Influence of Groundwater Level Rising on Mechanical Properties of Pile Foundations Under a Metro Depot in Loess Areas

Abstract

:1. Introduction

2. Test Materials and Instruments

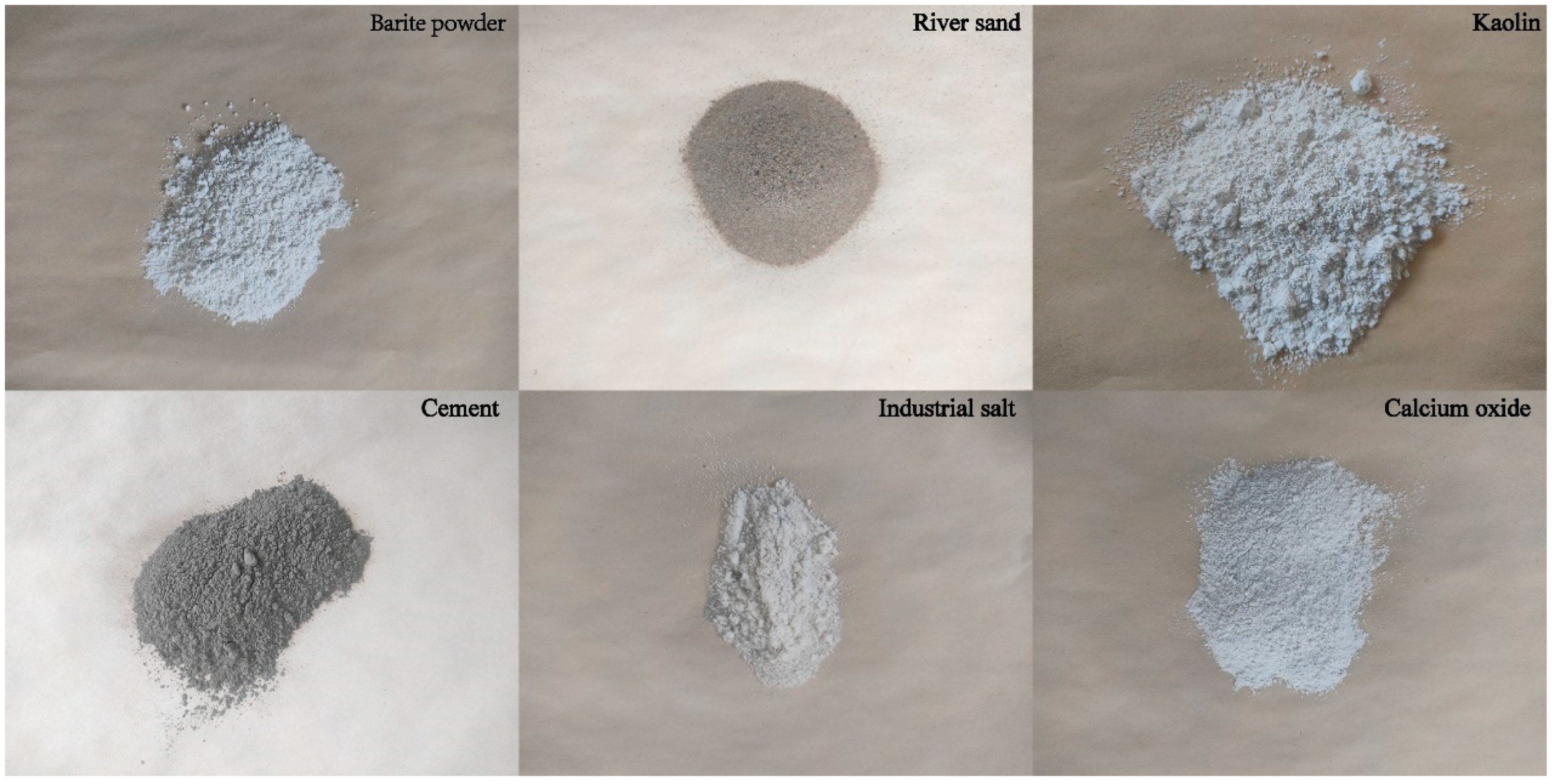

2.1. Artificial Collapsible Loess

- Barite powder and fluvial sand as granular constituents regulating bulk density through particle packing density modulation;

- Fluvial sand as shear strength modifiers controlling internal friction characteristics and deformation response;

- Hydraulic cement as supplementary cementitious agents;

- Kaolin forms clay cementations;

- Calcium oxide undergoing carbonation reactions with atmospheric CO2 in aqueous conditions to generate calcium carbonate cementation.

- (1)

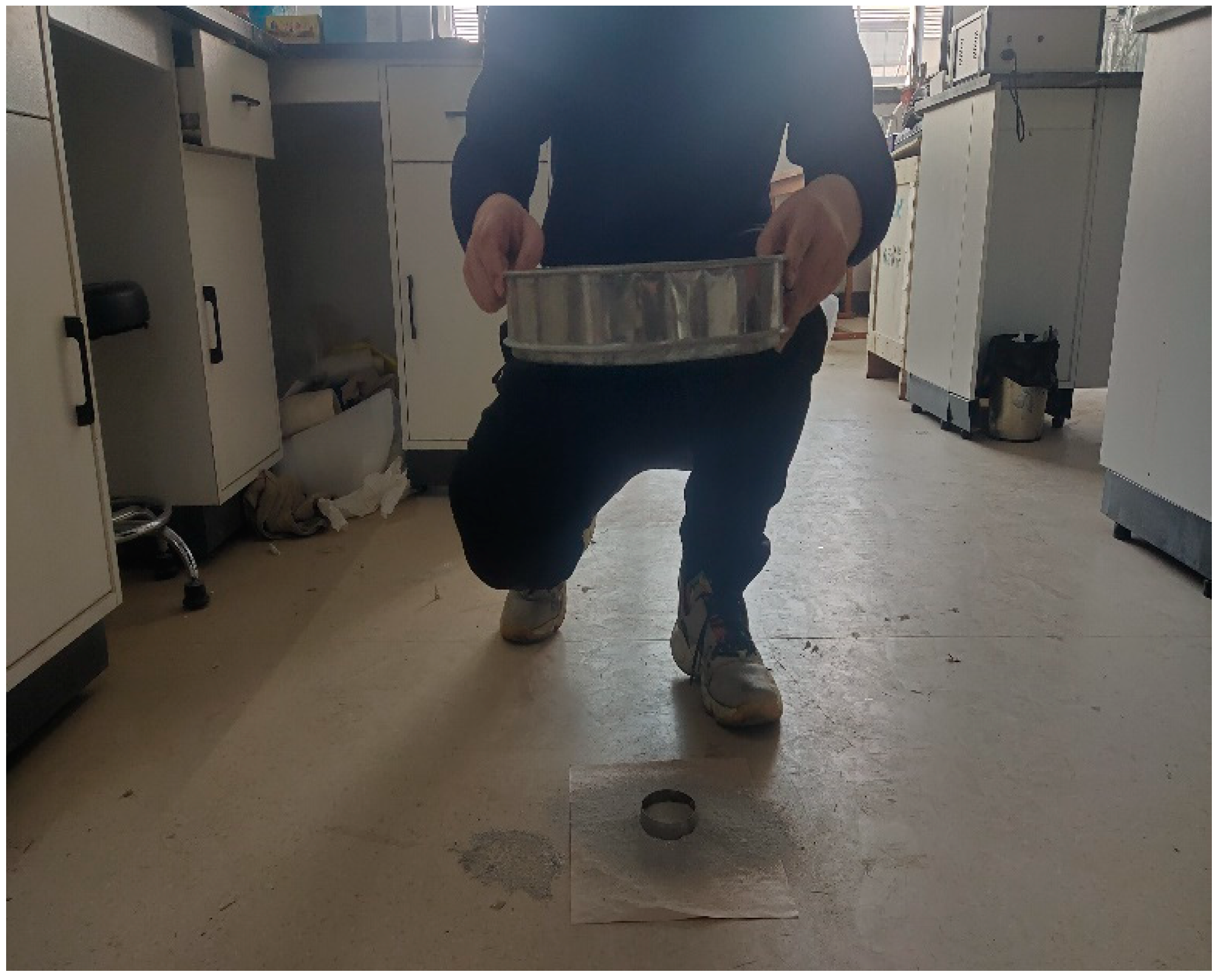

- Precisely proportioned constituent materials were homogenously blended through mechanical mixing. A granulometric sieve (2 mm aperture) was positioned vertically at 20–40 cm above a standardized sampling ring. The composite mixture was systematically introduced onto the sieve platform, followed by continuous vibration. This methodology can simulate natural depositional processes.

- (2)

- The prepared specimen surface was smoothed, followed by static compaction to achieve predetermined density specifications. Subsequently, specimens were subjected to isothermal desiccation in an oven maintained at 50 ± 1 °C for 24 h. Finally, a sprayer was used to sprinkle the sample with water mist and make it reach the optimum moisture content.

