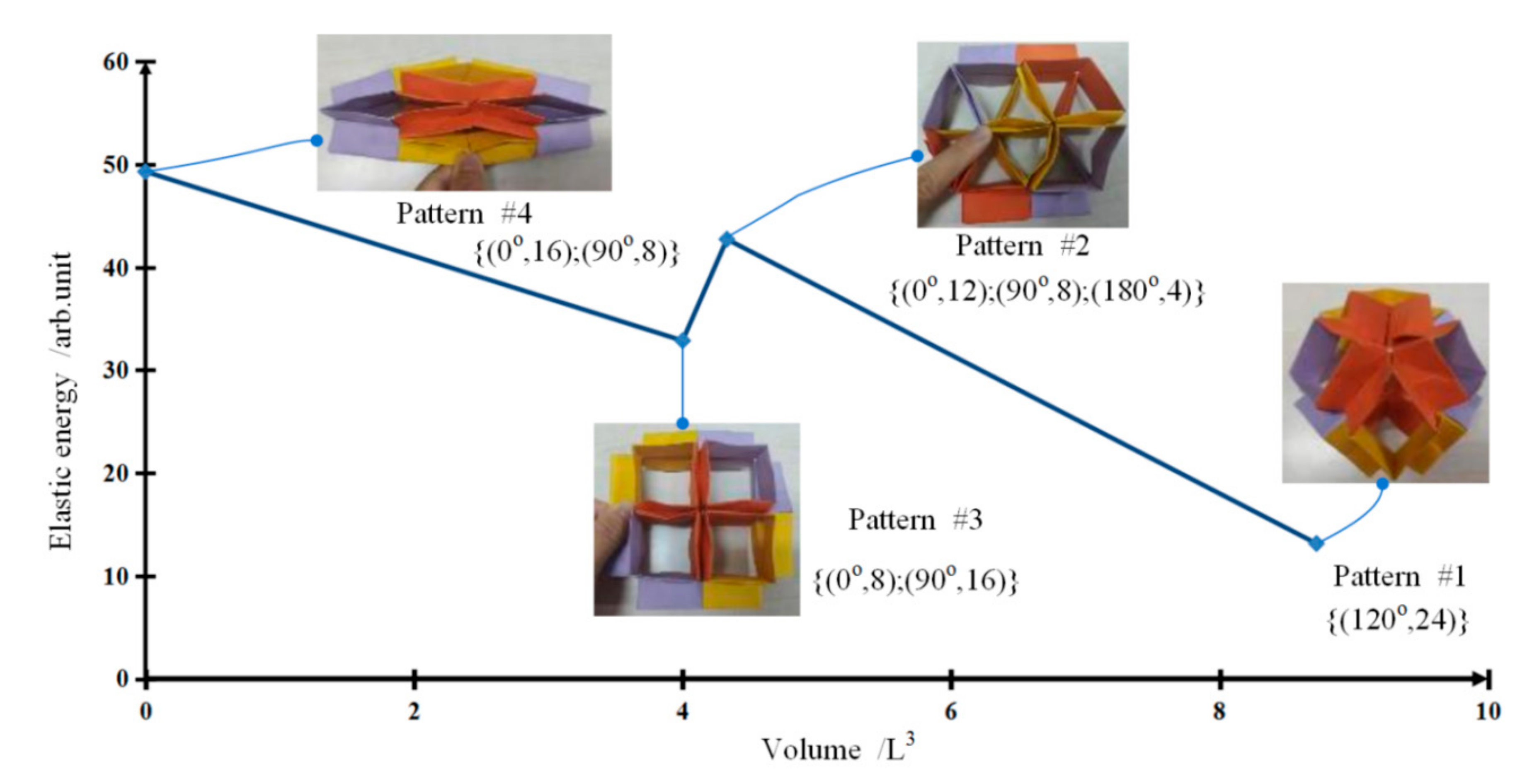

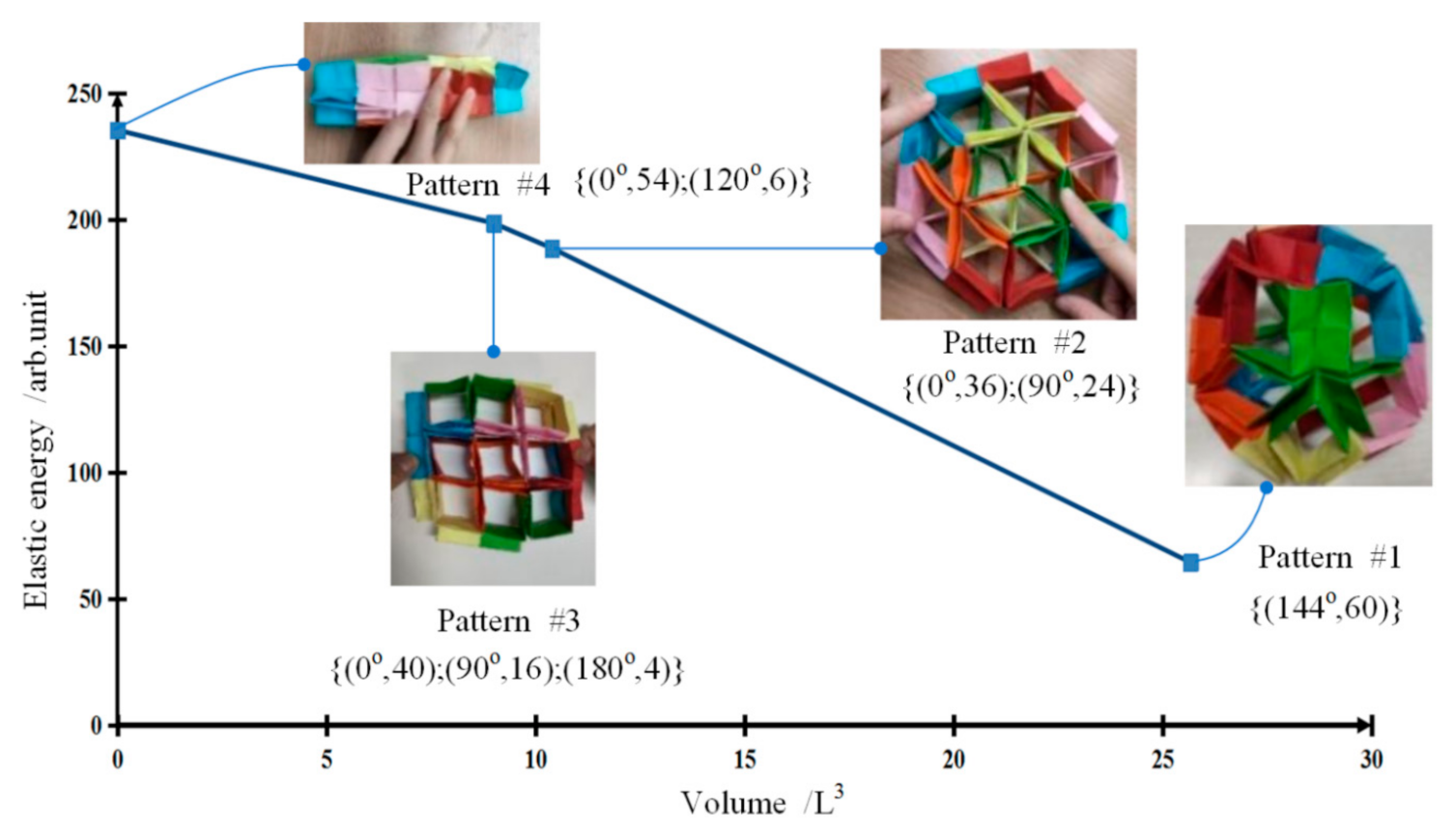

2.2. Energy Landscape of Origami Flexiball

2.3. Intrinsic Metamaterial Properties of Origami Flexiball

3. Magnetically Driven In-Pipe Robot Inspired by Origami Flexiball

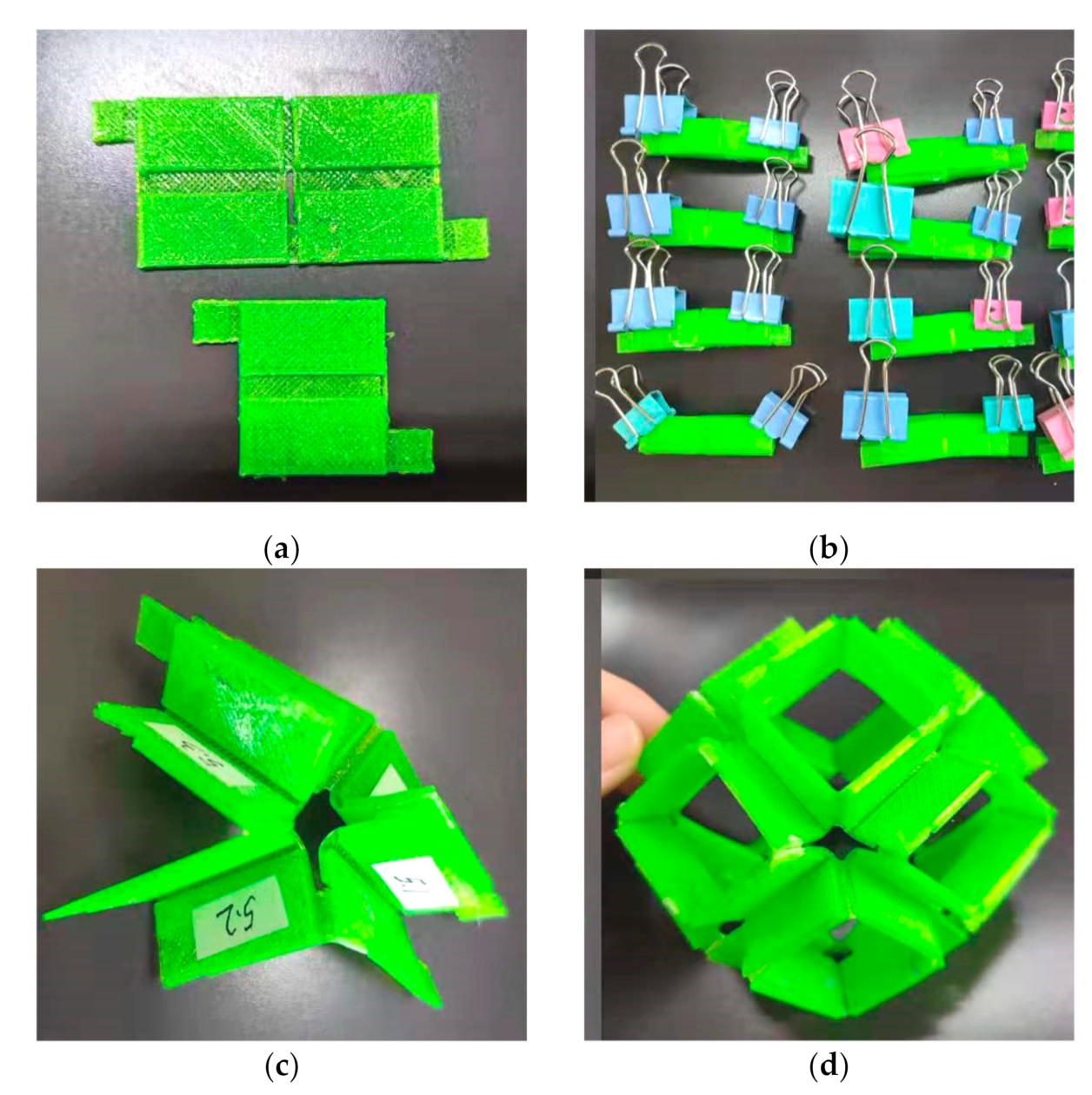

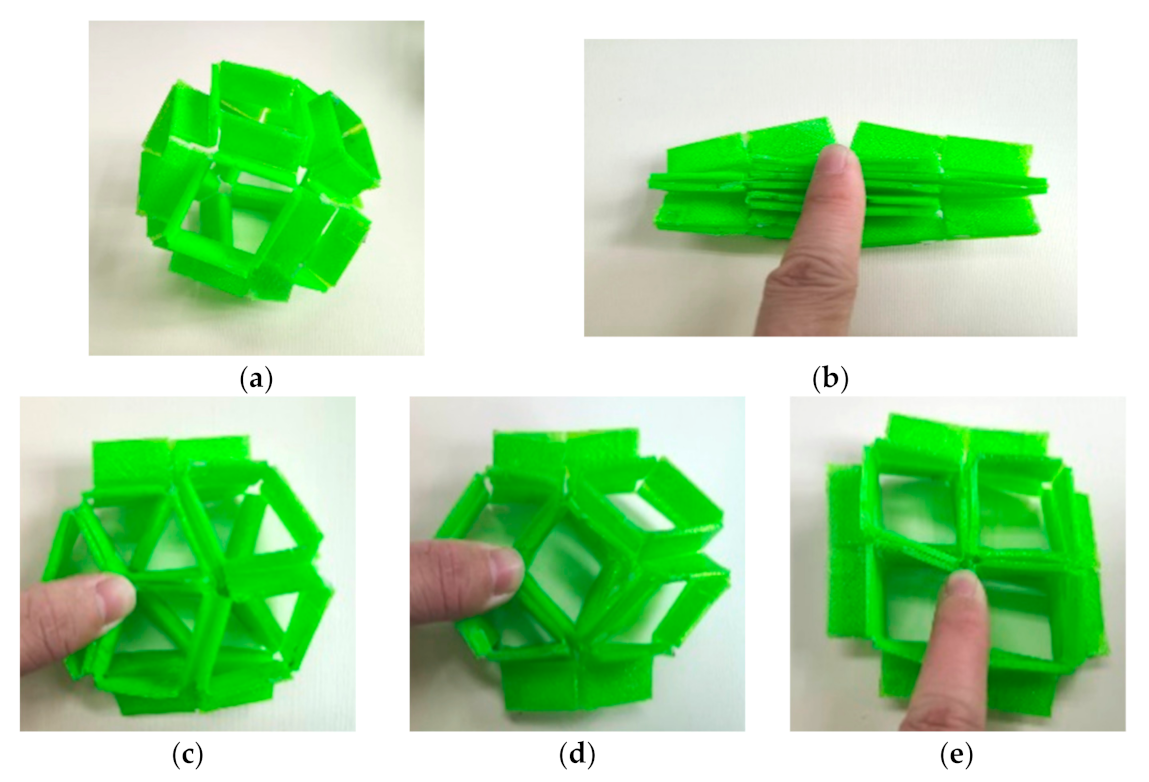

3.1. Digital Fabrication of Origami Flexiball Metamaterial

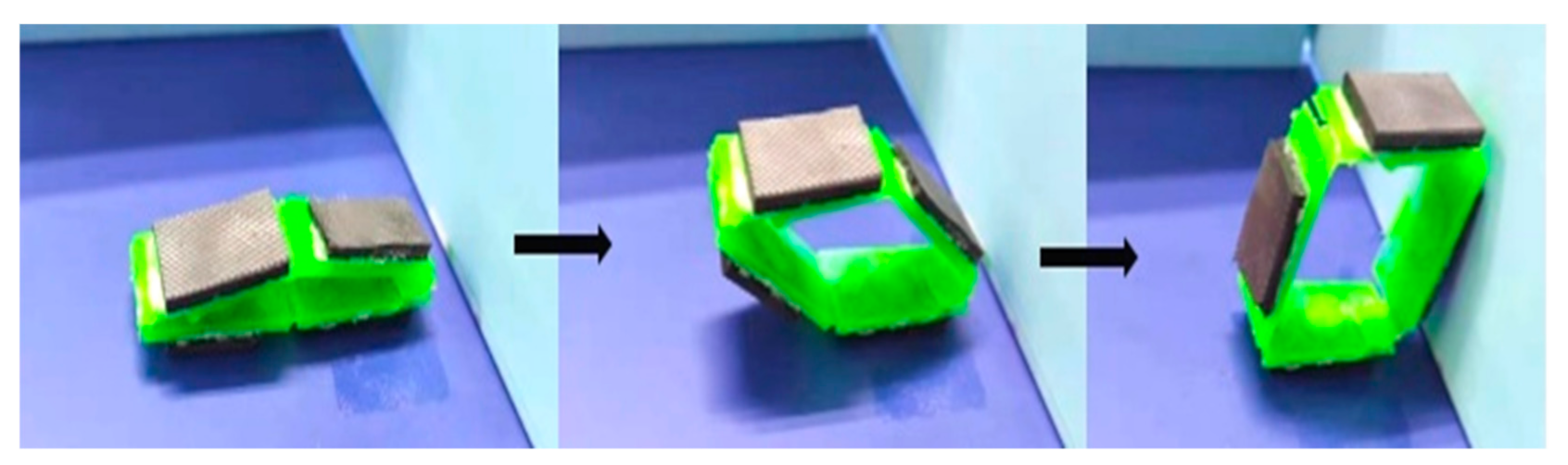

3.2. Actuation of Origami Flexiball Metamaterial Actuator

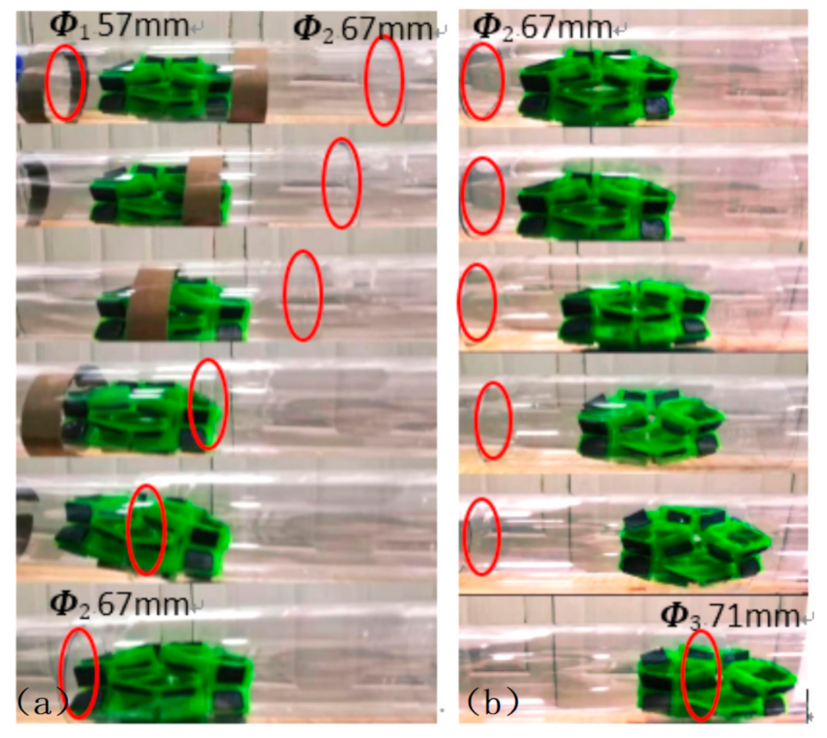

3.3. An In-Pipe Robot Prototype

