Improvement in Early-Age Strength and Durability of Precast Concrete by Shrinkage-Reducing C-S-H

Abstract

1. Introduction

2. Experiment

2.1. Materials

2.2. Mixture Proportion

2.3. Methods

2.3.1. Mechanical Strength

2.3.2. Setting Behavior Test

2.3.3. Hydration Behavior

2.3.4. SEM Test

2.3.5. XRD Analysis

2.3.6. Concrete Shrinkage

2.3.7. Pore Volume Distributions

2.3.8. Evaporation Rate of Pore Solution

2.3.9. Surface Tension of Pore Solution

3. Results and Discussion

3.1. Compressive Strength

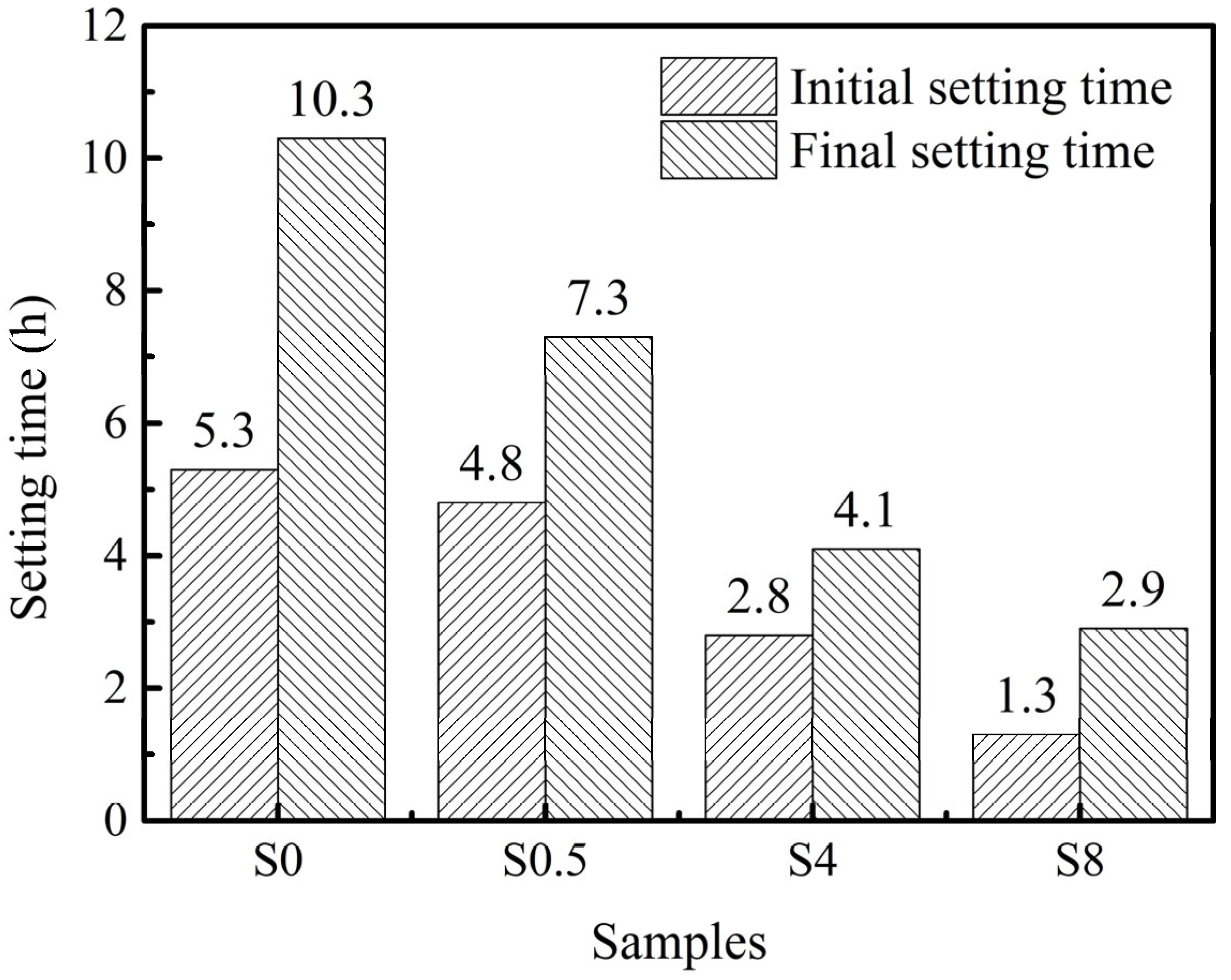

3.2. Setting Behavior

3.3. Hydration Behavior Results

