Investigation of Mix Proportion Optimization and Anti-Scouring Performance of Pervious Concrete Base

Abstract

1. Introduction

2. Materials and Experiments

2.1. Raw Materials and Specimens

2.1.1. Cement

2.1.2. Coarse Aggregate

2.1.3. Specimen Preparation

2.2. Test Methods

3. Results and Discussions

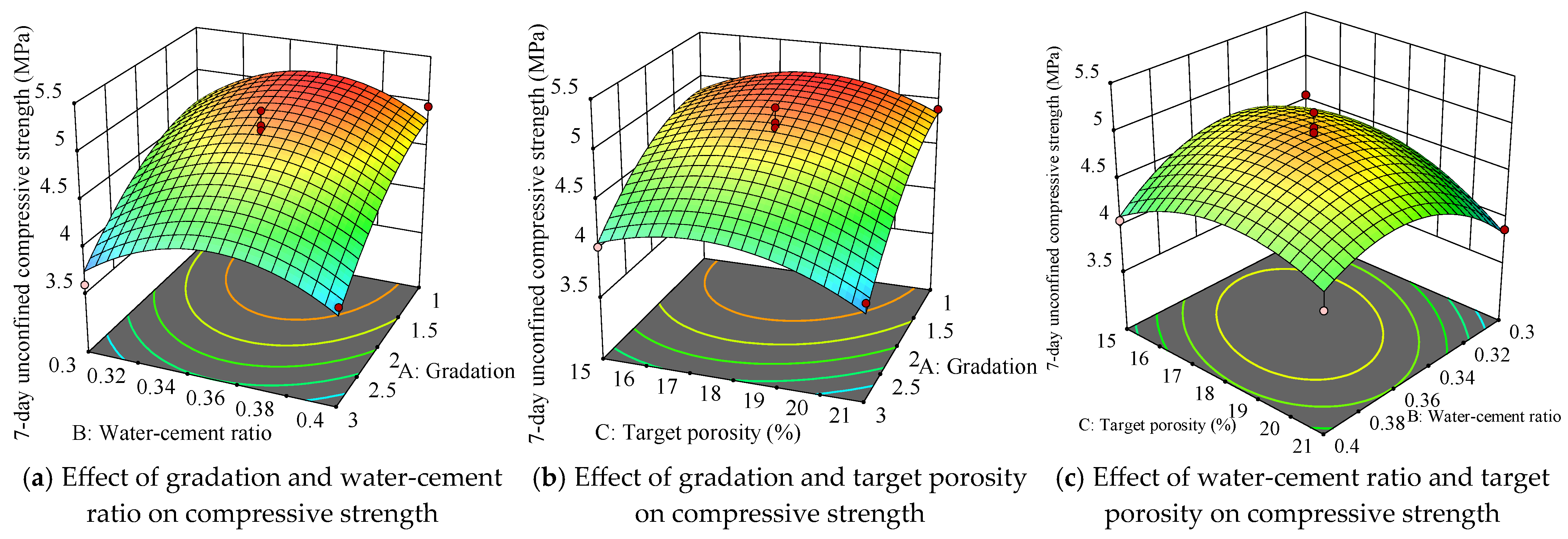

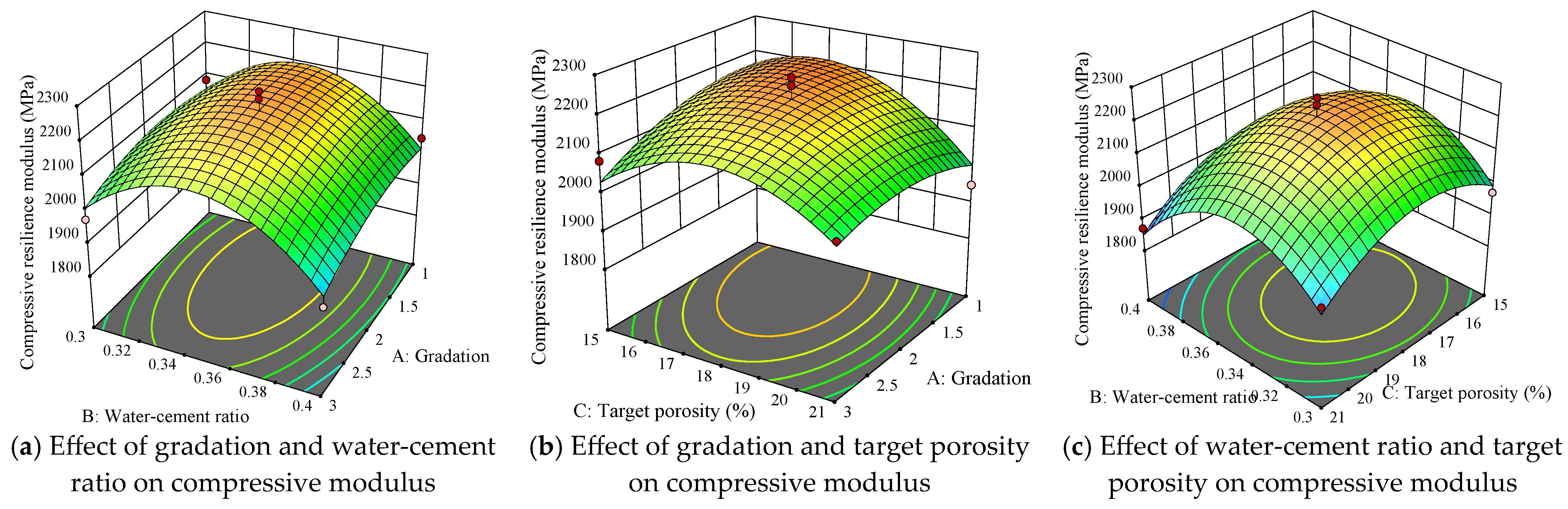

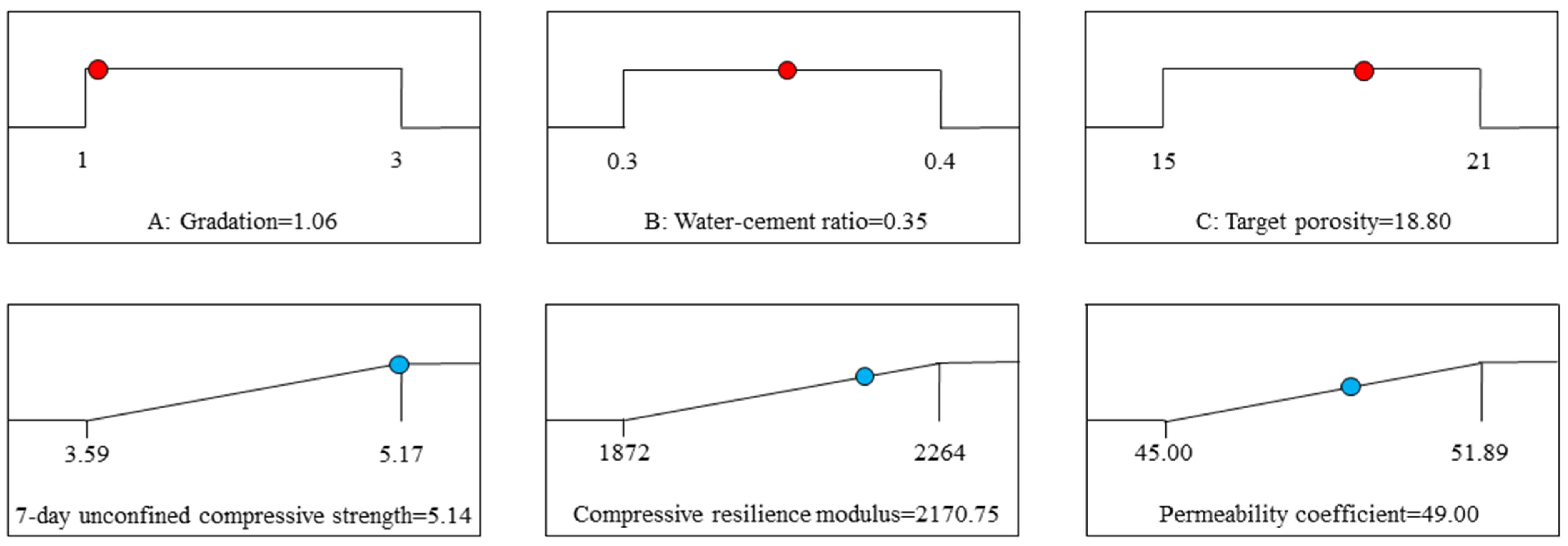

3.1. Optimized Design of Fit Ratio Based on Response Surface Methodology

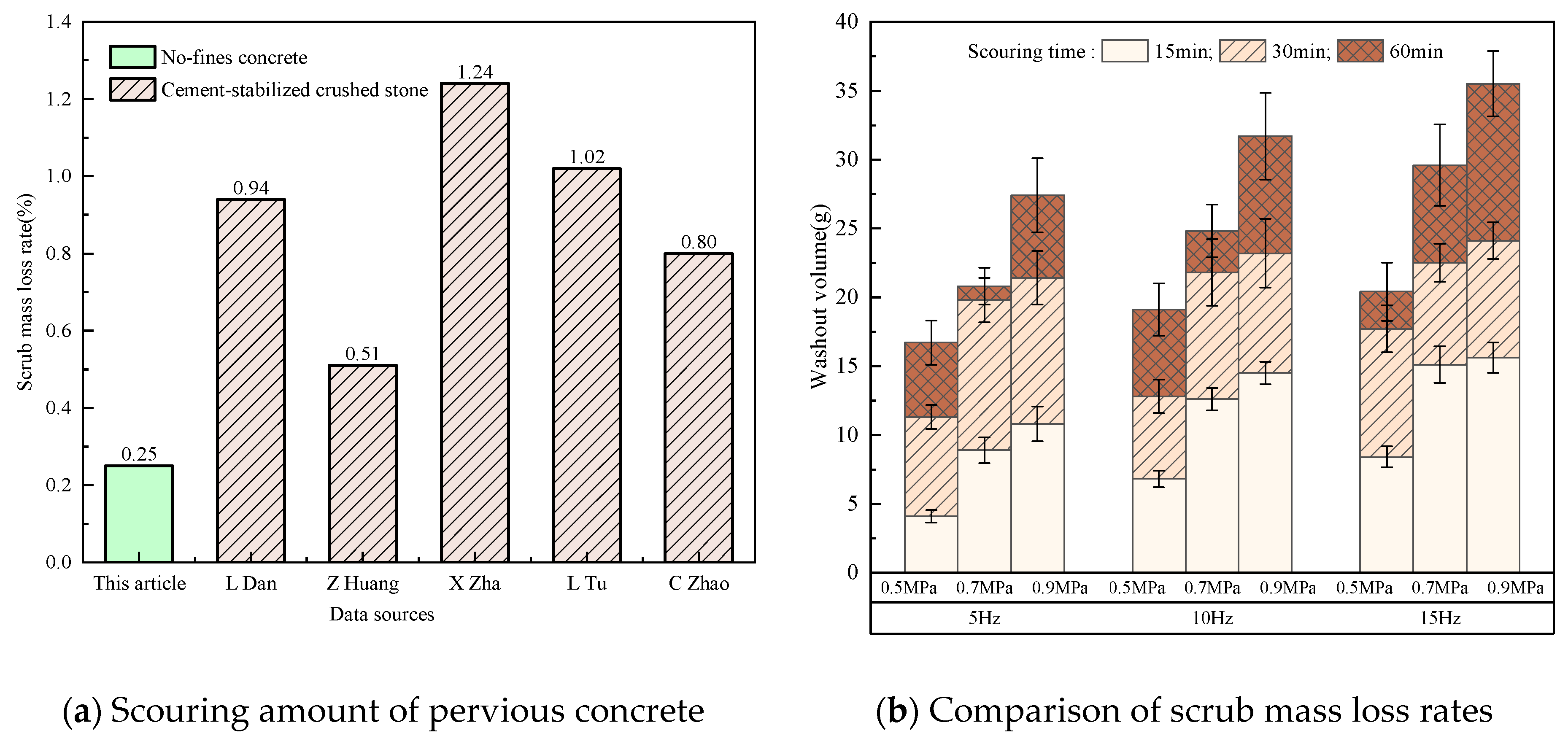

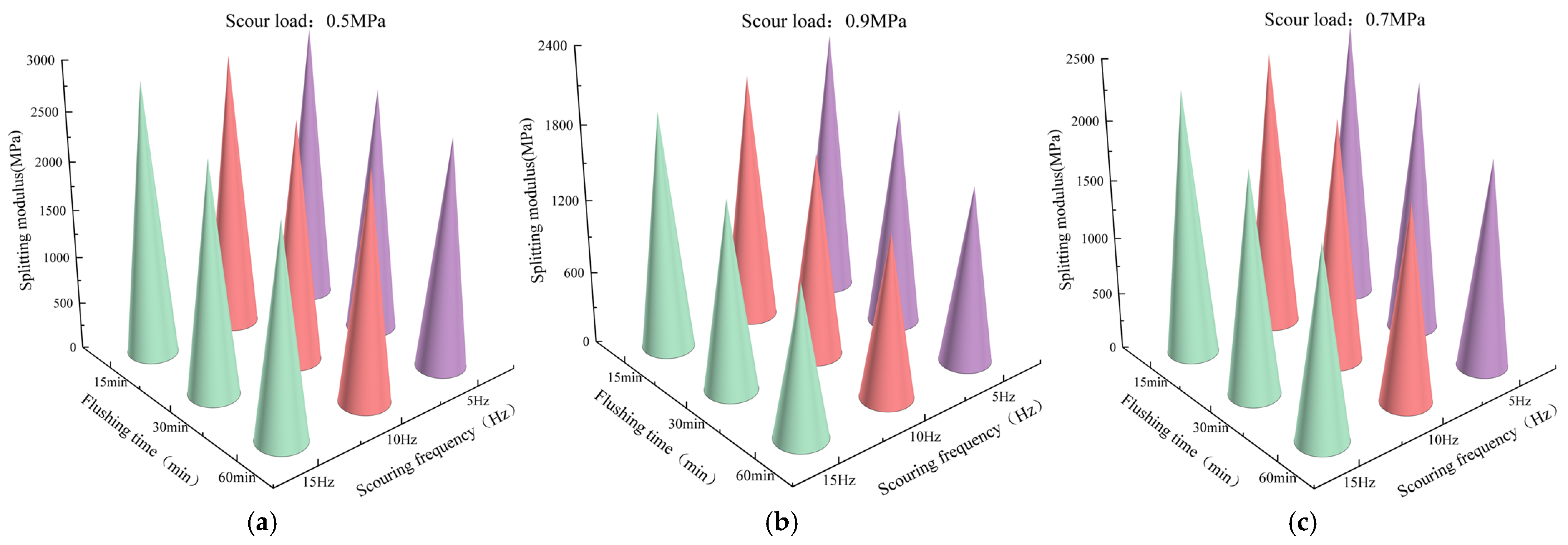

3.2. Analysis of Scour Resistance and Results of Strength and Modulus Under Different Scour Conditions

4. Conclusions

- (1)

- The optimal mix proportion of pervious concrete was determined as Grade I, a water-cement ratio of 0.35, and a target porosity of 18% based on a three-factor, three-level optimization framework. This proportion achieves a balance between hydraulic conductivity, mechanical strength, and durability, providing a reliable reference for practical applications.

