Locating Hidden Elements in Walls of Cultural Heritage Buildings by Using Infrared Thermography

Abstract

:1. Introduction

2. Methodology

3. Nondestructive Testing Methods of Buildings

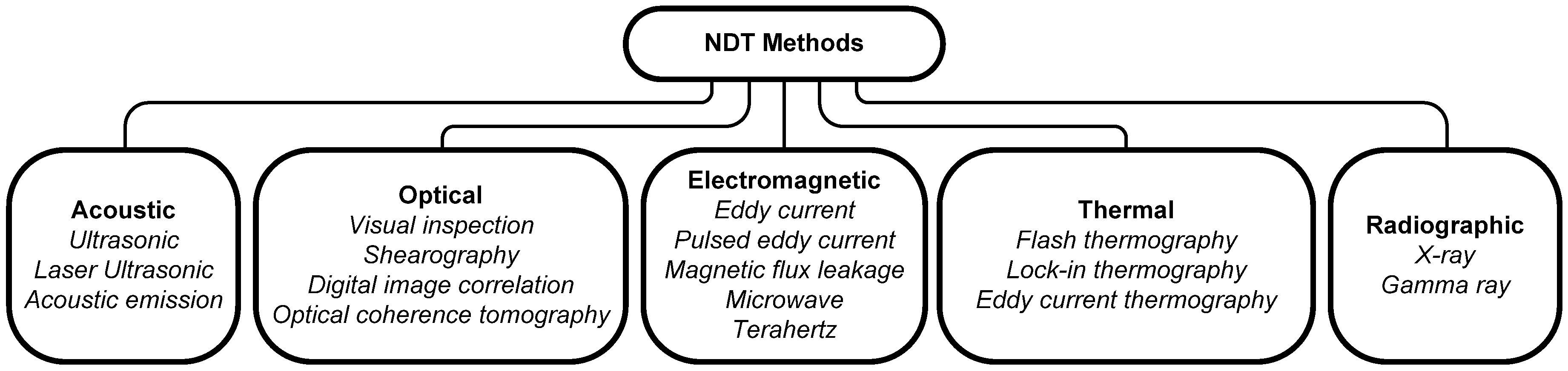

3.1. NDT Methods

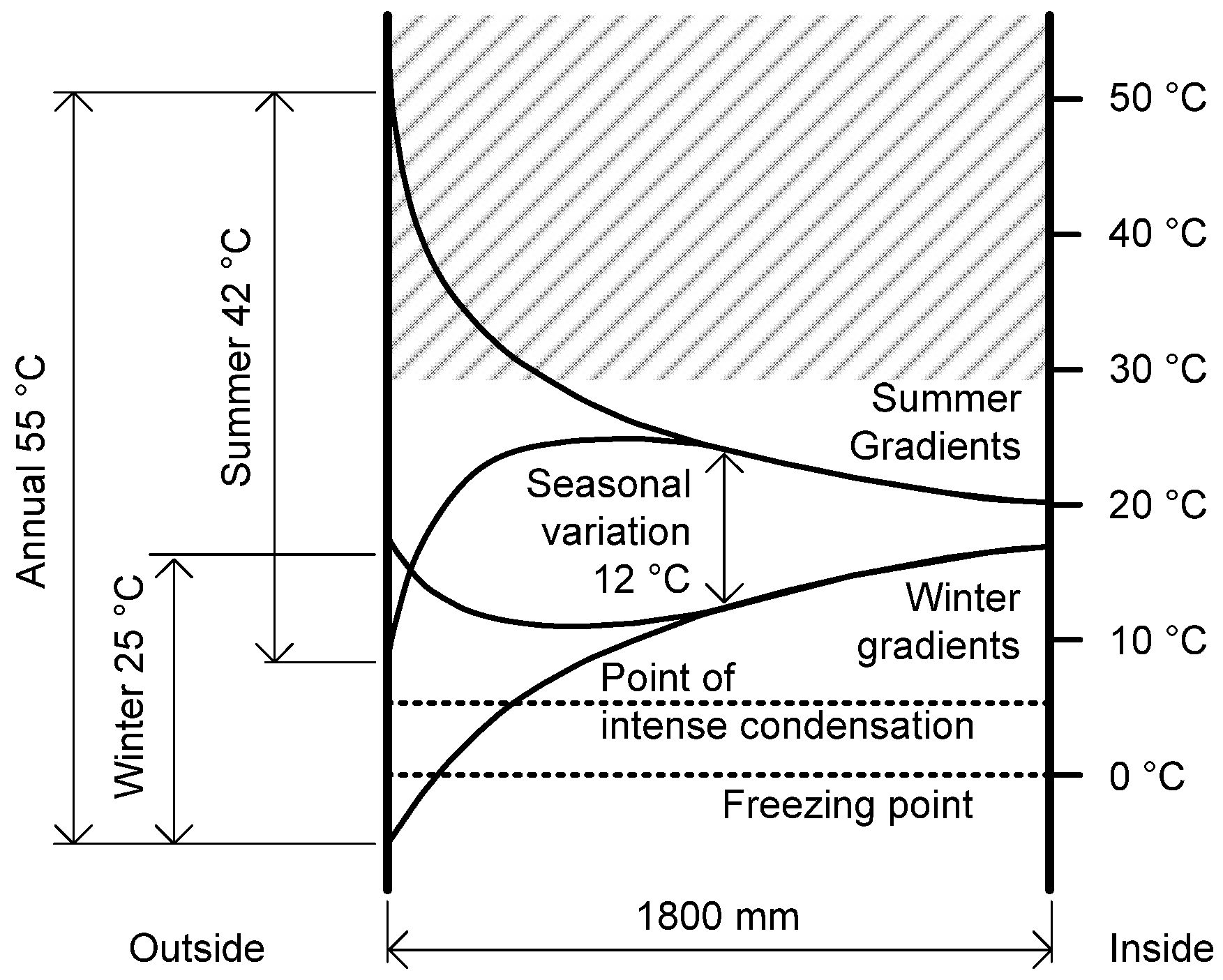

3.2. Infrared Thermography