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| DOF | Degree of Freedom |

| FDM | Fused Deposition Modeling |

| MAE | Magnetoactive Elastomer |

| PLA | Polylactic Acid |

| RHD | Rhombic Hexahedron |

| RDD | Rhombic Dodecahedron |

| RTD | Rhombic Triacontahedron |

References

- Turner, N.; Goodwine, B.; Sen, M. A review of origami applications in mechanical engineering. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 2345–2362. [Google Scholar] [CrossRef]

- Park, J.J.; Won, P.; Ko, S.H. A review on hierarchical origami and kirigami structure for engineering applications. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 147–161. [Google Scholar] [CrossRef]

- Zirbel, S.A.; Trease, B.P.; Thomson, M.W.; Lang, R.J.; Magleby, S.P.; Howell, L.H. Hanaflex: A large solar array for space applications. In Micro-and Nanotechnology Sensors, Systems, and Applications VII. Int. Soc. Opt. Photonics 2015, 9467, 94671C. [Google Scholar]

- Salazar, R.; Murthy, S.; Pellazar, C.; Stoica, A. TransFormers for lunar extreme environments: Large origami deployable solar reflectors. In Proceedings of the 2017 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2017; pp. 1–7. [Google Scholar]

- Lv, C.; Krishnaraju, D.; Konjevod, G.; Yu, H.; Jiang, H. Origami based mechanical metamaterials. Sci. Rep. 2014, 4, 5979. [Google Scholar] [CrossRef] [PubMed]

- Florijn, B.; Coulais, C.; van Hecke, M. Programmable mechanical metamaterials. Phys. Rev. Lett. 2014, 113, 175503. [Google Scholar] [CrossRef] [PubMed]

- Silverberg, J.L.; Evans, A.A.; McLeod, L.; Hayward, R.C.; Hull, T.; Santangelo, C.D.; Cohen, I. Using origami design principles to fold reprogrammable mechanical metamaterials. Science 2014, 345, 647–650. [Google Scholar] [CrossRef]

- Shigemune, H.; Maeda, S.; Hara, Y.; Hosoya, N.; Hashimoto, S. Origami robot: A self-folding paper robot with an electrothermal actuator created by printing. IEEE/ASME Trans. Mechatron. 2016, 21, 2746–2754. [Google Scholar] [CrossRef]

- Hu, F.; Wang, W.; Cheng, J.; Bao, Y. Origami spring–inspired metamaterials and robots: An attempt at fully programmable robotics. Sci. Prog. 2020, 103. [Google Scholar] [CrossRef]

- Göttler, C.; Elflein, K.; Siegwart, R.; Sitti, M. Spider Origami: Folding Principle of Jumping Spider Leg Joints for Bioinspired Fluidic Actuators. Adv. Sci. 2021, 2003890. [Google Scholar] [CrossRef]

