Abstract

With the breakthrough of modernism, various efforts were undertaken to rationalize architecture and building processes using industrial principles. Few architects explored these as intensively as Walter Gropius, the founder of the Bauhaus. Before World War One, and increasingly in the interwar years, Gropius and a number of colleagues undertook various experiments that manifested in a series of projects, essays, model houses and Siedlungen. These were aimed at conceptually different goals, i.e., they followed two different categories of industrial logic: First, a flexible construction kit and, second, an assembly line serial production. This article traces the genesis of these two concepts and analyses their characteristics using these early manifestations. Compared to existing literature, this article takes into account hitherto neglected primary sources, as well as technological and construction history aspects, allowing for a distinction based not only on theoretical, but also technological and structural characteristics. This article shows that Gropius succeeds in formulating and exploring the two principles, in theory and practice, as well as drawing conclusions by the end of the 1920s. With them, he contributed significantly to the rationalization of architecture, and his principles have been picked up and developed further by numerous architects since then.

1. Introduction

While the Industrial Revolution had brought about radical changes in many economic sectors by the end of the 19th century, it was slow to take on in the architecture and building industries. Apart from a few fields, such as industrial buildings or the mechanized production of certain materials and components, many areas of architecture and the building industry stuck to traditional craftmanship until well into the 20th century. It was not until the breakthrough of modernism—or Neues Bauen in the Weimar Republic—that increased efforts were undertaken to introduce industrial principles of rationalization, such as systematization, standardization, prefabrication and serial production, to architecture and to industrialize design and building processes. In the Weimar Republic, these rationalization efforts were motivated by the desolate economic situation after the war, by the acute shortage of affordable housing, as well as the obligation to make war reparations. These demands met with the successes achieved by mechanization, industrialization and rationalization, especially in the United States, as well as the general enthusiasm in the Weimar Republic for progressive American culture—despite the political and ideological differences.

Few architects explored the rationalization of architecture as constantly and intensively as Walter Gropius (1883–1969). Even before World War One, and increasingly in the interwar years, he undertook various efforts, which aimed at conceptually different goals. As will be shown in the following, Gropius, together with a number of colleagues, tested different approaches that can, broadly speaking, be assigned to two different categories of industrial production logic: On the one hand, a flexible construction kit and, on the other hand, assembly line serial production. Both approaches aimed at rationalizing design and building processes in order to turn the house into an industrially manufactured product in the sense of a modern machine architecture. Not only were these experiments formulated in a series of projects and essays, but they also manifested in a number of systems, structures and construction methods. They were also—with various degrees of success—tested with a number of model houses, exhibition buildings and Siedlungen. While some aspects turned out to be impracticable, others have since been widely adopted and used.

In the following article the genesis of the two concepts will be traced and their characteristics analysed on the basis of these early manifestations. The knowledge gain compared to the existing Gropius-monographs (; ; ) lies in the consideration of the technological or the construction history aspects of the various designs and model houses, as well as hitherto neglected primary sources, such as Walter Gropius’ unpublished manuscript on “Wohnmaschinen” from 1922 (), his little-known lecture “Stahlhausbau” (‘Steel Construction’) from 1929 () or historical studies of steel houses e.g., by Georg Muche (1895–1987) or Hans Spiegel (1893–1987) (, , ; )—to name a few of the most interesting ones. Taking them into account allows for a precise distinction—based not only on theoretical, but also on technological and structural characteristics—between the two rationalization principles, namely that of the construction kit and that of the assembly line. With them, Gropius contributed significantly to the development of two fundamental approaches to rationalizing architecture, which subsequently have been picked up and developed further by numerous architects in the course of the 20th and 21st centuries.

2. “Row Building” and the “Convention in a Good Sense”

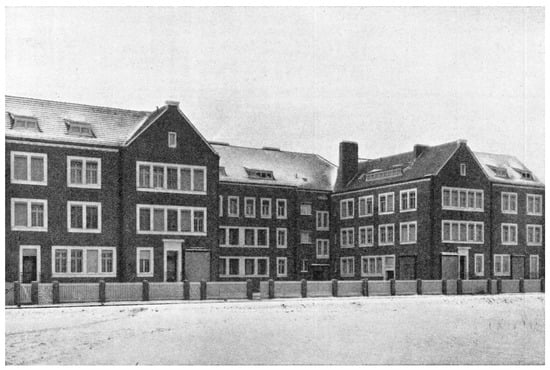

Already in the years 1908–1910, as an employee of Peter Behrens (1868–1940), Gropius became acquainted with a cooperation of architecture and industry. Working for Behrens, who, as the artistic advisor of Allgemeine Elektricitäts-Gesellschaft (AEG), was responsible for the design of all the company’s buildings, products and printed matter, Gropius learned about the “refinement of industrial work in a collaboration of art, industry and crafts” in the sense of Deutscher Werkbund (; ). The design of the AEG products, as Henning Rogge summarizes, is characterized by the fact that it “originates from forms designed for machine and mass production, from types developed for appropriate materials, and, where possible, builds on existing forms” (). In addition, with the workers’ rental houses in Henningsdorf (1910–1911)—Behrens’ first workers’ housing project built at about the same time as the AEG porcelain factory—Gropius encountered the idea of a Siedlung that “consists of a single wing of three-storied houses built as a continuous row-building” (Figure 1). As Fritz Hoeber pointed out as early as in 1913, “this method of construction (…) not only has the advantage of being of the greatest economic efficiency”, but also, “above all, to appear as with an architecturally cohesive entity” (; cf. ; ).

Figure 1.

Peter Behrens: Workers’ rental houses in Henningsdorf, 1910–1911. Photo from ().

In 1910 Gropius, probably together with Behrens (cf. ), formulated a “Programme for the establishment of a universal house building company on an artistically consistent basis” (‘Programm zur Gründung einer allgemeinen Hausbaugesellschaft auf künstlerischer einheitlicher Grundlage m.b.H.’), addressed to the AEG-management (). There, for the first time, he outlined the idea of industrializing house building with the help of standardized elements—pre-empting important aspects of his later rationalization efforts. He claims that “a convention in the good sense of the word, uniformity and established forms”, the “use of recurring components and materials in all houses”, the “recurring use of tested designs”, as well as a “uniform development” can cure the “bad state of affairs in today’s building industry.” He describes, how this “house building company” can unite the artistic and entrepreneurial endeavours and how it can be implemented by the means of “commercial principles” and “administration”. He did, however, not waste any thought on the technical implementation nor did he mention that not only in the United States and the United Kingdom, but also in Germany standardized prefabricated housing systems already existed (cf. ; ).

3. Americanism, Taylorism and Fordism in the Weimar Republic

The November Revolution of 1918 and the establishment of the Weimar Republic in the years 1918–1919 promoted a breakthrough of modernism—various Avantgarde movements most commonly subsumed under the term Neues Bauen that replaced the Historicism of the late Wilhelmine Empire (). These were characterized by a number of aspects that proved to be fundamental for subsequent rationalization efforts in architecture and included e.g., a general enthusiasm for machines, technology and industry, for American business and culture, as well as for certain tropes, such as the city, the skyscraper or the automobile. Americanism, in particular, was not only tied to a general notion of progress, but it was believed that the application of rationalization concepts used in the industry in the United States, such as Frederick Winslow Taylor’s (1856–1915) scientific management, Frank B. Gilbreth’s (1868–1924) motion studies or Henry Ford’s (1863–1947) assembly line production, could help to alleviate the economic hardship of the meagre post-war years. Especially Taylorism and Fordism became synonyms for Americanism and much-invoked models for industrial rationalization (cf. ), as the title of the book published by the economist Edgar Herbst in 1920, Der Taylorismus als Hilfe in unserer Wirtschaftsnot (‘Taylorism as an aid to our economic hardship’), most clearly expresses (). Though, strictly speaking, the roots of this reception originated before World War One, it was not until the interwar years that they exerted a great effect: For example, Frederick Winslow Taylor’s book The Principles of Scientific Management published in 1911 became known in the German-speaking countries through the translation published in 1914; at about the same time, a number of companies adopted the “Taylor system”, and from 1920 onwards a Taylor Zeitschrift (‘Taylor magazine’, full title Taylor Zeitschrift. Monatshefte für wissenschaftliche Betriebsführung und rationale Wirtschaft mit besonderer Berücksichtigung des Taylor-Systems) was published in Vienna (, ; ). In 1919 and 1920, the books by Frank B. Gilbreth, Primer of Scientific Management and Motion Study. A Method for Increasing the Efficiency of the Workman, published in 1912 and 1911 respectively, were printed in German translations (; ). In 1913–1914, Henry Ford in Detroit introduced the assembly line to develop a model of industrial manufacturing. But it was not until 1923, five years after the war and at the climax of the hyper-inflation, that a German translation of Ford’s autobiography was released—which significantly contributed to the long-term popularity of this production method (; cf. ; ).

In the first years of the Weimar Republic, these rationalization efforts were scarcely implemented in the now fallow building industry. One pioneer to change that was the engineer Max Mayer (1886–1967), who as early as 1914 started giving lectures on “Die Anregungen Taylors für den Baubetrieb” (‘Taylor’s ideas for the building industry’, ), published a book with the same title in 1915 () and held a professorship for statistics and economics in Weimar from 1926 to 1930—tirelessly promoting topics, such as “Fließbandarbeit auf der Baustelle” (‘Assembly line work on the construction site’, ) or “Die Anwendbarkeit der Maschine im Bauwesen” (‘The applicability of the machine in the building industry’, ). It was not until 1924, after overcoming the crisis of the first postwar years—with the end of the hyperinflation, the currency reform and the incipient effects of the Dawes Plan—that rationalization methods were more widely applied in the burgeoning building industry. This was partly due to the reception of developments in France and the Soviet Union. Considerable influence was exerted, for example by Le Corbusier (1887–1965), who propagated in his publications and illustrated in his projects Taylorism, rationalization and mechanization (cf. ).

4. Martin Wagner and other Pioneers of Rationalization

In the period immediately after World War One, the first initiatives for the rationalization in architecture were not undertaken by Gropius, but rather by Martin Wagner (1887–1957), who was city architect of Schöneberg from 1918–1921 and of greater Berlin from 1922–1933. As early as in 1918, before the end of the war, he propagated in his book Neue Bauwirtschaft (‘New building industry’) rationalization according to industrial principles and the American model (; cf. ). In 1920 he co-founded the journal Soziale Bauwirtschaft, the organ of the union-based association of Social Building Companies (Verband sozialer Baubetriebe), which continuously reported on Taylorism, rationalization, new machines and building systems (; cf. ). From 1922 onwards, the social building companies employed the so-called Jurko building system, a method using prefabricated slag concrete slabs, which were assembled on site with a crane; and in 1924 they developed the so-called “Arbeitsgraphikon” (‘working graph’) as a “scientific working method in the building industry”—a bar graph for scheduling and planning the building process (; ; cf. ).