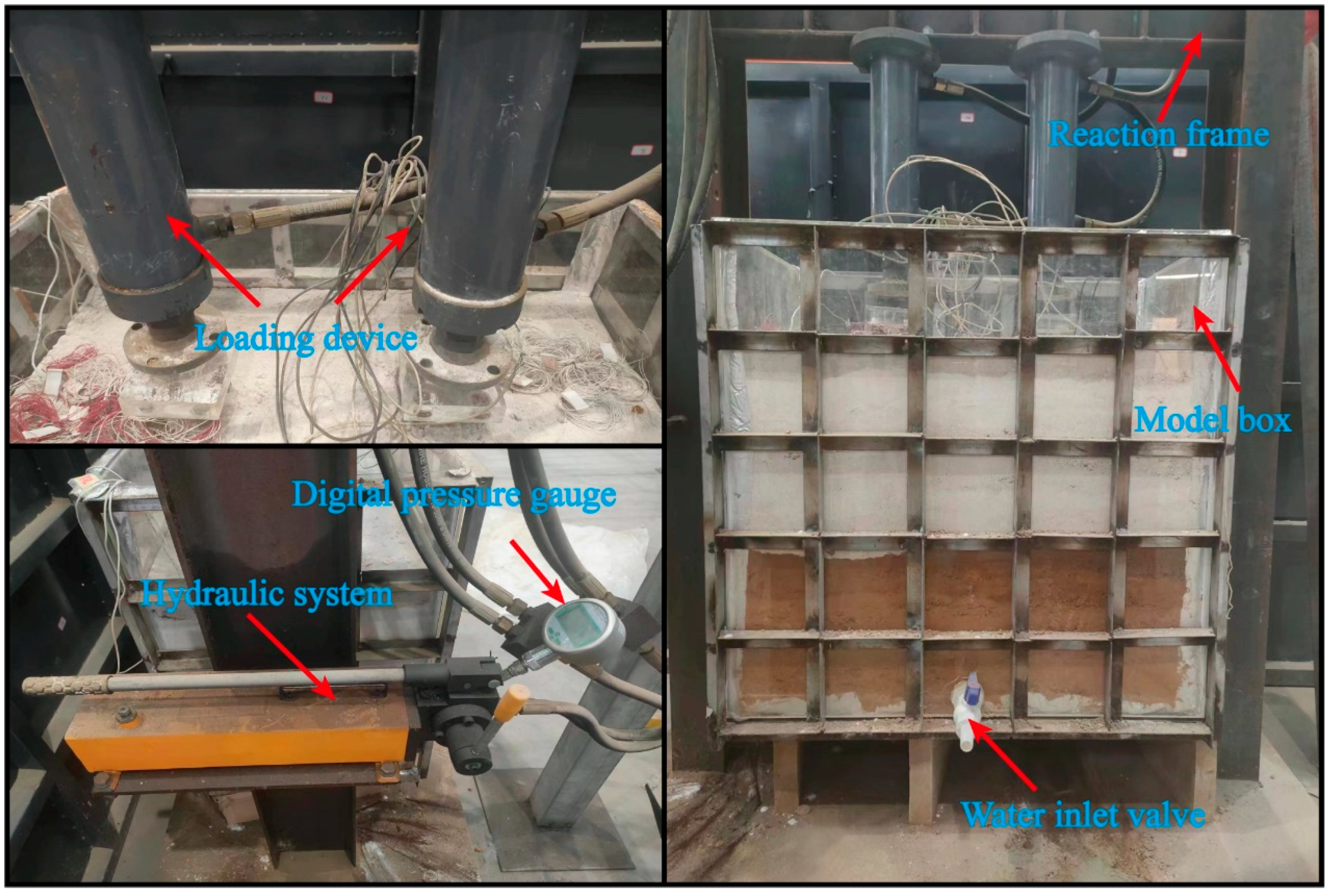

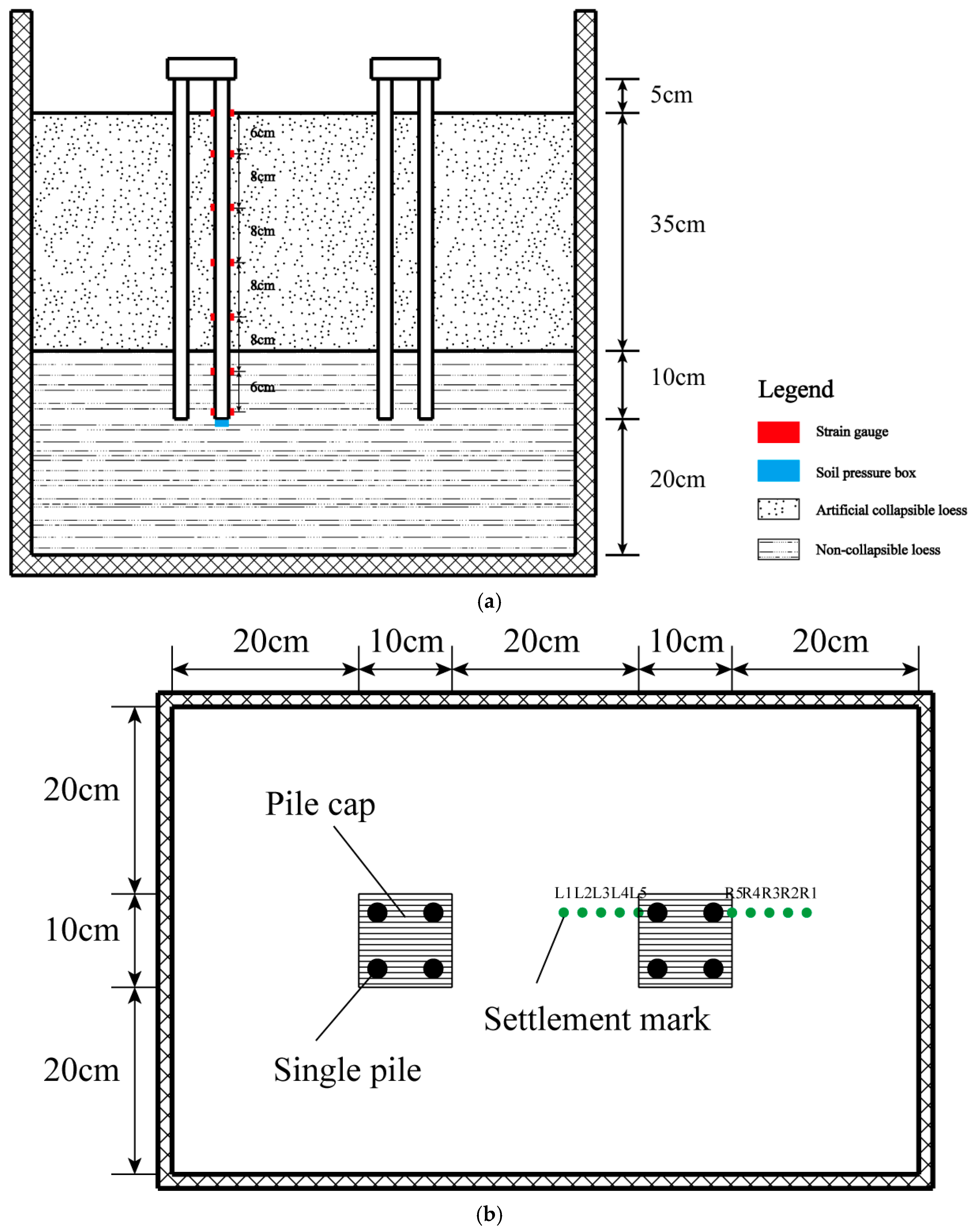

2.2. Model Box and Model Piles

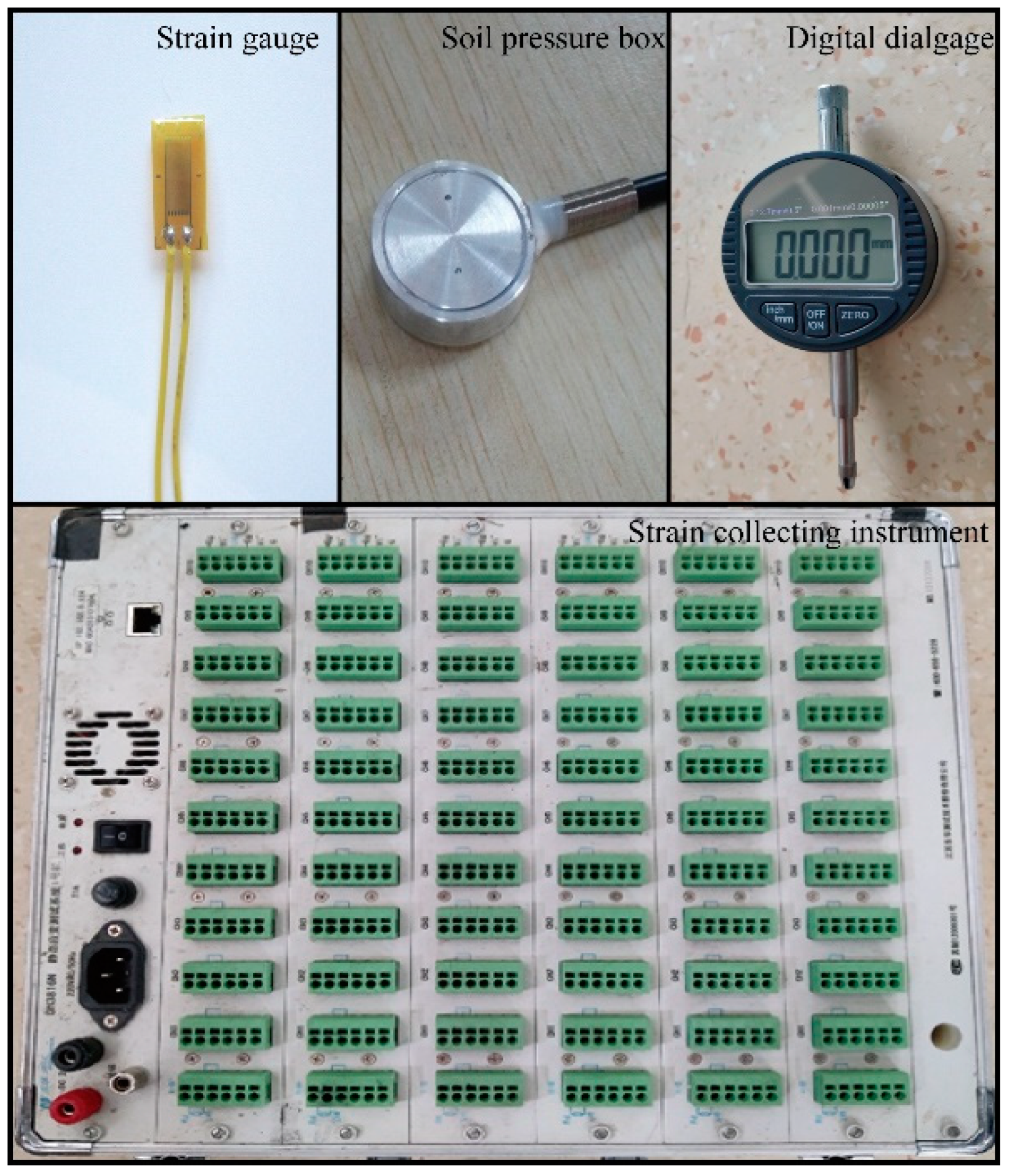

2.3. Test Condition Setting

2.3.1. The Layout of Pile Foundations

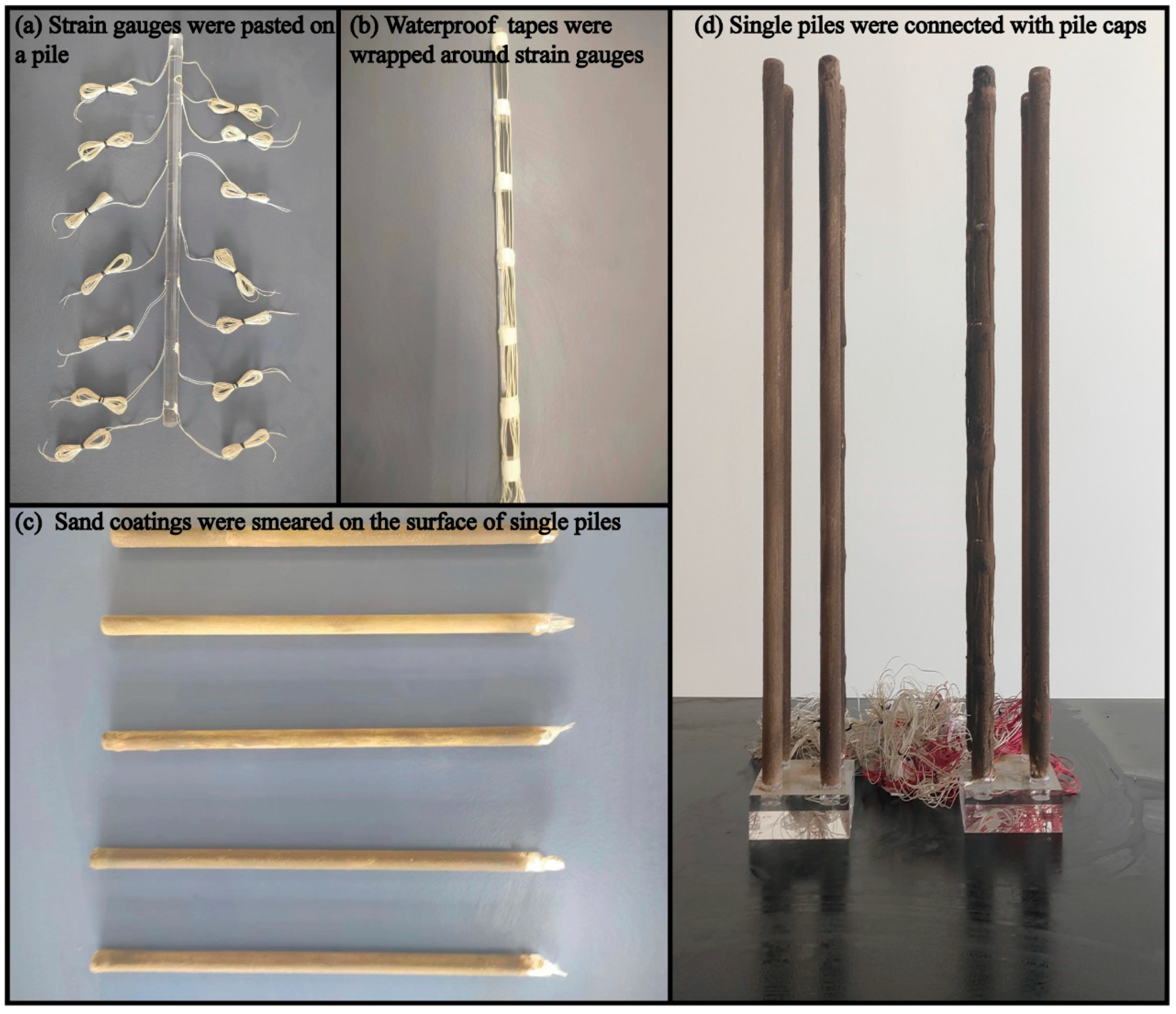

- Strain Analysis: Symmetrically distributed strain gauges (120 Ω foil-type, ±1 με accuracy) along pile shafts to capture strain change;

- Tip Resistance Monitoring: Miniaturized soil pressure transducers installed at pile tip.

2.3.2. The Loading Process of the Without Groundwater Condition

- Load incrementation:

- Primary stage: 2× graded load (1.0 kN);

- Subsequent stages: 0.5 kN increments (1/11 of ultimate bearing capacity);

- Stable criteria: ≤0.1 mm displacement over a consecutive 2 h monitoring period post 30 min load maintenance;

- Termination conditions: settlement exceeds twice the preceding stage’s displacement.

