Circular and Flexible Indoor Partitioning—A Design Conceptualization of Innovative Materials and Value Chains

Abstract

:1. Introduction

2. Background

2.1. Time, Change, and Circularity

2.2. The Amsterdam Context

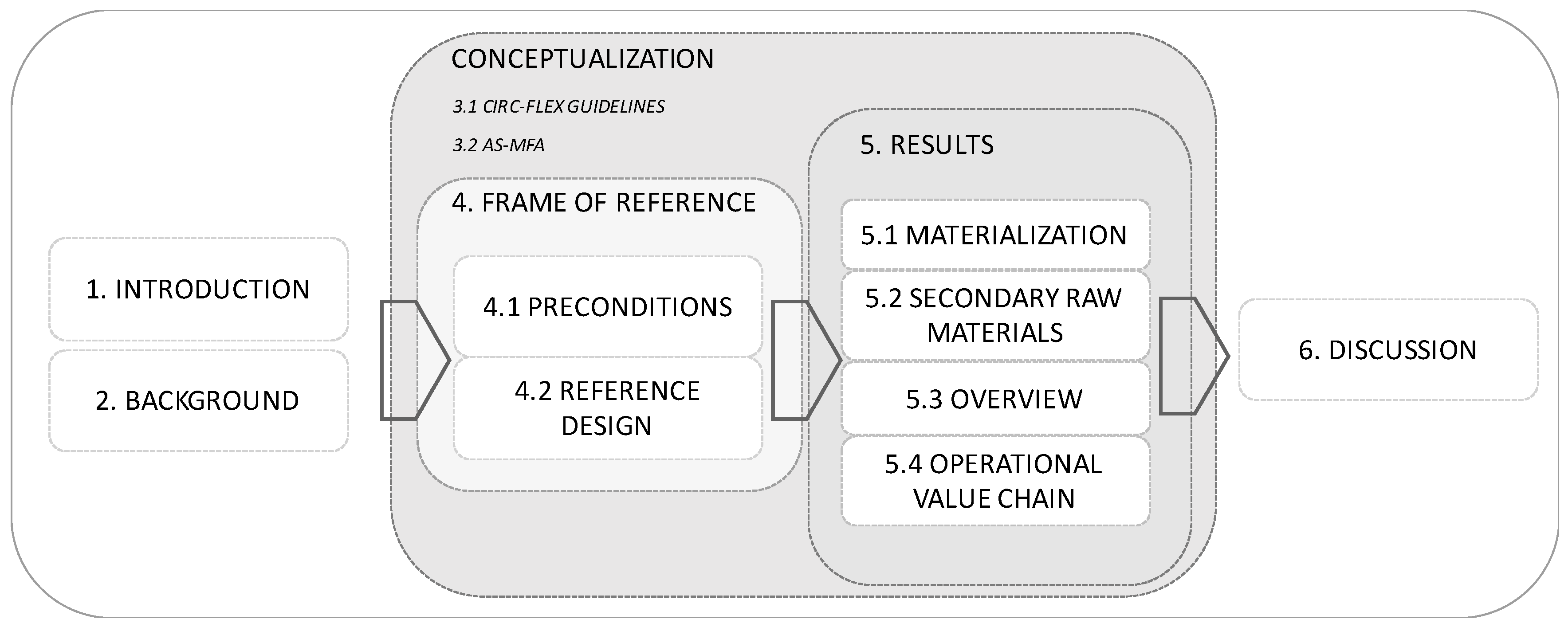

3. Conceptualization, Methods, and Tools

3.1. Circ-Flex Potential

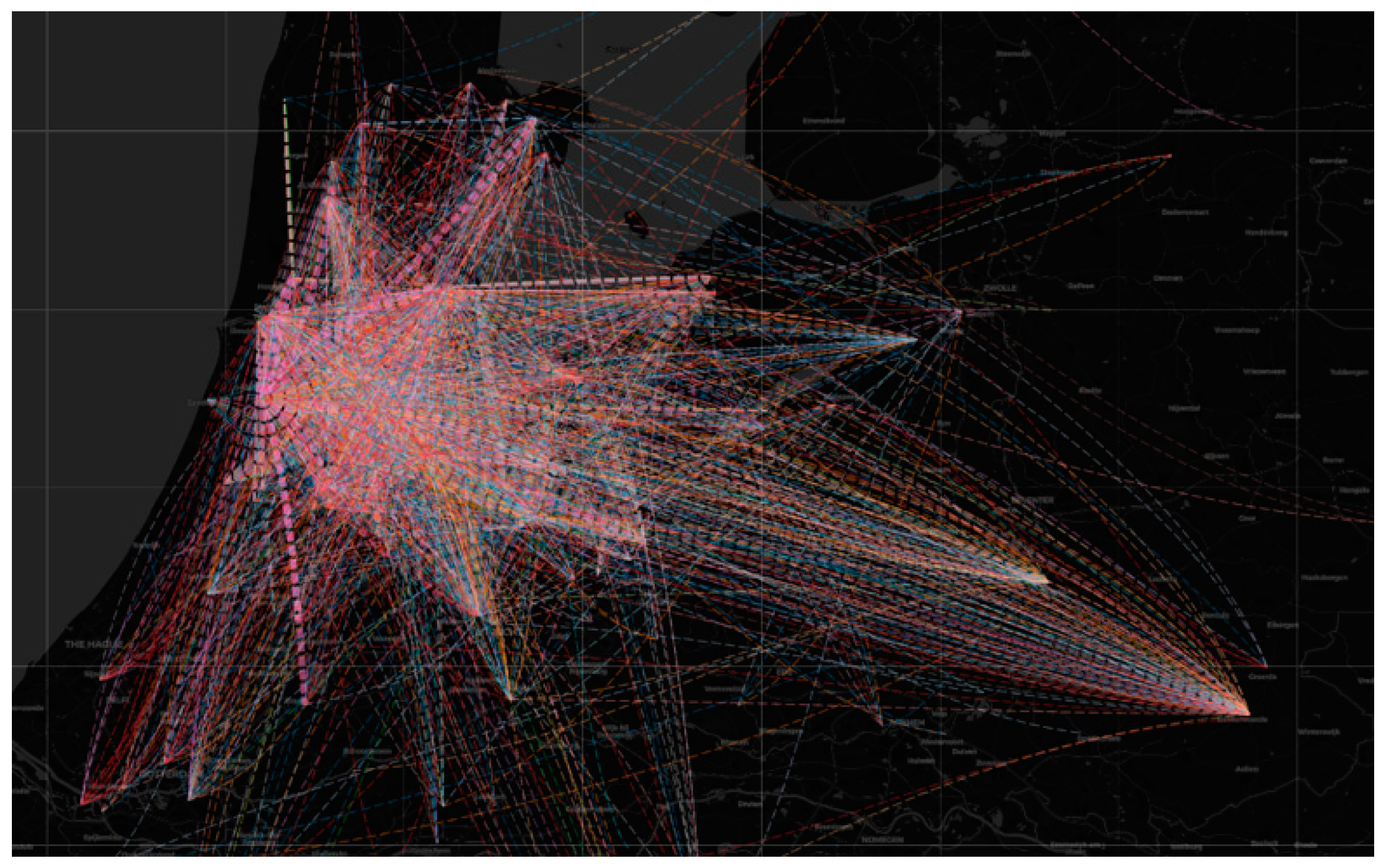

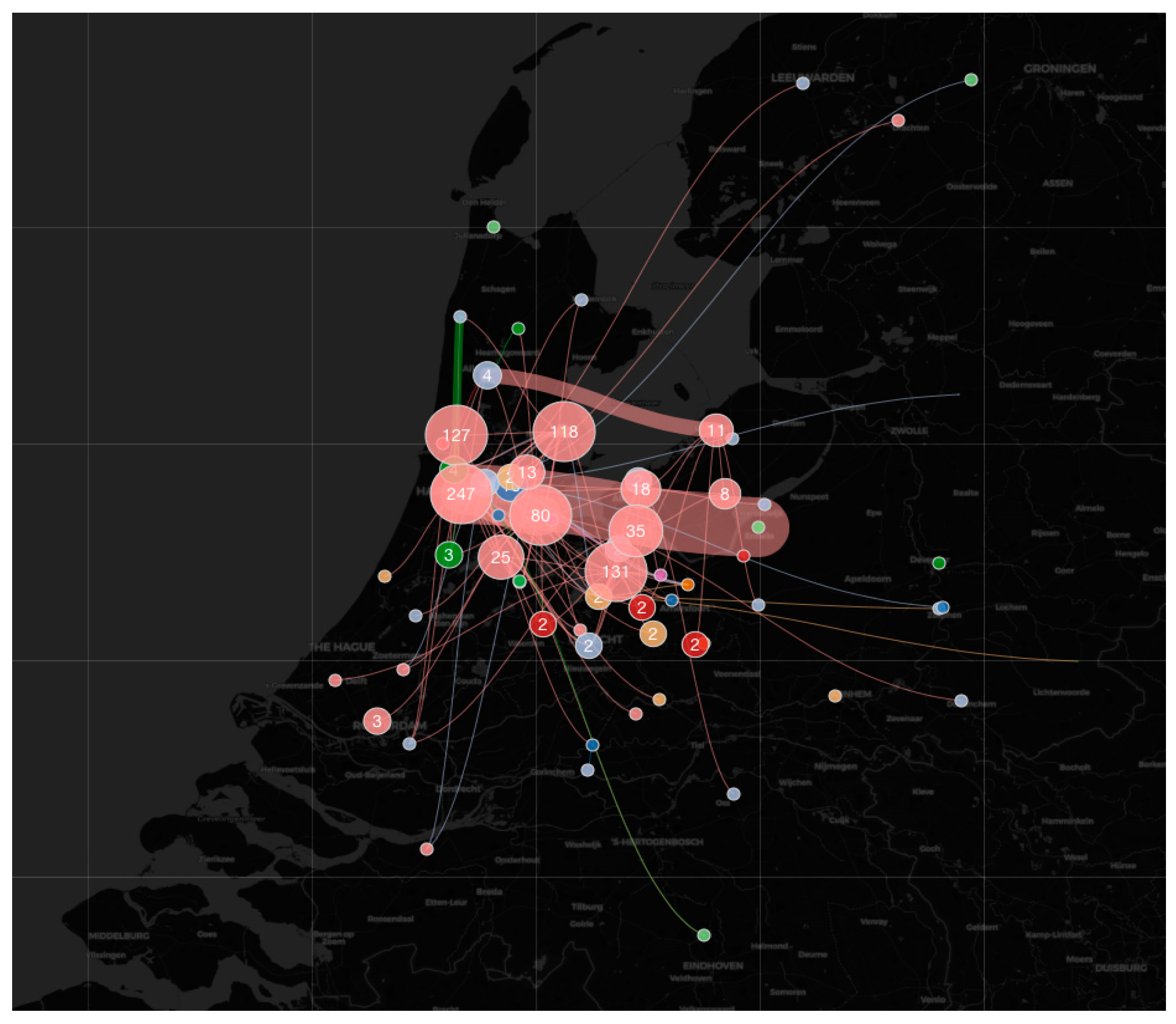

3.2. Activity-Based Spatial Material Flow Analysis

4. Design Preconditions and Frame of Reference

4.1. Design Preconditions

- The partitioning wall unlocks flexibility-capacity, through ease of assembly, disassembly, reassembly, and reutilization;

- The partitioning wall unlocks circularity capacity, through the ease of maintenance, reuse, redistribution, remanufacturing, recycling, and/or facilitating biological cycles;

- The partitioning wall unlocks user capacity, by an inclusive approach that takes account of willingness to engage, freedom of choice, and the health and well-being of end-users;

- The partitioning wall supports coordination between subsystems, particularly in regard to installations and electric or data provisions;

- The partitioning wall accommodates multiple duty ratings.

