Design for Deconstruction in the Design Process: State of the Art

Abstract

1. Introduction

2. Method

2.1. Scientific Article Review

- -

- Search 1: Keywords: “design for deconstruction” and building in academic journals.

- -

- Search 2: Keywords: “design for disassembly” and building in academic journals.

2.2. Professional Guidelines and Common Practice Review

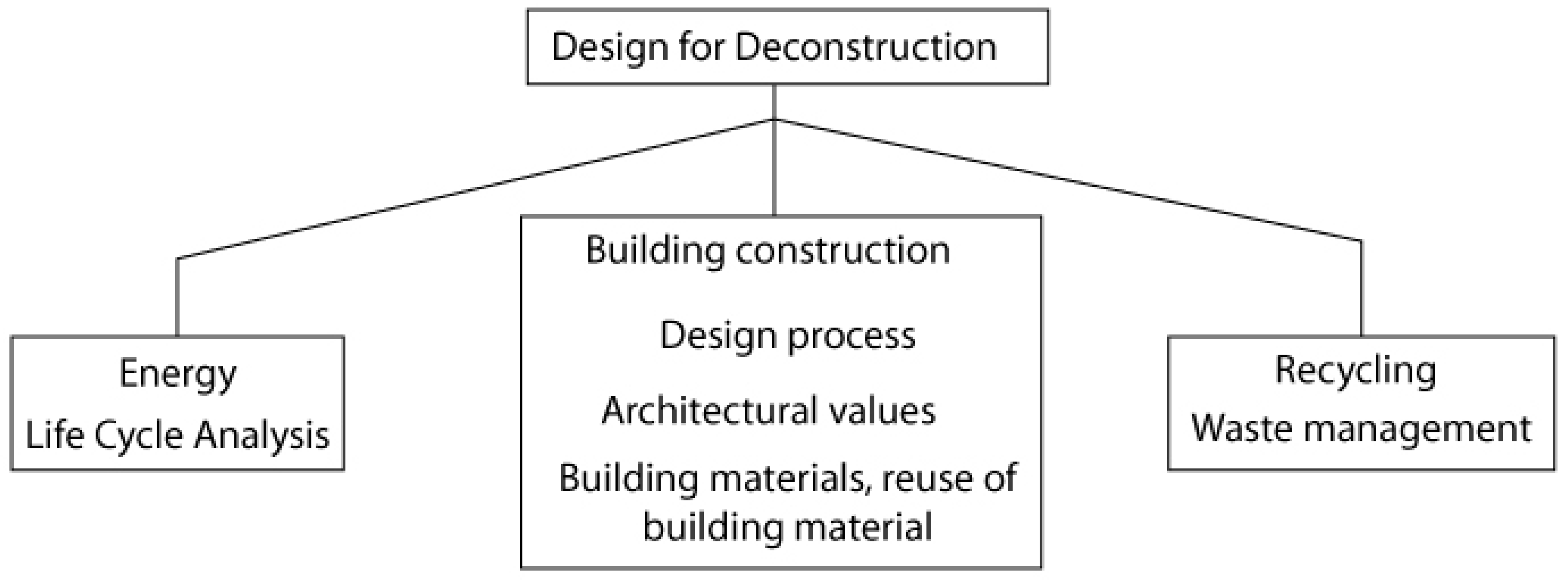

3. Results

- General design and construction principles

- Specific materials’ potential for DfD

- DfD throughout the design process

- Tools for DfD

- Existing building stock potential

- Barriers and drivers for DfD

3.1. General Design and Construction Principles

3.2. Specific Material Potential for DfD

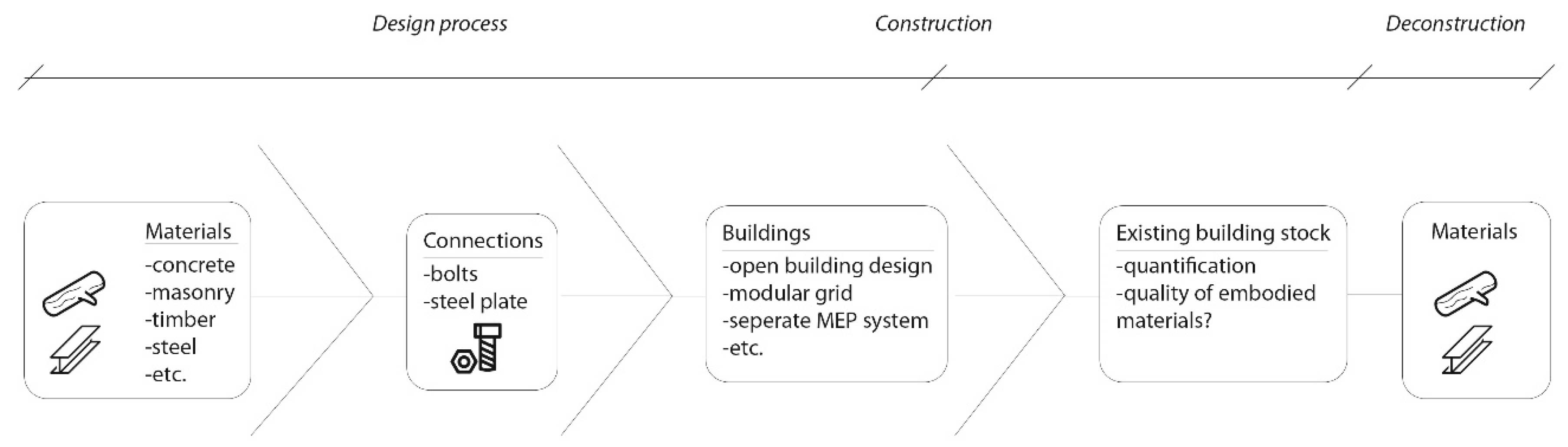

3.3. DfD Throughout the Design Proces

- The predesign phase, where interior elements, service system, and structure can be designed in such a way that future modifications are possible. It is also important that the involved key players are flexible: A fixed brief, for example, will limit the building’s future use, while working with scenarios might open up for solutions that will prolong the building’s life.

- In the concept design phase, the designer together with contractor meets with vendors to identify reused materials which support DfD.

- In the schematic design, the first design is checked by producing a plan to deconstruct the building.

- In the design development phase, a detailed plan for the deconstruction of the building is carried out.

- In the construction documents, it should be insured that details do not compromise their DfD integrity. Further, bid documents should reflect the commitment to a DfD construction.

- For the construction administration, as set of ‘as-built’ documents should be created.

- The facility operation services should brief all maintenance staff on the DfD strategy of the building.

- (a)

- A statement of the chosen strategy for DfD related to the building;

- (b)

- A list of building elements, normally embedded in ‘as-built’ drawings. In the future, Radio Frequency ID (RFID) identification tags could take over the drawings;

- (c)

- Instructions on how to deconstruct elements;

- (d)

- Distribution of DfD plans.

3.4. Tools for DfD

3.5. Existing Building Stock Potential for DfD

3.6. Barriers and Drivers for DfD

- ◾

- Lack of technical knowledge and supporting tools;

- ◾

- Belief that end-of-life may not occur for a long period;

- ◾

- Value of building materials and components of EoL is not guaranteed.