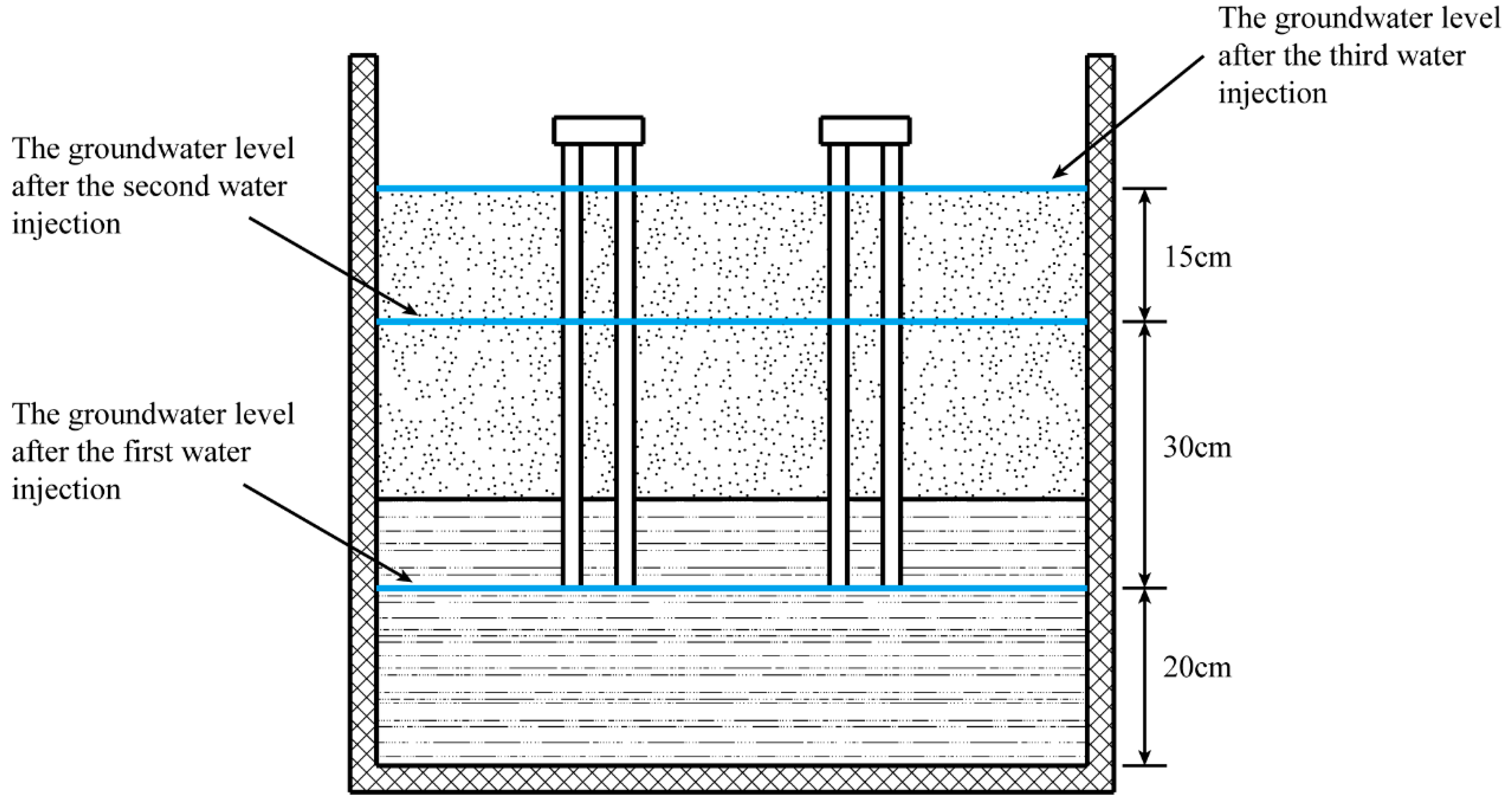

2.3.3. Setting of Groundwater Level and Upper Load

- Initial phase: stabilization of the water table within the bearing stratum post-injection.

- Second phase: groundwater rises to permeate the part of artificial collapsible loess stratum.

- Tertiary phase: full saturation of the soil matrix through complete inundation.

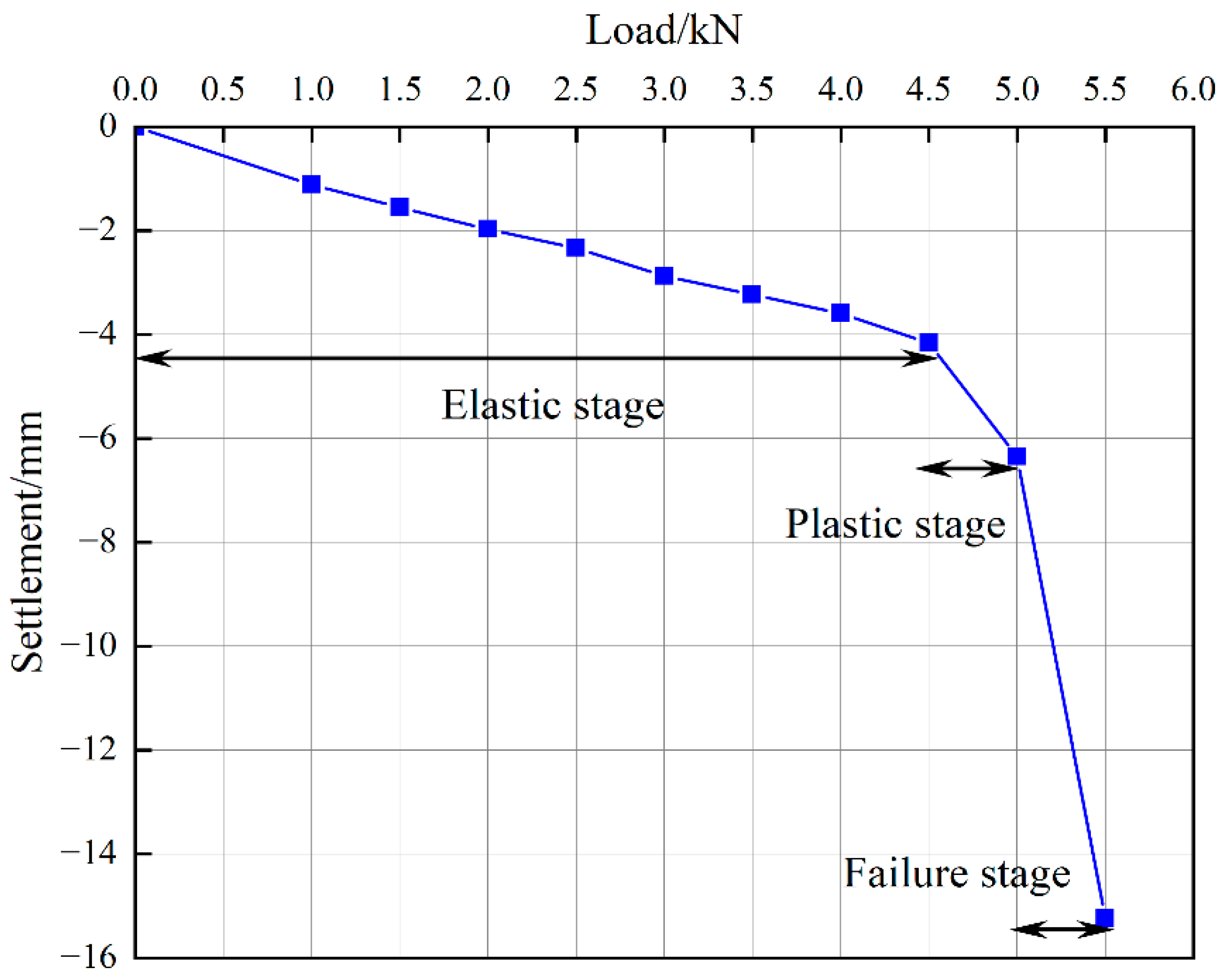

3. Static Load Test Under the Condition of No Groundwater

3.1. Change of Pile Foundations Settlement with the Applied Load

- Linear elastic phase (0–4.5 kN): axial displacement demonstrated proportionality to applied load, indicative of reversible elastic strain.

- Plastic yielding phase (4.5–5 kN): a nonlinear transition occurred, signaling the appearance of unrecoverable deformation.

- Structural failure phase (>5 kN): displacement escalates to 15.44 mm at 5.5 kN load, exceeding the 6.55 mm displacement at 5 kN by a factor of 2.36.

