1. Introduction

Nowadays, one of the challenges that must be faced by a growing society is its waste management. According to the World Bank, 1.3 billion tons per year of municipal solid wastes (MSW) are generated globally, which is expected double by 2025 (

Hoornweg and Bhada-Tata 2012). The main reasons for the increasing generation rate are linked to fast population growth and technological development. On the other hand, more than a half of MSW are disposed in dumpsites and/or landfills, carrying out three fundamental problems (i.e., availability of cultivable land, health hazard and loss of energy potential) (

Wilson et al. 2015).

In low- and middle-income countries (e.g., in Latin American and The Caribbean), this situation is even more difficult. It is not possible to ensure access to a proper waste management system addressed to eliminate uncontrolled disposal and burning. It is a priority for local governments to promote innovative and effective initiatives toward a sustainable system regarding solid waste management (

Wilson et al. 2015). Increasingly important is the role of sustainable waste management as part of sustainable development in the policies of many countries of Latin America and The Caribbean (LAC) (

Psomopoulos and Themelis 2014).

To gain significant improvements in the MSW management system, it is essential to develop a strategy, i.e., to set the targets and goals as well as to establish the stages during the system operation. It can be seeing as a guideline for all participants (i.e., policy makers, citizens, investors, etc.) involved in MSW management (

Rousta et al. 2015).

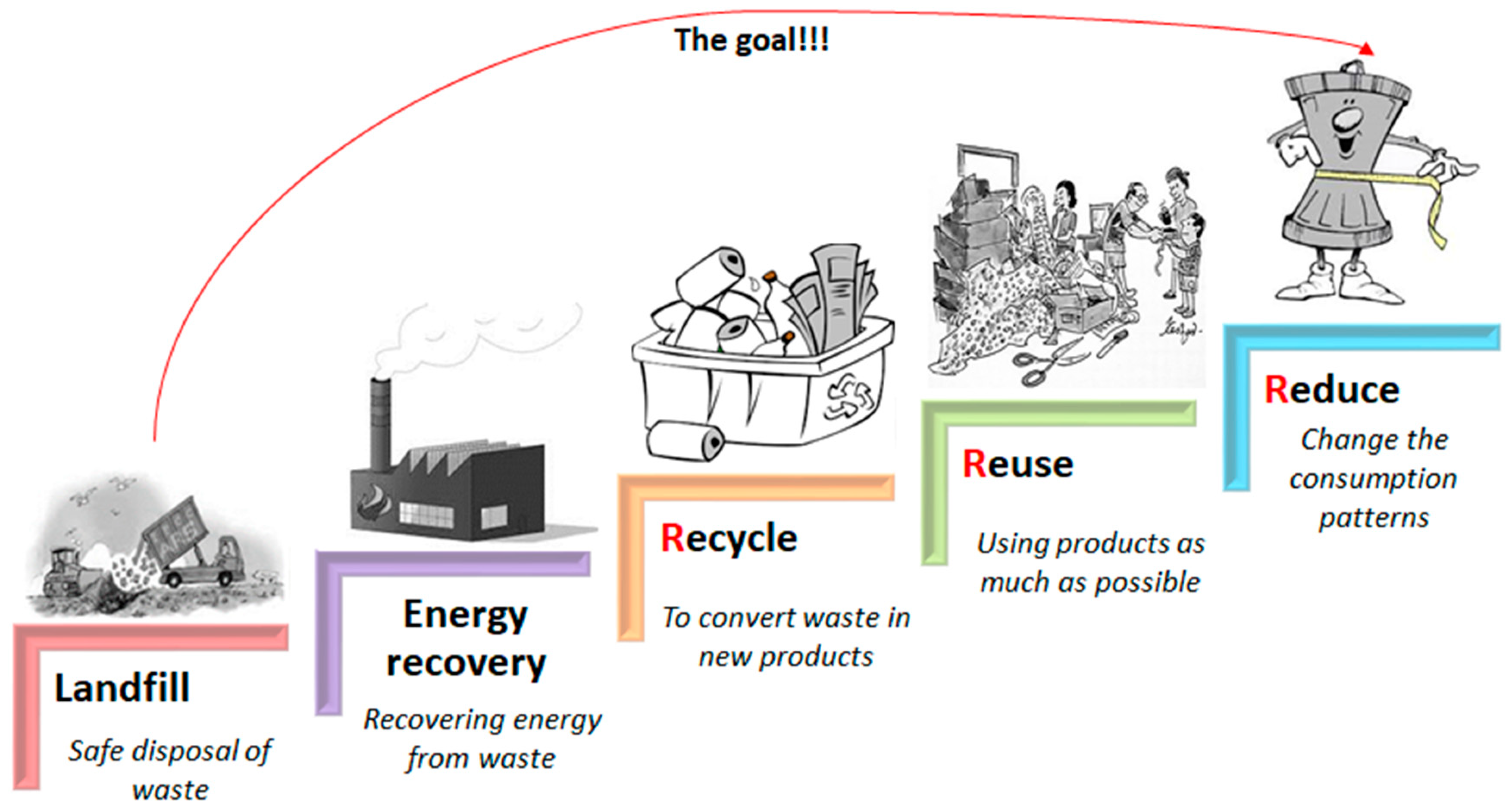

Figure 1 shows the well-known waste management hierarchy, which was established as the strategy to guide all actors in MSW management in the European Union (

European Commission 2008).

