1. Introduction

The construction sector is known for its high-risk nature and has poor safety performance in both developed and developing nations. For instance, in the USA, 1008 deaths were recorded in 2022, while in the UK, 49 deaths were recorded in 2023 within the construction sector [

1,

2]. In countries such as India, 11,614 deaths are recorded in the construction sector per annum and 20 are recorded in South Africa [

1,

3]. In China, there are 7275 deaths due to accidents in the construction sector per annum. Researchers have extensively studied construction H&S, which is a significant concern in management practices [

4]. It is also considered a top priority due to the dangerous and complex procedures within the construction sector [

5]. There has been a pressing need for legislative reform for the H&S practices of the construction industry, which remains unnecessarily hazardous in many parts of the world [

6]. According to Guo et al. [

7], the administration of H&S procedures in the construction sector has historically been labour-intensive, manual, and error-prone. They hypothesised that traditional monitoring and inspection methods make it difficult to monitor every employee and the entire facility. Additionally, traditional construction H&S methods often use hazard recognition systems that rely on paper, which impede timely risk communication.

Given this, various researchers [

8,

9,

10,

11] recommend the application of digital technologies (DTs) within the construction sector to manage safety, including wearable technology, unmanned aerial vehicles (UAVs), virtual and augmented reality (VR/AR), building information models (BIMs), and artificial intelligence (AI). These technologies have proven to be reliable and essential for H&S planning, training and education, and management [

12]. Li et al. [

13] and Razi et al. [

14] also confirmed that these technologies can better predict the potential risks and hazards that may arise during the various stages of construction. Users can also detect H&S issues through the use of visualising technologies, such as VR and AR [

15]. AI has also been used for risk prediction, and AI-powered picture identification can assist in determining whether construction workers are correctly wearing personal protective equipment [

16]. Despite the potential of these technologies to improve construction H&S, their adoption remains low [

17] in developing and developed countries.

Many studies have explored the general use, benefits, and barriers of DTs in managing construction H&S [

13,

18,

19], and others have conducted reviews on the implementation of DTs in managing construction H&S [

4,

15,

20,

21]. However, most of these studies do not highlight current academic trends, primary impacts, and the most prevalent DTs used in managing construction H&S, and neither do they attempt to compare how these current trends regarding DT use in construction H&S management differ between developed and developing countries. Understanding the current trends of DT application in construction H&S would support the implementation process and mainstream adoption of these technologies. As a result, this study intends to gain a deeper understanding of the current DT trends in building H&S for developed and developing countries from an academic and industrial viewpoint. The SLR was expedited with three research questions, which include the following:

RQ1: Which DTs are currently being used in the construction industry to manage health and safety?

RQ2: Which research techniques are employed in DTs for studying safety?

RQ3: What effect does DT have on the construction sector’s safety management?

2. Literature Review

2.1. Global Perspectives on Construction Safety

Construction work is well known for being conducted under hazardous, poor, and unpleasant working conditions. The International Labour Organisation (ILO) claims that construction workers are exposed to dangerous materials on a regular basis, including dangerous atmospheres, radiation, noise, and vibrations [

15,

22]. Umer et al. [

8] confirmed this by pointing out that in comparison to other industries, the construction sector has one of the highest rates of occupational fatalities and injuries. Incorrect posture, heavy machinery, falls from heights, hard lifting and carrying, and unfavourable weather and wind conditions are the main risk factors that lead to accidents and occupational injuries [

22]. Because construction crews produce high-performance buildings and other civil works, Nnaji and Karakhan [

23] came to the conclusion that their welfare is essential to construction productivity and quality. The construction industry accounted for 1061 of the 5333 fatal occupational accidents that occurred in the United States in 2019, according to a report released by the U.S. Bureau of Labour Statistics (BLS) [

1]. Similarly, Eurostat data show that in 2018, there were 3332 fatalities in Europe, with the construction sector accounting for one-fifth of these cases [

24,

25].

The construction industry has a fatal injury rate that is four times greater than that of other industries, and the total cost of injuries in 2020 rose by 34% from 2018 [

2]. These concerning figures demonstrate that building H&S is a worldwide issue. In light of this, scholars have criticised the construction sector, arguing that conventional methods used for construction safety are insufficient to safeguard the welfare of construction workers [

7,

26,

27] and have suggested more sophisticated methods to enhance construction H&S [

10].

2.2. Review Studies on Digital Tools for Managing Safety in Construction

As stated earlier, some studies have conducted reviews on the use of DTs for managing construction safety. However, most of these studies do not highlight current academic trends, primary impacts, and the most prevalent DTs used in managing construction H&S, and neither do they attempt to compare how these current trends regarding DT use in construction H&S management differ between developed and developing countries. Akinlolu et al. [

15] conducted a comprehensive bibliometric review of construction safety management technologies. Their study revealed a significant increase in research output on this topic over the past decade, indicating growing academic and industry interest. A thorough analysis of the use of immersive technology in construction safety management was presented by Babalola et al. [

21]. Their research demonstrated the industry’s increasing use of mixed reality (MR), augmented reality (AR), and virtual reality (VR) technologies. The authors noted that VR, in particular, has been effective in creating realistic simulations of construction sites, allowing workers to experience and respond to potential hazards in a safe, controlled environment.

Guo et al. [

7] explored the dynamics of behaviour-based safety programs in the construction industry using a system dynamics approach. Their study emphasised the importance of understanding the complex interactions between various factors that influence safety behaviours and proposed a model that considers the interplay between management commitment, worker participation, and safety performance. The potential of computer vision technologies for safety science and management in the construction industry was examined in a study by Guo et al. [

4]. The authors identified several promising applications, including automated hazard recognition, safety inspection, and worker behaviour analysis. Additionally, Dobrucali et al. [

20] conducted a bibliometric study of digital tools that can be used for building safety. Their study revealed an increasing trend in the use of several digital platforms and tools for safety management. In comparison, Trask and Linderoth, ref. [

28] provided a systematic mapping review of digital technologies. Their study highlighted the potential of digital tools to improve safety outcomes through better data collection, analysis, and procedures for decision-making. The writers also emphasised how crucial it is to take into account the human factors and organisational aspects when implementing these technologies to ensure their effectiveness and adoption.

3. Research Methodology

The current study used a systematic literature review (SLR) to look at the body of knowledge about the intersection of the following terms: “Virtual reality”, “Augmented reality”, “Digital technology”, “Machine learning”, “Artificial Intelligence”, “Health”, “safety”, and “Construction Industry”. An SLR comprises the synthesis of all data relevant to a certain field of study in order to obtain answers to specific research questions, according to Moher et al. [

29]. By revealing gaps and fresh paths for future research, systematic reviews, using simple approaches, lessen prejudice. According to Abam et al. [

30], SLR is a useful method for condensing research on the built environment. Subjects such as status and emerging research trends in construction safety, Akinlolu et al. [

15], the lean-offsite-simulation nexus for housing construction, Daniel and Oshodi [

31], and SLRs of digital technology use in the Architecture, Engineering, and Construction (AEC) Industry, Manzoor et al. [

32], have been explored prior. SLR is appropriate for addressing the research issue posed in the opening of this work because of the importance of the repeatability of outcomes.

Finding pertinent keywords, searching pertinent databases, filtering search results according to inclusion criteria, and content analysis of the publications that meet the inclusion criteria were the steps of the SLR employed in this work. The study question stated in the introduction was answered by the data gathered from the fourth stage.