- (2)

- Under standard scour conditions, the scour mass loss of pervious concrete was 0.25%, showing a 72% improvement in scour resistance compared to cement-stabilized aggregates. Due to its excellent resistance to scour-induced deterioration, pervious concrete effectively mitigates water-related pavement damage, ensuring long-term structural stability and offering a cost-effective solution for high-traffic pavement bases.

- (3)

- After scouring, the compressive strength, splitting tensile strength, dynamic compressive resilience modulus, and splitting resilience modulus of pervious concrete decreased by 16%, 33%, 40%, and 16%, respectively. Compared with cement-stabilized gravel (53% strength loss), pervious concrete exhibited significantly lower strength loss (16%) due to its interconnected porosity, which reduces internal water pressure during scouring. Overall, pervious concrete outperforms cement-stabilized gravel in mechanical strength, scour resistance, and durability, making it a promising material for high-load road base applications.

- (4)

- This study optimized the mix design of pervious concrete using RSA and ANOVA and evaluated its mechanical performance and scour resistance under different conditions. Future research will focus on field validation, long-term durability assessments, and integrating numerical simulations and machine learning to optimize mix design and predict material behavior.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Ministry of Transport of the People’s Republic of China. 2023 Transportation Industry Development Statistics Bulletin. China Communications New, 18 June 2024. [Google Scholar] [CrossRef]

- Zhu, T.; Tan, Z.; Zhou, Y. Experimental Research on Erosion-Resistance Performances of Semi-rigid Base Materials. J. Build. Mater. 2013, 16, 608–613. [Google Scholar] [CrossRef]

- Guo, R.; Nian, T.; Li, P.; Fu, J.; Guo, H. Anti-erosion performance of asphalt pavement with a sub-base of cement-treated mixtures. Constr. Build. Mater. 2019, 223, 278–287. [Google Scholar] [CrossRef]

- Li, S.; Wu, G.; Shi, H. Acoustic emission characteristics of semi-rigid bases with three moisture conditions during bending tests. Road Mater. Pavement Des. 2019, 20, 187–198. [Google Scholar] [CrossRef]

- Sheng, Y.; Chen, S.; Wang, D.; Wang, L. Pore water pressure characteristics of semi-rigid base for cement concrete pavement. J. Traffic Transp. Eng. 2012, 12, 6–12. [Google Scholar] [CrossRef]

- Zhao, M.; Xu, X.; Liu, Y.; Wu, C.; Sun, Q.; Pei, Y. Microcracking treatment mechanism of semi-rigid base asphalt pavement with discrete-continuous coupling simulation. Case Stud. Constr. Mater. 2024, 20, e2850. [Google Scholar] [CrossRef]

- Rokitowski, P.; Bzówka, J.; Grygierek, M. Influence of high moisture content on road pavement structure: A Polish case study. Case Stud. Constr. Mater. 2021, 15, e594. [Google Scholar] [CrossRef]

- Sha, A. Material characteristics of semi-rigid base. China J. Highw. Transp. 2008, 21, 1–5. [Google Scholar] [CrossRef]