In

Figure 1, the three highest levels in waste management are represented by the so-called

3Rs (i.e., reduce, reuse, recycle). Its role is the material flow minimization by decreasing the amount of waste or transforming the materials in new products by recycling to reduce both raw materials and energy. If the

3Rs implementation it is not possible, the waste should be converted into a valuable product, e.g., energy (

Rousta et al. 2015). However, even when the implementation level of the

3Rs is high, in practice, there is a large fraction of MSW that must be treated to recover its energy content (

Themelis et al. 2013).

According to the International Renewable Energy Agency, the capacity for power generation from municipal wastes in the world was around 11,540 MW in 2018 (

IRENA 2018). Energy recovery from waste could be carried out by two main routes (i.e., biological and thermal). The biological route is based on the biogas production as energy source from organic wastes. On the other hand, during the thermal route, the waste is prepared as refuse-derived-fuel for combustion, gasification or pyrolysis to produce electricity, heating or both (

Rousta et al. 2015;

Nordi et al. 2017).

Combustion (as waste-to-energy in the present work) can be classified as the most common thermal treatment where the mass and volume of waste can be reduced by 70% and 90%, respectively (

Gohlke and Martin 2007;

Nixon et al. 2013;

Kalogirou 2017). Even though waste-to-energy (WTE) is nowadays considered as an attrsactive option for waste treatment in developed countries such as US, Japan and EU (

Psomopoulos et al. 2009;

Kumar and Samadder 2017), it still has low presence in underdeveloped countries. Developing WTE facilities in low- and middle-income countries implies scale-up in the level of complexity in waste management systems which are already deficient.