- Kim, T.; Lee, Y.G. Shape transformable bifurcated stents. Sci. Rep. 2018, 8, 13911. [Google Scholar] [CrossRef]

- du Plessis d’Argentré, A.; Perry, S.; Iwata, Y.; Iwasaki, H.; Iwase, E.; Fabozzo, A.; Will, I.; Rus, D.; Damian, D.D.; Miyashita, S. Programmable medicine: Autonomous, ingestible, deployable hydrogel patch and plug for stomach ulcer therapy. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 1511–1518. [Google Scholar]

- Tao, K.; Yi, H.; Yang, Y.; Tang, L.; Yang, Z.; Wu, J.; Chang, H.; Yuan, W. Miura-origami-inspired electret/triboelectric power generator for wearable energy harvesting with water-proof capability. Microsyst. Nanoeng. 2020, 6, 56. [Google Scholar] [CrossRef]

- Ho, D.T.; Kim, S.Y.; Schwingenschlögl, U. Graphene origami structures with superflexibility and highly tunable auxeticity. Phys. Rev. B 2020, 102, 174106. [Google Scholar] [CrossRef]

- Lee, H.; Choi, S. An origami paper-based bacteria-powered battery. Nano Energy 2015, 15, 549–557. [Google Scholar] [CrossRef]

- Cunha, F.; Mota, C.; Reis, A.; Marques, P.; Pinto, R.; Fangueiro, R. Development of a flexible, light weight structure, adaptable to any space through a shape shifting feature. Procedia Eng. 2016, 155, 426–441. [Google Scholar] [CrossRef]

- Yasuda, H.; Tachi, T.; Lee, M.; Yang, J. Origami-based tunable truss structures for non-volatile mechanical memory operation. Nat. Commun. 2017, 8, 962. [Google Scholar] [CrossRef]

- Yasuda, H.; Yang, J. Reentrant origami-based metamaterials with negative Poisson’s ratio and bistability. Phys. Rev. Lett. 2015, 114, 185502. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Z.; Wang, Y.; Jiang, H. Origami-Inspired, On-Demand Deployable and Collapsible Mechanical Metamaterials with Tunable Stiffness. Proc. Natl. Acad. Sci. USA 2018, 115, 2032–2037. [Google Scholar] [CrossRef] [PubMed]

- Sengupta, S.; Li, S. Harnessing the Anisotropic Multistability of Stacked-Origami Mechanical Metamaterials for Effective Modulus Programming. J. Intell. Mater. Syst. Struct. 2018, 29, 2933–2945. [Google Scholar] [CrossRef]

- Fang, H.B.; Chu, S.; Xia, Y.T.; Wang, K.W. Programmable Self-Locking Origami Mechanical Metamaterials. Adv. Mater. 2018, 30, 1706311. [Google Scholar] [CrossRef]

- Mu, J.; Hou, C.; Wang, H.; Li, Y.; Zhang, Q.; Zhu, M. Origami-inspired active graphene-based paper for programmable instant self-folding walking devices. Sci. Adv. 2015, 1, e1500533. [Google Scholar] [CrossRef]

- Deshpande, A.R.; Tse, Z.T.H.; Ren, H. Origami-inspired bi-directional soft pneumatic actuator with integrated variable stiffness mechanism. In Proceedings of the 2017 18th International Conference on Advanced Robotics (ICAR), Hong Kong, China, 10–12 July 2017; pp. 417–421. [Google Scholar]

- Lee, K.; Wang, Y.; Zheng, C. Twister hand: Underactuated robotic gripper inspired by origami twisted tower. IEEE Trans. Robot. 2020, 36, 488–500. [Google Scholar] [CrossRef]

- Li, S.; Stampfli, J.J.; Xu, H.J.; Malkin, E.; Diaz, E.V.; Rus, D.; Wood, R.J. A vacuum-driven origami “magic-ball” soft gripper. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 7401–7408. [Google Scholar]

- Zhou, X.; Zang, S.; You, Z. Origami Mechanical Metamaterials Based on the Miura-Derivative Fold Patterns. Proc. Math. Phys. Eng. Sci. 2016, 2191, 20160361. [Google Scholar] [CrossRef] [PubMed]

- Paez, L.; Agarwal, G.; Paik, J. Design and analysis of a soft pneumatic actuator with origami shell reinforcement. Soft Robot. 2016, 3, 109–119. [Google Scholar] [CrossRef]