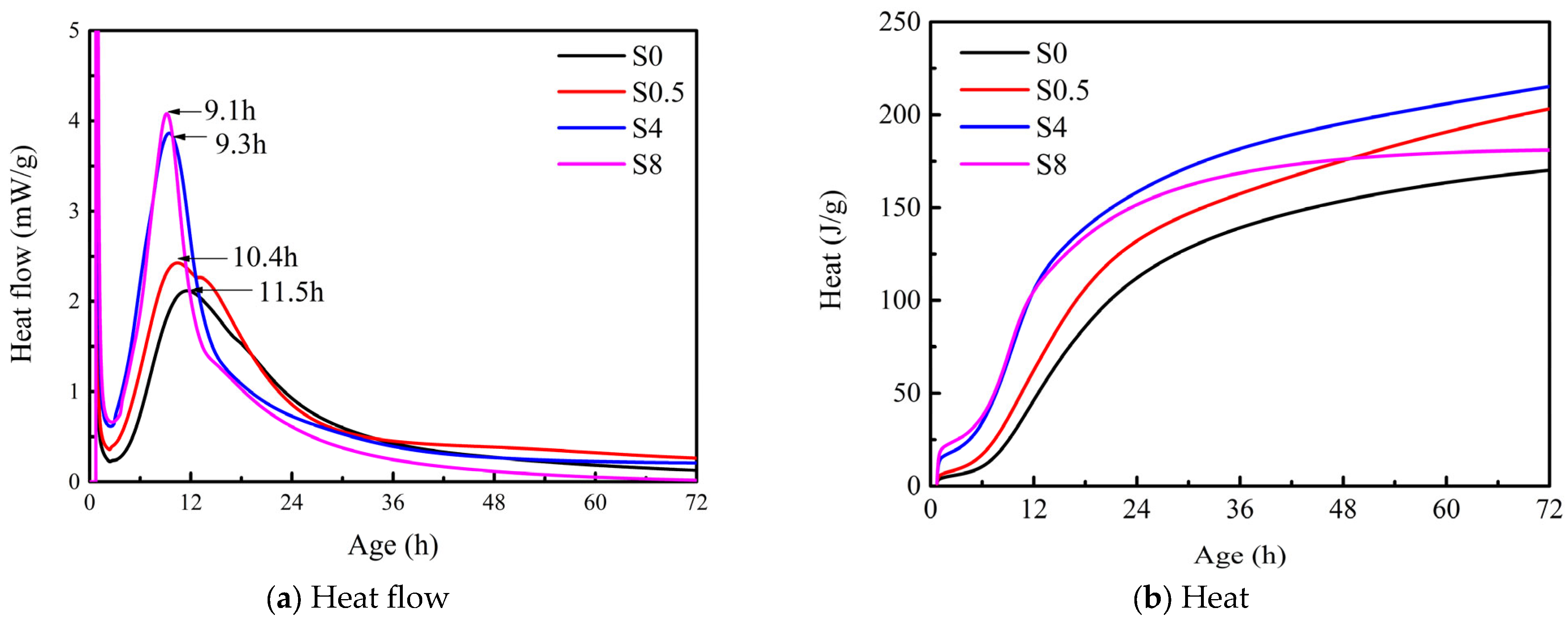

3.3.1. Hydration Heat Liberation

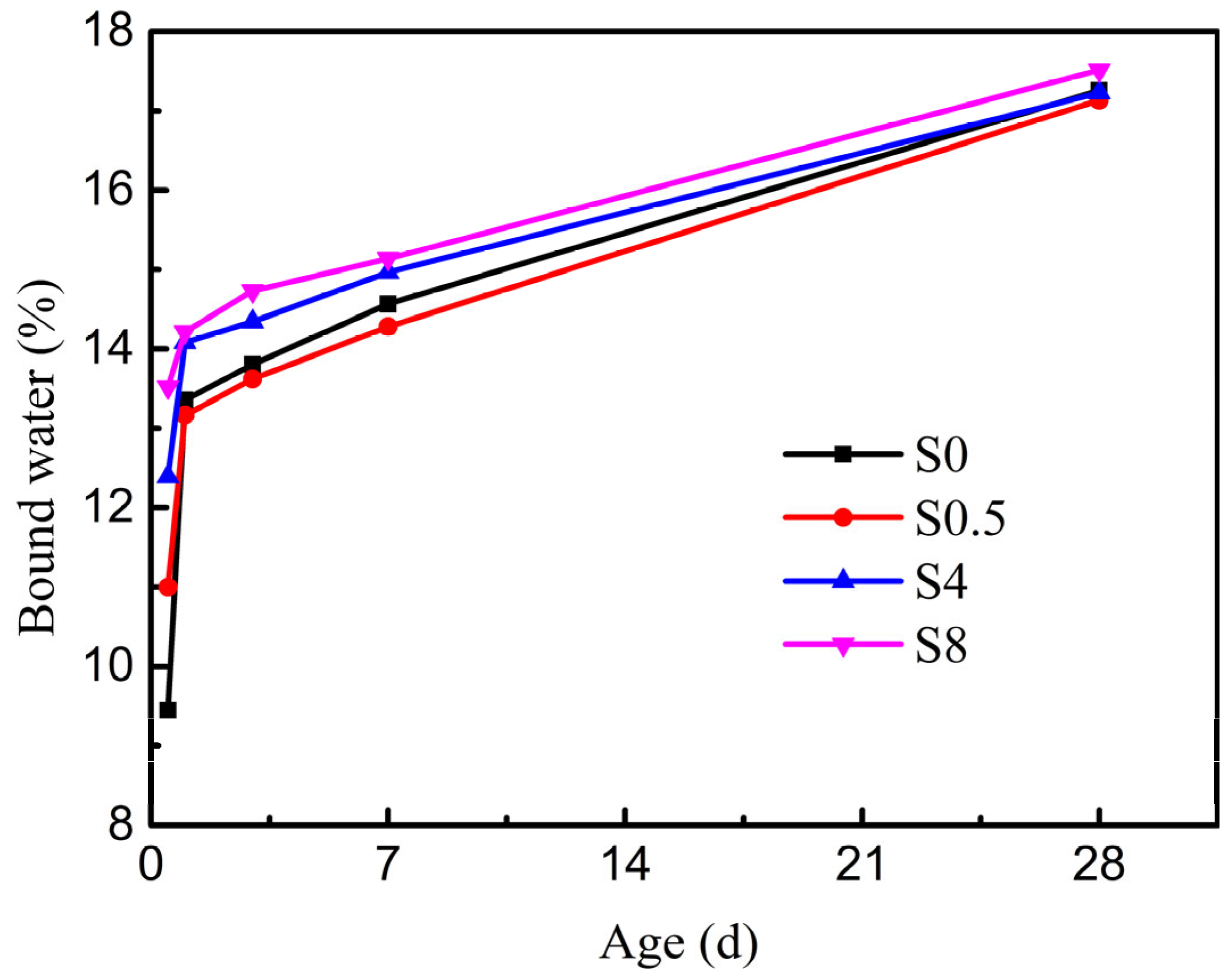

3.3.2. Hydration Degree

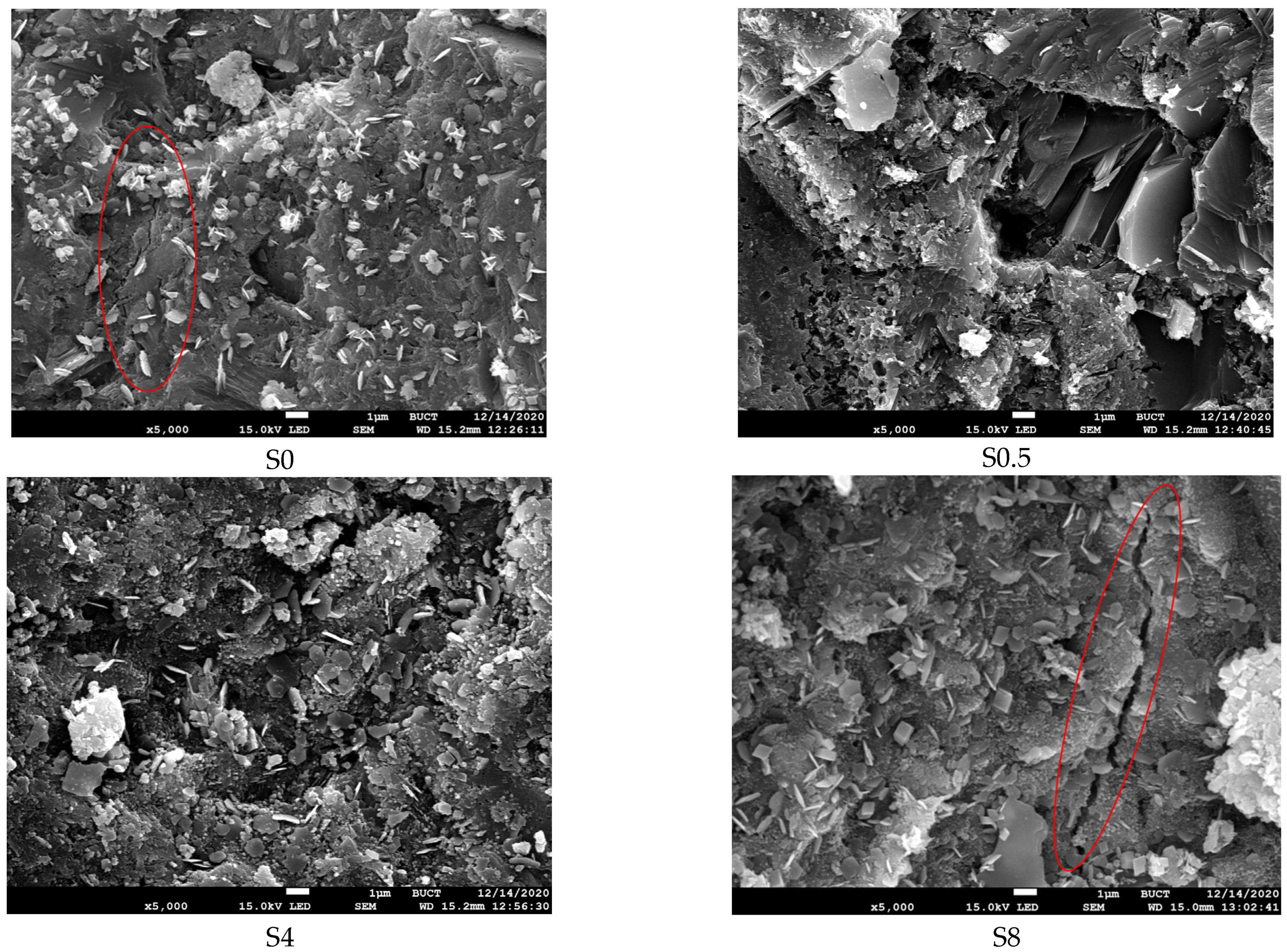

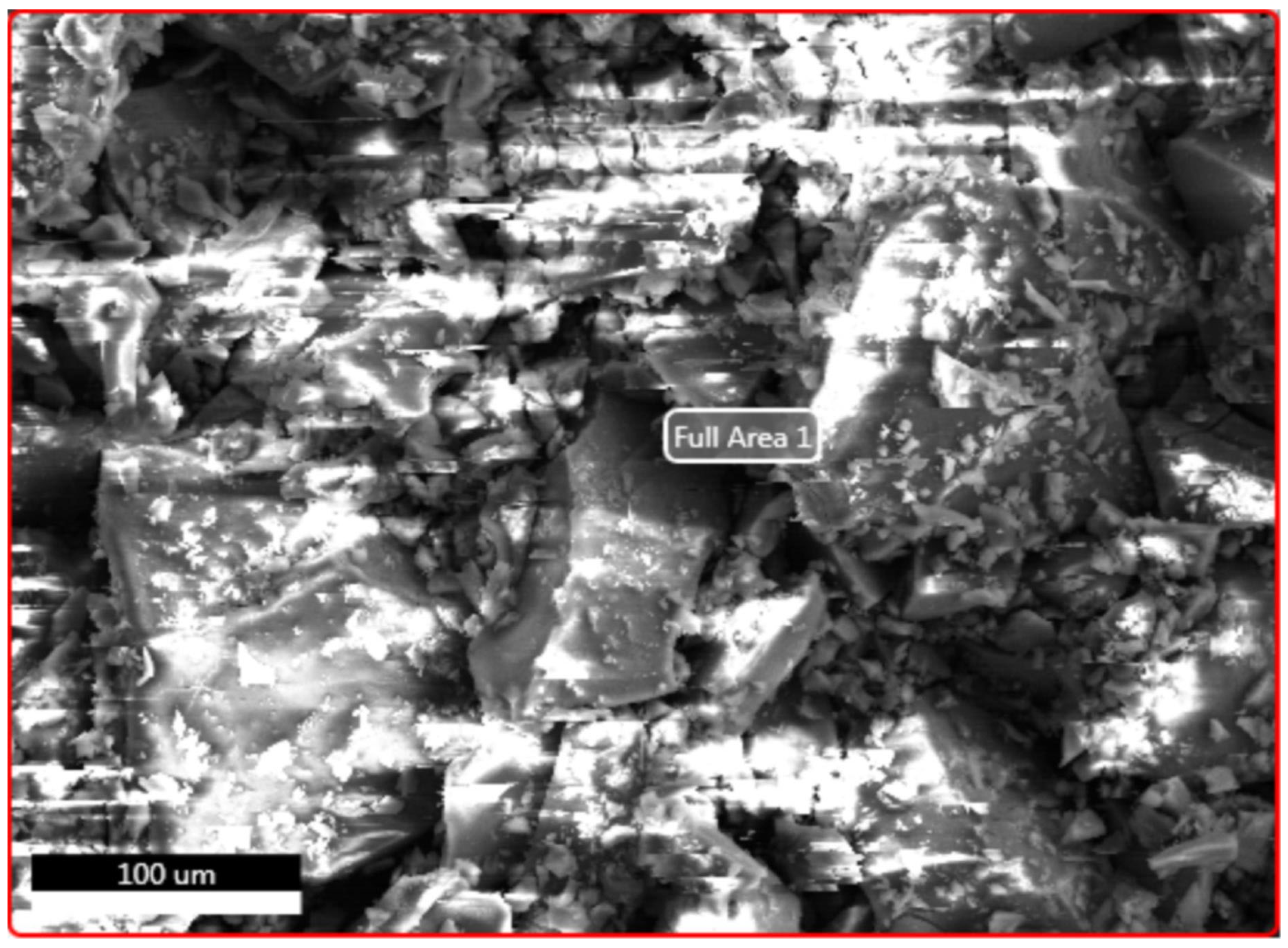

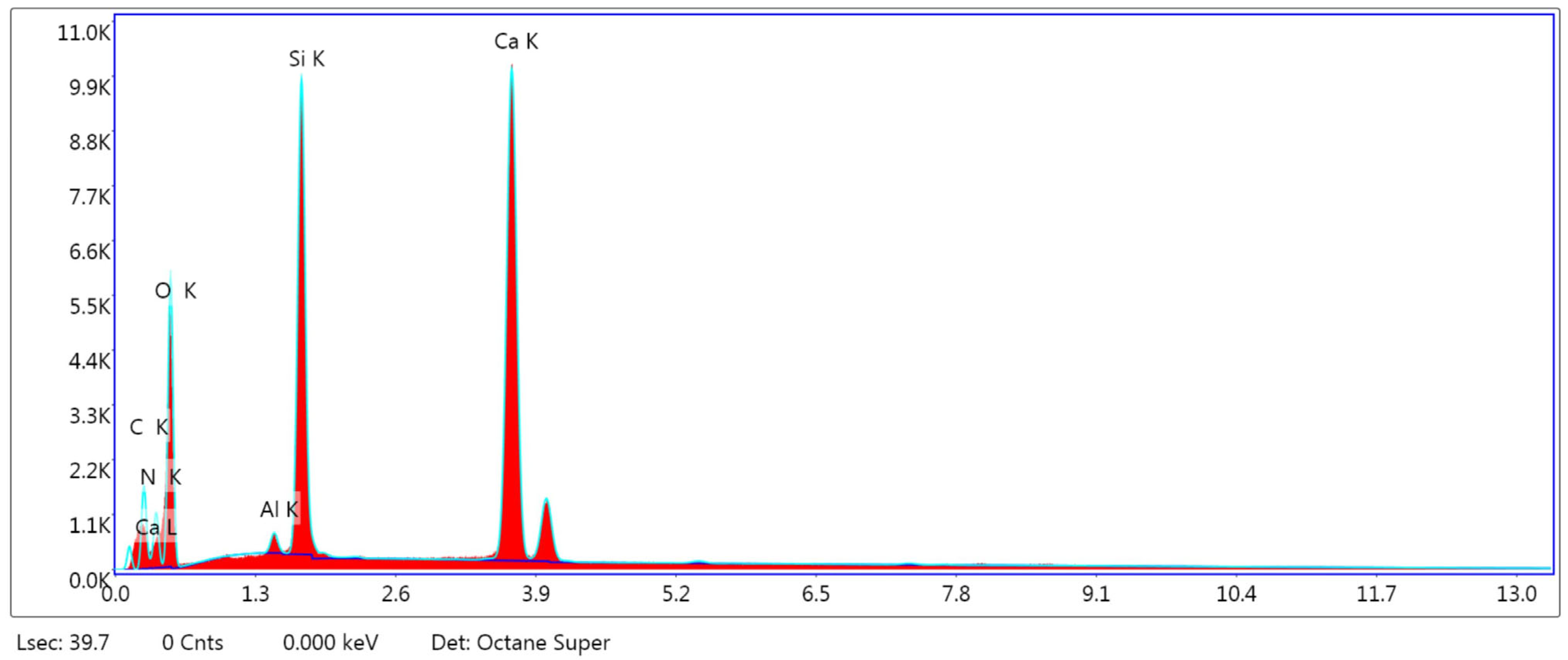

3.4. SEM Analysis Result

3.5. XRD Analysis of Cement Hydration Products

3.6. Concrete Shrinkage

3.6.1. Early-Age Shrinkage

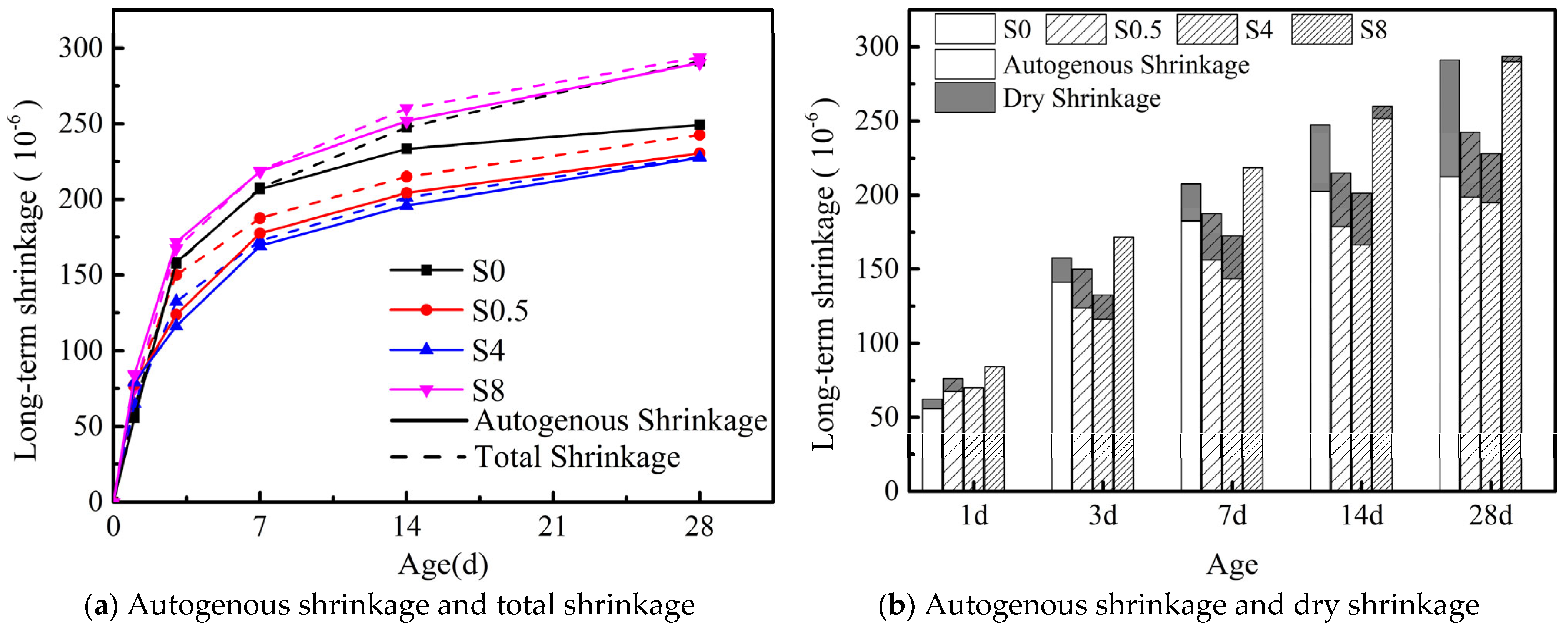

3.6.2. Long-Term Shrinkage (28 d)

3.7. Pore Volume Distributions

3.8. Evaporation Rate of Pore Solution

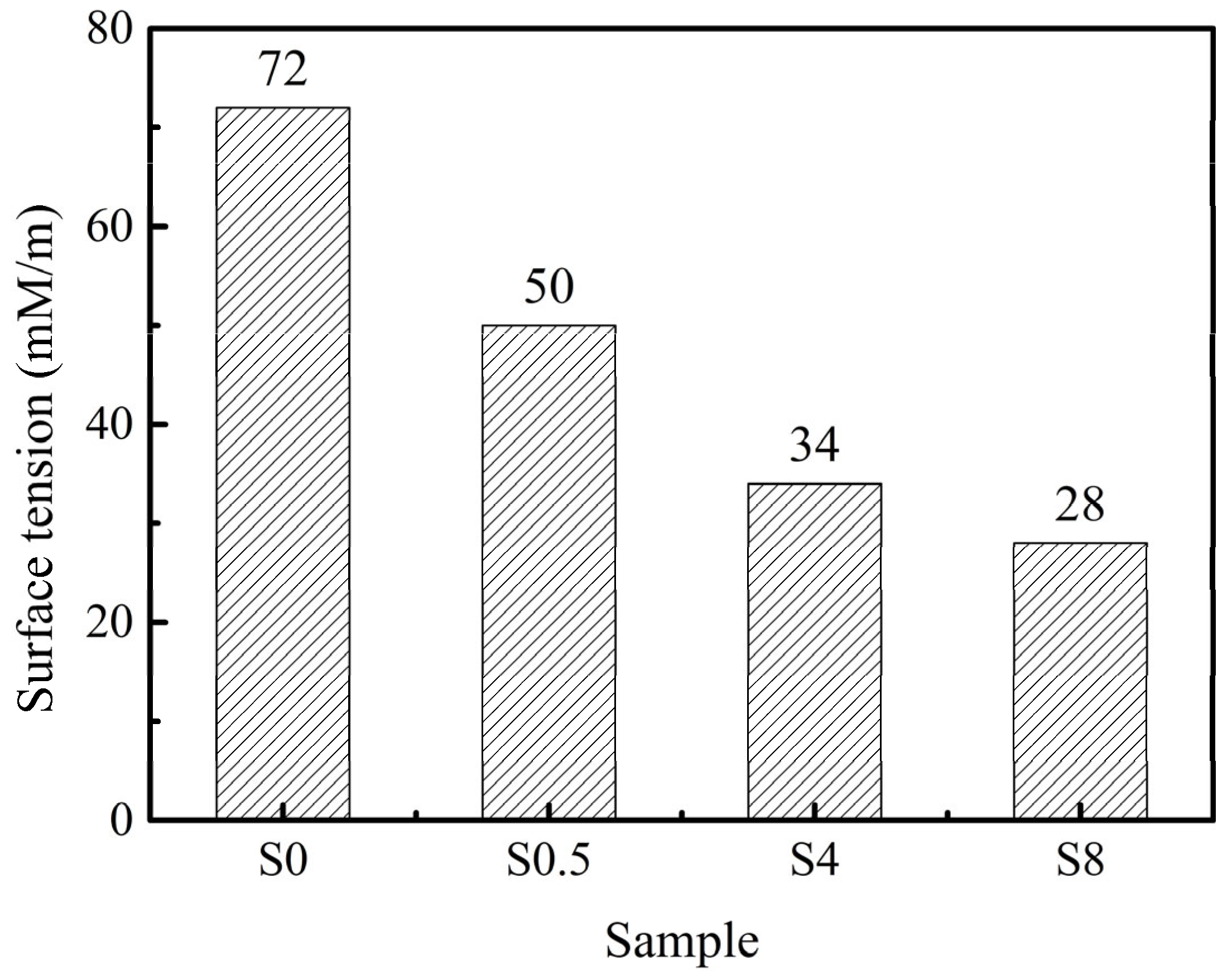

3.9. Surface Tension of Pore Solution