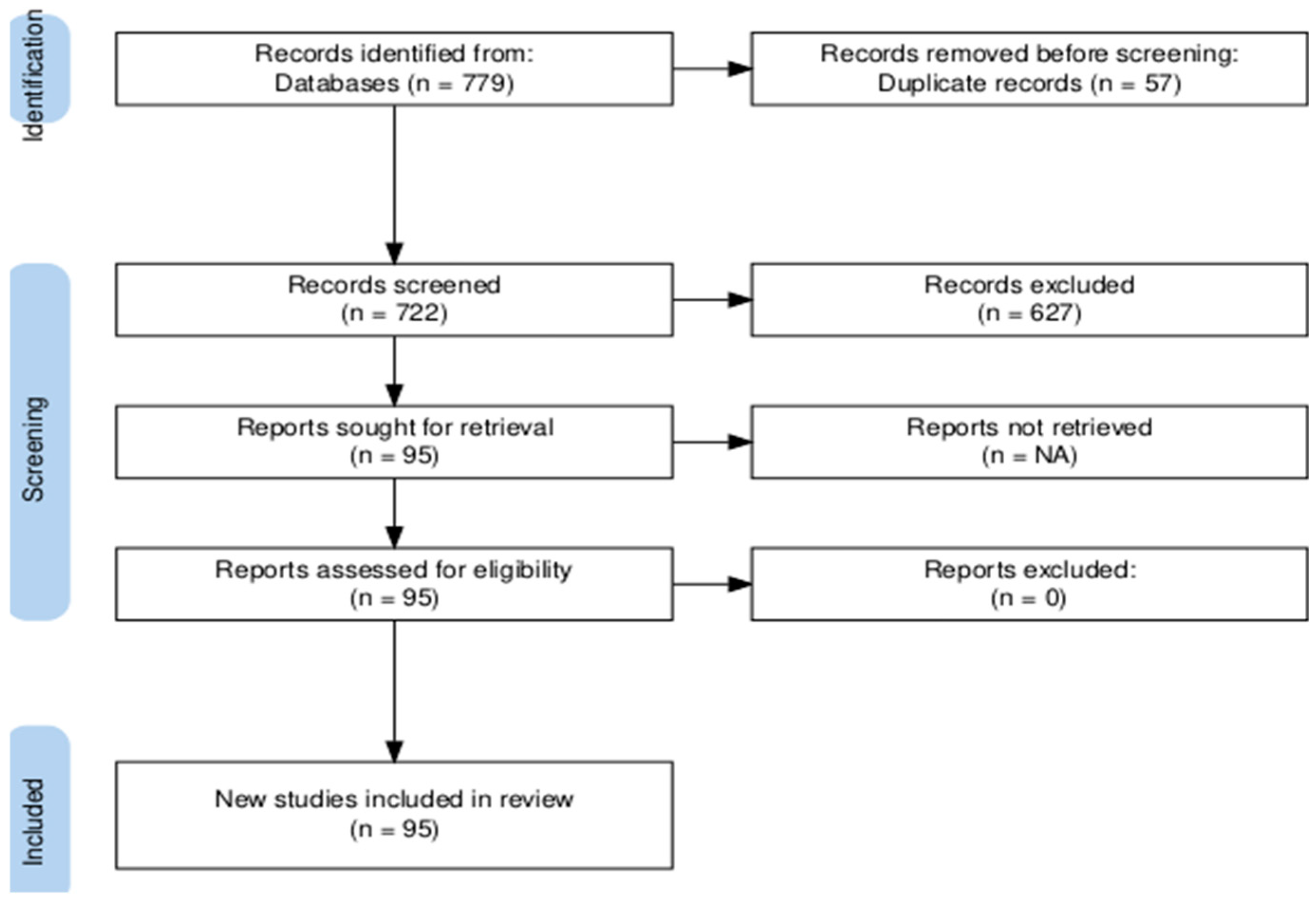

The process used for the SLR is depicted in a PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) flow diagram in

Figure 1. A popular method for representing the study selection process in systematic reviews and meta-analyses is the PRISMA flow diagram [

33]. It provides a clear visual representation of the screening and literature search procedure. There are typically four main sections in a PRISMA flow diagram:

Identification: The quantity of records discovered through database searches and other sources is shown in this section.

Screening: This displays the number of records that were screened and excluded, as well as the number of records that remain after duplicates are removed.

Eligibility: This section lists how many full-text articles were assessed for eligibility and how many were rejected, along with the reasons why.

The number of studies included in the qualitative synthesis and, if applicable, the quantitative synthesis (meta-analysis) are listed in the last section. According to Haddaway et al. [

34], the figure also guarantees transparency and reproducibility in the review process by explaining how the researchers chose the final group of included publications.

3.1. Search Keywords: Identification

Based on the study topic, seven keywords were initially chosen for the database search, i.e., “Virtual reality”, “Augmented reality”, “Digital technology”, “Machine learning”, “Artificial Intelligence”, “Health”, “safety”, and “Construction Industry”. Various terms such as immersive technology and serious gaming are used interchangeably with virtual reality as well as augmented reality in digital technology for H&S management literacy in construction. Similar terms and synonyms for the construction industry and occupational and safety that were found in previous literature review studies served as the basis for the keywords utilised to search pertinent databases [

4,

15,

20,

21]. The search terms used for the database search are shown in

Table 1.

3.2. Data Collection

To make sure all of the relevant studies were located, a comprehensive search strategy was employed when looking through the pertinent databases. The databases used in this study were Web of Science (WoS) and Scopus. Pranckutė [

35] asserts that WoS and Scopus, a multidisciplinary and selective bibliographic database, are the most reliable and authentic data sources. WoS and Scopus are large publications and citation databases, according to Li et al. [

13] (2018) and Dobrucali et al. [

20], who used them in related studies. These two databases were sufficient for finding relevant documents, guaranteeing the reproducibility of this study’s findings. The keyword combinations used in the database search are shown in

Table 1. An overview of the search results is shown in

Table 1. The search produced 779 published studies from the WoS and Scopus databases. The earliest publications on digital technologies in construction safety, according to the bibliometric search, were released in 1997 for Web of Science and in 2005 for Scopus. As a result, the scope was restricted to the period of 1997 to 2024 in WoS and 2005 to 2024 in Scopus.

3.3. Filtering of Search Results

The first set of search results, such as samples, was filtered using the inclusion and exclusion criteria. By using this screening technique, the sample was ensured to be free of research that was not pertinent. The screening process was divided into two stages. First, the title and abstract of each of the 779 journal articles and conference proceedings papers (115 from Scopus and 664 from WoS search) were read. Of the 779 items discovered during the search phase, 684 (356 journal articles and 328 conference proceedings) were excluded from the sample based on the following exclusionary criteria:

Out of the data gathered, 57 (34 journal articles and 23 conference proceeding articles) duplicates were removed as the results of the Scopus and WoS searches overlapped.

The purpose of the identified studies.

The application of digital technology in H&S construction management is the main topic of the current review. Therefore, studies that focused on applying these methods to other projects were ignored. Because Khean et al. [

36] focused on analysing potential socio-economic factors that affect machine learning research in the Architecture, Engineering, and Construction (AEC) Industry, for instance, their work was not included in the search results. The focus of the research led to the exclusion of 627 papers (320 journal articles and 307 conference proceedings articles). The search results included 95 papers (61 journal articles and 34 conference proceedings papers) at the conclusion of the first filtering step. Second, the 95 articles’ full texts were examined to make sure the inclusion criteria—that is, the study’s focus—were satisfied. As all 95 papers satisfied the inclusion criteria, these 95 articles remained in the search results after the filtering process and were used for the research analysis.

4. Qualitative Content Analysis of Search Results

The 95 pertinent articles underwent a comprehensive qualitative content analysis. When assessing the qualitative content data, the planned study objectives listed in the introduction were taken into account. Papers that satisfied the selection criteria were assigned code numbers (i.e., 1 to 95) to begin the qualitative content analysis. To address the goals of the research, the tagged publications were read. A portion of the qualitative content results was quantified for better visualisation; in particular, the study’s findings, which are covered in

Section 5 and are summarised and presented in

Figure 2 and

Figure 3.

Furthermore, a thematic mapping of the effects of DTs for construction safety management in both developed and developing nations can be found in

Section 5. This was accomplished through thematic analysis, or the development of themes. Thematic analysis, according to Braun and Clarke [

37], comprises identifying, evaluating, and summarising patterns (themes) in data. Large qualitative datasets can be analysed and made sense of with the help of thematic analysis. The data can be interpreted using a variety of methods, including deductive (theory-driven) and inductive (data-driven) approaches [

37,

38,

39,

40]. Therefore, using a systematic review and thematic analysis, this approach was utilised to find and classify the findings of the pertinent publications.