- ◾

- Uncertainty of the quantity and quality of the used material;

- ◾

- Lack of rules and standards related to the construction with such materials;

- ◾

- Components might get damaged on-site during deconstruction;

- ◾

- Common negative perception by the end user of reused materials;

- ◾

- Designer and constructors conceive their design to be permanent;

- ◾

- Time constraints due to the fact that disassembly might take significantly more time than mechanical demolition;

- ◾

- Costs constraints due to the perception that deconstruction costs more than demolition and disposal, which is not always true;

- ◾

- Contract constraints that could make reuse less feasible;

- ◾

- Lack of involvement to minimise waste amongst manufacturers;

- ◾

- Lack of accounting methods for the measuring the benefits of DfD.

4. Discussion

4.1. Environmental Benefits

4.2. Financial Benefits

4.3. The Effect on Architecture and the Design Process

4.4. (De-)Construction

4.5. Temporary Structures as Testbed for Design for Deconstruction

5. Conclusions

Future Research

Funding

Acknowledgments

Conflicts of Interest

References

- Swedish Energy Agency. Energiläget 2017; Swedish Energy Agency: Stockholm, Sweden, 2017. [Google Scholar]

- Liljenström, C.; Malmqvist, T.; Erlandsson, M.; Fredén, J.; Adolfsson, I.; Adolfsson, I. Byggproduktionens miljöpåverkan i förhållande till driften Livscykelberäkning av klimatpåverkan och energianvändning av ett nyproducerat flerbostadshus i betong med lågenergiprofil Byggproduktionens miljöpåverkan i förhållande till driften Livscykelberäkn; KTH: Stockholm, Sweden, 2014. [Google Scholar]

- Hradil, P. Barriers and Opportunities of Structural Elements Re-Use; European Commission: Brussels, Belgium; Luxembourg, 2012. [Google Scholar]

- Swedish Environmental Protection Agency. Avfall i Sverige 2016; Swedish Environmental Protection Agency: Stockholm, Sweden, 2018.

- Akinade, O.O.; Oyedele, L.O.; Ajayi, S.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A.; Bello, S.A.; Jaiyeoba, B.E.; Kadiri, K.O. Design for Deconstruction (DfD): Critical success factors for diverting end-of-life waste from landfills. Waste Manag. 2017, 60, 3–13. [Google Scholar] [CrossRef] [PubMed]

- Densley Tingley, D. Design for Deconstruction: An Appraisal; University of Sheffield: Sheffield, UK, 2012. [Google Scholar]

- Rios, F.C.; Chong, W.K.; Grau, D. Design for Disassembly and Deconstruction—Challenges and Opportunities. Procedia Eng. 2015, 118, 1296–1304. [Google Scholar] [CrossRef]

