Enhancing Construction Waste Transportation Management Using Internet of Things (IoT): An Evaluation Framework Based on AHP–FCE Method

Abstract

1. Introduction

2. Literature Review

2.1. Applications of IoT in Construction Waste Transportation

2.2. Advantages of IoT in Construction Waste Transportation Management

2.3. Challenges of IoT in Construction Waste Transportation Management

2.4. Methodological Developments and Research Gaps

3. Methodology

3.1. Delphi Method

3.2. Analytical Hierarchy Process (AHP) Method

3.3. Fuzzy Comprehensive Evaluation Method

4. Evaluation Model Development

4.1. The Identification of Indicators

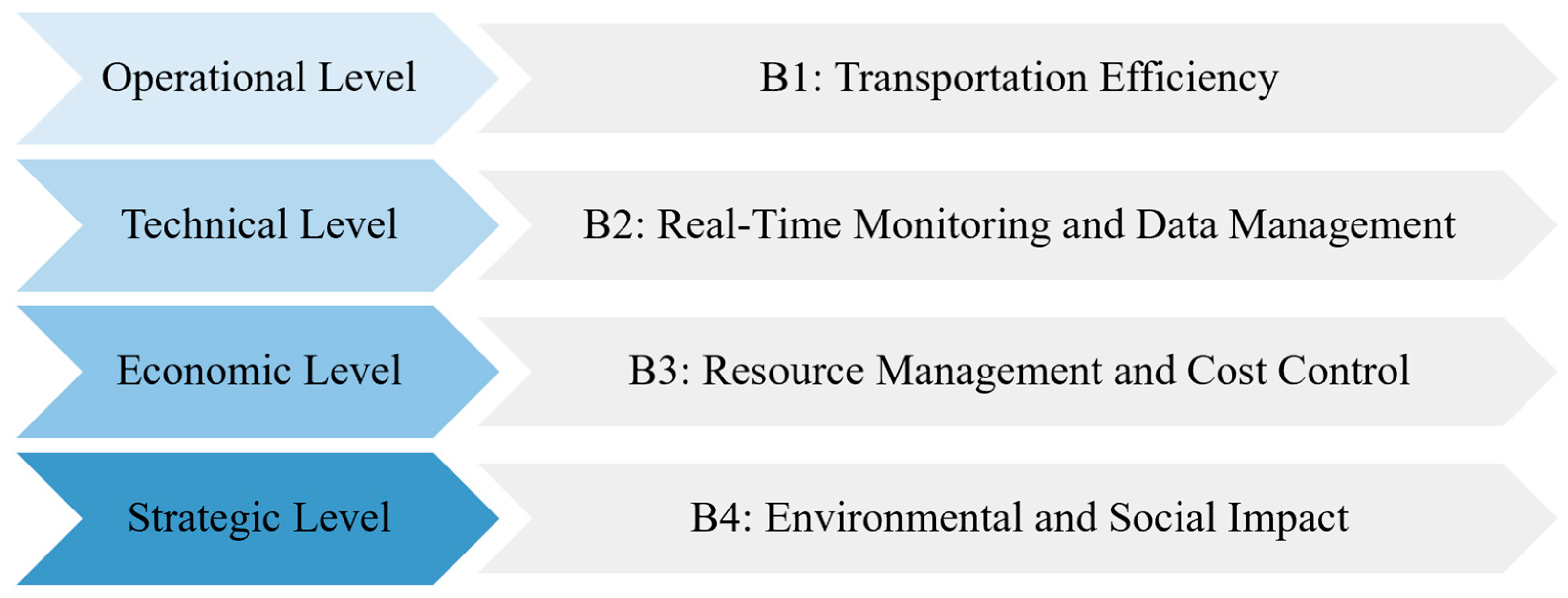

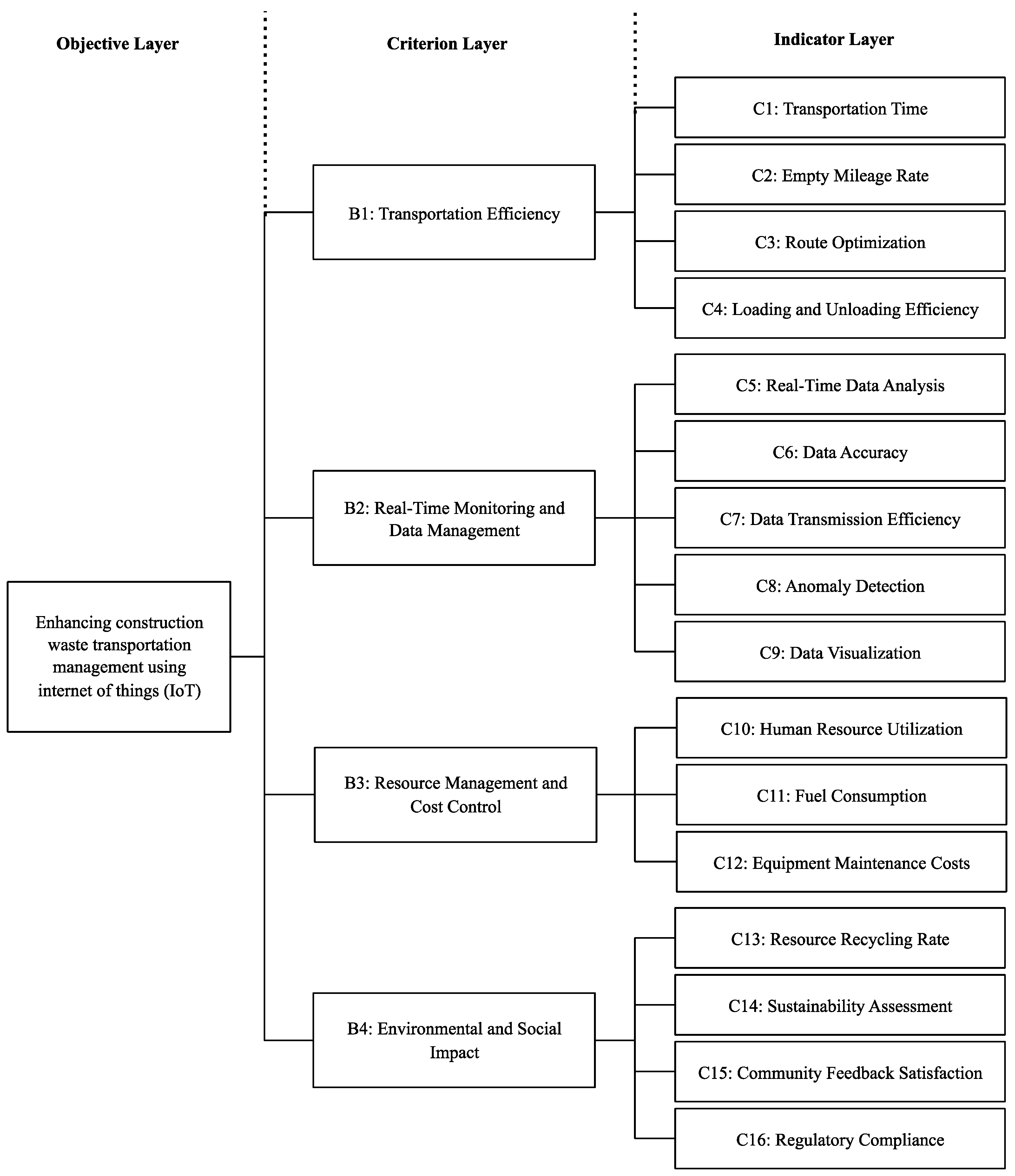

4.2. Establishment of the Hierarchical Model

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IoT | Internet of Things |

| AHP | Directory of open access journals’ analytic hierarchy process |

| FCE | Fuzzy comprehensive evaluation |

Appendix A

| Expert | Field of Specialization | Professional Qualification | Main Research Direction | Years of Work Experience |

|---|---|---|---|---|

| 1 | Construction Engineering | Associate professor | Civil engineering | 11–15 years |

| 2 | Construction Engineering | Associate professor | Road and bridge engineering | 6–10 years |