5. Discussion

5.1. Distribution of DT Application in Health and Safety Management in Developed and Developing Countries

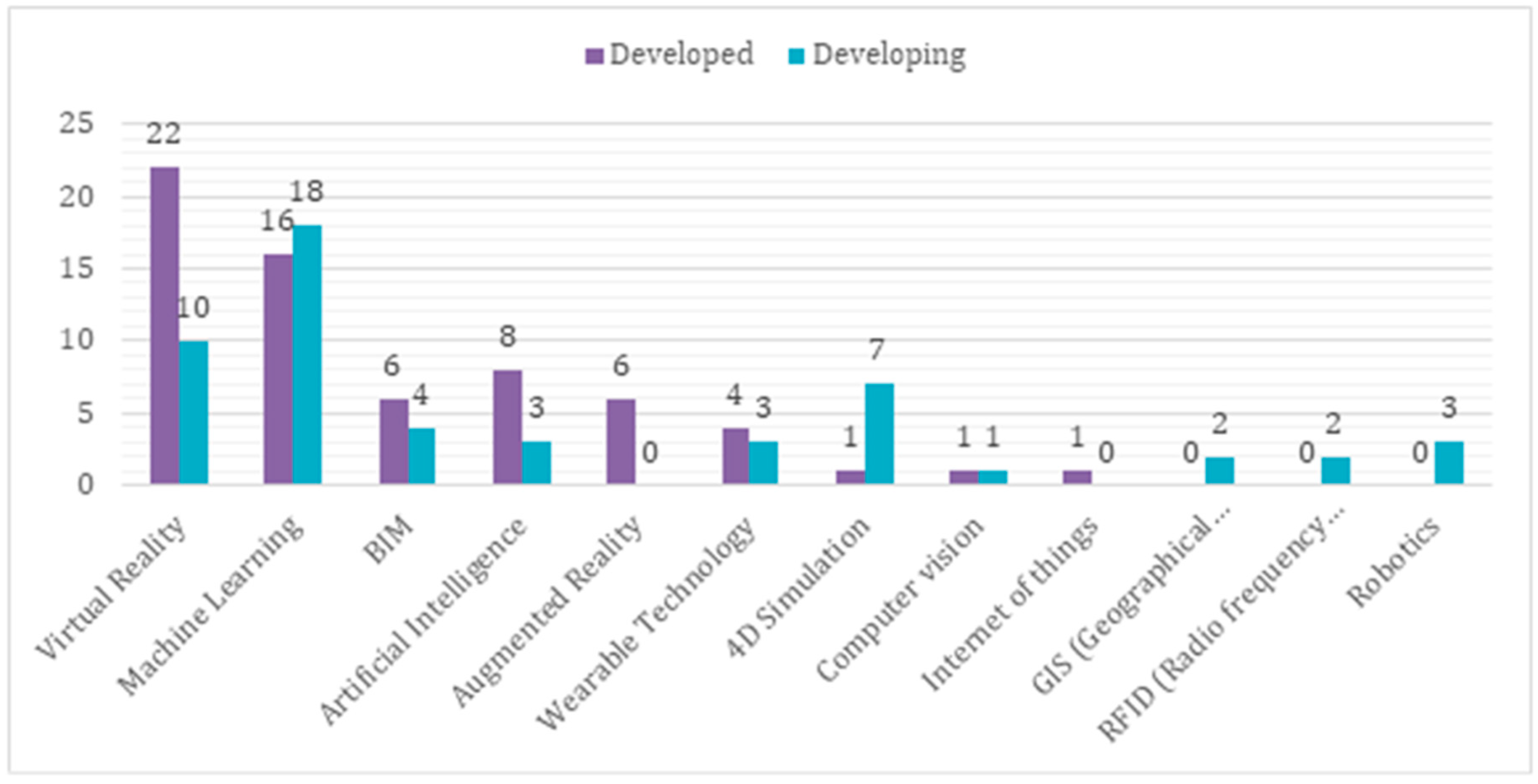

The findings shown in

Figure 2 illustrate how various digital technologies are currently being used in both developed and developing nations’ construction industries. It is evident that the developed and developing nations’ adoption of digital technology in health and safety management differs significantly.

In developed countries, it is evident that digital technology, such as virtual reality, machine learning, and artificial intelligence, is being utilised extensively in health and safety management. According to the available literature, these technologies are being utilised for a number of purposes, including worker monitoring, training, and risk assessment. For instance, a study by Sommerville et al. [

41] found that virtual reality technology effectively trained workers on safety procedures and reduced accidents. In another study by Demirbas et al. [

42], machine learning was utilised for risk assessment and predicting work-related accidents.

However, there is little usage of digital technology for managing health and safety in developing nations. The data presented in the chart show that only a few of these countries are actively incorporating digital technologies in their construction sector. This can be attributed to a lack of resources, limited access to technology, and a lack of skilled personnel. For instance, a study by Noura et al. [

43] found that developing countries, such as India and China, face challenges in fully implementing digital technology in the construction sector due to a shortage of skilled workers and limited access to technology.

However, efforts are being made to integrate digital technology into safety and health management in poor countries. For instance, a study by Ren et al. [

44] proposed that building information modelling (BIM) could be used for safety management in developing countries by creating 4D simulations and risk assessment. This shows the potential for use in underdeveloped nations; digital technology is being used to manage health and safety, and additional studies and funding are needed to utilise its benefits fully.

Regarding specific technologies, augmented reality, wearable technology, and 4D simulation have low adoption rates in developed and developing countries. These technologies can enhance construction site safety by providing workers with real-time information and warnings. The low adoption rate shows that these technologies are not widely used in the industry.

Table 2 shows the comparative differences between the use of AR and wearable technology adoption that are not seen for VR or AI.

5.2. Reasons for Lower Adoption Rates of AR and Wearables

Research suggests that AR and wearables face specific technological and design challenges that hinder their adoption compared to VR and AI. For AR, the cost of the hardware required for creating and running digital applications can be a significant barrier to its usage [

45]. Also, the use of wearables (such as hand vibration syndrome [HAV] watches) was limited, and this situation can be linked to the limited knowledge among the workforce [

46]; workers are not comfortable with long-term wear, battery life constraints, and ensuring data accuracy, particularly for health-related applications [

46].

Stakeholder perspectives on AR and wearable technologies often clash, creating barriers to effective implementation. Workers may resist these tools due to discomfort, increased cognitive load, or concerns over constant monitoring and data privacy, perceiving them as surveillance rather than support [

45,

46]. On the other hand, IT system integrators grapple with usability challenges such as ensuring seamless system integration, real-time data processing, device interoperability, and user-friendly interfaces [

38]. If these technologies are not intuitive or reliable, adoption rates drop significantly. Bridging this gap requires stakeholder collaboration, user-centred design, and ongoing feedback loops to align technical functionality with practical, on-the-ground usability and acceptance.

In contrast, VR benefits from established use cases in gaming and simulation, which have driven its adoption despite challenges like motion sickness [

47]. AI, being software-centric, is easily integrated into existing business processes, with adoption rates boosted by its utility in data analytics and customer service, despite barriers like data quality and ethical concerns [

48].

To elaborate, the barriers unique to AR and wearables, which are not as prevalent for VR or AI, include the following:

For AR:

Hardware Limitations: AR requires precise tracking and rendering for real-world integration, demanding high computational power. Current devices often have a limited field of view and poor display quality, hindering user experience [

45].

Real-World Integration Challenges: The need to overlay digital information accurately on the real world can lead to technical glitches and less intuitive interactions, unlike VR, which operates in a controlled digital environment, or AI, which is software-based and does not require physical overlays.

For Wearables:

Comfort and Design Issues: Wearables must be unobtrusive and comfortable for extended wear, a challenge not as critical for VR (used in short sessions) or AI (not worn). Current designs can be bulky or aesthetically unappealing, reducing adoption [

46,

49].

Battery Life Constraints: Wearables need a long battery life in small form factors, a unique challenge compared to VR, which often uses tethered systems, or AI, which does not rely on wearable hardware.

Data Accuracy and Reliability: For health-related wearables, ensuring sensor accuracy is crucial, a barrier not as prevalent for VR (focused on immersion) or AI (data quality is different, related to bias and completeness).

In comparison, VR faces unique barriers like motion sickness due to its immersive nature and isolation from the real world, which can have its own safety concerns, but these are less related to the hardware design and more to user experience [

50]. AI’s barriers, such as ethical concerns about bias, transparency, and job displacement, are software-related and do not overlap with the hardware and wearability issues of AR and wearables [

51].

Barriers such as cost, usability, and data concerns significantly impact the adoption of emerging safety technologies. Augmented reality (AR) often struggles with hardware limitations and poor integration with dynamic construction environments, as shown in Yan et al. (2017) [

52], a study conducted in Hong Kong regarding the accuracy of the captured body section. Wearables, though promising, face pushbacks due to discomfort and privacy issues, with workers rejecting biometric monitoring [

53,

54]. DT tools, despite their potential, often underperform due to poor data quality and a lack of skilled personnel, contributing to safety prediction failure.

