Guided Wave Transducer for the Locating Defect of the Steel Pipe Based on the Weidemann Effect

Abstract

:1. Introduction

2. Principle of the Transducer

3. The Design of the Transducer

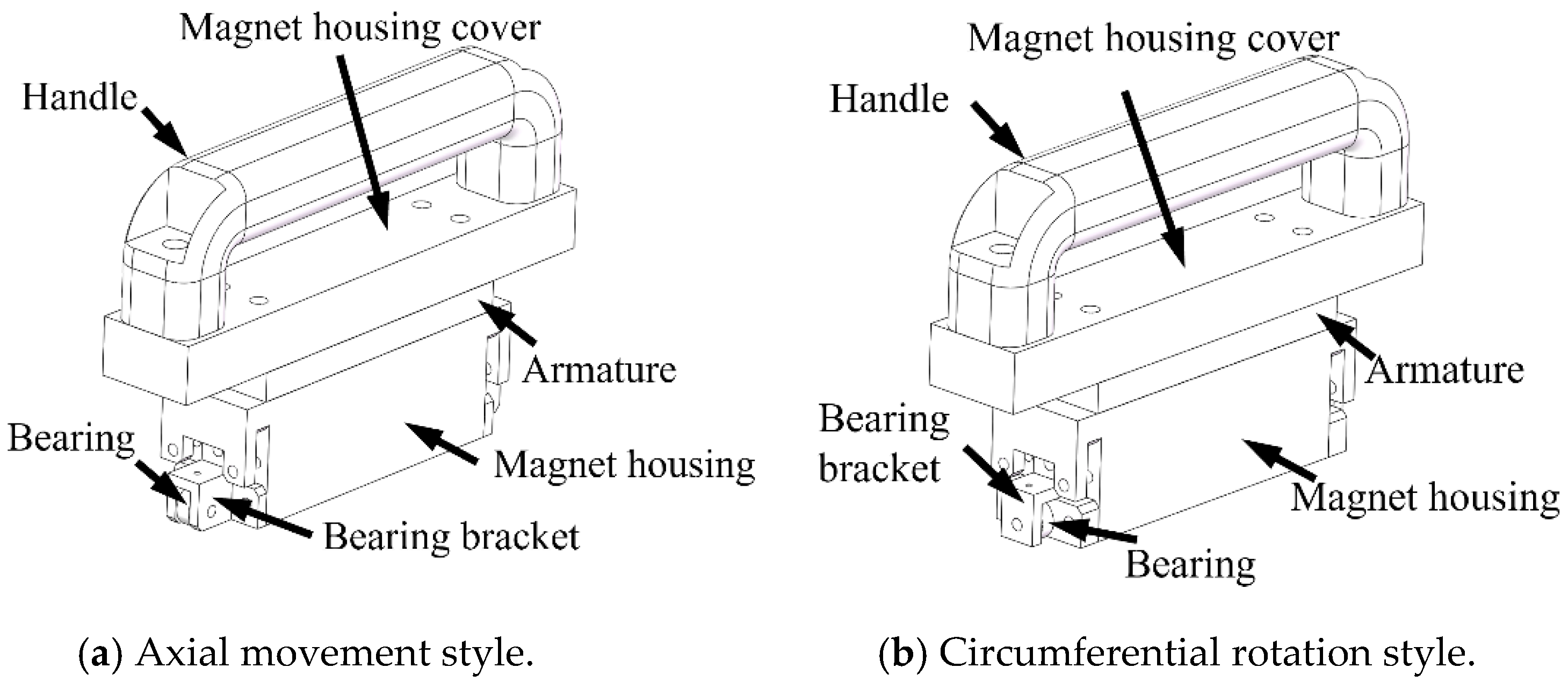

3.1. The Structure of the Transducer

3.2. The Key Parameters of the Transducer

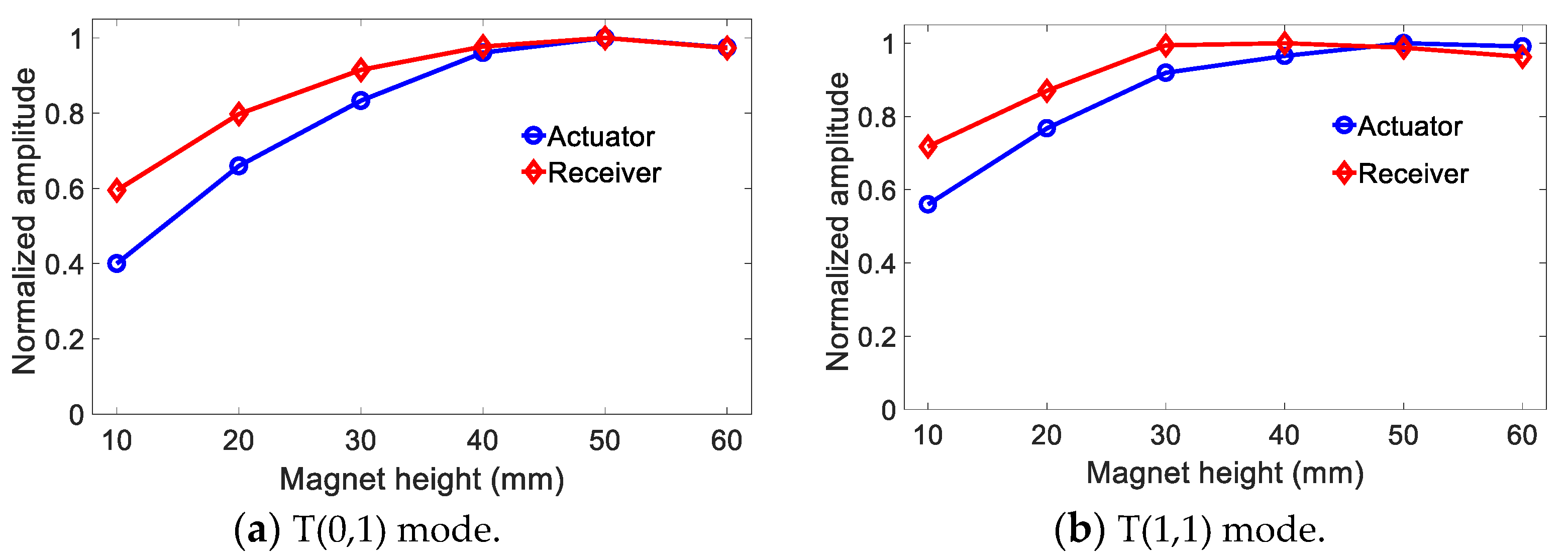

3.2.1. The Effect of Permanent Magnet Height

3.2.2. Influence of Permanent Magnet Width

3.2.3. The Effect of Permanent Magnet Length

3.2.4. The Lift-Off Effect of Permanent Magnet

3.2.5. The Effect of the Lift-Off of the Coil

3.3. The Prototype of the Sensor

4. Experiments of Validation

4.1. Defect Detection Ability and Effective Detection Range of the Transducer Using T (0,1)

4.2. Locating Defect Using T(0,1) and T(1,1)

5. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Herdovics, B.; Cegla, F. Structural health monitoring using torsional guided wave electromagnetic acoustic transducers. Struct. Health Monit. 2018, 17, 24–38. [Google Scholar] [CrossRef]

- Heinlein, S.; Cawley, P.; Vogt, T. Reflection of torsional T(0,1) guided waves from defects in pipe bends. NDT E Int. 2018, 93, 57–63. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, Z.; Lv, F.; Yang, K. Scattering of torsional flexural guided waves from circular holes and crack-like defects in hollow cylinders. NDT E Int. 2017, 89, 56–66. [Google Scholar] [CrossRef]