3.2. Distribution of Axial Force and Skin Friction in Pile Shafts

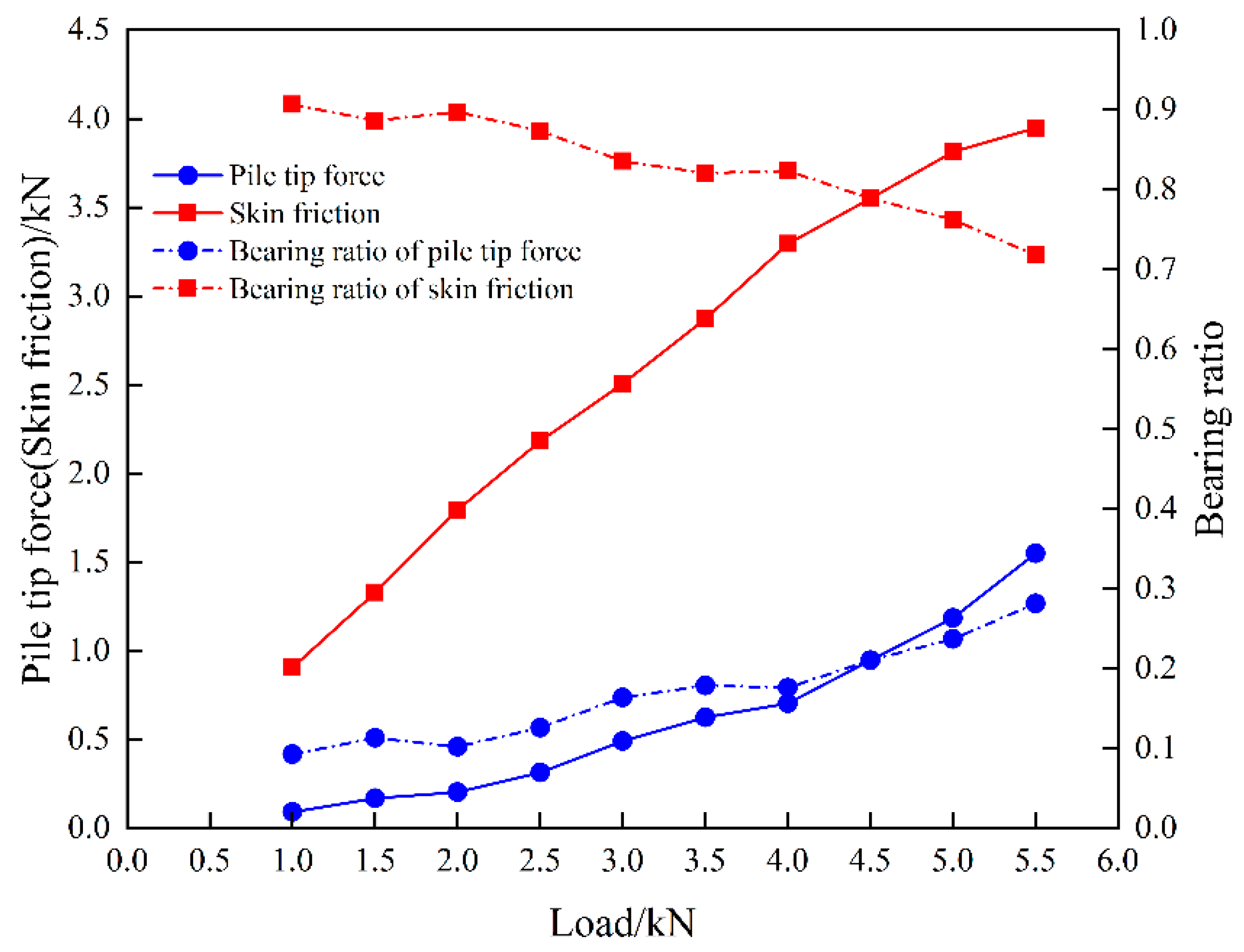

3.3. Change of Pile Tip Force with the Applied Load

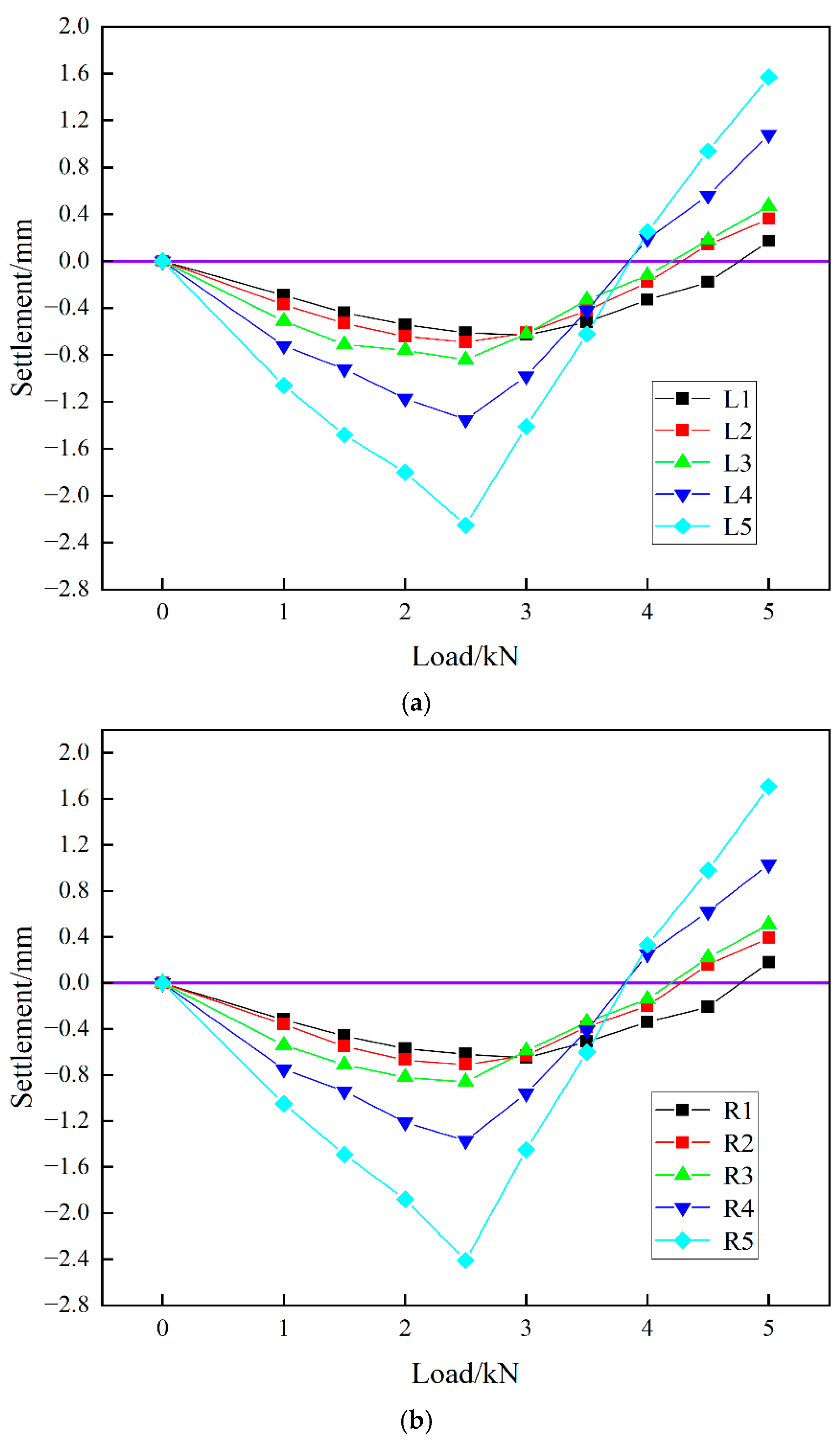

3.4. Change of Foundation Soil Settlement with the Applied Load

- Initial compression phase (0–1.5 kN): progressive settlement accumulation (∆s = 0.44–1.49 mm) under linearly increasing loads;

- Yield phase (1.5–2.5 kN): plastic deformation is generated gradually and maximum subsidence is attained finally;

- Post-yield heave phase (2.5 kN): when the load exceeds the elastic limit of the soil, a plastic zone is formed under the pile tip. At this time, the pile tip compresses the soil, resulting in the increase of radial stress. After extension of the plastic zone, the lateral earth pressure is released, resulting in the hump of the soil.