3.3. Qualitative/Quantitative Thermography

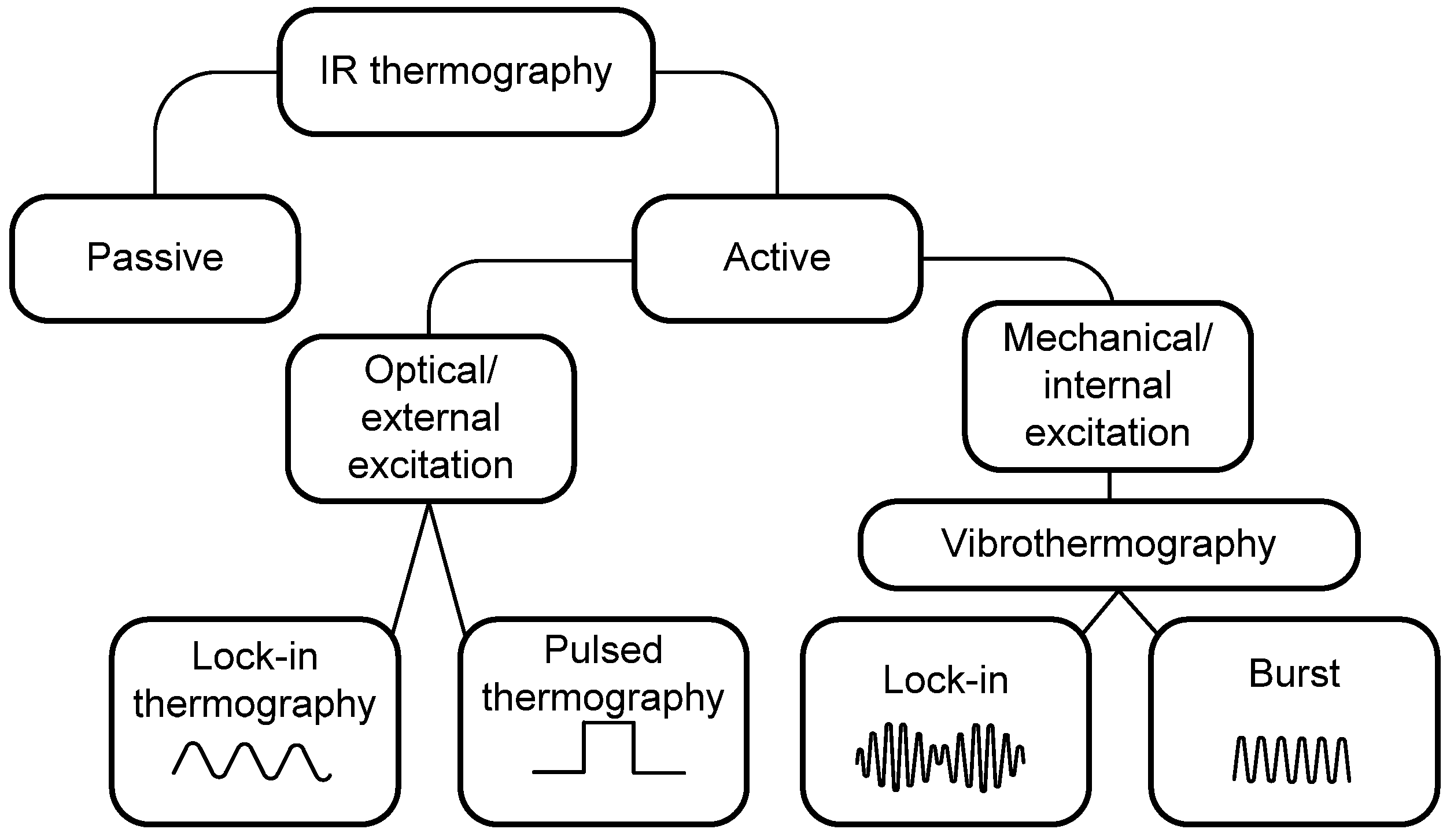

3.4. Passive/Active Thermography

3.5. Parameters Affecting Radiometric Accuracy of IR Thermography

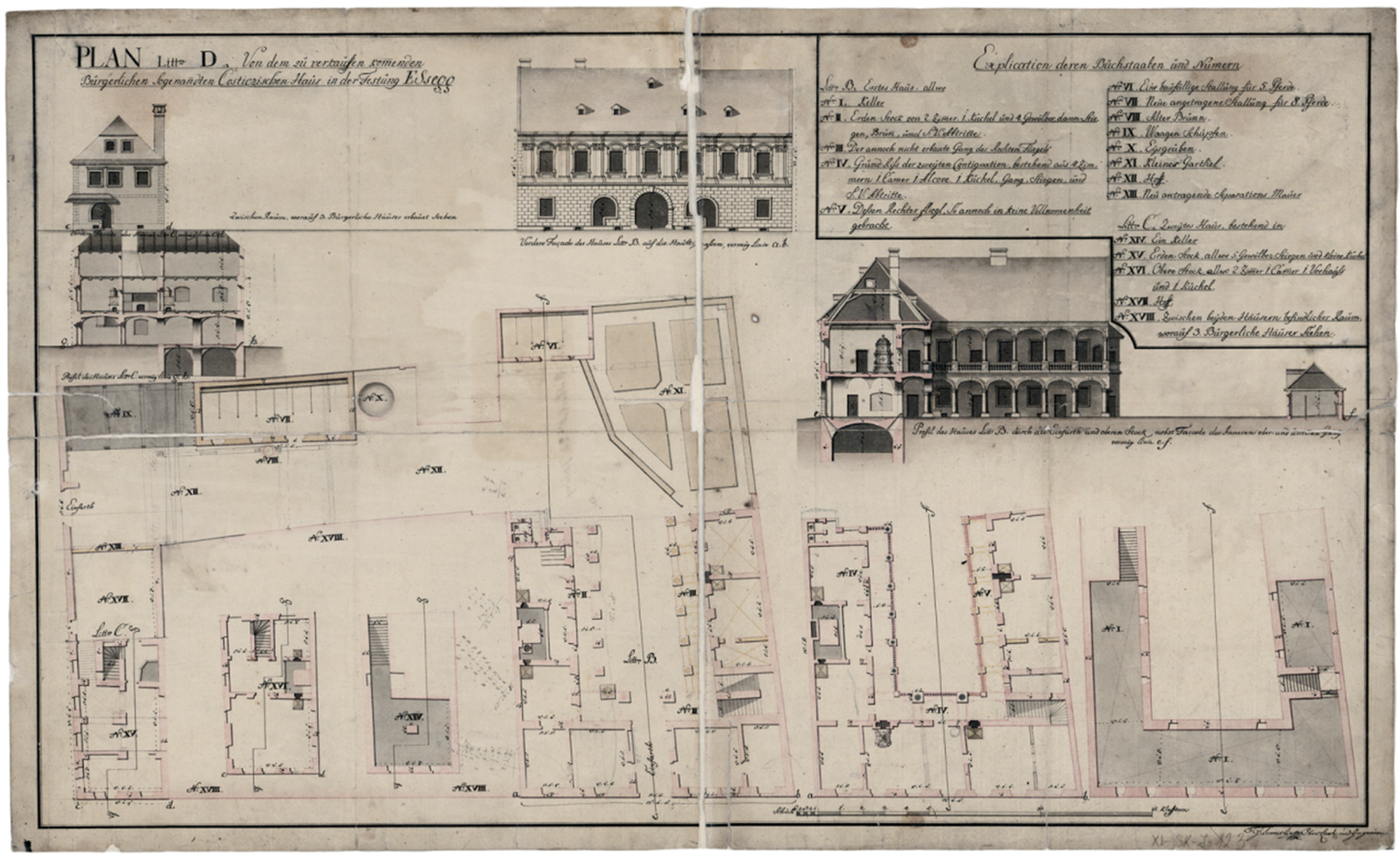

4. Study Area

Analyzed Elements of Kostić House

5. Results

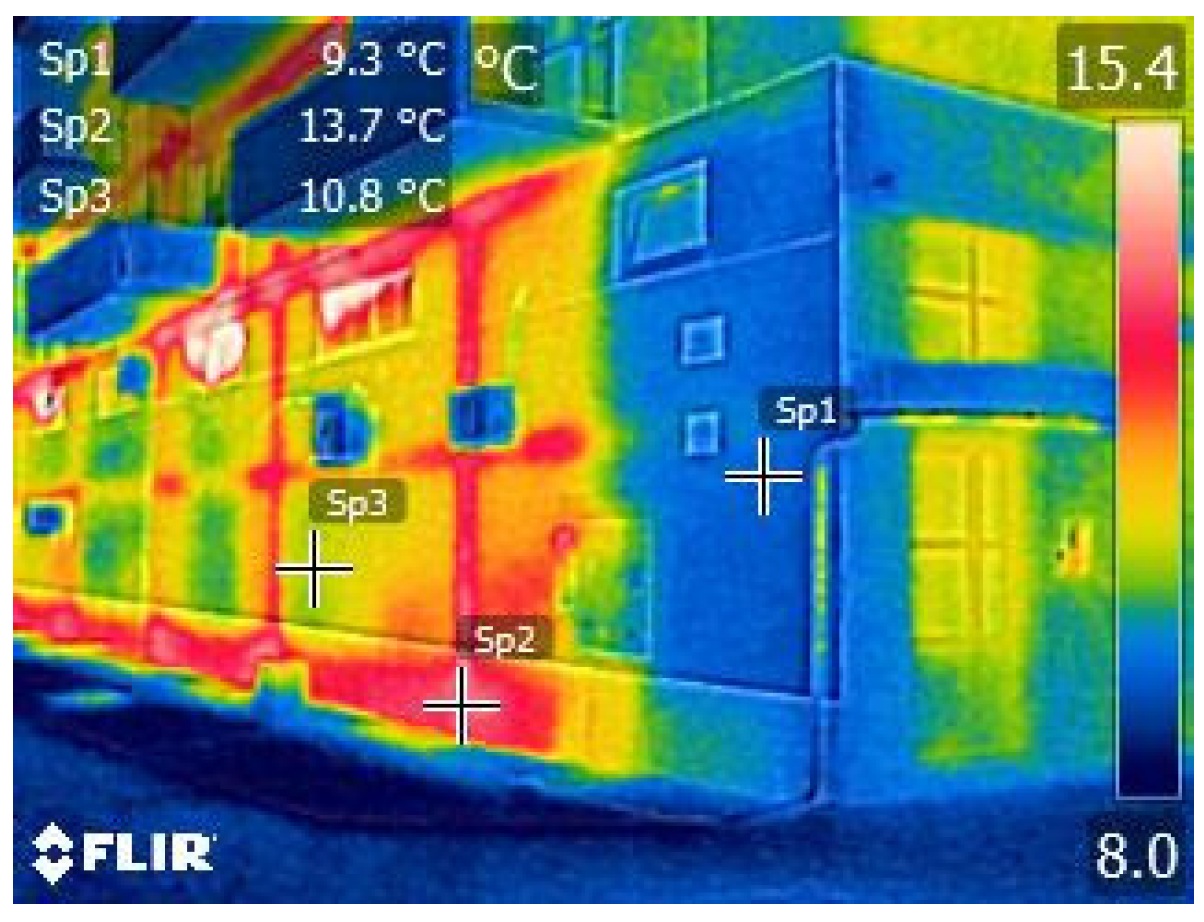

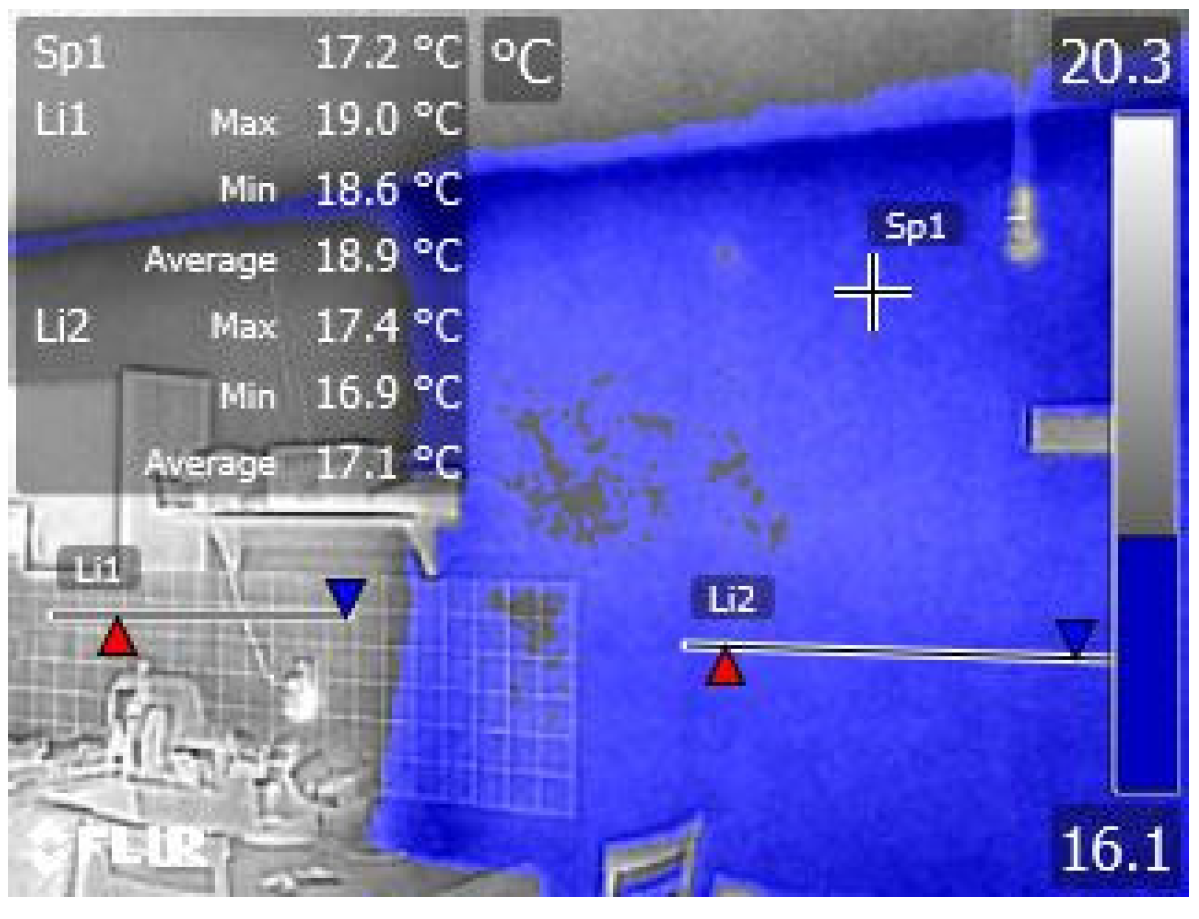

