Effect of Pile Spacing on Load Bearing Performance of NT-CEP Pile Group Foundation

Abstract

1. Introduction

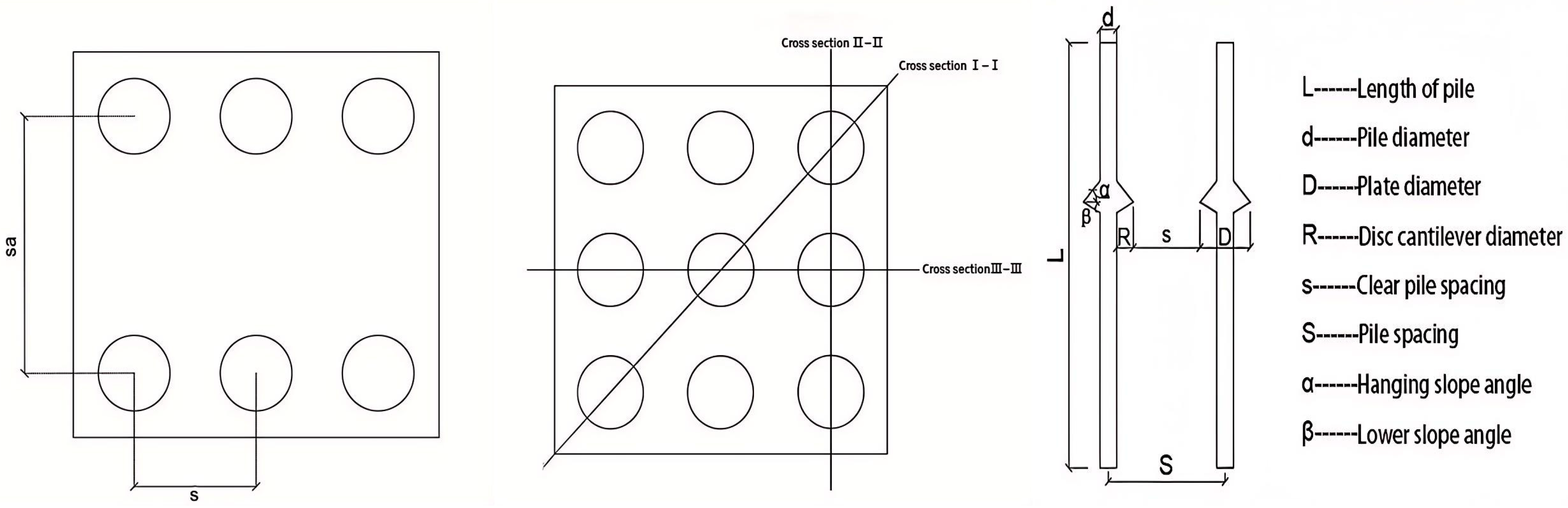

2. ANSYS Finite Element Modeling

2.1. Selection of Unit Type

2.2. Material Properties and Meshing

3. Analysis of ANSYS Finite Element Simulation Results

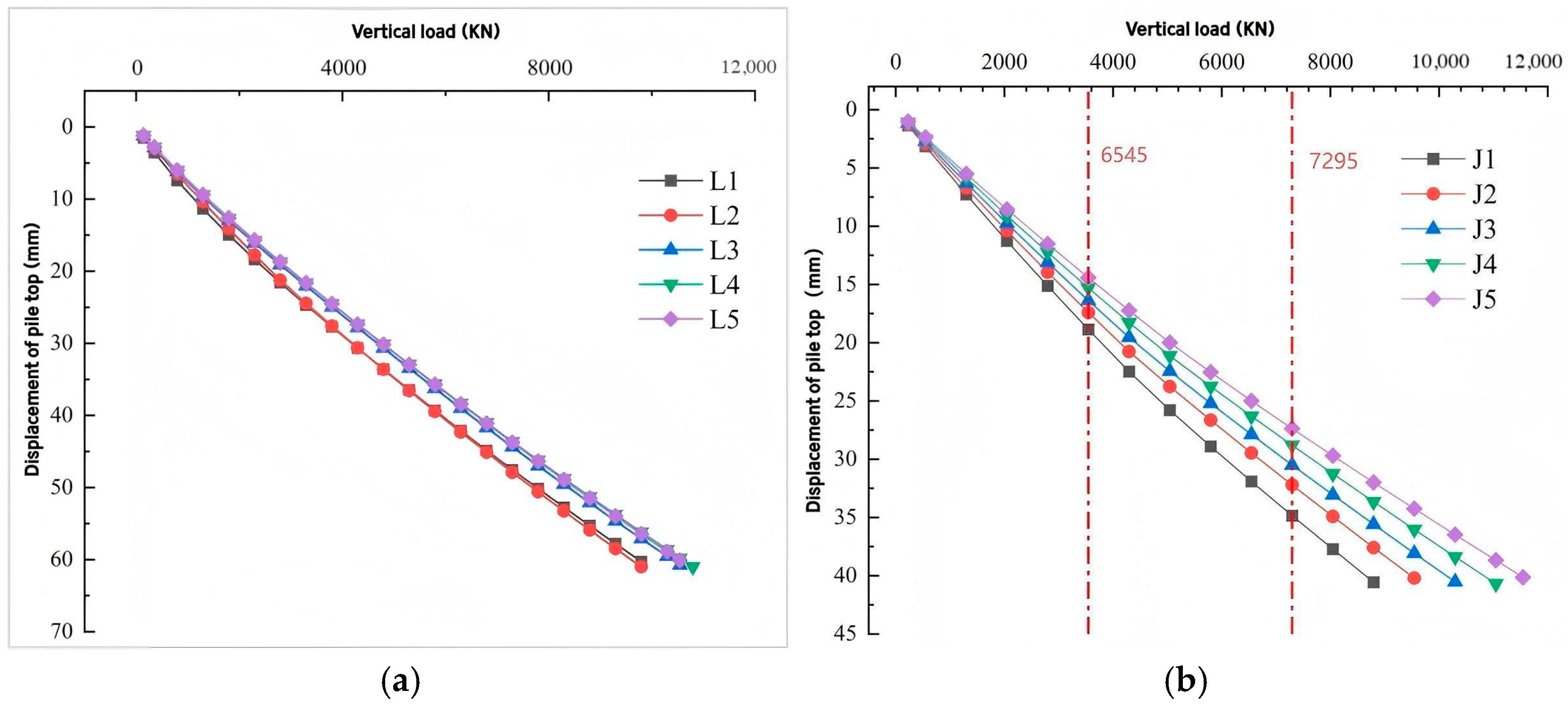

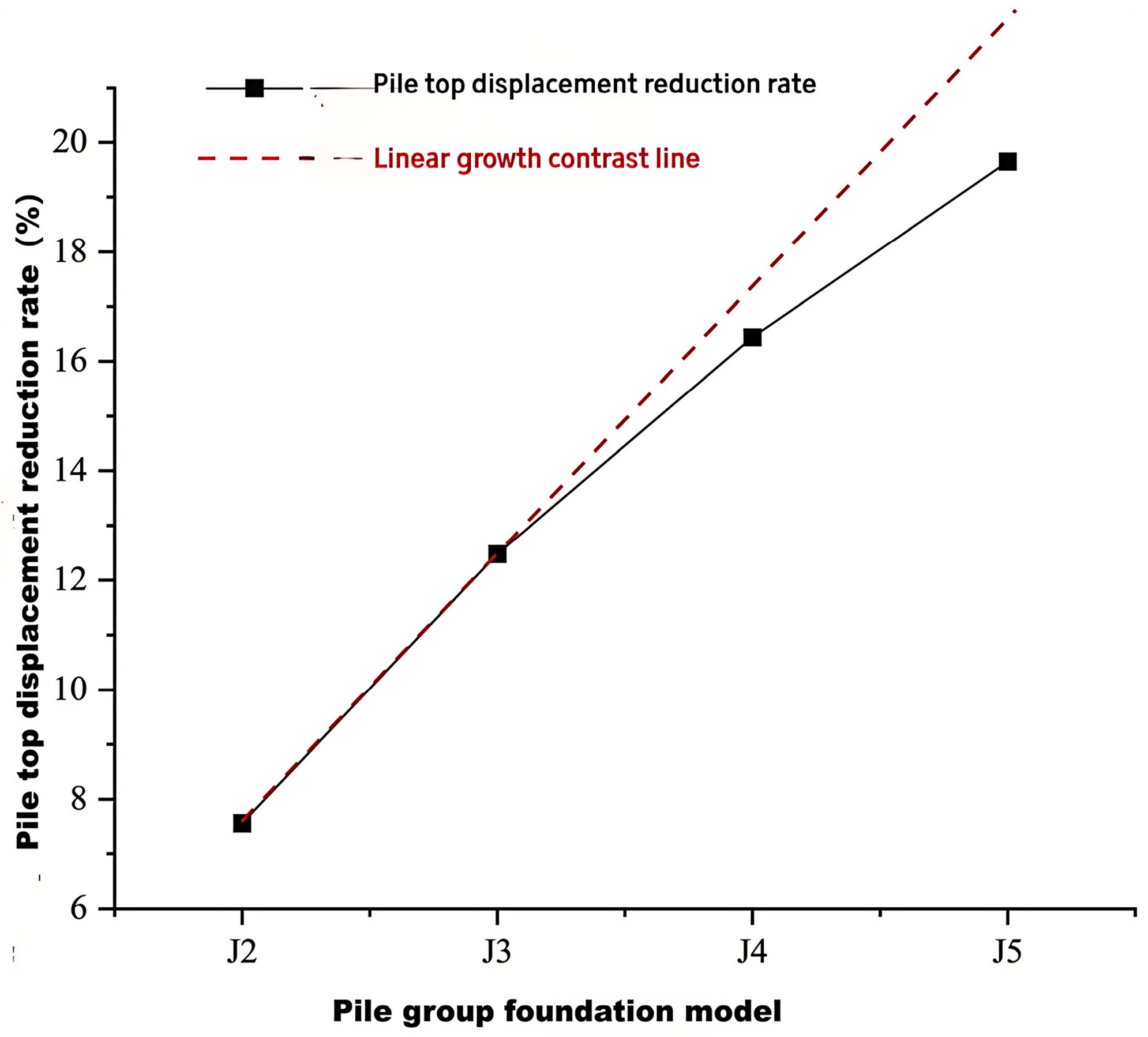

3.1. Analysis of Vertical Load–Pile-Top Displacement Curve

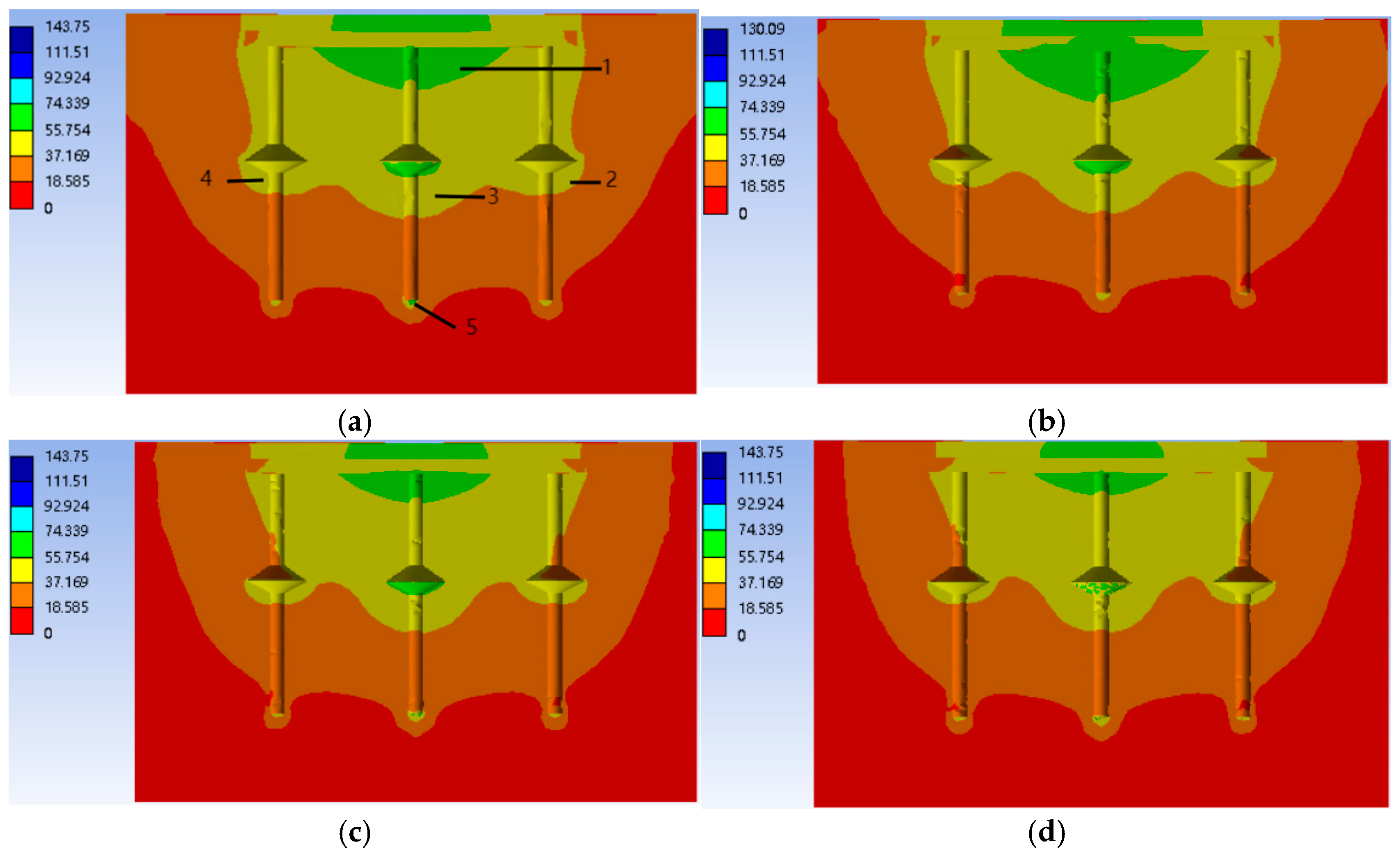

3.2. Comparative Analysis of Soil Displacement Cloud Map Around Pile