- Cai, J.; Liu, Z.; Xu, G.; Tian, Q.; Shen, W.; Li, B.; Chen, T. Mix design methods for pervious concrete based on the mesostructure: Progress, existing problems and recommendation for future improvement. Case Stud. Constr. Mater. 2022, 17, e1253. [Google Scholar] [CrossRef]

- Cai, J.; Chen, J.; Shi, J.; Tian, Q.; Xu, G.; Du, Y. A novel approach to evaluate the clogging resistance of pervious concrete. Case Stud. Constr. Mater. 2022, 16, e864. [Google Scholar] [CrossRef]

- Li, F.; Liu, C.H.; Wu, T.; Li, Z.W.; Shi, J.Q.; Lu, J.X. Optimization of mixing ratio of pervious concrete. Build. Mater. World 2024, 45, 46–51. [Google Scholar]

- Wang, C.; Zhang, T.; Xie, X.; Li, B.; Yang, D. Mix Proportion Design Method of Pervious Concrete Based on Aggregate Sphericity. J. Build. Mater. 2022, 25, 235–241. [Google Scholar] [CrossRef]

- Cosic, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of aggregate type and size on properties of pervious concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Moretti, L.; Di Mascio, P.; Fusco, C. Porous concrete for pedestrian pavements. Water 2019, 11, 2105. [Google Scholar] [CrossRef]

- Song, H.; Yao, J.; Xiang, J. The role of aggregate and cement paste in the deterioration of the transitional interface zone of pervious concrete during freeze-thaw cycles. Case Stud. Constr. Mater. 2022, 16, e1086. [Google Scholar] [CrossRef]

- Rangelov, M.; Nassiri, S.; Haselbach, L.; Englund, K. Using carbon fiber composites for reinforcing pervious concrete. Constr. Build. Mater. 2016, 126, 875–885. [Google Scholar] [CrossRef]

- Giustozzi, F. Polymer-modified pervious concrete for durable and sustainable transportation infrastructures. Constr. Build. Mater. 2016, 111, 502–512. [Google Scholar] [CrossRef]

- Elizondo-Martínez, E.; Andres-Valeri, V.; Jato-Espino, D.; Rodriguez-Hernandez, J. Review of porous concrete as multifunctional and sustainable pavement. J. Build. Eng. 2020, 27, 100967. [Google Scholar] [CrossRef]

- Yu, F.; Guo, J.; Liu, J.; Cai, H.; Huang, Y. A review of the pore structure of pervious concrete: Analyzing method, characterization parameters and the effect on performance. Constr. Build. Mater. 2023, 365, 129971. [Google Scholar] [CrossRef]

- Singh, A.; Sampath, P.V.; Biligiri, K.P. A review of sustainable pervious concrete systems: Emphasis on clogging, material characterization, and environmental aspects. Constr. Build. Mater. 2020, 261, 120491. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, G. Experimental study on properties of pervious concrete pavement materials. Cem. Concr. Res. 2003, 33, 381–386. [Google Scholar] [CrossRef]

- Adil, G.; Kevern, J.T.; Mann, D. Influence of silica fume on mechanical and durability of pervious concrete. Constr. Build. Mater. 2020, 247, 118453. [Google Scholar] [CrossRef]

- Wang, Q. Research on the structure of permeable asphalt pavement for urban roads. Eng. Constr. Des. 2025, 1, 128–130. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Material design and characterization of high performance pervious concrete. Constr. Build. Mater. 2015, 98, 51–60. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material–Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, Y.; Ni, K.; Yang, F.; Gao, J. Research on water permeability performance of permeable concrete based on X-CT technology. Concr. Cem. Prod. 2025, 1, 1–6. [Google Scholar] [CrossRef]

- Alimohammadi, V.; Maghfouri, M.; Nourmohammadi, D.; Azarsa, P.; Gupta, R.; Saberian, M. Stormwater runoff treatment using pervious concrete modified with various nanomaterials: A comprehensive review. Sustainability 2021, 13, 8552. [Google Scholar] [CrossRef]

- Qin, H.; Li, W.; Zhang, Y. Effects of rough aggregate particle size and grade on performance of permeable concrete. Concrete 2025, 185–187+192. [Google Scholar] [CrossRef]

- Xia, Q.; Zhao, C.; Zhu, P.; Yan, X.; Wang, S.; Zhu, X. Influence of fly ash on salt-freezing resistance and permeability of recycled permeable concrete with straight channels. Concrete 2024, 95–99+110. [Google Scholar] [CrossRef]

- Zhou, D.; Chen, D.; Yang, F.; Yao, Y.; Mei, J.; Wang, X. Study on the influence of material composition on the properties of permeable concrete. Concrete 2024, 120–124. [Google Scholar] [CrossRef]

- Ozel, B.F.; Sakallı, Ş.; Şahin, Y. The effects of aggregate and fiber characteristics on the properties of pervious concrete. Constr. Build. Mater. 2022, 356, 129294. [Google Scholar] [CrossRef]