4. Static Load Test with the Condition of Rising Groundwater

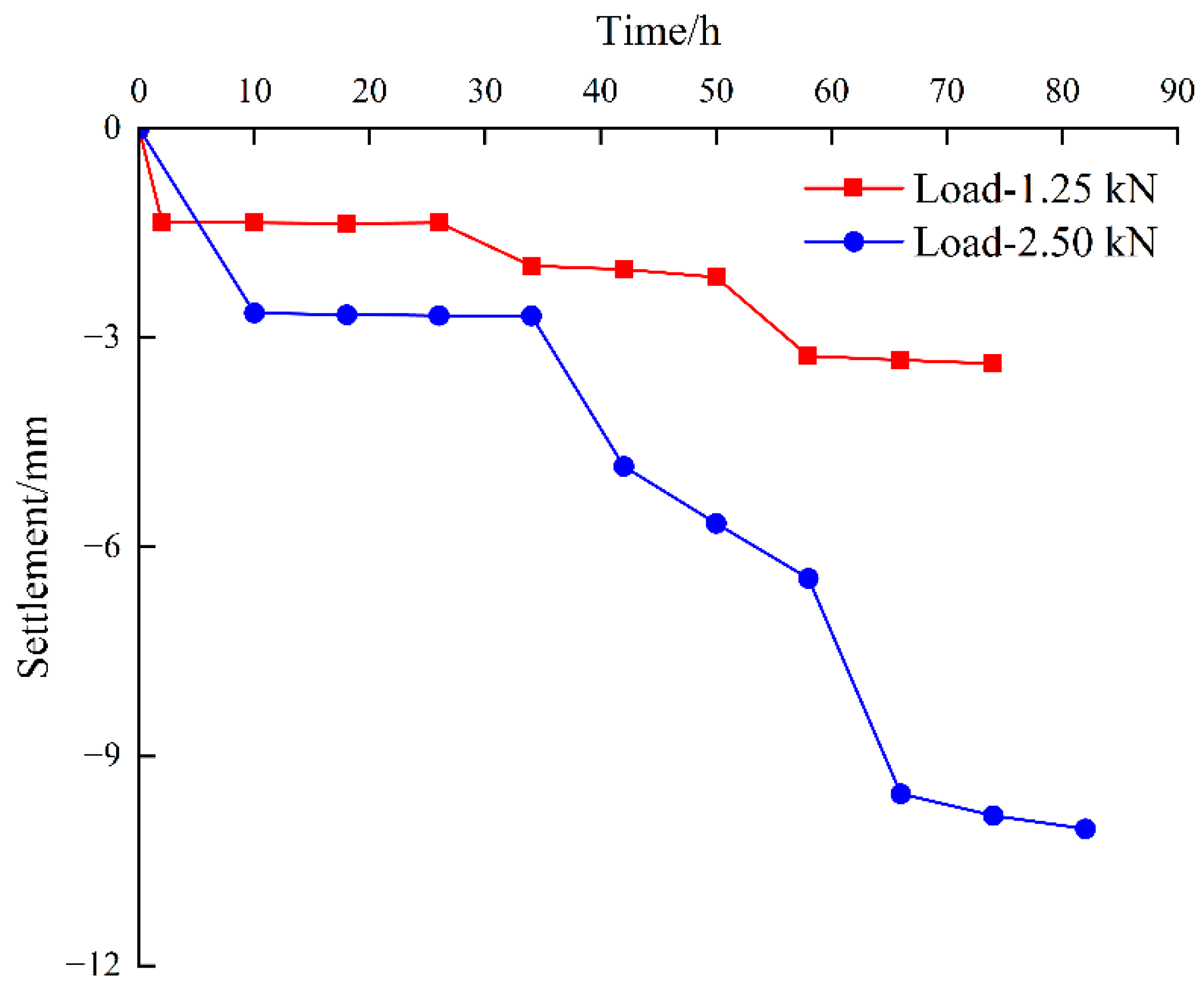

4.1. Change of Pile Foundations Settlemnt with the Immersion Time

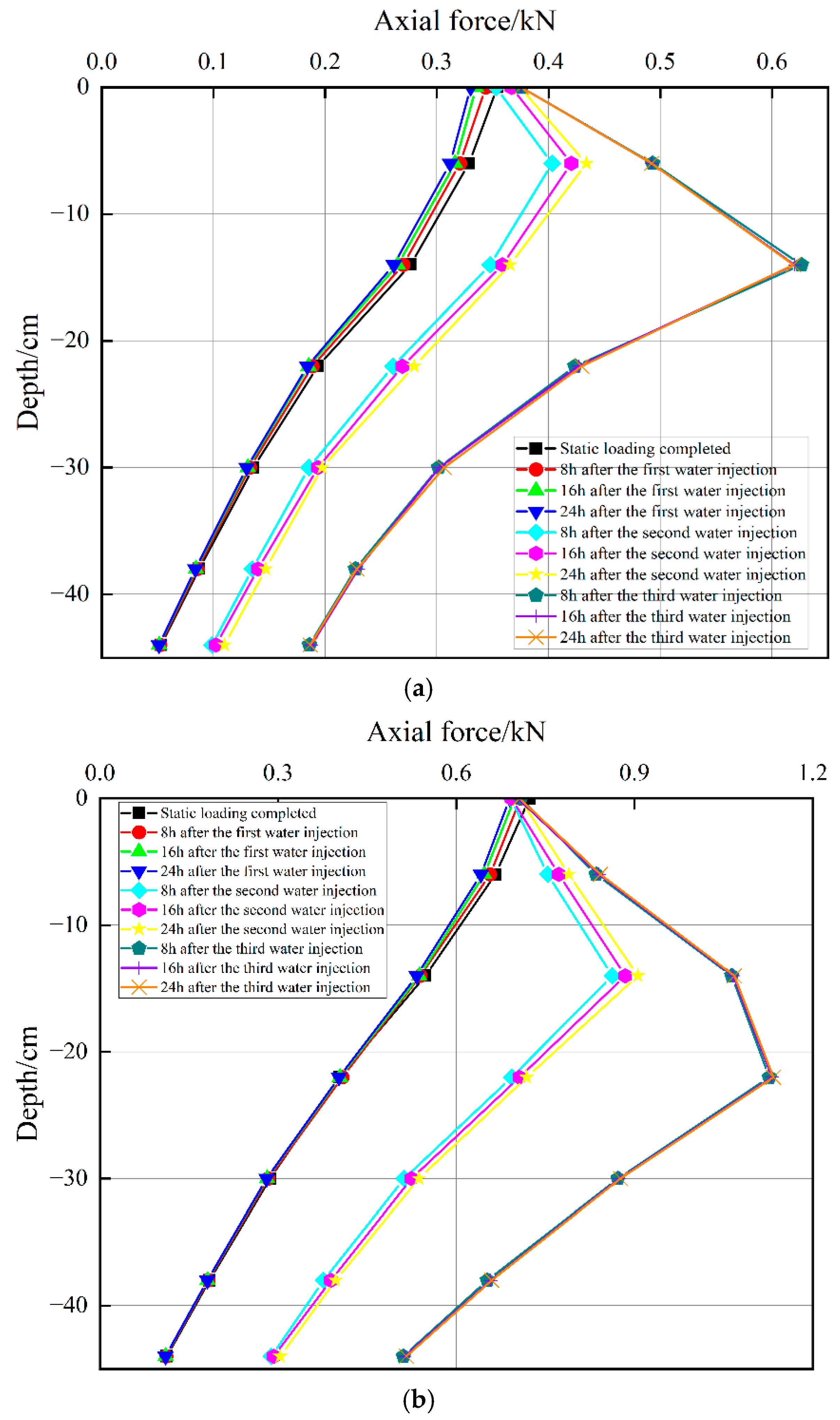

4.2. Distribution of Axial Force and Skin Friction in Pile Shafts

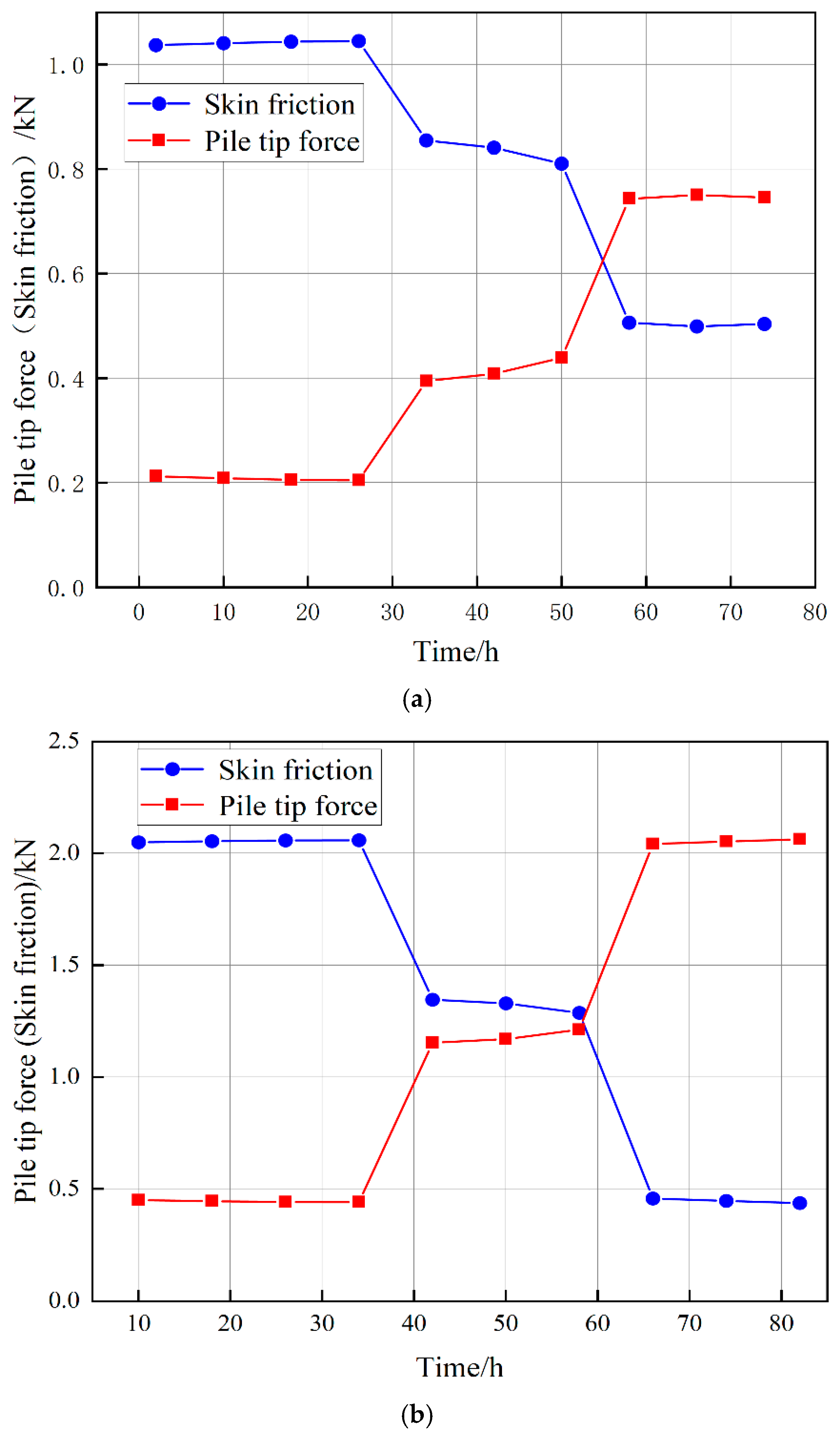

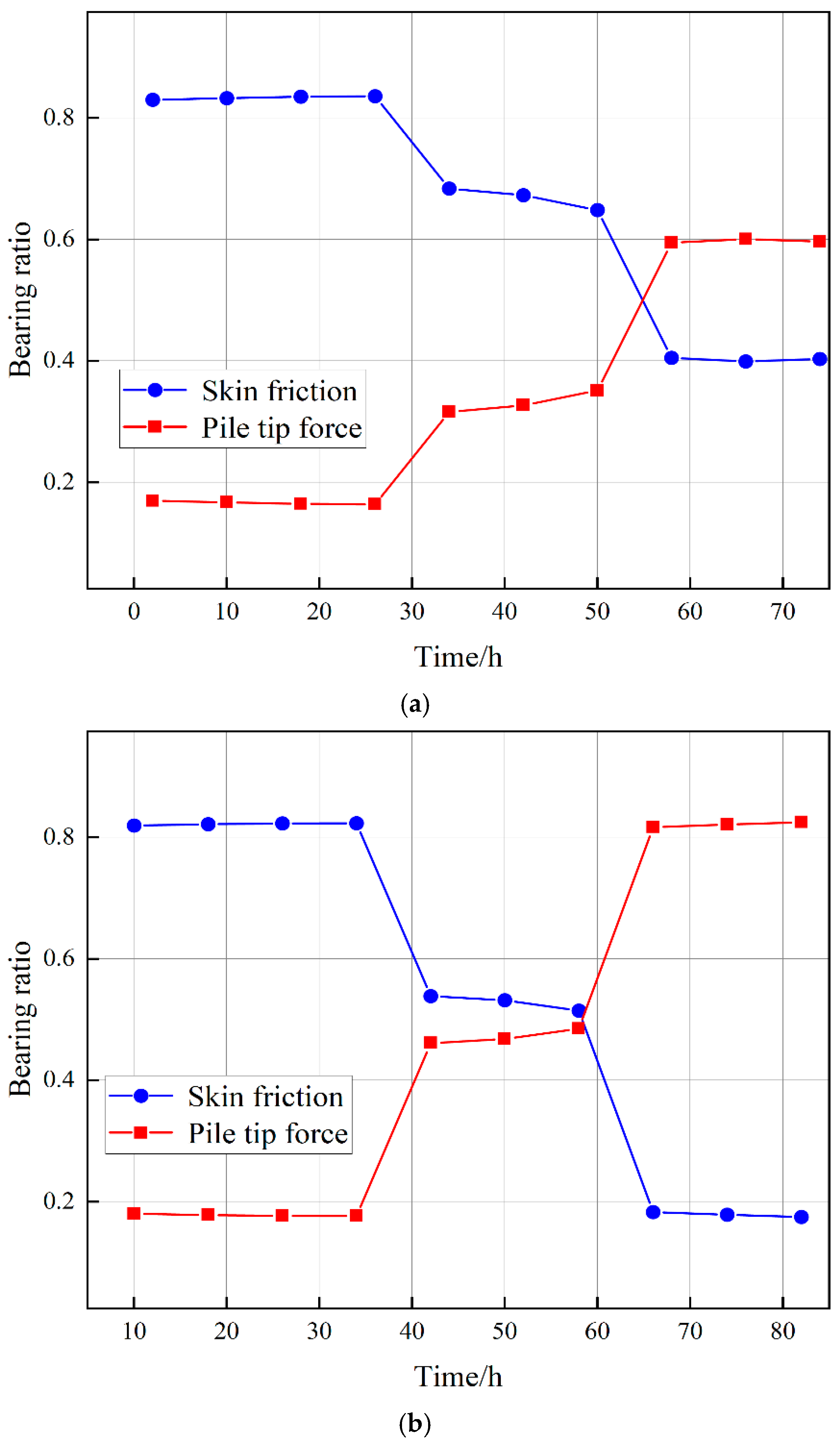

4.3. Change of Pile Tip Force with the Immersion Time

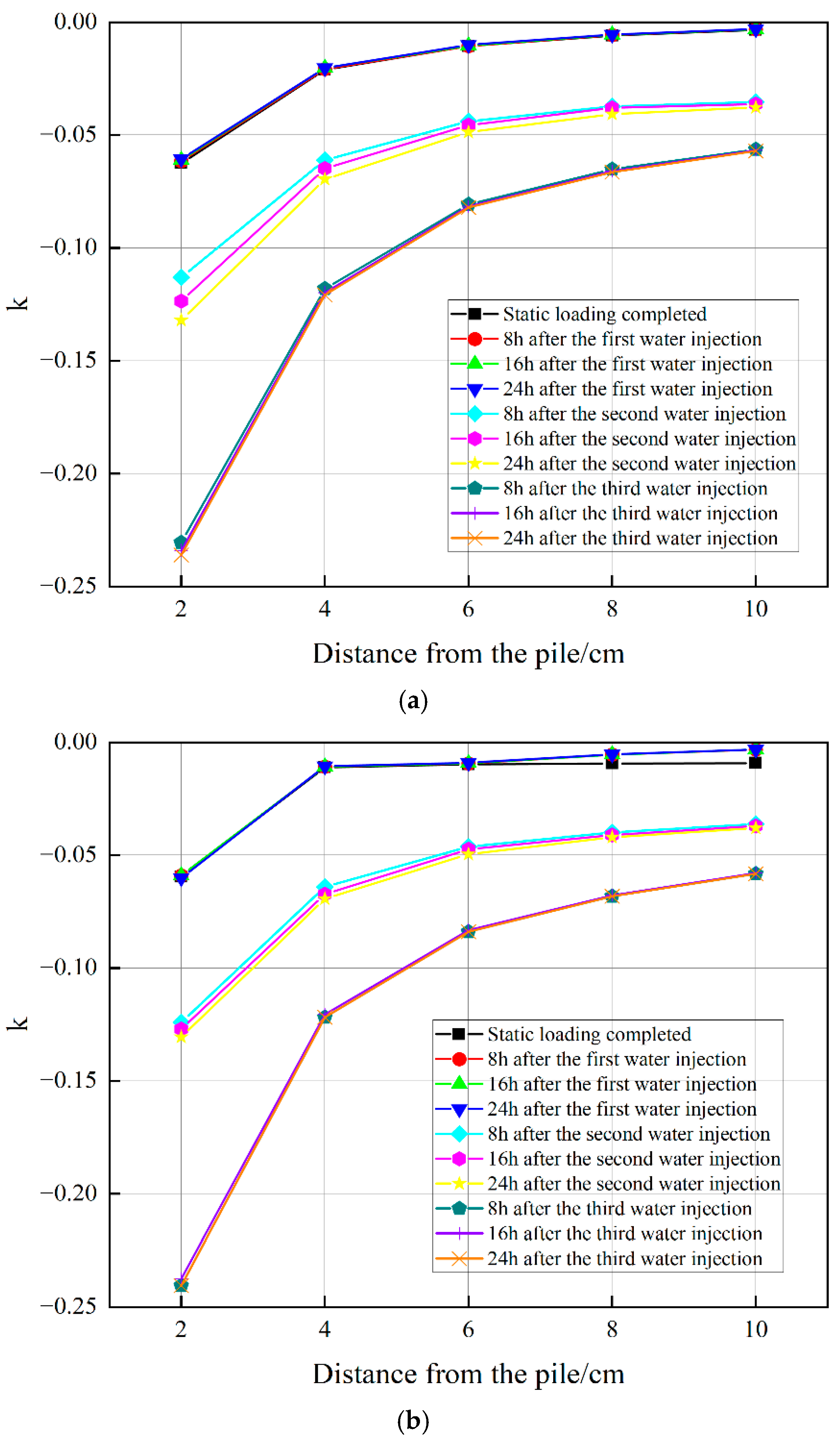

4.4. Change of Foundation Soil Settlement with the Immersion Time

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Weng, X.; Hu, J.; Mu, X.; Niu, H.; Huang, X. Model test study on the influence of the collapsibility of loess stratum on an urban utility tunnel. Environ. Earth Sci. 2022, 82, 32–48. [Google Scholar] [CrossRef]

- Wang, X.; Lu, H.; Zhang, H.; Wu, J.; Hou, X. Distribution, provenance, and onset of the Xiashu Loess in Southeast China with paleoclimatic implications. J. Asian Earth Sci. 2018, 155, 180–187. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, B.; Fan, W.; Dijkstra, T.A.; Wei, Y. 3D characterization of localized shear failure in loess subject to triaxial loading. Eng. Geol. 2023, 322, 107174. [Google Scholar] [CrossRef]

- Shen, Y.; Yan, H.; Wang, R.; Song, P.; He, Y. Review: Progress with Functional Materials Based on Loess Particles. Clays Clay Miner. 2021, 69, 301–314. [Google Scholar] [CrossRef]