Significantly, Wagner was also one of the first architects in the Weimar Republic to travel to the United States in 1924—to study the American building industry. In 1925 he summed up his travel observations in the book Amerikanische Bauwirtschaft (‘American Construction Industry’; ). He describes how “the replacement of men with machines (…) has made great progress in the American building industry.” He observes, for example, that the rationalization of brick construction according to the ideas of Frank B. Gilbreth has not been very successful, while the most promising progress has been achieved with the “still rarely used concrete slab construction”. He writes that “instead of small bricks, which require a lot of manual work already during fabrication (…) countless hand movements by bricklayers and unskilled workers, heavy concrete slabs of up to three tons can be used, with the slabs already furnished with interior and exterior rendering, and put in place with large cranes without any hand touching them.” This would allow “the output accomplished manually by 67 construction workers” to be now carried out “by 8 men with the help of machines and cranes”. Thus, “an American engineer, with the help of scientifically tested building methods, can complete building an apartment in one day while still reducing the cost (…) by 40 percent compared to the average” (). In addition, Wagner drew parallels to Henry Ford’s assembly line production in the automobile industry. In an essay published in 1924, the year of his trip to the United States, he praises “the teachings of the automobile king Henry Ford.” He proclaims that “Ford’s concepts are largely consistent with the ideas that have in essence already been implemented by our Bauhütten-movement [‘Bauhüttenbewegung’]” ().

With the implementation of these rationalization efforts in mind, Martin Wagner actively sought cooperation with other progressive architects. For DEWAG (Deutsche Wohnungsfürsorge Aktien-Gesellschaft für Beamte, Angestellte und Arbeiter) he established in 1924 the so-called “Kopfgemeinschaft” (‘head community’)—a working group, in which he invited Walter Gropius, Bruno Taut (1880–1938) and Ernst May (1886–1970) to develop a programme for rationalized housing types, as well as constructions for a “Volkswohnung” (‘a people’s dwelling’). Since the unions backing the group did not grant the necessary starting capital for the first trial houses, the working group was dissolved again in the middle of 1925. But over the next few years, each member continued to pursue the goal in his own way (cf. ).

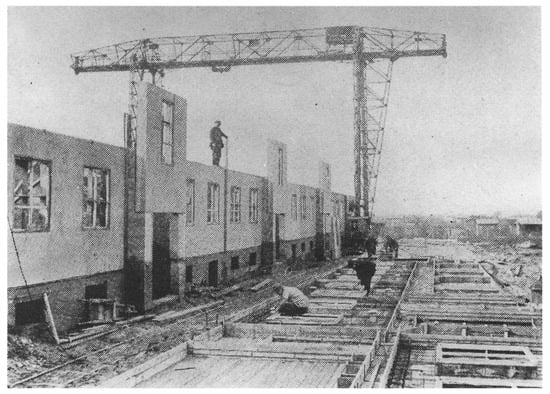

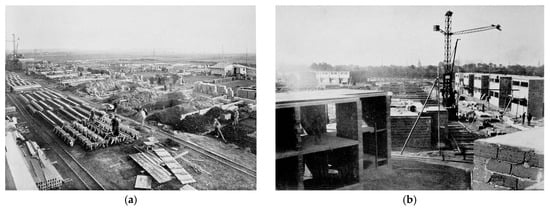

In the years 1924–1925, the construction method using large precast slabs as described by Wagner was tested for the first time at the small experimental Siedlung in Sewanstraße/Splanemannstraße in Berlin-Friedrichsfelde (Figure 2). The so-called Occident system from the Netherlands was used—a construction method with storey-high and up to 11 m long, double shell concrete slabs (with gravel concrete on the outside, slag concrete inside and a slag filling in between), which—to save transport costs—were produced outdoors on site and put into place using a gantry crane. Thanks to this construction method, it had been possible to reduce the building cost of row houses built in Amsterdam by 30–40% compared to a conventional brick structure. In Friedrichsfelde, however, this construction method led to disappointing results, and the anticipated cost reduction was not achieved. The small size of the project, the checkered quality and considerable inaccuracies of the large concrete slabs led to long downtimes of the crane and to a schedule overrun (cf. ; ). Although the project attracted a certain attention in contemporary professional publications as a “building method of the future” and was even the subject of an educational film, it was quickly forgotten due to its failure (; ).

Figure 2.

Martin Wagner: Experimental Siedlung in Sewanstraße/Splanemannstraße in Berlin-Friedrichsfelde (1924–1925)—Contruction with the Occident system using a gantry crane (Photo of unknown origin).

With subsequent projects, Wagner and his colleagues tried to learn from this experience and to rationalize only those aspects that promised significant improvements, such as the construction method, the building volume, i.e., the size of the Siedlung and the number of identical units.

For example, with GEHAG’s Hufeisensiedlung in Berlin-Britz, planned by Martin Wagner and Bruno Taut between 1925–1930, typified floor plans were used and the building process was organized with the help of diagrams; during construction, a bucket-wheel excavator was used for the first time in Germany. But Wagner and Taut did not use untested new building methods or structures; the Siedlung was executed as conventional brick structure. The Siedlung Britz is, as Ludovica Scarpa judges, more “the result of concentrating on one large construction site and not of rationalizing—in the sense of using machines instead of manual labor” (; cf. ).

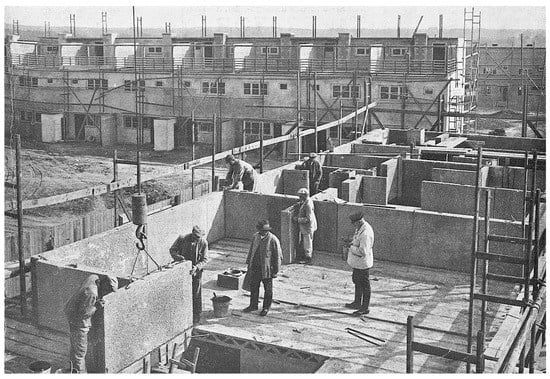

From 1925 onwards, Ernst May employed for the Siedlungen of Das Neue Frankfurt the especially developed “Frankfurter Montageverfahren” (‘Frankfurt assembly method’; , ; , , ; cf. ; ). Like the Occident building system, it was based on large prefabricated panels and slabs (Figure 3). However, May was successful in compensating for its disadvantages and to advance it considerably: On the one hand by improving on the construction method itself, i.a. by subdividing the panels and slabs into smaller formats, by using light pumice instead of heavy slag, as well as a method of assembly allowing for more dimensional tolerance; on the other hand, also by building on a much larger scale. And with the establishment of a dedicated prefabrication factory, it was possible to make the production less dependent on the weather, to introduce “assembly line work” (‘Fließarbeit’), to partially eliminate manual work, to save on molds and material and to improve the quality of the slabs. In doing so, May not only achieved a significant rationalization success, but also accomplished a corresponding architectural progress. He wrote, “the assembly process enforces objectivity and clarity in design” ().

Figure 3.

Ernst May: “Frankfurter Montageverfahren” (‘Frankfurt assembly method’). Photo from Das Neue Frankfurt, 1926/1927/2, title.

Starting from the first successes in Frankfurt, in the years 1927–1928, discussions about the rationalization of the building process flared up. They focused, for example, on the alternative options “Slab factory or brick building?” (‘Plattenfabrik or Ziegelsteinbau?’; ; ; ; , ) or on the “Outdoor house building factory” (‘Häuserfabrik im Freien’; , ; ).

5. “Honeycomb Construction”, “House Building Industry” and “The Big Construction Kit”

Walter Gropius, who in the early post-war years still adhered to the introverted utopian Expressionism of Gläserne Kette and the Bauhütte-mysticism of the early Bauhaus, converted from about 1921 on with growing enthusiasm to the principles of technology and industry according to the American model. His change of mind went hand in hand with the artistic exhaustion of Expressionism, the growing popularity of Neue Sachlichkeit and the sobering influence of groups, such as De Stijl in the Netherlands and Russian Constructivism—as can be seen most clearly in the change of artistic direction at the Bauhaus. It also followed the general economic stabilization of the Weimar Republic and the recovery of the construction industry (cf. ; cf. ; ).

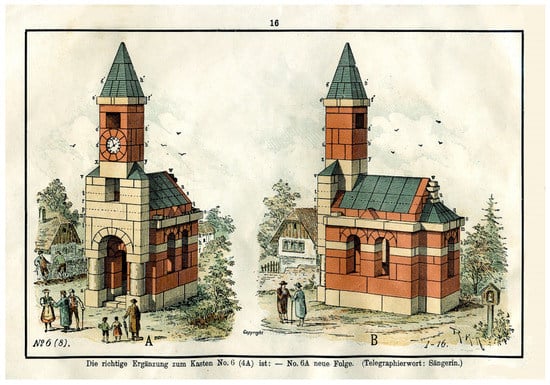

In 1922, Gropius, following Le Corbusier, formulated in an unpublished manuscript the idea of “Wohnmaschinen”. He celebrates America as a shining example of motorization and mechanization, calling Americans “the most determined inhabitants of Earth”, as they “have the best chance of implementing an ideal Wohnmaschine. This house will no longer be a dream of the rich, but will become a commonplace tool, the dwelling of every earth-dweller.” Since he regarded Germany as lagging far behind America concerning the degree of industrialization, he refrains from referring to Ford’s assembly line production. Rather, he formulated as an achievable goal “a house made up of variable set pieces, that are produced in stock and can be put together in a combinatorial way, say, in the manner of an Anker-Steinkasten, but only on a large scale” ().