- Wang, L.; Xu, J.; Hu, C. Magnetostrictive guided wave transducer with semicircular structure for defect detection of semi-exposed pipe. J. Nondestruct. Eval. 2021, 40, 96. [Google Scholar] [CrossRef]

- Zhang, H.; Du, Y.; Tang, J.; Kang, G.; Miao, H. Circumferential SH Wave Piezoelectric Transducer System for Monitoring Corrosion-Like Defect in Large-Diameter Pipes. Sensors 2020, 20, 460. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Li, A.; Wu, B.; He, C. Development of a wholly flexible surface wave electromagnetic acoustic transducer for pipe inspection. Int. J. Appl. Electromagn. Mech. 2020, 62, 13–29. [Google Scholar] [CrossRef]

- Fang, Z.; Tse, P.W. Methodology for circumferential localisation of defects within small-diameter concrete-covered pipes based on changing of energy distribution of non-axisymmetric guided waves. Appl. Acoust. 2020, 168, 107416. [Google Scholar] [CrossRef]

- Xu, J.; Hu, C.; Ding, J. An Improved Longitudinal Mode Guided Wave Received Sensor Based on Inverse Magnetostrictive Effect for Open End Pipes. J. Nondestruct. Eval. 2019, 38, 83. [Google Scholar] [CrossRef]

- Liu, K.; Wu, Z.; Jiang, Y.; Wang, Y.; Zhou, K.; Chen, Y. Guided waves based diagnostic imaging of circumferential cracks in small-diameter pipe. Ultrasonics 2016, 65, 34–42. [Google Scholar] [CrossRef] [PubMed]

- Mitra, M.; Gopalakrishnan, S. Guided wave based structural health monitoring: A review. Smart Mater. Struct. 2016, 25, 053001. [Google Scholar] [CrossRef]