5.3. Research Method Used in Previous Studies

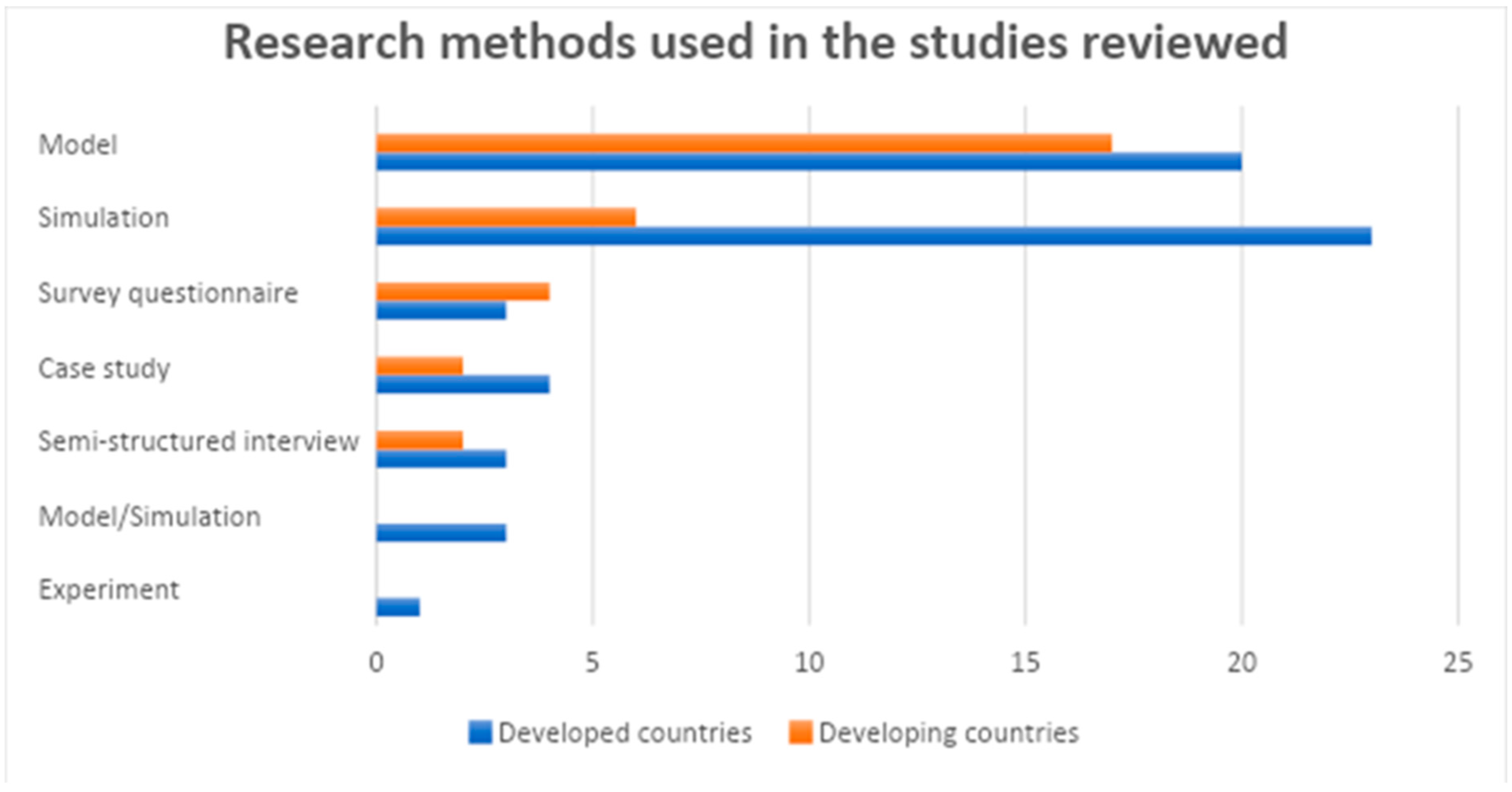

The research methods adopted in previous studies are presented in

Figure 3. The study techniques employed focused on applying immersive technology and AI in safety management, including modelling, simulation, questionnaire surveys, case studies, interviews and experiments. The prevalent research methods in this area are modelling and simulation. In contrast, experimentation is the least utilised research method. Also, there seems to be a difference in the use of simulation and experiments when comparing the quantity of research projects carried out in both developed and underdeveloped nations. Compared to the number of studies that have used modelling and simulation, the usage of case studies is relatively few. This observation could be linked to the reluctance of construction companies to adopt new technologies and researchers’ lack of access to real-world data.

5.4. The Impact of Digital Technology on Safety Management in the Construction Sector

Five themes covering the impact of DT were identified from 95 publications from developed and developing countries that were reviewed in a methodical manner. These included education training, prediction, proactive safety measures, monitoring and evaluation, predictive decision support, and communication and collaboration. These themes are discussed below.

5.4.1. Education and Training Impact

This study found that using DTs significantly impacts instruction and practice. With the increasing use of digital technology across industries, the construction sector has also started incorporating DTs into its safety management training programs.

One of the main themes highlighted in the sub-themes is the use of VR technology in safety training. According to refs. [

55,

56], VR technology allows for realistic and immersive training simulations which can improve safety competencies and motivation for workers. This is especially beneficial in the construction sector where workers are exposed to various hazards and risks. Through the use of VR simulations, workers can experience and practice dealing with potential safety incidents in a controlled environment, reducing the risk of real-life accidents. This is further supported by research conducted by [

57], which found that VR-based safety training led to increased safety knowledge, awareness, and positive attitudes among construction workers.

5.4.2. Flexible Use of Online Courses for Safety Training

Another sub-theme highlighted is the use of online courses for safety training. This approach offers flexibility for workers, as they can access training materials at their convenience. Additionally, online courses can incorporate VR simulations, making them more engaging and effective. Ref. [

55] found that VR-based online courses increased safety compliance and higher safety performance levels than traditional face-to-face courses.

Moreover, VR technology can provide workers with a better learning environment than traditional approaches. As highlighted in the text, visualising technology tools, including VR, can enhance the learning experience for workers. This is supported by research by [

56], which found that using VR technology can generate a higher level of engagement and improve learning outcomes for workers in the construction sector.

Furthermore, using drones in conjunction with simulation software can improve safety in handling health care equipment. Drones can be used to conduct safety inspections and monitor equipment, reducing the likelihood of accidents and worker injuries. This is in line with a study by [

58], which found that using drones for safety inspections in the construction sector significantly reduced the number of workplace injuries and fatalities. The use of digital technology, specifically VR, has a positive impact on H&S management in the construction industry. It provides innovative and effective solutions for education and training, leading to increased safety competencies and improved safety performance among workers. The use of virtual reality technology in safety instruction is supported by the literature, and its continued adoption in the construction sector is essential for creating a safer work environment for workers.

5.4.3. Prediction and Decision Support Impact

This study found that the use of digital technology provides predictive decision support. This includes the use of monthly forecasts of project safety performance through the integration of digital technologies. This has been made possible by means of data collection and analysis, allowing for the identification of potential hazards and risks that may arise during construction projects. As a result, safety professionals can make informed decisions and take preventive measures to reduce accidents. Matthews et al. [

59] noted that through BIM, it is possible to monitor building sites in real time, allowing for the early detection of safety hazards and improved decision-making for accident prevention.

Another sub-theme highlighted is automated safety surveillance systems integrated with AI. These systems can detect events and quickly forecast potential risks, enabling safety professionals to take prompt and accurate actions. Additionally, machine learning models and AI can provide decision support for safety professionals to develop effective safety strategies based on the data collected [

60]. This results in improved safety outcomes and reduced negative incidents in the building industry.

Furthermore, the research discovered that incorporating digital technologies in H&S management has also contributed to improving the well-being of workers. Using techniques such as the early detection of physically demanding tasks through IoT reduces the risk of musculoskeletal injuries among healthcare workers [

61]. Moreover, AI and machine learning also enable the rapid analysis of textual accident narratives, allowing timely interventions and improved safety outcomes [

62].

Also, this study revealed the role of digital technology in understanding the causation of unsafe behaviours by healthcare workers. By analysing data collected through digital technologies, it is possible to identify patterns and trends that may contribute to unsafe behaviour, allowing for the development of targeted interventions. This is crucial in promoting a safety culture in the building industry and lowering the probability of recurring incidents.

Utilising digital technology for the construction industry H&S management has resulted in several benefits. Through data sharing and analysis, improved decision-making and forecasting abilities have been achieved, resulting in the prevention of accidents and the improved well-being of workers. However, organisations must invest in the necessary infrastructure and personnel training to harness these technologies’ potential fully, which may be challenging in smaller organisations and developing countries.

5.4.4. Real-Time Monitoring and Evaluation Impact

According to this study, there has been a notable influence from the use of digital technology on the safety management of the construction industry. First of all, it has contributed to a reduction in occupational accidents and injuries by providing real-time monitoring and alerts. This has been highlighted in research by [

63], who found that using wearable devices and eye-tracking technology led to a reduction in accidents in the construction sector. Moreover, automated surveillance systems are highly efficient in detecting hazards and avoiding accidents. This suggests that companies can enhance their safety performance by incorporating digital technology into safety management.

However, implementing digital technologies for safety management in the construction industry also brings some challenges. One of the main concerns is the cost and accessibility of these technologies, particularly for small and medium-sized construction companies. Data privacy and security issues may also be a significant concern when using wearable devices and surveillance systems that collect sensitive personal information. To address these issues, the use of cloud platforms is being encouraged to reduce the cost of hardware and address data leakage [

59]. The push for cloud platforms to reduce hardware costs and mitigate data leakage reveals a core privacy–communication trade-off in system-level architecture. Cloud-based systems enhance scalability, processing power, and affordability, which are crucial for real-time safety analytics, digital twins, and wearable tech [

59,

64]. However, outsourcing data storage and processing to third-party servers increases vulnerability to data interception, unauthorised access, and regulatory non-compliance [

64]. For example, wearable devices that transmit biometric data via cloud services offer real-time insights but risk violating worker privacy if encryption or access controls are inadequate [

59]. Balancing low-latency communication with strong privacy protections remains a key architectural dilemma that affects trust, adoption, and system integrity.

5.4.5. Communication and Collaboration Impact

This study found that digital technologies have vastly improved collaboration and knowledge exchange between researchers and professionals in the field of construction. This has made it possible to create and execute more effective safety measures as expertise and information can be utilised and shared to improve current practices. Ref. [

65] found that using digital platforms for collaboration and communication significantly reduced workplace accidents and injuries in the construction industry.

Additionally, virtual reality (VR) safety training has greatly improved accessibility for construction employees. VR training provides a more immersive and engaging learning experience, making it easier for workers to understand and retain safety protocols. This is particularly effective in addressing language barriers and ensuring training is accessible to all employees, regardless of their native language [

56].

Additionally, digital tools like virtual reality (VR) and artificial intelligence (AI) have contributed to innovation in accident prevention approaches. By using these technologies, researchers and companies can simulate and analyse potential hazardous situations, allowing for the development of more proactive safety measures. A study by [

56] showed that using VR in safety planning significantly decreased accidents and injuries on construction sites.

However, while digital technology has undoubtedly brought about positive changes in the construction industry’s handling of safety, some challenges need to be addressed. For example, the rapid pace of technological advancement means that companies must constantly update their systems and training programs to stay effective.

5.4.6. Proactive Safety Measures Impact

Digital technologies, such as VR-based training programs, AI, and IoT, have significantly impacted the construction sector’s management of safety. This research discovered that these technologies have contributed to proactive risk mitigation plans and improved safety attitudes among professionals. For instance, VR-based training programs provide hands-on experience in a controlled environment, enhancing workers’ understanding and awareness of potential hazards.

Additionally, AI and IoT enable the collection and analysis of real-time data, allowing professionals to take necessary measures to prevent incidents. As stated by [

59,

60], this real-time monitoring helps identify potential hazards and implement preventive measures, thus reducing the likelihood of accidents. Furthermore, the automation of safety protocols through IoT devices has improved efficiency and reduced human error [

66]. Thus, using digital technology in safety management in the construction sector has proven beneficial in mitigating risks and promoting a more secure workplace.