3.2.1. Soil Displacement Diagram Around Six Piles

3.2.2. Cloud Map of Jiudang Soil Displacement

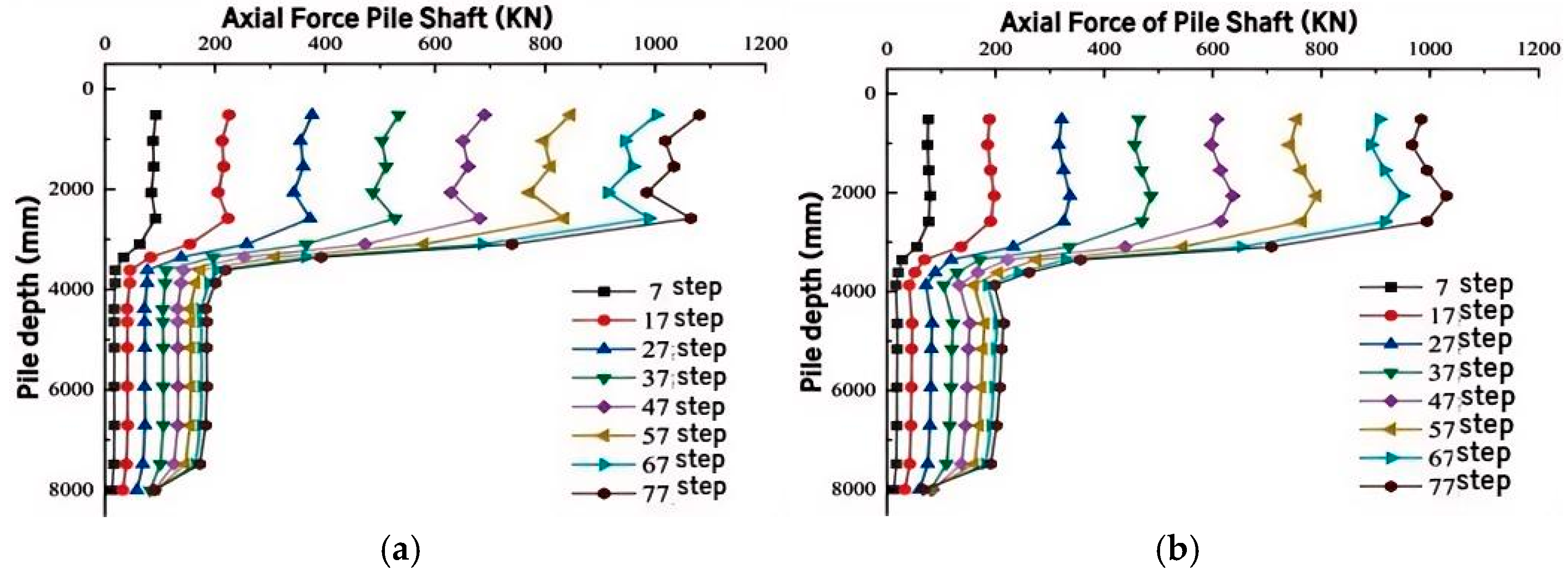

3.3. Analysis of Axial Force and Side Friction of Foundation Pile

3.3.1. Analysis of Axial Force and Side Friction of Six Piles

3.3.2. Analysis of Pile Axial Force and Pile Side Friction Resistance of Nine-Pile Foundations

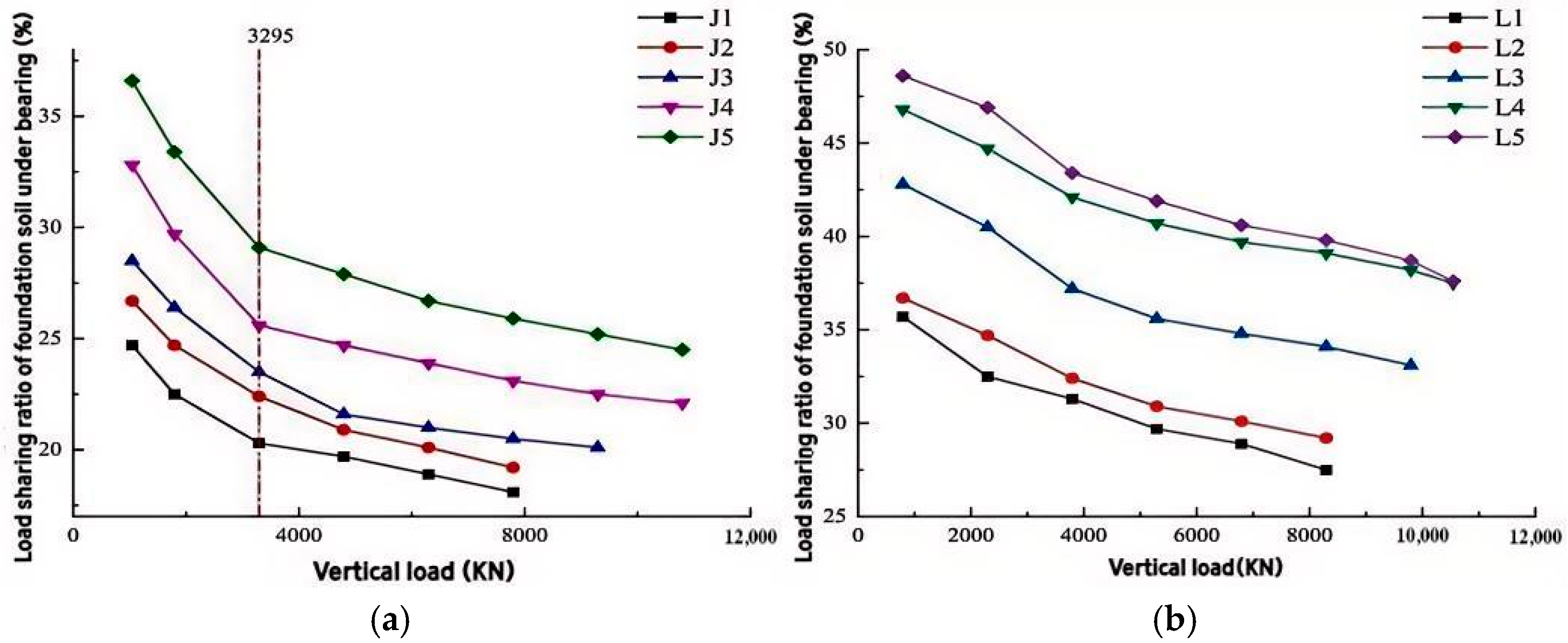

3.4. Analysis of Foundation Soil Under the Bearing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, H.-W.; Wu, Y.-Y.; Tong, Y.; Jiang, X.