4. Conclusions

- (1)

- C-S-H/SRPCA can significantly improve the early-age strength of concrete. At an optimum dosage of 4.0%, the 1-day compressive strength of concrete is increased by 29.6% compared to the control sample. This is mainly due to the nucleation effect of C-S-H in the composite, which accelerates the cement hydration process and promotes the formation of more hydration products in the early stage.

- (2)

- The addition of C-S-H/SRPCA shortens the setting time of concrete. The sample with 4.0% C-S-H/SRPCA has an initial setting time that is 2.5 h shorter and a final setting time that is 6.2 h shorter than those of the control sample.

- (3)

- C-S-H/SRPCA reduces the shrinkage of concrete. It decreases the porosity of the hardened cement paste, reduces the content of capillary pores at 10–50 nm, lowers the surface tension of the pore solution, and inhibits the volatilization of the pore fluid. At 28 days, the total shrinkage of the sample with 4.0% C-S-H/SRPCA is reduced by 21.7% compared to the control sample.

- (4)

- The optimum dosage of C-S-H/SRPCA for simultaneously improving the early-age strength and reducing the shrinkage of concrete is 4.0%. A higher dosage (8.0%) does not lead to further improvement in performance and may even have a negative impact on long-term strength development.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics–Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Hanif, A.; Kim, Y.; Lu, Z.; Park, C. Early-age behavior of recycled aggregate concrete under steam curing regime. J. Clean. Prod. 2017, 152, 103–114. [Google Scholar] [CrossRef]

- Reinhardt, H.-W.; Stegmaier, M. Influence of heat curing on the pore structure and compressive strength of self-compacting concrete (SCC). Cem. Concr. Res. 2006, 36, 879–885. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Ma, C.; Xie, Y.; He, J. Design and preparation of ultra-high performance concrete with low environmental impact. J. Clean. Prod. 2019, 214, 633–643. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Z.; Zou, D.; Zhou, A.; Du, J. Strength enhancement of recycled aggregate pervious concrete using a cement paste redistribution method. Cem. Concr. Res. 2019, 122, 72–82. [Google Scholar] [CrossRef]

- Wang, F.; Kong, X.; Wang, D.; Wang, Q. The effects of nano-C-S-H with different polymer stabilizers on early cement hydration. J. Am. Ceram. Soc. 2019, 102, 5103–5116. [Google Scholar] [CrossRef]