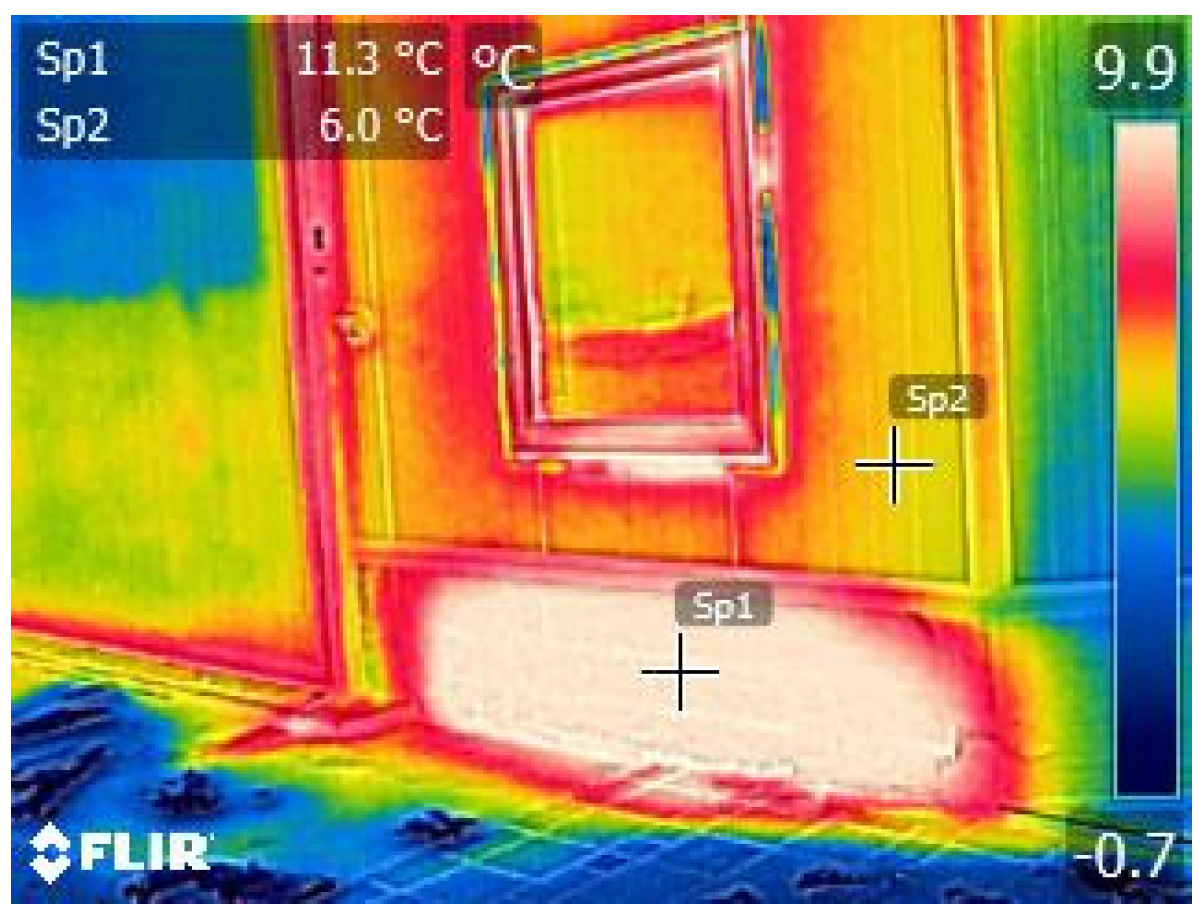

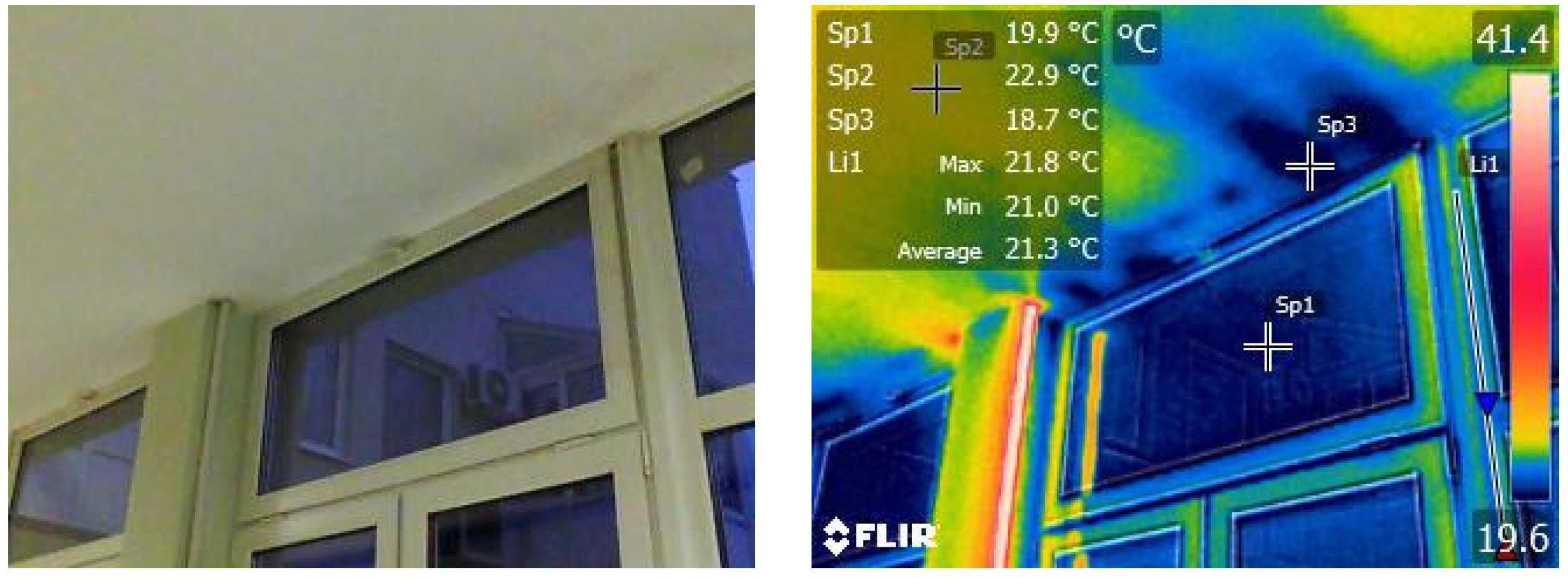

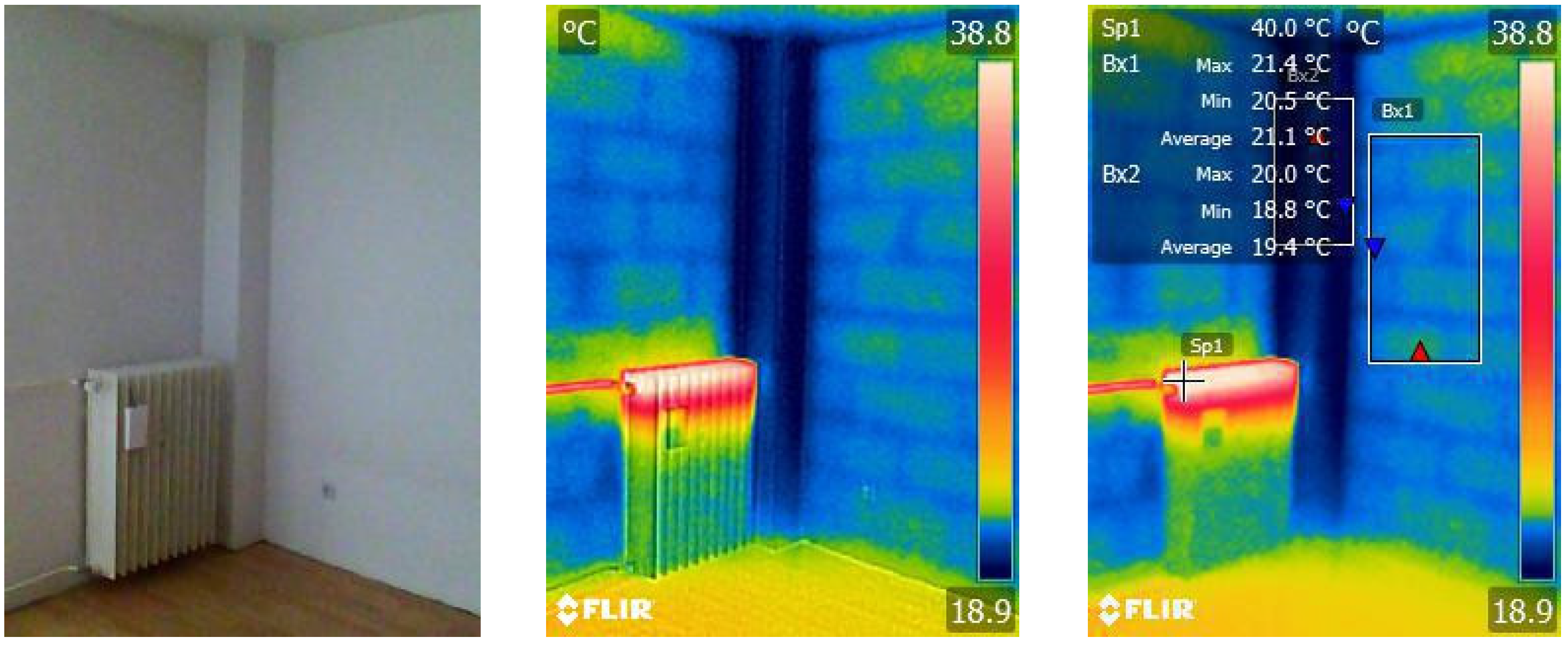

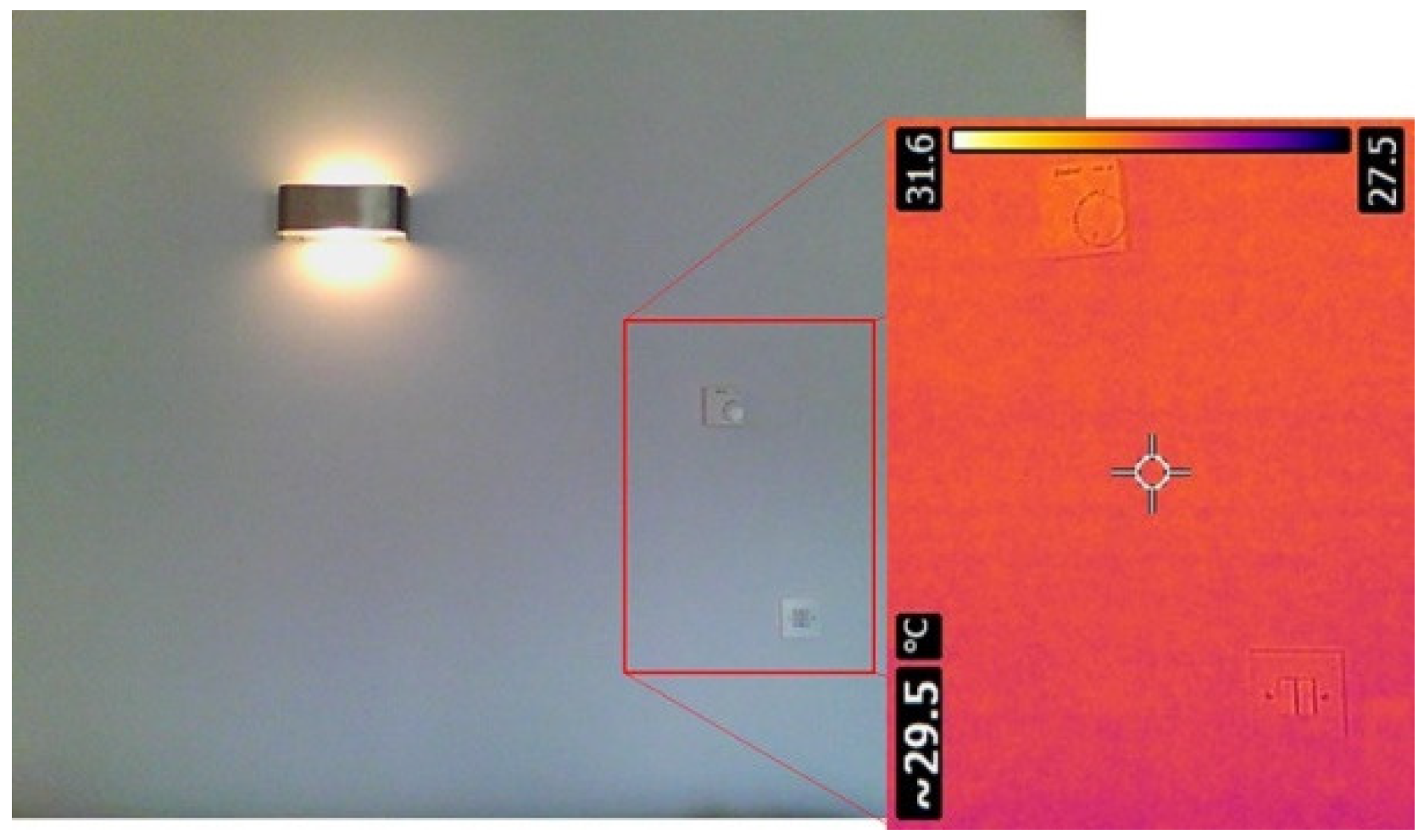

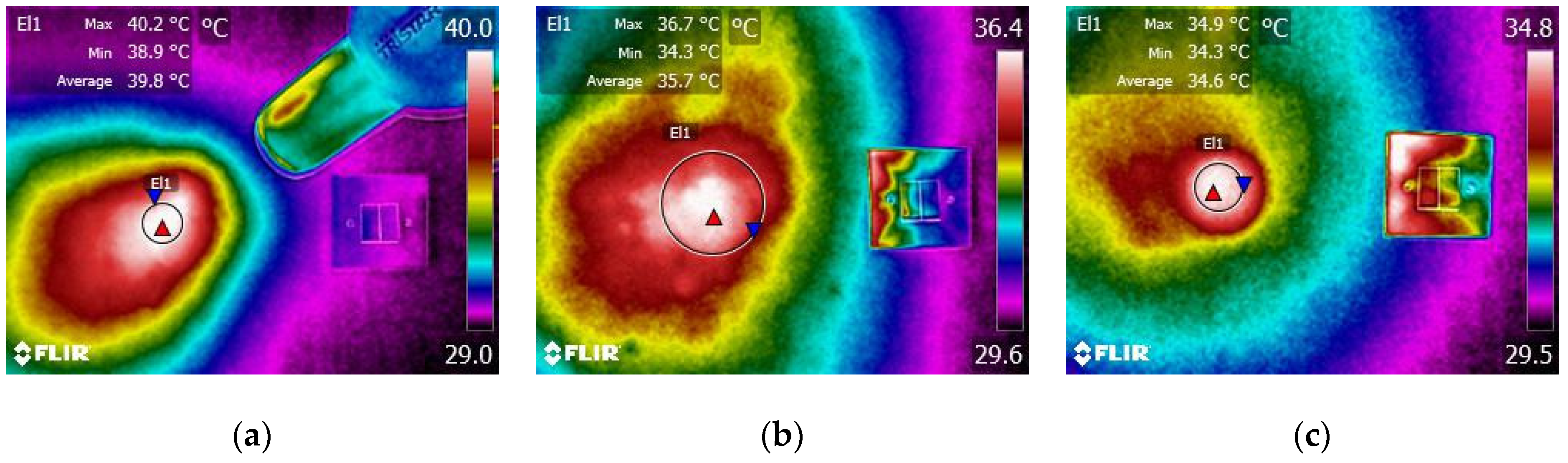

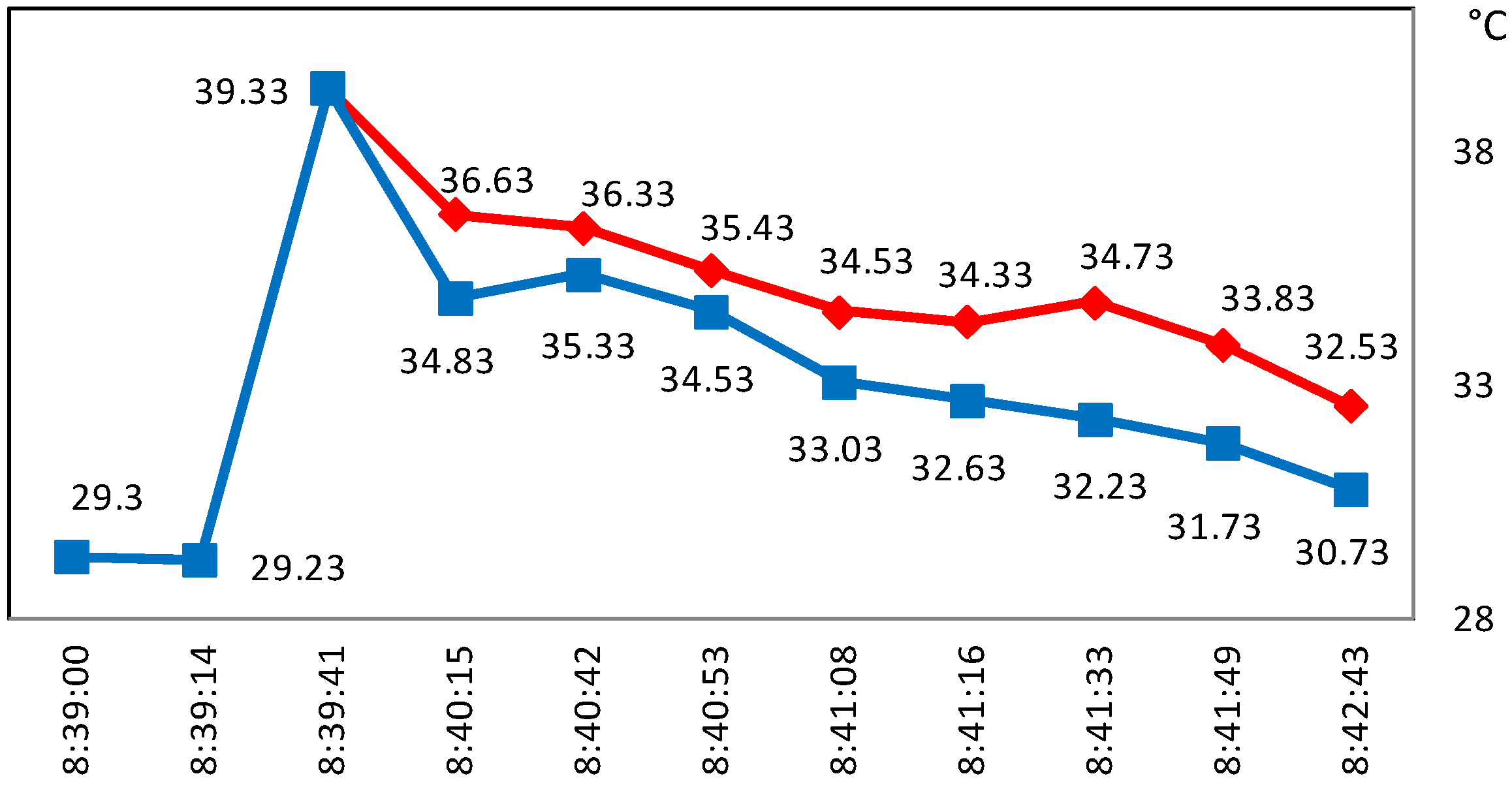

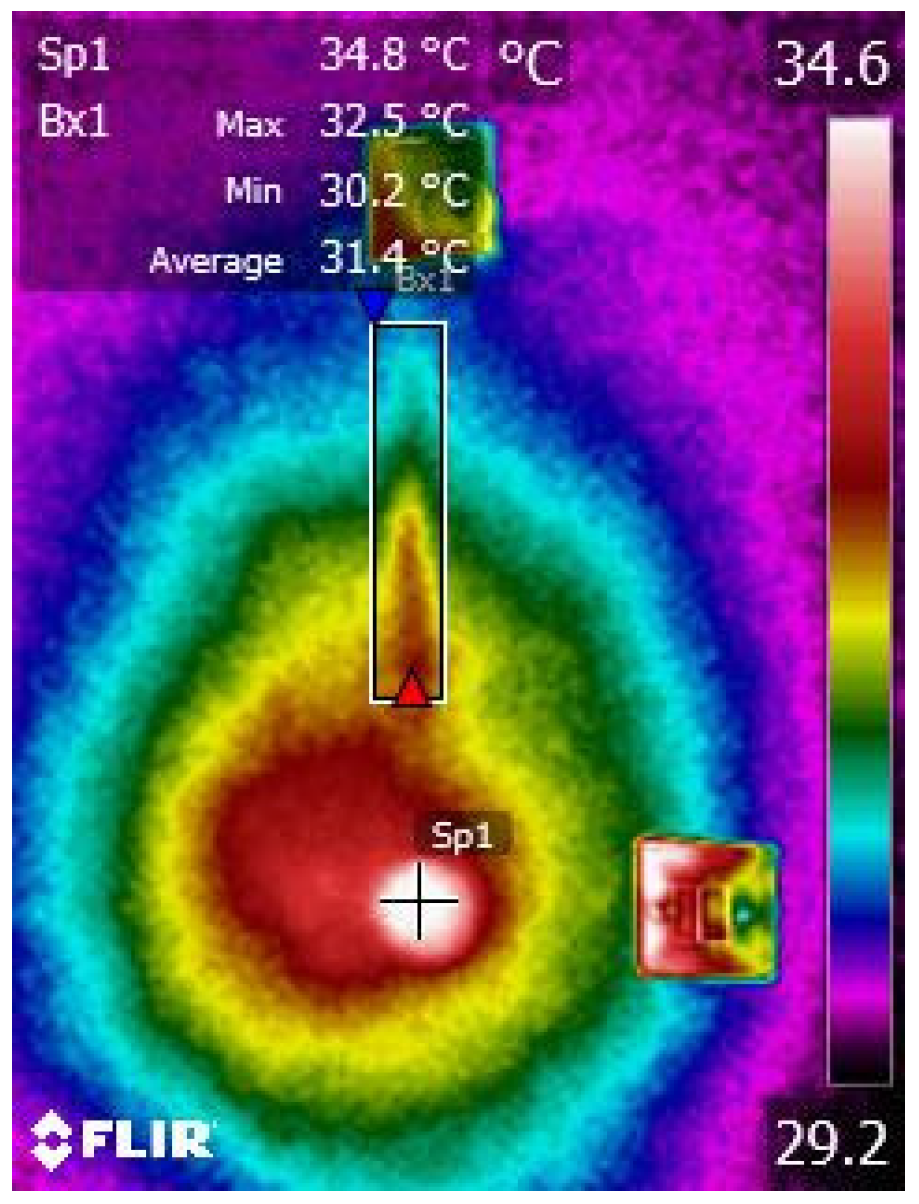

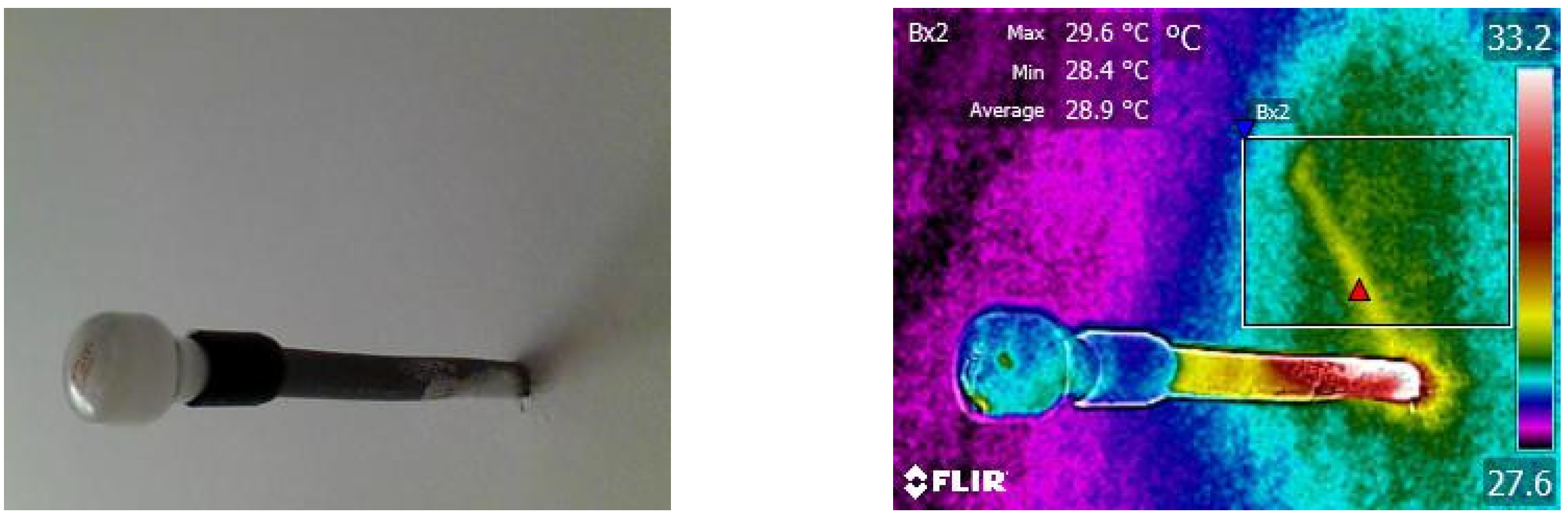