- Prouvé, J.; Cinqualbre, O. Jean Prouvé: La Maison Tropicale = The Tropical House; Centre Pompidou: Paris, France, 2009. [Google Scholar]

- Dean, A.O.; Hursley, T. Rural Studio: Samuel Mockbee and An Architecture of Decency; Princeton Architectural Press: New York, NY, USA, 2002. [Google Scholar]

- Ellen Macarthur Foundation. Growth Within: A Circular Economy Vision for a Competitive Europe; Ellen Macarthur Foundation: Cowes, UK, 2015. [Google Scholar]

- European Parliament and European Council. Directive on Waste; European Union: Brussels, Belgium, 2008. [Google Scholar]

- Chini, A.; Schultmann, F. Design for Deconstruction and Materials Reuse; CIB World: Karlsruhe, Germany, 2002. [Google Scholar]

- Sanchez, B.; Haas, C. Capital project planning for a circular economy. Constr. Manag. Econ. 2018, 36, 303–312. [Google Scholar] [CrossRef]

- Durmisevic, E.; Yeang, K. Designing for Disassembly (DfD). Archit. Des. 2009, 79, 134–137. [Google Scholar] [CrossRef]

- I. EBSCO Industries, “LUBsearch,” 2018. Available online: https://www.lub.lu.se/sok/lubsearch (accessed on 3 November 2018).

- Crowther, P. Design for Disassembly—Themes and Principles; RAIA/BDP Environment Design Guide; The Royal Australian Institute of Architects: Queentown, Australia, 2005. [Google Scholar]

- Guldager Jensen, K.; Sommer, J. Building a Circular Future; 3XN: Copenhagen, Denmark, 2016. [Google Scholar]

- Guy, B.; Ciarimboli, N. Design for Disassembly in the Built Environment: A Guide to Closed-Loop Design and Building; Pennsylvania State University: University Park, PA, USA, 2006. [Google Scholar]

- Sassi, P. Defining closed-loop material cycle construction. Build. Res. Inf. 2008, 36, 509–519. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C. Design issues of using prefabrication in Hong Kong building construction. Constr. Manag. Econ. 2010, 28, 1025–1042. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P.; Lim, M.K. The use of smart technologies in enabling construction components reuse: A viable method or a problem creating solution? J. Environ. Manag. 2018, 216, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Kibert, C.J. Sustainable Construction: Green Building Design and Delivery; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- National Building Specification. National BIM Report 2017; RIBA Enterprise: Newcastle, UK, 2017. [Google Scholar]

- Czmoch, I.; Pękala, A. Traditional Design versus BIM Based Design. Procedia Eng. 2014, 91, 210–215. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Bilal, M.; Ajayi, S.O.; Owolabi, H.A.; Alaka, H.A.; Bello, S.A. Waste minimisation through deconstruction: A BIM based Deconstructability Assessment Score (BIM-DAS). Resour. Conserv. Recycl. 2015, 105, 167–176. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Omoteso, K.; Ajayi, S.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Ayris, L.; Looney, J.H. BIM-based deconstruction tool: Towards essential functionalities. Int. J. Sustain. Built Environ. 2017, 6, 60–271. [Google Scholar] [CrossRef]

- Miatto, A.; Schandl, H.; Tanikawa, H. How important are realistic building lifespan assumptions for material stock and demolition waste accounts? Resour. Conserv. Recycl. 2017, 122, 143–154. [Google Scholar] [CrossRef]

- Stephan, A.; Athanassiadis, A. Quantifying and mapping embodied environmental requirements of urban building stocks. Build. Environ. 2017, 114, 187–202. [Google Scholar] [CrossRef]

- Mastrucci, A.; Marvuglia, A.; Popovici, E.; Leopold, U.; Benetto, E. Geospatial characterization of building material stocks for the life cycle assessment of end-of-life scenarios at the urban scale. Resour. Conserv. Recycl. 2017, 123, 54–66. [Google Scholar] [CrossRef]

- Swedish National Board of Housing, Building and Planning; Swedish Building Code BBR; National Board of Housing, Building and Planning: Boverket, Sweden, 2016.

- Kanters, J.; Horvat, M. The design process known as IDP: A discussion. Energy Procedia 2012, 30, 1153–1162. [Google Scholar] [CrossRef]

- Bureau SLA, “People’s Pavilion,” 2017. Available online: http://www.bureausla.nl/project/peoples-pavilion/ (accessed on 3 November 2018).

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kanters, J. Design for Deconstruction in the Design Process: State of the Art. Buildings 2018, 8, 150. https://doi.org/10.3390/buildings8110150

Kanters J. Design for Deconstruction in the Design Process: State of the Art. Buildings. 2018; 8(11):150. https://doi.org/10.3390/buildings8110150

Chicago/Turabian StyleKanters, Jouri. 2018. "Design for Deconstruction in the Design Process: State of the Art" Buildings 8, no. 11: 150. https://doi.org/10.3390/buildings8110150

APA StyleKanters, J. (2018). Design for Deconstruction in the Design Process: State of the Art. Buildings, 8(11), 150. https://doi.org/10.3390/buildings8110150