5.5. Analysis of Strategies for Digital Technology Adoption in Construction Safety

The construction industry, critical for infrastructure development, faces significant safety challenges, with digital technologies offering potential solutions like real-time monitoring and risk assessment. However, adoption rates vary, particularly in developing countries, due to barriers such as high costs and a lack of knowledge. This report aimed to identify strategies that have been underexplored, focusing on policy-level, organisational, and financial incentives and their comparison can be seen in

Table 3. Furthermore, digital inequality still exists. In developing regions, limited bandwidth, outdated devices, and unstable power grids severely hinder real-time digital twin, AI, and VR applications [

67,

68]. These infrastructure deficits create latency, data loss, and poor user experience, making safety tech deployment both unreliable and unsustainable without systemic upgrades.

5.5.1. Policy-Level Strategies

Policy-level strategies involve government interventions such as regulations, standards, and mandates to encourage DT adoption. Examples include the following:

Ireland’s National BIM Council strategy, which aims to reduce project delivery times by 20%, increase exports by 20%, and cut capital costs by 20% by 2021 compared to 2018 through the use of digital tools like BIM [

69].

The UK’s Infrastructure and Projects Authority, with a USD 780 billion investment plan from 2017 to 2027, aims to use purchasing power to drive modern methods, including digital tools [

69].

Policies in Tennessee, USA, require prime contractors and designers to use construction productivity software from March 2019 contract awards [

69].

Despite these examples, research on policy-level strategies is limited. Papers like Daniel et al. [

67] mention barriers but do not focus on policy interventions, suggesting an underexplored area. This gap indicates a need for more studies on how government policies can drive DT adoption for safety.

5.5.2. Financial Incentives

Financial incentives include tax breaks, grants, or prizes to offset adoption costs. The literature shows some examples, such as the following:

Blanco et al. [

69] suggest the use of public grants and national competitions to reward technology adoption, with Tennessee’s productivity software mandate as an example.

A study on incentivisation in Nigeria highlights the potential of financial incentives but notes a paucity of research, particularly in developing contexts [

70].

However, specific research on financial incentives for construction safety is scarce. Papers like Nnaji et al. [

71] focus on predictors like reliability and effectiveness, not financial aspects. This suggests that financial incentives are an overlooked strategy that require further exploration to understand their impact on safety-focused DT adoption.

5.5.3. Organisational Strategies

Organisational strategies involve internal company actions like training, policy development, and cultural shifts. These are more extensively covered:

Nnaji et al. [

71] identify 26 predictors, including organisational factors like training needs, with 12 that are highly influential, such as technology reliability.

Daniel et al. [

67] highlight training and knowledge gaps as barriers, suggesting origanisational strategies like education programs.

Other studies, like those on China’s adoption of DT, include organisational factors in models, indicating broader coverage [

72].

Given this, organisatonal strategies are well represented, contrasting with the limited focus on policy and financial incentives.

Table 3.

Detailed comparison of strategy coverage.

Table 3.

Detailed comparison of strategy coverage.

| Strategy Policy | Example in Literature | Coverage Level | Overlooked |

|---|

| Policy-Level | Ireland’s BIM strategy, UK’s investment plan, Tennessee’s software mandate [69] | Limited | Yes |

| Financial Incentives | Public grants, prizes mentioned, but specific studies scarce [69,70] | Minimal | Yes |

| Organisational | Training, knowledge gaps, internal policies [67,71] | Extensive | No |

5.6. Digital Technologies in Construction Safety Management

The construction industry has witnessed a significant digital transformation in safety management, leveraging advanced technologies to improve worker protection, risk mitigation, and overall site safety [

73].

Table 4 shows a summary of the new digital technologies of construction safety management in recent years, comparing their advantages and disadvantages and the scope of application.

Table 4 reveals significant overlaps between technologies across training, hazard detection, and long-term tracking, highlighting their multifunctionality and raising questions about integration and efficiency. Wearable tech and IoT sensors are heavily relied upon for real-time hazard detection and data-driven tracking, yet their effectiveness hinges on reliable connectivity and user compliance [

77]. Drone inspections, while helpful, are limited by weather and regulatory constraints [

75,

76]. AI safety systems show promise in predictive safety and training but may suffer from data bias or limited contextual understanding [

77]. BIM integration offers long-term value but is underutilised in training. Overall, adoption must consider context, scalability, and user training.

Furthermore, the functionalities of these safety technologies can be measured using specific performance metrics. For hazard detection, key metrics include detection accuracy, the response time, and the false alarm rate. Training technologies are evaluated by user engagement, knowledge retention, and simulation realism [

77]. Long-term tracking relies on data continuity, storage efficiency, and analytics capability. Wearables and IoT sensors are assessed by their uptime, data precision, and adaptability to various conditions [

53,

54]. Drones are measured by their inspection coverage, resolution quality, and operational flexibility. AI systems are judged by their prediction accuracy and adaptability, while BIM integration depends on interoperability, data integration quality, and usefulness in lifecycle planning.

5.7. Recommended Metrics and Indicators

Based on this review, the following concrete metrics and indicators are recommended to measure the long-term success of digital technology integration in construction safety and each metrics comparison can be seen in

Table 5.

5.7.1. Total Recordable Incident Rate (TRIR)

Definition: The number of recordable injuries and illnesses per 100 full-time workers, calculated as (Number of Recordable Incidents × 200,000)/Total Hours Worked, where 200,000 is the base for 100 full-time workers working 40 h per week for 50 weeks [

79].

Relevance: A decrease in the TRIR over time indicates that digital technologies, such as real-time monitoring systems or safety management software, reduce the overall incidence of negative safety events [

80].

Example: If a company implements wearable technology for hazard detection and sees the TRIR drop from 5.0 to 3.0 over five years, this suggests sustained safety improvements.

5.7.2. Days Away, Restricted, or Transferred (DART) Rate

Definition: The number of injuries or illnesses resulting in days away from work, restricted work, or job transfer per 100 full-time workers, calculated similarly to the TRIR [

79].

Relevance: A lower DART rate signifies fewer severe incidents, which can be attributed to digital tools like BIM for better planning or AR for training, reducing serious safety risks [

81].

Example: Post-implementation of digital inspection tools, a reduction in the DART rate from 2.5 to 1.5 over three years indicates fewer severe outcomes.

5.7.3. Lost Time Incident Rate (LTIR)

Definition: The number of lost time injuries (those resulting in days away from work) per 100 full-time workers, calculated as (Number of Lost Time Incidents × 200,000)/Total Hours Worked [

79].

Relevance: A lower LTIR suggests fewer injuries that stop work, potentially due to digital technologies like IoT sensors that alert workers to hazards in real time [

82].

Example: After adopting AI-based safety analytics, a company might see the LTIR decrease from 2.0 to 1.0 over five years, indicating fewer work stoppages.

5.7.4. Near-Miss Reporting Rate

Definition: The number of near-miss incidents reported per worker or per project, often facilitated by digital reporting platforms [

83].

Relevance: An increase in near-miss reporting can indicate a more proactive safety culture, often supported by digital tools that make reporting easier and more accessible, such as mobile apps or collaborative safety platforms [

80].

Example: A construction firm using a digital safety management system might see near-miss reports rise from 10 per 100 workers to 25 per 100 workers annually, suggesting improved hazard awareness.

5.7.5. Safety Training Completion Rate

Definition: The percentage of workers who have completed required safety training, often delivered through digital platforms like VR or online modules [

79].

Relevance: Higher completion rates suggest that digital training tools are effective in ensuring that workers are well prepared, reducing the likelihood of accidents due to a lack of knowledge [

81].

Example: After implementing AR-based training, a company might achieve a 95% completion rate compared to 75% previously, indicating better training coverage.

5.7.6. Safety Inspection Scores

Definition: Scores from regular site inspections that assess compliance with safety standards, often enhanced by digital tools like drones for inaccessible areas or AI for data analysis [

81].

Relevance: Improved scores over time indicate that digital technologies aid in better adherence to safety protocols, such as through real-time monitoring and reporting [

80].

Example: With digital inspection tools, inspection scores might improve from 80% to 95% compliance over two years, showing enhanced safety management.

5.7.7. Cost Savings from Reduced Downtime

Definition: Financial benefits from fewer accidents, quantified through reduced insurance claims, lower worker compensation costs, and less project delay due to accidents, often tracked via digital financial management systems [

84].

Relevance: This metric highlights the economic impact of safety improvements, potentially influencing company decisions to invest in digital technologies, and can be measured by comparing costs before and after implementation [

83].

Example: A company might see annual safety-related costs drop from USD 500,000 to USD 300,000 over five years, which can be attributed to to digital technologies reducing downtime.

Table 5.

Comparison of metrics.

Table 5.

Comparison of metrics.

| Metric | Applicability | Ease of Measurement | Relevance to Long Term Success |

|---|

| Total Recordable Incident Rate (TRIR) | High, standard in safety reporting | Moderate, requires data collection | Indicates overall reduction in incidents |

| Days Away, Restricted, or Transferred (DART) Rate | High, focuses on severe incidents | Moderate, needs incident tracking | Shows fewer severe safety issues |

| Lost Time Incident Rate (LTIR) | High, focuses on work stoppages | Moderate, needs incident tracking | Reflects fewer injuries stopping work |

| Near Miss Reporting Rate | High, promotes proactive culture | High, promotes proactive culture | High, promotes proactive culture |

| Safety Training Completion Rate | High, essential for worker preparedness | Easy, tracked via digital systems | Ensures workers are trained, reducing accidents |

| Safety Inspection Scores | High, assesses compliance | Moderate, requires regular inspections | Shows better adherence to safety protocols |

| Cost Savings from Reduced Downtime | High, economic impact | Difficult, needs financial analysis | Highlights financial benefits, influencing investment |

5.8. Regional Differences in Digital Technologies for Construction Health and Safety

Understanding the regional differences in digital technology (DT) adoption for construction health and safety management has several practical implications that directly influence adoption strategies in developing countries.