- Won, I.; Na, Y.; Kim, J.T.; Kim, S. Energy-efficient algorithms of the steam curing for the in situ production of precast concrete members. Energy Build. 2013, 64, 275–284. [Google Scholar] [CrossRef]

- John, E.; Matschei, T.; Stephan, D. Nucleation seeding with calcium silicate hydrate–A review. Cem. Concr. Res. 2018, 113, 74–85. [Google Scholar] [CrossRef]

- Kanchanason, V.; Plank, J. Effect of calcium silicate hydrate–polycarboxylate ether (CSH–PCE) nanocomposite as accelerating admixture on early strength enhancement of slag and calcined clay blended cements. Cem. Concr. Res. 2019, 119, 44–50. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Assmann, A.; Hesse, C.; Lura, P. Microstructure development and autogenous shrinkage of mortars with CSH seeding and internal curing. Cem. Concr. Res. 2020, 129, 105967. [Google Scholar] [CrossRef]

- Hubler, M.H.; Thomas, J.J.; Jennings, H.M. Influence of nucleation seeding on the hydration kinetics and compressive strength of alkali activated slag paste. Cem. Concr. Res. 2011, 41, 842–846. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of superplasticizer and shrinkage-reducing admixtures on alkali-activated slag pastes and mortars. Cem. Concr. Res. 2005, 35, 1358–1367. [Google Scholar] [CrossRef]

- He, Z.-h.; Hu, H.-b.; Casanova, I.; Liang, C.-f.; Du, S.-G. Effect of shrinkage reducing admixture on creep of recycled aggregate concrete. Constr. Build. Mater. 2020, 254, 119312. [Google Scholar] [CrossRef]

- Plank, J.; Sakai, E.; Miao, C.; Yu, C.; Hong, J. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–99. [Google Scholar] [CrossRef]

- Liu, J.; Tian, Q.; Wang, Y.; Li, H.; Xu, W. Evaluation method and mitigation strategies for shrinkage cracking of modern concrete. Engineering 2021, 7, 348–357. [Google Scholar] [CrossRef]

- Yan, Y.; Tang, J.; Geng, G. Exploring microstructure development of CSH gel in cement blends with starch-based polysaccharide additives. Case Stud. Constr. Mater. 2023, 19, e02589. [Google Scholar]

- Huang, L.; An, M.; Xie, Y.; Wang, Y.; Han, S. Time-varying moisture characteristics and CSH gel properties of concrete in dry and hot environments. Case Stud. Constr. Mater. 2024, 21, e03812. [Google Scholar]

- Qadri, F.; Garg, N. Early-stage performance enhancement of concrete via commercial CSH seeds: From lab investigation to field implementation in Illinois, US. Case Stud. Constr. Mater. 2023, 19, e02353. [Google Scholar]

- Fu, H.; Tian, L.; Wang, P.; Zuo, W.; Zhao, T.; Han, X. Microstructure, deformation and durability of high-strength non-steam-cured concrete with CSH seed. Constr. Build. Mater. 2023, 374, 130953. [Google Scholar] [CrossRef]

- Zarzuela, R.; Luna, M.; Coneo, J.G.; Gemelli, G.; Andreouli, D.; Kaloidas, V.; Mosquera, M.J. Multifunctional silane-based superhydrophobic/impregnation treatments for concrete producing CSH gel: Validation on mockup specimens from European heritage structures. Constr. Build. Mater. 2023, 367, 130258. [Google Scholar] [CrossRef]

- Fang, L.; Fu, D.; Yuan, Q.; Xu, S.; Zhang, D.; Cai, H.; Zeng, X.; Wang, Y.; Zhou, J. Combined effects of low-heat cement, expansive agent and shrinkage-reducing admixture on drying shrinkage and cracking of concrete. Case Stud. Constr. Mater. 2025, 22, e04344. [Google Scholar] [CrossRef]

- Hari, R.; Zhuge, Y. Performance assessment of pervious concrete incorporated with calcium silicate hydrates (CSH) cultivated on rice husk ash substrates–A trend surface analysis interpretation. Constr. Build. Mater. 2024, 446, 138050. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.; Zhou, S.; Tang, S.; Lu, X. Investigation of microstructure of CSH and micro-mechanics of cement pastes under NH4NO3 dissolution by 29Si MAS NMR and microhardness. Measurement 2021, 185, 110019. [Google Scholar] [CrossRef]

- Geng, Z.; Tang, S.; Wang, Y.; He, Z.; Wu, K.; Wang, L. Stress relaxation properties of calcium silicate hydrate: A molecular dynamics study. J. Zhejiang Univ. Sci. A 2024, 25, 97–115. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of nucleation seeding on the hydration mechanisms of tricalcium silicate and cement. J. Phys. Chem. C 2009, 113, 4327–4334. [Google Scholar] [CrossRef]

- Gong, J.; Zeng, W.; Zhang, W. Influence of shrinkage-reducing agent and polypropylene fiber on shrinkage of ceramsite concrete. Constr. Build. Mater. 2018, 159, 155–163. [Google Scholar] [CrossRef]

- Zou, F.; Hu, C.; Wang, F.; Ruan, Y.; Hu, S. Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C–S–H seeds towards a greener binder. J. Clean. Prod. 2020, 244, 118566. [Google Scholar] [CrossRef]