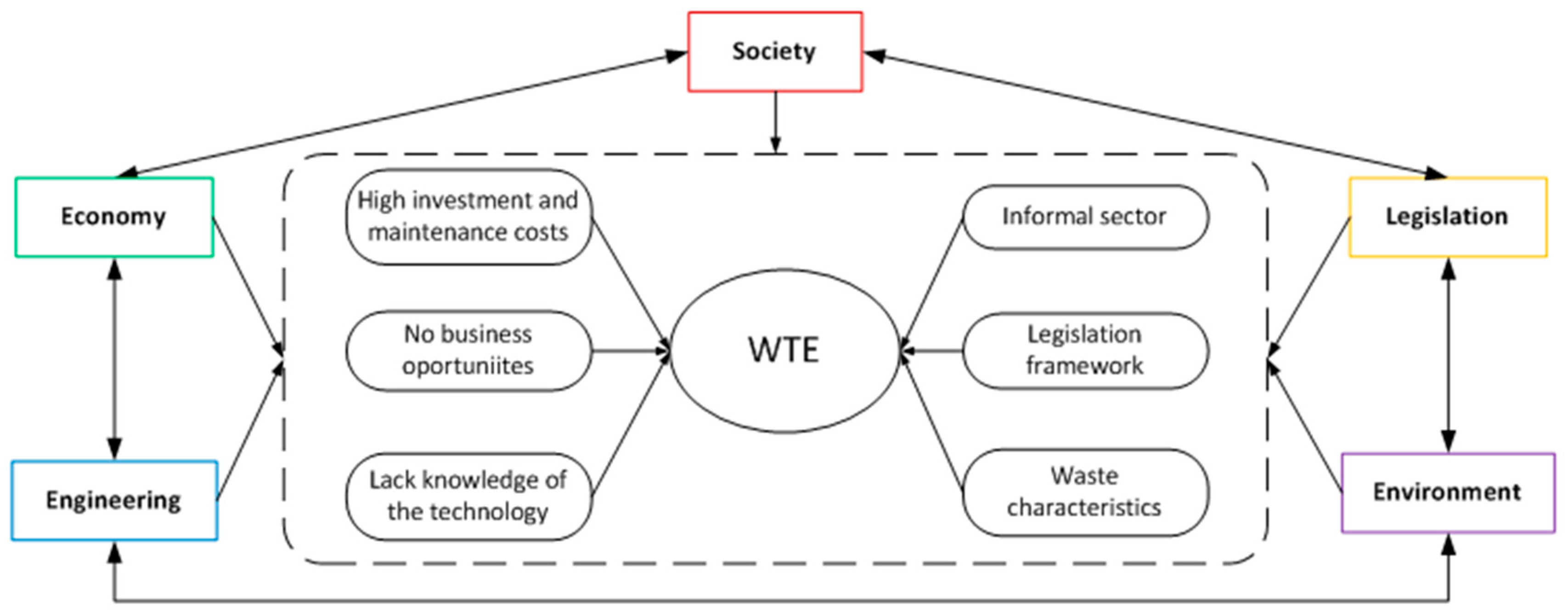

Figure 2 shows the main disciplines involved in waste management system (i.e., society, engineering, economy, legislation, and environment) (

Rousta et al. 2015) and the barriers that should be overcome for them to develop a reliable WTE project in underdeveloped countries.

Legal and environmental aspects are closely related in WTE, being necessary a legal framework to ensure certain degree of legacy and legitimacy to the project. Emissions standards and other environmental prescriptions require laws and regulatory controls by certified public authorities. Even though, in most underdeveloped countries, environmental laws exist, specific regulations concerning WTE are not always included.

Main challenges for engineering disciplines are the variations in the caloric value of the waste, mainly due to high moisture content and changes in consumption patterns, compared with developed countries. On the other hand, an experienced and certified staff is required for plant operation and maintenance. Economic aspects are related to the high investment and operating costs, which cannot be recovered by existing waste fees and generated additional income from energy sales alone. Social impact over the informal sector should be carefully studied, since these persons are dependent on the availability of recyclables in the waste. In

Figure 2, it is clear that technology transfer from developed scenarios (e.g., EU, Japan, and US) for WTE to low- and middle-income countries could not meet the financial, waste composition and local capacity expectations if the interactions of all disciplines involved are not properly studied.

In LAC, only three incineration plants (waste-to-energy plants) are currently in operation: in Bermuda, Martinique and Saint Barthelme Islands. The capacities range from 1.5 t⋅h

−1 to 7 t⋅h

−1. The plants on Bermuda and Martinique can supply ~3% and 4% of the electricity demand on those islands, respectively. It should be mentioned that these three island are overseas territories of France and England, countries with economic resources and experience for implementing waste-to-energy (

Themelis et al. 2013).

Even though there are no WTE plants in any other countries in LAC, many studies have been carried out to study the potential of this technology in the region. Three study cases (i.e., Toluca, Valparaiso, and Buenos Aires) were presented by

Themelis et al. (

2013). Results show that, for the city of Toluca (Mexico), it is possible to produce 96 GWh yearly based in a plant capacity of 160,000 tons of waste per year, being necessary to increase the gate fee three times compared to the base conditions to get profits. For the case of Valparaiso in Chili, a plant with a capacity of 336,000 tons of waste per year is projected. The generation capacity in this case is 182 GWh per year. Results from the technical and environmental evaluation show the benefits of the plant. However, it is not possible to obtain economic benefits from the investment at the current prices of gate fee and electricity in Chili. Finally, a plant with a processing capacity of 1 million tons per year for the city of Buenos Aires (Argentina) is also considered. The electricity generation is estimated at ~605 GWh per year. It is concluded that, for the project to be feasible, the gate fee should be higher than the current landfilling cost, unless a reduction in capital expenses to less than 6% could be reached (

Themelis et al. 2013).

The biological and thermal routes are studied for the evaluation of the energy recovery potential from MSW in Ecuador. Regarding WTE plants, the potential is estimated at ~3 GWh per year. No economic assessment is carried out to integrate the technical and financial results (