| 3 | Construction Engineering | Associate professor | Construction project management | 6–10 years |

| 4 | Project Management | Engineer | IoT applications | 6–10 years |

| 5 | Internet of Things Technology | Senior engineer | Intelligent transport systems | 11–15 years |

| 6 | Internet of Things Technology | Engineer | Sensor technology | 6–10 years |

| 7 | Transport management | Senior engineer | Construction engineering management | 11–15 years |

| 8 | Transport management | Engineer | Intelligent transport systems | 0–5 years |

| 9 | Data security | Engineer | Data privacy and security | 6–10 years |

| 10 | Artificial intelligence | Engineer | Computer science and technology | 0–5 years |

Appendix B

| Primary Indicators | Average Value | Standard Deviation | Coefficient of Variation |

|---|---|---|---|

| B1: Transportation Efficiency | 4.5000 | 0.6742 | 0.1498 |

| B2: Real-Time Monitoring and Data Management | 5.0000 | 0.0000 | 0.0000 |

| B3: Resource Management and Cost Control | 4.4167 | 0.5149 | 0.1166 |

| B4: Environmental and Social Impact | 4.5000 | 0.5222 | 0.1161 |

| Kendall’s Coefficient of Coordination | Kendall Wa coefficient = 0.2685 Cardinality = 9.6667 Asymptotic Significance: p = 0.0216 | ||

| Secondary Indicators | Average Value | Standard Deviation | Coefficient of Variation |

