Research has been carried out to study the mechanical properties of CHS steel tubular joints. Qian et al. [

3] undertook a finite element study regarding the static strength of moment-loaded thick-walled CHS X-joints, analysed how the geometric parameters of the joints and the tensile stress of the chord affect the ultimate strength of the joints, and proposed a new function for chord stress. Zhu et al. [

4] executed axial compression tests on CHS steel tubular X-joints with external annular stiffening rings and analysed the differences in failure modes and load–displacement curves between unreinforced specimens and reinforced counterparts. It was observed that the bearing capacity of the joints fitted with stiffening rings improved remarkably. Chen et al. [

5] executed fire resistance tests on CHS steel T-joints subjected to axial compression and reinforced with internal stiffening rings. It was found that internal ring stiffening effectively boosted the fire resistance of these T-joints, and how the geometrical parameters β and γ affect the joints’ fire resistance was analysed using numerical models. Choo et al. [

6] proposed CHS steel tubular X joints with collar plate reinforcement and analysed and compared the load transfer mechanism and failure mode of these reinforced joints. On the basis of the numerical results, the static strength equation was proposed. Kurobane et al. [

7] undertook an experimental study on tubular K joints to explore the local buckling behaviour exhibited by the braces. The results revealed that the local buckling of the braces was related not only to the wall thickness of the braces but also to the stiffness properties of the joints. Lee et al. [

8] undertook a numerical study focusing on CHS steel tubular KK joints, analysed how weld shape, boundary conditions, loading mode, tube length, and material properties affect the bearing capacity, and proved the numerical model’s validity by means of comparison with experimental results. Tong et al. [

9] performed fatigue tests focusing on CHS-CFSHS T-joints. Compared to hollow CHS-SHS T-joint connectors, CHS-CFSHS T-joints were found to possess enhanced fatigue properties, and novel Srhs-N fatigue design curves for CHS-CFSHS and CHS-CFCHS T-joints were developed. Young et al. [

10] conducted a numerical study on the static bearing capacity of high-strength steels that failed by chord face plastication, and an average strength calculation formula based on the design formulae was proposed. Yin et al. [