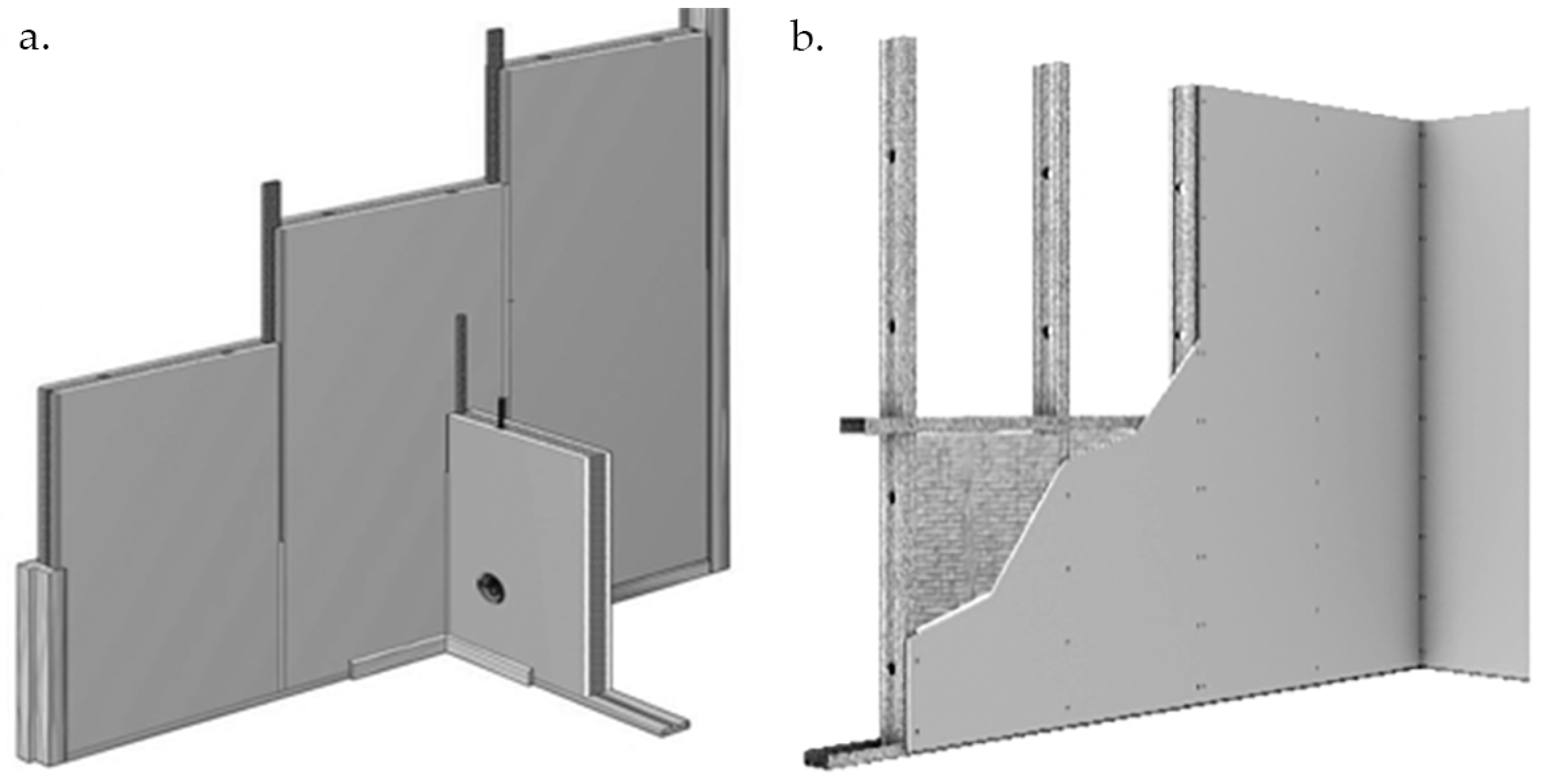

4.2. Frame of Reference

5. Results: Materialization and Operation Analysis

5.1. Materialization

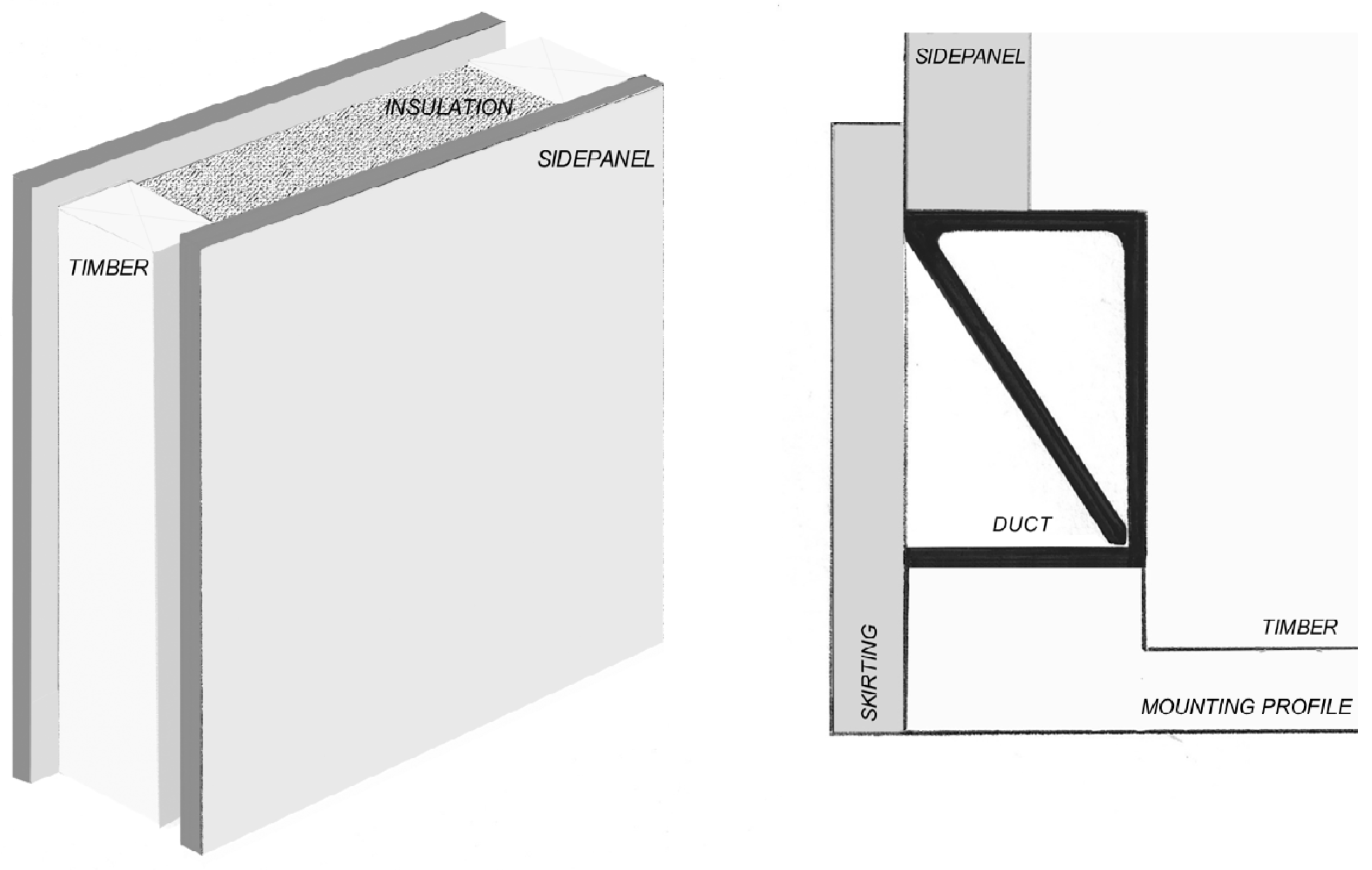

5.1.1. Side Panels

5.1.2. Insulation

5.2. Secondary Raw Materials and Waste

5.3. Materialization Overview

5.4. Operational Value-Chain

5.4.1. Niaga ECOR Panel

5.4.2. Mycelium Fiber Composite Insulation

6. Discussion of the Results

6.1. Technical Reflection

6.1.1. Fasteners and Coatings

6.1.2. Properties

6.1.3. Raw Materials

6.1.4. Mould

6.2. Organisational Reflection

6.2.1. Value-Chain Modifications

6.2.2. Data and Communication

6.2.3. Tenant Satisfaction

6.2.4. Validity in Other Contexts

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Laberge, R. Design criteria for adequate and affordable housing towards current social, demographic and economic trends. In Proceedings of the International Conference on Adequate and Affordable Housing for All, Toronto, ON, Canada, 24–27 June 2004. [Google Scholar]