|---|---|---|---|

| C1: Transportation Time | 4.5000 | 0.5222 | 0.1161 |

| C2: Empty Mileage Rate | 4.7500 | 0.4523 | 0.0952 |

| C3: Route Optimization | 4.3333 | 0.4924 | 0.1136 |

| C4: Loading and Unloading Efficiency | 4.5000 | 0.5222 | 0.1161 |

| C5: Real-Time Data Analysis | 4.5833 | 0.5149 | 0.1123 |

| C6: Data Accuracy | 4.4167 | 0.5149 | 0.1166 |

| C7: Data Transmission Efficiency | 4.6667 | 0.4924 | 0.1055 |

| C8: Anomaly Detection | 4.8333 | 0.3893 | 0.0805 |

| C9: Privacy Protection | 2.5833 | 0.6686 | 0.2588 |

| C10: Human Resource Utilization | 3.0000 | 0.7386 | 0.2462 |

| C11: Fuel Consumption | 3.3333 | 0.8876 | 0.2663 |

| C12: Transportation Costs | 2.2500 | 1.2154 | 0.5402 |

| C13: Equipment Maintenance Costs | 4.5000 | 0.5222 | 0.1161 |

| C14: Carbon Emissions | 1.9167 | 0.5149 | 0.2687 |

| C15: Resource Recycling Rate | 3.8333 | 0.7177 | 0.1872 |

| C16: Sustainability Assessment | 4.3333 | 0.4924 | 0.1136 |

| C17: Community Feedback Satisfaction | 4.5000 | 0.5222 | 0.1161 |

| C18: Regulatory Compliance | 4.7500 | 0.4523 | 0.0952 |

| Kendall’s Coefficient of Coordination | Kendall Wa Coefficient = 0.6278 Cardinality = 128.0778 Asymptotic Significance: p < 0.001 | ||

| Primary Indicators | Average Value | Standard Deviation | Coefficient of Variation |

|---|---|---|---|

| B1: Transportation Efficiency | 4.6667 | 0.4924 | 0.1055 |

| B2: Real-Time Monitoring and Data Management | 5.0000 | 0.0000 | 0.0000 |

| B3: Resource Management and Cost Control | 4.4167 | 0.5149 | 0.1166 |

| B4: Environmental and Social Impact | 4.5000 | 0.5222 | 0.1161 |

| Kendall’s Coefficient of Coordination | Kendall Wa Coefficient = 0.2904 Cardinality = 10.4545 Asymptotic Significance: p = 0.0151 | ||

| Secondary Indicators | Average Value | Standard Deviation | Coefficient of Variation |

|---|---|---|---|

| C1: Transportation Time | 4.5000 | 0.5222 | 0.1161 |

| C2: Empty Mileage Rate | 4.7500 | 0.4523 | 0.0952 |

| C3: Route Optimization | 4.3333 | 0.4924 | 0.1136 |

| C4: Loading and Unloading Efficiency | 4.5000 | 0.5222 | 0.1161 |

| C5: Real-Time Data Analysis | 4.5833 | 0.5149 | 0.1123 |

| C6: Data Accuracy | 4.4167 | 0.5149 | 0.1166 |

| C7: Data Transmission Efficiency | 4.6667 | 0.4924 | 0.1055 |

| C8: Anomaly Detection | 4.8333 | 0.3893 | 0.0805 |

| C9: Data Visualization | 2.5833 | 0.6686 | 0.2588 |

| C10: Human Resource Utilization | 3.0000 | 0.7386 | 0.2462 |

| C11: Fuel Consumption | 3.3333 | 0.8876 | 0.2663 |

| C12: Equipment Maintenance Costs | 4.5000 | 0.5222 | 0.1161 |

| C13: Resource Recycling Rate | 3.8333 | 0.7177 | 0.1872 |

| C14: Sustainability Assessment | 4.3333 | 0.4924 | 0.1136 |

| C15: Community Feedback Satisfaction | 4.5000 | 0.5222 | 0.1161 |

| C16: Regulatory Compliance | 4.7500 | 0.4523 | 0.0952 |

| Kendall’s Coefficient of Coordination | Kendall Wa Coefficient = 0.5082 Cardinality = 91.4713 Asymptotic Significance: p < 0.0001 | ||

| Indicator | B1 | B2 | B3 | B4 |

|---|---|---|---|---|

| B1 | 1 | 1/2 | 2 | 1/3 |

| B2 | 2 | 1 | 3 | 3 |

| B3 | 1/2 | 1/3 | 1 | 1/2 |

| B4 | 3 | 1/3 | 2 | 1 |

| Secondary Indicator | Excellent | Good | Fair | Poor | Very Poor |

|---|---|---|---|---|---|

| C1: Transportation Time | 2 | 3 | 2 | 2 | 1 |

| C2: Empty Mileage Rate | 1 | 3 | 4 | 2 | 0 |

| C3: Route Optimization | 2 | 3 | 3 | 2 | 0 |

| C4: Loading and Unloading Efficiency | 1 | 3 | 4 | 2 | 0 |

| C5: Real-Time Data Analysis | 3 | 4 | 1 | 1 | 1 |

| C6: Data Accuracy | 2 | 4 | 4 | 0 | 0 |

| C7: Data Transmission Efficiency | 3 | 3 | 2 | 2 | 0 |

| C8: Anomaly Detection | 2 | 3 | 3 | 1 | 1 |

| C9: Data Visualization | 2 | 3 | 2 | 2 | 1 |

| C10: Human Resource Utilization | 4 | 3 | 2 | 1 | 0 |

| C11: Fuel Consumption | 1 | 3 | 4 | 1 | 1 |

| C12: Equipment Maintenance Costs | 0 | 5 | 2 | 2 | 1 |

| C13: Resource Recycling Rate | 0 | 2 | 4 | 2 | 2 |

| C14: Sustainability Assessment | 1 | 3 | 3 | 2 | 1 |

| C15: Community Feedback Satisfaction | 3 | 2 | 3 | 1 | 1 |

| C16: Regulatory Compliance | 2 | 3 | 4 | 1 | 0 |

References

- Bi, W.; Lu, W.; Zhao, Z.; Webster, C.J. Combinatorial optimization of construction waste collection and transportation: A case study of Hong Kong. Resour. Conserv. Recycl. 2022, 179, 106043. [Google Scholar] [CrossRef]