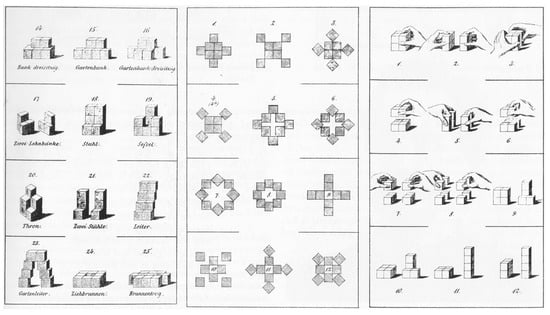

The “Anker-Steinkasten” (Figure 4) refers to the most famous of the numerous construction kit or system toys then available. It was invented in the 1870s by the brothers Otto and Gustav Lilienthal (1848–1896 and 1849–1933 respectively), the famous aviation pioneer and his brother, a master-builder and social reformer; in 1880 it was patented by the entrepreneur Friedrich Adolf Richter (1846–1910) and from 1882 onwards mass-produced (cf. ; ). The Anker blocks are geometrically shaped forms that are pressed with great precision from sand, writing chalk and linseed oil and then baked; and they are primarily produced in the primary colors red, yellow and blue. The blocks are assembled according to special manuals to form complex architectural models without using glue or fixation, just observing the laws of structural physics (cf. ). The idea of the construction kit as a toy largely dates back to the educator Friedrich Fröbel (1782–1852), who developed a series of so-called Spielgaben, in which playing with the basic geometric blocks, using the kits devised by him, has an essential role. For instance, the various divisions of a cube form the basic shapes of the 3rd to 6th kits of Spielgaben (cf. ; Figure 5). Fröbel exerted a considerable influence on the teaching at the Bauhaus as a model in pedagogic matters (cf. ; ; ; ). He was also honored with the project of the Friedrich-Fröbel House in Bad Liebenstein, which was designed by Walter Gropius and Adolf Meyer (1881–1929) in 1924, on the occasion of the 75th anniversary of Fröbel’s death, but which was unfortunately never built (cf. ).

Figure 4.

Assembly instructions for Anker Steinkasten kit 6A, late 19th-century.

Figure 5.

Friedrich Fröbel: Applications of Spielgabe 6: “Lebensformen” (‘life forms’), “Schönheitsformen” (‘beauty forms’) and “Erkenntnisformen” (‘learning forms’)—Drawings published in the journal Jugendlust, 1881.

With the Anker building blocks, Gropius also refers to a number of properties that are of great importance for the implementation of construction kit systems in architecture. The construction kit represents a prototypical open system. It was first used in architecture in the mid-19th century with the Crystal Palace designed by Joseph Paxton (1803–1853) and Charles Fox (1810–1874) for the First World Fair in Hyde Park in London (1850–1851), and it went hand in hand with the application of a number of industrial principles, such as modularization, serialization, typification and prefabrication. The Crystal Palace was designed as a strictly rasterized and modularized system and was built as a serialized and typified frame structure with standardized joints, made with mostly prefabricated cast-iron components and assembled on site within a very short time—without additional scaffolding structures. As Tom F. Peters points out, the Crystal Palace was not only an open system, but also the first multidirectionally expandable one ().

The construction kit, as described by Gropius, also features the characteristics of precision and interchangeability, which constitute a property called totipotency. In the field of history of technology, this term describes the ability of individual elements to form a larger unity, i.e., the flexible assembly and configuration of elements into a whole. The concept of totipotency came up in the military in the late the 18th century and it constitutes one of the essential prerequisites for the transition from handicraft production to a flexible industrial production (). But it was not until World War Two that the concept started to play a role in mass production in the aerospace industry and was developed as a theory. First used by Gropius in architecture, the concept was later adopted and applied by other architects, such as Konrad Wachsmann (1901–1980) or Fritz Haller (1924–2012)—yet their reception was also partly influenced by the aerospace industry (; ).

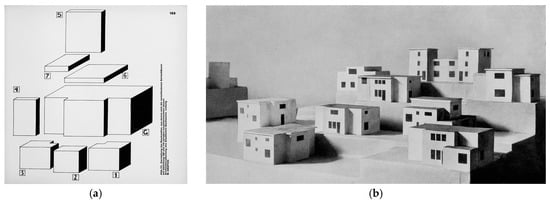

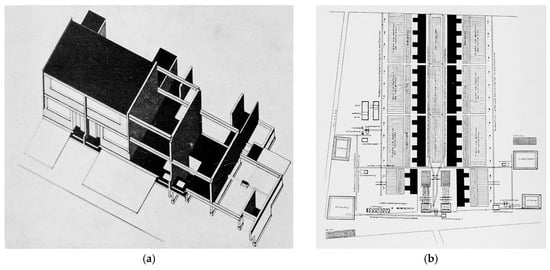

Gropius implemented the concept in a number of design projects, which were accompanied by programmatic texts and eventually resulted in a number of experimental houses. Among the designs made are two construction kit systems, both of which were exhibited at the big Bauhaus exhibition of 1923: First, the “Honeycomb System” (‘Wabenbau’) developed by Gropius in collaboration with his colleague Fred Forbát (1897–1972; cf. ) in 1922, and second, the “Big Construction Kit” (‘Baukasten im Großen’) for a “serial house type” (‘Typenserienhaus’) designed one a year later by Gropius and his partner Adolf Meyer (1881–1929). Both systems are aimed at a cellular typification, but are characterized by a different kind of modularization and by a distinctive kind of hierarchization of modules (; cf. ; ): On the one hand, the “honeycomb system” consists of a basic module that derives its “great variability” from the honeycomb-like “addition and attachment of linked space cells according to the number of heads and the needs of the inhabitants” (Figure 6a,b). On the other hand, the “Big Construction Kit” consists of six, more or less equivalent basic modules of different sizes which can be combined with one another and “put together to form different ‘Wohnmaschinen’ according to the number of heads and the needs of the residents and following well-prepared assembly plans” (; Figure 7a–d).

Figure 6.

Walter Gropius and Fred Forbát: “Honeycomb System” (‘Wabenbau’), 1922. Images from ().

Figure 7.

Walter Gropius and Adolf Meyer: “Big Construction Kit” (‘Baukasten im Großen’) for a “Serial House Type” (‘Typenserienhaus’), 1923—Conceptual diagrams, floor plans and model photos. Images from ().

Based on these projects, Gropius formulated the concept of flexible, industrially produced construction kits which he describes in the two programmatic articles “Wohnhaus-Industrie” (‘House Industry’) and “Der große Baukasten” (‘The Big Construction Kit’) published in 1925 in the Bauhaus book Das Versuchshaus des Bauhauses in Weimar (‘The Experimental House of the Bauhaus in Weimar’) and in 1926 in Das Neue Frankfurt, respectively (, ). In “Wohnhaus-Industrie” he advocates a “fundamental transformation of the entire construction industry towards an industrial direction ….” The goal is the dwelling as an industrially manufactured product, which is assembled from highly flexible construction kit elements. Gropius calls for an “industrial to stock production in large establishments of residential buildings which are no longer built at the construction site, but are produced as assembly-ready components in specialized factories.” If Gropius’ and Meyer’s “honeycomb”-system and Gropius and Meyer’s “big construction kit” are based on conventionally built elements, whose flexibility was not further explored, Gropius now describes a form of industrial production with flexible or totipotent elements that is customary in mechanical engineering. The aim, according to Gropius, is “to assemble the elements of houses which are previously manufactured in factories by a dry construction method on the construction site like machines.” He claims that with this dry construction method, i.e., by turning building into an industrial manufacturing process, the disadvantages and imponderabilities of conventional craftsmanshiplike building, such as “the annoying component changes (…) and the loss of time”, e.g., material or constructional imperfections, dimensional tolerances or seasonal weather, can be eliminated. It is not the goal, as in the past, to typify and industrially reproduce entire houses, but only individual components that then can be assembled into different types of houses, as is done in mechanical engineering: “All components for the construction are to be produced in various specialized factories” and only assembled on site according to “practically tested assembly plans”. Gropius promises that in this way building construction can reach the advantages and quality of industrial production, namely: “Absolute interfitting of the machine produced components, at a fixed price, and a short, firmly guaranteed construction process” ().

For the technical implementation, new industrial materials and structures have to be utilized: “Other construction materials than the old ones” are needed, “mechanically processed ones instead of the natural unprocessed”, including “improving natural products to form absolutely reliable materials of exact uniformity (wrought iron, cement alloys, artificial wood).” Moreover, Gropius proposes a skeleton construction method in which the structure is “divided into a load-bearing frame (of iron, reinforced concrete) and non-load-bearing in-fill of walls, roofs and ceilings”, where the “load-bearing skeleton [consists of] (…) iron girders and columns or reinforced concrete beams and columns joined together in a cantilever or frame system”. Furthermore, “the in-fill of the walls, ceilings and roof (…) is to consist of standardized building panels machine produced from weather-resistant, structurally reliable, yet porous, insulating and tough lightweight material”, such as pumice cement, plaster-board or reinforced Torfoleum-boards. While Gropius criticizes that “the question of the industrial production of wall, ceiling and roof elements and of the corresponding load-bearing structure” has not been solved, yet, he acknowledges that the “standardization and serial production of doors, windows, stairs, cornices, installations and interior components (…) is well underway to be perfected”. Though, as he points out, it is still directed “towards manual instead of industrial serial production” ().

This “Wohnhaus-Industrie” is also accompanied by fundamental changes in the architect’s profession. He must now orient himself by the “vehicle engineer” who designs “railway cars, ships, automobiles and aircraft (…) [and is] ahead of the building engineer [‘Bautechniker’], in that he already utilizes mechanically processed standardized building materials (iron, aluminum, glass) and mechanical manufacturing processes” ().

In “The Big Construction Kit”, Gropius essentially repeats the same arguments and formulates them in an even more acute way. He argues, that the “the most primitive economic demand is to satisfy our needs in an ever-more economical way, i.e., with less effort and money, pay and material, but by an ever-increasing intellectual setup. This drive leads to the machine, to industry!” He formulates the new “tasks for the architect”, the new “tasks for the engineer” and the new “tasks for the businessman”, and he outlines 13 points “for a thorough rationalization of house building and urban construction.” Finally, he arrives at the much-quoted prophecy: “The ready-made house off the shelf will soon be the main product of the industry” ().