5.8.1. Allocation of Resources

Developed nations tend to have more money, which enables them to invest in cutting-edge technologies like drones, wearable sensors, and monitoring systems driven by artificial intelligence [

80]. Budgetary restrictions frequently prevent developing nations from acquiring the latest technologies.

5.8.2. Infrastructure Requirements

A lot of digital safety solutions need dependable electricity and internet access which are sometimes unreliable in poor nations, and there modifications or different strategies are required [

67,

68].

5.8.3. Technical Expertise Gap

In underdeveloped nations, there is a greater lack of skilled workers to deploy and manage digital systems, which hinders their successful adoption [

68,

85].

5.8.4. Regulatory Frameworks

Research such as Daniel et al. [

67] shows that developing countries encounter more challenges, like financial constraints and inadequate infrastructure, which suggests that their safety regulations for digital technologies are less mature. This is corroborated by findings in Malaysia, where a lack of occupational safety and health regulations is a barrier [

68].

5.9. Influence on Adoption Strategies

5.9.1. Selecting the Right Technology

Developing countries should give priority to technologies that align with their infrastructure capabilities and economic realities rather than directly importing solutions from developed nations [

23].

5.9.2. Phased Implementation Approach

By concentrating on technologies with the highest impact-to-cost ratio first, poor nations can progressively increase their capacity for new technologies through a staged adoption process [

86].

5.9.3. Public–Private Partnerships

By working together, government organisations, academic institutions, and the private sector can share costs and build local knowledge [

87].

6. Directions for Future Research

From the content analysis of 95 articles, four areas were identified for future research in applying DT in H&S management in both developed and emerging nations’ building industries.

6.1. Regional Disparities in Digital Technology Adoption

This study highlights a significant difference in the number of studies conducted on the use of digital technology (DT) in H&S management between developed and developing countries. While the research suggests that the gap is closing, there is still a notable difference. Future research could delve deeper into understanding the factors that contribute to these regional disparities. For instance, the attribution theory could be used to uncover the methods used to successfully implement DT in developed countries. This information would help in the development of strategies to improve the uptake of DT when applied to the management of safety in emerging nations’ building industries. Such future studies could explore how economic conditions, cultural differences, technology infrastructure, and government policies influence the adoption of DT and AI in construction safety management in different regions.

6.2. Research Methods

The results of the current investigation show that modelling and simulation are the prevalent research methods in this field. This finding suggests that most of the applications of these technologies have been limited to controlled environments. The little evidence showcasing the advantages of using these technologies in practical settings could be responsible for its low uptake in the building sector. To close this disparity, there is a need for more collaboration between industry and academia to support the execution of case studies and action research. The findings of these future studies would provide concrete evidence to justify increased uptake.

6.3. Long-Term Impact Assessment

This study touches on the positive impacts of DT in terms of safety outcomes and well-being. However, a gap exists in the understanding of these technologies’ sustainability and long-term effects in the construction sector. Future research could focus on assessing the lasting effects of DT implementation, considering factors such as return on investment, continued worker safety improvements, and the adaptability of technologies over time. This would provide insights into the durability and effectiveness of these solutions.

6.4. Explore Policy Interventions

Policy interventions may include mandatory DT standards for safety and measurements of their effectiveness. Financial incentive models, like grant programs tailored for safety technologies, and their impact on adoption rates should be investigated. Organisational strategy research should continue but should integrate policy and financial aspects for a holistic approach.

6.5. Advancement in AR

Future studies should explore how advancements in AR hardware and wearable design can overcome these barriers and potentially close the adoption gap of VR and AI. Additionally, examining government and industry initiatives to support AR and wearable adoption could provide insights into how their use can be scaled. For more information, refs. [

52,

87,

88,

89,

90,

91] are good sources for understanding the underlying reasons for the low adoption of AR and wearable technology in the construction sector.

6.6. Longitudinal Analysis

Future studies should focus on longitudinal analyses to track these metrics over extended periods, ensuring that the benefits of digital technology integration are sustained [

81]. Additionally, comparative studies across different construction sectors (e.g., residential vs. commercial sectors) could provide insights into context-specific metric effectiveness. Research should also explore how digital technologies can be tailored to improve specific metrics, such as reducing DART rates through real-time hazard alerts [

79].

7. Study Contributions

The study findings contribute to both theory and practice in the field of construction H&S. In terms of theory, the systematic review of 95 articles provides a thorough understanding of the most recent studies on integrating DT in construction H&S management in the various sub-sectors of the industry, be it building or infrastructure projects. This contributes to the literature by identifying the gap between research carried out in both wealthy and poor nations, highlighting that more research is required in emerging nations to close this gap in the construction sector.

Furthermore, this study identified five key themes on the impact of DT in H&S management, providing a theoretical framework for future research. These themes provide insights into the potential benefits of integrating DT in construction H&S, providing a theoretical foundation for future studies in this area.

In terms of practice, this study identifies the potential benefits of using DT in H&S administration, including improved education and training, prediction and decision support, and the real-time monitoring and evaluation of potential hazards. This highlights the need for organisations to invest in technologies to improve their H&S management practices.

8. Conclusions

This study was conducted in order to better understand the application of DT application in construction H&S. The SLR study found a growing interest and adoption of DT in construction H&S. There is insufficient information on the current trends regarding DT use for construction safety management in both developed and poor nations. None of the reviewed studies examined how this gap could be closed. It was also highlighted that knowledge about boosting DT adoption in the construction industry is lacking. This study suggests that critical stakeholders in construction, including both public and private clients and top contractors, should invest in digital technology infrastructure and provide training for smaller contractors to make its uptake a norm in the sector.

This study indicates a notable rise in the number of papers published on this subject, especially in industrialised nations. Still, there remains a sizable discrepancy between research conducted in wealthy and developing nations and research conducted in underdeveloped nations, suggesting that additional study is required in poorer nations to close the gap.

This study shows a difference between developed and developing countries in the rate of use of DT. While developed countries have incorporated these technologies, developing countries face challenges in implementation due to a lack of resources and skilled personnel. Furthermore, the research has revealed that using DT provides several benefits, including improved education and training, prediction and decision support, real-time monitoring, and the promotion of a culture of safety. These technologies can prevent accidents, improve safety outcomes, and promote workers’ well-being. However, organisations must invest in the necessary infrastructure and personnel training to fully harness the potential of this technology.

The current study is limited to Scopus and WoS; using other databases may show some variation in the current search results. Also, studies that were not published in English were excluded. Nevertheless, the method used is described, which makes this study replicable.

Author Contributions

Conceptualisation, E.I.D., O.S.O., F.A.E. and E.C.; methodology, E.I.D. and N.I.N.; formal analysis, E.I.D. and N.I.N.; investigation, E.I.D. and N.I.N.; writing—original draft preparation, E.I.D., N.I.N., O.S.O. and E.C.; writing—review and editing, F.A.E. and E.I.D.; visualisation, E.I.D. and N.I.N.; supervision, E.I.D.; project administration, E.I.D.; funding acquisition, E.I.D. and O.S.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Lloyds Register Foundation, for which the authors are grateful. However, the view presented in this study is that of the authors.

Data Availability Statement

Data are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- U.S. Bureau of Labor Statistics (US BLS). Census of Fatal Occupational Injuries Summary. 2019. Available online: https://www.bls.gov/opub/mlr/2019/ (accessed on 29 September 2023).

- Health and Safety Matters (HSM). Construction Crisis: Data Highlights Concerning Statistics. 2022. Available online: https://www.hsmsearch.com/Construction-Data-highlights-injury-concerns (accessed on 27 September 2023).

- KhPlant. Top Construction Hazard. 2023. Available online: https://www.khplant.co.za/blog/top-construction-hazards/ (accessed on 3 October 2023).

- Guo, B.H.W.; Zou, Y.; Fang, Y.; Goh, Y.M.; Zou, P.X.W. Computer vision technologies for safety science and management in construction: A critical review and future research directions. Saf. Sci. 2021, 135, 105130. [Google Scholar] [CrossRef]

- Al-Sahar, F.; Przegalińska, A.; Krzemiński, M. Risk assessment on the construction site with the use of wearable technologies. Ain Shams Eng. J. 2021, 12, 3411–3417. [Google Scholar] [CrossRef]

- Loosemore, M.; Malouf, N. Safety training and positive safety attitude formation in the Australian construction industry. Saf. Sci. 2019, 113, 233–243. [Google Scholar] [CrossRef]

- Guo, B.H.W.; Goh, Y.M.; Le Xin Wong, K. A system dynamics view of a behavior-based safety program in the construction industry. Saf. Sci. 2018, 104, 202–215. [Google Scholar] [CrossRef]

- Umer, W.; Antwi-Afari, M.F.; Li, H.; Szeto, G.P.Y.; Wong, A.Y.L. The global prevalence of musculoskeletal disorders in the construction industry: A systematic review and meta-analysis. Int. Arch. Occup. Environ. Health 2017, 91, 125–144. [Google Scholar] [CrossRef] [PubMed]

- Antwi-Afari, M.F.; Li, H.; Wong, J.K.W.; Oladinrin, O.T.; Ge, J.X.; Seo, J.O.; Wong, A.Y.L. Sensing and warning-based technology applications to improve occupational health and safety in the construction industry: A literature review. Eng. Constr. Archit. Manag. 2019, 26, 1534–1552. [Google Scholar] [CrossRef]

- Xu, J.; Duryan, M.; Smyth, H. Digitalisation for Occupational Health and Safety in Construction: A Path to High Reliability Organising? In Proceedings of the CIB W099 & W123 Annual International Conference, Glasgow, UK, 9–10 September 2021; International Council for Research and Innovation in Building and Construction: Kanata, ON, Canada, 2021. Available online: https://cibworld.org/publications/ (accessed on 6 October 2023).