-Q. Research on bearing theory of squeezed branch pile. Adv. Civ. Eng. 2020, 2020, 6637261. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, P.; Cui, W.; Gao, Y. Bearing behavior and failure mechanism of squeezed branch piles. J. Rock Mech. Geotech. Eng. 2018, 10, 935–946. [Google Scholar] [CrossRef]

- Gao, X.-J.; Wang, J.-C.; Zhu, X.-R. Static load test and load transfer mechanism study of squeezed branch and plate pile in collapsible loess foundation. J. Zhejiang Univ.-Sci. A 2007, 8, 1110–1117. [Google Scholar] [CrossRef]

- Ju, Y.; Chen, Y.F. Experimental study for the bearing capacity calculation of concrete expanded plates in squeezed branch piles. Mater. Test. 2018, 60, 1118–1124. [Google Scholar] [CrossRef]

- Tang, S.T.; Chen, L.H. Field test of dx pile group. Adv. Mater. Res. 2011, 243–249, 2451–2455. [Google Scholar] [CrossRef]

- Do, D.H.; Pham, T.A. Investigation of performance of soil-cement pile in support of foundation systems for high-rise buildings. Civ. Eng. J. 2018, 4, 266–277. [Google Scholar] [CrossRef]

- Wang, H.; Ran, Z.; Yan, J. Design and application of expanded pile in bridge super-large diameter pile foundation. Jiangxi Build. Mater. 2022, 187–189+192. [Google Scholar]

- Wang, H.; Jin, X. Application of construction technology of super-large variable diameter consolidated disc expanding pile in confined space under silty sand geology. Eng. Constr. Des. 2022, 7, 144–146. [Google Scholar]

- Brown, D.A.; Morrison, C.; Reese, L.C. Lateral load behavior of pile group in sand. J. Geotech. Eng. 1988, 114, 1261–1276. [Google Scholar] [CrossRef]

- Hadi, D.H.; Waheed, M.Q.; Fattah, M.Y. Effect of Pile’s Number on the Behavior of Piled Raft Foundation. Eng. Technol. J. 2021, 39, 1080–1091. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Al-Obaydi, M.A.; Al-Jalabi, F.A. Effect of number of piles on load sharing in piled raft foundation system in saturated gypseous soil. Int. J. Civ. Eng. Technol. (IJCIET) 2018, 9, 932–944. [Google Scholar]

- Al-Suhaily, A.S.; Abood, A.S.; Fattah, M.Y. Bearing capacity of uplift piles with end gates. In Proceedings of China-Europe Conference on Geotechnical Engineering: Volume 2; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 893–897. [Google Scholar]