- Tachi, T. Designing freeform origami tessellations by generalizing Resch’s patterns. J. Mech. Des. 2013, 135, 111006. [Google Scholar] [CrossRef]

- Kshad, M.A.E.; Popinigis, C.; Naguib, H.E. 3D Printing of Ron-Resch-Like Origami Cores for Compression and Impact Load Damping. Smart Mater. Struct. 2019, 28, 015027. [Google Scholar] [CrossRef]

- Yamada, T. Superstructure formation in a ternary Yb-Cd-Mg 1/1 quasicrystal approximant. Philos. Mag. 2021, 101, 257–275. [Google Scholar] [CrossRef]

- Taylor, W.R. Exploring protein fold space. Biomolecules 2020, 10, 193. [Google Scholar] [CrossRef]

- Janner, A. Towards a classification of icosahedral viruses in terms of indexed polyhedra. Acta Crystallogr. Sect. A Found. Crystallogr. 2006, 62, 319–330. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Latteur, P.; Mueller, C. Grammar-based Rhombic Polyhedral Multi-Directional Joints and Corresponding Lattices. In Proceedings of the IASS Annual Symposia—International Association for Shell and Spatial Structures (IASS), Tokyo, Japan, 26–30 September 2016; Volume 2016, pp. 1–10. [Google Scholar]

- Fras, J.; Macias, M.; Noh, Y.; Althoefer, K. Fluidical bending actuator designed for soft octopus robot tentacle. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; pp. 253–257. [Google Scholar]

- Kim, W.; Byun, J.; Kim, J.K.; Choi, W.Y.; Jakobsen, K.; Jakobsen, J.; Lee, D.Y.; Cho, K.J. Bioinspired dual-morphing stretchable origami. Sci. Robot. 2019, 4. [Google Scholar] [CrossRef]

- Wang, T.; Ge, L.; Gu, G. Programmable design of soft pneu-net actuators with oblique chambers can generate coupled bending and twisting motions. Sens. Actuators A Phys. 2018, 271, 131–138. [Google Scholar] [CrossRef]

- Uppalapati, N.K.; Krishnan, G. Towards pneumatic spiral grippers: Modeling and design considerations. Soft Robot. 2018, 5, 695–709. [Google Scholar] [CrossRef]

- Mersch, J.; Koenigsdorff, M.; Nocke, A.; Cherif, C.; Gerlach, G. High-Speed, Helical and Self-Coiled Dielectric Polymer Actuator. Actuators 2021, 10, 15. [Google Scholar] [CrossRef]

- Laliberté, T.; Gosselin, C.M. Polyhedra with articulated faces. In Proceedings of the 12th IFToMM World Congress, Besançon, France, 17–20 June 2007. [Google Scholar]

- Waitukaitis, S.; Menaut, R.; Chen, G.; Van Hecke, M. Origami multistability: From single vertices to metasheets. Phys. Rev. Lett. 2015, 114, 055503. [Google Scholar] [CrossRef]

- Overvelde, J.T.B.; de Jong, T.A.; Shevchenko, Y.; Becerra, S.A.; Whitesides, G.M.; Weaver, J.C.; Hoberman, C.; Bertoldi, K. A Three-Dimensional Actuated Origami-Inspired Transformable Metamaterial with Multiple Degrees of Freedom. Nat. Commun. 2016, 7, 10929. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Kuang, X.; Wu, J.; Zhang, Q.; Paulino, G.H.; Qi, H.J.; Fang, D. 3D Printing of Complex Origami Assemblages for Reconfigurable Structures. Soft Matter 2018, 14, 8051–8059. [Google Scholar] [CrossRef] [PubMed]

- Walser, R.M. Metamaterials: What are they? What are they good for? In Proceedings of the APS March Meeting Abstracts, Minneapolis, MN, USA, 20–24 March 2000; p. Z5-001. [Google Scholar]

- Wu, W.; Hu, W.; Qian, G.; Liao, H.; Xu, X.; Berto, F. Mechanical design and multifunctional applications of chiral mechanical metamaterials: A review. Mater. Des. 2019, 180, 107950. [Google Scholar] [CrossRef]

- Correll, N.; Voyles, R. Robotic materials: From smart polymers to computational metamaterials. In Proceedings of the Robot Makers Workshop, Robotics: Science Systems Conference, Berkeley, CA, USA, 12–16 July 2014. [Google Scholar]