5.1. The Experimental House Am Horn

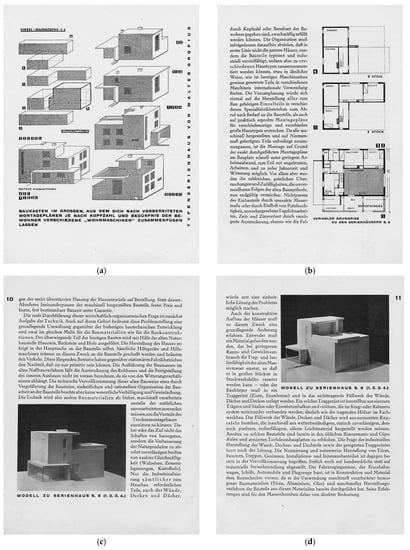

Walter Gropius and his colleagues only gradually succeeded in implementing the construction kit concept. They only partially achieved it with the experimental house Am Horn which was designed for the great 1923 Bauhaus exhibition by the Bauhaus master Georg Muche in collaboration with Bauhaus students and built by Adolf Meyer and Werner March (1894–1976) (; cf. ).

It is typologically derived from the “honeycomb” system—the various rooms of the square plan are grouped around a raised central living room lit by fanlights (Figure 8a,b). The house is however conventionally built and no dry construction method is used (Figure 8c). The walls are made with so-called Jurko blocks—large, mortar-bonded slag concrete blocks; the ceiling is a Berra hollow stone ceiling (‘Berrahohlsteindecke’)—one of the many reinforced light concrete brick systems of the time with a triangular cross-section, very economic reinforcement and little concrete cover (; ; cf. ).

Figure 8.

Georg Muche: Experimental house Am Horn, Weimar, 1923—Conceptual diagram, photo and construction site photo. Images taken from () and ().

Georg Muche asserts in the Bauhaus book published on this occasion that the house is “an attempt (…) to find a basic form of contemporary single-family dwelling” (). Moreover, four designs for “Variations of the Experimental House” by Adolf Meyer, the Bauhaus master Marcel Breuer (1902–1981), as well as the Bauhaus student Farkas Molnár (1897–1945) were exhibited to demonstrate the “versatility of the type” (). In his commentary, Meyer emphasizes that “in the choice of building materials and construction methods, those have been chosen that favour a new, synthetic concept of construction”, demonstrate “a resemblance between material and construction” and “beyond the present economic constraints point out a possible contemporary way forward” ().

5.2. The Steel House in Dessau-Törten

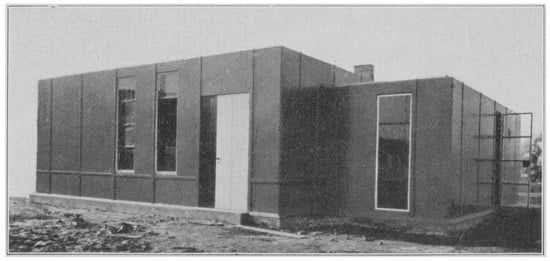

The steel house in Dessau-Törten (1926) by Georg Muche and Richard Paulick (1903–1979), who was an assistant of Walter Gropius, as well as the two experimental houses at the Weissenhof Siedlung (1927) by Gropius himself came closer to the ideal of a construction kit (Figure 9).

Figure 9.

Georg Muche and Richard Paulick: Steel House in Dessau-Törten, 1926. Image taken from ().

The turn towards steel structures can be traced back to the steel houses built by steel-manufacturing companies in Germany after 1926. They were inspired by English models and were initially based on steel lath and steel panel structures (; cf. ). In 1927 Muche referred in an essay explicitly to English models—comparing them with structures in Germany ().

Moreover, the steel house in Dessau-Törten continued a series of projects for steel houses developed at the Bauhaus, such as a small roundhouse (1923) by Carl Fieger (1893–1960), an employee of Gropius’ (cf. ), three projects by Marcel Breuer, namely for a small steel house (1926), a flexible system for small houses (1927) and houses for Bauhaus masters (1927), as well as a high-rise with terrace-roof gardens (1924) and a dry assembly system for Siedler-houses (1924) by Georg Muche (cf. ).

In this context, the numerous experiments undertaken by the aircraft-pioneer Hugo Junkers (1859–1935) and the Junkers factory in Dessau have to be mentioned, too. They range from steel lath roof structures to elaborate folded steel panel systems. Various attempts by the Bauhaus members to collaborate with Junkers remained, however, fruitless (cf. ; ).

The steel house in Dessau-Törten was based on the technology developed by the safe-building company Carl Kästner in Leipzig and was constructed in virtually the same way as the first Kästner house erected earlier the same year (). In two aspects it constituted a major step forward compared to both earlier steel houses, as well as the experimental house Am Horn: On the one hand, it was decidedly modern in design and not adapted to traditional types or forms; on the other hand, it was also a steel panel structure that utilized a dry-assembly method. Muche claims—following Gropius—that the “steel construction house” constitutes a contribution towards an “up-to-date housing production”, that it contributes to “replacing manual building methods with technological principles” and that it aims at turning “the house” into an “industrial product”. As a consequence, “the architectural design will not only be secondary—it will no longer be allowed at all”. It will be replaced by a “technological construction” with “an inherent beauty without further ado”. In this context he asserts that “the formal problems of technology are (…) scientific, not artistic in nature”, that the “technical form [is] (…) a synthesis of purpose and material”, and “from it (…) the organic structure—the aesthetic form beyond all ornamental intentions” will emerge. As he explains, the steel house—in the same way as the Kästner Haus—is a steel frame structure made of I-profiles; the façade is covered with 3 mm steel plates on the outside and with Torfoleum-plates and gypsum slag boards on the inside (; ; ; cf. ; Figure 10a,b).

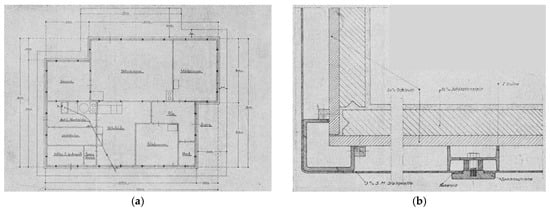

Figure 10.

Georg Muche and Richard Paulick: Steel House in Dessau-Törten, 1926—Floor plan and façade construction detail. Drawings taken from ().

However, the steel house only partially answers the claim to be a prototype for industrial mass production. Muche concedes that the goal of “structures for metal type houses based on a schematic and adaptable floor plan (…) could not be implemented in this case”, because the “funds for experiments were (…) not available” (). Muche and Paulick followed the goal of a construction kit in a rather pragmatic way, mainly from a superficial point of view. The house consists of two tight cubes with a repetitive modular façade. A close examination reveals, however, that the steel structure’s geometric grid is solely oriented on the plan and does not adhere to a serial logic of a grid or a module. Many inconsistencies regarding the construction details show that the structure is not the result of a systematic analysis of the technical issues (cf. ).

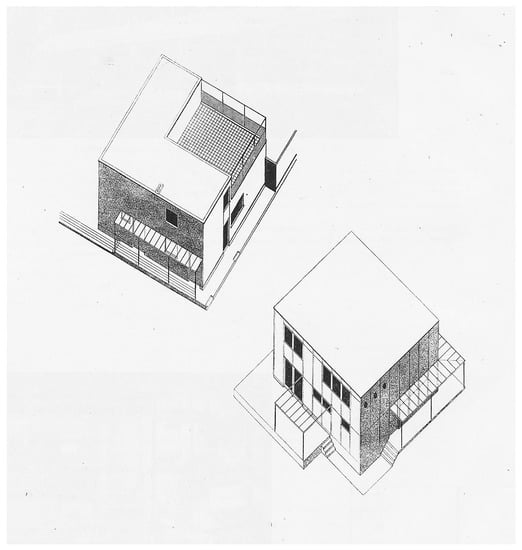

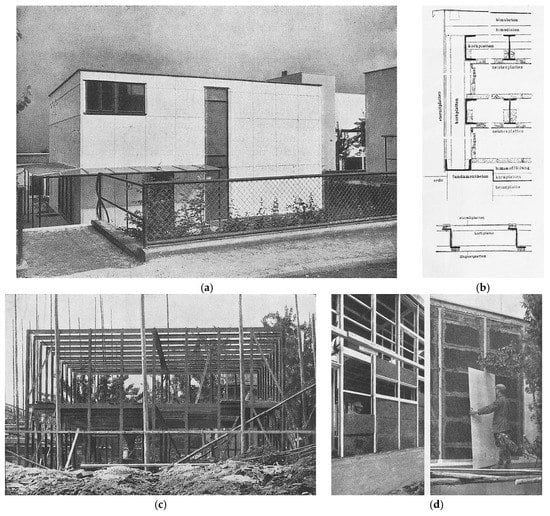

5.3. The Experimental Houses at the Stuttgart Werkbund exhibition

With the two experimental houses number 16 and 17 at the Stuttgart Werkbund exhibition Am Weißenhof (1926–1927), Gropius succeeded in implementing the evoked ideal of a construction kit with a “semi-dry construction method” and a “dry assembly method” (Figure 11). He is somewhat in opposition to the exhibition’s programmatic direction formulated by Ludwig Mies van der Rohe (1886–1929), according to which “the problem of the new dwelling [‘neue Wohnung’] is an architectural challenge [‘baukünstlerisches Problem’]” that can be solved “only with creative forces, but not with mathematical or administrative means” or “contemporary buzz-words such as ‘rationalization’ and ‘typification’” (). Gropius rather emphasizes that he wants to continue to explore “paths towards an industrialized house production [‘Wege zur fabrikatorischen Hausherstellung’]”. He seeks to find “new solutions for dry assembly construction [‘Montagebau’]” and to present individually configured examples for a rationalized and industrially produced construction kit system. With the “erection of individual houses” he wants to show that “the strong demand for cheap, serially produced, but individually available single-family homes” can be met ().

Figure 11.

Walter Gropius: Experimental houses number 16 and 17 at the Stuttgart Werkbund exhibition Am Weißenhof, 1926–1927—Isometric drawing. Image from ().

However, Gropius did not succeed in building both houses as dry assembly structures with steel skeletons. Due to external circumstances the two houses were executed in different ways (cf. ):

House 16 (Figure 12) was constructed in a rather conventional way, as Gropius writes, as a “semi-dry construction, based essentially on traditional building methods”. The walls consisted of large pumice bricks according to the Moskopf system, the roof of prefabricated concrete beams, the interior walls of various lightweight boards (lignat, celotex, enseo, and asbestos) and the floors were made of pumice and cork flooring; finally, the house’s façade was rendered in a traditional fashion. One leftover of the originally intended dry construction method was the strict grid according to which the floor plan, as well as all elements were designed, and which corresponds to a systematization and dimensional accuracy previously unknown in the building industry, but common in mechanical engineering ().

Figure 12.