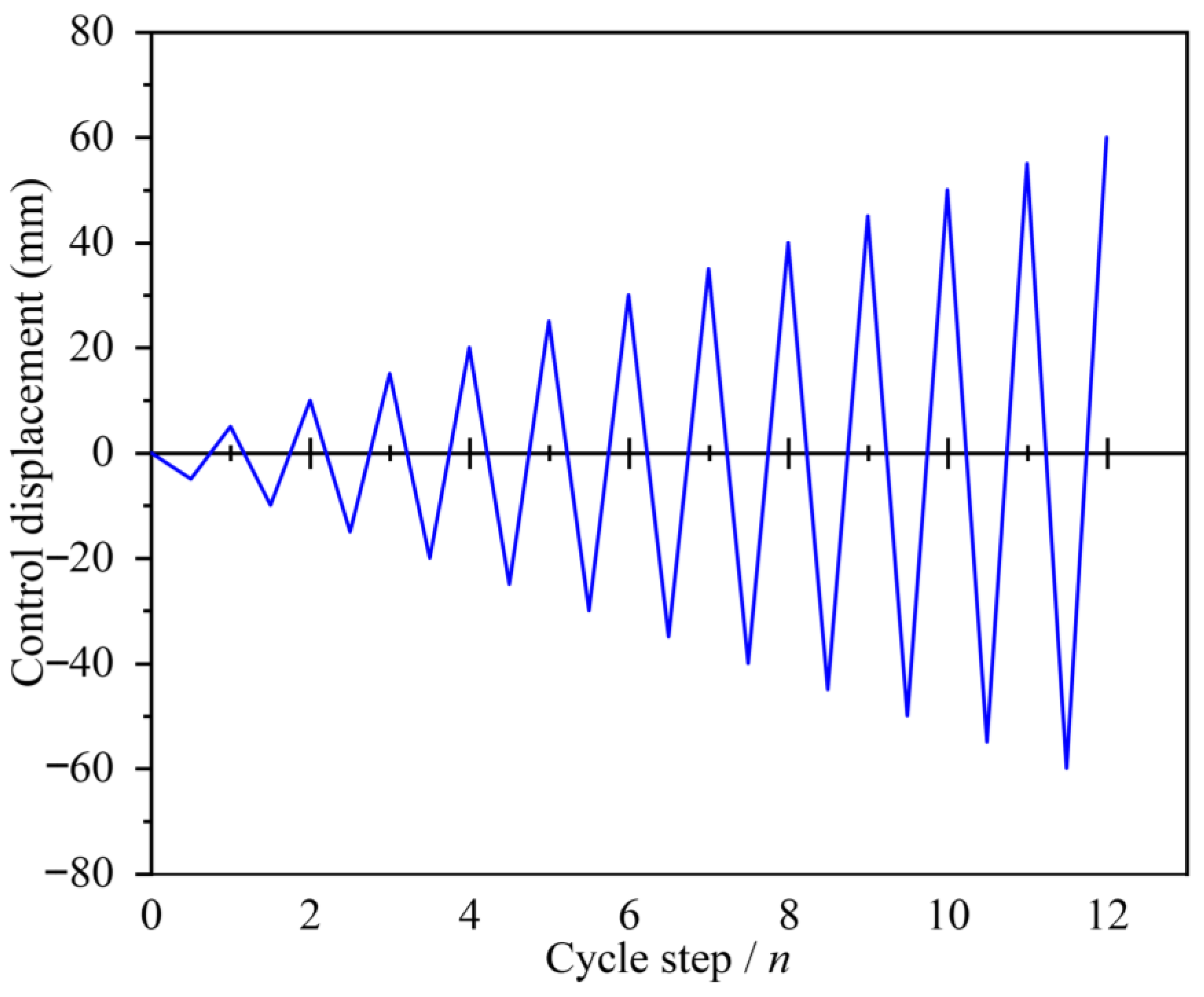

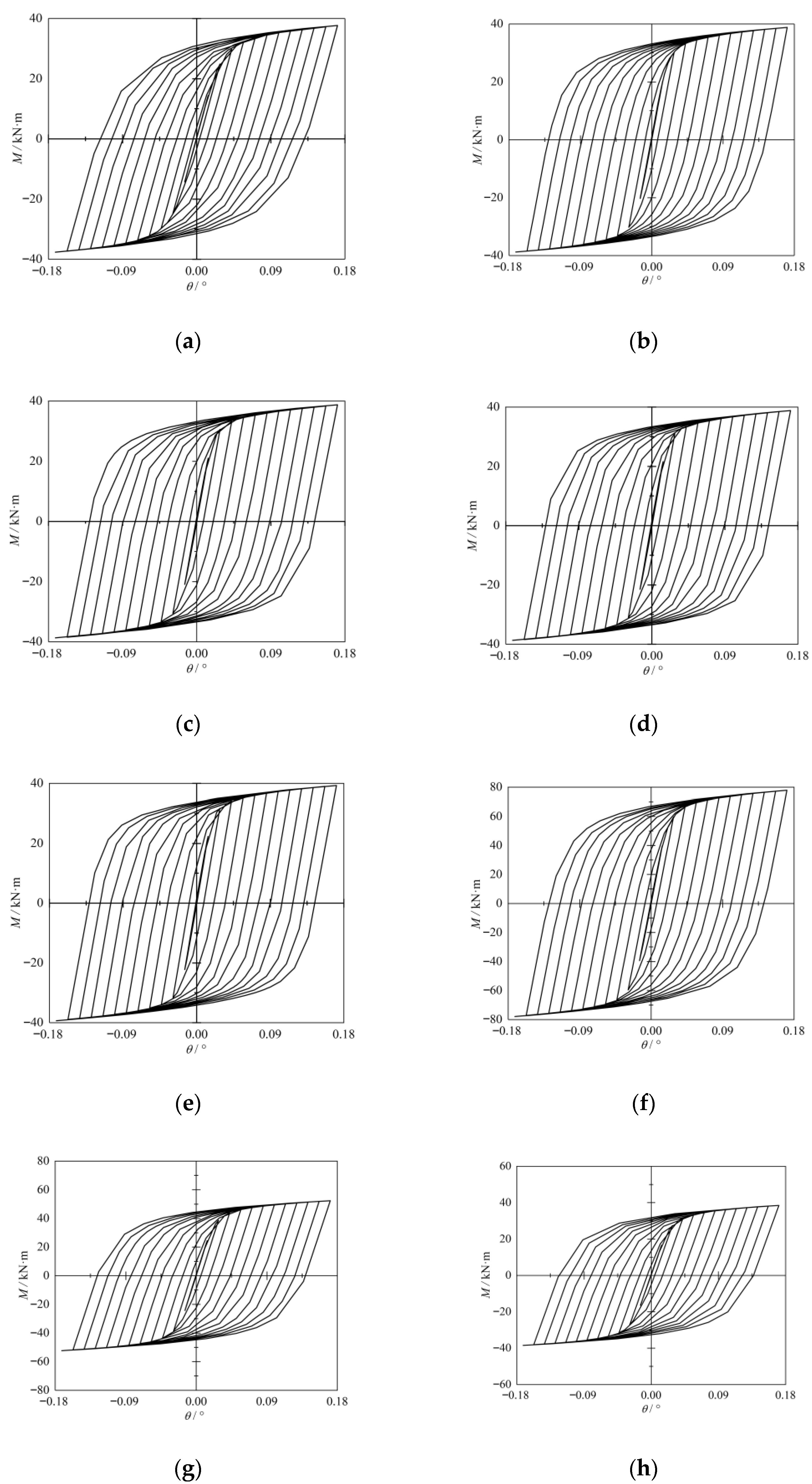

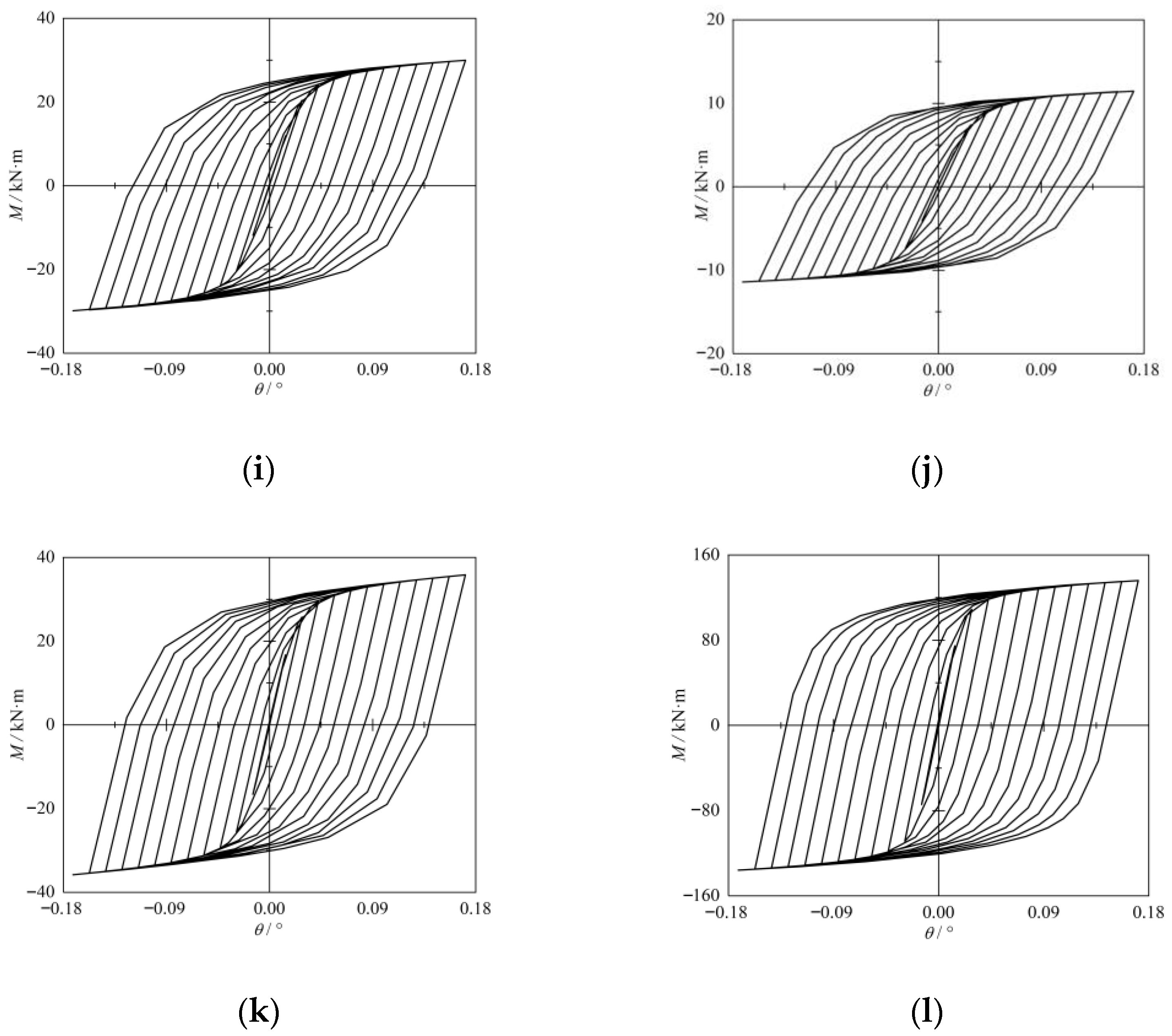

11] experimentally investigated the hysteretic behaviour of tubular N joints under quasi-static cyclic loading. Their study of four specimens included an analysis of failure modes and hysteresis loops, along with a comparative evaluation of key performance metrics: the ductility coefficient, energy dissipation capacity, and ultimate strength. Wang et al. [

12] experimentally investigated CHS T-joints under cyclic axial compression and in-plane bending to study their failure modes and energy dissipation. The results showed that energy was dissipated through plastic deformation of the chord wall under axial compression and through plastic deformation of the brace under bending. Chen et al. [

13] demonstrated that the failure modes of thick-walled CHS X-joints under out-of-plane bending are primarily governed by the brace-to-chord diameter ratio (

β) and the chord diameter-to-wall thickness ratio (

γ). Zhang et al. [

14] identified the structural performance of high-strength steel (HSS) tubular joints as a prerequisite for the safe and economical use of HSS structures. Their results further showed that increasing the welding heat input reduces both the deformation capacity and static strength of S960 joints, an effect that was less pronounced in S690 steels. Xu et al. [

15] conducted and presented a systematic experimental investigation focusing on the compressive performance of high-strength steel (HSS) transverse plate-to-CHS X-joints. Pandey et al. [

16] conducted a numerical investigation on the postfire structural performance of CFHSS T- and X-joints with CHS braces and SHS/RHS chords. Pandey et al. [

17] critically evaluated existing design provisions by validating FE models experimentally and performing a parametric study with an expanded range of geometric variables. They found the European code and CIDECT guidelines to be inadequate and inefficient, leading them to propose a superior set of design guidelines that are user-friendly, cost-effective, and reliable. Nassiraei et al. [