- Ramadhansyah, P.J.; Ibrahim, M.Y.M.; Hainin, M.R.; Ibrahim, M.H.W. A review of porous concrete pavement: Applications and engineering properties. Appl. Mech. Mater. 2014, 554, 37–41. [Google Scholar] [CrossRef]

- Qu, G.; Yan, Z.; Zhen, M.; Liu, H.; Yuan, Y. Performance Prediction of Porous Concrete Based on Neural Network and Regression Analysis. J. Jilin Univ. (Eng. Technol. Ed.) 2024, 55, 269–282. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, W.; Shen, W.; Zhou, M. The aggregate gradation for the porous concrete pervious road base material. J. Wuhan Univ. Technol.-Mater. Sci. Ed 2008, 23, 391–394. [Google Scholar] [CrossRef]

- JTG/T F30-2014; Technical Guidelines for Construction of Highway Cement Concrete Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2014.

- Tian, Z.; Ma, Y.; Li, J. Research Progress on Vibration Compaction of Concrete. J. Build. Mater. 2024, 27, 46–57. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Jing, H.; Wu, W.; Sun, Y. Vibration Compaction Time of Cement-Stabilized Crushed Rock Material Based on Micro-skeleton Indices. J. Build. Mater. 2019, 22, 553–558. [Google Scholar] [CrossRef]

- JTG 3441-2024; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2024.

- Wang, S.; Hu, P.; Chen, S.; Xiao, Y. Prediction of Concrete Compressive Strength Based on Coupled BAS-MLP. J. Build. Mater. 2023, 26, 705–715. [Google Scholar] [CrossRef]

- Huang, M.; Cai, S.; Liu, Q. Optimization of mining filling material ratios by coupling orthogonal testing and response surface methodology. Exp. Technol. Manag. 2023, 40, 35–41. [Google Scholar] [CrossRef]

- Huang, Z.; Xiao, M.; Peng, B.; Yu, X.; Zhu, Y. Study of Cement Stabilized Macadam Properties based on Fine Aggregate Filling Coefficient. Highway 2017, 62, 29–35. [Google Scholar]

- Dan, Z.; Chen, F.; Chen, W.; Wang, Q.; Wang, Q. Road Performance Study of Cement Stabilized Gravel Mixture Based on Vibratory Mixing Technology. Technol. Highw. Transp. 2018, 34, 21–26. [Google Scholar] [CrossRef]

- Tu, L.; Xu, M.; Fan, L.; Wang, L.; Liu, Z. Research on Mechanical Properties of Recycled Cement Stabilized Crushed Stone Based on Vibration Mode. J. Wuhan Univ. Technol. 2022, 44, 20–26. [Google Scholar]

- Zha, X.; Cao, Y.; Liu, G. Research on mix design and pavement performances for anti-crack cement stabilized macadam. J. Chang. Univ. Sci. Technol. (Nat. Sci.) 2013, 10, 1–6. [Google Scholar] [CrossRef]

- Zhang, C. Test and Analysis on the Performance of the Cement Treated Permeable Base. Highway 2014, 59, 161–164. [Google Scholar]

- Adamu, M.; Ayeni, K.O.; Haruna, S.I.; Mansour, Y.E.I.; Haruna, S. Durability performance of pervious concrete containing rice husk ash and calcium carbide: A response surface methodology approach. Case Stud. Constr. Mater. 2021, 14, e547. [Google Scholar] [CrossRef]

- CJJ/T 135-2009; Technical specification for pervious cement concrete pavement. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Guo, R.; Jiang, H.; Liu, C.; Chen, W. Experimental Study on Scour Resistance of Semi-Rigid Subgrade for Pavements. J. Shaanxi Univ. Technol. (Nat. Sci. Ed.) 2018, 34, 17–22. [Google Scholar] [CrossRef]

- Liu, J.; Wang, S.; Shi, K.; Zhang, C. Anti-erosion Performance and Fatigue Characteristics of Cement Concrete Pavement Base Materials. J. Highw. Transp. Res. Dev. 2022, 39, 43–49. [Google Scholar] [CrossRef]

- Han, H.; Li, J. Experimental Study on Strength Properties of Cement Stabilized Aggregate Base. Road Mach. Constr. Mech. 2016, 33, 41–45. [Google Scholar] [CrossRef]