Walter Gropius: House number 16 at the Stuttgart Werkbund exhibition Am Weißenhof, 1926–1927. Photo from ().

House 17 (Figure 13a), on the other hand, was erected as a true “dry construction structure”, where the “only element built locally (…) is the concrete floor slab”, whereas all other components were industrially pre-fabricated and only assembled on site. The structure was a steel skeleton made of Z-profiles, filled with cork panels and sealed with tar. On the outside it was covered with asbestos panels, on the inside with Celotex, lignat and asbestos panels. The house was likewise planned according to a strict grid. In addition, as Gropius points out, he “completely avoided any rendered surfaces (…) on the outside as well as inside”, so that the dry construction method with industrially prefabricated components was ostentatiously presented (). The continuous grid of façade profiles hinted both at the modularization employed, as well as the underlying steel skeleton. One might think that the didactic quality of presenting the construction kit principle utilizing a dry assembly method—despite all claims otherwise—was more important to Gropius than to satisfy categories of conventional architectural aesthetics (Figure 13b–d).

Figure 13.

House number 17 at the Stuttgart Werkbund exhibition Am Weißenhof, 1926–1927—Photo of house, façade section, steel skeleton during construction and construction process. Images from ().

Gropius regarded it a great success to have by way of example pioneered “the question of dry construction on an industrial basis”. He asserts that he was breaking ground for a “Modern Architecture [‘Neues Bauen’] on an industrial basis” and claims that “in one generation’s time (…) its components will have become universal, highly rationalized standard commodities” (). In this context, he also sees the role of the architect redefined as that of an “organizer who has to collect up all biological, social, technical and creative problems and merges them into one independent entity” ().

In fact, it turned out that the rationalization applied by Gropius did not at all lead to the cost reduction anticipated. The report of the Reichsforschungsgesellschaft für Wirtschaftlichkeit im Bau und Wohnungswesen stated that the construction cost of the two houses was among the highest of the entire exhibition (). Moreover, the two houses found little applause with critics. In essence, it was precisely the didactic presentation of the structure and construction methods that was criticized, for example, by Edgar Wedepohl:

The floor plans are concise and systematically thought out, but not uncommon. (…) The constructivist doctrinairism of the Bauhaus confers to the houses a peculiarly dry and pedantic note, as well as at the same time something temporary shantylike that robs them of any cheerfulness and grace.().

The Bauhaus students judged similarily; they liked Le Corbusier’s houses better and thought that “something like them should have been produced by the Bauhaus” (). It was only much later that the progressive aspects of the houses were appreciated. They were particularly highlighted by Ludwig Mies van der Rohe in a speech on the occasion of Walter Gropius’ 70th birthday. Mies praised them for being the most interesting buildings at the exhibition as a demonstration of “industrialization, standardization and prefabrication” ().

6. “Housing of the Future” Modeled after Assembly Line Automobile Production

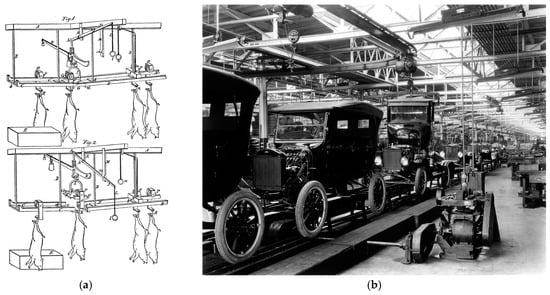

The concept of the assembly line originated in the milling industry as a conveyor belt for material transport in the late 18th century and from 1869 onwards it was used as a pace-setter in slaughterhouses in Cincinnati. But it was only with its introduction in the automobile production by Henry Ford in the Ford factory in Detroit in 1913/1914 that the assembly line had a breakthrough in industry (Figure 14a,b).

Figure 14.

Automatic hog-weighing apparatus for use in packing houses, Cincinnati, 1869, and Assembly line production of Ford Model T, Ford Motor Company, Detroit, after 1913. First image from (); second image of unknown origin.

There it was developed into a means for a ground-breaking efficiency improvement, resulting from the object principle, as well as from the subdivision of production processes into assembly cycles. Already in 1915, the first reports on this were published (). But it was not until 1922, with the publication of Henry Ford’s autobiography, and a year later the German translation, that the various aspects of assembly line production became known to a wide audience in Germany. The attractiveness of Ford’s model of assembly line production was not only based on a mere increase of efficiency, but also on the fact that it represented a comprehensive model of industrial production which promises, among other things, lower prices and higher wages. Fordism, despite its capitalist origin, was interpreted in the Weimar Republic in a rather romantic way as a contribution towards social security and stability. For many Socialdemocrats and members of the bourgeoisie the “practical solution to the social question” was a question between Ford or Marx as the title of famous book by the communist unionist Jakob Walcher (1887–1970) from 1925 stated (; ; cf. ; ; ).

Walter Gropius developed an interest in rationalization according to the assembly line principle around 1923/1924, after his first experiments with construction kit systems. He quickly became a fervent admirer of Henry Ford ()—like Adolf Behne who extensively quoted Ford’s autobiography in Der moderne Zweckbau (‘The modern functional building’, 1923/1926; ; cf. ) or Le Corbusier who dedicated his designs to automobile manufacturers and presented his buildings using the latest automobiles (cf. ; ). For Gropius, Henry Ford, assembly line production, and Americanism became magical incantations for the rationalization of architecture. From the mid 1920s onwards, Gropius referred in almost every single one of his publications to Ford and from 1928 onwards he frequently used—in a way very similar to Le Corbusier (; )—a diagram that compares the rising building costs with the falling prices of Ford automobiles. For Gropius, this diagram not only served as a conclusive proof for the efficiency increase brought about by Ford’s assembly line production, but it also demonstrated the long overdue necessity of the assembly line rationalization of building construction ().

Ford’s comprehensive model of industrial production also influenced Gropius’ belief in the egalitarian effects of technology in order to improve the general living conditions, which culminated in Gropius’ repeatedly recorded saying that he wanted to become the “housing-Ford [‘Wohn-Ford’]” of his time (). Though at this point, Gropius did not associate any further explicit political or ideological intentions with these architectural or technological concepts. He, like many other renowned Avantgarde architects, at best only half-heartedly leaned towards Social Democracy in the golden years of the Weimar Republic. Though the Bauhaus was a radical reform school supported by left and liberal political parties (SPD, USPD and DDP), Gropius, in fact, tried to maintain an “unpolitical” image to protect the school against accusations from conservative and Nazi critics who blamed it for being a socialist, even bolshevist institution (cf. ; ).

In his attempts to implement Ford’s assembly-line production in architecture, Gropius picked up on earlier rationalization efforts by Martin Wagner, Ernst May, and Bruno Taut—the other members of the “Kopfgemeinschaft” (; ). In 1925, for instance, in the essay “Wohnhausbau der Zukunft” (‘Housing of the future’), Gropius suggests proceeding, as Ford proceeded in the automotibile industry, and to start by designing experimental houses for testing purposes—in analogy to the development of prototypes for serial production in a laboratory. Then specialized factories could mass-produce the individual components, assembly-ready, so that they “could be put together on site in a dry-construction method like machines (!).” Gropius promises that the “the economic benefits (…) would be enormous. Knowledgeable experts estimate that the cost reduction can be expected to be 50% or even more” ().

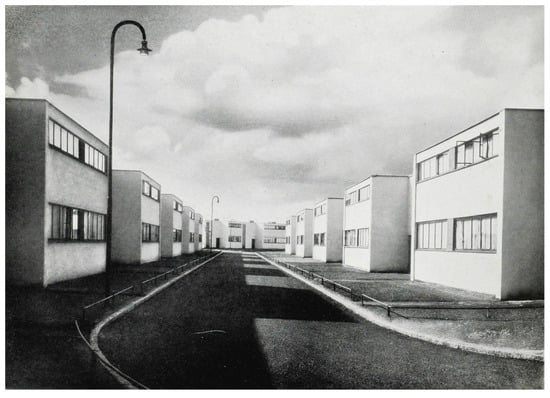

Dessau-Törten

The opportunity to implement the rationalization strategy according to the assembly line principle came up in 1925, with the relocation of the Bauhaus from Weimar to Dessau. Walter Gropius wanted to combine the inauguration of the new Bauhaus building with a presentation of a new building method. A contributing fact was that the mayor of the city of Dessau sought new impulses for housing and the Dessau-based Junkers company envisaged a rationalized building industry to be beneficial for its business (cf. ).

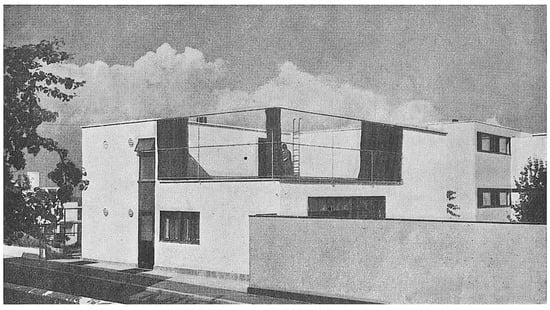

In the years 1926–1928 a total 316 row-houses were erected in the suburb of Dessu-Törten in three construction phases—first 60, then 100 and finally 156. Generally speaking, three different types of houses—with variations six types in total—were built: In the first and second phases two-storey row house types with a width of 5.59 and 7.79 m respectively, in the third phase a split-level row-house type with a width of 8.65 m (; cf. ; Figure 15).

Figure 15.

Walter Gropius: Dessau-Törten Housing, 1926–1928—Houses of the type built 1928. Image from ().

Dessau-Törten is characterized by the fact that Gropius consistently focused on as many aspects of the planning and building processes as possible according to the rationalization principles of assembly line production. A flexible typification using a “big construction kit” was no longer important. Rather, as he explains in detail in the 1930 Bauhaus book Bauhausbauten Dessau, “the task (…) is to reduce the rent of the houses by employing all possibilities for rationalization.” This was to be achieved with “economic design of the plans, timely preparation of works, careful awarding of contracts and economic choice of construction method” ().