- Qiang, G.; Tang, S.; Hao, J.; Di Sarno, L. BIM, IoT, and Big Data Integration Framework in the Green Building Industry. In Proceedings of the International Conference on Sustainable Buildings and Structures Towards a Carbon Neutral Future, Suzhou, China, 17–20 August 2023; Springer: Berlin/Heidelberg, Germany, 2023; pp. 15–23. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Hassanien, E.; Hassanien, A.E. IoT-based intelligent waste management system. Neural Comput. Appl. 2023, 35, 23551–23579. [Google Scholar] [CrossRef]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Hao, J.L.; Zhao, W.; Gong, G.; Ma, W.; Li, L.; Zhang, Y. Catalyzing sustainability through prefabrication: Integrating BIM-LCA for assessing embodied carbon in timber formwork waste. Sustain. Chem. Pharm. 2024, 41, 101698. [Google Scholar] [CrossRef]

- IEA. Global Energy Review: CO2 Emissions in 2020. 2020. Available online: https://www.iea.org/articles/global-energy-review-co2-emissions-in-2020 (accessed on 1 March 2025).

- Islam, M.T.; Iyer-Raniga, U.; Trewick, S. Recycling perspectives of circular business models: A review. Recycling 2022, 7, 79. [Google Scholar] [CrossRef]

- Singh, R.; Khan, S.; Dsilva, J.; Centobelli, P. Blockchain integrated IoT for food supply chain: A grey based Delphi-DEMATEL approach. Appl. Sci. 2023, 13, 1079. [Google Scholar] [CrossRef]

- Henaien, A.; Elhadj, H.B.; Fourati, L.C. A sustainable smart IoT-based solid waste management system. Future Gener. Comput. Syst. 2024, 157, 587–602. [Google Scholar] [CrossRef]

- Rathore, M.M.; Paul, A.; Hong, W.; Seo, H.; Awan, I.; Saeed, S. Exploiting IoT and big data analytics: Defining smart digital city using real-time urban data. Sustain. Cities Soc. 2018, 40, 600–610. [Google Scholar] [CrossRef]

- Alahi, M.E.E.; Sukkuea, A.; Tina, F.W.; Nag, A.; Kurdthongmee, W.; Suwannarat, K.; Mukhopadhyay, S.C. Integration of IoT-enabled technologies and artificial intelligence (AI) for smart city scenario: Recent advancements and future trends. Sensors 2023, 23, 5206. [Google Scholar] [CrossRef]

- Jagatheesaperumal, S.K.; Bibri, S.E.; Huang, J.; Rajapandian, J.; Parthiban, B. Artificial intelligence of things for smart cities: Advanced solutions for enhancing transportation safety. Comput. Urban Sci. 2024, 4, 10. [Google Scholar] [CrossRef]

- Eltoukhy, A.E.; Hussein, M.; Xu, M.; Chan, F.T. Data-driven game-theoretic model based on blockchain for managing resource allocation and vehicle routing in modular integrated construction. Int. J. Prod. Res. 2023, 61, 4472–4502. [Google Scholar] [CrossRef]

- Zhao, W.; Hao, J.L.; Gong, G.; Fischer, T.; Liu, Y. Applying digital technologies in construction waste management for facilitating sustainability. J. Environ. Manag. 2025, 373, 123560. [Google Scholar] [CrossRef]

- Talla, A.; McIlwaine, S. Industry 4.0 and the circular economy: Using design-stage digital technology to reduce construction waste. Smart Sustain. Built Environ. 2024, 13, 179–198. [Google Scholar] [CrossRef]

- Anagnostopoulos, T.; Zaslavsky, A.; Kolomvatsos, K.; Medvedev, A.; Amirian, P.; Morley, J.; Hadjieftymiades, S. Challenges and opportunities of waste management in IoT-enabled smart cities: A survey. IEEE Trans. Sustain. Comput. 2017, 2, 275–289. [Google Scholar] [CrossRef]

- Zhao, W.; Hao, J.L.; Gong, G.; Ma, W.; Zuo, J.; Di Sarno, L. Decarbonizing prefabricated building waste: Scenario simulation of policies in China. J. Clean. Prod. 2024, 458, 142529. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S.; Kannan, D.; Govindan, K.; Singh, R.; Purohit, H. Internet of Things (IoT) adoption barriers of smart cities’ waste management: An Indian context. J. Clean. Prod. 2020, 270, 122047. [Google Scholar] [CrossRef]