- Oorschot, J.H.; Durmisevic, E.; Halman, J.I. Implementation of innovation: The inertia of implementing the open building concept in practice. In Proceedings of the International Conference on Management and Innovation for a Sustainable Built Environment, Amsterdam, The Netherlands, 20–23 June 2011. [Google Scholar]

- Geldermans, B.; Tenpierik, M.; Luscuere, P. Circular and Flexible Infill Concepts: Integration of the Residential User Perspective. Sustainability 2019, 11, 261. [Google Scholar] [CrossRef]

- Habraken, N.J. The Use of Levels; Keynote Address Unesco Regional Seminar on Shelter for the Homeless Seoul 1988; Open House International: Gateshead, UK, 2002; Volume 27. [Google Scholar]

- Geldermans, B.; Tenpierik, M.; Luscuere, P. Human Health and Well-Being in Relation to Circular and Flexible Infill Design: Assessment Criteria on the Operational Level. Sustainability 2019, 11, 1984. [Google Scholar] [CrossRef]

- Hendriksen, L.; de Graaf, J. Ontwikkelplan Circulaire Economie Metropoolregio Amsterdam; Metropoolregio Amsterdam: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Alexander, C. The Timeless Way of Building; Oxford University Press: Oxford, UK, 1977; ISBN 0195019199. [Google Scholar]

- Habraken, N.J. De Dragers en de Mensen—Het Einde van de Massawoningbouw; Scheltema & Holkema: Amsterdam, The Netherlands, 1961. [Google Scholar]

- Poldma, T. Transforming Interior Spaces: Enriching Subjective Experiences Through Design Research. J. Res. Pract. 2010, 6, M13. [Google Scholar]

- Poldma, T. Dwelling futures and lived experience: Transforming interior space. Des. Philos. Pap. 2008, 6, 141–155. [Google Scholar] [CrossRef]

- Poldma, T. Adapting the Interior Environment: A Case Study Using Light, Color and Research as Catalysts for Interior Design Problem-Solving; Interiors + Sources: Cedar Rapids, IA, USA, 2006. [Google Scholar]

- Vaikla-Poldma, T. An Investigation of Learning and Teaching Processes in an Interior Design Class: An Interpretive and Contextual Inquiry. Unpublished Doctoral Dissertation, McGill University, Montreal, QC, Canada, 2003. [Google Scholar]

- Mitchell, C.T. Refining Designing: From Form to Experience; Van Nostrand Reinhold: New York, NY, USA, 1993. [Google Scholar]

- Malnar, J.M.; Vodvarka, F. The Interior Dimension: A Theoretical Approach to Enclosed Space; John Wiley: New York, NY, USA, 1992. [Google Scholar]

- Brand, S. How Buildings Learn; Viking: New York, NY, USA, 1994; ISBN 9780670835157. [Google Scholar]

- O’Neill, R.V.; De Angelis, D.L.; Waide, J.B.; Allen, T.F.H. A Hierarchical Concept of Ecosystems; Princeton University Press: Princeton, NJ, USA, 1986. [Google Scholar]

- Guy, B.; Ciarimboli, N. Design for Disassembly in the Built Environment: A Guide to Closed Loop Design and Building; Hamer Centre for Community Design: State College, PA, USA, 2008. [Google Scholar]

- Durmisevic, E. Transformable Building Structures, Design for Disassembly as a Way to Introduce Sustainable Engineering to Building Design & Construction; Delft University of Technology: Delft, The Netherlands, 2006. [Google Scholar]

- Kendall, S. Notes on ‘open systems’ in building technology. Build. Environ. 1987, 22, 93–100. [Google Scholar] [CrossRef]

- Nicolic, J. Building “with the Systems” vs. Building “in the System” of IMS Open Technology of Prefabricated Construction: Challenges for New “Infill” Industry for Massive Housing Retrofitting. Energies 2018, 11, 1128. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle, Remaking the Ways We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Debacker, W.; Manshoven, S. Synthesis of the State of the Art: Key Barriers and Opportunities for Materials Passports and Reversible Building Design in the Current System; Buildings as Material Banks: Brussels, Belgium, 2016. [Google Scholar]

- Geldermans, R.J. Design for change and circularity: Accommodating circular material & product flows in construction. Energy Procedia 2016, 96, 301–311. [Google Scholar]

- Circle Economy and Fabric. Circular Amsterdam—A Vision and Action Agenda for the City and Metropolitan Area; Municipality of Amsterdam: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Amsterdam Smart City. Perspectief op Amsterdam als Circulaire Stad; ASC: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Booi, H.; Ahamiane, S.; De Graaff, L.; Schmitz, D.; Sleutjes, B.; Smits, A.; Tepic, M. Factsheet Wonen in Amsterdam 2017; Gemeente Amsterdam: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Ministry of the Interior and Kingdom Relations. Cijfers over Wonen en Bouwen 2016; Ministerie BZK: The Hague, The Netherlands, 2016.