- Ion, A.; Frohnhofen, J.; Wall, L.; Kovacs, R.; Alistar, M.; Lindsay, J.; Lopes, P.; Chen, H.T.; Baudisch, P. Metamaterial mechanisms. In Proceedings of the 29th Annual Symposium on User Interface Software and Technology, Tokyo, Japan, 16–19 October 2016; pp. 529–539. [Google Scholar]

- Gul, J.Z.; Sajid, M.; Rehman, M.M.; Siddiqui, G.U.; Shah, I.; Kim, K.H.; Lee, J.W.; Choi, K.H. 3D printing for soft robotics—A review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef]

- Peraza-Hernandez, E.A.; Hartl, D.J.; Malak, R.J., Jr.; Lagoudas, D.C. Origami-inspired active structures: A synthesis and review. Smart Mater. Struct. 2014, 23, 094001. [Google Scholar] [CrossRef]

- Bowen, L.; Springsteen, K.; Feldstein, H.; Frecker, M.; Simpson, T.W.; von Lockette, P. Development and Validation of a Dynamic Model of Magneto-Active Elastomer Actuation of the Origami Waterbomb Base. J. Mech. Robot. 2015, 7, 011010. [Google Scholar] [CrossRef]

- Shao, L.; Wang, Y.; Guo, B.; Chen, X. A review over state of the art of in-pipe robot. In Proceedings of the 2015 IEEE International Conference on Mechatronics and Automation (ICMA), Beijing, China, 2–5 August 2015; pp. 2180–2185. [Google Scholar]

- Wang, Z.; Gu, H. A bristle-based pipeline robot for ill-constraint pipes. IEEE/ASME Trans. Mechatron. 2008, 13, 383–392. [Google Scholar] [CrossRef]

- Dorgan, K.M. Environmental constraints on the mechanics of crawling and burrowing using hydrostatic skeletons. Exp. Mech. 2010, 50, 1373–1381. [Google Scholar] [CrossRef]

- Wang, P.; Conn, A.T. Elastic cube actuator with six degrees of freedom output. Actuators 2015, 4, 203–216. [Google Scholar] [CrossRef]

- Yan, H.; Tong, Z.; Park, D.; Lu, H. A Reconfigurable Joint Based on Extruded Polyhedrons. In Proceedings of the 25th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA), Bangkok, Thailand, 5–6 August 2020; Volume 1, pp. 455–464. [Google Scholar]

| Polyhedra | Geometry | Vertex Type (See Table 2) | Face Type | Dihedral Angle | Origami Flexiball |

|---|---|---|---|---|---|

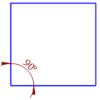

| Cube |  (V,F,E) = (8,6,12) | 8{3} |  | 90° |  |

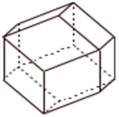

| Rhombic dodecahedron |  (V,F,E) = (14,12,24) | 8{3} + 6{4} |  | 120° |  |

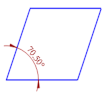

| Rhombic triacontahedron |  (V,F,E) = (32,30,60) | 20{3} + 12{5} |  | 144° |  |

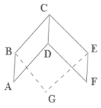

| Vertex Degree | 3 | 4 | 5 |

|---|---|---|---|

| Schematic |  |  |  |

| Snapping module |  |  |  |

| Origami Flexiball | Polyhedron Volume | RhombusVolume | Total Volume | Elastic Energy |

|---|---|---|---|---|

| Rhombic hexahedron | ||||

| Rhombic dodecahedron | ||||

| Rhombic triacontahedron |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, F.; Li, T. An Origami Flexiball-Inspired Metamaterial Actuator and Its In-Pipe Robot Prototype. Actuators 2021, 10, 67. https://doi.org/10.3390/act10040067

Hu F, Li T. An Origami Flexiball-Inspired Metamaterial Actuator and Its In-Pipe Robot Prototype. Actuators. 2021; 10(4):67. https://doi.org/10.3390/act10040067

Chicago/Turabian StyleHu, Fuwen, and Tian Li. 2021. "An Origami Flexiball-Inspired Metamaterial Actuator and Its In-Pipe Robot Prototype" Actuators 10, no. 4: 67. https://doi.org/10.3390/act10040067

APA StyleHu, F., & Li, T. (2021). An Origami Flexiball-Inspired Metamaterial Actuator and Its In-Pipe Robot Prototype. Actuators, 10(4), 67. https://doi.org/10.3390/act10040067