- Wu, W.; Lyu, Y.; Zheng, C.; Hao, J.L.; Shen, S.; Yu, S. Digital supervision in construction pollution control: Utilizing advanced information models for enhanced supervision and sustainability. Environ. Technol. Innov. 2025, 37, 104038. [Google Scholar] [CrossRef]

- Brandín, R.; Abrishami, S. IoT-BIM and blockchain integration for enhanced data traceability in offsite manufacturing. Autom. Constr. 2024, 159, 105266. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P.; Shelden, D.R.; Tang, S. Internet of things enabled data acquisition framework for smart building applications. J. Constr. Eng. Manag. 2021, 147, 04020169. [Google Scholar] [CrossRef]

- Rao, A.S.; Radanovic, M.; Liu, Y.; Hu, S.; Fang, Y.; Khoshelham, K.; Palaniswami, M.; Ngo, T. Real-time monitoring of construction sites: Sensors, methods, and applications. Autom. Constr. 2022, 136, 104099. [Google Scholar] [CrossRef]

- Gholamhosseini, L.; Sadoughi, F.; Rezayi, S.; Nasiri, S. Identifying cloud internet of things requirements in healthcare: A Delphi-based study. J. Supercomput. 2024, 80, 20201–20228. [Google Scholar] [CrossRef]

- Pathak, S.K.; Sharma, V.; Chougule, S.S.; Goel, V. Prioritization of barriers to the development of renewable energy technologies in India using integrated modified delphi and AHP method. Sustain. Energy Technol. Assess. 2022, 50, 101818. [Google Scholar] [CrossRef]

- Song, P.; Wu, L.; Zhao, W.; Ma, W.; Hao, J. Life cycle sustainability assessment: An index system for building energy retrofit projects. Buildings 2024, 14, 2817. [Google Scholar] [CrossRef]

- Oyewale, J.A.; Tartibu, L.K.; Okokpujie, I.P. Decision analysis approaches on the collection methods of polyethylene terephthalate waste. Recycling 2024, 9, 124. [Google Scholar] [CrossRef]

- Guo, X.; Xie, W.; Zhang, Y.; Qiao, J.; Lian, H. Fuzzy comprehensive evaluation of imported alcohol safety risk based on AHP and risk matrix. Chin. J. Food Hyg. 2023, 35, 1080–1087. [Google Scholar] [CrossRef]

- He, Y.; Zhao, G.; Tang, Y.; Song, J.; Chen, Y. Available target evaluation of underground gas storage based on AHP-FCE methods. Geoenergy Sci. Eng. 2024, 242, 213255. [Google Scholar] [CrossRef]

- Rabelo, L.; Ballestas, A.; Valdez, J.; Ibrahim, B. Using delphi and system dynamics to study the cybersecurity of the IoT-based smart grids. ParadigmPlus 2022, 3, 19–36. [Google Scholar] [CrossRef]

- Xu, S.; Sun, Y. Research on evaluation of green smart building based on improved AHP-FCE method. Comput. Intell. Neurosci. 2021, 2021, 5485671. [Google Scholar] [CrossRef]

- Deja, A.; Ślączka, W.; Kaup, M.; Szołtysek, J.; Dzhuguryan, L.; Dzhuguryan, T. Supply chain management in smart city manufacturing clusters: An alternative approach to urban freight mobility with electric vehicles. Energies 2024, 17, 5284. [Google Scholar] [CrossRef]

- Mishra, A.; Kumar Ray, A. IoT cloud-based cyber-physical system for efficient solid waste management in smart cities: A novel cost function based route optimisation technique for waste collection vehicles using dustbin sensors and real-time road traffic informatics. IET Cyber-Phys. Syst. Theory Appl. 2020, 5, 330–341. [Google Scholar] [CrossRef]

- Han, H.; Tang, J.; Jing, Z. Wireless sensor network routing optimization based on improved ant colony algorithm in the Internet of Things. Heliyon 2024, 10, e23577. [Google Scholar] [CrossRef] [PubMed]

- Narsimhulu, P.; Chithaluru, P.; Al-Turjman, F.; Guda, V.; Inturi, S.; Stephan, T.; Kumar, M. An intelligent fl-based vehicle route optimization protocol for green and sustainable IoT connected IoV. Internet Things 2024, 27, 101240. [Google Scholar] [CrossRef]

- Song, Y.; Yu, F.R.; Zhou, L.; Yang, X.; He, Z. Applications of the Internet of Things (IoT) in smart logistics: A comprehensive survey. IEEE Internet Things J. 2020, 8, 4250–4274. [Google Scholar] [CrossRef]

- Al-Hadhrami, Y.; Hussain, F.K. Real time dataset generation framework for intrusion detection systems in IoT. Future Gener. Comput. Syst. 2020, 108, 414–423. [Google Scholar] [CrossRef]

- Bian, J.; Al Arafat, A.; Xiong, H.; Li, J.; Li, L.; Chen, H.; Wang, J.; Dou, D.; Guo, Z. Machine learning in real-time Internet of Things (IoT) systems: A survey. IEEE Internet Things J. 2022, 9, 8364–8386. [Google Scholar] [CrossRef]