- Buys, A.; Reijden, H.; Van der Hagen, L. Rapportage Raming Woningbehoefte Metropoolregio Amsterdam 2017–2015; RIGO: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Municipality of Amsterdam. Circulair Innovatie Programma; Municipality Amsterdam: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Municipality of Amsterdam and Circle Economy. Amsterdam Circulair—Evaluatie en Handelingsperspectieven; Municipality Amsterdam: Amsterdam, The Netherlands, 2018. [Google Scholar]

- C40 Cities Climate Leadership Group and Climate-KIC Circular Cities. Mapping Municipality-Led Circular Economy Case Studies; C40 Cities: London, UK, 2018. [Google Scholar]

- World Health Organization. Circular Economy and Health: Opportunities and Risks; World Health Organization Regional Office for Europe: Copenhagen, Denmark, 2018; ISBN 9789289053341. [Google Scholar]

- Girardet, H. Regenerative Cities. In Green Economy Reader: Lectures in Ecological Economics and Sustainability; Shmelev, S., Ed.; Springer: Cham, Switzerland, 2017; pp. 183–204. [Google Scholar]

- Barles, S. Comprendre et maîtriser le métabolisme urbain et l’empreinte environnementale des villes. In Responsabilité et Environnement; Annales des Mines: Paris, France, 2008; Volume 52, pp. 21–26. [Google Scholar]

- Kennedy, C.; Pincetl, S.; Bunje, P. The Study of Urban Metabolism and Its Applications to Urban Planning and Design. Environ. Pollut. 2011, 159, 1965–1973. [Google Scholar] [CrossRef]

- Allen, A.; Broto, V.C.; Rapoport, E. Interdisciplinary Perspectives on Urban Metabolism: A review of the literature. J. Ind. Ecol. 2012, 16, 851–861. [Google Scholar]

- Van der Leer, J.; van Timmeren, A.; Wandl, A. Social-Ecological-Technical systems in urban planning for a circular economy: An opportunity for horizontal integration. Archit. Sci. Rev. 2018, 61, 298–304. [Google Scholar] [CrossRef]

- Minx, J.C.; Baiocchi, G. Time use and sustainability. In Handbook for Input–Output Economics in Industrial Ecology; Suh, S., Ed.; Springer: Dordrecht, The Netherland, 2009; pp. 819–846. [Google Scholar]

- Geldermans, B.; Wandl, A.; Steenmeijer, M.; Furlan, C.; Streefland, T.; Formato, E.; Cerreta, M.; Amenta, L.; Varju, V.; Inglese, P.; et al. REPAiR: REsource Management in Peri-urban AReas: Going Beyond Urban Metabolism: D3.3 Process Model for the Two Pilot Cases: Amsterdam, The Netherlands & Naples, Italy; Revised Version 30 April 2019; Delft University of Technology: Delft, The Netherlands, 2019. [Google Scholar]

- Association of Interior Specialists. Best Practice Guide Installation of Partitioning; AIS: Solihull, UK, 2013. [Google Scholar]

- Holicky, M.; Materna, A.; Sedlacek, G.; Arteaga, A.; Sanpaolesi, L.; Vrouwenvelder, T.; Kovse, I.; Gulvanessian, H. Implementation of Eurocodes, Handbook 3 Action effects for Buildings; Leonardo da Vinci Pilot Project CZ/02/B/F/PP-134007; University of Technology Aachen: Aachen, Germany, 2005. [Google Scholar]

- European Patent Office. Method and System for Invisibly Arranging Cabling in a Room; Infill Systems B.V.: Delft, The Netherlands, 2016. [Google Scholar]

- Post, J.M. Van ‘Aap, Noot, Mies, Huis’ Naar ‘Zon, Wind en Water’; Technische Universiteit Eindhoven: Eindhoven, The Netherland, 2010. [Google Scholar]

- Koskela, L. An Exploration Towards a Production Theory and Its Application to Construction. Ph.D. Thesis, VTT Building Technology, Helsinki, Finland, 2010. [Google Scholar]

- Durmisevic, E.; Linthorst, P. Industrialization of housing (Building with systems). In Proceedings of the Continuous Customization in Housing, Tokyo, Japan, 16–18 October 2000. [Google Scholar]

- Vreedenburgh, E.; Mooij, M.; van Randen, A. Leidingsystematiek in Relatie tot Flexibiliteit, Verslag IOP-Onderzoek ‘Leidingen’; Werkgroep OBOM, Technische Universiteit Delft: Delft, The Netherlands, 1990. [Google Scholar]

- Schneider, T.; Till, T. Flexible housing: Opportunities and limits. Archit. Res. Q. 2005, 9, 157–166. [Google Scholar] [CrossRef]

- Smith, R.E. Prefab Architecture, A Guide to Modular Design and Construction; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Habraken, N.J. The Control of Complexity. Places 1987, 4, 3–15. [Google Scholar]

- European Commission. BIO by Deloitte Resource efficient use of mixed wastes. In Case Study Gypsum-to-Gypsum, from Production to Recycling, A Circular Economy for the European Gypsum Industry with the Demolition and Recycling Industry; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Ministry of Infrastructure and Water. LAP3, Deel B: Afvalbeheer en Overbrenging; DGMI: The Hague, The Netherlands, 2017.

- Sávoly, A.; Dawn, E. Gypsum Wallboard Chemical Additives; GEO Specialty Chemicals: Southhampton, UK, 2015. [Google Scholar]

- Mueller, M.; Hampel, C. Influence of the Gypsum Raw Material on the Performance of PCE-based HRWRA during Gypsum Board Production. In Proceedings of the Global Gypsum Conference, Paris, France, 25–26 October 2010. [Google Scholar]

- Zeeg, E.; Geldermans, B.; Siniat, Delfzijl, The Netherlands. Personal communication, 2019.

- Van der Veen, H.C.J. Het Effect van Milieubeleid op Locatiebeslissingen van Bedrijven. Ph.D. Thesis, University of Groningen, Groningen, The Netherland, 2004. [Google Scholar]

- Bodemrichtlijn Rijksoverheid. Bouwstoffase Isolatiemateriaal. Available online: https://www.bodemrichtlijn.nl/Bibliotheek/bouwstoffen-en-afvalstoffen/isolatiemateriaal/bouwstoffase-isolatiemateriaal (accessed on 8 May 2019).

- Lunn, R.; Jahnke, G.; Spencer, D.; Jameson, C.W.; Garner, S.; Atwood, S.; Carter, G.; Ewens, A.; Greenwood, D.; Ratcliffe, J.; et al. Final Report on Carcinogens Background Document for Glass Wool Fibers; National Toxicology Program: Durham, NC, USA, 2009.

- Cartwright, G. Is It Time to Legislate the Mineral Wool Industry More Tightly at EU Level? EU Today Ltd.: London, UK, 2018. [Google Scholar]

- Environmental Protection Agency. Fact Sheet Fine Mineral Fibers; EPA: Washington, DC, USA, 2016.

- National Toxicology Program. Certain Glass Wool Fibers (Inhalable)—Report on Carcinogens Status; National Institute of Environmental Health Sciences: Durham, NC, USA, 2011.

- Ministry of Infrastructure and Environment. Background Document Sector Plan 84: Other Recyclable Monoflows (National Waste Management Plan); Update 28 November 2017; Ministry of Infrastructure and Environment: The Hague, The Netherlands, 2017.