18] utilised 263 finite element models to investigate stress concentration factors (SCFs) in tubular T/Y connections strengthened with FRP under out-of-plane bending. Their results demonstrated that FRP reinforcement could reduce the SCF to as low as 29% of that in unreinforced joints, culminating in the proposal of a new design equation. Lyu et al. [

19] systematically assessed the axial load-carrying capacity of CHS X-joints retrofitted with externally applied in-plane stiffeners through experimentally validated finite element models and comprehensive parametric analyses. Their findings revealed that these stiffeners augment joint resistance by functioning as equivalent diagonal braces, thereby redistributing stresses and enhancing overall structural integrity. Ding et al. [

20] experimentally and numerically investigated the use of external stiffeners to enhance the axial tensile capacity of CHS X-joints. Lyu et al. [

21] validated 976 parametric simulations to propose a mechanical model that considers geometric properties, service load, and welding. It was found that external stiffeners increased the stiffness and strength, cover plates increased the effect by avoiding local ovalisation, and welding reduced the ultimate resistance by up to 10%. Chen et al. [

22] conducted experiments and numerical analyses on an innovative stiffened CHS X-joint, determined its strength via relevant parameters, and showed that it provides up to 811% strength enhancement over traditional unstiffened joints, proving that the stiffening method is highly effective. Chen et al. [

23] conducted experiments and numerical analyses on CHS X-joints stiffened with external ring stiffeners and gusset plates under various chord loads, reported negligible loading path differences, explained tension-induced strength reduction, and proposed a chord stress function with a lower-bound multiplier for conservative design. At present, for CHS steel tubular joints, most research has focused on straight tubules.