- Alam, F.; Mehmood, R.; Katib, I.; Albogami, N.N.; Albeshri, A. Data fusion and IoT for smart ubiquitous environments: A survey. IEEE Access 2017, 5, 9533–9554. [Google Scholar] [CrossRef]

- Fathy, Y.; Barnaghi, P. Quality-based and energy-efficient data communication for the internet of things networks. IEEE Internet Things J. 2019, 6, 10318–10331. [Google Scholar] [CrossRef]

- Zappile, J.C.; de Andrade, R.P.; Lima, G.S.; Schiffini, G.B.; Maranhão, F.L. Influence of construction materials density on data transmission performance of IOT devices. Autom. Constr. 2024, 166, 105635. [Google Scholar] [CrossRef]

- Chatterjee, A.; Ahmed, B.S. IoT anomaly detection methods and applications: A survey. Internet Things 2022, 19, 100568. [Google Scholar] [CrossRef]

- Liu, Y.; Pang, Z.; Karlsson, M.; Gong, S. Anomaly detection based on machine learning in IoT-based vertical plant wall for indoor climate control. Build. Environ. 2020, 183, 107212. [Google Scholar] [CrossRef]

- Yin, C.; Xi, J.; Sun, R.; Wang, J. Location privacy protection based on differential privacy strategy for big data in industrial internet of things. IEEE Trans. Ind. Inform. 2017, 14, 3628–3636. [Google Scholar] [CrossRef]

- Zhu, F.; Yi, X.; Abuadbba, A.; Khalil, I.; Nepal, S.; Huang, X. Cost-effective authenticated data redaction with privacy protection in IoT. IEEE Internet Things J. 2021, 8, 11678–11689. [Google Scholar] [CrossRef]

- Strohmeier, S. Smart HRM–a Delphi study on the application and consequences of the Internet of Things in human resource management. Int. J. Hum. Resour. Manag. 2020, 31, 2289–2318. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, Q.; Wu, S. Research on the construction process of human resources supply chain of small and micro enterprises based on Internet of Things technology. Internet Things 2023, 22, 100714. [Google Scholar] [CrossRef]

- Sanchez, O.T.; Raposo, D.; Rodrigues, A.; Boavida, F.; Marculescu, R.; Chen, K.; Silva, J.S. An IIoT-based approach to the integrated management of machinery in the construction industry. IEEE Access 2023, 11, 6331–6350. [Google Scholar] [CrossRef]

- Shahnavaz, F.; Akhavian, R. Automated estimation of construction equipment emission using inertial sensors and machine learning models. Sustainability 2022, 14, 2750. [Google Scholar] [CrossRef]

- Fredriksson, A.; Sezer, A.A.; Angelakis, V.; Gundlegård, D. Construction related urban disturbances: Identification and linking with an IoT-model. Autom. Constr. 2022, 134, 104038. [Google Scholar] [CrossRef]

- Louis, J.; Dunston, P.S. Integrating IoT into operational workflows for real-time and automated decision-making in repetitive construction operations. Autom. Constr. 2018, 94, 317–327. [Google Scholar] [CrossRef]

- Ma, M.; Tam, V.W.; Le, K.N.; Li, W. Challenges in current construction and demolition waste recycling: A China study. Waste Manag. 2020, 118, 610–625. [Google Scholar] [CrossRef]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, J. Research on the application of block chain big data platform in the construction of new smart city for low carbon emission and green environment. Comput. Commun. 2020, 149, 332–342. [Google Scholar] [CrossRef]

- Tao, X.; Mao, C.; Xie, F.; Liu, G.; Xu, P. Greenhouse gas emission monitoring system for manufacturing prefabricated components. Autom. Constr. 2018, 93, 361–374. [Google Scholar] [CrossRef]

- Arshad, R.; Zahoor, S.; Shah, M.A.; Wahid, A.; Yu, H. Green IoT: An investigation on energy saving practices for 2020 and beyond. IEEE Access 2017, 5, 15667–15681. [Google Scholar] [CrossRef]

- Christensen, T.H.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.; Starostina, V.; Boldrin, A.; Astrup, T.F. Application of LCA modelling in integrated waste management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef]

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Opportunities for enhanced lean construction management using Internet of Things standards. Autom. Constr. 2016, 61, 86–97. [Google Scholar] [CrossRef]

- Rane, N.; Choudhary, S.; Rane, J. Artificial Intelligence (Ai) and Internet of Things (Iot)–Based Sensors for Monitoring and Controlling in Architecture, Engineering, and Construction: Applications, Challenges, and Cpportunities. SSRN; 2023. Available online: https://ssrn.com/abstract=4642197 (accessed on 13 April 2025). [CrossRef]

- Bibri, S.E. The IoT for smart sustainable cities of the future: An analytical framework for sensor-based big data applications for environmental sustainability. Sustain. Cities Soc. 2018, 38, 230–253. [Google Scholar] [CrossRef]