- Väntsi, O.; Kärki, T. Mineral wool waste in Europe: A review of mineral wool waste quantity, quality, and current recycling methods. J. Mater. Cycles Waste Manag. 2013, 16, 62–72. [Google Scholar] [CrossRef]

- Vercalsteren, A.; van der Linden, A.; Gillabel, J. Onderzoek over het Sluiten van de Materiaalketen van Minerale wol; Steunpunt Duurzaam Materialen Beheer: Heverlee, Belgium, 2014. [Google Scholar]

- Lopez Hurtado, P.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A review on the properties of cellulose fibre insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, A.; Clausen, A.U.; Astrup Jensen, A.; Kamstrup, O. A Comparative Life Cycle Assessment of Building Insulation Products made of Stone Wool, Paper Wool and Flax: Part 1: Background, Goal and Scope, Life Cycle Inventory, Impact Assessment and Interpretation. Int. J. Life Cycle Assess. 2004, 9, 53–66. [Google Scholar] [CrossRef]

- Silvestre, J.D.; de Brito, J.; Pinheiro, M.D. Life-cycle assessment of thermal insulation materials for external walls of buildings. In Proceedings of the International Conference of Constructions, Innsbruck, Austria, 27–28 May 2011. [Google Scholar]

- Everuse. Circulaire Isolatieplaat. Available online: https://www.everuse.com/everuse-circulaire-isolatieplaat (accessed on 20 May 2019).

- C2C Certified Products Registry. Available online: https://www.c2ccertified.org/products/registry (accessed on 20 April 2019).

- Material Passport Platform (Prototype). Available online: https://passports.bamb2020.eu/#!/products (accessed on 20 April 2019).

- Irle, M.; Barbu, M.C. Wood-Based Panel Technology. In Wood-Based Panels, An Introduction for Specialists; Thoemen, H., Irle, M., Sernek, M., Eds.; Brunel University Press: London, UK, 2010. [Google Scholar]

- Ross, R.J. Wood Handbook—Wood as an Engineering Material; General Technical Report; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010.

- Carus, M.; Dammer, L. Food or Non-Food: Which Agricultural Feedstocks Are Best for Industrial Uses? Ind. Biotechnol. 2013, 9. [Google Scholar] [CrossRef]

- Gerbinet, S.; Briard, V.; Pigeolet, J.P.; Hampson, C.; Belboom, S.; Groslambert, S.; Léonard, A. Use of a Bio-Based Binder in the Building Sector; University of Liège: Liège, Belgium, 2017. [Google Scholar]

- Saravia Cortez, A.M.; Herva, M.; Garcia-Dieguez, C.; Roca, E. Assessing environmental sustainability of particleboard production process by ecological footprint. J. Clean. Prod. 2013, 52, 301–308. [Google Scholar] [CrossRef]

- Noble Environmental Technologies. ECOR. Available online: https://ecorglobal.com (accessed on 3 April and 24 May 2019).

- Noble Environmental Technologies. ECOR Core Catalog Guide; Noble Environmental Technologies: San Diego, CA, USA, 2011. [Google Scholar]

- Pauli, G. The Blue Economy; Academic Foundation: New Delhi, India, 2015. [Google Scholar]

- Hahs, R. System Reset—Part 3: Flame Retardants from Food. Available online: https://www.thinkbiomimicry.com/2017/03/02/systemreset-part-3-flame-retardants-from-food/ (accessed on 2 March 2019).

- Nilsson, M.; Biomimetic Technology Ltd., Toronto, ON, Canada. Personal communication, 2019.

- Wouters, M.; Burghoorn, M.; Ingenhut, B.; Timmer, K.; Rentrop, C.; Bots, T.; Oosterhuis, G.; Fischer, H. Tuneable adhesion through novel binder technologies. Progress Org. Coat. 2011, 72, 152–158. [Google Scholar] [CrossRef]

- Tichelaar, M.P.; Koning, C.E.; Udding, J.H.; Westerhof, W.; Reutelingsperger, C. Methods for Producing Textile Products, Products Obtainable Therefrom and Method to Reclaim the Product. US Patent US2017/0152417A1, 1 June 2017. [Google Scholar]

- Evonik. Calostat High Performance Insulation Material; Evonik: Hanau, Germany, 2018. [Google Scholar]

- Leefmilieu Brussel. Thermische en Akoestische Isolatie—Infofiche Ecoconstructie voor Particulieren MAT14; Brussels Instituut voor Milieubeheer: Brussels, Belgium, 2009. [Google Scholar]

- Van Dam, J.E.G.; van den Oever, M.J.A. Catalogus Biobased Bouwmaterialen; Wageningen UR—Food & Biobased Research—118: Wageningen, The Netherlands, 2012. [Google Scholar]

- McIntyre, G. Presentation: Ecovative, We Grow Materials; World Materials Forum: Nancy, France, 2016. [Google Scholar]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Bayer, E.; McIntyre, G. An evaluation study of mycelium-based acoustic absorbers grown on agricultural by-product substrates. Ind. Crops Prod. 2013, 51, 480–485. [Google Scholar] [CrossRef]

- Jones, M.P.; Wang, C.H.; Bhat, T.; Moinuddin KJohn, S. Thermal degradation and fire reaction properties of mycelium composites. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Ecovative. MycoComposite Specifications Sheet. Available online: https://s3-us-west-2.amazonaws.com/ecovative-website-production/documents/MycoComposite029.pdf (accessed on 23 May 2019).

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, F.; Still, B.; White, M.; Amstislavski, P. Physical and mechanical properties of fungal mycelium-based biofoam. J. Mater. Civ. Eng. 2017, 29, 1–9. [Google Scholar] [CrossRef]

- Critical Concrete. Producing Mycelium Insulation. Available online: https://criticalconcrete.com/category/summer-school-2018/ (accessed on 24 May 2019).