- Salzburger, H.J.; Niese, F.; Dobmann, G. EMAT pipe inspection with guided waves. Weld. World 2012, 56, 35–43. [Google Scholar] [CrossRef]

- Zhou, W.; Yuan, F.-G.; Shi, T. Guided torsional wave generation of a linear in-plane shear piezoelectric array in metallic pipes. Ultrasonics 2016, 65, 69–77. [Google Scholar] [CrossRef]

- Nakamura, N.; Ogi, H.; Hirao, M. EMAT pipe inspection technique using higher mode torsional guided wave T(0,2). NDT E Int. 2017, 87, 78–84. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, Y.; Fan, J.; Yin, W.; Liu, X.; He, C.; Wu, B. Longitudinal mode magnetostrictive patch transducer array employing a multi-splitting meander coil for pipe inspection. NDT E Int. 2016, 79, 30–37. [Google Scholar] [CrossRef]

- Vinogradov, S.; Cobb, A.; Light, G. Review of magnetostrictive transducers (MsT) utilizing reversed Wiedemann effect. In Review of Progress in Quantitative Nondestructive Evaluation; AIP Publishing: Provo, UT, USA, 2017; Volume 1806, p. 020008. [Google Scholar]

- Kim, Y.Y.; Kwon, Y.E. Review of magnetostrictive patch transducers and applications in ultrasonic nondestructive testing of waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef] [Green Version]

- Kwun, H.; Bartels, K. Magnetostrictive sensor technology and its applications. Ultrasonics 1998, 36, 171–178. [Google Scholar] [CrossRef]

- Kwun, H.; Kim, S.Y.; Light, G.M. The magnetostrictive sensor technology for long range guided wave testing and monitoring of structures. Mater. Eval. 2003, 61, 80–84. [Google Scholar]

- Cho, S.H.; Kim, H.W.; Kim, Y.Y. Megahertz-range guided pure torsional wave transduction and experiments using a magnetostrictive transducer. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2010, 57, 1225–1229. [Google Scholar]

- Kim, H.W.; Cho, S.H.; Kim, Y.Y. Analysis of internal wave reflection within a magnetostrictive patch transducer for high-frequency guided torsional waves. Ultrasonics 2011, 51, 647–652. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.W.; Kwon, Y.E.; Lee, J.K.; Kim, Y.Y. Higher torsional mode suppression in a pipe for enhancing the first torsional mode by using magnetostrictive patch transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2013, 60, 562–572. [Google Scholar]

- Kwon, Y.E.; Kim, H.W.; Kim, Y.Y. High-frequency lowest torsional wave mode ultrasonic inspection using a necked pipe waveguide unit. Ultrasonics 2015, 62, 237–243. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, J.; Hu, Y.; He, C.; Wu, B. Torsional mode magnetostrictive patch transducer array employing a modified planar solenoid array coil for pipe inspection. NDT E Int. 2015, 69, 9–15. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, J.; Hu, C.; Chen, G.; Li, Y. A flexural mode guided wave transducer for pipes based on magnetostrictive effect. Int. J. Appl. Electromagn. Mech. 2020, 64, 335–342. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Park, C.I.; Cho, S.H.; Han, S.W. Torsional wave experiments with a new magnetostrictive transducer configuration. J. Acoust. Soc. Am. 2005, 117, 3459–3468. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Xu, Z.Y.; Wu, X.J. Research on the lift-off effect of generating longitudinal guided waves in pipes based on magnetostrictive effect. Sens. Actuators A Phys. 2012, 184, 28–33. [Google Scholar] [CrossRef]

- Xu, J.; Sun, Y.; Zhou, J. Research on the Lift-off Effect of Receiving Longitudinal Mode Guided Waves in Pipes Based on the Villari Effect. Sensors 2016, 16, 1529. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Chen, G.; Xu, J.; Zhang, Q. Guided Wave Transducer for the Locating Defect of the Steel Pipe Based on the Weidemann Effect. Actuators 2021, 10, 333. https://doi.org/10.3390/act10120333

Xu J, Chen G, Xu J, Zhang Q. Guided Wave Transducer for the Locating Defect of the Steel Pipe Based on the Weidemann Effect. Actuators. 2021; 10(12):333. https://doi.org/10.3390/act10120333

Chicago/Turabian StyleXu, Jin, Guang Chen, Jiang Xu, and Qing Zhang. 2021. "Guided Wave Transducer for the Locating Defect of the Steel Pipe Based on the Weidemann Effect" Actuators 10, no. 12: 333. https://doi.org/10.3390/act10120333

APA StyleXu, J., Chen, G., Xu, J., & Zhang, Q. (2021). Guided Wave Transducer for the Locating Defect of the Steel Pipe Based on the Weidemann Effect. Actuators, 10(12), 333. https://doi.org/10.3390/act10120333