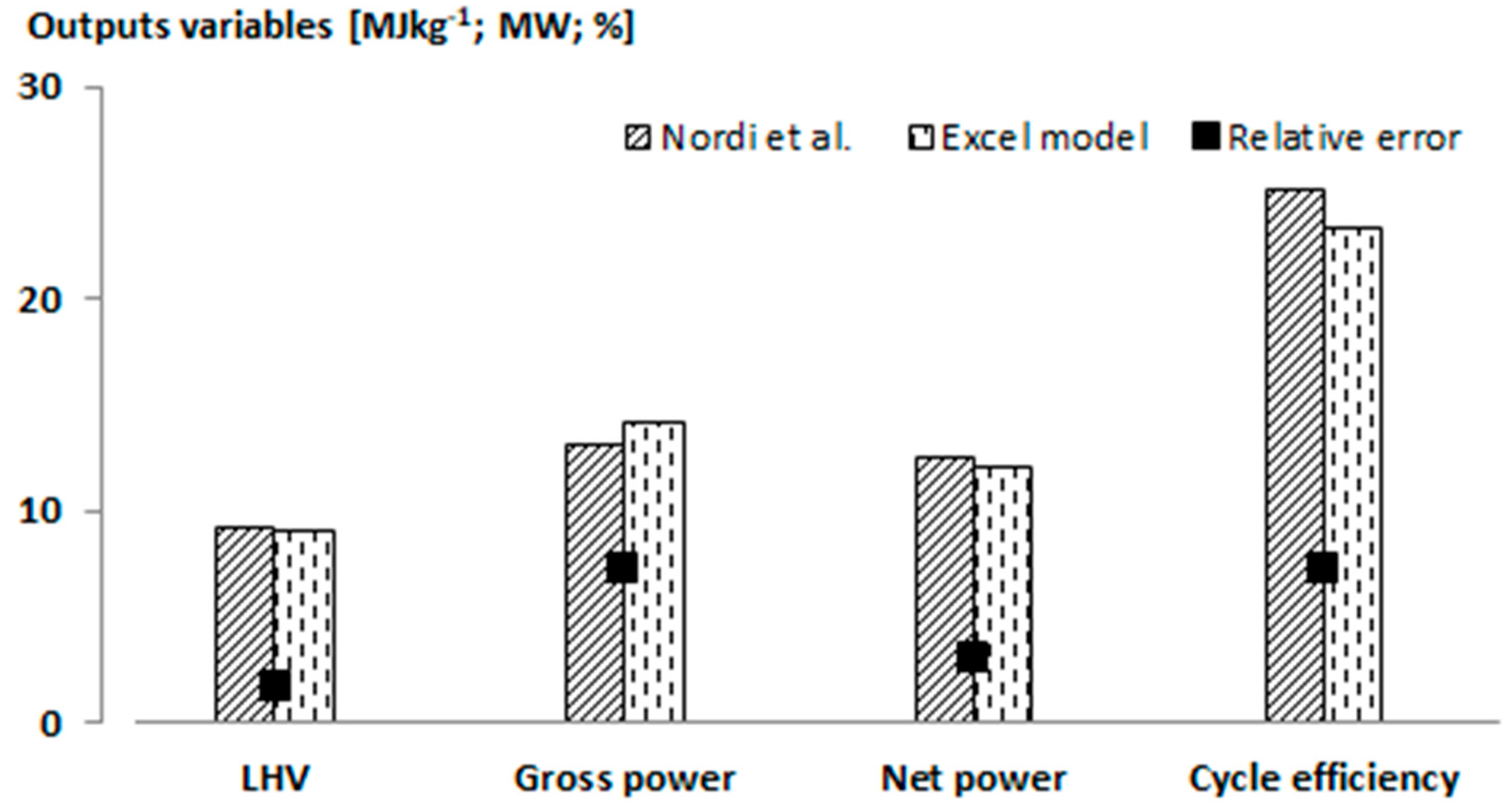

Vargas and Espinoza 2013). Recently, the electricity generation through a steam cycle from MSW in Santo André city (Brazilian State of São Paulo) ia carried out (

Nordi et al. 2017). In this work, the influence of the MSW composition on the cycle performance ia studied. In all the cases presented, it is concluded that the lower are the moisture and inert contents, the better is the cycle performance. The financial assessment shows that, for a fixed gate fee, the electricity price should vary between 60 and 150 USD per MWh for the WTE project to be feasible.

Cuba is the biggest island in the Caribbean; however, this does not mean that compared with the rest of the neighboring islands there is enough space for landfilling. Tourism is one of the main income sources to the Cuban economy as well as waste generation sector. Regarding the energy mix, only 4% of the electricity generated is based on renewable sources, while the other 96% is shared by fuel oil and natural gas (

ONEI 2017). These facts impose the necessity to move toward more sustainable waste management and energy generation systems. In this context, WTE should play a key role as treatment method as well as renewable energy source.

WTE has proven to be a better option for waste treatment compared with landfilling, providing cleaner electricity, heat and final disposal for MSW. A large reduction in waste volume can be achieved, reducing surface requirements, waste toxicity and the impact on groundwater due to formed leachate. Depending on the composition of the combustible fraction, MSW can be considered as a renewable energy source, having a direct impact on the greenhouse gases balance. The more MSW is diverted from landfills to WTE plants, the less waste is biologically degraded, reducing methane and carbon dioxide emissions. In addition, carbon dioxide emissions can be reduced even more by substituting fossil fuels as a primary energy source in power plants. It is estimated that the combustion of 1 metric ton of MSW in modern WTE plants can save the utilization of 1 barrel of oil (

Psomopoulos et al. 2009). WTE provides an integrated solution to meet both the waste management, in terms of environmental and sanitary requirements, as well as energy generation goals.