- Eurostat. NACE Rev. 2—Statistical Classification of Economic Activities in the European Community; Eurostat: Brussels, Belgium, 2008; ISBN 978-92-79-04741-1. [Google Scholar]

- Duijvestein, P.; Roemers, G. De Metropoolregio Amsterdam als circulaire grondstoffen hub, Database bouw-en sloopafval in de MRA; Metabolic and D2R New Economy: Amsterdam, The Netherlands; The Hague, The Netherlands, 2018. [Google Scholar]

- Amenta, L.; van Timmeren, A. Beyond Wastescapes: Towards Circular Landscapes. Addressing the Spatial Dimension of Circularity through the Regeneration of Wastescapes. Sustainability 2018, 10, 4740. [Google Scholar] [CrossRef]

- British Gypsum. White-Book CO2 Technical Performance, Updated Version; British Gyspum: Loughborough, UK, 2019. [Google Scholar]

- Siniat. LaDura Premium Technical Specifications; Etex Building Performance B.V.: Delfzijl, The Netherlands, 2015. [Google Scholar]

- Knauf. Diamond Board Technical Specifications; Knauf: Iphofen, Gemany, 2017. [Google Scholar]

- Saint-Gobain. Gypwall Systems, Incorporating Gyproc Habito; Saint-Gobain: Paris, France, 2018. [Google Scholar]

- Tavakolly, N.; Paanakker, G.; ECOR, Amsterdam, The Netherlands; Udding, H.J.; DSM-Niaga, Geleen, The Netherlands. Personal communication, 2019.

- Critical Concrete. Insights into Mycelium, Interview with Maurizio Montalti. Available online: https://criticalconcrete.com/insights-mycelium/ (accessed on 17 May 2019).

- Berbee, J.; Krown-Design, Hedel, The Netherlands. Personal communication, 2019.

- Wesselink Isolatie. Everuse Cellulose Isolatieplaat. Available online: https://www.wesselinkisolatie.nl/shop/everuse-isolatieplaat-cellulose-60-mm/ (accessed on 20 May 2019).

- BNR. Everuse: Van Papierafval tot Circulair Isolatiemateriaal. Available online: https://www.bnr.nl/podcast/the-green-quest/10362043/14-everuse-van-papierafval-tot-circulair-isolatiemateriaal (accessed on 20 May 2019).

- Saint-Gobain. Technical Performance and Principles of System Design. Available online: https://www.gyproc.ie/sites/default/files/Sustainability.pdf (accessed on 7 May 2019).

- Straub, A.; van Nunen, H.; Janssen, R.; Liebregts, M.A.A.M. Levensduur van Bouwproducten, Methode voor Referentiewaarden; SBR: Rotterdam, The Netherland, 2011. [Google Scholar]

- Vandenbroucke, M. Technische Levensduur van Gebouwcomponenten; OVAM: Mechelen, Belgium, 2018. [Google Scholar]

- Hildebrand, L. Strategic Investment of Embodied Energy during the Architectural Planning Process. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2014. [Google Scholar]

- Frank, P. This Living, Sustainable Mushroom Building Could Be the Future of Green Architecture. Available online: https://www.huffingtonpost.com/2014/07/02/moma-hy-fi-_n_5549107.html (accessed on 15 May 2019).

- A.T. Kearney LLC. Chemical Industry Vision 2030: A European Perspective; A.T. Kearney LLC: Seoul, Korea, 2012. [Google Scholar]

- Kües, U. Wood Production, Wood Technology, and Biotechnological Impacts; Universitätsverlag Göttingen: Göttingen, Germany, 2007. [Google Scholar]

- Sharkey, G. An Overview of the European Flour Milling Industry. Available online: https://ec.europa.eu/agriculture/sites/agriculture/files/market-observatory/crops/reports/presentations/efm-gary_sharkey-2018-12-03.pdf (accessed on 24 April 2019).

- Annevelink, E.; Bos, H.L.; Meesters, K.P.H.; van den Oever, M.J.A.; de Haas, W.; Kuikman, P.J.; Rietra, R.P.J.J.; Sikirica, N. Circular Solutions—From Waste to Resource. Wageningen University & Research: Wageningen, The Netherlands, 2016. [Google Scholar]

- Remoy, H.; Furlan, C.; Wandl, A.; Dabrowski, M.; Amenta, L.; Arciniegas, G.; Muñoz Unceta, P.; Streefland, T.; Geldermans, B.; Heurkens, E.; et al. Catalogue of Solutions and Strategies for Amsterdam; Horizon 2020, Resource management in peri-urban areas, report D5.2; Delft University of Technology: Delft, The Netherlands, 2018. [Google Scholar]

- SADC. Duurzaamheid Schiphol Trade Park; Schiphol Area Development Company: Schiphol, The Netherland, 2016. [Google Scholar]

- Van der Sluis, T.; Poppens, R.; Kraisvitnii, P.; Rii, O.; Lesschen, J.P.; Galytska, M.; Elbersen, W. Reed Harvesting from Wetlands for Bioenergy—Technical Aspects, Sustainability and Economic Viability of Reed Harvesting in Ukraine; Alterra Wageningen UR: Wageningen, The Netherlands, 2013. [Google Scholar]

- Wamelink, J.W.F.; Heintz, J.L. Overcoming Barriers to Innovation in the Building Industry. BOSS Mag. 2015, 52, 25–31. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations, 4th ed.; Simon & Schuster: New York, NY, USA, 2003. [Google Scholar]

- Gambatese, J.A.; Hallowell, M. Enabling and measuring innovation in the construction industry. Constr. Manag. Econ. 2011, 29, 553–567. [Google Scholar] [CrossRef]

- Witjes, S.; Lozano, R. Towards a more Circular Economy: Proposing a framework linking sustainable public procurement and sustainable business models. Resour. Conserv. Recycl. 2016, 112, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Simkens, B.; Themans, S. Circular Kitchens—The Willingness of Homeowners to Purchase Circular Kitchens; Delft University of Technology: Delft, The Netherlands, 2018. [Google Scholar]

- Cerulli-Harms, A.; Suter, J.; Landzaat, W.; Duke, C.; Rodriguez Diaz, A.; Porch, L.; Peroz, T.; Kettner, S.; Thorun, C.; Svatikova, K.; et al. Behavioural Study on Consumers’ Engagement in the Circular Economy; European Commission, Directorate-General for Justice and Consumers: Brussels, Belgium, 2018. [Google Scholar]

- Bocken, N.M.P.; Bakker, C.; de Pauw, I.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Van Stijn, A.; Gruis, V.; van Bortel, G. Circular Components in the Built Environment; AMS Institute: Amsterdam, The Netherlands, 2017. [Google Scholar]

- De Rooij, B. A Kitchen for Life—Designing a Service That Engages Social Housing Tenants in Using A Circular Kitchen System. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2019. [Google Scholar]