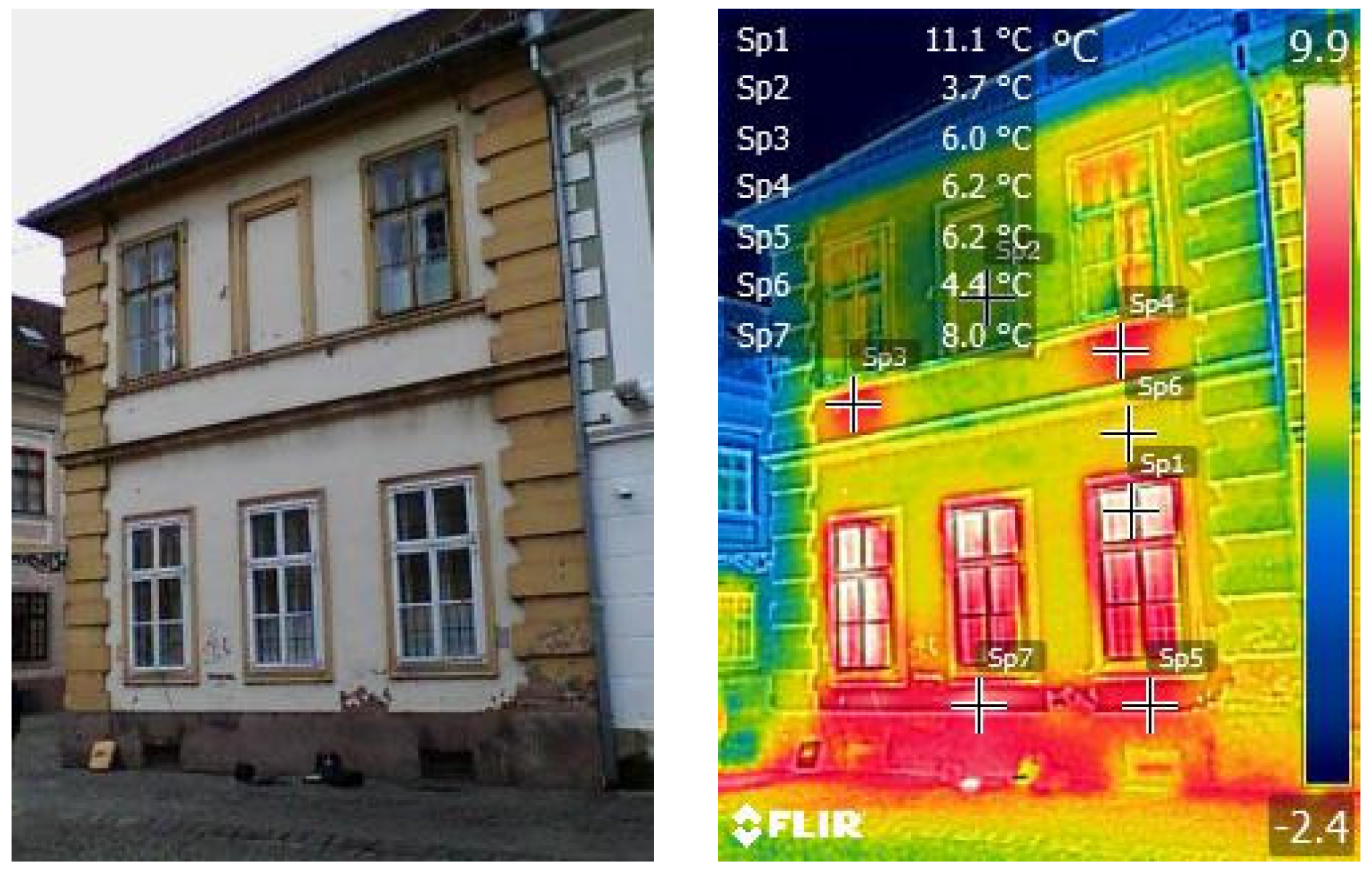

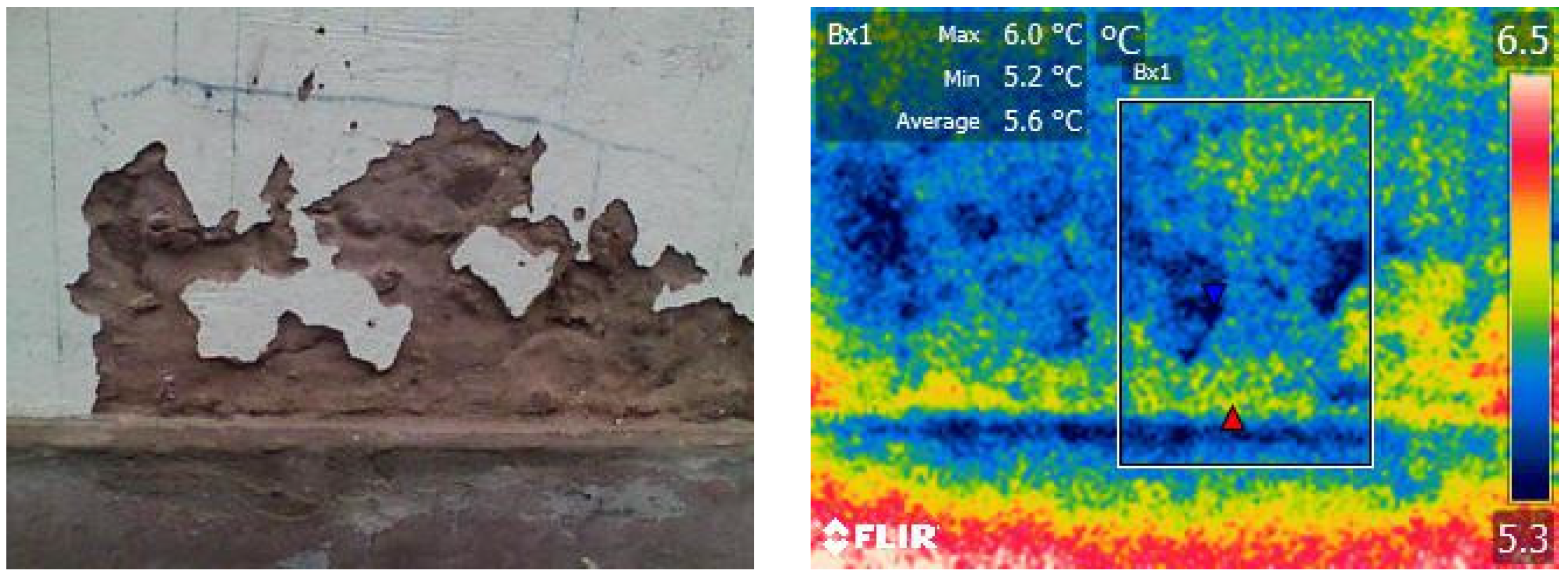

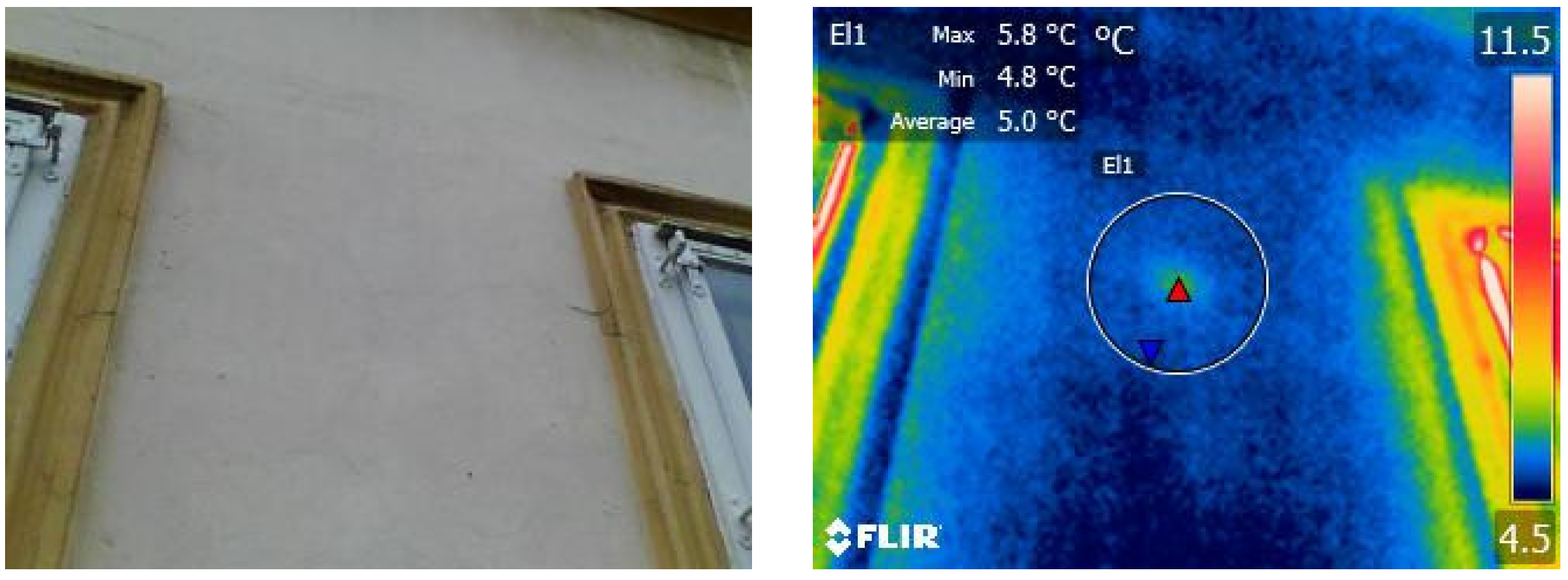

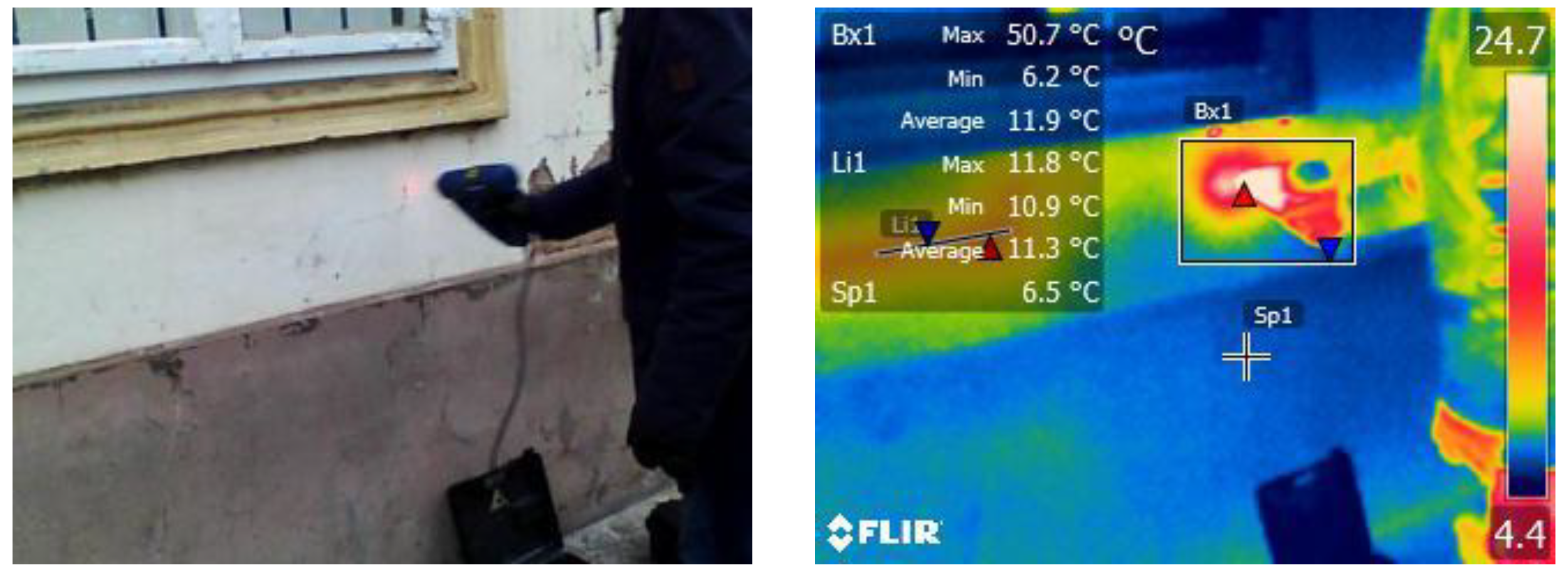

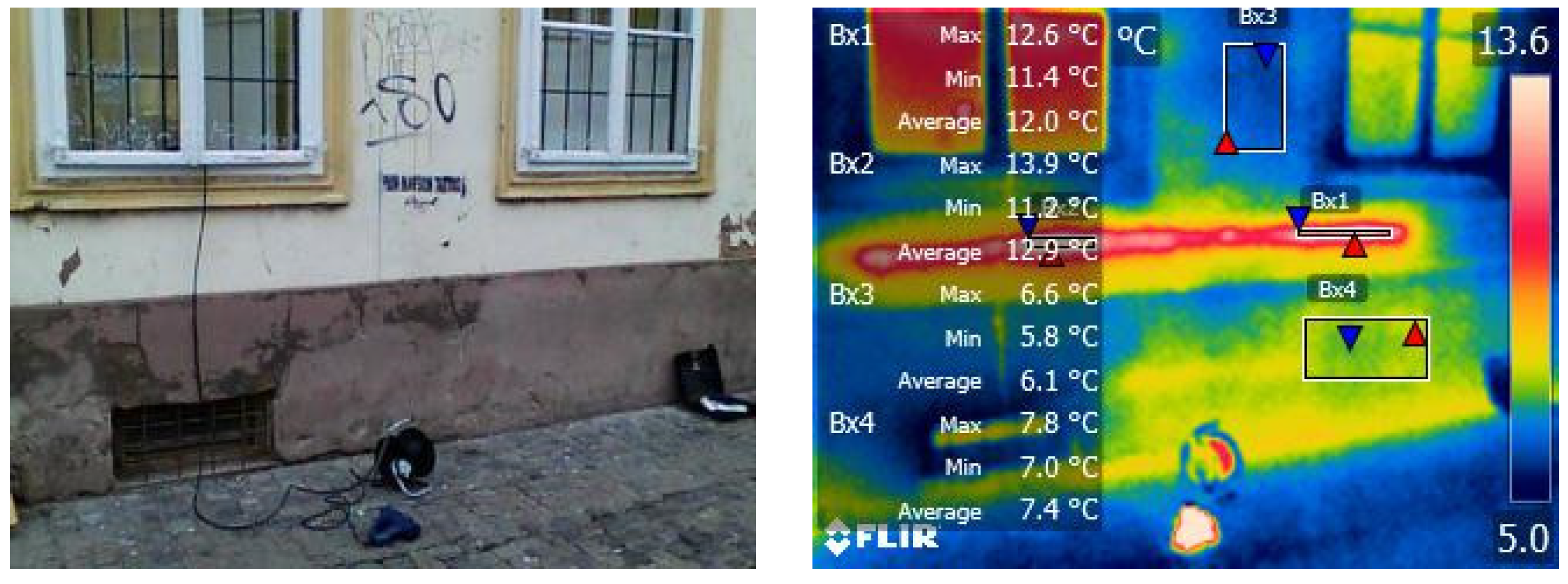

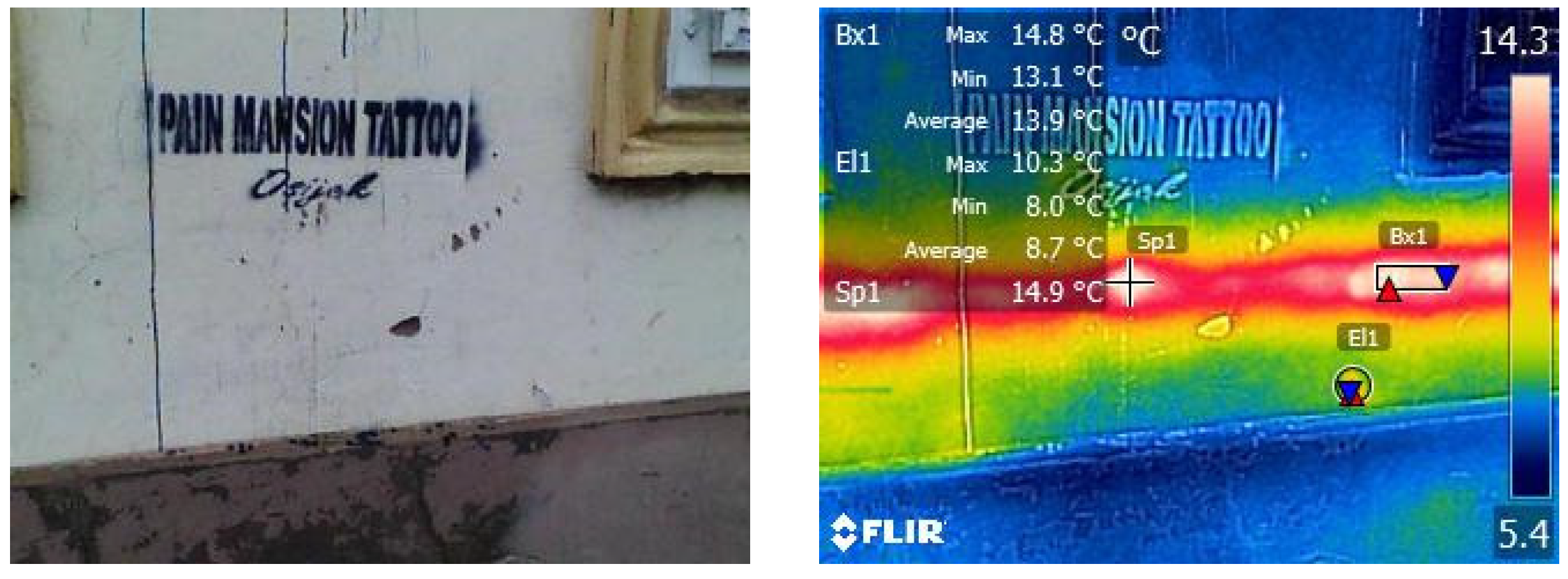

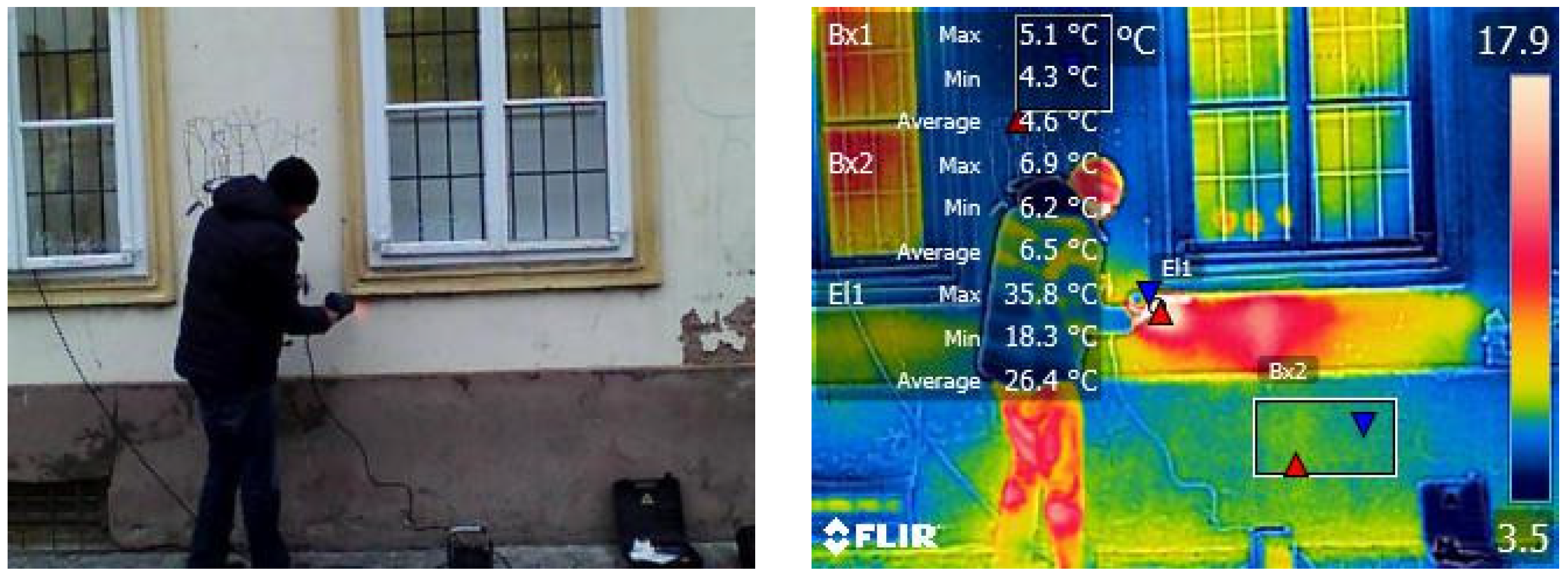

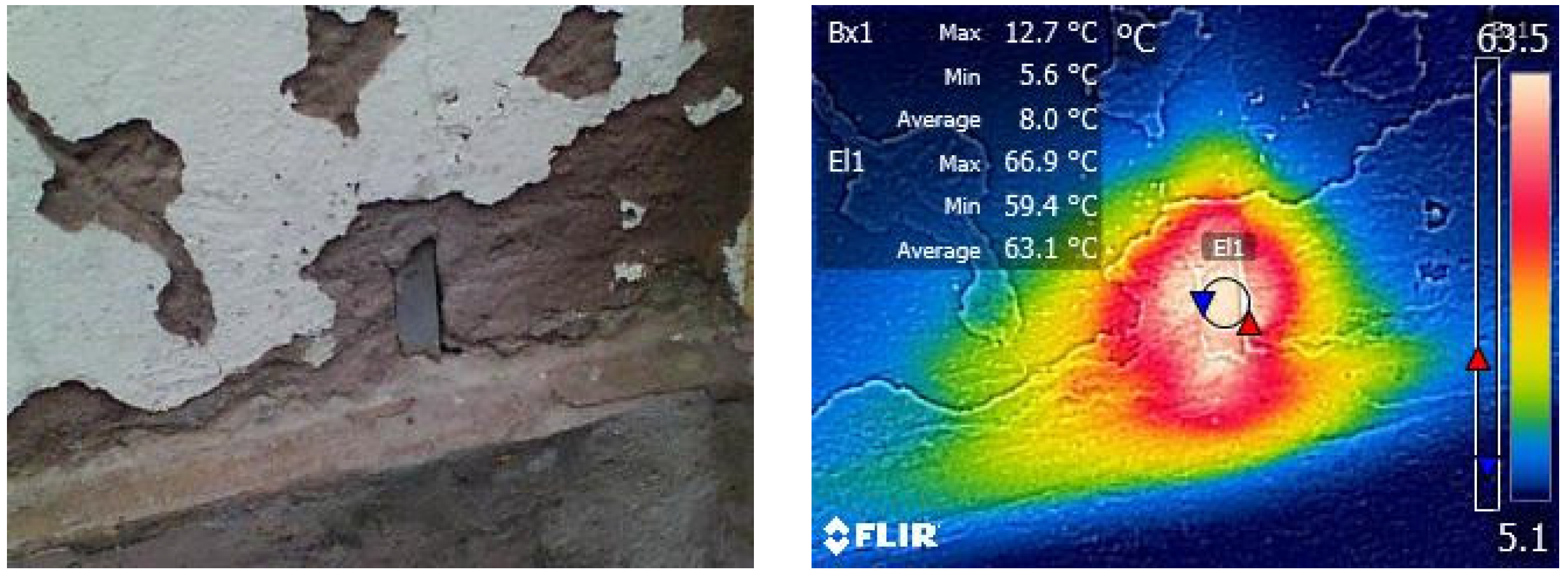