To begin with, Gropius allegedly considered a system for a comprehensive or total prefabrication, but had to dismiss it due to the high cost for the lifting equipment necessary. He did learn from the experiences made by the other members of the “Kopfgemeinschaft” and learned his lesson from Wagner’s failure with the large precast slabs used in Berlin-Friedrichsfelde. Gropius decided to rely on a semi-dry construction method with relatively lightweight, only partially prefabricated elements (Figure 16a). For walls, for instance, hollow slag concrete blocks were used, that are still “of a size, so that one man can carry them”; and as roof structure a so-called “fast ceiling [‘Rapiddecke’]” was used, a mortarless dry structure made of concrete beams with an I-shaped cross-section and stretching from wall to wall (; cf. ). Gropius claimed, that the “abundant availability of good sand and gravel” motivated him to use this construction method, since in this way “the volumes of material that had to be transported to the site could remain low” and “only a delivery of cement and coke slag” was necessary ().

Figure 16.

Walter Gropius: Dessau-Törten Housing, 1926–1928—Structural diagram and construction site diagram. Drawings from ().

During the design process, in a way unique in housing, “all the plans are drawn on a scale of 1:20” by Gropius and his collaborators, “before contracts are awarded, so that even all installations—gas, water, light, heating—are fixed beforehand, including all dimensions and wall penetrations”. For the construction process, a 1.5 t tower crane was employed, whose rail track system defined the “production axis” of the construction process—in a way vaguely similar to the linearity of the assembly line (Figure 16b and Figure 17a,b). Gropius stated that the “rational arrangement of the construction site” provided both the layout for the Siedlung, as well as the arrangement of the houses—in parallel, mirrored rows. With the help of a precise construction site plan, the slag concrete hollow bricks and concrete beams were manufactured “on the site itself with machines in an assembly-line-like process (…) systematically reducing idle times and friction losses.” Every worker was encouraged to increase his performance according to the assembly-line principle by repeatedly executing the same task over and over again ().

Figure 17.

Walter Gropius: Dessau-Törten Housing, 1926–1928—Construction site. Photos from ().

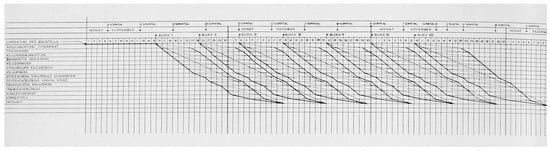

The organization of the work processes, as well as the synergy of the individual construction phases, was precisely directed by a pre-planned schedule. Gropius used the “Arbeitsgraphikon” (‘work graph’), a combination of a bar graph and a scheme “in the manner of a railway operating plan” first developed by the Soziale Baubetriebe (, ; ; Figure 18). This type of presentation of a rationalized serial house production goes back to Adolf Loos (1870–1933), who first developed the “System Loos” for the Siedlung Heuberg in 1921 (; cf. ), which was seen even by contemporaries as a precursor to Gropius’ concept ().

Figure 18.

Walter Gropius: Dessu-Törten Housing, 1926–1928—“Work graph” (‘Arbeitsgraphikon’). Image taken from ().

Even during its construction the Siedlung Dessau-Törten was considered the prime example for rationalization according to the assembly-line principle. In addition to the aforementioned Bauhaus book, the construction process was documented in the film Das Bauhaus und seine Bauweise (‘The Bauhaus and its method of construction’) produced by the Berlin based Humboldt-Film for the opening of the Bauhaus building in 1926—as part of the cultural film series Wie wohnen wir gesund und wirtschaftlich (‘How do we reside in a healthy and economic way’).

The success of these rationalization measures was, however, ambivalent. On the one hand, the time saving was enormous. Although construction didn’t start until September 1926, Gropius managed to present the first two houses completely built and furnished at the opening of the Bauhaus building in December the same year. And in 1928 he succeeded in building 130 houses in 88 days. On the other hand, the financial cost reduction was not as great as hoped for. Instead of savings of 50%, as promised by Gropius in 1925, only 5% to 25% were achieved in the end (cf. ).

Gropius drew two conclusions from Dessau-Törten which proved to be fundamental for the subsequent rationalization in architecture using this assembly-line principle: First, to reduce costs even further, the use of heavy machinery, as well as a larger building volume would be required. Gropius therefore—in a way similar to Wagner—proposed building large housing projects (; ). Second, the subordination of architecture to the requirements of rationalization and industrialized construction was also evident. In Dessau-Törten, the layout of the Siedlung was designed to follow the crane rail system, and the use of the same type of individual house oriented in two different directions was accepted by Gropius as a “necessary” result, vulgo an unavoidable side effect of rationalization ().

7. Epilogue

In the late 1920s Walter Gropius drew first conclusions from his rationalization efforts: In 1928, in his essay “Der Architekt als Organisator der modernen Bauwirtschaft und seine Forderungen an die Industrie” (‘The Architect as Organizer of the Modern Building Industry and his Demands on Industry’) he states that besides the improvement of the “traditional, purely craftsmanshiplike way of individual construction” only two choices remain: First, the assembly line type of serial production, i.e., as he writes, the “simultaneous construction of many identical dwellings in a series”, and second, the flexible construction kit system, “the factory-like (…) building of construction kit houses”. It is clear that Gropius saw the future less in an assembly line serial production, but rather in open and modular construction kit systems which are based on flexible or totipotent elements, as well as dry or assembly construction methods. Based on this, he formulated seven demands on industry, which include among others the development of a lightweight building material that is superior to brick, the improvement of lightweight panels and the production of flexible lightweight walls, in addition to improved window mechanisms, new façade materials, heat meters, as well as mechanical ventilation systems. Significantly, this list does not include any aspects of the assembly line construction system employed e.g., in Dessau-Törten ().

Gropius made similar comments in his lecture “Stahlbau” (‘Steel Construction’) at the Leipzig Spring Building Trade Fair in 1929. Comparing the various types of construction and building methods, he concludes that improving the conventional brick building method, as well as the serial production inspired by industry, but still relying on craftsmanship, leads to nothing. He claims that the future lies rather in an “industrial assembly factory” in which “the components are largely prefabricated in stationary factories and assembled on call at the construction site.” The goal is the “individual house off the shelf” ().

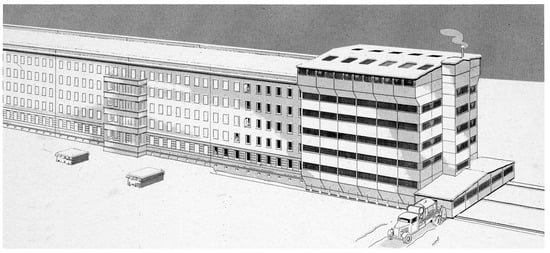

Even later, Gropius never resorted back to the concept of the assembly-line serial production—emblematic maybe for the general shift in functional thinking in the interwar years (cf. ). Rather, it is Ernst Neufert (1900–1986), who from 1921 onwards was an employee and 1924–1926 chief architect of Gropius’ studio (cf. ), who further developed this concept into a “house building machine” (‘Hausbaumaschine’) published in his Bauordnungslehre in 1943 (Figure 19; ). This concept has little to do with Gropius’s earlier assembly line concepts and much less with flexible or individually configurable construction kit systems, but rather exemplifies mass housing for the Nationalsocialist Volksgemeinschaft (cf. ).

Figure 19.

Ernst Neufert: “House building machine” (‘Hausbaumaschine’), 1943. Drawing from ().

Gropius, on the other hand, in his subsequent rationalization efforts explored various modular systems. This is clearly to be seen as a foreshadowing and in relation to the political and social background of Gropius’ later career—in particular, after his emigration first to England in 1934 and then to the United States in 1937. As early as 1934, Gropius wrote that it had been a mistake to try to bring modern architecture to the masses. In the future he wanted to convert the affluent to modernism—exactly what he later did in the United States (). In this sense it is no surprise that Gropius abandoned the concepts of assembly line mass production, as the flexible construction kit more closely corresponds with the idea of the house as an individual consumer product rather than the assembly line, which, with its goal of cost reduction, pursues a social motive.

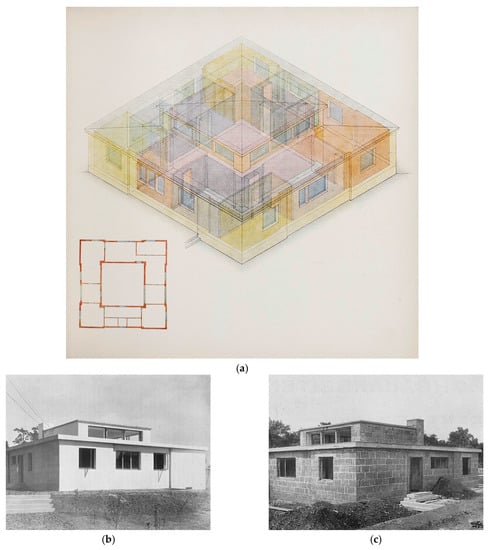

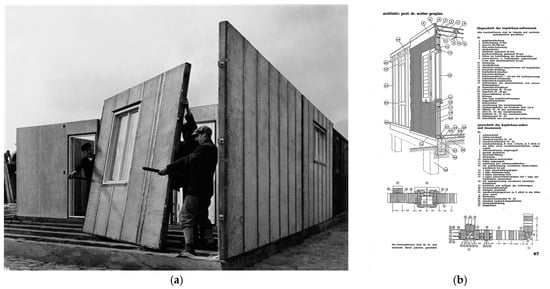

Gropius’ subsequent experiments with different construction kit systems are based on flexible or totipotent components, as well as various dry or assembly construction methods. And although they were intended for industrial mass production, none of them met with success: In 1929, Gropius designed for the Berlin-based contractor Adolf Sommerfeld a type of construction kit house that is based on a steel skeleton structure and storey-high steel panels, but which was not built. In the years 1931–1932, he revised for the Hirsch Kupfer- und Messingwerke (‘Hirsch copper and brass works’) the so-called Förster-Krafft-System, developed by Frigyes Förster and Robert Krafft. It is based on a modular panel construction system with storey-high self-supporting wooden frames joined together with small U-shaped clasps and covered on the outside with embossed copper sheets. Only two houses of this type were displayed at the exhibition “Das wachsende Haus” (‘The Growing House’) organized by Martin Wagner in Berlin in 1932 (; cf. ; ; ; Figure 20a,b).

Figure 20.

Walter Gropius: Förster-Krafft-System House exhibited at “Das wachsende Haus” (’The Growing House’) exhibition, Berlin, 1931–1932—Assembly process and façade construction detail. Images from ().