- Sun, J.; Shi, H.; Qian, B.; Xu, Z.; Li, W.; Shen, X. Effects of synthetic CSH/PCE nanocomposites on early cement hydration. Constr. Build. Mater. 2017, 140, 282–292. [Google Scholar] [CrossRef]

- Moghadam, H.A.; Mirzaei, A.; Dehghi, Z.A. The relation between porosity, hydration degree and compressive strength of Portland cement pastes in the presence of aluminum chloride additive. Constr. Build. Mater. 2020, 250, 118884. [Google Scholar] [CrossRef]

- Alizadeh, R.; Raki, L.; Makar, J.M.; Beaudoin, J.J.; Moudrakovski, I. Hydration of tricalcium silicate in the presence of synthetic calcium–silicate–hydrate. J. Mater. Chem. 2009, 19, 7937–7946. [Google Scholar] [CrossRef]

- Zhou, Z.; Sofi, M.; Liu, J.; Li, S.; Zhong, A.; Mendis, P. Nano-CSH modified high volume fly ash concrete: Early-age properties and environmental impact analysis. J. Clean. Prod. 2021, 286, 124924. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. The influence of nano-silica on the hydration of ordinary Portland cement. J. Mater. Sci. 2012, 47, 1011–1017. [Google Scholar] [CrossRef]

- Lavergne, F.; Sab, K.; Sanahuja, J.; Bornert, M.; Toulemonde, C. Investigation of the effect of aggregates’ morphology on concrete creep properties by numerical simulations. Cem. Concr. Res. 2015, 71, 14–28. [Google Scholar] [CrossRef]

- Singh, S.; Khan, S.; Khandelwal, R.; Chugh, A.; Nagar, R. Performance of sustainable concrete containing granite cutting waste. J. Clean. Prod. 2016, 119, 86–98. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Bentz, D.; Geiker, M.R.; Hansen, K.K. Shrinkage-reducing admixtures and early-age desiccation in cement pastes and mortars. Cem. Concr. Res. 2001, 31, 1075–1085. [Google Scholar] [CrossRef]

- Kovler, K.; Zhutovsky, S. Overview and future trends of shrinkage research. Mater. Struct. 2006, 39, 827–847. [Google Scholar] [CrossRef]

| Specific Surface Area (m2/kg) | Density (g/cm3) | Main Chemical Compositions (wt, %) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | Na2O | SO3 | LOI | ||

| 345 | 3.11 | 62.61 | 21.98 | 4.70 | 3.69 | 2.51 | 0.47 | 0.21 | 1.91 | 1.92 |

| Specific Surface Area (m2/kg) | 28 d Activity Index (%) | MgO (wt, %) | SO3 (wt, %) |

|---|---|---|---|

| 627 | 109 | 10.45 | 0.51 |

| Samples | Cement | Superfine Mineral Powder | Water | C-S-H/SRPCA | PCE | Sand | Aggregate |

|---|---|---|---|---|---|---|---|

| S0 | 366 | 65 | 125 | 0.00 | 2.08 | 690 | 1174 |

| S0.5 | 366 | 65 | 125 | 2.16 | 1.99 | 690 | 1174 |

| S4 | 366 | 65 | 125 | 17.24 | 1.38 | 690 | 1174 |

| S8 | 366 | 65 | 125 | 34.48 | 0.71 | 690 | 1174 |

| Samples | Mass (g) | Mass Fraction of C-S-H/SRPCA in Binder (wt, %) | ||||

|---|---|---|---|---|---|---|

| Cement | Superfine Mineral Powder | Water | C-S-H/SRPCA | PCE | ||

| S0 | 366 | 65 | 125 | 0.00 | 2.08 | 0 |

| S0.5 | 366 | 65 | 125 | 2.16 | 1.99 | 0.5 |

| S4 | 366 | 65 | 125 | 17.24 | 1.38 | 4.0 |

| S8 | 366 | 65 | 125 | 34.48 | 0.71 | 8.0 |

| Element | Weight% | Atomic% |

|---|---|---|

| Ca | 26.6 | 12.6 |

| Si | 10.9 | 7.3 |

| O | 36.6 | 43.4 |

| N | 16.4 | 22.1 |

| C | 9.0 | 14.1 |

| Al | 0.5 | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; Li, S.; Zhang, C.; Zheng, X.; Wang, T.; Liu, X.; Pan, Y. Improvement in Early-Age Strength and Durability of Precast Concrete by Shrinkage-Reducing C-S-H. Buildings 2025, 15, 1576. https://doi.org/10.3390/buildings15091576

Yu P, Li S, Zhang C, Zheng X, Wang T, Liu X, Pan Y. Improvement in Early-Age Strength and Durability of Precast Concrete by Shrinkage-Reducing C-S-H. Buildings. 2025; 15(9):1576. https://doi.org/10.3390/buildings15091576

Chicago/Turabian StyleYu, Peiyun, Shuming Li, Chi Zhang, Xinguo Zheng, Tao Wang, Xianghui Liu, and Yongjian Pan. 2025. "Improvement in Early-Age Strength and Durability of Precast Concrete by Shrinkage-Reducing C-S-H" Buildings 15, no. 9: 1576. https://doi.org/10.3390/buildings15091576

APA StyleYu, P., Li, S., Zhang, C., Zheng, X., Wang, T., Liu, X., & Pan, Y. (2025). Improvement in Early-Age Strength and Durability of Precast Concrete by Shrinkage-Reducing C-S-H. Buildings, 15(9), 1576. https://doi.org/10.3390/buildings15091576