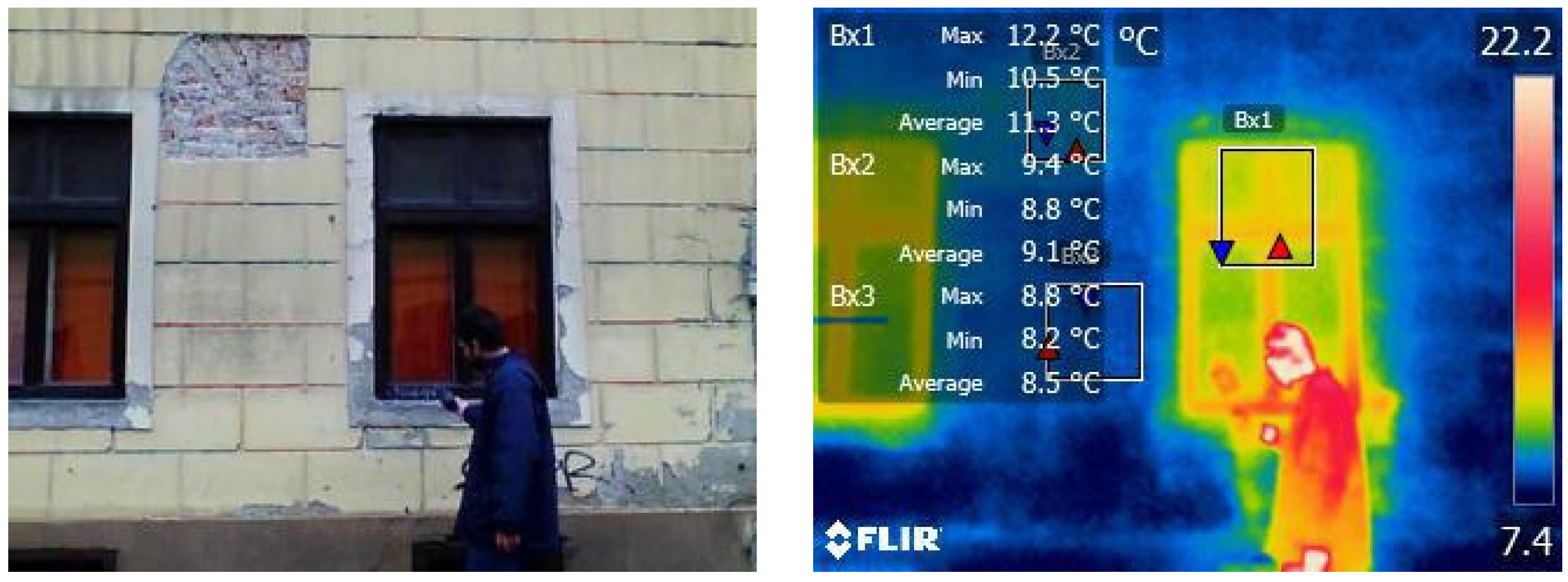

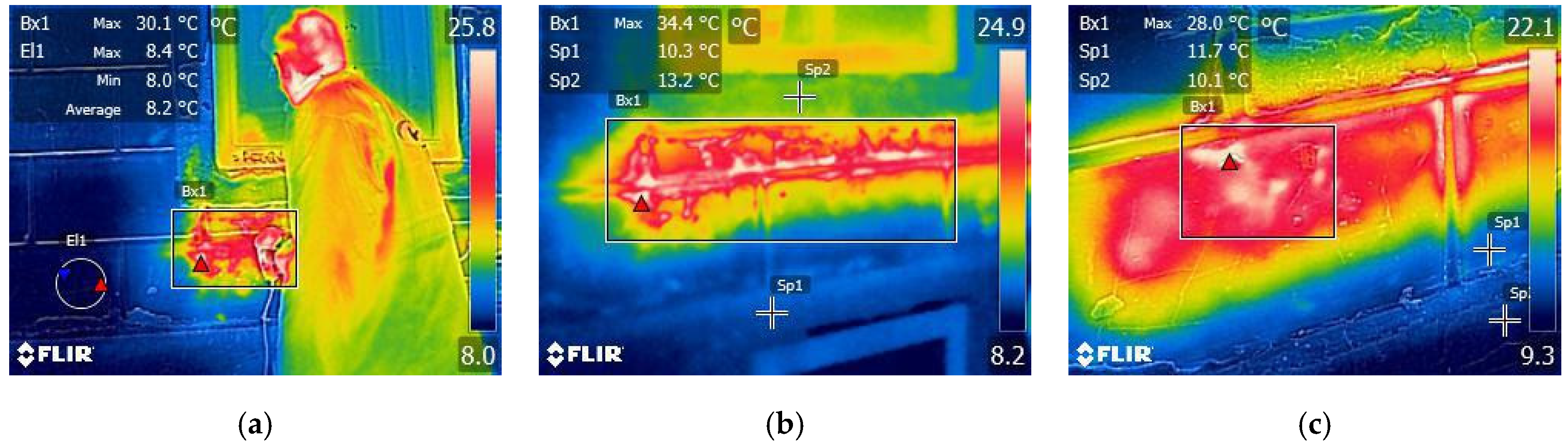

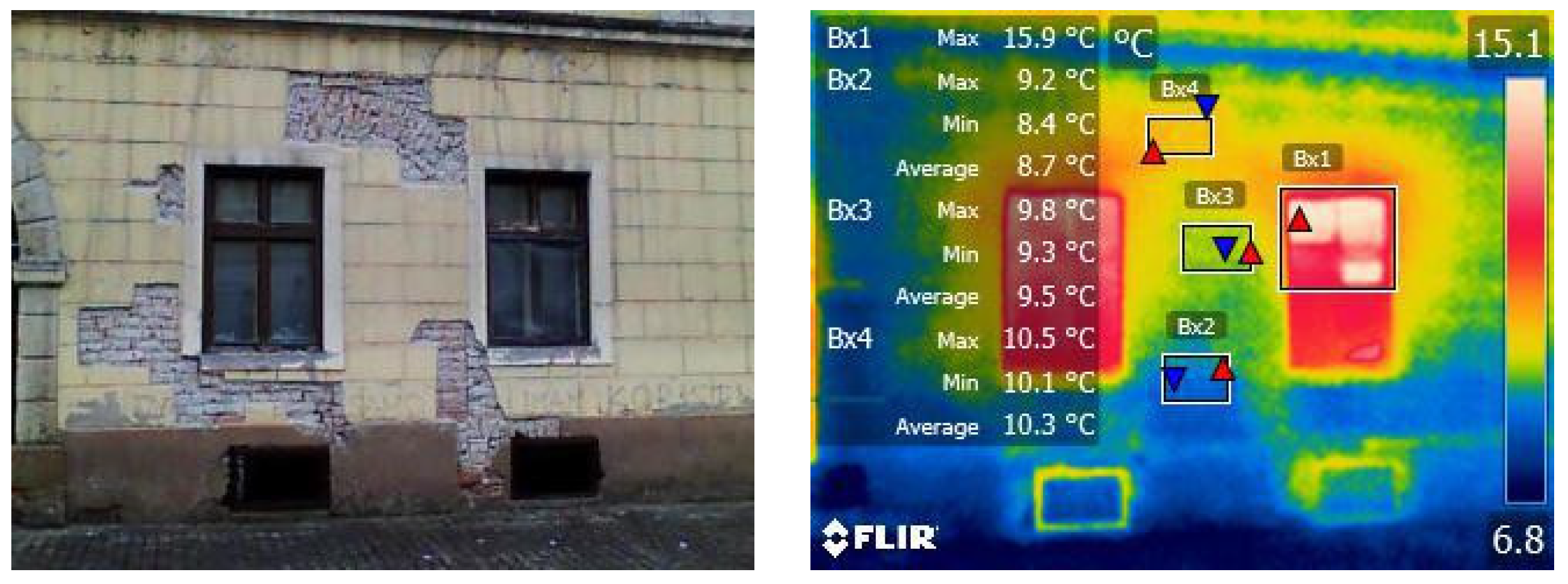

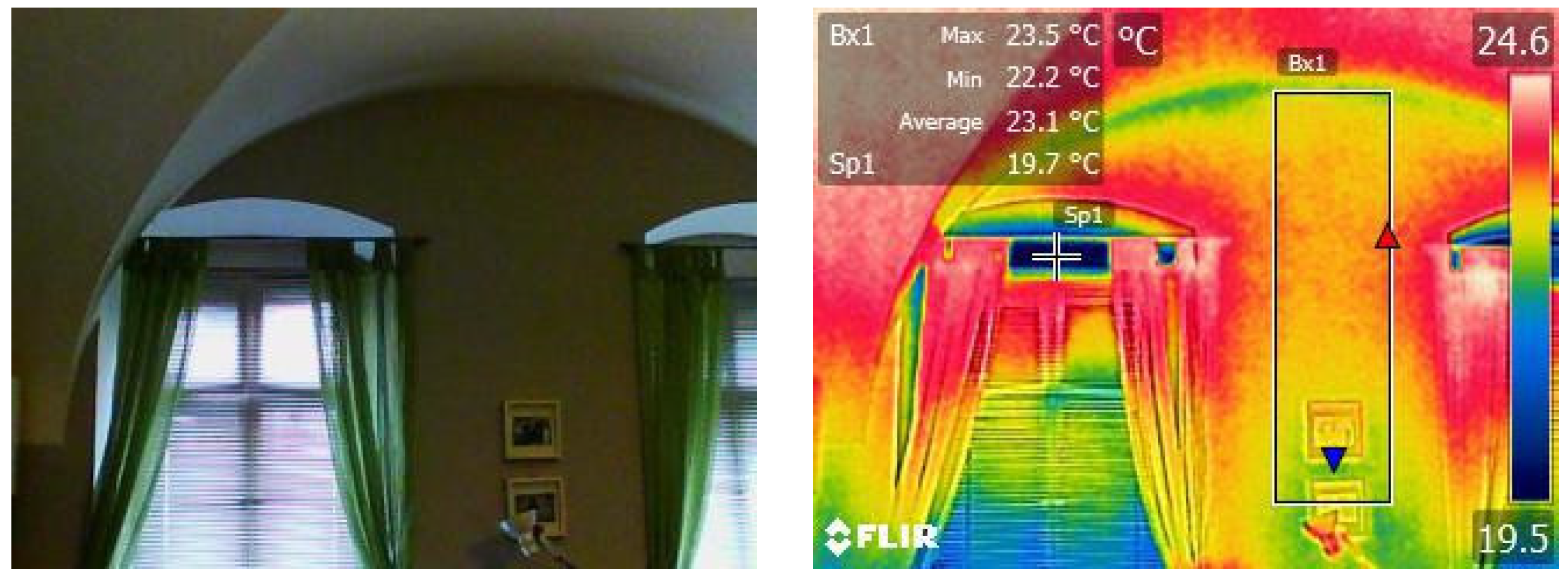

Thermographic Analysis of Kostić Houses

6. Further Investigations

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hadzima-Nyarko, M.; Mišetić, V.; Morić, D. Seismic vulnerability assessment of an old historical masonry building in Osijek, Croatia, using Damage Index. J. Cult. Herit. 2017, 28, 140–150. [Google Scholar] [CrossRef]

- Hadzima-Nyarko, M.; Morić, D.; Pavić, G.; Mišetić, V. Spectral Functions of Damage Index (DI) for Masonry Buildings with Flexible Floors. Tehnički vjesnik 2018, 25, 181–187. [Google Scholar] [CrossRef]

- Horvat-Levaj, K.; Vareško, G.; Vučetić, R. Conservation Study with Guidelines for Restoration of House on Franjo Kuhač Street 23 in Osijek Tvrđa. Institute of Art History: Zagreb, Croatia, 2017. Available online: http://bib.irb.hr/prikazi-rad?rad=921557 (accessed on 15 August 2018).