- Zhou, R.; Yan, G.; Wang, J. Study on mechanical properties of water-stabilized gravel under moisturizing and nourishing membrane nourishment. Highw. Transp. Sci. Technol. (Appl. Technol. Ed.) 2016, 12, 205–206. [Google Scholar]

| Test Items | Test Outcomes | Technical Specifications | Test Procedures | |

|---|---|---|---|---|

| Fineness detection (%) | 0.5 | ≤10% | T0502-2005 | |

| Time to Set (in minutes) | Initial Set | 284 | ≥180 | T0502-2005 |

| Final Set | 403 | ≥360 | T0502-2005 | |

| Specific surface area (m2/kg) | 382 | 300 m2/kg~450 m2/kg | T0504-2005 | |

| Stability (mm) | 3 | ≤5 | T0505-2020 | |

| Cement Mortar Strength (MPa) | Flexural Strength (3 Days) | 4.6 | ≥2.5 | T0506-2005 |

| Compressive Strength (3 Days) | 19.5 | ≥10 | T0506-2005 | |

| Aggregate Size (mm) | Densities (g/cm2) | Mud Content (%) | Content of Needle and Flake Particles (%) | Crushing Value (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Apparent Density | Superficial Dry Density | Gross Bulk Compactness | Test Findings | Technical Condition | Test Findings | Technical Condition | Test Findings | Technical Condition | |

| 26.5~19 | 2.843 | 2.812 | 2.803 | 0.38 | ≤1 | 3.3 | ≤15 | 7.8 | ≤28 |

| 19~16 | 2.835 | 2.811 | 2.801 | 0.49 | 5.2 | ||||

| 16~13.2 | 2.830 | 2.808 | 2.797 | 0.65 | 7.4 | ||||

| 13.2~9.5 | 2.827 | 2.804 | 2.794 | 0.81 | 8.6 | ||||

| 9.5~4.75 | 2.825 | 2.798 | 2.791 | 0.93 | 10.1 | ||||

| Factor | Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A Gradation | 1 | 2 | 3 |

| B Water-cement ratio | 0.3 | 0.35 | 0.4 |

| C Target porosity (%) | 15 | 18 | 21 |

| Serial Number | Coding Level | Variable Value | ||||

|---|---|---|---|---|---|---|

| A Gradation | B Water-Cement Ratio | C Target Porosity (%) | A Gradation | B Water-Cement Ratio | C Target Porosity (%) | |

| 1 | 0 | 1 | −1 | II | 0.4 | 15 |

| 2 | 0 | 0 | 0 | II | 0.35 | 18 |

| 3 | 0 | −1 | 1 | II | 0.3 | 21 |

| 4 | 1 | 1 | 0 | III | 0.4 | 18 |

| 5 | 0 | 1 | 1 | II | 0.4 | 21 |

| 6 | 1 | 0 | 1 | III | 0.35 | 21 |

| 7 | 0 | 0 | 0 | II | 0.35 | 18 |

| 8 | 1 | 0 | −1 | III | 0.35 | 15 |

| 9 | −1 | 0 | 1 | I | 0.35 | 21 |

| 10 | 0 | 0 | 0 | II | 0.35 | 18 |

| 11 | 0 | 0 | 0 | II | 0.35 | 18 |

| 12 | 0 | −1 | −1 | II | 0.3 | 15 |

| 13 | −1 | 1 | 0 | I | 0.4 | 18 |

| 14 | 1 | −1 | 0 | III | 0.3 | 18 |

| 15 | 0 | 0 | 0 | II | 0.35 | 18 |

| 16 | −1 | −1 | 0 | I | 0.3 | 18 |

| 17 | −1 | 0 | −1 | I | 0.35 | 15 |

| Serial Number | A Gradation | B Water-Cement Ratio | C Target Porosity (%) | Rc 7-day Unconfined Compressive Strength (MPa) | Ec Compressive Resilience Modulus (MPa) | K Permeability Coefficient (mL/s) |

|---|---|---|---|---|---|---|

| 1 | II | 0.4 | 15 | 4.5 | 2084 | 48.1 |

| 2 | II | 0.35 | 18 | 3.5 | 1974 | 46.5 |

| 3 | II | 0.3 | 21 | 4.9 | 2046 | 47.2 |

| 4 | III | 0.4 | 18 | 3.8 | 1905 | 47.5 |

| 5 | II | 0.4 | 21 | 4.7 | 2156 | 46.4 |

| 6 | III | 0.35 | 21 | 4.0 | 2084 | 45.0 |

| 7 | II | 0.35 | 18 | 4.8 | 1948 | 51.8 |

| 8 | III | 0.35 | 15 | 3.8 | 2031 | 50.4 |

| 9 | I | 0.35 | 21 | 4.5 | 1972 | 45.0 |

| 10 | II | 0.35 | 18 | 4.0 | 1935 | 46.5 |

| 11 | II | 0.35 | 18 | 3.8 | 1945 | 49.8 |

| 12 | II | 0.3 | 15 | 4.1 | 1872 | 49.3 |

| 13 | I | 0.4 | 18 | 5.1 | 2264 | 48.1 |

| 14 | III | 0.3 | 18 | 5.0 | 2243 | 48.1 |

| 15 | II | 0.35 | 18 | 4.5 | 2184 | 47.1 |

| 16 | I | 0.3 | 18 | 4.8 | 2158 | 47.4 |

| 17 | I | 0.35 | 15 | 4.9 | 2195 | 48.8 |

| Source | Squared Sum | Degree of Freedom | Squared Mean | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Mould | 3.65 | 9 | 0.4053 | 7.84 | 0.0064 | ** |