- Munir, M.; Mujtaba, H.; Usama, K.; Khalid, F.; Zia, U. Study on Sustainable Utilization of CKD for Improvement of Collapsible Soil. Arab. J. Sci. Eng. 2023, 48, 5667–5682. [Google Scholar]

- Chai, Q.; Chen, T.; Li, Z.; Shen, D.; Wu, C. Experimental Study on the Negative Skin Friction of Piles in Collapsible Loess. Sustainability 2023, 15, 8893. [Google Scholar] [CrossRef]

- Li, P.; Vanapalli, S.; Li, T. Review of collapse triggering mechanism of collapsible soils due to wetting. J. Rock Mech. Geotech. Eng. 2016, 8, 256–274. [Google Scholar] [CrossRef]

- Wang, L.; Shao, S.; She, F. A new method for evaluating loess collapsibility and its application. Eng. Geol. 2020, 264, 105376. [Google Scholar] [CrossRef]

- Wang, M. Study on Structure of Collapsible Loess in China; Taiyuan University of Technology: Taiyuan, China, 2010. (In Chinese) [Google Scholar]

- Zhang, Y.; Hu, Z.; Chen, H.; Xue, T. Experimental Investigation of the Behavior of Collapsible Loess Treated with the Acid-addition Pre-soaking Method. KSCE J. Civ. Eng. 2018, 22, 4373–4384. [Google Scholar] [CrossRef]

- Zhu, Y.; Jia, X.; Shao, M. Thickness Variations Across the Loess Plateau of China. Surv. Geophys. 2018, 39, 715–727. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Guo, X.; Pan, Z.; Li, Y. Spatial-temporal distribution and variation characteristics of precipitation in China during 1956–2016. Adv. Water Sci. 2025, 36, 1–17. (In Chinese) [Google Scholar]