- Ismail, M.P. Selection of suitable NDT methods for building inspection. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012085. [Google Scholar] [CrossRef]

- He, Y.; Gao, B.; Sophian, A.; Yang, R. Transient Electromagnetic-Thermal Nondestructive Testing; Elsevier: Oxford, UK, 2017; ISBN 9780128128367. [Google Scholar]

- Hoła, J.; Bień, J.; Sadowski, Ł.; Schabowicz, K. Non-destructive and semi-destructive diagnostics of concrete structures in assessment of their durability. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 87–96. [Google Scholar] [CrossRef]

- Kamoi, A.; Okamoto, Y.; Vavilov, V. Study on Detection Limit of Buried Defects in Concrete Structures by Using Infrared Thermography. Key Eng. Mater. 2004, 270–273, 1549–1555. [Google Scholar] [CrossRef]

- Diersch, N.; Kind, T.; Taffe, A.; Kurz, J. Untersuchung vorgespannter Brückenplatten unter Verkehr mit zerstörungsfreien Prüfverfahren. Beton- Stahlbetonbau 2014, 109, 444–452. [Google Scholar] [CrossRef]

- Kilic, G. Using advanced NDT for historic buildings: Towards an integrated multidisciplinary health assessment strategy. J. Cult. Herit. 2015, 16, 526–535. [Google Scholar] [CrossRef]

- Imposa, S. Infrared thermography and Georadar techniques applied to the “Sala delle Nicchie” (Niches Hall) of Palazzo Pitti, Florence (Italy). J. Cult. Herit. 2010, 11, 259–264. [Google Scholar] [CrossRef]

- Tuckwell, G.W. NDT of historic buildings using GPR. Insight-Non-Destr. Test. Cond. Monit. 2005, 47, 491–493. [Google Scholar] [CrossRef]

- Capozzoli, L.; Rizzo, E. Combined NDT techniques in civil engineering applications: Laboratory and real test. Constr. Build. Mater. 2017, 154, 1139–1150. [Google Scholar] [CrossRef]

- Corsi, C. New frontiers for infrared. Opto-Electron. Rev. 2015, 23, 1–23. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Moropoulou, A. Applications of infrared thermography for the investigation of historic structures. J. Cult. Herit. 2004, 5, 119–127. [Google Scholar] [CrossRef]

- Grinzato, E. IR Thermography Applied to the Cultural Heritage Conservation. In Proceedings of the 18th World Conference on Nondestructive Testing, Durban, South Africa, 16–20 April 2012. [Google Scholar]

- Sadowski, Ł.; Mathia, T.G. Multi-scale metrology of concrete surface morphology: Fundamentals and specificity. Constr. Build. Mater. 2016, 113, 613–621. [Google Scholar] [CrossRef]

- Paoletti, D.; Ambrosini, D.; Sfarra, S.; Bisegna, F. Preventive thermographic diagnosis of historical buildings for consolidation. J. Cult. Herit. 2013, 14, 116–121. [Google Scholar] [CrossRef]

- Sadowski, Ł. Methodology for Assessing the Probability of Corrosion in Concrete Structures on the Basis of Half-Cell Potential and Concrete Resistivity Measurements. Sci. World J. 2013, Article ID 714501. [Google Scholar] [CrossRef] [PubMed]

- Kwan, A.K.H.; Ng, P.L. Building Diagnostic Techniques and Building Diagnosis: The Way Forward. In Engineering Asset Management—Systems, Professional Practices and Certification; Tse, P., Mathew, J., Wong, K., Lam, R., Ko, C.N., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2015; pp. 849–862. [Google Scholar] [CrossRef]

- Tejedor, B.; Casals, M.; Gangolells, M.; Roca, X. Quantitative internal infrared thermography for determining in-situ thermal behaviour of facades. Energy Build. 2017, 151, 187–197. [Google Scholar] [CrossRef]

- Gonçalves, L.M.S.; Rodrigues, H.; Gaspar, F. Nondestructive Techniques for the Assessment and Preservation of Historic Structures; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2018; ISBN 978-1-138-7104-4. [Google Scholar]

- Ibarra-Castanedo, C.; Genest, M.; Piau, J.-M.; Guibert, S.; Bendada, A.; Maldague, X.P.V. Active Infrared Thermography Techniques for the Nondestructive Testing of Materials. Ultrason. Adv. Methods Nondestruct. Test. Mater. Charact. 2007, 325–348. [Google Scholar] [CrossRef]

- Sfarra, S.; Cicone, A.; Yousefi, B.; Ibarra-Castanedo, C.; Perilli, S.; Maldague, X. Improving the detection of thermal bridges in buildings via on-site infrared thermography: The potentialities of innovative mathematical tools. Energy Build. 2019, 182, 159–171. [Google Scholar] [CrossRef]

- Laureti, S.; Silipigni, G.; Senni, L.; Tomasello, R.; Burrascano, P.; Ricci, M. Comparative study between linear and non-linear frequency-modulated pulse-compression thermography. Appl. Opt. 2018, 57, D32–D39. [Google Scholar] [CrossRef]

- Feilden, B.M. Conservation of Historic Buildings, 3rd ed.; Architectural Press, Elsevier: New York, NY, USA, 2003. [Google Scholar]

- Sršan, S. Zemljišna knjiga grada Osijeka (Tvrđa) 1687–1821. godine, Osijek. 1995. [Google Scholar]

- Tomerlin, G. Plan Litt. D von den zu verkaufen komenden Bürgerlichen sogenandten Costiczischen Haus in der Festung Esseg, Essegg. 1774. [Google Scholar]

- Dietrich, U. Urban Street Canyons–Impact of Different Materials and Colours of Facades and Ground and Different Positions of Persons on Outdoor Thermal Comfort. Int. J. Sus. Dev. Plann. 2018, 13, 582–593. [Google Scholar] [CrossRef]

- FLIR Systems AB, ThermaCAM PM695 Operator’s Manual, Emissivity tables, Publ. No. 1 557 454–Rev. B; FLIR Systems: Wilsonville, OR, USA, 2001.

- Cupa, A.; Felczak, M.; Kurkiewicz, T.; Lament, A.; Rogal, R.; Rogóz, J.; Szroeder, P.; Więcek, B. Thermovision and ground penetrating radar for investigation of architectural decorations–potential and limitations. In Proceedings of the 11th International Conference on Quantitative InfraRed Thermography (QIRT 2012), Naples, Italy, 11–14 June 2012. [Google Scholar]

- Grinzato, E.; Bison, P.G.; Marinetti, S. Monitoring of ancient buildings by the thermal method. J. Cult. Herit. 2002, 3, 21–29. [Google Scholar] [CrossRef]

- Johnston, B.; Ruffell, A.; McKinley, J.; Warke, P. Detecting voids within a historical building facade: A comparative study of three high frequency GPR antenna. J. Cult. Herit. 2018, 32, 117–123. [Google Scholar] [CrossRef]

| Items | Strength | Elastic modulus | Thickness | Crack depth | Crack width | Crack distribution | Crack development | Honeycombing - voids | Lamination | Bar location | Bar size | Bar corrosion | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NDT methods | |||||||||||||

| Rebound hammer | ● | ||||||||||||

| Penetration resistance | ● | ||||||||||||

| Pull-out | ● | ||||||||||||

| Ultrasonic | ● | ● | ● | ● | ● | ● | ● | ||||||

| Radar | ● | ● | ● | ||||||||||

| Thermography | ● | ● | ● | ||||||||||

| Radiography | ● | ● | ● | ● | ● | ||||||||

| Acoustic emission | ● | ||||||||||||

| Magnetic or eddy current | ● | ● | ● | ||||||||||

| Half-cell potential | ● | ||||||||||||

| Photography | ● | ● | |||||||||||

| Material | Density (kg m−3) | Specific Heat (J kg−1 K−1) | Thermal Conductivity (W m−1 K−1) | Thermal Diffusivity (×10−9 m2 s−1) | Thermal Effusivity (Ws0.5 m2 K−1) | Emissivity (λ = 8–12 μm) |

|---|---|---|---|---|---|---|

| Limestone | 2600 | 920 | 2.1 | 877.92 | 2241.25 | 0.93 |

| Plaster | 1440 | 800 | 0.5 | 434.03 | 758.95 | 0.91 |

| White marble | 2695 | 870 | 3.14 | 1339.22 | 2713.33 | 0.95 |

| Grey marble | 2650 | 870 | 6.7 | 2906.09 | 3930.25 | 0.95 |

| Cement marble | 3100 | 840 | 0.85 | 326.42 | 1487.75 | 0.86 |

| Concrete | 2400 | 1008 | 1.65 | 682.04 | 1997.92 | 0.94 |

| Red brick | 2025 | 800 | 0.6 | 370.37 | 985.90 | 0.90 |

| Air | 1.16 | 1007 | 0.026 | 22257.98 | 5.51 | - |

| Water | 1000 | 4193 | 0.586 | 139.76 | 1567.51 | 0.96 |

| Brick: Common | 0.81–0.86 |

|---|---|

| Brick: common, red | 0.93 |

| Concrete | 0.92 |

| Concrete: dry | 0.95 |

| Concrete: rough | 0.92–0.97 |

| Mortar | 0.87 |

| Mortar: dry | 0.94 |

| Plaster | 0.86–0.90 |

| Plaster: rough coat | 0.91 |

| Heading | Max. Value °C | Min. Value °C | Average °C |

|---|---|---|---|

| Wall | 5.5 | 4.9 | 5.2 |

| Wall parapet | 6.7 | 6.1 | 6.5 |

| Window | 8.5 | 6.7 | 7.7 |

| Heated area | 14.4 | 11.8 | 13.3 |

| Heading | Max. Value °C | Min. Value °C | Average °C |

|---|---|---|---|

| Wall outside | 9.6 | 9.0 | 9.2 |

| Wall inside | 22.3 | 21.5 | 21.6 |

| Window | 12.7 | 11.5 | 12.0 |

| Heated area | 27.9 | 14.1 | 18.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glavaš, H.; Hadzima-Nyarko, M.; Haničar Buljan, I.; Barić, T. Locating Hidden Elements in Walls of Cultural Heritage Buildings by Using Infrared Thermography. Buildings 2019, 9, 32. https://doi.org/10.3390/buildings9020032

Glavaš H, Hadzima-Nyarko M, Haničar Buljan I, Barić T. Locating Hidden Elements in Walls of Cultural Heritage Buildings by Using Infrared Thermography. Buildings. 2019; 9(2):32. https://doi.org/10.3390/buildings9020032

Chicago/Turabian StyleGlavaš, Hrvoje, Marijana Hadzima-Nyarko, Ivana Haničar Buljan, and Tomislav Barić. 2019. "Locating Hidden Elements in Walls of Cultural Heritage Buildings by Using Infrared Thermography" Buildings 9, no. 2: 32. https://doi.org/10.3390/buildings9020032

APA StyleGlavaš, H., Hadzima-Nyarko, M., Haničar Buljan, I., & Barić, T. (2019). Locating Hidden Elements in Walls of Cultural Heritage Buildings by Using Infrared Thermography. Buildings, 9(2), 32. https://doi.org/10.3390/buildings9020032