| A Gradation | 1.81 | 1 | 1.81 | 35.07 | 0.0006 | ** |

| B Water-cement ratio | 0.025 | 1 | 0.025 | 0.483 | 0.5095 | |

| C Target porosity (%) | 0.0558 | 1 | 0.0558 | 1.08 | 0.3335 | |

| AB | 0.0019 | 1 | 0.0019 | 0.0374 | 0.8521 | |

| AC | 0.0261 | 1 | 0.0261 | 0.5044 | 0.5005 | |

| BC | 0.1418 | 1 | 0.1418 | 2.74 | 0.1417 | |

| 0.2002 | 1 | 0.2002 | 3.87 | 0.0898 | ||

| 0.8209 | 1 | 0.8209 | 15.88 | 0.0053 | ** | |

| 0.412 | 1 | 0.412 | 7.97 | 0.0257 | * | |

| Deviation | 0.362 | 7 | 0.0517 | |||

| Fit Failure | 0.161 | 3 | 0.0537 | 1.07 | 0.4563 | |

| Unexplained error | 0.201 | 4 | 0.0502 | |||

| Full correlation | 4.01 | 16 |

| Source | Squared Sum | Degree of Freedom | Squared Mean | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Mould | 2.26 × 105 | 9 | 25,082.73 | 8.85 | 0.0045 | ** |

| A Gradation | 7200 | 1 | 7200 | 2.54 | 0.155 | |

| B Water-cement ratio | 5886.12 | 1 | 5886.12 | 2.08 | 0.1927 | |

| C Target porosity (%) | 15,400.13 | 1 | 15,400.13 | 5.43 | 0.0525 | |

| AB | 240.25 | 1 | 240.25 | 0.0848 | 0.7794 | |

| AC | 6006.25 | 1 | 6006.25 | 2.12 | 0.1888 | |

| BC | 324 | 1 | 324 | 0.1143 | 0.7452 | |

| 7216.67 | 1 | 7216.67 | 2.55 | 0.1546 | ||

| 1.15 × 105 | 1 | 1.15 × 105 | 40.52 | 0.0004 | ** | |

| 53,431.67 | 1 | 53,431.67 | 18.85 | 0.0034 | ** | |

| Residual | 19,839.55 | 7 | 2834.22 | |||

| Lack of fit | 12,236.75 | 3 | 4078.92 | 2.15 | 0.2372 | |

| Pure error | 7602.8 | 4 | 1900.7 | |||

| Cor total | 2.46 × 105 | 16 |

| Source | Squared Sum | Degree of Freedom | Squared Mean | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Mould | 45.18 | 3 | 15.06 | 25.31 | <0.0001 | ** |

| A Gradation | 2.26 | 1 | 2.26 | 3.8 | 0.073 | |

| B Water-cement ratio | 0.1845 | 1 | 0.1845 | 0.3101 | 0.5871 | |

| C Target porosity (%) | 42.73 | 1 | 42.73 | 71.81 | <0.0001 | ** |

| Residual | 7.74 | 13 | 0.5951 | |||

| Lack of fit | 5.96 | 9 | 0.6623 | 1.49 | 0.371 | |

| Pure error | 1.78 | 4 | 0.4438 | |||

| Cor total | 52.92 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, X.; Peng, X.; Liu, H. Investigation of Mix Proportion Optimization and Anti-Scouring Performance of Pervious Concrete Base. Buildings 2025, 15, 1485. https://doi.org/10.3390/buildings15091485

Du X, Peng X, Liu H. Investigation of Mix Proportion Optimization and Anti-Scouring Performance of Pervious Concrete Base. Buildings. 2025; 15(9):1485. https://doi.org/10.3390/buildings15091485

Chicago/Turabian StyleDu, Xiaoxuan, Xinghai Peng, and Hongfu Liu. 2025. "Investigation of Mix Proportion Optimization and Anti-Scouring Performance of Pervious Concrete Base" Buildings 15, no. 9: 1485. https://doi.org/10.3390/buildings15091485

APA StyleDu, X., Peng, X., & Liu, H. (2025). Investigation of Mix Proportion Optimization and Anti-Scouring Performance of Pervious Concrete Base. Buildings, 15(9), 1485. https://doi.org/10.3390/buildings15091485