With 2,129,553 inhabitants reported in 2017 (

ONEI 2018), Havana has the highest population in Cuba and is the capital of the republic. It is one of the top tourist destinations as well as the place where many process industries are sited. In 2017, the volume of waste generated in the City of Havana represented ~25% of the amount generated in the entire country (

ONEI 2018). In Havana, the final deposition method for MSW is mainly landfills. However, in most of cases, the operation lifetime is exceeded, becoming in real dumpsites without energy recovery.

Many studies regarding MSW management in the city of Havana have been carried out (

López Torres et al. 2004;

Espinosa Lloréns et al. 2007;

Espinosa Lloréns et al. 2005;

NIPPON KOEI 2007). The first physicochemical characterization of the three biggest landfills in Havana shows that the heating value varied in the range from 7.1 to 12 MJ⋅kg

−1 in the biggest dumpsite of the city. However, no information about the gravimetric composition is reported (

Espinosa Lloréns et al. 2005). Regarding energy recovery, the biogas generation from the organic fraction of MSW has been studied, showing that it is possible to recover the investment in three years (

López Torres et al. 2004). The most recent characterization of MSW in Havana was carried out in collaboration with the Japan International Cooperation Agency in 2007 (

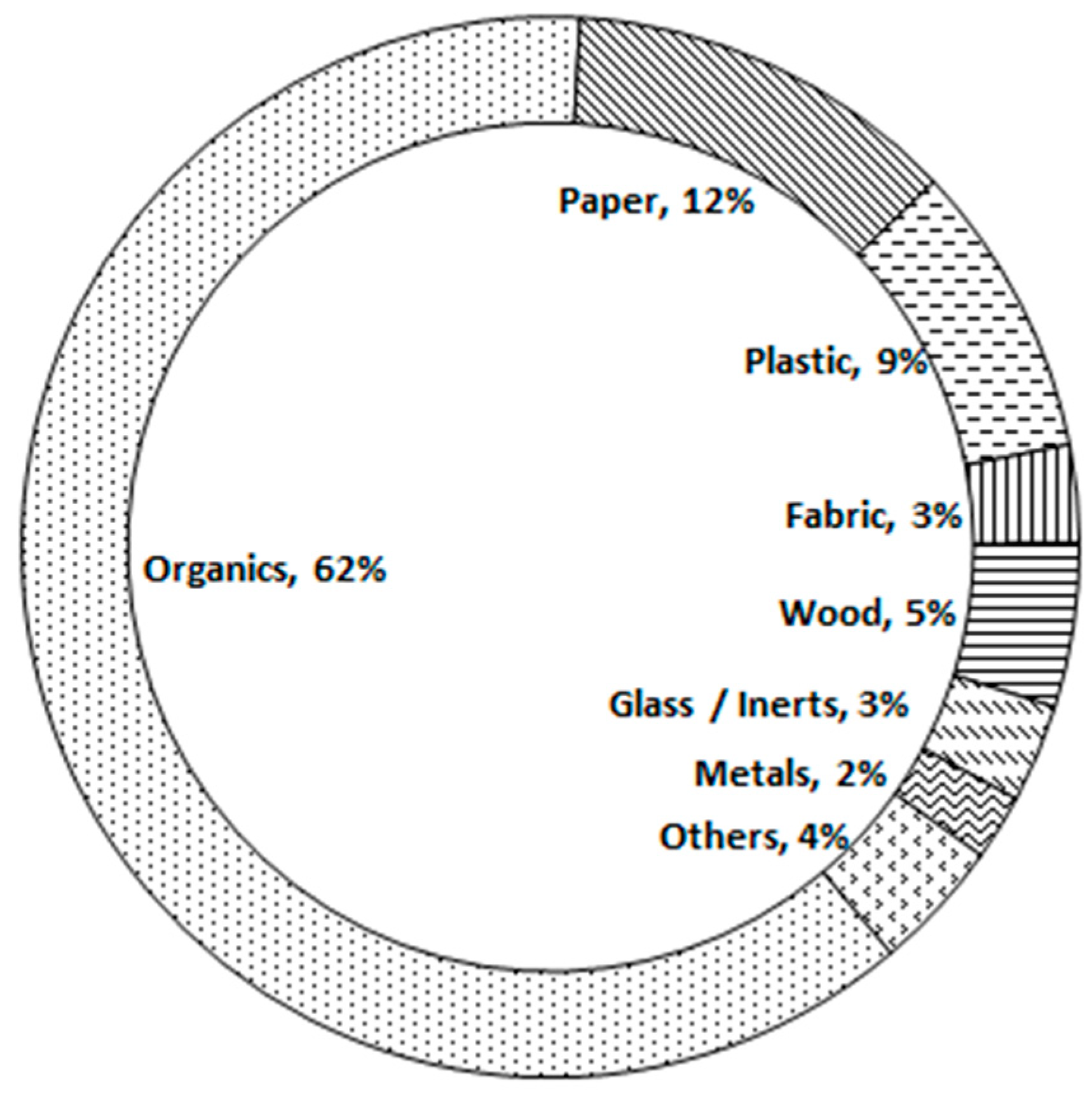

NIPPON KOEI 2007). In this study, the results are based on the gravimetric composition; an Integrated Solid Waste Management Strategy is also presented. Despite different alternative being considered in the strategy, none of them include WTE as an integral part.