- Chandrasekaran, H.; Subramani, S.E.; Partheeban, P.; Sridhar, M. IoT-and GIS-based environmental impact assessment of construction and demolition waste dump yards. Sustainability 2023, 15, 13013. [Google Scholar] [CrossRef]

| Research Area | Research Gaps |

|---|---|

| IoT-Based Smart Waste Collection | Limited scalability and no life cycle assessment. Future work should address dynamic C&D waste conditions and scalability. |

| Sensor Technologies and Real-Time Monitoring | Need for integration of advanced methods like system dynamics and multi-objective optimization for predictive decision making. |

| Blockchain and Game Theory in Logistics | Not tailored to dynamic conditions of C&D waste management. Exploration of adaptive models is needed. |

| Methodological Advancements | Lack of integration of advanced methods such as system dynamics, multi-objective optimization, and digital twin modeling. |

| Scalability and Predictive Support | Need for scalable and predictive decision support systems that can handle complex large-scale construction waste logistics. |

| Scale Value | Importance Degree | Implication |

|---|---|---|

| Equally important | Both elements are equally important. | |

| Slightly more important | The former element is slightly more important than the latter. | |

| Significantly important | The former element is significantly more important than the latter. | |

| Strongly important | The former element is more strongly important than the latter element. | |

| Absolutely important | The former element is more important than the latter element. | |

| Median value | Indicates the median value of the above two scales. | |

| Corresponds to the above | The latter element is the inverse of the above value compared with the former element. |

| Primary Indicators | Secondary Indicators | Explanation | References |

|---|---|---|---|

| B1: Transportation Efficiency | C1: Transportation Time | The time required for transportation vehicles to complete tasks from the starting point to the end point, reflecting the response speed and efficiency of the logistic. | [30] |

| C2: Empty Mileage Rate | The proportion of mileage driven by transport vehicles without cargo in the total mileage, which directly affects fuel consumption and cost control. | [31,32] | |

| C3: Route Optimization | Provide optimal route planning for transport vehicles by analyzing real-time traffic data and transport network characteristics, aiming to reduce transport time, reduce fuel consumption, and improve transport efficiency. | [33,34] | |

| C4: Loading and Unloading Efficiency | The ability to complete the loading and unloading of goods per unit time, which is a key factor to improve the overall transportation efficiency and the turnover rate of resources. | [35] | |

| B2: Real-Time Monitoring and Data Management | C5: Real-Time Data Analysis | Collect, process, and interpret the data generated during transportation through the IoT technology to provide a scientific basis for decision making in transportation management. | [36,37] |

| C6: Data Accuracy | Reflect how accurately IoT devices collect and transmit data, the reliability of which is critical to system operation and optimal management. | [38] | |

| C7: Data Transmission Efficiency | Measure the speed and reliability of data transmission from the acquisition end to the receiving end, which directly affects the real-time and response ability of the transportation management system. | [39,40] | |

| C8: Anomaly Detection | Monitor unexpected situations during transportation. By accurately capturing these anomalies, the management system can alert relevant parties the first time to achieve rapid response and problem resolution. | [41,42] | |

| C9: Privacy Protection | Involve the security of transport data during collection, transmission, and storage to ensure that sensitive information is not abused or disclosed. | [43,44] | |

| B3: Resource Management and Cost Control | C10: Human Resource Utilization | Optimize the workload of employees through the rational allocation of labor in the transportation process, thereby improving labor efficiency and reducing labor costs. | [45,46] |

| C11: Fuel Consumption | Measure the amount of fuel used per unit time or mileage of a transport vehicle, which directly affects operating costs and environmental sustainability. | [47,48] | |

| C12: Transportation Costs | The core variables of economic analysis in transportation management include fuel, labor, maintenance, and other operating expenses. | [49,50] | |

| C13: Equipment Maintenance Costs | Measure the regular maintenance and fault repair costs of transport vehicles and related equipment that directly affect the long-term availability and operational efficiency of equipment. | [51,52] | |

| B4: Environmental and Social Impact | C14: Carbon Emissions | Evaluate the impact of the transportation system on the environment directly related to sustainable development goals. | [53,54] |

| C15: Resource Recycling Rate | Measure the proportion of recyclable materials in construction waste, an important reference to promote the development of waste resources and circular economy. | [55] | |

| C16: Sustainability Assessment | Measure whether transport management complies with the principles of sustainable development through the comprehensive consideration of environmental protection, economic benefits, and social impacts. | [56] | |

| C17: Community Feedback Satisfaction | Reflect public acceptance and support for transport management by assessing the impact of transport activities on the local community, such as noise pollution, road congestion, and so on. | [57,58] | |

| C18: Regulatory Compliance | Measure whether transport management meets the requirements of relevant laws, regulations, and policies, and is a key factor in ensuring the legitimacy and standardization of transport activities. | [59,60] |