Finally, in the United States, he developed in collaboration with Konrad Wachsmann the so-called “Packaged House” system between 1942 and 1952. Their work was aimed at standardizing and industrializing the production of individually configurable houses as a consumer product. The system consists of a modular system of wooden frame panels that are spatially connected with Y-shaped hooks. Gropius’ and Wachsmann’s developmental efforts focused less on the modular wooden frame panels and more on the panel connectors, which here, for the first time, were the object of comprehensive and systematical research. But even this system was not a success. Apart from a few prototypes and roughly 150–200 units that were built, the project ended with the bankruptcy of the General Panel Corporation founded for this purpose (; cf. ).

8. Conclusions

Walter Gropius and his colleagues in the Weimar Republic can be counted as predecessors to and forecasters of the rationalization of design and building processes following industrials principles; they laid the foundational work for many subsequent industrialization efforts in modern architecture. Gropius, in particular, not only succeeded in discovering two different concepts for the rationalization of architecture—the construction kit and the assembly line—and in exploring them in theory and practice in the course of the 1920s, but also in drawing his first conclusions by the end of the decade. Gropius formulated these concepts in a series of projects and essays, tested and—often in a demonstratively didactic manner—presented them in a number of model houses, exhibition buildings and Siedlungen. For Gropius, these concepts were not only a means to rationalize design and building processes, but also an expression of his belief in the ability of technology to improve the general living conditions.

It has to be noted that the two rationalization concepts are not only of completely different origin—Anker-Steinbaukasten vis-à-vis Henry Ford’s assembly line production, but that they are also based on different types of components, adhere to distinct forms of industrial production logic and seek different goals. Construction kits, on the one hand, are based on open systems with flexible or totipotent typified elements that are industrially prefabricated and assembled into individual structures; they aim at flexibility and individual configuration. The assembly line, on the other hand, seeks to increase the efficiency of serial fabrication through a production in assembly cycles and according to the object principle, i.e., the serial multiplication of a uniform object through a streamlined repetition of the same process of reproduction. In fact, the motives behind these two rationalization methods differ greatly from each other, in the first case, it is the flexibility of industrial production, in the second, the cost reduction through serial mass production. Although both objectives are only partly or not at all achieved by Gropius as promised, they have nonetheless proven to be important goals of rationalization in architecture and have lost none of their appeal.

Ironically, Gropius’ inclination towards construction kit systems runs counter to the general trend. Assembly-line serial production, on the one hand, has proven to be a great success, in particular after World War Two, and to this day continues to dominate industrially rationalized construction. However, the proverbial factory-produced house has become synonymous with an inhuman architecture and has partly contributed to the rejection of modernism. On the other hand, the principle of the flexible construction kit has been picked up and utilized only a few times. In some cases, e.g., with Konrad Wachsmann or Fritz Haller, this has been under the direct influence of Gropius. In other cases, e.g., with Richard Buckminster Fuller’s (1895–1983) Dymaxion House (1927–1930, 1944–1947), Jean Prouvé’s (1901–1984) Maison Tropicale (1949–1951) or Jørn Utzon’s (1918–2008) Espansiva (1966–1969) Systems, the development has taken place independently from the work of the Bauhaus founder. In all instances, these experiments have remained limited to individual projects or buildings. In contrast to toys or furniture—think of the Anker-Steinkasten, Lego blocks (1949/1958) or Fritz Haller’s modular USM Haller furniture system (1963–), in architecture, flexible modular construction kit systems have never reached the breakthrough to industrial mass production, as Gropius envisioned they would; they have never had the opportunity to fully demonstrate the potential of a flexibility motivated among other things by totipotency. Only recently have the rationalization strategies based on construction kit and assembly line principles gained a new relevance through digital design tools and robot-assisted fabrication. Therefore, one can only hope that the pioneering work undertaken by Gropius will be transferred to the digital age (cf. ; ).

Acknowledgments

All translations by the author. All images are public domain or are taken from books that are electronically available as public domain.

Conflicts of Interest

The author declares no conflict of interest.

References

- Alder, Ken. 1997. Innovation and Amnesia. Engineering Rationality and the Fate of Interchangeable Parts Manufacturing in France. Technology and Culture. The International Quarterly of the Society for the History of Technology 38: 273–331. [Google Scholar] [CrossRef]

- Amado, Antonio. 2011. Voiture Minimum. Le Corbusier and the Automobile. Cambridge: MIT Press, ISBN 978-0-262-01536-3. [Google Scholar]

- Anderson, Stanford. 2000. Peter Behrens and a New Architecture for the Twentieth Century. Cambridge and London: MIT Press, ISBN 0-262-01176-X. [Google Scholar]

- Behne, Adolf. 1926. Der Moderne Zweckbau. Munich: Drei Masken Verlag. Reprint 1964. Bauwelt Fundamente 10. Edited by Ulrich Conrads. Berlin, Frankfurt am Main and Vienna: Ullstein. [Google Scholar]

- Benning, Th. 1928. Nochmals ‘Eine Häuserfabrik im Freien’. Stein Holz Eisen 42: 24. [Google Scholar]

- Bergdoll, Barry. 2008. Home Delivery: Viscidities of a Modernist Dream from Taylorized Serial Production to Digital Customization. In Home Delivery. Fabricating the Modern Dwelling. Edited by Barry Bergdoll and Peter Christensen. New York and Basel: The Museum of Modern Art and Birkhäuser, pp. 12–26. ISBN 978-0-87070-733-9. [Google Scholar]

- Betten, Albert. 1928. Bauweisen der Zukunft. In Probleme des Bauens. Edited by Fritz Block. Potsdam: Müller & Kiepenheuer Verlag, pp. 176–83. [Google Scholar]

- Bletter, Rosemarie Haag. 1996. Introduction. In Adolf Behne. The Modern Functional Building. Santa Monica: The Getty Research Institute, pp. 1–83. ISBN 0-89-236-364-9. [Google Scholar]

- Borgert, Ulrich. 2004. Eine Plattenbausiedlung der 1920er-Jahre—Reichsbundsiedlung Berlin-Friedrichsfelde. In Häuser aus Beton. Vom Stampfbeton zum Großtafelbau. Edited by Uta Hassler and Hartwig Schmidt. Tübingen and Berlin: Ernst Wasmuth, pp. 77–85. ISBN 3-8030-0638-4. [Google Scholar]

- Brenne, Winfried. 1984. Wie die Siedlungen gebaut wurden. Damals—Heute. Bautechnik, Konstruktion und Ausstattung. In Siedlungen der zwanziger Jahre—Heute. Vier Berlinger Großsiedlungen 1924–1984. Edited by Norbert Huse. Berlin: Publica, pp. 47–58. ISBN 3-89087-012-0. [Google Scholar]

- Buddensieg, Tilmann, and Henning Rogge. 1979. Industriekultur. Peter Behrens und die AEG 1907–1914. Berlin: Gebr. Mann Verlag, ISBN 3-7861-1155-3. [Google Scholar]

- Dickerman, Leah. 2009. Bauhaus Fundaments. In Bauhaus 1919–1933. Workshops for Modernity. Edited by Barry Bergdoll and Leah Dickerman. New York: The Museum of Modern Art, pp. 15–39. ISBN 978-0-87070-758-2. [Google Scholar]

- Fehl, Gerhard. 1995. Welcher Fordismus eigentlich? Eine einleitende Warnung vor dem leichtfertigen Gebrauch des Begriffs. In Zukunft aus Amerika. Fordismus in der Zwischenkriegszeit. Edited by Regina Bittner, Henning Brüning, Gerhard Fehl and Harald Kegler. Dessau: Stiftung Bauhaus Dessau and RWTH Aachen, pp. 19–37. ISBN 3-910022-06-5. [Google Scholar]

- Forcht, D. 1927. Plattenfabrik oder Backsteinbau? Ein Wort zugunsten des gegossenen Hauses. Stein Holz Eisen 41: 152–53. [Google Scholar]

- Ford, Henry, and Samuel Crowther. 1922. My Life and Work. Garden City: Garden City Publishing Company. Reprint in German 1923. Mein Leben und Werk. Leipzig: Paul List. [Google Scholar]

- Franciscono, Marcel. 1971. Walter Gropius and the Creation of the Bauhaus in Weimar: The Ideals and Artistic Theories of its founding Years. Urbana: University of Illinois Press. [Google Scholar]

- Giedion, Sigfried. 1948. Mechanization Takes Command. A Contribution to Anonymous History. New York: Oxford University Press, Reprint 2013. Edited by Stanislaus von Moos. Minneapolis: University of Minnesota Press, ISBN 978-0-8166-9043-5. [Google Scholar]

- Giedion, Sigfried. 1954a. Walter Gropius. Mensch und Werk. Stuttgart: Hatje. [Google Scholar]

- Giedion, Sigfried. 1954b. Mies van der Rohes Rede im Blackstone Hotel in Chicago, am 18. Mai 1953, zum Geburtstag von Walter Gropius. In Walter Gropius. Mensch und Werk. Stuttgart: Hatje, pp. 20–22. [Google Scholar]

- Gilbreth, Frank Bunker. 1911. Motion Study. A Method for Increasing the Efficiency of the Workman. New York: D. Van Nostrand Company, Reprint in German 1920. Angewandte Bewegungsstudien. Neun Vorträge aus der Praxis der wissenschaftlichen Betriebsführung. Berlin: Ver. deutscher Ing. [Google Scholar]

- Gilbreth, Frank Bunker. 1912. Primer of Scientific Management. New York: D. Van Nostrand Company, German 1919. Das ABC der wissenschaftlichen Betriebsführung. Berlin: Springer. [Google Scholar]

- Gleye, Paul. 1995. Fordismus und Amerika in den 20er Jahren—Vorstellung und Realität. In Zukunft aus Amerika. Fordismus in der Zwischenkriegszeit. Edited by Regina Bittner, Henning Brüning, Gerhard Fehl and Harald Kegler. Dessau: Stiftung Bauhaus Dessau and RWTH Aachen, pp. 92–105. ISBN 3-910022-06-5. [Google Scholar]

- Gropius, Walter. 1910. Programm zur Gründung einer allgemeinen Hausbaugesellschaft auf künstlerischer einheitlicher Grundlage m.b.H. Unpublished work. Reprint in Hartmut, Probst and Christian Schädlich. 1987. Ausgewählte Schriften. Berlin: Verlag für Bauwesen, pp. 18–25. ISBN 3-345-00119-5. [Google Scholar]

- Gropius, Walter. 1922. Wohnmaschinen. unpublished manuscript dated 6th February 1922. Cambridge: Gropius Archive, Houghton Library, vol. 19, pp. 694–97. [Google Scholar]