Modern design of WTE plants should be seen as a combination of techno-economic and ecological aspects. Design methods aided by computer-simulation tools are required to achieve this goal. Computer-aided process simulation tools can handle high volume of calculations quickly and with a high level of accuracy, allowing design engineers to focus on other tasks such as alternative assessments. Nowadays, process simulation is extensively used to forecast the behavior of physicochemical processes for a given number of inputs (

Elyas and Foo 2017). The development of process simulation models for WTE technologies allows the prefeasibility and optimization analyses as support for design decisions.

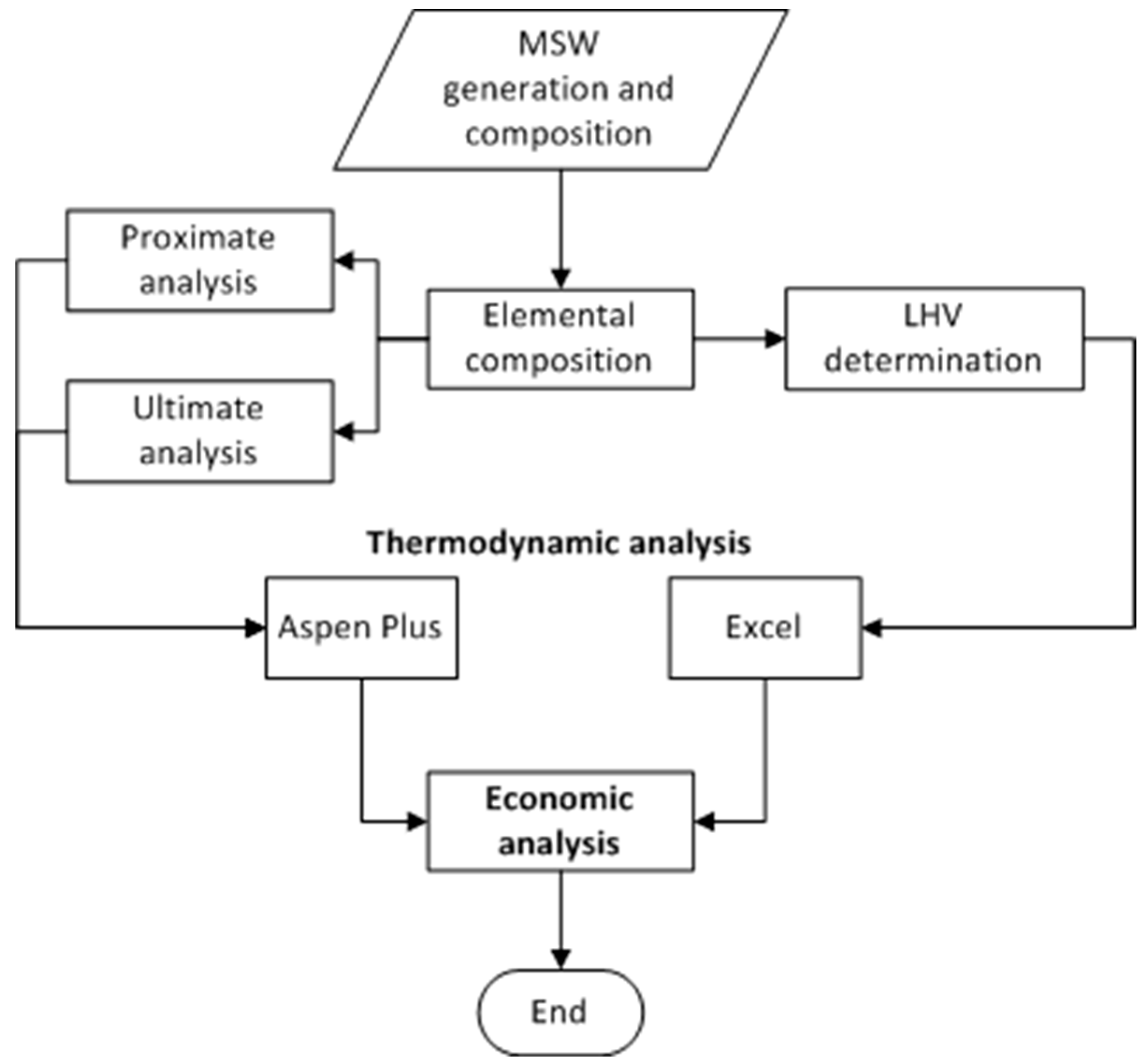

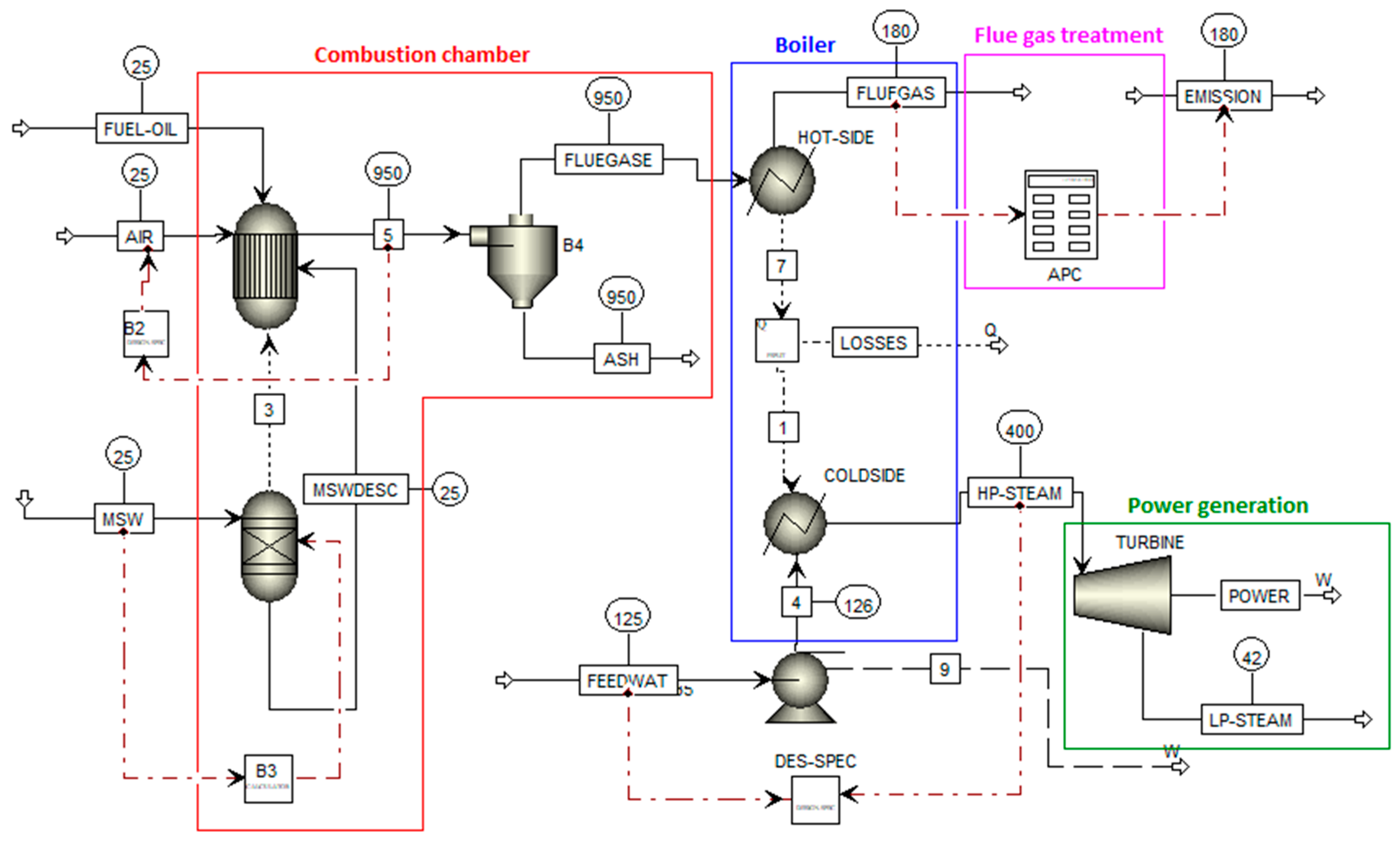

Aspen Plus

® is one of the most powerful frameworks for process simulation, design, optimization, sensitivity and economic analyses that allows great flexibility compared with other process simulator. It is successfully applied in many applications involving thermo-chemical conversion of biomass, coal and MSW (

Haydary 2018). Aspen Plus allows solving the material and energy balances to determine stream compositions, energy flows and physical properties among other parameters. In contrast with Aspen Plus, for which a certain level of knowledge about the interface is required, Excel sheets in many cases are preferred among engineers. The main advantage of Excel is that the calculation sheets can be customized by the user making easier the user-tool interaction. It is very useful for carrying out preliminary studies based on general data.