- Perera, C.S.; Gao, S.; Manu, P.; Francis, V.; Urhal, P. Unmanned aerial vehicles (UAV) for safety in the construction industry: A systematic literature review. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 092008. [Google Scholar] [CrossRef]

- Agyekum, K.; Pittri, H.; Ayebeng Botchway, E.; Amudjie, J.; Maame Afriyie Kumah, V.; Nikoi Kotei-Martin, J.; Animapauh Oduro, R. Exploring the Current Technologies Essential for Health and Safety in the Ghanaian Construction Industry. Merits 2022, 2, 314–330. [Google Scholar] [CrossRef]

- Li, X.; Yi, W.; Chi, H.L.; Wang, X.; Chan, A.P.C. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Razi, P.Z.; Sulaiman, S.K.; Ali, M.I.; Ramli, N.I.; Saad, M.S.H.; Jamaludin, O.; Doh, S.I. How Artificial Intelligence Changed the Construction Industry in Safety Issues. IOP Conf. Ser. Earth Environ. Sci. 2023, 1140, 012004. [Google Scholar] [CrossRef]

- Akinlolu, M.; Haupt, T.C.; Edwards, D.J.; Simpeh, F. A bibliometric review of the status and emerging research trends in construction safety management technologies. Int. J. Constr. Manag. 2020, 22, 2699–2711. [Google Scholar] [CrossRef]

- Nath, N.D.; Behzadan, A.H.; Paal, S.G. Deep learning for site safety: Real-time detection of personal protective equipment. Autom. Constr. 2020, 112, 103085. [Google Scholar] [CrossRef]

- Malomane, R.; Musonda, I.; Okoro, C.S. The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety. Int. J. Environ. Res. Public Health 2022, 19, 846. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Wu, P.; Wang, J.; Chi, H.L.; Wang, X. A Critical Review of the Use of Virtual Reality in Construction Engineering Education and Training. Int. J. Environ. Res. Public Health 2018, 15, 1204. [Google Scholar] [CrossRef]

- Raliile, M.T.; Haupt, T.C. Machine learning applications for monitoring construction health and safety legislation and compliance. Proc. Int. Struct. Eng. Constr. 2020, 7, CON-23-1–CON-23-6. [Google Scholar] [CrossRef]

- Dobrucali, E.; Sadikoglu, E.; Demirkesen, S.; Zhang, C.; Tezel, A.; Kiral, I.A. A bibliometric analysis of digital technologies use in construction health and safety. Eng. Constr. Archit. Manag. 2023, 31, 3249–3282. [Google Scholar] [CrossRef]

- Babalola, A.; Manu, P.; Cheung, C.; Yunusa-Kaltungo, A.; Bartolo, P. A systematic review of the application of immersive technologies for safety and health management in the construction sector. J. Saf. Res. 2023, 85, 66–85. [Google Scholar] [CrossRef]

- Bagir, M. Adoption of Digital Occupational Safety and Health Technologies in the Construction Sector. 2021. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-307375 (accessed on 2 October 2023).

- Nnaji, C.; Karakhan, A.A. Technologies for safety and health management in construction: Current use, implementation benefits and limitations, and adoption barriers. J. Build. Eng. 2020, 29, 101212. [Google Scholar] [CrossRef]

- Umar, T.; Egbu, C.; Wamuziri, S.; Honnurvali, M.S. Briefing: Occupational safety and health regulations in Oman. Proc. Inst. Civ. Eng. Manag. Procure. Law 2018, 171, 93–99. [Google Scholar] [CrossRef]

- Eurostat. Accidents at Work Statistics. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Accidents_at_work_statistics (accessed on 19 May 2023).

- Wolf, M.; Teizer, J.; Wolf, B.; Bükrü, S.; Solberg, A. Investigating hazard recognition in augmented virtuality for personalized feedback in construction safety education and training. Adv. Eng. Inform. 2022, 51, 101469. [Google Scholar] [CrossRef]

- Haupt, T.C.; Akinlolu, M.; Raliile, M.T. Applications of digital technologies for health and safety management in construction. In Proceedings of the 8th World Construction Symposium, Colombo, Sri Lanka, 8 November 2019; pp. 88–97. [Google Scholar] [CrossRef]

- Trask, C.; Linderoth, H.C. Digital technologies in construction: A systematic mapping review of evidence for improved occupational health and safety. J. Build. Eng. 2023, 80, 108082. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Prisma-P Group. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Syst. Rev. 2015, 4, 148–160. [Google Scholar] [CrossRef] [PubMed]

- Abam, F.I.; Nwachukwu, C.O.; Emodi, N.V.; Okereke, C.; Demirbas, O.E.; Owolabi, A.B.; Owebor, K.; Suh, D.; Huh, J.-S. A systematic literature review on the decarbonisation of the building sector–a case for Nigeria. Front. Energy Res. 2023, 11, 1253825. [Google Scholar] [CrossRef]

- Daniel, E.I.; Oshodi, O. Lean-offsite-simulation nexus for housing construction: A state-of-the-art review of the existing knowledge. Constr. Innov. 2022, 23, 994–1017. [Google Scholar] [CrossRef]

- Manzoor, B.; Othman, I.; Pomares, J.C. Digital Technologies in the Architecture, Engineering and Construction (AEC) Industry–A Bibliometric–Qualitative Literature Review of Research Activities. Int. J. Environ. Res. Public Health 2021, 18, 6135. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Haddaway, N.R.; Page, M.J.; Pritchard, C.C.; McGuinness, L.A. PRISMA2020: An R package and Shiny app for producing PRISMA 2020-compliant flow diagrams, with interactivity for optimised digital transparency and Open Synthesis. Campbell Syst. Rev. 2022, 18, e1230. [Google Scholar] [CrossRef]

- Pranckutė, R. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Khean, N.; Fabbri, A.; Gerber, D.; Haeusler, M.H. Examining Potential Socio-economic Factors that Affect Machine Learning Research in the AEC Industry. Commun. Comput. Inf. Sci. 2019, 1028, 247–263. [Google Scholar] [CrossRef]

- Braun, V.; Clarke, V. Using thematic analysis in psychology. Qual. Res. Psychol. 2006, 3, 77–101. [Google Scholar] [CrossRef]

- Mas-Tur, A.; Roig-Tierno, N.; Sarin, S.; Haon, C.; Sego, T.; Belkhouja, M.; Porter, A.; Merigó, J.M. Co-citation, bibliographic coupling and leading authors, institutions and countries in the 50 years of Technological Forecasting and Social Change. Technol. Forecast. Soc. Change 2021, 165, 120487. [Google Scholar] [CrossRef]

- Leydesdorff, L.; Nerghes, A. Co-word maps and topic modeling: A comparison using small and medium-sized corpora (N > 1000). J. Assoc. Inf. Sci. Technol. 2017, 68, 1024–1035. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Sacks, R.; Perlman, A.; Barak, R. Construction safety training using immersive virtual reality. Constr. Manag. Econ. 2013, 31, 1005–1017. [Google Scholar] [CrossRef]

- Demirbas, A.; Demirkan, H.; Mustafa, D. Using Machine Learning for Risk Assessment of Work Related Occupational Accidents. Int. J. Electr. Comput. Eng. 2019, 9, 2872–2880. [Google Scholar]

- Noura, A.; Iqbal, U.; Tawfik, H. Advancement in Digital Platform for Construction Industry. Int. J. Eng. Technol. 2018, 7, 301–305. [Google Scholar]

- Akram, R.; Thaheem, M.J.; Khan, S.; Nasir, A.R.; Maqsoom, A. Exploring the role of BIM in construction safety in developing countries: Toward automated hazard analysis. Sustainability 2022, 14, 12905. [Google Scholar] [CrossRef]

- Jabil. Six Factors Affecting Augmented & Virtual Reality Adoption. Available online: https://www.jabil.com/blog/human-factors-impacting-augmented-reality-and-virtual-reality-adoption.html (accessed on 6 March 2025).

- Padyab, A.; Habibipour, A. Issues and Adoption Barriers in Wearable Technologies. Int. J. Technol. Diffus. 2021, 12, 75–89. [Google Scholar] [CrossRef]

- Statista. Barriers to Mass Consumer Adoption of VR Worldwide. 2019. Available online: https://www.statista.com/statistics/1099109/barriers-to-mass-consumer-adoption-of-vr/ (accessed on 6 March 2025).

- Marr, B. 11 Barriers to Effective AI Adoption and How to Overcome Them. 2024. Available online: https://www.forbes.com/sites/bernardmarr/2024/05/10/11-barriers-to-effective-ai-adoption-and-how-to-overcome-them/ (accessed on 6 March 2025).