- Gropius, Walter. 1924. Wie wollen wir in Zukunft bauen? Wohnungswirtschaft 1: 152–54. [Google Scholar]

- Gropius, Walter. 1925a. Wohnhaus-Industrie. In Ein Versuchshaus des Bauhauses in Weimar. Bauhausbücher 3. Edited by Walter Gropius and László Moholy-Nagy. Munich: A. Langen, pp. 5–14, Reprint in Hartmut, Probst and Christian Schädlich. 1987. Walter Gropius III. In Ausgewühlte Schriften. Berlin: Verlag für Bauwesen, pp. 97–100. ISBN 3-345-00119-5. [Google Scholar]

- Gropius, Walter. 1925b. Wohnhausbau der Zukunft. Wohnungswirtschaft 2: 11–12. [Google Scholar]

- Gropius, Walter. 1926–1927. Der große Baukasten. Das Neue Frankfurt 1: 25–30, Reprint in Hartmut, Probst and Christian Schädlich. 1987. Walter Gropius III. In Ausgewählte Schriften. Berlin: Verlag für Bauwesen, pp. 111–13, ISBN 3-345-00119-5. [Google Scholar]

- Gropius, Walter. 1927a. Wege zur fabrikatorischen Hausherstellung. In Bau und Wohnung. Edited by Deutscher Werkbund. Stuttgart: Akad. Verlag Dr. Fr. Wedekind & Co., Reprint 1992. Edited by Jürgen Joedicke. Stuttgart: Karl Krämer. pp. 58–67. ISBN 3-7828-1316-2. [Google Scholar]

- Gropius, Walter. 1927b. Systematische Vorarbeit für rationellen Wohnungsbau. Bauhaus 2: 1–2. [Google Scholar]

- Gropius, Walter. 1927c. Systematische Vorarbeit für rationellen Wohnungsbau. Bauwelt 17: 197–200. [Google Scholar]

- Gropius, Walter. 1928. Der Architekt als Organisator der modernen Bauindustrie und seiner Forderungen an die Industrie. In Probleme des Bauens. Edited by Fritz Block. Potsdam: Müller & Kiepenheuer Verlag, pp. 202–14, Reprint in Hartmut, Probst and Christian Schädlich. 1987. Walter Gropius III. In Ausgewählte Schriften. Berlin: Verlag für Bauwesen, pp. 118–22. ISBN 3-345-00119-5. [Google Scholar]

- Gropius, Walter. 1929a. Der Gedanke der Rationalisierung in der Bauwirtschaft. In Druckschrift der Reichsforschungsgesellschaft für Wirtschaftlichkeit im Bau- und Wohnungswesen e.V. Technische Tagung in Berlin vom 15. bis 17. April 1929. Berlin: Reichsforschungsgesellschaft für Wirtschaftlichkeit im Bau- und Wohnungswesen, pp. 14–26. [Google Scholar]

- Gropius, Walter. 1929b. Bericht über die Versuchssiedlung in Dessau. In Reichsforschungsgesellschaft für Wirtschaftlichkeit im Bau- und Wohnungswesen. Sonderheft Nr. 7, April 1929. Berlin: Reichsforschungsgesellschaft für Wirtschaftlichkeit im Bau- und Wohnungswesen, p. 23. [Google Scholar]

- Gropius, Walter. 1927d. Der Stahlbau. Stein Holz Eisen 43: 224–25. [Google Scholar]

- Gropius, Walter. 1930. Bauhausbauten Dessau. Edited by Walter Gropius and László Moholy-Nagy. Bauhausbücher 12. Munich: A. Langen. [Google Scholar]

- Hasak, E. H. 1927. Plattenfabrik oder Backsteinbau? Stein Holz Eisen 41: 70–71. [Google Scholar]

- Herbert, Gilbert. 1984. The Dream of the Factory-Made House. Walter Gropius and Konrad Wachsmann. Cambridge and London: MIT Press, ISBN 0-262-08140-7. [Google Scholar]

- Herbst, Edgar. 1920. Der Taylorismus als Hilfe in unserer Wirtschaftsnot. Leipzig and Vienna: Anzengruber Verlag. [Google Scholar]

- Hoeber, Fritz. 1913. Peter Behrens. Moderne Architekten 1. Munich: Müller & Rentsch. [Google Scholar]

- Huse, Norbert. 1985. ‘Neues Bauen’ 1918 bis 1933. Moderne Architektur in der Weimrer Republik, 2nd ed. Berlin: Wilhelm Ernst & Sohn Verlag für Architektur und technische Wissenschaften, ISBN 3-433-02027-2. [Google Scholar]

- Isaacs, Reginald. 1985. Walter Gropius. Der Mensch und sein Werk. Frankfurt am Main and Berlin: Ullstein, vol. I, ISBN 3-548-27538-9. [Google Scholar]

- Isaacs, Reginald. 1986. Walter Gropius. Der Mensch und sein Werk. Frankfurt am Main and Berlin: Ullstein, vol. II, ISBN 3-548-27544-3. [Google Scholar]

- Jaeggi, Annemarie. 1984. Das Großlaboratorium für die Volkswohnung. Wagner. Taut. May. Gropius. 1924/1925. In Siedlungen der zwanziger Jahre—Heute. Vier Berlinger Großsiedlungen 1924–1984. Edited by Norbert Huse. Berlin: Publica, pp. 27–32. ISBN 3-89087-012-0. [Google Scholar]

- Junghanns, Kurt. 1994. Das Haus für alle. Zur Geschichte der Vorfertigung in Deutschland. Berlin: Ernst, ISBN 978-3-433-01274-1. [Google Scholar]

- Kaufmann, Eugen. 1927. Plattenfabrik oder Backsteinbau? Eine Erwiderung. Stein Holz Eisen 41: 111–12. [Google Scholar]

- Kirsch, Karin. 1987. Die Weissenhofsiedlung. Werkbund-Ausstellung ‘Die Wohnung’—Stuttgart 1927. Stuttgart: Deutsche Verlags-Anstalt, ISBN 978-3-421-02881-5. [Google Scholar]

- Krucker, Bruno. 2001. Das Fabrizieren von Architektur: Zum entwerferischen Potenzial des industrialisierten Bauens. In Konstruktive Konzepte der Moderne. Fallstudien aus dem 20. Jahrhundert. Edited by Arthur Rüegg and Bruno Krucker. Sulgen: Niggli, pp. 77–88. ISBN 978-3-7212-0416-2. [Google Scholar]

- Kulka, Heinrich. 1931. Adolf Loos. Vienna: A. Schroll & Co. [Google Scholar]

- Le, Corbusier. 1925. Urbanisme. Paris: Crès et Cie. [Google Scholar]

- Le, Corbusier, and Pierre Jeanneret. 1929. Analyse des éléments fondamentaux du problème de la maison minimum. In CIAM. Internationale Kongresse für Neues Bauen. Congrès Internationaux d’Architecture Moderne. Dokumente 1928–1939. Edited by Martin Steinmann. Schriftenreihe Band 11. Basel and Stuttgart: Institut für Geschichte und Theorie der Architektur an der Eidgenössischen Technischen Hochschule Zürich and Birkhäuser, pp. 60–63. [Google Scholar]

- Logan, Frederick M. 1950. Kindergarten and Bauhaus. College Art Journal 10: 36–43. [Google Scholar] [CrossRef]

- Matz, Stefan. 2001. (Un)geliebtes Muster. Neue Einsichten zum Haus Am Horn. Weimar: VDG, ISBN 978-3-89739-224-3. [Google Scholar]

- May, Ernst. 1926–1927a. May, Ernst. 1926–1927a. Die Mechanisierung des Wohnungsbaues. Das Neue Frankfurt 1: 33–39. [Google Scholar]

- May, Ernst. 1926–1927b. Der Weg vom Ziegelmauerwerk zum Frankfurter Montageverfahren. Das Neue Frankfurt 1: 40. [Google Scholar]

- Mayer, Max. 1914. Die Anregungen Taylors für den Baubetrieb. Deutsche Bauzeitung 48: 618. [Google Scholar]

- Mayer, Max. 1915. Die Anregungen Taylors für den Baubetrieb. Berlin: Springer. [Google Scholar]

- Mayer, Max. 1926. Fließbandarbeit auf der Baustelle. Bauwelt 16: 794f. [Google Scholar]

- Mayer, Max. 1927. Die Anwendbarkeit der Maschine im Bauwesen. Bauwelt 17: 551f. [Google Scholar]

- McLeod, Mary. 1983. ‘Architecture or Revolution’: Taylorism, Technocracy, and Social Change. Art Journal 43: 132–47. [Google Scholar] [CrossRef]

- Merkel, Patricia. 2017. Das Wirken Ernst Neuferts in den Jahren 1920 bis 1940. Mit einem Werkverzeichnis und einer Werkübersicht in Bildern. Wiesbaden: Springer Vieweg, ISBN 978-3-658-16856-8. [Google Scholar]

- Meyer, Adolf. 1925a. Ein Versuchshaus des Bauhauses in Weimar. Edited by Walter Gropius and László Moholy-Nagy. Bauhausbücher 3. Munich: A. Langen. [Google Scholar]

- Meyer, Adolf. 1925b. Der Aufbau des Versuchshauses. In Adolf Meyer. Ein Versuchshaus des Bauhauses in Weimar. Edited by Walter Gropius and László Moholy-Nagy. Bauhausbücher 3. Munich: A. Langen, p. 24. [Google Scholar]

- Mies van der Rohe, Ludwig. 1927. Vorwort. In Bau und Wohnung. Edited by Deutscher Werkbund. Stuttgart: Akad. Verlag Dr. Fr. Wedekind & Co., Reprint 1992. Edited by Jürgen Joedicke. Stuttgart: Karl Krämer. p. 7. ISBN 3-7828-1316-2. [Google Scholar]

- Mohr, Christoph, and Michael Müller. 1984. Funktionalität und Moderne. Das Neue Frankfurt und seine Bauten 1925–1933. Frankfurt am Main: Edition Fricke, ISBN 3-481-50171-4. [Google Scholar]

- Muche, Georg. 1925. Das Versuchshaus des Bauhauses. In Adolf Meyer. Ein Versuchshaus des Bauhauses in Weimar. Edited by Walter Gropius and László Moholy-Nagy. Bauhausbücher 3. Munich: A. Langen, pp. 15–23. [Google Scholar]