- Qian, Y.; Dong, Y.; Tian, W.; Jin, Y. Theoretical Analysis on the Influence of the Slope Angle of Plate for the Failure Mechanism of the Concrete Expanded-Plates Pile Applied for Oceanographic Engineering under the Horizontal Force. J. Coast. Res. 2019, 98, 10–13. [Google Scholar] [CrossRef]

- Qian, Y.; Cheng, Q.; Tian, W.; Xu, G. Field test study on compressive failure mechanism of concrete dish-expanded pile with large proportion of half-sided pile. Ind. Archit. 2015, 45, 120–123+130. [Google Scholar]

- Yu, H.; Qian, Y.; Niu, L.; Li, Z. Study on the effect of disc cantilever diameter on the uplift bearing performance of double piles of concrete expanded pile. Build. Struct. 2023, 53, 147–151. [Google Scholar] [CrossRef]

- Qian, Y.; Zhai, R. Analysis of the Effect of the Space of the Bearing Plate on the Uplift Bearing Capacity of the Concrete Plates-expanded Pile. Open Civ. Eng. J. 2015, 9, 610–615. [Google Scholar] [CrossRef]

- Zhu, H.T. Application of reinforced concrete element SOLID65 in ANSYS software. Heilongjiang Sci. Technol. Inf. 2008, 143+269. [Google Scholar]

- Lv, T.; Zhao, J.; Xue, L. The Influence of Modeling Methods on the Meshing when Solid Element Was Used in ANSYS—Taking the Design by Analysis of Dry Welding Experiment Module as an Example. Appl. Mech. Mater. 2010, 42, 232–235. [Google Scholar] [CrossRef]

- Xing, J.; Li, J. The modeling method and the mesh division of the ANSYS. China Water Transp. (Acad.) 2014, 10, 116–118. [Google Scholar]

- Song, Y.J.; Hu, W.; Wang, D.S. Analysis of compacted pile squeezing effect based on modified Cambridge model. Rock Soil Mech. 2011, 32, 811–814. [Google Scholar]

- Li, Q.L. Research on Meshing Methods in ANSYS. J. Shanghai Dianji Univ. 2006, 28–30. [Google Scholar]

| Materials | Density (t/mm3) | Modulus of Elasticity (MPa) | Poisson’s Ratio | Cohesion (MPa) | Friction Angle (°) | Pile–Soil Friction Coefficient |

|---|---|---|---|---|---|---|

| concrete | 2.25 × 10−9 | 3.465 × 104 | 0.2 | -- | -- | 0.3 |

| clay | 1.488 × 10−9 | 25 | 0.35 | 0.04355 | 10.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, Y.; Li, H.; Tian, W.; Yu, H.; Zhang, Y.; Guan, M.; Ma, Z. Effect of Pile Spacing on Load Bearing Performance of NT-CEP Pile Group Foundation. Buildings 2025, 15, 1404. https://doi.org/10.3390/buildings15091404

Qian Y, Li H, Tian W, Yu H, Zhang Y, Guan M, Ma Z. Effect of Pile Spacing on Load Bearing Performance of NT-CEP Pile Group Foundation. Buildings. 2025; 15(9):1404. https://doi.org/10.3390/buildings15091404

Chicago/Turabian StyleQian, Yongmei, Hualong Li, Wei Tian, Hang Yu, Yingtao Zhang, Ming Guan, and Zhongwei Ma. 2025. "Effect of Pile Spacing on Load Bearing Performance of NT-CEP Pile Group Foundation" Buildings 15, no. 9: 1404. https://doi.org/10.3390/buildings15091404

APA StyleQian, Y., Li, H., Tian, W., Yu, H., Zhang, Y., Guan, M., & Ma, Z. (2025). Effect of Pile Spacing on Load Bearing Performance of NT-CEP Pile Group Foundation. Buildings, 15(9), 1404. https://doi.org/10.3390/buildings15091404