| Primary Indicators | Secondary Indicators |

|---|---|

| B1: Transportation Efficiency | C1: Transportation Time |

| C2: Empty Mileage Rate | |

| C3: Route Optimization | |

| C4: Loading and Unloading Efficiency | |

| B2: Real-Time Monitoring and Data Management | C5: Real-Time Data Analysis |

| C6: Data Accuracy | |

| C7: Data Transmission Efficiency | |

| C8: Anomaly Detection | |

| C9: Data Visualization | |

| B3: Resource Management and Cost Control | C10: Human Resource Utilization |

| C11: Fuel Consumption | |

| C12: Equipment Maintenance Costs | |

| B4: Environmental and Social Impact | C13: Resource Recycling Rate |

| C14: Sustainability Assessment | |

| C15: Community Feedback Satisfaction | |

| C16: Regulatory Compliance |

| Secondary Indicator | Excellent | Good | Fair | Poor | Very Poor | Score |

|---|---|---|---|---|---|---|

| C1: Transportation Time | 0.2000 | 0.3000 | 0.2000 | 0.2000 | 0.1000 | 3.3000 |

| C2: Empty Mileage Rate | 0.1000 | 0.3000 | 0.4000 | 0.2000 | 0.0000 | 3.3000 |

| C3: Route Optimization | 0.2000 | 0.3000 | 0.3000 | 0.2000 | 0.0000 | 3.5000 |

| C4: Loading and Unloading Efficiency | 0.1000 | 0.3000 | 0.4000 | 0.2000 | 0.0000 | 3.3000 |

| C5: Real-Time Data Analysis | 0.3000 | 0.4000 | 0.1000 | 0.1000 | 0.1000 | 3.7000 |

| C6: Data Accuracy | 0.2000 | 0.4000 | 0.4000 | 0.0000 | 0.0000 | 3.8000 |

| C7: Data Transmission Efficiency | 0.3000 | 0.3000 | 0.2000 | 0.2000 | 0.0000 | 3.7000 |

| C8: Anomaly Detection | 0.2000 | 0.3000 | 0.3000 | 0.1000 | 0.1000 | 3.4000 |

| C9: Data Visualization | 0.2000 | 0.3000 | 0.2000 | 0.2000 | 0.1000 | 3.3000 |

| C10: Human Resource Utilization | 0.4000 | 0.3000 | 0.2000 | 0.1000 | 0.0000 | 4.0000 |

| C11: Fuel Consumption | 0.1000 | 0.3000 | 0.4000 | 0.1000 | 0.1000 | 3.2000 |

| C12: Equipment Maintenance Costs | 0.0000 | 0.5000 | 0.2000 | 0.2000 | 0.1000 | 3.1000 |

| C13: Resource Recycling Rate | 0.0000 | 0.2000 | 0.4000 | 0.2000 | 0.2000 | 2.6000 |

| C14: Sustainability Assessment | 0.1000 | 0.3000 | 0.3000 | 0.2000 | 0.1000 | 3.1000 |

| C15: Community Feedback Satisfaction | 0.3000 | 0.2000 | 0.3000 | 0.1000 | 0.1000 | 3.5000 |

| C16: Regulatory Compliance | 0.2000 | 0.3000 | 0.4000 | 0.1000 | 0.0000 | 3.6000 |

| Criterion Layer | Excellent | Good | Fair | Poor | Very Poor | Evaluation Results |

|---|---|---|---|---|---|---|

| B1: Transportation Efficiency | 0.1643 | 0.3000 | 0.3219 | 0.2000 | 0.0138 | Fair |

| B2: Real-Time Monitoring and Data Management | 0.2490 | 0.3695 | 0.2259 | 0.0882 | 0.0675 | Good |

| B3: Resource Management and Cost Control | 0.2811 | 0.3209 | 0.2514 | 0.1104 | 0.0361 | Good |

| B4: Environmental and Social Impact | 0.1352 | 0.2796 | 0.3359 | 0.1644 | 0.0848 | Fair |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ateeq, M.; Zhang, N.; Zhao, W.; Gu, Y.; Wen, Z.; Zheng, C.; Hao, J. Enhancing Construction Waste Transportation Management Using Internet of Things (IoT): An Evaluation Framework Based on AHP–FCE Method. Buildings 2025, 15, 1381. https://doi.org/10.3390/buildings15081381

Ateeq M, Zhang N, Zhao W, Gu Y, Wen Z, Zheng C, Hao J. Enhancing Construction Waste Transportation Management Using Internet of Things (IoT): An Evaluation Framework Based on AHP–FCE Method. Buildings. 2025; 15(8):1381. https://doi.org/10.3390/buildings15081381

Chicago/Turabian StyleAteeq, Muhammad, Nan Zhang, Wenbo Zhao, Yaoqian Gu, Ziying Wen, Caimiao Zheng, and Jianli Hao. 2025. "Enhancing Construction Waste Transportation Management Using Internet of Things (IoT): An Evaluation Framework Based on AHP–FCE Method" Buildings 15, no. 8: 1381. https://doi.org/10.3390/buildings15081381

APA StyleAteeq, M., Zhang, N., Zhao, W., Gu, Y., Wen, Z., Zheng, C., & Hao, J. (2025). Enhancing Construction Waste Transportation Management Using Internet of Things (IoT): An Evaluation Framework Based on AHP–FCE Method. Buildings, 15(8), 1381. https://doi.org/10.3390/buildings15081381