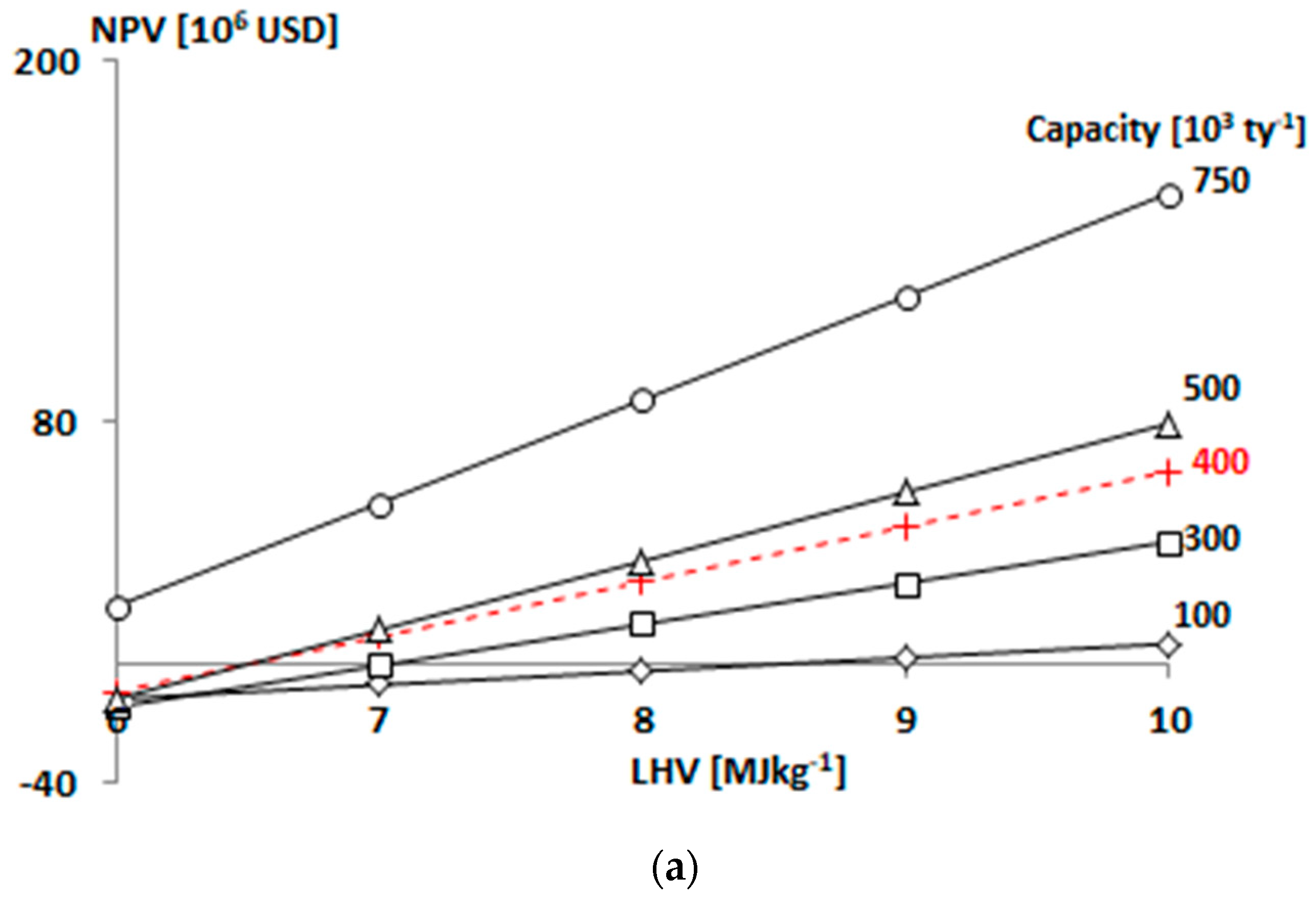

The particular case of Cuba (socialist economy), where waste management is subsidized by the government (no gate fee is paid by the citizens) and the electricity prices are lower compared to other Latin and Caribbean countries, makes it suitable as special case to study the development of WTE. The Cuban reality is different to those present in other Latin American and Caribbean cities discussed above. In this regard, the aim of this work was to carry out a techno-economic assessment of a WTE plant in the City of Havana. To reach this goal, two process simulation tools (i.e., Excel and Aspen Plus) were used to accomplish the technical evaluation. All calculations were based on the estimated low heating value (LHV) from the waste composition. Finally, the financial performance was assessed to analyze the feasibility of the project. It should be mentioned that, to the authors’ best knowledge, this first time that WTE technology is considered as a waste treatment in Cuba and particularly in Havana.