- IPG Media Lab. Barriers to Wearable Adoption. Available online: https://ipglab.com/ (accessed on 6 March 2025).

- Garrison, N. Why Haven’t AR And VR Changed Our Lives Yet? 5 Barriers To Adoption. 2019. Available online: https://arpost.co/2019/11/27/ar-and-vr-changed-our-lives-5-barriers-adoption/ (accessed on 6 March 2025).

- Robinson, M. 3 Common Barriers to AI Adoption and How to Overcome Them. 2024. Available online: https://www.uipath.com/blog/ai/overcome-ai-adoption-barriers (accessed on 6 March 2025).

- Yan, X.; Li, H.; Li, A.R.; Zhang, H. Wearable IMU-based real-time motion warning system for construction workers’ musculoskeletal disorders prevention. Autom. Constr. 2017, 74, 2–11. [Google Scholar] [CrossRef]

- Chen, H.; Mao, Y.; Xu, Y.; Wang, R. The impact of wearable devices on the construction safety of building workers: A systematic review. Sustainability 2023, 15, 11165. [Google Scholar] [CrossRef]

- Flor-Unda, O.; Fuentes, M.; Dávila, D.; Rivera, M.; Llano, G.; Izurieta, C.; Acosta-Vargas, P. Innovative technologies for occupational health and safety: A scoping review. Safety 2023, 9, 35. [Google Scholar] [CrossRef]

- Kustandi, C.; Fadhillah, D.N.; Situmorang, R.; Prawiradilaga, D.S.; Hartati, S. VR use in online learning for higher education in Indonesia. Int. J. Interact. Mob. Technol. 2020, 14, 31–47. [Google Scholar] [CrossRef]

- Zhang, M.; Shu, L.; Luo, X.; Yuan, M.; Zheng, X. Virtual reality technology in construction safety training: Extended technology acceptance model. Autom. Constr. 2022, 135, 104113. [Google Scholar] [CrossRef]

- Fernández, A.; Muñoz La Rivera, F.; Mora Serrano, J. Virtual Reality Training for Occupational Risk Prevention: Application Case in Geotechnical Drilling Works. Int. J. Comput. Methods Exp. Meas. 2023, 11, 55–63. [Google Scholar] [CrossRef]

- Szóstak, M.; Nowobilski, T.; Mahamadu, A.M.; Pérez, D.C. Unmanned aerial vehicles in the construction industry—Towards a protocol for safe preparation and flight of drones. Int. J. Intell. Unmanned Syst. 2023, 11, 296–316. [Google Scholar] [CrossRef]

- Matthews, J.; Love, P.E.D.; Heinemann, S.; Chandler, R.; Rumsey, C.; Olatunj, O. Real time progress management: Re-engineering processes for cloud-based BIM in construction. Autom. Constr. 2015, 58, 38–47. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Davila Delgado, J.M.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Gbadamosi, A.-Q.; Oyedele, L.; Mahamadu, A.-M.; Kusimo, H.; Olawale, O. The Role of Internet of Things in Delivering Smart Construction. In Proceedings of the CIB World Building Congress, Hong Kong, 17–21 June 2019. [Google Scholar]

- Reddy, H.G.; Kone, V. Study on implementing smart construction with various applications using internet of things techniques. Int. J. Recent Technol. Eng. 2019, 7, 188. [Google Scholar]

- Aksüt, G.; Eren, T.; Alakaş, H.M. Using wearable technological devices to improve workplace health and safety: An assessment on a sector base with multi-criteria decision-making methods. Ain Shams Eng. J. 2023, 15, 102423. [Google Scholar] [CrossRef]

- Morteza, A.; Chou, R.A. Distributed Matrix Multiplication: Download Rate, Randomness and Privacy Trade-Offs. In Proceedings of the 2024 60th Annual Allerton Conference on Communication, Control, and Computing, Urbana, IL, USA, 24–27 September 2024; IEEE: Piscataway, NJ, USA; pp. 1–7. [Google Scholar]

- Bühler, M.M.; Nübel, K.; Jelinek, T.; Riechert, D.; Bauer, T.; Schmid, T.; Schneider, M. Data Cooperatives as a Catalyst for Collaboration, Data Sharing and the Digital Transformation of the Construction Sector. Buildings 2023, 13, 442. [Google Scholar] [CrossRef]

- Costin, A.; Wehle, A.; Adibfar, A. Leading Indicators—A Conceptual IoT-Based Framework to Produce Active Leading Indicators for Construction Safety. Safety 2019, 5, 86. [Google Scholar] [CrossRef]

- Daniel, E.I.; Oshodi, O.S.; Nwankwo, N.; Emuze, F.A.; Chinyio, E. Barriers to the application of digital technologies in construction health and safety: A systematic review. Buildings 2024, 14, 2386. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Lam, C.G.Y.; Skitmore, M.; Talebian, N. Barriers to the adoption of new safety technologies in construction: A developing country context. J. Civ. Eng. Manag. 2022, 28, 120–133. [Google Scholar] [CrossRef]

- Blanco, J.L.; Dohrmann, T.; Julien, J.P.; Law, J.; Palter, R. Governments Can Lead Construction into the Digital Era. 2019. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/governments-can-lead-construction-into-the-digital-era#/ (accessed on 6 March 2025).

- Ebekozien, A.; Samsurijan, M.S. Incentivisation of digital technology takers in the construction industry. Eng. Constr. Archit. Manag. 2022, 31, 1373–1390. [Google Scholar] [CrossRef]

- Nnaji, C.; Gambatese, J.; Karakhan, A.; Eseonu, C. Influential safety technology adoption predictors in construction. Eng. Constr. Archit. Manag. 2019, 26, 2655–2681. [Google Scholar] [CrossRef]

- Xu, J.; Li, J.; Chen, X. Assessment of technology adoption in construction safety management: Case study in China. Sci. Prog. 2024, 107, 00368504241304198. [Google Scholar] [CrossRef]

- Samuelson, O.; Stehn, L. Digital transformation in construction—A review. J. Inf. Technol. Constr. 2023, 28, 385–404. [Google Scholar] [CrossRef]

- Svertoka, E.; Saafi, S.; Rusu-Casandra, A.; Burget, R.; Marghescu, I.; Hosek, J.; Ometov, A. Wearables for industrial work safety: A survey. Sensors 2021, 21, 3844. [Google Scholar] [CrossRef]

- Yıldız, S.; Kıvrak, S.; Arslan, G. Using drone technologies for construction project management: A narrative review. J. Constr. Eng. Manag. Innov. 2021, 4, 229–244. [Google Scholar] [CrossRef]

- Katar, I.M. Drone Technology in Contemporary Construction Engineering Management. J. Namib. Stud. 2023, 33, 1321–1334. [Google Scholar]

- Park, J.; Kang, D. Artificial Intelligence and Smart Technologies in Safety Management: A Comprehensive Analysis Across Multiple Industries. Appl. Sci. 2024, 14, 11934. [Google Scholar] [CrossRef]

- Rahimian, F.P.; Goulding, J.S.; Abrishami, S.; Seyedzadeh, S.; Elghaish, F. Industry 4.0 Solutions for Building Design and Construction: A Paradigm of New Opportunities; Routledge: Abingdon-on-Thames, UK, 2021. [Google Scholar]

- Holt, M.; McBride, E. Top Construction Safety Metrics You Need to Measure. HM-EC. 2023. Available online: https://www.hm-ec.com/blog-posts/top-construction-safety-metrics-you-need-to-measure-hm (accessed on 6 March 2025).

- Edirisinghe, R. Overview and Analysis of Digital Technologies for Construction Safety Management. 2017. Available online: https://www.researchgate.net/publication/318250628_Overview_and_analysis_of_digital_technologies_for_construction_safety_management (accessed on 6 March 2025).

- Liu, H.; Li, S.; Wen, H. Effect of Smart Construction Technology Characteristics on the Safety Performance of Construction Projects: An Empirical Analysis Based on Structural Equation Modeling. Buildings 2024, 14, 1894. [Google Scholar] [CrossRef]

- Notify Technology. Technology Solutions for Improving Safety on Construction Sites. 2023. Available online: https://www.notifytechnology.com/technology-solutions-for-improving-safety-on-construction-sites/ (accessed on 6 March 2025).

- Construction Digital. Boustead and TraceSafe Develop Digital Safety System. 2023. Available online: https://constructiondigital.com/technology-and-ai/boustead-and-tracesafe-develop-digital-safety-system (accessed on 6 March 2025).

- Column. The Impact of Technology and Digital Processes on Safety in Construction. 2023. Available online: https://column.construction.com/the-impact-of-technology-and-digital-processes-on-safety-in-construction/ (accessed on 6 March 2025).

- Osunsanmi, T.O.; Oke, A.E.; Aigbavboa, C.O. Barriers for the Adoption of Incorporating RFID with Mobile Technology for Improved Safety of Construction Professionals. In The Construction Industry in the Fourth Industrial Revolution, Proceedings of the 11th Construction Industry Development Board (CIDB) Postgraduate Research Conference, Johannesburg, South Africa, 28–30 July 2019; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; Volume 11, pp. 297–304. [Google Scholar]

- Olaniyan, R. Barriers to Technology Adoption Among Construction Project Managers in Nigeria. Ph.D. Thesis, Walden University, Minneapolis, MN, USA, 2019. [Google Scholar]