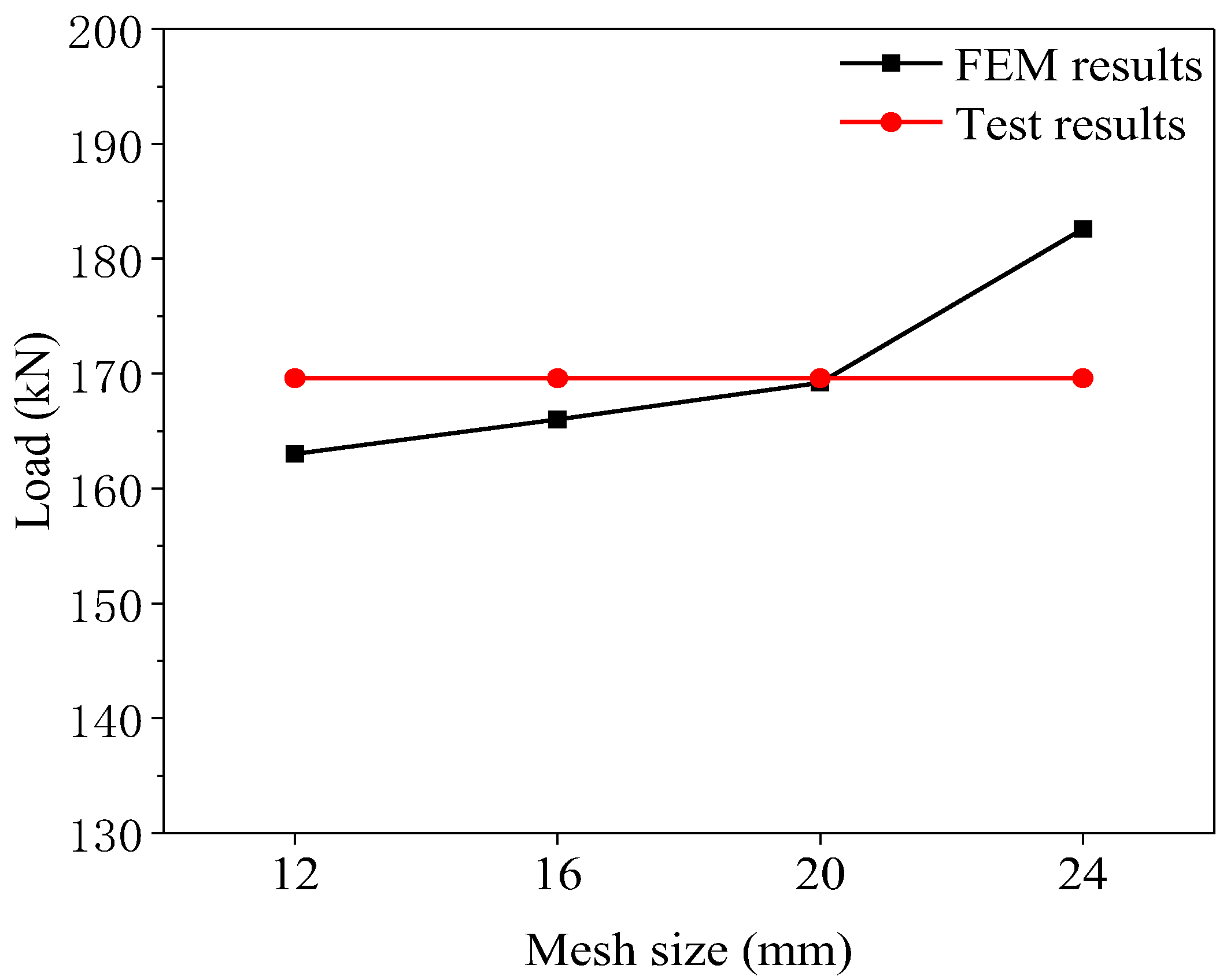

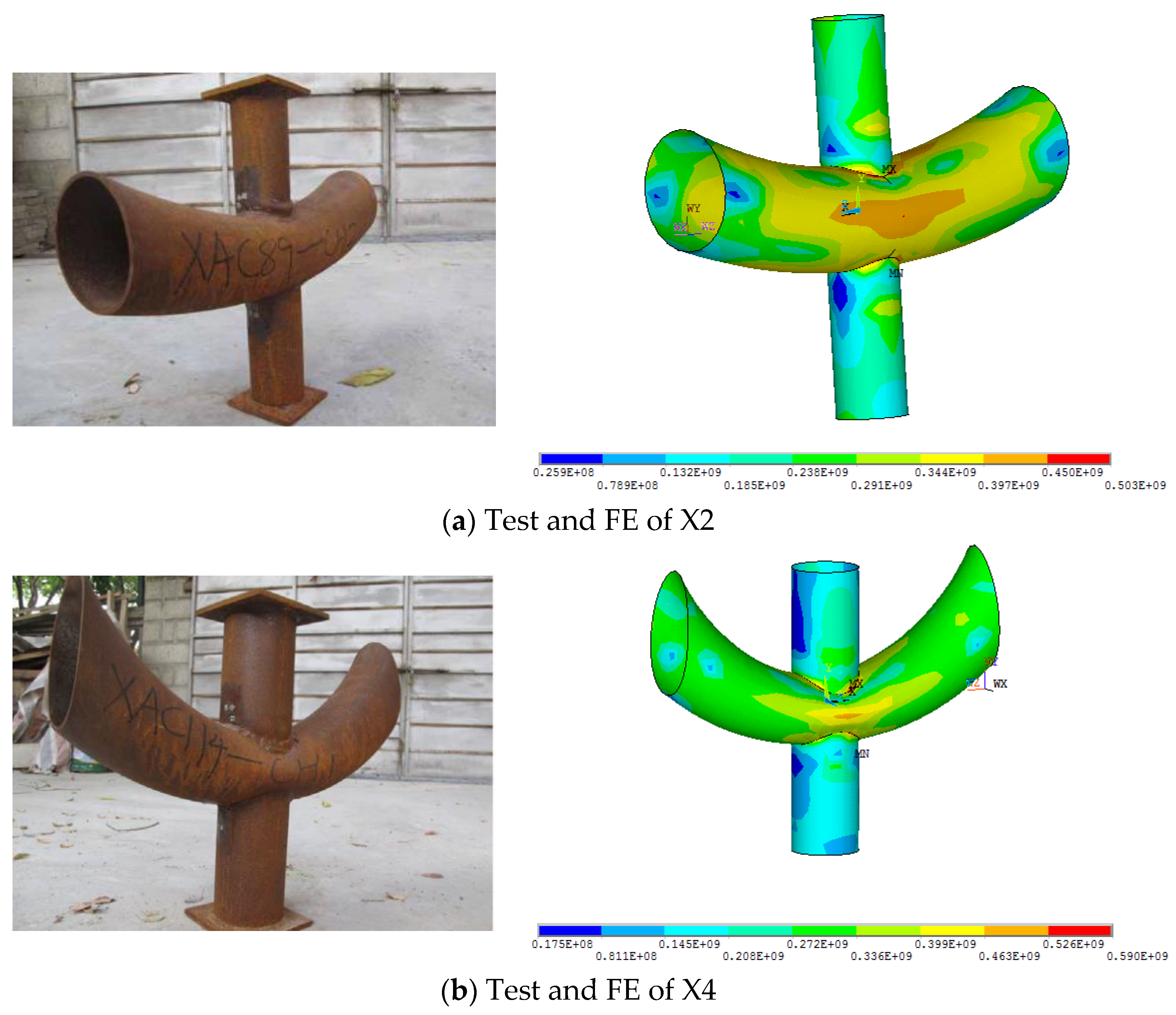

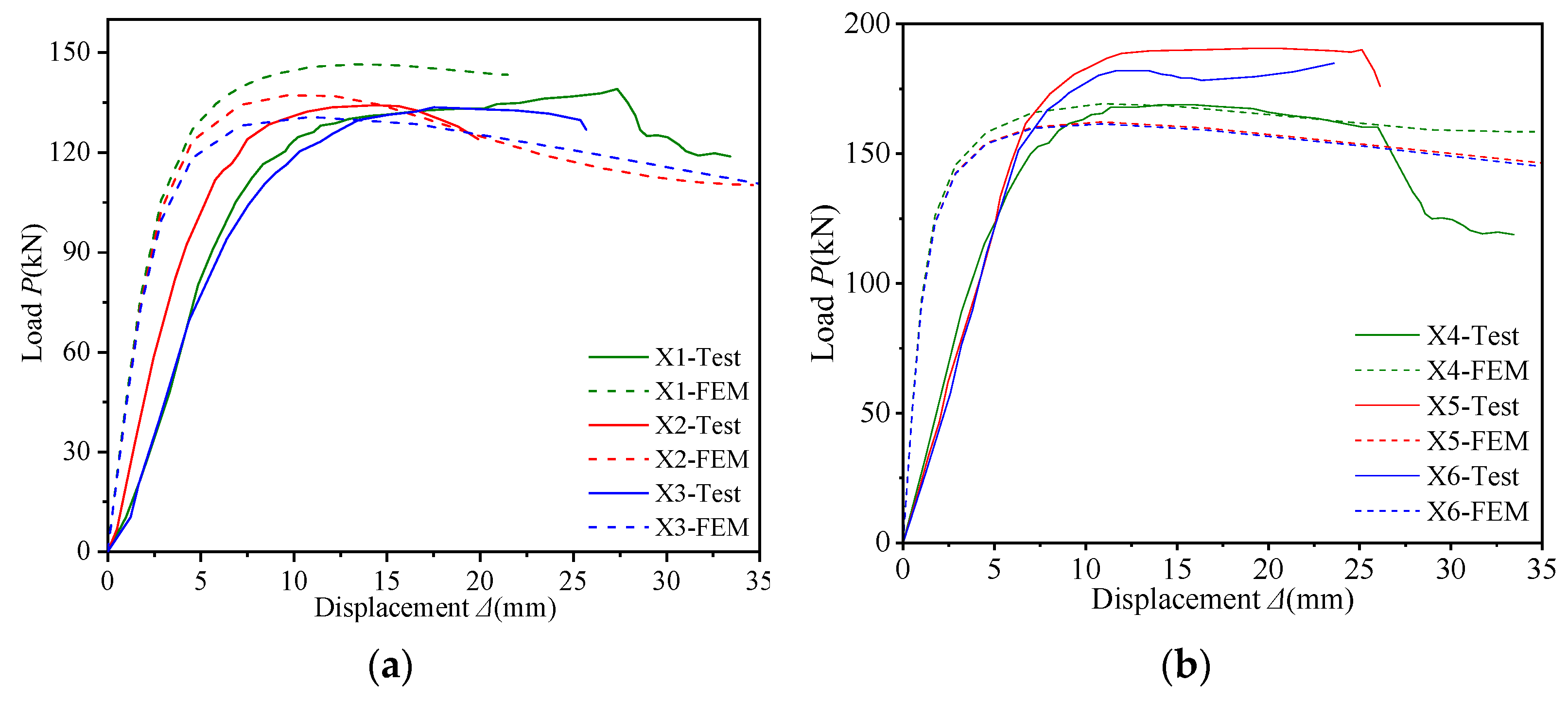

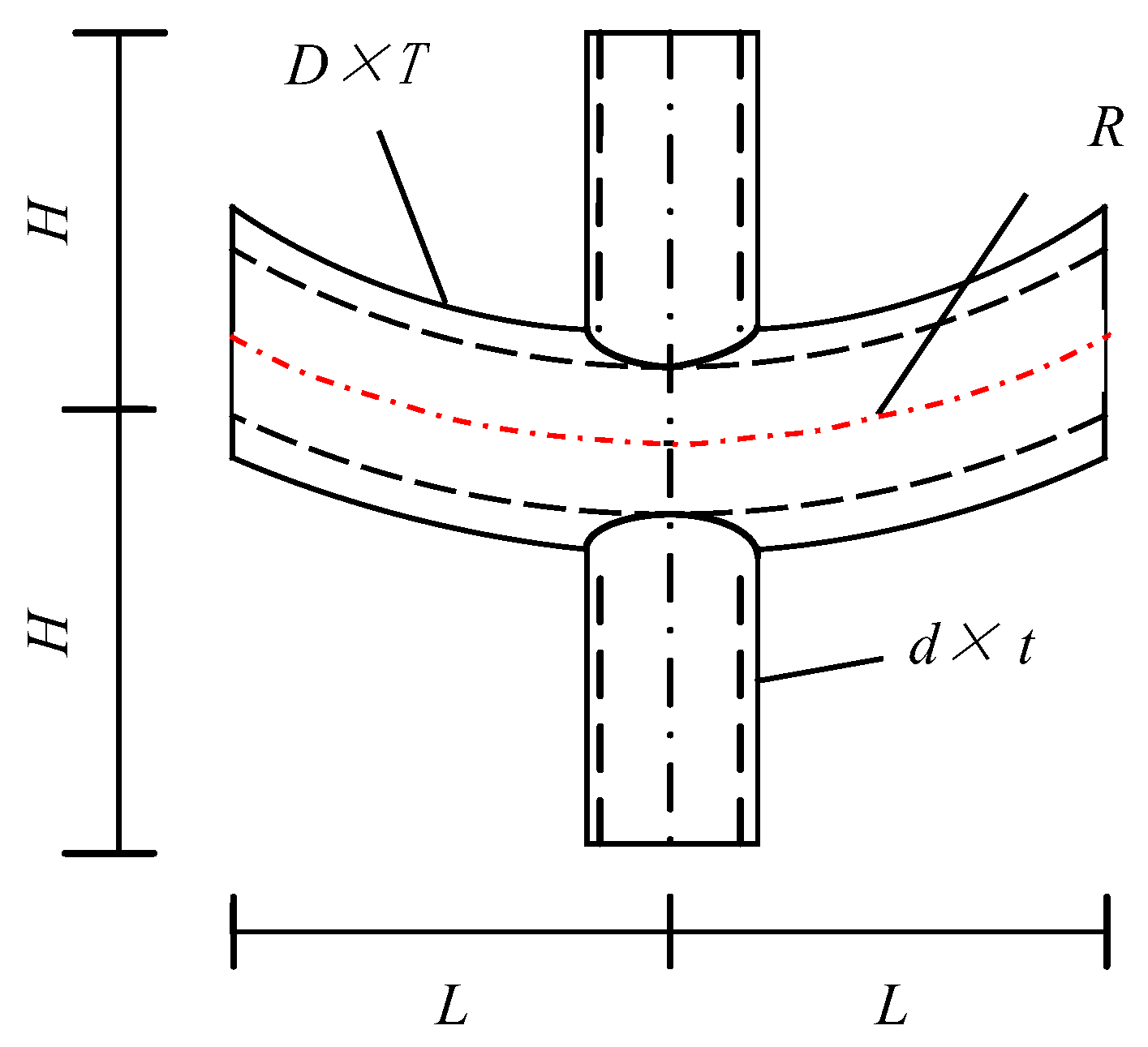

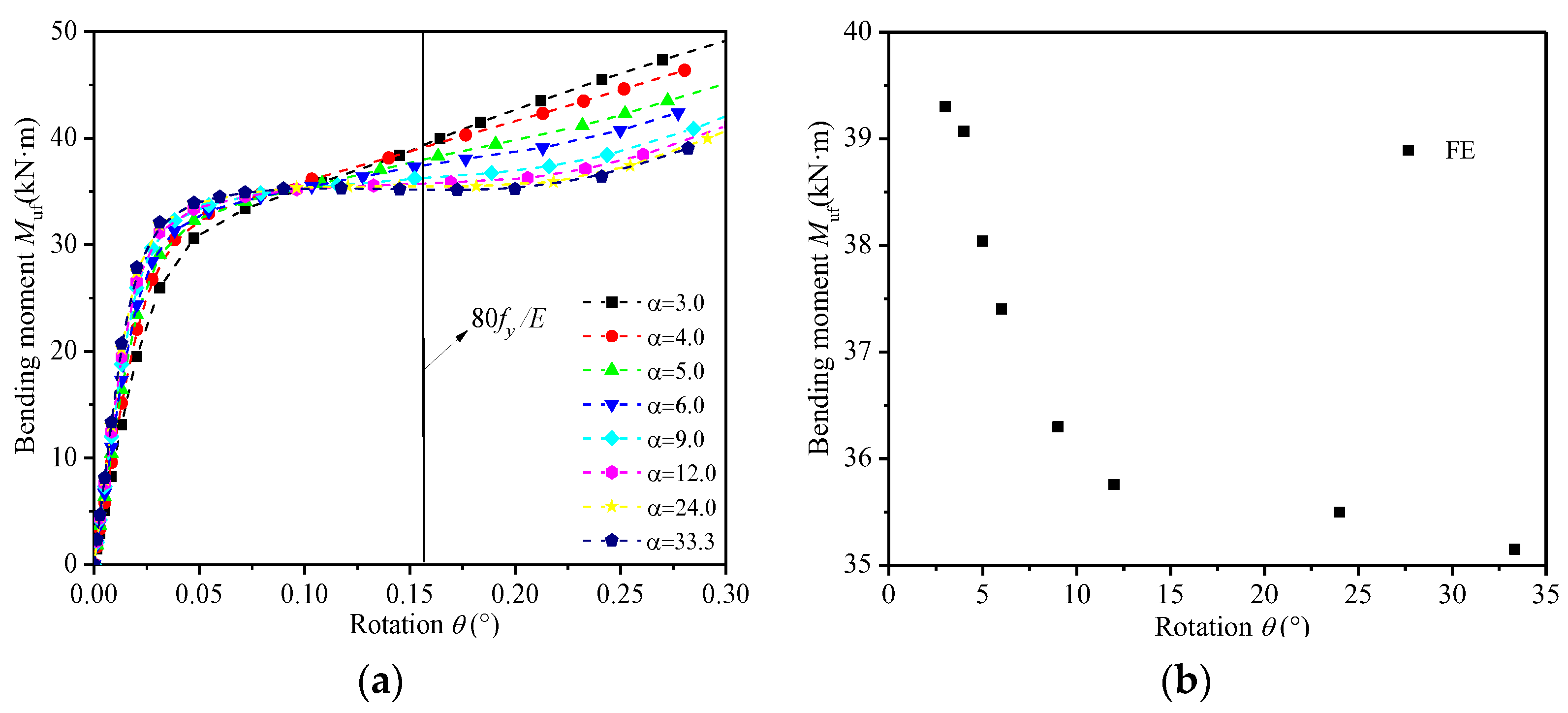

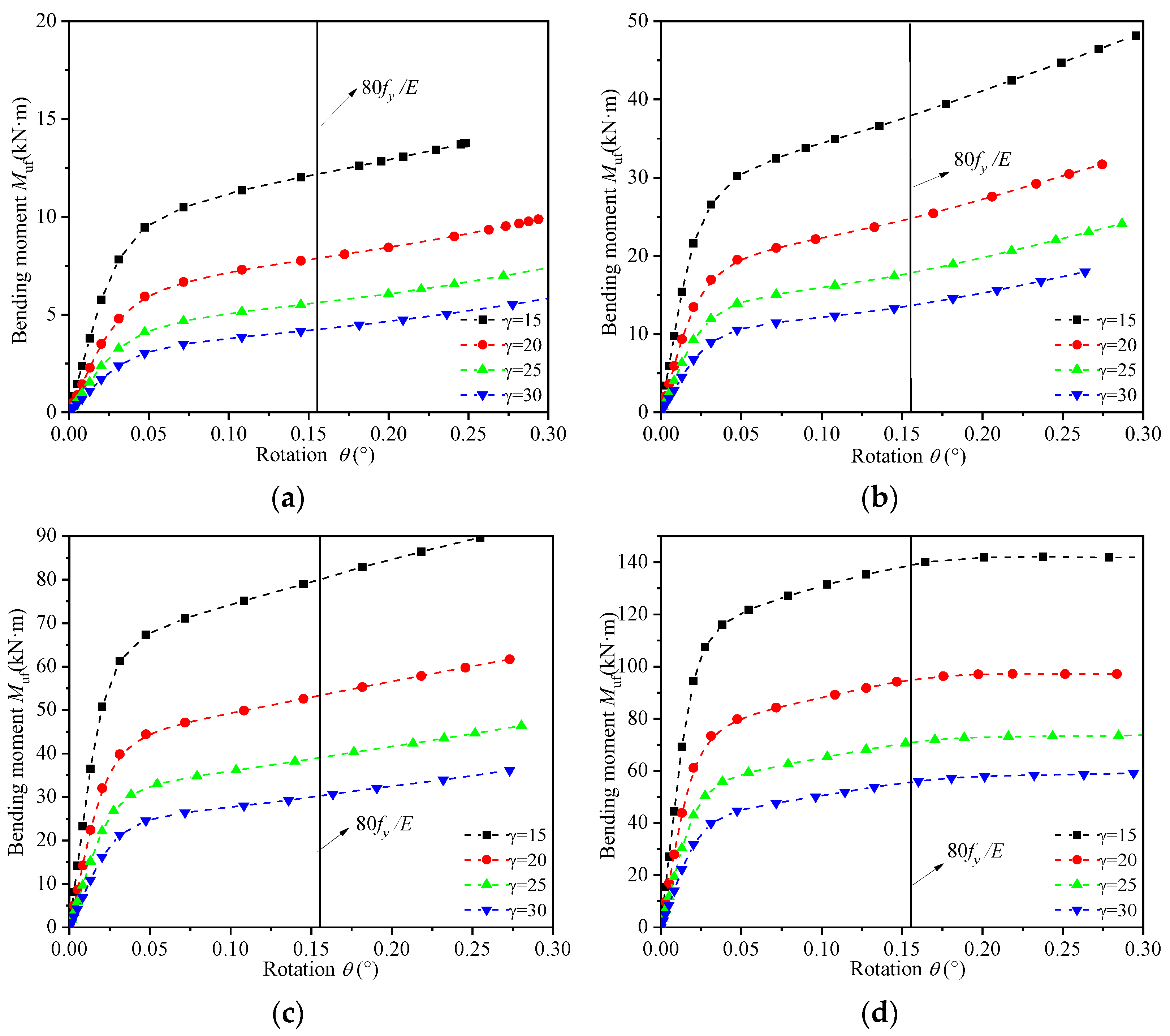

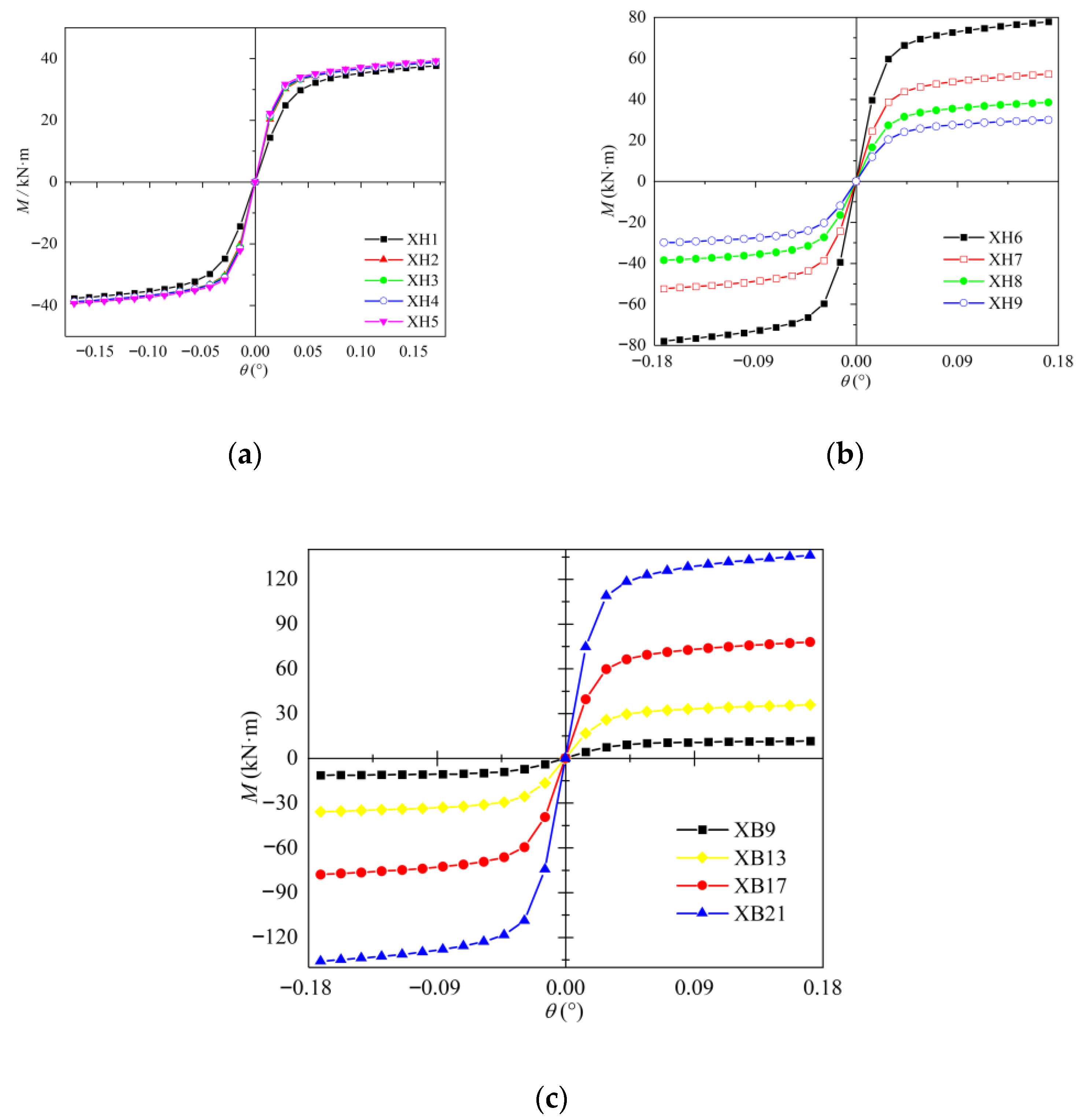

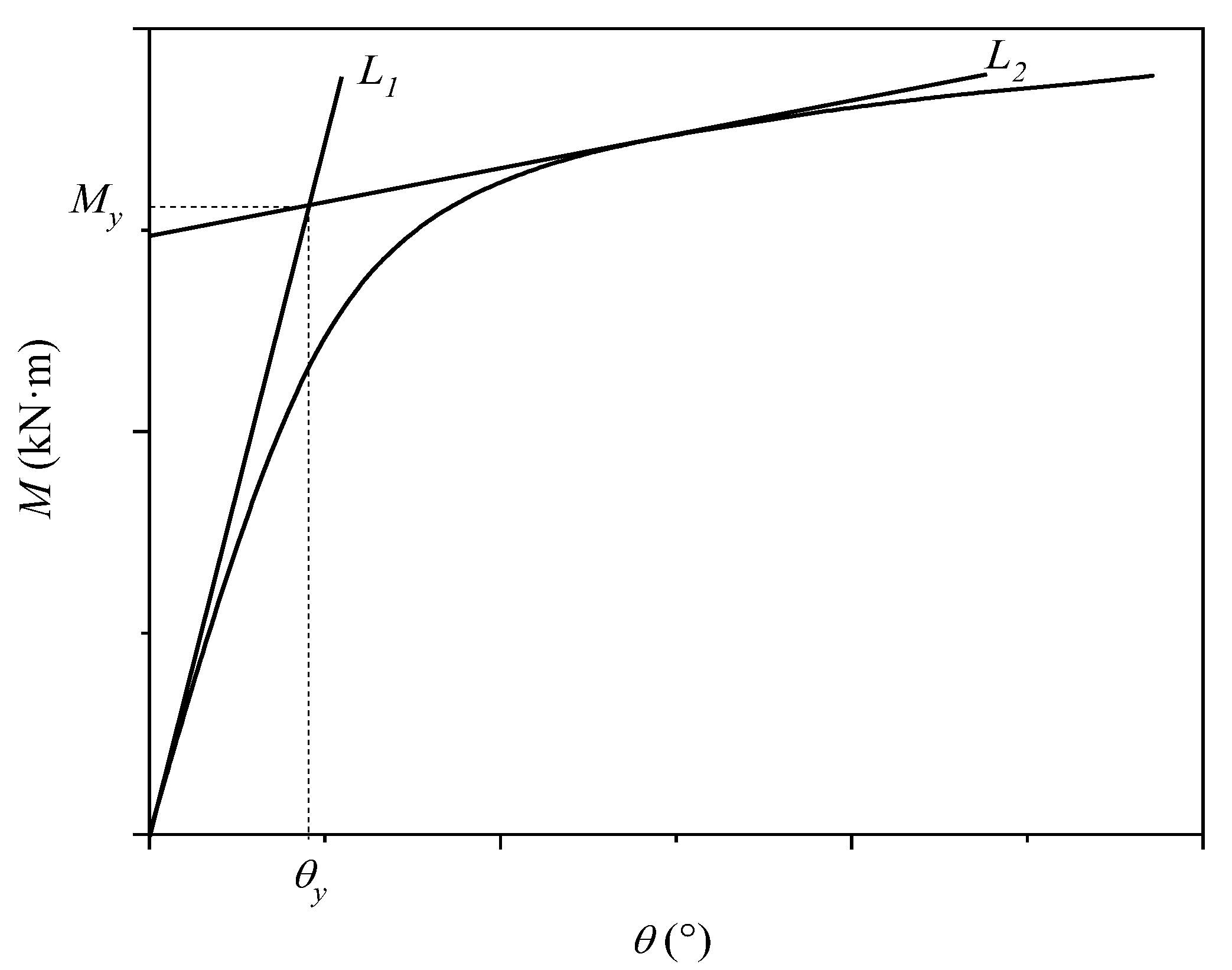

A new CHS steel tubular joint with a curved chord was proposed for engineering structures. To obtain better mechanical properties, Chen et al. [

24] and Ran et al. [

25] analysed CHS steel tubular joints with curved chords. Experimental tests revealed that the ultimate bearing capacity of a joint increases with increasing curvature within a certain curvature range. However, there has not been enough research on this type of joint, and there is no design method or calculation formula for this joint to guide engineering design. Most of these studies focus on performance under static loads. Moreover, to the authors’ knowledge, no other relevant reports have been found, as most research has concentrated more on curved dampers. For example, Fageeri et al. [

26] presented an experimental investigation into a novel energy dissipation damper. The proposed device is fabricated from a curved steel plate, which is welded to end flanges and incorporates reinforcing elements to form subpanels. Jiang et al. [

27] introduced a novel planar circular C-shaped variable-section device (CCVSD) for seismic control of HSRTBS. A multi-method investigation—entailing theoretical model establishment, experimental cyclic tests, and numerical parametric studies—was conducted. The study validated the model and reported that the CCVSD effectively dissipated energy without buckling, achieving a 76.2% reduction in bearing deformation for the CCVSD-32 configuration.