- Yao, Y.; Zhang, M.; Deng, Y.; Dong, Y.; Wu, X. Evaluation of environmental engineering geology issues caused by rising groundwater levels in Xi’an, China. Eng. Geol. 2021, 294, 106350. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, D. Analysis of dynamic characteristics of groundwater level in Xi’an during 33 years. Groundwater 2018, 40, 66–67. (In Chinese) [Google Scholar]

- He, X.; Tao, F.; Tao, H.; Ding, J.; Li, H. Analysis on Groundwater Level Variation Regulation of Guanzhong Plain and Its Influencing Factors. Groundwater 2015, 37, 52–54. (In Chinese) [Google Scholar]

- Zhang, J.; Chen, X.; Li, J.; Zhang, C. Research on the Slurry Diffusion and Load-Bearing Characteristics of Postgrouted Piles in Loess Areas. Int. J. Geomech. 2024, 24. [Google Scholar] [CrossRef]

- Xue, Z.; Zhang, Y.; Luo, J.; Yan, C.; Emmanuel, M.; Jia, X. Analysis of compressive strength, durability properties, and micromechanisms of solidified loess using industrial solid waste: Slag–white mud–calcium carbide residue. J. Build. Eng. 2024, 84, 108511. [Google Scholar] [CrossRef]

- Qian, C.; Li, M.; Liao, H.; Zhang, C.; Li, H. Research on the Vibration Fatigue Characteristics of Ancient Building Wood Materials. Buildings 2024, 14, 2840. [Google Scholar] [CrossRef]

- Adbullah, R.; Xavier, B.; Namgung, H.; Varghese, V.; Fujiwara, A. Managing transit-oriented development: A comparative analysis of expert groups and multi-criteria decision making methods. Sustain. Cities Soc. 2024, 115, 105871. [Google Scholar]

- Cao, Z.; Zhang, H.; Geng, J.; Tian, Z.; Sun, Y. Research on traffic accessibility of transit-oriented development of urban high-speed beltway service area: Take Qujiang service area as an example. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2023, 55, 827–833+839. (In Chinese) [Google Scholar]

- He, L.; Xu, H.; Tang, B.; Liu, Q.; Tu, Q. Analysis of Vibration Test of Over-track Buildings in Different Areas of Depots. Noise Vib. Control. 2024, 44, 235–241. [Google Scholar]

- Jin, B. Mechanical Analysis and Optimization of Variable Mobile Trolley Bracket Based on Modular Construction of Upper Cover Plate of Metro Vehicle Section; Shijiazhuang Tiedao University: Shijiazhuang, China, 2024. [Google Scholar]

- Feng, Q.; Zhang, Y.; Jiang, J.; Wang, Z.; Lei, X. Field measurement and evaluation of vibration in different areas of a metro depot. Earthq. Eng. Eng. Vib. 2022, 21, 529–542. [Google Scholar]

- Chen, Y.; Feng, Q.; Liu, Q.; Jiang, J. Experimental study on the characteristics of train-induced vibration in a new structure of metro depot. Environ. Sci. Pollut. Res. Int. 2021, 28, 41407–41422. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Zhu, H.; Yan, S.; Liang, Q.; Zhang, J. Seismic Fragility Analysis of Shallow-Buried Subway Station Structure in Loess Strata. J. Southwest Jiaotong Univ. 2025, 1–9. Available online: https://link.cnki.net/urlid/51.1277.U.20240219.1015.002 (accessed on 12 April 2025). (In Chinese).

- Xu, W.; Liu, Y.; Huang, Q.; Liu, X.; Zhao, C. Influence of Combination Types on Vibration Response of Superstructure of Subway Station. J. Southwest Jiaotong Univ. 2024, 59, 653–662. (In Chinese) [Google Scholar]

- Peng, H.; Pang, F.; Li, Z.; Xiao, X.; Tang, S. Study on the Impact of a Metro Depot Cover Structure on the Existing Metro Structure and Additional Settlement of Tracks. Buildings 2023, 13, 1914. [Google Scholar] [CrossRef]

- Ding, P.; Tao, L.; Yang, X.; Zhao, J.; Shi, C. Force Transfer and Deformation Mechanism of Single Ring Structure of Prefabricated Subway Station. J. Southwest Jiaotong Univ. 2020, 55, 1076–1084+1110. (In Chinese) [Google Scholar]

- Mu, Q.; Dai, B.; Zhou, C.; Meng, L.; Zheng, J. A new and simple method for predicting the collapse susceptibility of intact loess. Comput. Geotech. 2023, 158, 105408. [Google Scholar] [CrossRef]

- Liu, X.; Li, M.; Liao, H.; Huang, B.; Liu, S. Mechanical Properties of Adjacent Pile Bases in Collapsible Loess under Metro Depot. Appl. Sci. 2024, 14, 5819. [Google Scholar] [CrossRef]

- Chen, Y.; Li, X.; Huang, R.; Huang, L.; Li, L. Micro experimental research on influence factors of loess collapsibility. J. Eng. Geol. 2015, 23, 646–653. (In Chinese) [Google Scholar]

- Gu, T.; Wang, J.; Guo, L.; Chu, D.; Li, K. Study of Q3 loess microstructure changes based on image processing. Chin. J. Rock Mech. Eng. 2011, 30, 3185–3192. (In Chinese) [Google Scholar]

- Assallay, A.M.; Jefferson, I.; Rogers, C.D.F.; Smalley, I.J. Fragipan formation in loess soils: Development of the Bryant hydroconsolidation hypothesis. Geoderma 1998, 83, 1–16. [Google Scholar] [CrossRef]

- Assallay, A.M.; Rogers, C.D.F.; Smalley, I.J. Formation and collapse of metastable particle packings and open structures in loess deposits. Eng. Geol. 1997, 48, 101–115. [Google Scholar] [CrossRef]

- Jefferson, I.; Ahamd, M. Formation of Artificial Collapsible Loess. In Problematic Soils and Rocks and In Situ Characterization; ASCE Press: Reston, VA, USA, 2012; pp. 1–10. [Google Scholar]

- JGJ 94-2008; Technical Code for Building Pile Foundations. MoHURD: Beijing, China, 2008. (In Chinese)

- JGJ 106-2014; Technical Code for Testing of Building Foundation Piles. MoHURD: Beijing, China, 2014. (In Chinese)

- Zhang, Y. Research on Engineering Properties of Artificial Prepared Collapsible Loess and Calculation Method of Vertical Bearing Capacity of Deep Foundation; Lanzhou Jiaotong University: Lanzhou, China, 2017. (In Chinese) [Google Scholar]

- Tian, J. Research on Vertical Bearing Characteristics of Necking Pile Based on Load Transfer Method; Henan University of Technology: Zhengzhou, China, 2024. (In Chinese) [Google Scholar]

| Physical Properties | Specific Ratio | Optimum Moisture Content/% | Void Ratio | Liquid Limit/% | Plastic Limit/% |

|---|---|---|---|---|---|

| Artificial collapsible loess | 2.72 | 12 | 1.12 | 25.5 | 15.4 |

| Non-collapsible loess | 2.71 | 16 | 0.63 | 26.8 | 17.5 |

| Mechanical Properties | Compression Modulus/MPa | Cohesion/kPa | Internal Friction Angle/° |

|---|---|---|---|

| Artificial collapsible loess | 4.16 | 24.7 | 23.2 |

| Non-collapsible loess | 6.52 | 33.4 | 28.7 |

| Pressure | 50 kPa | 100 kPa | 200 kPa | 300 kPa |

|---|---|---|---|---|

| Collapsible coefficient | 0.075 | 0.082 | 0.088 | 0.089 |

| Elastic Modulus/MPa | Poisson’s Ratio | Gravity/(kN/m3) |

|---|---|---|

| 3300 | 0.2 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rong, X.; Li, M.; Liao, H.; Zhang, A.; Dang, T.; Li, H.; Wu, Z. Influence of Groundwater Level Rising on Mechanical Properties of Pile Foundations Under a Metro Depot in Loess Areas. Buildings 2025, 15, 1341. https://doi.org/10.3390/buildings15081341

Rong X, Li M, Liao H, Zhang A, Dang T, Li H, Wu Z. Influence of Groundwater Level Rising on Mechanical Properties of Pile Foundations Under a Metro Depot in Loess Areas. Buildings. 2025; 15(8):1341. https://doi.org/10.3390/buildings15081341

Chicago/Turabian StyleRong, Xuewen, Mingze Li, Hongjian Liao, Ao Zhang, Tao Dang, Hangzhou Li, and Zheng Wu. 2025. "Influence of Groundwater Level Rising on Mechanical Properties of Pile Foundations Under a Metro Depot in Loess Areas" Buildings 15, no. 8: 1341. https://doi.org/10.3390/buildings15081341

APA StyleRong, X., Li, M., Liao, H., Zhang, A., Dang, T., Li, H., & Wu, Z. (2025). Influence of Groundwater Level Rising on Mechanical Properties of Pile Foundations Under a Metro Depot in Loess Areas. Buildings, 15(8), 1341. https://doi.org/10.3390/buildings15081341