- Steen, K.; van Bueren, E. A Living Lab Way of Working; Amsterdam Institute for Advanced Metropolitan Solutions: Amsterdam, The Netherlands, 2017. [Google Scholar]

| Category | Summary of Criteria |

|---|---|

| Material Health & Transparency | X-listed chemicals in raw materials/product or process, following the Cradle to Cradle ® Certification Standard; Complete characterization of applied (raw) materials; Materials defined as biological or technological ingredients; Short term and long term emission control regarding potentially damaging offset of chemicals; Protective practices in repair/maintenance/disposal, linked to hazardous materials. |

| Material Reutilization | Defined appropriate cycle/reutilization route (biological or technological); Designed for the cycle, following a reutilization score expressed in percentages of recycled content, rapidly renewable content, recyclable content, and/or biodegradable content; Management strategy for logistics and recovery pathways; Collection and reutilization program. |

| Mould control | Anticipation of (delayed) moisture related issues, in relation to operational conditions. |

| Health & Wellbeing Awareness | Provision of information and guidelines throughout the whole value network, highlighting the relationship between health & well-being and buildings/building components. |

| Integrative Design | Facilitation of stakeholder co-creation towards continuous improvement. |

| Perceived Performance | Short and long-term performance-evaluations relating the component’s functioning. Primarily aimed at the use stage but also anticipating construction and disposal. |

| COMPONENT | MATERIAL | PRODUCTION LOCATION | RAW MATERIAL | RAW MATERIAL ORIGIN | GEOGRAPHICAL SCALE | MATERIAL/m2 | REUTILIZATION POTENTIAL |

|---|---|---|---|---|---|---|---|

| Side panel | Gypsum board | the Netherlands | Flue Gas Desulfurization Gypsum | Coal-fired powerplants | State; Continent | Roughly 25 kg/m2 (2 sides of 12.5 mm medium duty panel). 90–95% gypsum + 5–10% additives and paper. | Direct reutilization possible but compromised by impact of common fasteners. High recycling potential in the case of basic panels, but value of most raw materials is destructed (i.e. downcycling). Low recycling potential in the case of boards with enhanced properties. No direct take-back system in place, but gypsum recycling market is growing in the Netherlands. |

| Recycled Gypsum | Construction residues | State; Continent | |||||

| Demolition waste | State; Continent | ||||||

| Natural Gypsum | Mined gypsum | Currently not applicable | |||||

| Recycled Paper/Cardboard | Paper and cardboard waste post-use | State; Continent | |||||

| Secondary Paper/Cardboard | Residual flows from industry | State; Continent | |||||

| Additives: process accelerant, foaming agent, fluidizer, fire retardant, filler, bonding agent, binding retardant, reinforcement | Chemical industry | State; Continent; Globe | |||||

| Niaga ECOR Panel | the Netherlands and Serbia | Fibers (paper, cardboard, flax, wood chips, straw etc.) | Post-use and residual flows | Region; State; Continent | Roughly 25 kg/m2 (2 sides of 12.5 laminated NEP). ≈ 95% fibers, 5% polyester | Direct reutilization possible but compromised by impact of common fasteners. High recycling potential: polyester binder can be "unclicked", liberating the ECOR fiber material and Niaga binder as two separate flows that can be fully reused without quality-loss. Additives for enhanced properties are not anticipated yet. Options for Take-back model are being explored. | |

| Polyesters based on carboxylic acid and glycol | Chemical industry | State; Continent; Globe | |||||

| Additives: none reported, but potentially a fire retardant or biocide * | Unknown | Region; State; Continent | |||||

| Insulation | Mycelium-fiber composite (MFC) | The Netherlands | Mycelium | Fungal mycelium species | State; Continent; Globe | <1 kg/m2 (30–50 mm). Dry weight. Dependent on mycelium/fiber ratios | Direct reutilization possible, within limits of service life. Product is fully biodegradable. |

| Agricultural fibers | Agricultural by-products and residual flows | Region; State; Continent | |||||

| Additives: none reported, but potentially a process accelerator | Wheat flour | Region; State; Continent | |||||

| Everuse® | the Netherlands | Cellulose | Post-industrial paper residues | State | <1 kg/m2 (30–40 mm) | Direct reutilization possible, within limits of service life. Take-back system in place. Product is recycled in manufacturer’s facility. No details available | |

| Additives: fire retardant, biocide | no data | no data |

| COMPONENT | MATERIAL | DENSITY | NAIL PULL RESISTANCE | DIMENSIONAL STABILITY: Linear Expansion Coeff. | FIRE RATING | THERMAL CONDUCTIVITY | SERVICE LIFE | WHOLESALE PRICE INDICATION |

|---|---|---|---|---|---|---|---|---|

| Side panel | Gypsum board-reinforced, medium duty (12.5 mm) | ≈1000 kg/m3 | ≈15 kg (safetyfactor 4) * | 0.0065 mm/m/Δ RH (change in relative humidity) | Class A1-B = not (easily) combustible | 0.19–0.25 W/mK | ≈40 years | ≈€7–10/m2 |

| Niaga ECOR Panel (12.5 mm) | ≈1000 kg/m3 | NEP: no data FlatCOR (2.5 mm): ≈ 30 kg ** | NEP: no data available yet. FlatCOR (2.5 mm): 0.029 mm/m/Δ RH | NEP: no data available yet. FlatCOR raw panel: Class B = not easily combustible | No data | No data. Estimation: ≈30 years | NEP: no data FlatCOR (2.5 mm): €3–4/m2 | |

| Insulation | Mycelium-fiber composite | 80–110 kg/m3 | Class A: not (easily) combustible, reported for Ecovative product. Otherwise Insufficient data | 0.035–0.06 W/mK | ≈20 years | €10–50/m2 | ||

| Everuse® | ≈ 75 kg/m3 | Class A1-B/s1/d0 = not (easily) combustible/little smoke production/no production of burning parts | 0.035–0.04 W/mK | ≈30 years | €17.50/m2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geldermans, B.; Tenpierik, M.; Luscuere, P. Circular and Flexible Indoor Partitioning—A Design Conceptualization of Innovative Materials and Value Chains. Buildings 2019, 9, 194. https://doi.org/10.3390/buildings9090194

Geldermans B, Tenpierik M, Luscuere P. Circular and Flexible Indoor Partitioning—A Design Conceptualization of Innovative Materials and Value Chains. Buildings. 2019; 9(9):194. https://doi.org/10.3390/buildings9090194

Chicago/Turabian StyleGeldermans, Bob, Martin Tenpierik, and Peter Luscuere. 2019. "Circular and Flexible Indoor Partitioning—A Design Conceptualization of Innovative Materials and Value Chains" Buildings 9, no. 9: 194. https://doi.org/10.3390/buildings9090194

APA StyleGeldermans, B., Tenpierik, M., & Luscuere, P. (2019). Circular and Flexible Indoor Partitioning—A Design Conceptualization of Innovative Materials and Value Chains. Buildings, 9(9), 194. https://doi.org/10.3390/buildings9090194